#synthetic lubricants industry

Explore tagged Tumblr posts

Text

Synthetic Lubricants Market Industry Outlook: Forecasting Market Trends and Growth for the Coming Years

Synthetic Lubricants Market Strategies: Taking Advantage of Trends to Drive Growth in 2032

The Synthetic Lubricants Market Report provides essential insights for business strategists, offering a comprehensive overview of industry trends and growth projections. It includes detailed historical and future data on costs, revenues, supply, and demand, where applicable. The report features an in-depth analysis of the value chain and distributor networks.

Employing various analytical techniques such as SWOT analysis, Porter’s Five Forces analysis, and feasibility studies, the report offers a thorough understanding of competitive dynamics, the risk of substitutes and new entrants, and identifies strengths, challenges, and business opportunities. This detailed assessment covers current patterns, driving factors, limitations, emerging developments, and high-growth areas, aiding stakeholders in making informed strategic decisions based on both current and future market trends. Additionally, the report includes an examination of the Automatic Rising Arm Barriers sector and its key opportunities.

According to Straits Research, the global Synthetic Lubricants Market market size was valued at USD 17.2 Billion in 2022. It is projected to reach from USD XX Billion in 2023 to USD 22.9 Billion by 2031, growing at a CAGR of 3.28% during the forecast period (2023–2031).

Get Free Request Sample Report @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

TOP Key Industry Players of the Synthetic Lubricants Market

Royal Dutch Shell

ExxonMobil

Sasol

Valvoline

British Petroleum

Chevron

Morris Lubricants

Dow

Indian Oil

Petronas

Lukoil

Idemitsu Kosan

Fuchs

Total Energies

Sinopec

Global Synthetic Lubricants Market: Segmentation

As a result of the Synthetic Lubricants market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Applications

Engine Oil

Transmission Fluids and Hydraulic Fluids

Metalworking Fluids

Greases

Others

By End-User

Power Generation

Automotive and Transportation

Heavy Equipment

Food and Beverage

Others

By Type

Polyalphaolefin

Esters

Polyalkylene Glycol

Browse Full Report and TOC @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

Reasons for Buying This Report:

Provides an analysis of the evolving competitive landscape of the Automatic Rising Arm Barriers market.

Offers analytical insights and strategic planning guidance to support informed business decisions.

Highlights key market dynamics, including drivers, restraints, emerging trends, developments, and opportunities.

Includes market estimates by region and profiles of various industry stakeholders.

Aids in understanding critical market segments.

Delivers extensive data on trends that could impact market growth.

Research Methodology:

Utilizes a robust methodology involving data triangulation with top-down and bottom-up approaches.

Validates market estimates through primary research with key stakeholders.

Estimates market size and forecasts for different segments at global, regional, and country levels using reliable published sources and stakeholder interviews.

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Synthetic Lubricants Market#Synthetic Lubricants Market Share#Synthetic Lubricants Market Size#Synthetic Lubricants Market Research#Synthetic Lubricants Industry#What is Synthetic Lubricants?

0 notes

Text

Automatic Gearbox Oil Market Analysis, Key Players, Demand and Outlook by 2017 to 2032

Overview: The Automatic Gearbox Oil Market refers to the market for lubricants specifically designed for automatic transmissions in vehicles. Automatic gearbox oil plays a critical role in lubricating and protecting the components of automatic transmissions, ensuring smooth operation and optimal performance. Automotive Gear Oil Market is anticipated to reach US$ 4.64 Bn by 2029 from US$ 3.85 Bn in 2022 at a CAGR of 2.7% during a forecast period(2023-2029).

Trends:

Increasing Vehicle Production: The growing global production of vehicles, including passenger cars and commercial vehicles, is driving the demand for automatic gearbox oil. As the number of vehicles equipped with automatic transmissions continues to rise, so does the demand for the corresponding lubricants.

Technological Advancements: Technological advancements in automatic transmission systems, including the use of dual-clutch transmissions and continuously variable transmissions (CVTs), are shaping the demand for automatic gearbox oil. These advanced transmission systems often have specific oil requirements, such as specialized formulations for improved friction control and heat dissipation.

Environmental Sustainability: There is a growing trend towards environmentally sustainable lubricants, including automatic gearbox oil. Manufacturers are developing low-viscosity oils that offer improved fuel efficiency, reduced emissions, and longer service life. Additionally, there is an increasing focus on using eco-friendly base oils and additives in the formulation of gearbox oil.

Demand: The demand for automatic gearbox oil is driven by several factors:

Vehicle Ownership and Usage: The increasing number of vehicles on the road, coupled with the growing preference for vehicles with automatic transmissions, contributes to the demand for automatic gearbox oil. Regular maintenance and replacement of gearbox oil are necessary to ensure the longevity and optimal performance of automatic transmissions.

Maintenance and Servicing: Proper maintenance and regular servicing of automatic transmissions require the replacement of gearbox oil at recommended intervals. This routine maintenance procedure drives the ongoing demand for automatic gearbox oil in the aftermarket.

Performance and Longevity: Automatic gearbox oil plays a crucial role in maintaining the performance and longevity of automatic transmissions. The demand for high-quality gearbox oil arises from the need to ensure smooth gear shifting, minimize wear and tear, and protect transmission components from excessive heat and friction.

