#titanium cooling tube

Explore tagged Tumblr posts

Note

What materials is Biohazard made of? I guess not everything resists radiation

Indeed! No material is totally resistant to radiation; it always depends on the amount of radiation and the exposure time.

Let me get a little nerdy

I clarify and repeat: I'm not an expert on the subject. I did research for this AU in general and thus determined the right materials for the construction of Biohazard. I may be wrong. But this is sci-fi, and some things are improbable but intentional, like Biohazard's melting rays!

Endoskeleton and joints: titanium alloys, stainless steel, and aluminum reinforced with carbon fiber.

Internal components:

Microchips and components: specifically designed to withstand high doses of radiation and encased in a dense layer of ceramic material within a tungsten protective box.

Sensors made with materials resistant to radiation and high temperatures. Integrated into the endoskeleton and protected by a dense covering material.

Actuators: electric or hydraulic motors made with corrosion- and wear-resistant materials. Located within the joints and protected by the endoskeleton.

Metallic lithium-Ion batteries specially designed to operate in extreme environments, housed in a tungsten protective box, away from sensitive components.

Cooling system: copper tubes and non-flammable, radiation-resistant cooling fluids integrated into the endoskeleton to dissipate heat generated by electronic components and shielding.

Protection systems:

Primary shielding: lead sheets and boron-based composite materials, 1.5 centimeters thick.

Secondary/Exterior shielding: tungsten sheets, 1 cm thick.

Biohazard has numerous limbs and components functioning as redundant systems. In the event of a failure, he can continue operating with backups.

He used to integrate cameras and sensors for remote monitoring and data collection. These are no longer operational.

Being made of very dense materials, he's extremely robust and heavy! You practically couldn't lift one of his arms if he were off!

He was very, very expensive to manufacture as well. The frustration was very great when the project "didn't work".

#long post#Biohazard oc#GC Biohazard#Gamma Code AU#Gamma Code fic#GC concepts#fnaf eclipse#fnaf sun#fnaf moon#sundrop#moondrop#fnaf dca fandom#dca community#fnaf#fnaf security breach#security breach#five nights at freddy's#beloved moot#asks

119 notes

·

View notes

Text

I am not a baby!! (Yes you are)

(Ao3) (Masterpost) (Previous) (Next)

(Part seven lmao)

Sometimes Danny hated being right. Mentally he cursed himself as he clamored into his lifepod. The Aurora was spilling radiation into the water just like predicted it would. A damaged drive core... That didn't bode well for him or the local wildlife. He was a Fenton! He knew the terminology for "This might blow up," in every language, no matter how needlessly complicated you said it.

A radiation suit would be helpful when the ship blew up, if not for him, then for the other survivors. Danny grew up surrounded by radioactive material, he was about as fucked up as one could get, but there was still time left for the other survivors. If there even were any left.

Shaking his head, Danny opened the storage plucking out the remaining Creepvine clusters, and started fabricating. It was hypnotic, Creepvine clusters to lubricant, copper and mushrooms to a battery and copper wire all that and a piece of titanium gave Danny a functioning Seaglide. The device was heavy, the PDA altering the blueprint so it was usable for him.

Opening the hatch up, eager to test his new toy out, Danny dove back into the water faster than ever before. Propellers spun at speeds that would chop his finger clean off if he touched them. A glowing map at the top and a flashlight he could turn off by squeezing the handles. Quick enough to keep up with the peepers while still being able to make quick sharp turns.

The Device whirled as he swam in circles, up, down, left, right, zigzag! Through coral tubes, around stone arches till he got dizzy, divebombing fish and kicking up sand.

"Congratulations, survivor. you have exceeded your weekly exercise quotient by 500 percent. Data indicates that swimming was your favorite activity,"

Heck yeah it was! Swimming is great! He's fast as hell man, radiation could eat shit! Stalkers wouldn't stand a chance, he'd just outpace them! Swimming around, breaking outcrops, and taking samples of table coral for a computer chip. Danny was having a blast!

In time he would have the materials to fabricate a habitat builder and in turn a super cool sea base! A home away from home while he's stuck outside federation space. Currently, the seabase blueprints he had were...limited, but he could work with that!

Rushing to his fabricator the blue lights felt agonizingly slow as he bounced on the heels of his feet, flippers squeaking against the floor. A habitat builder fell into Danny's impatient hands.

Back in the water, Danny scoped out the area. Access to an abundance of resources, food, and water was a necessity. Along with awareness of local predators. The shallows are a perfect place for him to build right now. A temp base to rest and store stuff before moving somewhere more convenient as he explored and met up with any of the other survivors.

Deciding to test out his new tool, Danny placed down a basic compartment. A tiny little tube that would've been big enough if he only needed a place to sleep. Yeah, that wasn't going to work. How was he supposed to pace aimlessly while he wrote notes? How was he supposed to work and live in a high-tech pool noodle? Disassembling the pathetic tube, Danny swam through the shallows plucking up the quartz needed for glass. More materials would be needed to build his base. Thankfully, he’d crashed in a ship made from and carrying the materials he needed. Danny saw no moral issue with “borrowing” titanium from supply crates light enough to lift, but the PDA seemed to have a small issue with it. With a few minutes of tinkering, it was easy to change the machine’s artificial mind.

A loop, he was going to make a base shaped like a zero because that’s how many fucks he gave about Alterra’s dumb rule. Placed upon foundations was the start of his perfect space base. The sides of the Zero became glass compartments, a perfect place to observe the local wildlife. Solar panels mounted jumpstarted the oxygen production, lights blinding when they snapped on. Fish drifted by his base, some ducking underneath his foundations settling comfortably in the shade provided. Maybe if he was here long enough, he’d grow some plants for fish to nibble on?

A hatch was placed on the front of the Zero, finally giving him access to his new base. Cold air punched him in the face as he stepped inside, but it was a welcome attack. Air conditioning at last! Throwing himself to the floor, Danny giggled, noise bouncing against barren walls. A sterile smell cycled through the base with the air filtered in. Like his parent's lab or a hospital room freshly sanitized. Familiar, it smelled like home.

Peeling off his flippers, Danny propped them against the wall. Bare feet against metal floors, Danny took to running through the loop. Brushing his hands against empty walls, he ran laps like it was gym class. The only difference was this wasn't gym class, so it didn't feel like hell. Several laps ran throughout his base until his breath ran out, and he collapsed to the floor.

Winded and panting, he glanced around his base mentally, planning where everything would go. Blueprints were limited, but brainpower wasn't. Making new blueprints for shelving units or a bed should be easy enough. The hard part would be finding the space for it. If he tinkered with the PDA, he could fabricate some blankets and pillows that he could sleep on and store away when he was awake.

First things first, he needed to get a fabricator and some storage set up. A few wall lockers on each side of the fabricator made his little crafting station. His base still felt bare. White walls would get boring real fast. No paint or paper he could use to decorate. No stickers or wallpaper to paint his base to match the stars. Untapped Potential, something to add to his to-do list. If he couldn't decorate anything else, changing the locker's text font would have to do.

Walking in a loop, Danny muttered, his brain working better than his mouth. Words failed, coming out jumbled if they were more than one or two easy syllables. Fangs created a lisp that'd get him verbally castrated if he was back at Casper. That was if he didn't maul them with his newfound face knives. Like a piranha, he was dangerous! Fierce!

Tap...Tap...Tap

Feet freezing, Danny turned to the window, heart jumping to his throat. Several glowing eyes stared back at him, burning a hole into his soul. Stripes of colors ranging from blue, purple, and forest green ran along its massive scaly body and dragon-like head. Two razor-sharp fangs poked out of a closed mouth. Arms glowing blue that faded to pitch black when reaching its four-fingered hands, each claw sharper than a sword. Hands, oh ancients, why does this one have hands? The other one didn't have hands! Curled up, it would be the same size as his base. Danny pointed his scanner at the guy, the results striking terror into the deepest depths of his core...

What the fuck do you mean this guy's a juvenile!?!

@ashoutinthedarkness @avelnfear @meira-3919 @thought-u-said-dragon-queen @hugsandchaos @blep-23 @zeldomnyo @bytheoldwillowtree @justwannabecat @shepherdsheart @starlightcat04 @stargazing-bookwyrm @pupstim

#Danny the moment he gets a seaglide: I'm fast as fuck boii#Danny upon seeing Damian: I'm scared as fuck boii#Imagine playing Subnautica and you're chilling in the shallows and you see a ghost gargantuan hybrid leviathan at your door#I'd simply perish at that point#subnautica au#dpxdc#dc x dp#dcxdp#dp x dc#DPXDC#DCXDP#All the tags so people can filter

226 notes

·

View notes

Text

This render IS of N, though as you can see he looks a bit more…rough. This is just a fun redesign thing I did to flex my texturing muscles.

