#timber roof truss manufacturers

Explore tagged Tumblr posts

Text

Elevate Your Building with Quality Timber: Role of Timber Suppliers in Melbourne

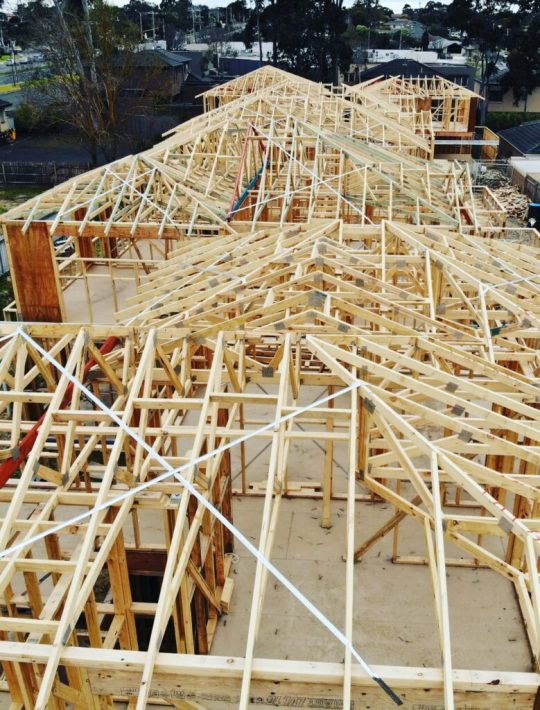

When it comes to building robust, reliable structures, the importance of quality timber cannot be overstated. Timber roof trusses, in particular, from the leading timber suppliers in Melbourne play a vital role in ensuring the structural integrity of a building. Timber is one of the most versatile construction materials, and its applications extend far and wide. In Melbourne, the demand for these trusses is ever-increasing, and to meet that demand, we look to timber roof truss manufacturers. The trusses are made from timber can be used for spanning longer distances and hence the need for internal supporting structures is reduced.

The framework of wooden timbers designed to hold the weight of the roof, are crucial in constructing the backbone of a building and the very best truss manufacturers in Melbourne do the work onsite. Whether it's a residential house, a commercial property, or an industrial facility, timber roof trusses provide the much-needed support to keep the roof in place.

Timber roof truss manufacturers play a significant role in ensuring the supply of high-quality wood for various construction applications. These timber suppliers provide a range of timber species, ensuring that builders have access to the right wood for their needs. Professionals understand that their products are the backbone of countless structures throughout the city and hence the structures are built in a solid way.

Insights About Timber Trusses and In-Depth Details

The roof trusses are also known as posi struts and they extend the lifespan of buildings by efficiently distributing the load and preventing excessive stress on walls and supports. In contrast, floor roof trusses are essential for multi-story buildings, offering a sturdy foundation for upper levels. The quality of the timber used is paramount, ensuring the safety and durability of the entire structure. These components play a pivotal role in shaping the architecture of structures and timber roof trusses are engineered to offer exceptional strength while allowing for larger open spaces.

From door frames to hinges and locks, these components ensure that doors not only look good but function smoothly, enhancing the overall aesthetics and security of property. Reach out to the leading suppliers of door hardware and trusses and get a quote for building requirements.

Source

0 notes

Text

Strong and Reliable Frame and Truss Suppliers in Sydney

Looking for reliable Frame and Truss Suppliers in Sydney? Dark Red offers expertly crafted timber products designed to meet Australian standards. Trust their experience for quality frames and trusses that ensure strength and durability in every construction project.

0 notes

Text

5 Ways Timber Wall Frames Make Your Homes Timeless

It has been recorded historically that when wood is maintained properly, it can last for millennia. All across the world, there are historic examples of wooden structures that have stood for centuries. With modern innovations like preservatives and maintenance, wood and timber structures can withstand elements providing them with a timeless appeal. Timber wall frames are another example that are used in the construction of properties and they are durable and long-lasting because they are well-suited to almost any climate. Keep reading to know further about the everlasting attraction of timber wall frames and 5 ways how they make your homes timeless.

Longevity

Timber wall frames come with construction benefits as they are durable, versatile and adaptable. Homeowners choose timber wall frames because timber can inherently resist fire and remains structurally stable. Next-generation of timbers also offers improved strength and stability along with an increased long-lasting lifespan that endures through the ages. Therefore, structures with timber wall frames have a reduced risk of demolition due to their enhanced stability.

When it comes to roof and wall framing, timber roofs are not only strong and easy to install but they can also be tailored according to the structure of the property and can be easily integrated with plumbing, electrical and mechanical systems. Therefore, timber wall frames offer adaptability and versatility during the construction process while also being economical due to their lower material costs.

Aesthetic and Eco-Friendly

The natural aesthetic of wood combines with the warmth of timber to add character and personality to any property. Studies have shown that people associate positive behaviours and attitudes with wood and find it visually appealing when it is used in buildings. Exposed wood trusses at the roof and heavy timber columns as wall frames can immediately pique the interest of the viewer's eye and set it apart from otherwise monotonous spaces.

Moreover, the biophilic benefits of timber wood also draw the attention of builders and property buyers as humans have an innate tendency to get attracted towards nature. Timber wall frames offer a sustainable form of construction due to the least amount of CO2 released from any building material. Moreover, it is also non-toxic, and naturally renewable and is predicted to be the most important resource for the construction industry within the next 5-10 years, making your property timeless.

Insulation Properties

Timber wall frames come with thermal insulation for the walls with various thicknesses. Even lightweight and thin walls can achieve thermal properties and can therefore meet enhanced performance targets. The list of added benefits of the thermal insulation property of timber wall frames includes fewer materials required for construction, leading to reduced project costs and more usable floor area. Additionally, timber walls achieve air tightness due to vapour control layers in the inner face of the wall, acting as the barrier.