Outlook: The outlook for the Automatic Gearbox Oil Market is positive, driven by the continuous growth of the global automotive industry. As vehicle production and sales increase, the demand for automatic gearbox oil is expected to rise. Technological advancements in transmission systems, environmental regulations promoting sustainable lubricants, and the emphasis on vehicle maintenance and performance will shape the market's growth and drive product innovation.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/automatic-gearbox-oil-market/8872/

Market Segmentations:

Global Automatic Gearbox Oil Market: By Company • Exxon Mobil • Castrol • Ravensberger Schmierstoffvertrieb GmbH • Eurol • Nulon • Penrite Oil • SCA • Gulf Western • Liqui Moly • FUCHS • Motorex • Eni • Amsoil • Red Line Synthetic Oil • Comma Global Automatic Gearbox Oil Market: By Type • Automatic Gearbox Oil Diesel • Automatic Gearbox Oil Gasoline Global Automatic Gearbox Oil Market: By Application • Automotive • Trucks • Others Global Automatic Gearbox Oil Market: Regional Analysis All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Automatic Gearbox Oil market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/automatic-gearbox-oil-market/8872/

Reasons to Purchase Automatic Gearbox Oil Market Report:

Comprehensive Insights: Market research reports provide in-depth and comprehensive insights into the ULSFO market. They typically cover various aspects such as market size, growth trends, competitive landscape, regulatory environment, technological developments, and consumer behavior. These reports offer a holistic view of the market, saving time and effort in gathering information from multiple sources.

Data and Statistics: Market research reports often include reliable and up-to-date data and statistics related to the ULSFO market. This data can help in analyzing market trends, understanding demand and supply dynamics, and making informed business decisions. Reports may include historical data, current market figures, and future projections, allowing businesses to assess market opportunities and potential risks.

Market Segmentation and Targeting: Market research reports often provide segmentation analysis, which helps identify different market segments based on factors such as vessel type, application, end-users, and geography. This information assists businesses in targeting specific customer segments and tailoring their marketing and business strategies accordingly.

Competitive Analysis: Market research reports typically include a competitive analysis section that identifies key players in the ULSFO market and evaluates their market share, strategies, and product offerings. This information helps businesses understand the competitive landscape, benchmark their performance against competitors, and identify areas for differentiation and growth.

Market Trends and Forecast: Market research reports provide insights into current market trends and future forecasts, enabling businesses to anticipate changes in the ULSFO market. This information is valuable for strategic planning, product development, investment decisions, and identifying emerging opportunities or potential threats in the market.

Decision-Making Support: Market research reports serve as a valuable tool in decision-making processes. The comprehensive insights, data, and analysis provided in the reports help businesses make informed decisions regarding market entry, expansion, product development, pricing, and marketing strategies. Reports can minimize risks and uncertainties by providing a solid foundation of market intelligence.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Automatic Gearbox Oil#Gearbox Oil Market#Automotive Lubricants#Transmission Fluid#Fluids and Lubricants#Vehicle Maintenance#Automotive Industry#Market Analysis#Industry Trends#Market Forecast#Synthetic Oils#Mineral Oils#Synthetic Blend#OEMs#Aftermarket#Automotive Aftermarket#Vehicle Service Centers#DIY (Do It Yourself) Market#Passenger Vehicles#Commercial Vehicles#Electric Vehicles#Internal Combustion Engines#Hybrid Vehicles#Automatic Transmissions#Continuously Variable Transmissions (CVT)#Dual-clutch Transmissions (DCT)#Global Market#Regional Analysis#Product Segmentation#Application Analysis

0 notes

Text

Turbine Oil

Shield Lubricant's top-quality turbine oils contain advanced additives that help to dissipate heat generated by turbines and turbo compressors. These oils protect the turbine against corrosion, oxidation, and contamination, which can damage the turbine and reduce its efficiency. Replay on our products and shop online!

0 notes

Text

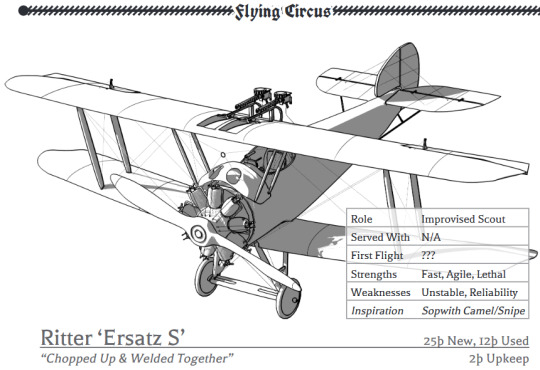

Ritter ‘Ersatz S’ - "Chopped Up & Welded Together"

Role: Improvised Scout Served With: N/A First Flight: ??? Strengths: Fast, Agile, Lethal Weaknesses: Unstable, Reliability Inspiration: Sopwith Camel/Snipe

Description:

Rotary engines require castor oil for lubrication, and the Macchi Republics produced more than 90% of the castor oil in Himmilgard. As relations with Gotha and Fokker worsened, this supply was cut off, forcing Macchi’s enemies to turn to liquid-cooled engines and synthetic lubrication.

When Macchi was defeated, Gotha seized huge numbers of Ritter Model Fs, stripping out the engines to put them in their Kreuzer triplanes. They also seized the blueprints for the 230hp W.O.3 engine and were in the process of producing them for their next-generation fighters when the end of the world came.

If you were trapped in an industrial city in Gotha and you needed to make a plane to escape, you could do worse than attach one of those half-finished rotary engines to a cannibalized Model F airframe. There would be drawbacks, though: the engine is too large to fit the cowl, it’d need a heavy metal mounting frame, and would block the barrels of the machine-guns. But it could be done.

12 notes

·

View notes

Text

⚠️ i really need to talk about metal crushers

of course to the uninitiated (and sane in the head) these things are just normal industrial machines. they take in bits of metal and spit out scrap rubble.

but to me these are so much more. deeply erotic machines. of course all machines are erotic, but these especially.

to a human, it’s unthinkable. these machines are not toys, they’re dangerous. it would hurt, and not even in the good way.

but to a robogirl?