WARNING: Dark stuff below the cut. If you don't like explorations of artificial humans made chop-shop style, please do not click.

Murder Drone redesign notes.

Basic body plan: Each drone has a titanium endoskeleton with silicone coverings. This is because the next layer is literally just human musculature adapted to the more animalistic body plan, with specialized organs safely under the hardened muscle. The silicone protects the muscles from being scratched by the bones.

On top of this musculature is a carapache of silicone and metal to serve as an exoskeleton. Areas that need to move a lot are not covered.

You might have noticed that the transition from the muscles to the exoskeleton is not smooth. To avoid causing wounds when the droid's exoskeleton and musculature touch, a layer of rubber cushions the flesh parts. The Absolute Solver decided it was good enough and stapled the whole thing onto the droids. It has held so far.

Tail: The tail is still a stinger, though a bit shorter and thicker. It is a flesh-and-bone tail covered by a flexible carbon fiber sleeve to protect it. Given that a tail is literally just a tube of muscle and bone, this was a cakewalk for the solver to do. The tail is very strong and can be used to fling people around.

Hands, feet and ears: To protect the areas most likely to be exposed, the palms, soles and ears are covered with a strong weatherproof fabric.

-Warning tape designs on ankles, wrists and tail cylinder. Because aestetic~

Changes from a typical human/droid body: -Larger, moving ears with good hearing.

Larger and more animalistic hands for killing with semi-retractable claws. -Larger jaw muscles and wider mouth for better killing power and eating all parts of the prey. -Semi-digitigrade feet with non-retractable claws to aid in case the droid needs to run on all fours/perch. -Wider and larger ribcage for bigger muscles and wing muscle connection points. -Large, wide eyes with multiple vision settings. -'Raccoon' mask and black sclera to minimize being blinded by glaring light. -Titanium teeth with extra pointiness to allow for more stabbining bites. Since they are titanium, the teeth don't break even if used in crushing.

A more robust circulatory system with a 'stomach' for storing oil/burning matter.

Notes: Despite the musculature and organs, they are not human in origin and do not need to breathe or perform any other biological functions beyond eating and hunting. Oil/burning matter runs the internal (insufficient) fans, and they cannot sweat or cool in any other way.

#murder drones#murder drones n#serial designation N#body horror //#gore //#my art 3d#headcanon#redesign

9 notes

·

View notes

Text

formula E drivers and their stethoscopes

@watercolor-hearts and I discussed what stethoscopes each driver would use after they created a list for Formula 1 drivers. then we had the ideas for formula e drivers (+ André and James) so I made a list. Thanks to V for creating the collages!

André Lotterer - Littmann CORE Digital Stethoscope 8572 - High Polish Rainbow, Littmann Cardiology IV Diagnostic Stethoscope: Black & Black - Red Stem.

He’d want a digital one to save it for later. And the rainbow chest piece is obvious (for the gay in him). Sleek black with a hint of dark red is perfect for our war criminal.

Jev - MDF procardial® titanium adult cardiology stethoscope - cheetah/blackout.

Like Cheetah the cat.

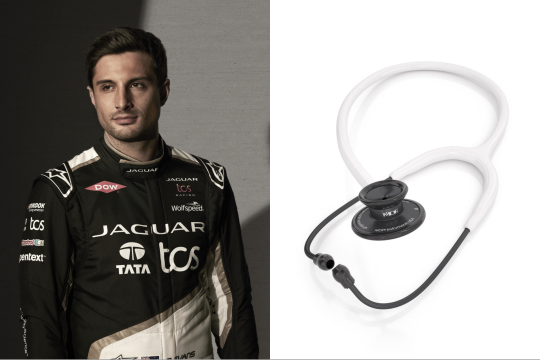

Mitch Evans - MDF acoustica® stethoscope - white/black.

When I think of jaguar I think of Mitch. The colours remind me of him.

Nick Cassidy - Littmann Cardiology IV Diagnostic Stethoscope: Hunter Green

I just looked at it and thought, oh yeah, he’d look good with that.

Maximilian Günther - Littmann Cardiology IV Diagnostic Stethoscope: High Polish Rainbow & Navy Blue - Black Stem, Littmann Classic III Monitoring Stethoscope: Ceil Blue (suggested by V).

Maserati prince. Rainbow chest piece gives gay vibes.

James Rossiter - MDF MD one® adult stethoscope - white/perla noire, Littmann Cardiology IV Diagnostic Stethoscope: Satin Alabaster Tube

The vibe. Simple but a little bit posh, sophisticated. He likes the white.

Sam Bird - MDF MD one® epoch® titanium adult stethoscope - orange

The orange suits him.

Stoffel Vandoorne - MDF procardial® titanium cardiology stethoscope - green/blackout

It's illegal how good he looks in green.

Robin Frijns - MDF MD one® epoch® titanium adult stethoscope - graffiti/blackout, Littmann Classic III Monitoring Stethoscope: Smoke & Lime Green - Blue Stem

Given the pokemon obsession I feel like robin would like this one. can also imagine the green to rep Envision.

Edo Mortara - MDF procardial® titanium cardiology stethoscope - pink glitter/rose gold

Girl dad. I think he would love the pink and would enjoy using it.

Sacha Fenestraz - MDF MD one® epoch® titanium adult stethoscope - sunflower

A sunny personality that would look great with flowers.

Nyck De Vries - MDF MD one® epoch® titanium adult stethoscope - tie dye

Sunny personality, a bit of fun away from his on track crimes. He’d look cute with it.

Oliver Rowland - MDF procardial® titanium cardiology stethoscope - white glitter/rose gold

Another girl dad. Secure enough in his masculinity to own the glitter. I was imagining red glitter, but this is close enough.

António Félix da Costa - Littmann Cardiology IV Diagnostic Stethoscope: Black & Black - Red Stem

I think he’d like the black with a surprise bit of red. Porsche vibes.

Nico Müller - Littmann Classic III Monitoring Stethoscope: Turquoise

He looks good with this blue.

Jake Hughes -MDF sprague-x stethoscope - burgundy

Aston Villa FC vibes.

Sérgio Sette Câmara - Littmann Classic III Monitoring Stethoscope: Grey

Reminds me of the ERT. Subtle . Sort of quiet but still there.

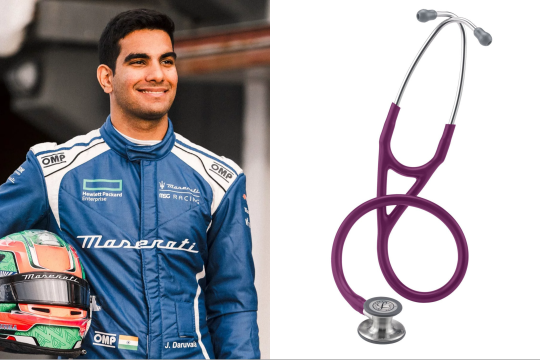

Jehan Daruvala - Littmann Cardiology IV Diagnostic Stethoscope: Plum

Immediate thought was blue but I think he’d look good with plum.

Jake Dennis - MDF procardial® titanium cardiology stethoscope - paws

Jake loves his dog so He’d 100% get a paw print.

Sébastien Buemi - MDF MD one® epoch® titanium adult stethoscope - vulcan - carbon fiber/blackout

“Its dark, like my soul.”

Pascal Wehrlein - Littmann Master Cardiology Stethoscope: All Black

Dark and mysterious. Gives me his vibe.

Dan Ticktum - MDF procardial® titanium cardiology stethoscope - poseidon - carbon fiber/blackout

He'd go for this purely because he thinks it looks cool.

Norman Nato - Littmann Master Cardiology Stethoscope: Burgundy

He just looks like he'd suit it.

Lucas Di Grassi - Littmann Lightweight II SE Nurses Stethoscope: Black

I didn’t put much thought into this one lmao. Could imagine him using it.

these are all my personal opinion so there is literally nothing proving this, was just a bit of fun. If you have any other ideas though let me know. Hope you enjoyed! :)

#formula e#stethoscope#jean eric vergne#mitch evans#nick cassidy#maximilian günther#james rossiter#sam bird#robin frijns#stoffel vandoorne#edo mortara#sacha fenestraz#oliver rowland#nyck de vries#antonio felix da costa#nico mueller#jake hughes#sergio sette camara#jake dennis#sebastien buemi#pascal wehrlein#norman nato#dan ticktum#lucas di grassi#Formula e medical au#andré lotterer#cardiophilia#nurse max au#formula e medical au#Formula e/wec cardiophilia collection

17 notes

·

View notes

Text

In every beat

---

Pairing: Kirishima x Reader x Bakugou (Poly)

Genre: Angst / Comfort / Medical Drama / Hurt-Comfort

---

You'd always been the tough one. You had to be, growing up in a world of heroes, quirks, and impossible expectations. But nothing—absolutely nothing—prepared you for the moment your doctor looked you in the eye and said the words:

"You need spinal surgery. Soon."