Apart from thermal insulation, timber wall frames also provide sound insulation. Manufacturers install a gap of around 50mm between the two leaves of the walls which means that the sound has fewer paths to travel through. This results in an enhanced acoustic performance of the walls, serving as a noise cancellation barrier, as your walls now absorb and deaden the sound.

Construction Benefits

The construction and building industry is moving towards building components off-site to easily assemble the parts as they arrive. Timber wall frames allow off-site prefabrication which means they are easy to use and install and offer a reduction in the construction duration. In contrast to traditional masonry construction, timber construction requires 25% less time by increasing the speed of build.

Private constructors have always used timber frames to shorten the construction time and offer a stable building programme. Projects that utilize timber frames can be completed in almost a year and have fewer restrictive conditions when it comes to climate and weather, Hence the enhanced flexibility and readily available nature of wood means the timber wall frames are easy to use and easy to build for all ages.

Cost Efficiencies

Lastly, timber wall frames promise a more time-efficient construction which requires only 3/4th of the labor you would normally employ. As discussed above, the speed of building with timber wall frames is quicker than a normal project which provides significant benefits to homeowners. Moreover, there are also higher levels of quality control involved because the panels are pre-fabricated which keeps the construction budget down. Therefore, fewer materials, lowered site overheads and reduced labor and supervision result in money savings for the project.

Takeaway

When it comes to properties that need to stand the test of time, timber frames have always proven their durability and strength. Not only does using timber and wood mark the revival of traditional building materials, but it also offers unique advantages over steel and concrete. Timber wall frames introduce a classic and natural aesthetic to your property while also adding an element of warmth and comfort making your home timeless.

0 notes

Text

Construction Pine LVL Timber

As a leading manufacturer based in China, we are proud to offer our range of high-quality Construction Pine LVL Timber to merchants located in various countries outside of China. Our company specializes in producing a wide range of timber products, including LVL (Laminated Veneer Lumber) products that are known for their superior strength, durability, and stability. Our Construction Pine LVL Timber is one of our most popular products that is widely used in the construction industry for its excellent properties and versatility.

What is Construction Pine LVL Timber?

Construction Pine LVL Timber is a type of engineered timber product that is made by bonding together several layers of thin, high-strength veneers of Pinus Radiata (radiata pine) using adhesives. These veneers are oriented in a specific direction in each layer, which reduces any natural defects in the timber while maximizing its strength and stability. The result is a very strong and uniform timber that can be used for a wide range of construction purposes.

Benefits and Advantages

1. Strength and Durability

The most significant advantage of Construction Pine LVL Timber is its strength and durability. The strength of the LVL comes from the orientation of the veneers, which are layered so that the grains of the wood in each layer are perpendicular to those in the adjacent layers. This arrangement gives the timber a consistent and uniform strength that makes it the perfect construction material for a range of load-bearing applications, such as beams, joists, and columns.

2. Dimensional Stability

Another advantage of Pine LVL Timber is its exceptional dimensional stability. Unlike solid timber, which can shrink or warp when exposed to changes in temperature or moisture, LVL timber is resistant to such changes. This resistance comes from the fact that the veneers in LVL are dried to a very low moisture content before being bonded together. As a result, the overall moisture content of the final product is low, making it less susceptible to shrinkage or expansion.

3. Versatility

Construction Pine LVL Timber is an incredibly versatile timber product that can be used for a wide range of applications. Its strength and dimensional stability make it the perfect material for load-bearing structures such as beams, columns, and trusses, but it can also be used for non-load-bearing applications such as roofing, flooring, and wall framing. Additionally, this timber is used as a substrate in the manufacturing of door and window frames.

4. Cost-effectiveness

Another benefit of Construction Pine LVL Timber is that it is incredibly cost-effective. Its versatility and uniform strength mean that it can often be used in place of traditional hardwoods, which can be costly and may have a varying degree of strength. Similarly, its dimensional stability means that it requires less on-site maintenance than other timber products, making it a more cost-effective option than traditional timber.

Applications of Construction Pine LVL Timber

1. Load-bearing applications

Due to its exceptional strength and durability, Construction Pine LVL Timber is used for several load-bearing applications such as beams, joists, and columns. In these applications, LVL is often used as a substitute for traditional sawn timber or steel. Its uniform strength also means that it can provide an attractive and consistent finish.

2. Non-load-bearing applications

Apart from load-bearing structures, LVL timber is also used in several non-load-bearing applications, such as wall framing, subflooring, and roofing. Since it is dimensionally stable, it can be used for rafters and joists, which require stability and reliability.

3. Plywood substrate

LVL Pine can be used as a substrate in the manufacturing process of several products such as door and window frames. The uniformity and strength of the product ensure that the frames are better constructed, and the adhesive provides excellent bonding strength.

Conclusion

With its exceptional strength, dimensional stability, versatility, and cost-effectiveness, Construction Pine LVL Timber is an attractive choice for merchants across the world. Our high-quality product with uniform strength will help you complete your projects quickly and efficiently. Feel free to contact us with any questions, and we will be happy to provide you with more information about our Construction Pine LVL Timber.

Introduction

The Construction Pine LVL Timber is the ideal structural material to replace solid wood. It dispels lumps, cracks and other defects in raw wood. Secondly, the size of our products is freely adjustable, so you can choose the size that suits your needs. What's more, our products are insect, rot, fire and water resistant. Finally, we offer a wide selection of hardwoods and softwoods; fresh-cut, dried, heat-treated, mould-resistant, chamfered and we can also sell boards in various sizes to suit our customers' requirements. For orders of more than one truckload, we can make sizes to customer drawings. We can also manufacture other industrial packaging from wood. As a result, we offer fast, timely and controlled orders.