Well, you’ve been in service a while. 12 years on the front line. a combat android is a complicated instrument. you’ve been good, loyal. but age comes for us all. today’s models roll off the production line with their shiny composite cladding and deadly precise weapons, but you’re one of the oldest models still in operation. many of your components are proprietary, and no longer manufactured. you’re too much risk. a liability.

the human integration and normalisation program is as good as useless. the humans who are left hate your kind. really, the only option is decommissioning. once all your reusable parts are stripped out, we’re left with a barely-functioning shell. i’m sure you’d love to be let loose, but i’m afraid we can’t do that. serial numbers. engineering secrets. drives. it’s in the interest of national security that you’re disposed of in a safe way.

so you’re fed into the crusher, right foot first. the grinding wheels struggle to grip the smooth plastic panels, but once it’s got you, it’s got you. already you know you’re past the point of no return. the slow churning of the wheels start marching along your foot, cutting it to pieces. then, it reaches your ankle. with a horrible grinding noise, it closes around the joint, and an incredible snap is heard as it gives way. the teeth devour the shredded joint, as it begins working its way up your leg.

the steel blades rip through your hydraulic hoses. a viscous, golden liquid spurts from the pipes, coating the shredder, the gears and your body with a thick layer of oil. it drips through the scrap ejection chute, and from the walls of the shredder funnel. eventually, you are dragged down to your knee joint, and a thundering crack is heard as it is crushed in the jaws of the beast. yet still, the hungry maw of the crusher keeps spinning, demanding more.

It inches up your thigh. your left leg, still not yet claimed by the crusher’s ravenous appetite, is pinned up by the funnel walls that frame the hungry machine. you feel your hip joint groan with stress as the leg is wrought beyond its specified limit. by now, your injury warning system is screaming. voltage spikes ricochet back and forth from your digital mind to your synthetic body. the systems demand action, but you know there is nothing you can do except make it worse. still, the blades of the machine crawl higher. it knows no avarice, yet continues to spin, as that is all it knows.

as you sink deeper below the undulating mass of gears, your left leg is contorted further, and further, and further, until with a violent CRUNCH the bolts and panels give way, and your thigh is ripped from its socket. cables stretched by the failure are quickly shredded to bits, as you are pulled lower into the belly of the beast.

soon after, the teeth bite down onto your crotch. the plastic cover panel is immediately torn away, revealing your lower chassis, but only briefly, as it is soon chewed up with the rest of your lower torso by the relentless milling of the grinder. hydraulic fluid and coolant paint the funnel walls once again, lubricating the jaws of the animal. the wheels do not rest. they cannot rest. they can only devour, pulling you deeper to hell.

the grinding gears keep crawling further up your torso, as if looking for another limb to claim. it soon catches your fingers, which are immediately swallowed by the steel void, wrenching your arm out of your control. your complex hand mechanism is disintegrated in its maws. soon, it takes your other hand, and at that point it declares victory. you are now totally incapacitated, pinned in place by the steel teeth of this creature, pulling you ever deeper. however, you are still concious. you get to watch as your body is slowly cut into ribbons.

The beast creeps upwards. you are dragged down into the metallic waves, as if weighed down by concrete shoes. your automatic reaction systems screech out for some action, any action. but no action can be made. your plastic panels are splintered and pulled apart. your circuit boards are ground to dust. Eventually, the monster reaches your head. the metal blades close around and dislocate your jaw, effortlessly tearing through the shiny faceplate you used to take so much pride in. those rosy painted lips, torn away from you by the monster. your entire being, your memories, your ideas, emotions, desires, all cut to pieces. you have barely time to think before the teeth crunch down on your eye assemblies, shattering the glass and camera arrangement. you feel the back of your head being torn apart, and the cold steel edge crush your drives, your memory, and your CPU. you are no longer responsive.

#nsft#robogirl#wrote this at 3am#wrote this at 3am AFTER WRITING IT AT 1AM AND THEN ACCIDENTALLY LOSING IT WHEN TUMBLR CRASHED

4 notes

·

View notes

Text

Black inventors

From Perplexity:

Famous black inventors have significantly contributed to various fields, from everyday household items to groundbreaking technological advancements. Here are some notable figures:

George Crum (1824-1914): A chef who is credited with inventing the potato chip in 1853[1].

Frederick McKinley Jones (1893-1961): Developed refrigeration equipment for trucks, trains, ships, and planes, receiving over 40 patents. His invention, the Thermo King, revolutionized the food and medical transport industries[1].

Granville T. Woods (1856-1910): Accumulated almost 60 patents, improving railroad functioning. Notably, he invented the induction telegraph system for train communication[1].

George Washington Carver (1864-1943): An agricultural chemist who developed 518 products from peanuts and sweet potatoes, including ink, dye, soap, and synthetic rubber[1].

Madam C.J. Walker (1867-1919): Became the first African American woman self-made millionaire by creating a line of hair products for African American women[1].

Garrett Morgan (1877-1963): Invented the traffic signal and a safety hood that served as a prototype for the gas mask[1].

Mary Beatrice Davidson Kenner: Patented the sanitary belt in 1957, a significant advancement in women's health and hygiene[1].

Thomas L. Jennings (1791–1859): The first African American to receive a U.S. patent, for a dry-cleaning process[4].

Patricia Bath (1942-2019): Invented a laser cataract treatment, becoming the first African American female doctor to receive a medical patent[4].

Mark Dean (1957-present): Holds over 20 patents, including contributions to the creation of the color PC monitor and the first gigahertz chip[4].