The pain had crept in over the past few months—numbness, weakness, that deep, stabbing ache in your lower back that never quite went away. Kirishima noticed first, watching the way you hesitated before lifting anything heavy. Bakugou noticed when you collapsed in the gym.

Now, the three of you sat in the cold pre-op room, with Kirishima gripping your hand tightly and Bakugou pacing like a tiger behind the curtain. His explosions were quiet—barely a twitch at his palms—but you knew him well enough to read the tension.

"It's gonna go great, babe," Kirishima said, trying to smile, but his voice cracked.

You swallowed hard. "Yeah. Just getting my spine sliced open. No biggie."

A nurse entered the room, soft smile on her lips, and held a clipboard. “Alright, Y/N. We’re ready. Time to prep you for the OR.”

Kirishima kissed your forehead. Bakugou stepped forward, finally still, his jaw clenched. He didn't say much, just took your other hand and muttered, "Don’t fuckin’ die in there."

---

Bright lights. Sterile white. The air had that sharp, antiseptic tang. Nurses bustled quietly, checking machines, laying out instruments. The operating table was narrow, padded only slightly, and intimidating under the large round surgical light above.

You were wheeled in, eyes flicking over every detail. The table of tools gleamed—retractors, clamps, bone saws, suction tubes, a drill. A tall IV pole stood beside you, a saline bag already hooked and ready. Beside it, a pulse oximeter beeped faintly with each of your anxious heartbeats.

A nurse gently placed a nasal cannula just under your nostrils. “This is just oxygen to help you breathe better,” she said, adjusting the flow on a nearby machine. Cool air hissed faintly.

Next came the blood pressure cuff wrapped snugly around your arm. It inflated automatically, making your fingers tingle. Then the EKG electrodes—small sticky pads—were applied across your chest, feeding data into the heart monitor beside the table. The beep-beep-beep of your heartbeat felt far too loud in your ears.

A soft voice at your side. “Hi, I’m Dr. Himura, your anesthesiologist. We’re going to start with an IV, and then I’ll have you breathe through a mask. You’ll be asleep before the first incision.”

A sharp pinch in your hand as the IV catheter was inserted. Cold fluid began to flow almost immediately.

Finally, the anesthesia mask was lowered over your face—a clear dome connected by tubing to a humming machine. “Deep breaths now. You might feel a little lightheaded.”

The scent of plastic and gas—sweet, artificial—flooded your senses. The room blurred.

---

With the patient fully under general anesthesia, the team scrubbed in. The area of operation—your lower back—was sterilized with povidone-iodine, then draped in blue sterile sheets.

An incision approximately 4 inches long was made along the lumbar spine with a #10 scalpel blade, carefully slicing through skin and subcutaneous fat. Blood welled immediately; suction tips removed it quickly while hemostats clamped bleeding vessels.

Electrocautery was used to dissect deeper, through muscle layers, revealing the vertebrae. Self-retaining retractors were placed, pulling the muscle away from the bone with a tense metallic click.

The damaged disc between L4 and L5 was removed with pituitary rongeurs, the grating crunch of cartilage audible in the quiet room. A hollow remained.

A high-speed surgical drill was used to clean the bony edges, shaping them to receive the bone graft. Screws were inserted with a pedicle screw system, each one turned precisely with a torque wrench. Titanium rods were placed and locked in with set screws, realigning your spine and relieving pressure on the nerves.

Finally, a bone graft—a mix of harvested marrow and synthetic matrix—was packed into the hollow space to promote fusion over time.

Drainage tubing was inserted. Then came the long, careful closure: layer by layer, muscle sutures, fascial closure, subcutaneous tissue, and skin—closed with nylon sutures and surgical staples.

The total blood loss was 550cc, managed via suction and sponges. Your vitals were stable. Oxygen saturation stayed strong. Total OR time: 4 hours, 22 minutes.

---

You came to slowly. A heavy weight in your spine, an ache so deep it felt molecular. Beeping surrounded you again. Oxygen hissed faintly from a nasal cannula, and the IV line in your arm felt sore but present.

You blinked, vision hazy—and saw them.

Kirishima, his eyes red-rimmed, still in his hero gear. Bakugou, arms crossed, looking like he’d fought an entire army just to sit in that chair.

“You’re awake,” Kirishima whispered, voice breaking. “You made it.”

Bakugou leaned forward, fists clenched. “Told you not to die, dumbass.”

Your throat was dry. You couldn’t speak yet, but the weak squeeze of your fingers was enough.

They both leaned in, hands holding yours.

And through the haze of painkillers, blood loss, and surgical trauma—you smiled.

---

2 notes

·

View notes

Text

Ulta's Cooling Eye Shadow Stick, infused with sunflower seed oil and vitamin E, glides across eyes leaving behind the perfect wash of color and a cooling sensation for a quick refresh. I THINK THESE ARE REALLY "COOL", PARDON THE PUN. THE COLOR IS NOT REAL DEEP, IT IS LIGHT AND AIRY AND COOL / FROSTY. NICE MINT GREEN. AND, THE COOLING, MINTY, SENSATION IS FOR REAL. I BOUGHT MYSELF A TUBE TO TRY (AND INCLUDED A COLOR SWATCH)--SEE PICS. IT ACTUALLY TINGLES IN A PLEASANT SORT OF WAY. THIS COMES IN A TWIST UP TUBE SO YOU REALLY DON'T HAVE TO SHARPEN IT. THIS IS A CRAYON STICK, NOT A HARD STICK--SO THE TEXTURE IS MORE WAXY AND OILY THAN A TRADITIONAL POWDERED EYE SHADOW. PLEASE SEE MY OTHER ULTA BEAUTY LISTINGS, AS WELL.INGREDIENTS:

Octyldodecanol, Ethylhexyl Palmitate, Hydrogenated Polyisobutene, Synthetic Wax, Castor Oil Bis-Hydroxypropyl Dimethicone Esters, Helianthus Annuus (Sunflower) Seed Wax, Isohexadecane, Microcrystalline Wax, Polymethylsilsesquioxane, Isododecane, Methyl Methacrylate Crosspolymer, Isobutylmethacrylate/Bis-Hydroxypropyl Dimethicone Acrylate Copolymer, Rhus Verniciflua Peel Wax, Shorea Robusta Resin, Ethyl Menthane Carboxamide, Phenoxyethanol, Tin Oxide, Tocopheryl Acetate, Tocopherol, Ascorbyl Palmitate, Pentaerythrityl Tetra-di-t-butyl Hydroxyhydrocinnamate. May Contain: Mica, Titanium Dioxide (CI 77891), Carmine (CI 75470), Iron Oxides (CI 77491, CI 77492, CI 77499), Yellow 5 Lake (CI 19140), Blue 1 Lake (CI 42090).

PRECAUTIONS: External use only. Avoid contact with eye. Discontinue use if irritation occurs.

Ulta Beauty is cruelty-free. Ulta Beauty has confirmed that it is truly cruelty-free. They don't test finished products or ingredients on animals, and neither do their suppliers or any third-parties. They also don't sell their products where animal testing is required by law.

2 notes

·

View notes

Text

Cooling system with silicone hoses and rebuilt radiator

Front with PVM forged rim, Andreani cartridge with coated inner tubes, Beringer dual six-piston calipers and disks, bespoke titanium axle and titaniun fasteners (left). Rebuilt wiring harness, injection system and idle control system (right).

1 note

·

View note

Text

Best Laser Engraver for Small Business

The evolution of laser technology has led to significant advancements in tube laser cutting machines. Modern tube laser cutters come equipped with sophisticated computer numerical control (CNC) that features precision and consistency in cutting. Additionally, most advanced tube laser cutters also come with an array of automated features that reduce human error and increase efficiency. Hence, it is essential to look for laser cutting machines that possess modern features to ensure the production of high-quality products - Tube laser.

The variety that laser tube cutting can handle shows the broad flexibility these machines can deal with. A quarter of an inch of carbon steel is no match for laser tube cutting. And on titanium, laser tube cutting gets through inches with no problems either. Watching them in action reveals the level of coordination happening simultaneously, as they perform multiple complex tasks to produce precise and intricate cuts - laser cutter.

Professional tube laser cutting machine manufacturers is expertly designed for high-precision cutting of metal tubes, I-beams, C channels & wide range of structure components. Equipped with advanced laser technology, it is ideal for industries that demand efficiency and precision, on a variety of tube shapes and structure components. Easily accessible emergency stop button for immediate shutdown and robust machine guards that prevent accidental contact with hazardous components. Equipped with individual extraction points for different zones, allowing targeted removal of fumes from multiple sources within a facility, The user-centric control system is designed for continual improvement, with regular software updates that enhance functionality and introduce new features based on user feedback.