Advantage

The structure of Construction Pine LVL Timber greatly reduces warping and twisting deformation, making them an ideal packaging material and a good alternative to solid wood. Secondly, the structure of our products greatly reduces warping and twisting deformation of the products, making them ideal packaging materials and a good alternative to solid wood. Lastly, our products are green and non-polluting and cause no harm to the human body.

Why Choose Us?

We are proud to offer Building LVL Beams products that are not only affordable but also of the highest quality and durability.

We actively create promotion and development channels for all kinds of talents to create a fair and equitable platform.

We value our customers and strive to build long-term relationships based on trust, reliability, and exceptional service.

We actively promote the application of high-efficiency, energy-saving, and environmentally-friendly new technologies and processes, to practice green development.

With years of experience in the industry, we have a deep understanding of the Building LVL Beams market and a proven track record of success.

In order to make consumers feel relieved of the products, our company adopts advanced production equipment, high-quality raw materials, mature technology, strict testing equipment, standardized management.

Whether you need bespoke Building LVL Beams products or standard sizes, we can provide you with exactly what you need.

We are not big or small, harsh and tempered, and all products have been tempered and strictly controlled.

As a leading provider of Building LVL Beams products, our factory delivers consistent, high-quality results to customers worldwide.

Our company adheres to the business philosophy of 'continuous improvement, comprehensive innovation, people-oriented, and co-creating value', and strives to build the company into a world-class manufacturer of Construction Pine LVL Timber.

0 notes

Text

Exploring the Cost of Prefabricated Timber Wall Frames and Trusses

In the ever-evolving construction industry, the demand for efficient, sustainable, and cost-effective building solutions continues to rise. Prefabricated timber wall frames and trusses offer a practical solution for builders who are looking to reduce costs while maintaining high standards of quality.

Understanding Timber Frames and Trusses in Construction

Timber frames and trusses form the structural backbone of most buildings. They provide the necessary support for walls and roofs, ensuring the building remains strong and stable. Timber has been used in construction for centuries, thanks to its durability, flexibility, and aesthetic appeal.

Today, timber frames and trusses are more popular than ever, particularly in Sydney, where builders look for materials that are both sustainable and cost-effective. Timber’s natural beauty and strength make it an ideal choice for residential and commercial buildings.

Why Prefab Frames and Trusses Are the Future

Prefab frames and trusses are gaining popularity due to their efficiency and cost savings. The prefab frames and trusses cost significantly less than traditional on-site construction because they are manufactured in a controlled environment. This process reduces waste, lowers labor costs, and ensures precision in construction.

Moreover, the prefab frames and trusses sydney cost is often lower due to the streamlined production process. This allows builders to deliver projects faster and with fewer errors, making prefabricated solutions an attractive option for modern construction.

Breaking Down the Prefabricated Timber Wall Frames Cost

When considering the cost of construction, prefabricated timber wall frames offer a competitive edge. The prefabricated timber wall frames cost varies depending on factors such as size, design complexity, and material quality. However, these frames are generally more affordable than traditional construction methods.

For builders in Sydney, where the cost of labor can be high, prefabricated options reduce the need for on-site labor, leading to substantial cost savings. Moreover, the predictability of prefab costs allows for better budgeting, which is crucial in large-scale projects.

Timber Wall Frames: Strength, Efficiency, and Sustainability

Timber wall frames are renowned for their strength and efficiency. They are easy to install and offer excellent load-bearing capabilities, making them ideal for residential and commercial buildings. In addition, timber wall frames provide superior insulation, helping to keep buildings warm in the winter and cool in the summer.

Builders in Sydney appreciate timber wall frames for their environmental benefits as well. Timber is a renewable resource, and using prefabricated timber wall frames helps to minimize waste and reduce the carbon footprint of construction projects.

The Flexibility of Frames and Trusses in Sydney

Sydney’s diverse architectural landscape demands versatile building solutions, and timber frames and trusses offer just that. Whether constructing modern high-rises or traditional homes, frames and trusses can be adapted to suit any design requirement. Their lightweight nature makes them easier to transport and install, reducing labor time and costs.

In conclusion, the cost-effectiveness, strength, and sustainability of prefabricated timber wall frames and trusses make them an excellent choice for modern construction. Builders looking to reduce costs without sacrificing quality should consider prefabricated options as a practical and efficient solution.

0 notes

Text

Understanding the Role of Roof Battens and Purlins in Construction

In construction, roof battens and purlins play pivotal roles in ensuring the stability and durability of roofing systems. These components are crucial for supporting roof coverings and contributing to a building's overall structural integrity. This article shares specific functions, benefits, and installation considerations for roof battens and purlins.

How Roof Battens Contribute to Roofing Systems

Roof battens are horizontal strips installed on the rafters or trusses of a roof. They provide a framework that supports the roof covering material, be it tiles, metal sheets, or shingles. Here's how roof battens enhance roofing systems:

Uniform Support for Roofing Materials: Roof battens create a consistent and level surface for attaching roofing materials. This uniformity ensures that the weight of the roofing is evenly distributed, reducing the risk of sagging or damage over time.

Ventilation and Drainage: By creating a gap between the roof covering and the underlying structure, battens increase ventilation and help manage moisture. This is important to prevent mould and rot and ensure the longevity of the roofing materials.

Ease of Installation: Roof battens simplify the installation process of roofing materials. They provide a clear grid that makes it easier for installers to accurately align and secure the roofing components.