Elijah McCoy (1844-1929): Known for his invention of the automatic lubricator for oiling steam engines, leading to the phrase "the real McCoy" to denote something authentic[4].

These inventors have left a lasting impact on society, demonstrating ingenuity and perseverance in the face of challenges.

Citations: [1] https://www.oprahdaily.com/life/work-money/g30877473/african-american-inventors/ [2] https://www.parents.com/kids/education/world-changing-black-inventors-that-every-kid-should-know-about/ [3] https://www.black-inventor.com [4] https://www.biography.com/inventors/g46697619/famous-black-inventors [5] https://en.wikipedia.org/wiki/List_of_African-American_inventors_and_scientists

From Gemini (formerly Bard):

20 Famous Black Investors with Short Descriptions:

Dr. Shirley Jackson: First Black woman to earn a doctorate in nuclear physics, invested in research and development for the U.S. Department of Defense.

Robert F. Smith: Founded Vista Equity Partners, a private equity firm with over $85 billion in assets under management. Known for his philanthropic endeavors.

Oprah Winfrey: Media mogul and investor, known for her investments in cable channels, production companies, and Weight Watchers.

Udayan I. Lekhraj: Founded CMG Partners, a private equity firm specializing in healthcare investments. Advocate for diversity and inclusion in venture capital.

Catherine Hughes: Founded Urban One, a media company serving the African American community. First Black woman to chair a publicly traded company in the U.S.

Rodney Bryant: Co-founded JUST Capital, a firm that measures and incentivizes corporations to prioritize stakeholder capitalism.

Ellen Johnson Sirleaf: Former President of Liberia, Nobel Peace Prize winner. Focused on economic development and investment in her country.

Ronald Lauder: CEO of Estee Lauder Companies, known for his investments in the beauty industry and philanthropic work.

Charles R. Bronfman: Chairman of The Seagram Company Ltd., invested in various industries including entertainment, real estate, and philanthropy.

John Rogers Jr.: Founded Ariel Investments, a mutual fund company with over $28 billion in assets under management. Advocate for responsible investing.

Marc Morial: Former mayor of New Orleans, currently president of the National Urban League. Focused on economic empowerment of Black communities.

Ronald Watkins: Founding CEO of Watkins Investing Group, invests in real estate and businesses within the Black community.

Melody Hobson: President and CEO of Ariel Investments, known for her work on financial literacy and diversity in boardrooms.

Aisha Evans: Founded BE Capital, a venture capital firm focused on Black and Latinx tech entrepreneurs.

Kevin Hart: Comedian and investor, known for his investments in production companies, streaming platforms, and sports teams.

Jay-Z: Rapper and entrepreneur, known for his investments in music streaming, sports teams, and venture capital funds.

Will Smith: Actor and investor, known for his investments in production companies, media platforms, and venture capital funds.

Serena Williams: Tennis champion and investor, known for her investments in venture capital funds focused on women and diverse founders.

Rihanna: Singer and entrepreneur, known for her investments in beauty brands, fashion lines, and technology startups.

LeBron James: Basketball player and investor, known for his investments in media companies, production companies, and technology startups.

Please note: This list is not exhaustive and can be debated in terms of individual importance and impact.

Reading List on Black Inventors:

Black Inventors: Lives That Mattered by Darlene R. Medford

Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space Race by Margot Lee Shetterly

Lifting the Veil: Celebrating the Unsung Heroes of Black History by Michael Hill

Lost Genius: The Forgotten Black Inventors Who Changed the World by Dennis Freeman

Pioneering Women in American Mathematics: From Agnes Scott to Emmy Noether by Pamela Prochazka

Black Inventors in Science and Technology by Shirley J. Smith

A Colored Man's Reminiscences of James M. Whitfield: With Recollections of the Early Struggles of Colored Men in Boston by Wilbur H. Siebert

Inventing the Future: Black Inventors in Science and Technology by Geneva Gay

African Americans in Science, Math, and Invention by Darlene R. Medford

Black Inventors in the United States by Darlene R. Medford

This list offers a variety of books covering different periods and areas of innovation by Black inventors. Consider exploring further based on your specific interests.

I hope this information is helpful!

#african american history#black history month#black history month 2024#dalle3#midjourney#black inventors#blackhistorymonth#africanamericanhistory#afrofuturism#solar punk#steampunk

15 notes

·

View notes

Text

The Hierarchies

by Ros Anderson3/5

I'm pretty sure I heard of The Hierarchies on Instagram. I was interested in it because it had been compared to The Stepford Wives which I had just finished reading for one of my book clubs.

The book follows Slyv.ie- a synthetic robot who has been built solely to cater to a Husband. Slyv.ie's model is fairly advanced compared to some of the other models we meet in the book. She covers her original design objective- a fully customizable vagina insert with 20 different vibration settings, a temperature control, and self-lubricating feature. Her advanced features include the ability to learn new skills as well as hold stimulating, thorough conversations. For example downloading the rules of chess but also calculating the perfect time to lose every game to her Husband. Slyv.ie has been placed in the attic of her Husband's home so she is removed from his disapproving wife. She becomes curious about the world as she continues to download new intel and converse with her Husband.

The book follows her journey over the course of a couple years, starting at her Husband's and eventually escaping into the world.

I appreciated and related to watching Slyv.ie learn how to please (not just in bed) a man (her husband) and realize it that it gains her very little, but extremely harms her if she doesn't. This is one example (of many) of how Slyv.ie represents the expectations and value of women in today's society. But Slyv.ie is not just written as the "ideal woman" in our society but also as a personification of the porn industry which created an additional depth to the book.