High-quality linear guides ensure smooth and accurate movement, contributing to the machine’s overall precision and performance. Advanced control systems provide intuitive operation, precise motion control, and real-time monitoring, enhancing overall machine functionality. Reliable cooling systems maintain optimal operating temperatures, ensuring consistent performance and extending the life of the laser source. For more information, please visit our site https://impactmachinery.com.au/

0 notes

Text

Monel K500: Properties, Applications, Composition & More

Introduction to Monel K500

Monel K500 is a nickel-copper alloy that provides the excellent corrosion resistance of Monel 400 with added superior strength and greater hardness. This increased performance is attained by adding small percentages of aluminum and titanium to the base alloy and by using a process known as age hardening (also precipitation hardening). The final material is very desirable for high-demand industrial uses where strength, toughness, and corrosion resistance are paramount.

Monel K500 not only resists corrosion in a wide range of environments including seawater, chemicals, and industrial atmospheres but it also retains its mechanical properties across a broad range of temperatures, from sub-zero to high temperatures.

Key Characteristics of Monel K500

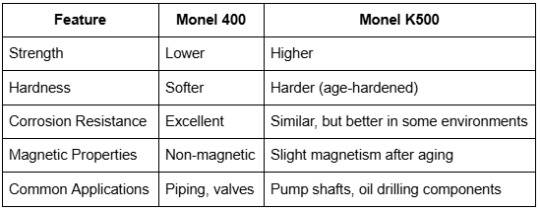

Outstanding Strength: Exceptional Strength: Nearly twice the tensile strength and triple the yield strength of Monel 400.

Enhanced Corrosion Resistance: Excellent protection against saltwater, marine environments, chemicals, and acidic conditions.

Excellent Toughness: Maintains mechanical integrity from cryogenic to elevated temperatures (~480°C / 900°F).

Non-Magnetic Nature: Monel K500 remains generally non-magnetic in its annealed state. However, slight magnetism may develop after age-hardening.

Spark Resistant: Safe for use in explosive environments.

Chemical Composition of Monel K500

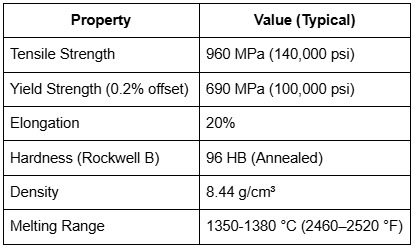

Mechanical Properties of Monel K500

Monel K500 vs Monel 400

Applications of Monel K500

Monel K500 is applied in various industries that require high strength and outstanding corrosion resistance.

Some of the major applications include:

Marine Engineering: Used for propeller shafts, pump shafts, and valves that are subject to seawater.

Oil and Gas Industry: Applied in drill collars, non-magnetic housings, and oil-well tools.

Chemical Processing Equipment: Pumps, valves, and heat exchangers.

Medical Equipment: Specialized surgical instruments and implants.

Defense and Military: Components requiring resistance to corrosive and explosive environments.

Heat Treatment and Hardening

Monel K500 attains its remarkable strength through age-hardening, a process also referred to as precipitation hardening. The typical heat treatment process involves:

Solution Annealing: Heating to about 980°C (1800°F) and rapid cooling.

Aging: Holding the alloy at a lower temperature (~590°C / 1100°F) for several hours to precipitate Ni₃(Al, Ti) particles, which strengthen the matrix.

Proper heat treatment is critical for achieving the best combination of mechanical properties and corrosion resistance.

Corrosion Resistance of Monel K500

Monel K500 offers excellent resistance to:

Seawater: Outstanding for marine applications.

Hydrofluoric Acid: One of the rare alloys that exhibit resistance to hydrofluoric acid.

Alkalis: Strong resistance to caustic solutions.

Salts and Brines: Resistant to various chloride and bromide salts.

Organic and Inorganic Acids: Sulfuric, hydrochloric, and nitric acids in moderate concentrations.

However, it can suffer from stress-corrosion cracking in some conditions, especially in the presence of high concentrations of chlorides.

Forms Available in Monel K500

Monel K500 is available in several product forms, including:

Sheets and Plates

Bars and Rods

Pipes and Tubes

Wires

Forgings

Fittings and Flanges

Fasteners (bolts, nuts, washers)

Conclusion

Monel K500 is the preferred material for applications that demand both high strength and outstanding corrosion resistance. Its unique properties make it indispensable in demanding environments such as marine, chemical processing, aerospace, and oil & gas industries. Though it is more expensive compared to many standard stainless steels, its performance benefits often outweigh the cost in critical applications.

Choosing Monel K500 ensures long-term reliability, fewer maintenance concerns, and superior mechanical performance even under the harshest operating conditions.

FAQs About Monel K500

Q1. Is Monel K500 magnetic?

Monel K500 is non-magnetic in the annealed condition, although it can develop slight magnetism after age-hardening.

Q2. Can Monel K500 be welded?

Yes, but special care must be taken. Welding should ideally be performed using Monel filler metal and proper post-weld heat treatment to prevent cracking.

Q3. What is the maximum temperature Monel K500 can withstand?

Monel K500 can perform reliably at temperatures as high as 480°C (900°F).

Q4. Is Monel K500 expensive?

Yes, Monel K500 is considered a premium material due to its nickel content and specialized manufacturing processes.

Q5. What differentiates Monel K500 from Monel 400?

Monel K500 has higher strength and hardness compared to Monel 400 due to its age-hardening capabilities, while both offer similar corrosion resistance.

#monel#monelfasteners#fasteners#monelk500#monel400#ananka#anankafasteners#articles#blog#fastenersmanuafcturer#manufacturer#supplier#mumbai#tumblr blog#tumblr

0 notes

Text

Heat Exchanger Tubes Manufacturers and Why Their Quality Matters

Modern industries heavily depend on heat exchangers for their operations across various sectors such as power generation and food production. Each heat exchanger tube contains different temperature fluids that control heat movement. A system failure will result when the tubes stop working. You must carefully select the best heat exchanger tubes manufacturers because their selections have direct impacts on your system. Tubes made with optimal materials improve performance while saving both downtime and financial expenditures in the long term. This blog explains why choosing high-quality heat exchanger tubes is essential and lists what to seek from your vendor.

Material Choice Impacts Performance

The selection of material in heat exchanger tubes directly affects their performance capacity. Stainless steel tubes plus alloys made from carbon steel must resist the specific conditions where they operate. When selecting, the improper material can let the tube break down through corrosion and cracking.

Expert heat exchanger tube producers present multiple material choices for customers. They assist you in making the right pick by evaluating heat exchanger needs concerning temperature, pressure, and fluid. A supplier's capacity to design and sell stainless steel tubes and cold drawn seamless tubes greatly enhances their tubing quality and durability.

Precision Manufacturing Reduces Failure

The production of heat exchanger tubes requires specific attention. A tiny problem in the manufacturing process can produce severe damages. The quality of welding and layer thickness directly affects how well the system heats and cools. When hiring tube manufacturers focus on their advanced technology and strict quality processes because they ensure superior products.

Experienced suppliers can deliver Welded Steel pipe products that include A106 Grade B and P11 Pipe as well as other vital products. Their work with various materials lets them know what heat exchanger applications need in terms of performance requirements.

Compatibility with Industry Standards

Different industries follow different standards. Power plants and chemical plants have different specific requirements when it comes to purchasing tubes. The best manufacturing company supplies tubing that meets official industry standards defined by ASME, ASTM, and international organizations. This practice ensures that the tubes operate without risk inside any industrial system.

The top heat exchanger tube manufacturers also supply API 5L pipes, P22 pipes, and stainless steel 316 pipes. Their long history in the field helps them recognize all necessary standards to deliver accurate first-time solutions.

Fast Delivery and Full Documentation

In large-scale operations, time matters. The entire project stops working when tubes take too long to arrive. A trustworthy supplier needs to maintain sufficient product inventory for quick delivery. They must give you all the necessary paperwork such as material test records and certification documents.

Distribution networks improve when suppliers provide carbon steel pipe services along with being manufacturers of duplex pipe in india and titanium pipe suppliers. You receive the items you need on time without worrying about being held back.

Conclusion

Deciding which heat exchanger tubes manufacturers to use must consider more than low prices. The key elements are maintaining safe operations while delivering top-notch results over time. Check for materials that received proper certification, clear production methods and dependable assistance services. Tubos India provides high-quality tubes with products from our approved suppliers who produce ss pipe products Galvanized Steel Pipes and alloy steel pipes. Our company supplies you dependable materials to enable your next project

0 notes

Text

Overview of Nitinol Material

Titanium nickel alloy, also known as Nitinol, is a binary alloy composed of nickel and titanium. The atomic percentages of these two elements are approximately equal.