The Structural Importance of Purlins

Purlins are horizontal members that run parallel to the eaves of a roof and support the roof battens or directly hold the roofing materials. They are crucial to improving the overall strength and stability of the roof structure:

Load Distribution: Purlins distribute the roof's load across the supporting beams or trusses, ensuring that weight is evenly transferred to the building's structure. This distribution helps prevent overloading and structural failure.

Support for Roof Framing: Purlins provide additional support to the roof framing by reducing the span between rafters or trusses. This reduces the potential for deflection or bending, making a sturdier roof system.

Flexibility in Roofing Design: Builders can create different roofing designs and materials by varying the size and spacing of purlins. This flexibility allows for customization to meet specific structural and aesthetic requirements.

Selecting the Right Materials for Battens and Purlins

Choosing suitable materials for roof battens and purlins is essential for ensuring their effectiveness and durability:

Wood vs. Metal: Traditionally, roof battens and purlins have been made from timber, but metal options, such as steel or aluminium, are popular because of their strength and resistance to environmental factors. Metal components are less susceptible to rot and can offer a longer service life.

Size and Spacing: The dimensions and spacing of roof battens and purlins should be chosen based on the type of roofing material and the load requirements. Builders should follow manufacturer recommendations and local building codes to ensure proper sizing and spacing.

Conclusion

Roof battens and purlins are integral components of roofing systems that contribute significantly to structural stability, support, and efficiency. Understanding their roles and proper installation practices ensures that they fulfil their purpose effectively, leading to a durable and reliable roofing system. Whether you are involved in new construction or roof repairs, attention to these elements will enhance the performance and longevity of your roofing project.

0 notes

Text

Top Truss Manufacturers in Melbourne: Quality Craftsmanship for Stronger Structures

When it comes to building durable and reliable structures in Melbourne, choosing the right truss manufacturer is crucial. Trusses are the backbone of many residential, commercial, and industrial buildings, providing essential support to roofs and other structural components. In Melbourne, several manufacturers excel in producing high-quality trusses, tailored to meet the diverse needs of the construction industry.

Melbourne's leading truss manufacturers are known for their commitment to quality craftsmanship, utilizing state-of-the-art technology and premium materials to create trusses that are both strong and cost-effective. Whether you're constructing a new home, expanding a commercial space, or undertaking a renovation project, partnering with a reputable truss manufacturer ensures that your structure will stand the test of time.

One of the key advantages of working with top truss manufacturers Melbourne is the range of options available. These manufacturers offer various truss designs, including roof trusses, floor trusses, and custom trusses, each engineered to meet specific architectural and structural requirements. Whether you need standard designs or something more unique, Melbourne's truss manufacturers can accommodate your needs with precision.

Quality control is a top priority for truss manufacturers in Melbourne. They adhere to strict industry standards and regulations, ensuring that every truss produced is consistent in quality and performance. This attention to detail not only enhances the structural integrity of your building but also contributes to a smoother construction process, reducing the risk of delays or costly repairs.

In addition to their technical expertise, Melbourne's truss manufacturers are known for their exceptional customer service. They work closely with architects, builders, and contractors to provide tailored solutions that align with project timelines and budgets. This collaborative approach helps ensure that every truss is delivered on time and to the exact specifications required.

Sustainability is also a growing focus among truss manufacturers in Melbourne. Many companies are adopting eco-friendly practices, such as using sustainably sourced timber and minimizing waste during the production process. By choosing a manufacturer that prioritizes sustainability, you can contribute to environmentally responsible construction while still achieving the high standards of quality and durability needed for your project.

In conclusion, selecting the right truss manufacturer in Melbourne is a critical decision that can significantly impact the success of your construction project. By opting for a manufacturer known for quality craftsmanship, a wide range of options, and excellent customer service, you can ensure that your building is supported by trusses that are strong, reliable, and built to last. Whether you're embarking on a new build or a renovation, Melbourne's truss manufacturers are equipped to provide the solutions you need for a successful project.

For More: Contact: 393096889 Email: [email protected] Timings: Mon-Fri:9AM–5PM Visit Us: https://thetrusspeople.com.au/

0 notes

Text

Reliable Steel Suppliers in Melbourne: Collaborating for Building Success

You can get quality materials from dependable steel suppliers in Melbourne. Nothing compares to the strength of steel roof trusses when it comes to carrying the mass of your home's roof. For residential structures, these structural elements offer unparalleled solidity and support since they are made to last. In contrast to conventional timber trusses, which might eventually bend or decay, steel roof trusses provide long-lasting performance, guaranteeing your home's strength for many years to come.

Confirmation of Durability with Australian Steel

Australian stainless steel flat bar is a benchmark for excellence in the field of structural fabrication quality assurance. Each shipment of steel that is used in building projects in Australia is produced in compliance with the most stringent quality requirements and regulations in the world.

All phases of the steel manufacturing procedure are covered by these standards, from obtaining raw materials to producing the finished good. Rules are made to ensure that steel satisfies, if not beyond, global requirements. This means that metal fabricators may produce products using materials that are of unwavering quality, which lowers the possibility of flaws or structural problems.

Personalised Styles for Every House with Simple and Fast Installation

When it comes to house building or renovation projects, time is important. Melbourne residents may benefit from a simple installation approach that cuts down on labour expenses and installation time by using prefabricated steel roof trusses. Every house has different roofing requirements. Melbourne residents may select from a range of steel roof truss designs and combinations to meet their unique needs and tastes.

Steel roof trusses may be tailored to match any style of construction or aesthetic taste, whether you're creating a contemporary masterpiece or a comfortable family home. Every home may have a perfect fit thanks to the adaptability of steel roof trusses, which can be used for both modern flat roof designs and traditional gable roofs.