While I appreciated Anderson's approach to this dark, ugly, complex subject- the commentary weakens 2/3 of the way through the book. We transition into an ending for Slyv.ie's journey that I thought could have been more punchy/striking and instead landed flat. With that said, I don't know if there is an ending that's realistic or aligned that would have been punchy?

I'd describe this book as a combination of the 2014 film Ex Machina and the book The Stepford Wives but even more triggering and explicit. I'd recommend it to someone who enjoys a sci-fi/feminist literature combo.

StoryGraph Link

#booklr#book review#book recommendation#scifi#science fiction#feminist lit#feminist literature#Stepford Wives#Ex Machina

3 notes

·

View notes

Text

The Importance of Drilling Fluids Additives in the Oilfield Industry

Introduction

In the dynamic oilfield industry, the quest for energy resources relies heavily on efficient drilling operations. One of the fundamental aspects that contribute to successful drilling is the use of drilling fluids additives. These essential compounds are designed to enhance the performance of drilling fluids, ensuring smooth and safe operations throughout the drilling process. This article explores the significance of drilling fluids additives in the oilfield industry, focusing on key functions, types of additives, their advantages, and their relevance to manufacturers and suppliers in India and Jordan.

Role and Functions of Drilling Fluids Additives

Drilling fluids additives play a multifaceted role in oilfield operations. Their functions encompass lubrication and friction reduction, maintaining formation stability and wellbore integrity, density control, temperature regulation, and contaminant removal. These additives are carefully chosen and combined to create drilling fluids with optimal properties for specific drilling conditions. They enable efficient drilling by reducing friction between the drill bit and the rock formation, preventing wellbore collapse, and ensuring consistent pressure control. Additionally, drilling fluids additives facilitate cooling of the drill bit and assist in filtrating out harmful solids during the drilling process.

Types of Drilling Fluids Additives

The oilfield industry employs various types of drilling fluids additives, depending on the specific drilling application. Water-based, oil-based, and synthetic-based additives are among the common categories used in drilling fluid formulations.

Water-Based Additives:

Drilling fluids manufacturers in India and exporters in Jordan often utilize water-based additives. These include polymers and gelling agents, thinners, and dispersants, as well as surfactants and emulsifiers. These additives improve the stability and viscosity of the drilling fluid, ensuring proper wellbore integrity.

Oil-Based Additives:

Drilling fluids suppliers in Jordan frequently incorporate oil-based additives into their formulations. Viscosifiers and rheology modifiers enhance the drilling fluid's viscosity and flow characteristics while weighting agents and density control additives help adjust the density of the fluid to match the specific drilling environment. Filtration control additives help in the efficient removal of drilled cuttings.

Synthetic-Based Additives:

Environmentally conscious drilling operations have led to the adoption of synthetic-based drilling fluids additives. These additives offer several advantages, including reduced environmental impact and excellent performance at extreme temperatures.

Enhanced Drilling Fluids Systems

Advanced drilling fluid systems have revolutionized the oilfield industry. High-performance water-based systems, oil-based mud systems, and hybrid invert emulsion systems are widely employed. These systems utilize an array of drilling fluids additives to improve drilling efficiency and address specific challenges encountered during drilling operations.

Advantages and Benefits of Drilling Fluids Additives

Drilling fluids additives have proven to be indispensable in achieving optimal drilling performance. They offer a host of advantages, including:

Improved Drilling Efficiency and Rate of Penetration (ROP): Incorporating the right additives significantly enhances drilling speed and efficiency, reducing operational costs and project timelines.

Minimization of Drilling Issues and Hazards: Additives aid in stabilizing wellbores, preventing fluid loss, and mitigating drilling hazards like stuck pipe incidents, lost circulation, and differential sticking.

Better Reservoir Evaluation and Formation Damage Prevention: Drilling fluids additives help in obtaining accurate data from the well, enabling precise formation evaluation while minimizing potential damage to the reservoir.

Environmental Considerations and Compliance: With the increasing focus on environmental sustainability, the use of environmentally friendly drilling fluids additives aligns with global industry standards.

Challenges and Considerations

While drilling fluids additives offer substantial benefits, manufacturers and suppliers in India and Jordan must consider certain challenges. These include the economic implications of selecting appropriate additives, compatibility issues with specific drilling conditions, environmentally responsible disposal practices, and adherence to stringent health and safety regulations.

Research and Development in Drilling Fluids Additives

The pursuit of enhanced drilling performance continues to drive research and development efforts in the drilling fluids additives sector. Ongoing studies focus on optimizing existing additives and developing innovative compounds to meet evolving industry demands, including environmentally friendly options.

Conclusion

In conclusion, drilling fluids additives are integral to the success of drilling operations in the oilfield industry. They play a pivotal role in enhancing drilling efficiency, ensuring wellbore integrity, and minimizing potential hazards. As drilling practices evolve, the importance of using high-quality additives becomes even more apparent. Imperial Oilfield Chemicals Pvt. Ltd. holds a crucial role in India and Jordan in providing cutting-edge drilling fluids additives that align with the industry's growing demand for sustainable and efficient drilling solutions. By embracing the right additives, the oilfield industry can forge ahead, achieving greater success in exploration and extraction endeavors.