Austenitic phase and martensite phase

Due to changes in temperature and mechanical pressure, Nitinol has two different crystal structure phases, namely an austenite phase and a martensite phase. In Nitinol, austenite is called the mother phase, which is the crystalline phase of the alloy at high temperatures. When the temperature decreases, austenite will gradually transform into martensite (child phase).

Two characteristics of Nitinol

-Shape memory

When the mother phase of a certain shape cools from above the Af temperature to below the Mf temperature and completely forms martensite, shape memory occurs, thereby deforming the martensite below the Mf temperature. After heating below the Af temperature, the material will automatically recover its parent phase shape by reverse phase transition. In fact, the shape memory effect is a thermally induced phase transformation process of nitinol. It refers to the ability of Nitinol to deform at a certain temperature and then restore its original, undeformed shape when the temperature is higher than its "transition temperature".

-Super elastic

The so-called superelasticity refers to the phenomenon that the strain generated by the sample under the action of external force is much greater than the elastic limit strain, and the strain will automatically recover during the unloading process. In the parent phase, due to the effect of external stress, the strain triggers the martensite transformation, so the alloy exhibits different mechanical properties from ordinary materials. Its elastic limit is much larger than ordinary materials. And it no longer follows Hooke& #39;s law. Compared with the shape memory effect, superelasticity does not involve heat.

Application of Nitinol

1. Glasses frame

2. Orthodontics

3. Medical equipment

4. Other applications

A well-known computer manufacturer used Nitinol equipment to eject PCMCIA (International Personal Computer Memory Card Association) cards. In addition, Nitinol is also used to connect the end of the aircraft hydraulic tubing. In less severe applications, nitinol can bend the magic shop spoon when it is placed in hot water.

https://www.edge-techind.com/Products/Non-ferrous-Metals/Titanium-Ti/Nitinol/Nitinol-Tube-780-1.html

0 notes

Text

Titanium Fittings, Plates, and Tubes Industrial Uses and Benefits

Titanium’s exceptional properties make it an indispensable material across industries such as aerospace, automotive, marine, chemical processing, and healthcare. With their superior strength-to-weight ratio, lightweight nature, and excellent corrosion resistance, titanium fittings, titanium tubes, titanium plates, and titanium rods are vital for applications demanding durability and high performance. Icon Steel, a trusted name in the UAE, offers premium-quality titanium products tailored to meet diverse industrial needs. This guide explores the industrial applications and benefits of titanium products, highlighting why Icon Steel in the UAE is the preferred choice for high-performance environments.

Why Titanium?

Titanium has a remarkable strength-to-weight ratio, offering the robustness of steel at nearly half the weight. This balance of strength and weight makes titanium ideal for industries needing lightweight yet durable materials. Additionally, its corrosion resistance makes it highly suitable for challenging environments, such as marine settings and chemical plants, where durability against harsh elements is critical. Titanium’s biocompatibility also makes it invaluable in the medical sector, where it’s used for orthopedic implants and surgical tools. Key Titanium Products and Their Industrial Applications 1. Titanium Fittings Titanium fittings are essential in industries where corrosion resistance and durability are non-negotiable. These fittings are designed to handle high pressures and harsh chemicals without compromising performance, making them an industry favorite for longevity and efficiency.Chemical Processing: Titanium fittings are particularly popular in chemical plants, where their corrosion resistance minimizes replacements, even under harsh chemical exposure. Aerospace: Due to their lightweight and strength, titanium fittings contribute to fuel efficiency in aircraft, reducing overall weight without sacrificing safety. Medical Industry: In healthcare, titanium’s biocompatibility makes it a safe choice for orthopedic implants and medical devices, ensuring high durability and minimal risk of adverse reactions.

2. Titanium Tubes Titanium tubes are highly valued for their ability to withstand extreme temperatures and corrosive environments while maintaining structural integrity. Their lightweight nature adds to their appeal, allowing for effective application in various high-stress settings.Chemical Processing: Titanium tubes safely transport corrosive chemicals in processing plants, ensuring no compromise in structural integrity even under tough conditions. Heat Exchangers: Due to excellent thermal conductivity and corrosion resistance, titanium tubes are an ideal choice for heat exchangers in industries like power generation and desalination, where they enable efficient cooling and heating in aggressive environments.

3. Titanium Plates Titanium plates offer high structural integrity and durability, making them a preferred choice for components that face challenging conditions. These plates are designed for applications that require exceptional strength and resistance to environmental stressors.Marine Industry: Titanium’s resistance to seawater corrosion makes titanium plates perfect for marine applications, including shipbuilding and underwater equipment. Defense and Aerospace: In the defense and aerospace sectors, titanium plates are essential due to their light weight and exceptional strength, used in protective armor and aircraft parts where both performance and weight savings are crucial.

4. Titanium Rods Titanium rods serve as raw materials in manufacturing and machining, known for their strength, flexibility, and resilience in high-demand settings. These rods are popular across multiple industries for their durability and high performance.Automotive Industry: Titanium rods help reduce vehicle weight and improve fuel efficiency, offering strength without adding unnecessary bulk. Medical Implants: Titanium’s biocompatibility allows titanium rods to be used in medical implants, such as spinal and dental devices, where they offer high safety and integration with human tissue.

Benefits of Using Titanium Products Exceptional Strength and Lightweight: Titanium’s high strength combined with low weight allows it to be used in weight-sensitive applications without compromising durability, making it a superior choice over heavier metals. Corrosion Resistance: Titanium’s resistance to corrosion from seawater, acids, and industrial chemicals ensures long-lasting performance even in aggressive environments. High-Temperature Tolerance: Titanium maintains its structural integrity and strength under high temperatures, making it suitable for heat-intensive applications. Biocompatibility: For medical use, titanium’s compatibility with human tissues makes it ideal for implants, minimizing the risk of rejection and improving patient safety.With these robust properties, titanium products play a critical role in advancing industrial applications from medical devices to aerospace structures. Whether you need high-quality titanium fittings, tubes, plates, or rods for your industrial requirements, our selection offers performance you can rely on, even in the toughest conditions.Contact us today to learn how titanium products can benefit your industry, improve efficiency, and elevate your projects.

FAQs About Titanium Fittings, Plates, and Tubes

What industries benefit most from titanium fittings, plates, and tubes? Titanium products are widely used in aerospace, marine, medical, automotive, and chemical processing industries due to their unique combination of strength, corrosion resistance, and lightweight. Why is titanium often chosen over other metals for high-performance applications? Titanium’s high strength-to-weight ratio, corrosion resistance, and biocompatibility make it an ideal choice in applications where durability, safety, and performance are crucial. Are titanium rods safe for use in medical implants? Yes, titanium is biocompatible and integrates well with human tissues, making it safe and commonly used in medical implants, such as in orthopedic and dental applications. Categories Titanium Titanium fittings Titanium tube Titanium Plate Titanium rods

Read the full article

0 notes

Text

Heat exchanger manufacturer in India

Anpam Engineering is a leading manufacturer of heat exchangers in India, considered for its high quality goods and innovative technology. The company has established itself as a prominent player in the heat exchanger industry, and serves various industrial sectors together with chemical, petrochemical, energy production, prescribed medication, food processing and HVAC (heating, ventilation and air conditioning) industries.

Heat exchanges are important components of business processes, designed to move between heat or large fluids. Anpam Engineering specializes in the production of a comprehensive selection of heat exchangers, such as shells and tube heat exchangers, plate heat exchangers, air -cooled heat exchangers and spiral heat exchangers. These products are engineered to handle extreme temperatures, pressure and intoxicants, ensuring maximum performance and efficiency.

One of the main reasons behind the success of anpam engineering in the heat exchanger market is its commitment to provide corresponding solutions to meet the unique needs of its customers. With years of experience and a team of highly skilled engineers, anpam provides custom design based on specific requirements such as engineering size, material and operational conditions. This flexibility allows them to fulfill the comprehensive spectrum of industries ranging from small -scale businesses to large multinational corporations.

The production manner of ANPAM engineering follows strict control strategies and industry requirements to ensure that every heat exchanger survives. The employer uses excessive-grade substances which includes chrome steel, titanium and copper alloys to make certain durability and efficiency.

Advanced construction techniques, including welding, soldering and pressure tests, are used to guarantee the integrity and performance of each product.

In addition, Anpam gives a strong emphasis on engineering stability. They focus on producing energy -efficient heat exchangers that help reduce energy consumption and environmental impact. Their innovative design and continuous investments in research and development are at the forefront of industry, making them a reliable partner for heat exchanger solutions in India.

In conclusion, Anpam Engineering is its reputation as a pinnacle heat exchanger manufacturer in India as an end result of its dedication to excellence, consumer satisfaction and innovation. The enterprise keeps to steer the industry by means of imparting dependable, durable and efficient heat exchanger solutions for diverse business applications.