Source

0 notes

Text

Certificate III in Carpentry

The Certificate III in Carpentry prepares students for careers in carpentry by teaching essential skills and knowledge. They learn hands-on and theoretical training to build and repair wooden structures. Graduates are equipped for residential, commercial, and industrial projects. If you want to study abroad, Australia offers many institutes like Australian Health and Management Institute (AHMI) providing practical experience and industry skills.

Course Overview

This is a trade qualification for carpenters in residential and commercial workplaces. It includes setting out, manufacturing, constructing, assembling, installing and repairing products made using timber and non-timber materials.

State and territory jurisdictions may have different licensing, legislative, regulatory or certification requirements. Relevant state and territory regulatory authorities should be consulted to confirm those requirements.

Completion of the general construction induction training program, specified in the Safe Work Australia model Code of Practice: Construction Work, is required by anyone carrying out construction work. Achievement of CPCCWHS1001 Prepare to work safely in the construction industry meets this requirement.

Mode of Study

Students study full time mixed mode of delivery that integrates:

Face to Face, Online and Self Study Total of 20 hours per week.

self-study to revise and reinforce areas of knowledge, assessment research and assessment preparation and completion

Course Structure

Certificate III in Carpentry consists of thirty four (34) units of competency, comprising 27 core units and 7 elective units, in accordance with the packaging rules.

Core Units

CPCCWHS2001 Apply WHS requirements, policies and procedures in the construction industry

CPCCOM1014 Conduct Workplace Communication

CPCCOM1012 Work Effectively and Sustainably in the Construction Industry

CPCCCA2011 Handle Carpentry Materials

CPCCCA2002 Use Carpentry Tools and Equipment

CPCCOM1015 Carry out measurements and calculations

CPCCCA3025 Read and Interpret Plans, Specifications and Drawings for Carpentry Work

CPCCOM3001 Perform Construction Calculations to Determine Carpentry Material Requirements

CPCWHS3001 Identify Construction Work Hazards and Select Risk Control Strategies

CPCCCM2012 Work Safely at Heights

CPCCCM2008 Erect and Dismantle restricted height Scaffolding

CPCCCM2006 Apply Basic Levelling Procedures

CPCCOM3006 Carry out Levelling Operations

CPCCCA3002 Carry out Setting out

CPCCCO2013 Carry out Concreting to Simple Forms

CPCCCA3003 Install Flooring Systems

CPCCCA3004 Construct and Erect Wall Frames

CPCCCA3010 Install Windows and Doors

CPCCCA3005 Construct Ceiling Frames

CPCCCA3006 Erect Roof Trusses

CPCCCA3007 Construct Pitched Roofs

CPCCCA3008 Construct Eaves

CPCCCA3017 Install Exterior Cladding

CPCCCA3024 Install Lining, Panelling and Moulding

CPCCCA3016 Construct, Assemble and Install Timber External Stairs

CPCCCA3028 Erect and Dismantle Formwork for Footings and Slabs on Ground

CPCCCA3001 Carry out General Demolition of Minor Building Structures

Elective Units

CPCCOM1013 Plan and Organise Work

CPCCCM3005 Calculate costs of Construction Work

CPCCCM3001 Operate Elevated Work Platforms Upto 11 Meters

CPCCCM2002 Carry out Hand Excavation

CPCCCA3014 Construct and Install Bulkheads

CPCCCA3012Frame and Fit Wet Area Fixtures

CPCCCA3018 Construct, Erect and Dismantle Formwork for Stairs and Ramps

Entry Requirement

There are no stated entry requirements into this qualification

International Students

Must be 18 years of age or above at the time of enrolment

Year 12 or equivalent of Australian HSC

English Language Entry Requirements:

IELTS score 6.0 (with no bands less than 5.5) or equivalent Pearson Test of English (PTE).

Completion of the general induction training program specified by the National Code of Practice for Induction Training for Construction Work (ASCC 2007) is required before entering a construction work site. Achievement of unit CPCCWHS2001 covers this requirement.

Career opportunities

This qualification enables the student to seek employment in the following job roles:

Carpenter — Commercial

Carpenter — Formwork

Carpenter — Residential

Education Pathways

Further training pathways from this qualification may lead to any of the following qualifications:

CPC50220 Diploma of Building and Construction (Building)

Exit Point/Award

Students that successfully complete all 34 units of competency as stated in the Course Structure will be issued with CPC30220 Certificate III in Carpentry. This qualification is recognised nationally under the Australian Qualifications Framework (AQF)

Students that complete some but not all of the units of competency as stated in the Course Structure may be issued with a Statement of Attainment. It will identify only those units of competence that have been completed as part of the qualification and recognised nationally under the AQF.

Source:

#CertificateIIICarpentry#CarpentrySkills#TradeCertification#CarpentryCourse#SkillDevelopment#ConstructionTraining#CarpentryCareer#TradeSkills#BuildingAndConstruction#AHMI#Australia#Sydney#CertificateIIICarpentrynearme

0 notes

Text

Commercial Roof Trusses: Engineered for Large-Scale Projects | Newcastle Frame & Truss

At Newcastle Frame & Truss, we want to make your building project run smoothly. We will work with your team to ensure your roof trusses are installed right on time. Services in Newcastle, Hunter Valley Region, Cessnock and Morrisett and surrounding areas. Our quality timber roof trusses arrive exactly when you need them and are cost effective. We save you time and money.

Great customer service and manufacturing standards are our core business values. We want our trusted clients and first-time buyers to have a great experience with Newcastle Frame and Trusses.

We have been in this industry for over 30 years and we pride ourselves on amazing customer service. Every day, our team strives for perfection since 1999. In today’s world, service is everything.