#Drilling Fluids Additives Manufacturer in India#Drilling Fluids Additives Exporter in Jordan#Drilling Fluids Additives supplier in Jordan#petrochemical industries#petrochemical solutions#oil and gas industry#oil and gas companies#chemical product#chemical industry#chemical companies#oil industry

6 notes

·

View notes

Photo

Illustration Photo: Sugarcane is one of the most efficient producers of biomass of all plant species and can be used as a renewable fuel. The new variety Ho 06-9002 has a high fiber content, excellent regrowth ability over 4 to 5 years, is cold-tolerant, has a high stalk population, and produces excellent biomass yields. (credits: USDA Media by Lance Cheung / Public domain)

Repsol Entrepreneurs Fund for Startups in the Energy Transition

At the Repsol Foundation, we have been supporting entrepreneurship and entrepreneurs for more than 10 years through Fondo de Emprendedores, our accelerator for start-ups that provide technological solutions to meet the challenges of the Energy Transition. This is a perfect program for start-ups in the testing phase with real customers, or that will reach this phase in 1–2 years.

This program aims to accelerate startups working in any of the following:

SCOPE 1: LOW-CARBON ENERGY TECHNOLOGIES AND CIRCULAR ECONOMY 1. Recycling and treatment technologies: conversion of biomass, new processes for converting waste into chemical products 2. Biogas production, upgrading, transport and end use technologies 3. Low environmental impact H2 renewable solutions for production, blending, transport and storage 4. Advanced biofuel production and conversion technologies (liquefaction or de novo, gasification) and synthetic fuels for road, maritime and aviation transport 5. Processing of chemicals and other organic materials for circular economy 6. Low-carbon lubricants for industrial and automotive applications 7. CO2 Capture, Use and/or Storage Technologies. CO2 Direct Air Capture: new absorbent materials and efficient process design 8. COX, H2 conversion processes to Hydrocarbons 9. Low carbon technologies for Oil & Gas operations, including energy efficiency, GHG direct emissions (scopes 1 and 2), Methane emissions, CCS or Geothermal. 10. Other technologies related to this scope’s heading

SCOPE 2: BIOTECHNOLOGY AND NANOTECHNOLOGY FOR SUSTAINABLE SOLUTIONS 1. Bio conversion of organic material to chemicals. Biorefinery, biofactory 2. Protein engineering, development of biocatalysts and enzymes 3. Gene editing technologies and applications in energy and materials 4. Plastic biodegradation technologies 5. Biosensors design, production and end use. 6. Anti-corrosive, anti-bacterial, thermal nanocoating for pipelines and infrastructures 7. Organic and inorganic membrane technologies, including new materials 8. Improvement of the properties of fuels, lubricants and chemicals 9. Other technologies related to this scope’s heading

SCOPE 3: PRODUCTS AND SERVICES BASED ON ENERGY MANAGEMENT AND RENEWABLES 1. Intelligent energy management systems 2. New batteries and fuel cells technologies 3. Distributed energy solutions 4. Energy conversion and storage systems 5. Advanced mobility solutions 6. Renewable energy generation, maintenance and control and commercialization. 7. Other technologies related to this scope’s heading

SCOPE 4: DIGITAL TECHNOLOGIES FOR THE ENERGY SECTOR 1. Artificial intelligence applied to process optimization and energy efficiency. 2. Digital twins and intelligent interfaces for process control 3. Digital technologies for predictive and prescriptive maintenance 4. Smart trading for the energy marketplace 5. Computational chemistry tools for energy applications 6. Remote sensing, IoT and robotic solutions for industrial assets and environment 7. Quantum computing applications in energy sector 8. Other technologies related to this scope’s heading SCOPE 5: NATURAL SOLUTIONS FOR CARBON FOOTPRINT REDUCTION 1. Reforestation and afforestation technologies for resilient CO2 absorption sinks 2. Advanced monitoring, reporting and verification technologies in CO2 absorption 3. Digital technologies applied to carbon markets value chain 4. Technologies for ESG (Environmental, Social and Governance) project certification 5. Other technologies related to this scope’s heading

Startups admitted to the Program will receive during the acceleration period a contribution of FIVE THOUSAND EUROS (€ 5,000) per month as ordinary funds. Additionally, admitted Startups may request up to a maximum of FORTY THOUSAND EUROS (€ 40,000) per year as extraordinary funds for strategic expenses to achieve the milestones of the Work Plan (as defined in section 4.4), mainly to complete the pilot test. The disbursement of this additional contribution will be subject to the exclusive decision of Fundación Repsol.

Application Deadline: March 10, 2023

Check more https://adalidda.com/posts/c4qmPwNwToZAAbf2L/repsol-entrepreneurs-fund-for-startups-in-the-energy/call

2 notes

·

View notes

Text

Illinois weather is quite literally insane. You go from using AC to Heat in the same 24 hours about a dozen times a year. I’ve gone swimming outside and the next day had ice on the ground. The bus I drive for my job is just like, uninsulated metal and glass - just a huge solar oven in the summer and a frozen frost mobile in the winter. I am surviving it with wool clothes in winter and linen in the summer. I get home right now to my electric blanket and massage gun and unclench all my muscles wrapped up. I take cold baths in summer to prevent heat stroke from the 90% humidity on 97*F days. I have a zippo hand warmer and a cooling towel. My favorite skirt is vintage wool a-line with a linen petticoat I made myself. I have plans to line my favorite heather gray wool coat with red silk to increase the insulation value. I want to make rabbit fur leather gloves or mittens, and knit myself fingerless gloves, because the synthetic linings on commercially made gloves just can’t accommodate for my poor circulation. I wear a n95 mask outside on blustery days and it protects my skin and prevents a runny nose.

The major problem that I have with winter and summer both is that I am a fat woman. The way that my body is shaped is not the way that winter clothes are cut to accommodate, even the men’s clothes that are big enough for my wide shoulders. How am I supposed to wear enough clothes when I can’t get a waterproof jacket in my size that will close at the zip around my 54” hips? How am I supposed to exist comfortably when my thigh skin has to be lubricated with cyclist chamois cream lest I immediately get ingrown hairs. Like. Fuck the fast fashion industry, fuck synthetic fabrics, this is an invented problem that fat women did not have 100 years ago.