#Best Heat Exchangers#Heat exchanger design#Heat exchanger types#Heat Exchanger Companies in India#Heat exchanger diagram#Heat Exchanger manufacturer#Heat exchanger price

0 notes

Text

Shell and Tube Heat Exchanger: Design, Applications, and Advantages

Introduction to Shell and Tube Heat Exchanger

The shell and tube heat exchanger is one of the most widely used types of heat exchangers in industrial applications. Its robust design, efficiency, and versatility make it suitable for various processes, including power generation, chemical processing, and HVAC systems. This article explores the working principle, components, applications, and benefits of shell and tube heat exchangers.

How a Shell and Tube Heat Exchanger Works

A shell and tube heat exchanger operates by transferring heat between two fluids—one flowing inside the tubes (tube-side fluid) and the other outside the tubes but within the shell (shell-side fluid). The heat transfer occurs through the tube walls, allowing efficient thermal exchange without direct mixing of the fluids.

Key Components of a Shell and Tube Heat Exchanger

Shell – The outer vessel that houses the tube bundle and shell-side fluid.

Tubes – Small-diameter pipes through which the tube-side fluid flows.

Tube Sheets – Plates that hold the tubes in place and separate the shell and tube sides.

Baffles – Plates that direct shell-side fluid flow to enhance heat transfer.

Inlet and Outlet Nozzles – Entry and exit points for both fluids.

The design ensures maximum surface area for heat exchange while maintaining structural integrity under high pressures and temperatures.

Types of Shell and Tube Heat Exchangers

Several configurations exist based on flow arrangement and construction:

1. Fixed Tube Sheet Exchanger

Tubes are permanently attached to the tube sheets.

Simple and cost-effective but less suitable for thermal expansion.

2. Floating Head Exchanger

One tube sheet is fixed, while the other can move ("float").

Accommodates thermal expansion, making it ideal for high-temperature applications.

3. U-Tube Exchanger

Tubes are bent in a U-shape, allowing free expansion.

Reduces stress but can be harder to clean.

4. Kettle Reboiler

A specialized shell and tube heat exchanger used for vaporizing liquids.

Common in distillation processes.

Each type serves specific operational needs, ensuring flexibility across industries.

Applications of Shell and Tube Heat Exchangers

Due to their durability and efficiency, shell and tube heat exchangers are used in:

1. Oil Refineries and Petrochemical Plants

Cooling hydrocarbons and condensing vapors.

2. Power Plants

Acting as condensers in steam turbines.

3. HVAC Systems

Regulating temperatures in large-scale heating and cooling systems.

4. Food and Beverage Industry

Pasteurization and sterilization processes.

5. Marine Applications

Cooling engine systems and other machinery.

Their adaptability to high-pressure and high-temperature conditions makes them indispensable in heavy industries.

Advantages of Shell and Tube Heat Exchangers

1. High Efficiency

Large surface area and turbulent flow (enhanced by baffles) improve heat transfer.

2. Durability

Constructed from materials like stainless steel, titanium, or copper alloys for corrosion resistance.

3. Easy Maintenance

Modular design allows for cleaning and tube replacement without dismantling the entire unit.

4. Scalability

Can be designed for small or large capacities by adjusting tube numbers and shell size.

5. Pressure and Temperature Resistance

Suitable for extreme operating conditions, unlike plate heat exchangers.

These benefits explain why shell and tube heat exchangers remain a preferred choice in demanding environments.

Design Considerations for Shell and Tube Heat Exchangers

To optimize performance, engineers must consider:

1. Fluid Properties

Viscosity, thermal conductivity, and fouling tendencies affect material selection.

2. Flow Arrangement

Counter-flow (most efficient), parallel flow, or cross-flow configurations.

3. Thermal Expansion

Differential expansion between shell and tubes must be managed to avoid damage.

4. Fouling Resistance

Proper material selection and periodic cleaning prevent buildup.

5. Cost vs. Performance

Balancing initial investment with long-term efficiency and maintenance costs.

A well-designed shell and tube heat exchanger ensures longevity and operational efficiency.

Conclusion

The shell and tube heat exchanger remains a cornerstone of thermal management in industrial systems. Its versatility, efficiency, and robustness make it indispensable across multiple sectors. By understanding its design, types, and applications, engineers can select the best configuration for their specific needs.

Whether in power plants, refineries, or HVAC systems, the shell and tube heat exchanger continues to play a vital role in energy transfer and process optimization.

This article provides a comprehensive overview of shell and tube heat exchangers, covering their functionality, variations, uses, and benefits. If you have further questions or need assistance in selecting the right heat exchanger, consulting a thermal engineering expert is recommended.

1 note

·

View note

Text

Spiral Plate Heat Exchanger: Efficiency and Applications in Modern Industry

Introduction

Heat exchangers play a crucial role in various industrial processes, enabling efficient heat transfer between fluids. Among the different types available, the spiral plate heat exchanger stands out due to its unique design and superior performance in handling challenging fluids. This article explores the working principle, advantages, applications, and maintenance of spiral plate heat exchangers, providing a comprehensive understanding of their significance in modern industries.

What Is a Spiral Plate Heat Exchanger?

A spiral plate heat exchanger is a specialized heat transfer device consisting of two long metal plates wound into a spiral formation. These plates create two separate channels for hot and cold fluids, allowing efficient thermal exchange. The compact and robust design makes it suitable for handling viscous, fouling, and corrosive fluids that would typically clog or damage conventional heat exchangers.

Key Features of Spiral Plate Heat Exchangers

Spiral Flow Design – The coiled structure ensures a long flow path, maximizing heat transfer efficiency.

Self-Cleaning Mechanism – The turbulent flow reduces fouling, making maintenance easier.

Compact and Space-Saving – The spiral configuration requires less space compared to shell-and-tube heat exchangers.

Handles High-Viscosity Fluids – Ideal for slurries, sludge, and sticky fluids.

Corrosion Resistance – Available in various materials, including stainless steel and titanium, for harsh environments.

How Does a Spiral Plate Heat Exchanger Work?

The spiral plate heat exchanger operates on the principle of counter-current flow, where two fluids move in opposite directions through the spiral channels. Here’s a step-by-step breakdown of its operation:

Fluid Entry – The hot fluid enters through the center and flows outward, while the cold fluid enters from the periphery and moves inward.

Heat Transfer – As the fluids travel along the spiral channels, heat is exchanged through the metal plates.

Exit Points – After heat exchange, the cooled hot fluid exits from the outer port, and the heated cold fluid exits from the center.

This counter-flow arrangement ensures maximum thermal efficiency, making the spiral plate heat exchanger highly effective in industrial applications.

Advantages of Spiral Plate Heat Exchangers

1. High Thermal Efficiency

The extended surface area and turbulent flow enhance heat transfer rates, outperforming traditional heat exchangers in many scenarios.

2. Reduced Fouling and Blockages

The self-cleaning action minimizes sediment buildup, reducing downtime and maintenance costs.

3. Versatility in Fluid Handling

Capable of processing viscous, abrasive, and particulate-laden fluids without clogging.

4. Compact Design

Requires less installation space than shell-and-tube or plate-and-frame heat exchangers.

5. Durability in Harsh Conditions

Constructed from corrosion-resistant materials, making them ideal for chemical and wastewater treatment applications.

Applications of Spiral Plate Heat Exchangers

1. Chemical Processing

Used for heating or cooling aggressive chemicals, acids, and solvents due to their corrosion-resistant construction.

2. Food and Beverage Industry

Ideal for pasteurization, sterilization, and viscous fluid handling (e.g., syrups, dairy products).

3. Wastewater Treatment

Effectively treats sludge and effluents by recovering heat from waste streams.

4. Oil and Gas Industry

Handles crude oil, refinery fluids, and high-viscosity hydrocarbons efficiently.

5. Power Generation

Used in heat recovery systems to improve energy efficiency in power plants.

Maintenance and Cleaning of Spiral Plate Heat Exchangers

While spiral plate heat exchangers are designed to resist fouling, periodic maintenance ensures optimal performance. Key maintenance practices include:

Regular Inspection – Check for corrosion, leaks, or plate damage.

Mechanical Cleaning – Use high-pressure water jets or brushes for deposits.

Chemical Cleaning – Acid or alkaline solutions can dissolve stubborn scales.

Gasket Replacement – Ensure seals are intact to prevent leaks.

Proper maintenance extends the lifespan of the exchanger and maintains efficiency.

Comparison with Other Heat Exchanger Types

FeatureSpiral Plate Heat ExchangerShell-and-TubePlate-and-FrameFouling ResistanceHighModerateLowSpace RequirementCompactBulkyModerateFluid HandlingViscous, SlurriesClean FluidsMedium ViscosityMaintenanceLowHighModerateCostModerateHighLowThe spiral plate heat exchanger excels in handling difficult fluids where other exchangers fail.