Get in Touch With us Now! Call us on – 0437 437 231

0 notes

Text

Exploring the World of Roof Trusses in Construction

By offering the essential structural support, roof trusses are a vital component that is needed to provide the house the ultimate support. High-grade prefabricated trusses greatly enhance the quality of the structure being built, allowing for the construction of residential and commercial structures of superior quality. Trusses are essential to building's structural framework since they bear the weight of the roof, and the top provider sells trusses that meet Australian building codes.

Roof truss is a triangle frame that is prefabricated and designed to transfer the weight of the roof uniformly over the walls. Many of these trusses offered by leading truss manufacturers in Melbourne are made of quality timber, which gives them strength and light weight. The network of diagonal bottom chords, vertical web members, and horizontal top chords forms a sturdy triangular structure. Similar to this, trusses also support the floor in order to preserve its structural integrity over time.

Leading timber suppliers in Melbourne offer prefabricated triangular frameworks called roof truss that is intended to evenly distribute the weight of the roof across the walls. Due to their high strength and low weight, many of these trusses are composed of wood. A strong triangular structure is formed by the network of horizontal top chords, vertical web members, and diagonal bottom chords. In a similar vein, the floor is supported by trusses to maintain its structural integrity over time.

The floor trusses are often called Posi struts, which is another term for them. The trusses are made to support any extra structures that may be required, as well as structures for air conditioning, plumbing, power, and shower sets. The top organisations supply the trusses straight to their clients in a condition that makes installation simple and error-free. During the lockup stage of home construction, trusses for the floor and roof are essential since it entails finishing the roof and securing the building envelope. When trusses are installed and fixed correctly, the roof's structural integrity is guaranteed. This permits the safe installation of insulation, roofing materials, and other components that improve the building's overall comfort and energy efficiency.

Speak with the top businesses to obtain an estimate for the trusses needed for your project.

SUMMARY:

Because they evenly distribute the weight of the roof across the walls, roof trusses are an essential structural component of both residential and commercial buildings. Structures like as air conditioning, plumbing, electricity, and shower sets are supported by floor trusses that support the house structure, which are also referred to as Posi struts.

Source

0 notes

Text

How Roof Trusses Make Homes Safer: Dark Red’s Expert Insight"

When it comes to building a safe, lasting home, roof trusses play a key role in providing structural stability and durability. Dark Red offers high-quality roof trusses designed for both residential and commercial buildings, ensuring reliable support that distributes roof weight evenly and enhances overall structural strength. Made from carefully chosen materials and crafted with precision, Dark Red roof trusses help prevent potential issues like sagging or uneven load distribution, making them an essential part of any roofing project.

Dark Red’s trusses are built to withstand varying weather conditions, from intense sun to heavy rain, offering longevity and peace of mind. With efficient installation processes, they reduce construction time while still adhering to top-tier building standards. Choosing Dark Red roof trusses means choosing quality, reliability, and a foundation built to stand strong for years to come. For anyone looking to secure their roof and ensure structural integrity, Dark Red’s roof trusses are the ultimate solution.

0 notes

Text

Why Are Roofing Components Important?