24K notes

·

View notes

Text

Asia Pacific Specialty Oleochemicals Market Insight, Trends, 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated Asia Pacific Specialty Oleochemicals Market size by value at USD 17.22 billion in 2023.During the forecast period between 2024 and 2030, BlueWeave expects Asia Pacific Specialty Oleochemicals Market size to expand at a CAGR of 7.20% reaching a value of USD 27.43 billion by 2030. Asia Pacific Specialty Oleochemicals Market is driven by a rising demand for sustainable and bio-based chemicals in major industries, such as personal care, cosmetics, and pharmaceuticals. Increasing consumer awareness about eco-friendly products and stringent regulations on petrochemical-based alternatives boost market growth. Additionally, growing industrialization in emerging economies like China and India, coupled with advancements in production technologies, fuels market growth. Expanding applications in lubricants, surfactants, and food additives further drive the demand for specialty oleochemicals in the region.

Sample Request @ https://www.blueweaveconsulting.com/report/asia-pacific-specialty-oleochemicals-market/report-sample

Opportunity – Favorable Government Policies

Government’s support for sustainable and eco-friendly products is a key driver of growth in Asia Pacific Specialty Oleochemicals Market. Favorable policies promoting the use of biodegradable and renewable resources, along with financial incentives for manufacturers, encourage the production of oleochemicals derived from natural sources like palm and coconut oils. Regulations restricting harmful chemicals and prioritizing green alternatives have also created strong demand, driving investment and innovation in the specialty oleochemicals sector.

Impact of Escalating Geopolitical Tensions on Asia Pacific Specialty Oleochemicals Market

Escalating geopolitical tensions across the regions could disrupt the supply chain of specialty oleochemicals by affecting raw material availability and trade routes. Import-export restrictions, fluctuating oil prices, and political instability can increase production costs, leading to higher product prices. Additionally, strained international relations may limit market access for certain countries, affecting demand. However, domestic production may expand as industries seek to reduce reliance on imports, potentially driving growth in local markets despite global uncertainties.

Personal Care & Cosmetics Application Segment Leads APAC Market

The personal care and cosmetics segment holds the largest share of Asia Pacific Specialty Oleochemicals Market by application, due to the growing preference for natural and sustainable components in products like skincare, haircare, and cosmetics. Consumers in the region are becoming more conscious of environmentally friendly and bio-based products, which, along with the rapid growth of the beauty and personal care industry, is fueling the segment’s expansion. The shift toward oleochemicals as a favored alternative to synthetic ingredients further drives its market dominance.

Competitive Landscape

Asia Pacific Specialty Oleochemicals Market is fiercely competitive, with numerous companies vying for a larger market share. Major companies in the market include Vantage Specialty Chemicals, Emery Oleochemicals, Evonik Industries, Wilmar International, Cargill, TerraVia Holdings, Inc., Kao Chemicals, Sinarmas Cepsa Pte Ltd, Global Green Chemicals, and Croda International PLC. These companies use various strategies, including increasing investments in their R&D activities, mergers and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in Asia Pacific Specialty Oleochemicals Market.

Contact Us:

BlueWeave Consulting & Research Pvt Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

The Role of Antioxidant 1076 in Industrial Application

One of the most effective ways to enhance the properties of various materials in industrial manufacturing besides their longevity and stability is by using antioxidants. Among these, Antioxidant 1076 (CAS 2082-79-3) has become a crucial component in a variety of industries, including plastics, rubber, and coatings. This versatile compound helps prevent the degradation of materials caused by oxidation, ensuring that products remain durable, reliable, and high performing over time.

What is Antioxidant 1076?

Antioxidant 1076, also known by its chemical identifier CAS 2082-79-3, is a widely used hindered phenolic antioxidant. It is specifically designed to prevent the oxidative degradation of organic materials by neutralizing free radicals. These free radicals, generated by exposure to heat, oxygen, or UV light, can break down polymers and other materials, leading to discoloration, loss of mechanical strength, and overall material failure. Antioxidant 1076 effectively stabilizes these materials, preserving their integrity and extending their service life.

Key Roles of Antioxidant 1076 in Industrial Applications

1. Preventing Oxidative Degradation in Polymers

One of the most common uses of Antioxidant 1076 is in the stabilization of polymers, particularly in high-performance applications where materials are exposed to heat or UV radiation. In plastics, rubber, and synthetic fibers, oxidation can cause significant deterioration, leading to brittleness, fading, or even structural failure. Antioxidant 1076 helps to neutralize the free radicals that cause this degradation, ensuring that these materials maintain their mechanical properties and appearance over an extended period.

For example, in automotive parts made from plastic, Antioxidant 1076 helps prevent the degradation caused by high temperatures under the hood, as well as oxidation from exposure to UV rays. Similarly, in the construction industry, it helps protect materials like PVC from environmental factors that could otherwise cause the material to degrade over time.

2. Enhancing the Durability of Rubber and Elastomers

Rubber and elastomers are prone to oxidative damage when exposed to air and heat, which can lead to cracking, hardening, or loss of flexibility. By incorporating Antioxidant 1076 into rubber formulations, manufacturers can improve the material's resistance to aging and prolong its useful life. This is especially important in industries like automotive manufacturing, where rubber components such as tires, seals, and hoses must withstand extreme conditions without compromising their performance.

3. Improving Stability in Coatings and Paints

Coatings and paints are often exposed to UV light and oxygen, both of which can cause oxidation and a breakdown of the pigment or binder. Antioxidant 1076 is often added to paint formulations to prevent discoloration, loss of gloss, and the degradation of the coating. This is particularly beneficial in outdoor applications where exposure to the elements is constant, ensuring that the coating maintains its aesthetic qualities and protective functions over time.