Future Trends in Spiral Plate Heat Exchanger Technology

With increasing industrial demand for energy efficiency, spiral plate heat exchangers are evolving with:

Advanced Materials – Enhanced alloys for extreme temperatures and corrosive environments.

Smart Monitoring – IoT-enabled sensors for real-time performance tracking.

3D-Printed Designs – Customizable spiral geometries for specialized applications.

These innovations will further solidify their role in sustainable industrial processes.

Conclusion

The spiral plate heat exchanger is a highly efficient, durable, and versatile solution for industries dealing with challenging fluids. Its unique spiral design, self-cleaning capability, and compact structure make it superior to conventional heat exchangers in many applications. By understanding its benefits and maintenance requirements, industries can maximize operational efficiency and reduce downtime.

As technology advances, spiral plate heat exchangers will continue to play a pivotal role in energy recovery and sustainable industrial processes, making them indispensable in modern engineering.

1 note

·

View note

Text

S1 E20

"Paclantis"

Journal entry 14.10.2537

I couldn't write in this journal for two weeks because I injured my hand but I'm all better now. Anyways, two weeks ago me and Pac encountered the Pacinator. I didn't expect to see that man after twelve years but I did. I was quite nervous upon finding out from Inky, Blinky, and Clyde that Betrayus had hired the Pacinator to ice out me and Pac, since that man had defeated my father who was even faster than I am now, so I thought I would have to hide out forever.

I discovered I made the same fatal mistake my father did; underestimate the durability of the Pacinator's yogurt gun. I tried to punch it out of his hand but I injured my hand upon striking it, which led to me being frozen. Me, Pac, and our friend Spiral who tried to save us, were taken to a factory and were saved by Pinky and Cylindria. Right when me and Pac cornered the Pacinator, he jumped into a yogurt tub, and when Pac drank up the yogurt, he was gone. President Spheros sent his best agents to track down the Pacinator but we haven't gotten any leads yet. I did manage to steal the yogurt gun so maybe we could make better weapons using parts of it.

I can't help but wonder; since one enemy from twelve years ago rose up, does that mean he will come back too? Why would he? He's already been to Pacworld once, why would he need to come again? Then again, just two days after we met him, the Pacinator showed up and somehow knew exactly where to find us. Maybe he's the one who hired that frozen yogurt psycho. I guess time will tell if we meet again.

---------------------------------------------------------------

In Dr Buttocks' lab, Spiral and Cylindria were capturing ghosts in their PSCs while Pac and Christina were going around eating others.

Christina was in a titanium form while Pac was ice Pac-Man. He flies around and headbutts a fire ghost and an ice ghost.

"Some ghosts are red, some ghosts are blue! I'm super cool and now so are you!" Pac exclaims as he slips out his tube-like tongue that's frozen on the end.

The ghost panic and disperse but Pac shoots out ice and freezes them.

"Aw yeah! Way cool!" Cylindria exclaims as Pac sucks the ghosts into his mouth.

"Argh! Brain freeze!" Pac exclaims as he grabs his head with both hands and belches out frozen eyeballs.

Meanwhile with Christina, she was chasing after three ghosts that were escaping the lab, when she suddenly got surrounded by more of them.

"You can't eat us all at once metal girl!" A red ghost says as the others laugh.

Christina smirks and slithers out her magnetic tongue. "Wanna bet?"

The magnetic tongue pulls the ghosts in and Christina eats before belching out their eyeballs.

"Oh yeah. That's attractive!" Cylindria says as she gives Christina finger guns.

Christina and Pac then turn their attention to Dr Buttocks who panics as they fly over to him.

"Did you really think we'd let you get away with stealing all of these inventions from Sir Cumference?" Pac asks.

"Of course not! I was counting on you trying to steal them back so I could finish you off with my newest, ingenious, buttocksified invention!" Dr Buttocks exclaims as he points a weapon at the four of them.

As Christina is about to punch Dr Buttocks, he fires out a small triangular bullet that lands on the floor and does nothing. The four friends stare at the bullet in confusion as Dr Buttocks looks disappointed.

"Oh! Lousy Netherworld ammo!"

"So how do we get all this stuff back?" Christina asks.

"Easy! Just Pac it up!" Cylindria replies.

Pac slithers this tongue out and starts sucking in the invention while Dr Buttocks tries to stop him.

"I've still got room for more!" Pac exclaims as he goes to suck up more inventions.

Dr buttocks picks up a scroll and flies up.

"I win! I have the scroll unt my eyeballs—" Dr Buttocks is cut off as Christina flies towards him and tries to snatch the scroll out of his hands.

However, Dr Buttocks had a grip on it, so she only tears a piece of it off as the light blue ghost quickly flies away and out of their sights.

Pac frowns. "Like I said, I still got room for—" He suddenly gets stopped by Spiral who grabs his arm and stops him from going after Dr Buttocks.

"Yo bro, our berry powers running low. Time to blow!" Spiral exclaims as Christina flies back towards them.

"Yeah..before my stomach does." Pac says as he burps.

"Ew! Pac!" Christina exclaims as the four of them start leaving the Netherworld.

"Okay seriously gross!" Cylindria says.

Betrayus watches them leave and glares at Dr Buttocks as he floats over to him.

"I can't believe you let those overgrown lemon balls get away with everything we stole!" The fire ghost exclaims.

"Those yellow pests have nothing compared to what they didn't get." Dr Buttocks smirks as he takes out the scroll. "We still have the greatest discovery of all time!"

---------------------------------------------------------------

"What could possibly be better than finally destroying the Pac Pain and his stupid lightning lemon ball of a cousin?!" Betrayus exclaims.

Dr Buttocks opens up the scroll which opens up a map that looks like a pony; making Betrayus yawn.

"Oh look, you tried to draw a pony." Buttler dryly remarks.

Dr Buttocks frowns. "Give me a minute!"

The light blue scientist folds up the scroll into a star with the Pac-Man symbol eating pellets over a sun, and shows Betrayus and Buttler.

"Oooh! Can you make a swan?" Betrayus teases.

"Look closer." Dr Buttocks says.

Betrayus focuses more on what Dr buttocks is showing him before his eyes suddenly widen. The ghost gang are flying past the door of Betrayus' throne room when they stop upon hearing Betrayus giggling in excitement.

"Could this be?!" Betrayus exclaims.

"Yes!" Dr Buttocks replies.

"So this map will lead me to.."

"Indubitably!"

Betrayus then snatches the map away from Dr Buttocks.

"And now that I have the map, I don't need you! Ahahaha!!" Betrayus laughs as he accidentally burns the map to a crisp.

"I suppose you have no need for my photographic memory either?" Dr Buttocks asks.

"New plan! You, Dr Heiny Headcase, are going to take me there immediately!" Betrayus demands while pointing at Dr Buttocks.

Buttler turns to Betrayus in shock. "You?! Venture away from the safety, comfort, and slimy serenity of the Netherworld?!" He exclaims.

"I need to be sure that no one gets there before me." Betrayus then flies over to Dr Buttocks. "It's not too far from here right?"

Dr Buttocks clears his throat. "Well no, not far, but deep. You do realize it's underwater?"

The ghost gang watches in surprise with Inky eating someone peeled slugs.

"Underwater?" Inky whispers then panics slightly when he talks out loud.

"Shhh!!" Pinky shushes him and Blinky throws the box of peeled slugs over his head.

Blinky, Pinky, and Clyde then leave before Blinky pulls Inky along with them, as Betrayus pushes Dr Buttocks through the doors.

"But the water..." Dr Buttocks begins.

"Don't bother me with details! Just get me there!" Betrayus demands as he pushes the light blue scientist along with Buttler trailing behind them. The ghost gang come out from hiding as they leave.

"What's underwater?" Pinky says while looking at the rest of the ghost gang.

"For Betrayus to leave the Netherworld it's gotta be really good!" Blinky exclaims.

"Or really bad." Clyde says as they leave to follow Betrayus, Buttler, and Dr Buttocks.

----------------------------------------------------------------

Meanwhile in Sir Cumference's lab, Sir C is getting his inventions back from Pac's stomach.

"Oh thank you for getting my best inventions back from that ectoplasmic crook. Heheh no chance he'll ever steal you." Sir Cumference says to Grinder who bleeps in response. The old scientist checks Pac's mouth for anymore inventions. "I think that's all of them."

Christina's eyes suddenly widen in realization. "Wait hold on. Buttocks really didn't want us to get this."

She reaches into her pocket and gets out the torn piece of the map. Sir Cumference looks at it in interest as he turns off the lights and then Grinder uses his eyes to shine a light on the table. Christina sets down the map and Sir Cumference examines it.

"Hmm..looks like part of a map." He says as he puts a hand on his monocle to focus better on it. "Definitely very old paper. Writing in the ancient language of Paclatin which I'm fluent in of course."