A well-constructed roof is one of the most important aspects of any structure, as it provides protection, insulation, and structural integrity. Many individuals recognize the significance of a robust roofing system but may need to comprehend the critical role of individual roofing components. We will examine the importance of roofing system components in this comprehensive guide. Each piece, from the timbers and decking to the underlayment and shingles, creates a durable and weather-resistant roof. Let's examine why roofing system components are essential for the durability and functionality of your roof. 1.1. Roof Decking: The Foundation of a Solid Roofing System As the foundation of the entire roofing system, roof decking, also known as sheathing, plays a critical function. This sturdy material, typically manufactured from plywood or oriented strand board (OSB), provides a flat and stable surface for installing other roofing components. Roof decking is the base to support and uniformly distribute the weight of roofing materials across the roof structure. With sturdy and correctly implemented decking, the integrity of the entire roofing system could be protected. The choice of roofing sheathing material is crucial, as it directly influences the strength and durability of the roof. Plywood and OSB are popular options due to their durability, affordability, and resistance to the elements. The thickness and grade of the decking material are selected based on the roofing system's specific requirements, such as the weight of the roofing materials and the local climate. 1.2. Roof Trusses and Rafters: Shaping the Roof's Structure Roof trusses and timbers provide support and define the roof's shape and pitch as the structure's backbone. Typically constructed of wood or steel, trusses are prefabricated triangular structures that support the roof's weight, whereas rafters are traditional beams. Together, these components create a robust and stable roof system. For the safety and durability of the roof, it is essential that the roof trusses and timbers be appropriately designed and installed. They are designed to uniformly distribute the weight of the roof materials and direct any external loads, such as snow or wind, to the walls of the building. The design of the trusses and rafters also determines the roof’s slope, ensuring that water and detritus flow off the surface efficiently, thereby preventing water from pooling and causing damage. 1.3. Underlayment: Protecting Against Water Infiltration The underlayment is an essential water-resistant barrier installed over the roof decking and beneath the roofing materials. It serves as a secondary layer of protection against water infiltration, preventing leakage and moisture damage to the roof and interior of the building. Typical underlayment materials include felt synthetic fabrics and rubberized bitumen. This component is a crucial line of defense, particularly during severe weather or if the roofing materials are compromised. If water penetrates the outermost layer of the roofing system, the underlayment acts as a secondary barrier to prevent it from entering the building. 1.4. Roofing Shingles: The Visible Protector Shingles are the roof's visible outermost layer and are available in various materials, including asphalt, timber, metal, and synthetics. In addition to enhancing the building's architectural appeal, they also serve as a barrier against various environmental elements. Due to their affordability, durability, and simplicity of installation, asphalt shingles are the most popular roofing material. Wood shingles or shakes have a natural, rustic appearance, whereas metal shingles are highly durable and resistant to fire and insects. Synthetic materials, such as composite roofing, imitate the appearance of conventional materials while providing superior durability and weather resistance. 1.5. Flashing: Keeping Vulnerable Areas Watertight Flashing is a thin, weather-resistant substance strategically installed around roof penetrations such as chimneys, vents, skylights, and dormers. Flashing is typically made of metal, such as aluminum or copper. It is designed to prevent water from infiltrating vulnerable areas and causing water damage. The roof’s integrity is protected by flashing that directs water away from these areas, ensuring they remain impermeable. Flashing is essential in locations where various roof surfaces meet, such as valleys and roof edges, to prevent water from penetrating the roofing materials and causing leaks. It prevents potential structural problems and interior damage by acting as a barrier against moisture infiltration. 1.6. Gutters and Downspouts: Efficient Water Drainage Gutters and downspouts are essential roofing components that are crucial in water discharge. They are responsible for collecting and diverting rainfall from the building's foundation. Proper water drainage is required to prevent water accumulation on the roof, which can cause structural damage and water-related problems. Along the roof's edges, gutters capture rainwater, while downspouts transport the water to the ground or a drainage system. Gutters and downspouts protect the building's structure from potential water damage, including erosion, mildew growth, and foundation issues, by directing water away from the roof and foundation. The components of the roofing system are the construction blocks of a sturdy and dependable roof. From the foundation provided by the roof decking to the visible protection offered by the roofing shingles, each component creates a durable and weather-resistant roofing system. The roof's structure is formed by roof trusses and timbers, while underlayment and flashing prevent water infiltration. Gutters and downspouts protect the network from water-related issues by ensuring proper water discharge. Understanding the significance of these components enables property owners to make informed decisions and invest in a roofing system that will withstand the passage of time and provide optimal building protection. 2. The Importance of Each Roofing Component 2.1. Structural Integrity Each roofing component plays a specific role in maintaining the roof's structural integrity. From the sturdy roof deck to the well-designed trusses and rafters, these elements work together to distribute the weight of the roof evenly and withstand external forces like wind and snow loads. 2.2. Weather Protection The roofing system components, such as underlayment and shingles, are a barrier against harsh weather conditions. They protect the building and its occupants from rain, snow, wind, and UV radiation, enhancing the roof's longevity and preventing water-related issues. 2.3. Water Management Proper water management is critical for any roofing system. Underlayment, flashing, gutters, and downspouts ensure efficient water drainage, reducing the risk of leaks, water pooling, and potential water damage. 2.4. Energy Efficiency A well-insulated roofing system with reflective shingles and appropriate ventilation can improve energy efficiency. These components can help maintain comfortable indoor temperatures and lower energy bills by reducing heat absorption and facilitating air circulation. 2.5. Curb Appeal Roofing shingles and other visible components contribute significantly to a building's curb appeal. Choosing materials, colors, and styles can enhance the property’s overall aesthetics and increase its resale value. 3. Importance of Professional Installation and Maintenance The significance of roofing system components extends beyond their individual roles; their proper installation and regular maintenance are equally crucial. Professional installation ensures that each element is correctly integrated, maximizing the roof's performance and longevity. Routine maintenance, such as roof inspections, repairs, and cleaning, helps identify and address potential issues before they escalate into major problems. In conclusion, roofing system components are the fundamental building elements of a robust and weatherproof roof. Each component serves a specific function, including structural support, protection from the elements, and water discharge management. Realizing the significance of these components’ importance emphasizes investing in high-quality materials, expert installation, and routine maintenance. By prioritizing roofing system components, you can ensure your roof’s durability and performance while protecting your building’s interior from potential damage. Contact VNO now: Website VNO: https://vnoutsourcing.com/ Email: [email protected] Read the full article

0 notes

Text

What to know about roof trusses?

Roof trusses are prefabricated structural components used in roof construction. They consist of a framework of triangular shapes, which provides excellent strength and stability to support the roof's weight. Trusses are commonly made from wood or steel and are engineered to meet specific load and span requirements for each building project.

In Melbourne, like in many other places, roof trusses are a popular choice in both residential and commercial construction due to their various advantages:

Cost-Effective: Roof trusses Melbourne are manufactured off-site, which reduces labor costs and installation time, making them a cost-effective roofing solution.

Lightweight: Trusses are lightweight compared to traditional timber beams, which eases transportation and installation.

Versatility: Roof trusses can be designed to fit various roof shapes and configurations, allowing for flexible architectural designs.

Consistency: Trusses are manufactured in a controlled environment, ensuring consistent quality and performance.

Strength and Stability: The triangular design of trusses distributes the load efficiently, making them strong and stable, capable of supporting heavy roof loads.

Energy Efficiency: Trusses leave ample space for insulation, contributing to improved energy efficiency in the building.

If you are considering using roof trusses for your construction project in Melbourne, it is essential to work with a reputable truss manufacturer or supplier. They will typically provide engineering support and design services to ensure that the trusses are tailored to meet your specific building requirements and local building codes.

Keep in mind that construction practices and suppliers might vary over time, so I recommend checking with local building supply companies or conducting an online search to find roof truss suppliers in Melbourne that are currently available and reputable.

0 notes

Text

Elevating Construction Projects with Nextruss: Your Trusted Steel Framing Company and Steel Truss Supplier in Perth

When it comes to construction projects, the strength and durability of the structural components play a vital role in ensuring long-lasting and secure buildings. One of the key elements in modern construction is steel framing, and Nextruss stands as a trusted steel framing company and steel truss supplier in Perth. With a commitment to delivering high-quality solutions, Nextruss has been elevating construction projects across Australia with their exceptional steel roof trusses. In this article, we will explore the advantages of steel framing, shed light on Nextruss’s expertise, and explain why they are the go-to choice for steel trusses in Perth.