Sir Cumference's eyes suddenly widen. "Great globes! It says Paclantis!"

The four friends look eachother in surprise before looking back at Sir C.

"You mean like the ancient city that sunk into the ocean centuries ago from a book of legends I once read?" Christina asks.

"But that's all Paclantis is; a legend." Spiral says.

"Oh I believe it was once very real!" Sir Cumference says.

"But how can Dr Buttocks have gotten his slimy hand on a map to Paclantis?" Cylindria asks.

"Found in bottle, stolen from a sea captain.." Sir Cumference then gasps. "It may have been hidden inside one of my early inventions! Possibly by your father!" He says at Pac.

"My dad!?" Pac exclaims.

Sir Cumference hops towards a compartment while throwing off his monocle and opens it up.

"At Pacworlds leading archaeologist, one of your father's passions was searching for Paclantis." He explains while throwing out random things to look for something.

"But no one's ever found it right?" Cylindria questions.

Sir Cumference takes out a photo and smiles. Grinder carries a bunch of random inventions as Sir Cumference sits down at the table and Pac and Christina join him. Sir C puts down the photo and lets the yellow duo see it. It's a photo of Zac and Sunny in Paclantis with scuba gear on.

"Wow! Mom and Dad—" Christina then covers her mouth after realising she accidentally called Pac's parents her parents. "I'm so sorry! I didn't mean to call them that!" She blushes slightly from embarrassment.

Pac laughs. "It's okay. They did raise you for a little while so it's only natural."

Christina scratches her head and smiles slightly before looking back at the photo.

Pac looks over at Sir Cumference. "Maybe my parents did find Paclantis. Maybe that's where they disappeared to!"

"That's a lot of maybes." Cylindria says.

"There's no maybe about this! Paclantis was home to the berry bush of Youth!" Sir Cumference exclaims.

"Berry bush of youth? Do the berries make you young or something?" Christina questions.

"Indeed young lass." Sir Cumference replies.

"You don't actually believe that dopey story berries making people young." Spiral says.

As Grinder is carrying the inventions around, Fuzbitzs pokes him with his ears which makes the robot drop all the inventions. The little fuzz monster puts his ears to his mouth as if holding back a laugh, as Grinder spins his head around and steam shoots out of his ears in annoyance.

"Well if there's a berry that can turn me and Pac into the form of a chameleon, I don't think a berry turning people young is a far fetch." Christina says.

Cylindria agrees. "Christina does have a point there."

"Yes well I know the berry of youth is real and so did Pac's father." Sir Cumference says before becoming alarmed and frustrated. "Good heavens! If that nitwitted Buttocks knows where Paclantis is, so does Betrayus! And if Betrayus eats one of the berries of youth, his body will be restored!"

"And with the bush of those berries, Betrayus could bring back his entire army!" Cylindria says.

"There's no time to waste! You four need to leave immediately to find.."

Sir Cumference taps something on his device and an image of Paclantis appears on a screen.

"Paclantis."

----------------------------------------------------------------

Meanwhile in the Netherworld, Dr Buttocks was pulling Betrayus' arm to try and stop him from going into the water, while Buttler was following behind them.

"Hurry up! Let's go!" Betrayus exclaimed.

"But uh-" Dr Buttocks began.

"Leave your buts out of this! My destiny awaits. Nothing can stop me!" Betrayus snaps back.

As Betrayus floats over the water, the tips of his ghost form touch it and causes his body to sizzle and smoke up. Dr Buttocks floats over to the other side of Betrayus and chuckles.

"As I was attempting to say, water and fire ghosts don't mix." He says as Buttler chuckles.

A little while later, Betrayus is inside of a circular chamber with Dr Buttocks and Buttler floating infront of it.

"Inside this chamber I invented—" Dr Buttocks starts saying before Buttler cuts him off.

"Translation: Stole from Sir Cumference."

The two of them blow raspberries at eachother before they turn back towards Betrayus and Dr Buttocks continues.

"You will be completely safe from water."

Betrayus looks at them both; looking disoriented before putting his hand up to his ears. "What?"

"You're safe from water." Dr Buttocks repeats.

"Huh?"

"You're safe from water!" The bum twins say in union.

"Who is Walter!?" Betrayus exclaims.

"Nevermind." Buttler says.

"Thanks to my latest invention.." Dr Buttocks begins.

"Sir C ripoff!" Buttler says.

"We'll get to Paclantis in no time unt find the berry bush of youth" Dr Buttocks says as the ghost gang listen in.

Blinky chuckles. "Not if we find it first."

------------------------------------------------------------------

Back in the lab, the four friends were getting ready to go to Paclantis.

"I've modified your hoverboards for underwater travel." Sir Cumference says as Spiral and Cylindria hold up their hoverboards.

Sir Cumference approaches the two and gives them two light blue power berries which makes them grow fins on their heads. Their mouths open and close like a fish before they stop.

"These gill berries will allow you to breathe underwater. Oh and I forgot to say, I did some changes to the lemon rocket and made it slightly bigger so it's a two seater for you and Pac, Christina." Sir Cumference says.

"Oh nice." Christina says as she hops into the lemon rocket where Pac is waiting.

"You both ready?" Sir Cumference says.

"Ready!" The yellow duo say as the door to the lemon rocket closes behind them.

There's a second seat next to Pac's as Sir Cumference said. Christina sits down while getting a little excited about this journey as Pac sits down next to her.

"Toying beam activated!" Sir Cumference says as he presses a button.

A beam shoots out of the lemon rocket's engine and latches onto Grinder who jumps back and disconnects himself from it. The beam connects to the hoverboards and lifts them up into the air with Cylindria and Spiral on them.

"I'm programming the lemon rocket's autopilot to take you to where the Netherworld meets the sea. From there, you'll find the ghosts, follow them to Paclantis, and get to the berry bush they do." Sir Cumference explains.

"Uh one question. How are you going to get us from here to the sea?" Cylindria asks.

Sir Cumference responds immediately. "Easy! Down the drain." As he looks at his tablet that shows Pac and Christina.

"What? That's impossible. We're way too big to—" Christina gets cut off by Sir Cumference.

"Activating rocket shrinking ray!" He exclaims as he presses a button which makes the lemon rocket, along with Spiral and Cylindria shrink down.

Grinder then picks them up and drops them down in the drain in the sink.

"Happy hunting!" Sir Cumference says.

The lemon rocket zooms through the drain as Spiral and Cylindria yell, and Christina and Pac try to control the lemon rocket while keeping an eye on their surroundings. Eventually they exit the drain and Pac drives them through the sea.

"Ugh..I think I got sea sick before we got to sea." Pac says as he covers his mouth to prevent himself from throwing up.

Christina shakes her head in an attempt to clear off the dizziness and looks around at the fish.

"Wow it's so pretty down here." She says.

"Yeah, the fish down here are like gigunda!" Spiral exclaims.

"Or we're still shrunken." Cylindria says.

Suddenly three blue fish see them and decide they look like a tasty snack. The pink and red duo look at them in shock as Pac and Christina turn around.

"Either way, they think we're fish food!" Pac says.

"Pac go!" Christina yells as she drives the lemon rocket with the fish following after them.

"Christina wait—!" Pac exclaims as they suddenly reach their normal size again.

The fish gasp in surprise at the now giant lemon rocket and pink and red duo before quickly dispersing. The four of them sigh in relief as Pac contacts Sir Cumference.

"Sir C, we're in the sea." He says.

"Excellent." Sir Cumference exclaims as Fuzbitz jumps and down excitedly. "Activating the lemon rocket plasma detector!"

Christina looks down at the radar and sees three blips.

"It worked! I'm picking up three ghosts." She says.

"Up periscope!" Pac exclaims.

"Wait does this thing even have a periscope?" Christina says.

"For sure bro. Look at it go!" Spiral says as a long metal thing that resembles a mouth comes out of the front of the lemon rocket.

Christina pulls down the periscope and looks through it to look for Betrayus, Dr Buttocks, and Buttler. She soon manages to spot Betrayus in a chamber-like ball with Dr Buttocks and Buttler dragging it along in a vehicle.

"Got em! The three big bad Bs: Betrayus, Buttocks, and Buttler." Christina exclaims.

Betrayus is spinning around the wheel inside of the chamber.

"Are we there yet? Are we there yet? Are we there yet?"

Christina pushes the periscope back up and glances back at the radar.

"Hey that's weird. The plasma detector is picking up more ghosts." She says while narrowing her eyes. "I wonder if it's—"

Cylindria suddenly speaks up. "Well whoever they are doesn't matter. Betrayus is the one with the map to Paclantis."

"Right. Follow the big bad Bs Pac." Christina says while turning towards him.

"Let's rocket on." Pac says as he drives them forward.