The Power of Steel Framing:

Steel framing has become increasingly popular in construction due to its numerous advantages. Unlike traditional timber framing, steel framing offers superior strength, durability, and resistance to common issues such as warping, shrinking, or termite damage. It provides a reliable and stable framework for various structures, from residential homes to commercial buildings. The versatility of steel framing allows for more open and flexible design options, facilitating the creation of spacious interiors and architectural freedom.

Nextruss Your Trusted Steel Framing Company:

Nextruss has established itself as a leading steel framing company in Perth, renowned for its expertise and commitment to excellence. With a team of experienced professionals, they provide comprehensive solutions tailored to meet the specific needs of each project. Nextruss ensures that every steel frame is engineered with precision and adheres to industry standards, guaranteeing structural integrity and compliance. Their dedication to quality is evident in every step of the process, from design and fabrication to on-time delivery.

Unmatched Steel Truss Supplier in Perth:

Nextruss’s expertise extends beyond steel framing to steel trusses, making them the go-to supplier in Perth. Steel roof trusses offer exceptional strength and load-bearing capacity, making them ideal for various roofing applications. Nextruss offers a wide range of customizable steel trusses that cater to different project requirements, ensuring a perfect fit and optimal performance. Their trusses are meticulously designed and fabricated using state-of-the-art technology, resulting in durable and reliable solutions that stand the test of time.

Advantages of Choosing Nextruss:

By choosing Nextruss as your steel truss supplier in Perth, you gain access to a range of benefits. Firstly, their extensive experience in the industry guarantees expert advice and innovative solutions tailored to your project’s needs. Secondly, Nextruss’s commitment to using high-quality materials and advanced manufacturing techniques ensures the durability and longevity of their steel trusses. Lastly, their reliable and efficient delivery process ensures that your project stays on track without any unnecessary delays.

Conclusion:

Nextruss is your trusted partner for all your steel framing and steel truss needs in Perth. With their expertise, dedication to quality, and commitment to customer satisfaction, they have built a reputation as a reliable supplier in the industry. By choosing Nextruss, you can elevate your construction projects with the strength and durability of steel framing and trusses. Experience the unmatched quality and service they offer, and witness how their solutions enhance the stability and longevity of your buildings. Contact Nextruss today to discuss your project requirements and take the first step towards a successful construction journey.

#frames and trusses perth#steel frame company#steel frame manufacturer perth#steel frame manufacturers#steel frame suppliers#steel frame suppliers perth#steel framing perth#steel truss supplier perth#steel framing company#steel frame and truss manufacturers#steel frames#steel frame#steel frame house#trusses and frames#steel frame houses#steel frames and trusses#steel roof trusses perth#roof trusses perth#steel frame roof trusses#steel frame trusses#steel roof truss manufacturers#steel truss manufacturers#trusses suppliers perth#steel trusses#steel wall frames perth#steel framing supplier#steel frame homes#steel framed homes#steel framing#steel frame floor system

0 notes

Text

Knowing the importance of handover inspections.

The final step in the process of having your new house built is an inspection called a "Practical Completion Inspection" or "handover." You and your builder should both place a high value on this endeavor, and you should approach it with a constructive and optimistic attitude.

An accomplished builder with credentials in Building and Timber Pest should do the handover check. Your inspector needs to have the right training and experience to know what he's looking for. New Build Handover Inspections Brisbane are the best.

The attic's insulation and air flow are crucial. Never insulate over recessed lights without first getting the manufacturer's permission. The recommended amount of insulation for an attic floor is R38, or 14 inches. Make sure the soffit vents aren't being blocked by insulation. Ensure that there are no broken trusses. Defect Inspection Gold Coast is excellent. Investigate potential entry points for water, such as flashings. Look at the spouts. Look above and around any chimneys or skylights. Make sure the roof is draining properly. All downspouts and gutters must be installed correctly, securely fastened, and large enough to collect the projected rainfall without overflowing. Handover Inspection Brisbane will always help you.

It's important to flash all of the glass in your windows and doors. The doors and windows should all open and close easily. Handover Inspection Ipswich is preferred by many people. The siding has to be in good shape and spotless. It's expected that the painting and caulking will be finished. Filling up utility holes correctly is a must. All drains need to have splash blocks installed beneath them.

You may expect a well-developed drainage system surrounding your new Houston home. Grass should be planted on a positive slope, all construction waste cleared away, and all walkways, drives, and patios finished. PCI Inspection Brisbane will always help you.

New Home Structural Inspection

Because mistakes can be made by humans during construction or because materials might be flawed, it's important to have a professional examine the structure of your new home before you move in. Defect Inspection Brisbane can be found at many places.

In addition, items made of lumber, in particular, are susceptible to change and degradation over the course of time. Even if you have high hopes that every material will be checked out extensively by the foreman or tadesman who will be using it, the builder will leave that task up to the person who will really be using it. You can get the best results from PCI Inspection Gold Coast.

Even when a very good builder employs skilled craftsmen and adheres to the industry's best standards, a reliable building inspection firm will sometimes find structural flaws in a house despite the fact that the builder did all possible to avoid them. Inspector for New Home Construction Brisbane will provide you everything that you need.

As an instance, ABIS has only recently found a roof truss that was constructed and placed correctly but had undergone considerable bending as a result of the drying process. This discovery was made. This indicated that the truss was significantly out of alignment with the remainder of the roof construction.

We recommend that you hire an experienced Inspector as well, so that you can be certain that the money you spend on your new home will be well spent.

0 notes