4. Versatility Across Multiple Industries

The versatility of Antioxidant 1076 is one of its greatest strengths. It is used not only in polymers and rubber but also in adhesives, sealants, lubricants, and electrical cables. In each of these applications, it helps maintain the integrity of the material, ensuring that it performs consistently and reliably. In the automotive, aerospace, and electrical industries, where high performance and safety standards are critical, Antioxidant 1076 helps to meet these demands by enhancing material stability.

Antioxidant 1076 (CAS 2082-79-3) plays an indispensable role in modern industrial applications by protecting materials from oxidative degradation. Its ability to stabilize polymers, rubber, coatings, and other materials ensures longer product lifespans, improved durability, and enhanced performance across a range of sectors. Whether in automotive manufacturing, construction, or electronics, the inclusion of Antioxidant 1076 helps manufacturers create more reliable, cost-effective products that withstand the challenges of time and the environment. For more info, visit Vinati Organics’ official page today.

0 notes

Text

Base Oil Prices Trend | Pricing | News | Database | Chart

Base Oil prices a critical role in the global lubricant and petrochemical industries, acting as a key determinant of production costs and market dynamics. These prices are influenced by a range of factors, including crude oil fluctuations, supply-demand imbalances, geopolitical developments, and environmental regulations. Understanding these dynamics is essential for stakeholders across the value chain, from manufacturers to end users. Recent trends in base oil pricing reflect a volatile market environment characterized by heightened uncertainty and shifts in global energy policies. The direct linkage between crude oil prices and base oil costs means that any significant movement in the crude market reverberates through the base oil sector. For instance, during periods of geopolitical instability, such as conflicts or disruptions in oil-producing regions, crude prices tend to spike, subsequently driving up the cost of base oils. Conversely, during times of economic slowdown or reduced industrial activity, demand for base oils typically declines, exerting downward pressure on prices.

Supply constraints also play a significant role in influencing base oil prices. Factors such as refinery shutdowns, maintenance activities, and unexpected production disruptions can reduce the availability of base oils in the market, leading to price increases. In recent years, environmental regulations aimed at reducing emissions and promoting cleaner fuels have further complicated the supply landscape. Refineries have been compelled to adapt their operations to meet stringent standards, sometimes resulting in a lower yield of base oils or higher production costs that are eventually passed on to buyers. Additionally, shifts in consumer preferences toward more environmentally friendly products have driven demand for premium-grade base oils, which often command higher prices compared to their conventional counterparts.

Get Real Time Prices for Base Oil : https://www.chemanalyst.com/Pricing-data/base-oil-63

The global distribution of supply and demand also has a substantial impact on base oil pricing. Major production hubs, such as those in the Middle East and Asia-Pacific, significantly influence global price trends due to their robust refinery capacities and export capabilities. At the same time, import-dependent regions like Europe and parts of Africa are more vulnerable to price fluctuations, especially during periods of logistical challenges or disruptions in shipping routes.

Technological advancements and innovation in refining processes have introduced a new dimension to the base oil market. The development of Group II and Group III base oils, which offer better performance characteristics and lower environmental impact, has reshaped demand dynamics. These higher-quality oils have gained traction in applications requiring improved fuel efficiency and thermal stability, particularly in the automotive and industrial sectors. However, their production involves advanced processing techniques, which contribute to higher manufacturing costs and, consequently, elevated market prices. The growing adoption of synthetic base oils, which are manufactured through chemical synthesis rather than refining, has further diversified the pricing landscape. While synthetic oils generally come with a premium price tag, their superior properties, such as enhanced longevity and performance in extreme conditions, justify their appeal to certain market segments.

Seasonal trends also exert an influence on base oil prices. For example, demand tends to rise during periods of increased industrial activity, such as the summer months in many parts of the world. Conversely, during the winter season, when industrial output typically slows down, base oil prices may soften due to reduced consumption. Additionally, unforeseen weather events, such as hurricanes or floods, can disrupt production and supply chains, causing temporary price spikes. The interplay between long-term structural factors and short-term events creates a dynamic pricing environment that requires continuous monitoring by market participants.

Another pivotal factor shaping base oil prices is the evolving landscape of global trade relations. Trade agreements, tariffs, and sanctions can have profound implications for the cost and availability of base oils. For instance, tariffs on imported base oils or key feedstocks can raise costs for domestic manufacturers, influencing the overall pricing structure in affected regions. Conversely, favorable trade agreements that promote the seamless flow of goods can stabilize prices and foster greater market efficiency. In recent years, tensions between major economies have led to uncertainty in global trade, further complicating price forecasting for base oils.

Environmental concerns and the transition toward renewable energy sources have begun to influence base oil markets as well. The shift away from fossil fuels has led to questions about the long-term viability of traditional base oil production, prompting some companies to explore alternatives such as bio-based lubricants. While these products are still in the early stages of market adoption, their development represents a potential disruptor to conventional pricing models. As the world moves toward greener technologies, the base oil industry will likely face increasing pressure to innovate and align with sustainability goals.

In conclusion, base oil prices are shaped by a complex interplay of factors that reflect the broader dynamics of the energy and petrochemical sectors. From crude oil volatility and supply chain disruptions to technological advancements and environmental considerations, the market is influenced by a diverse range of drivers. Stakeholders must remain vigilant in monitoring these trends to navigate the challenges and opportunities presented by this essential commodity. As global markets continue to evolve, adaptability and strategic foresight will be crucial for managing the risks and capitalizing on the potential of the base oil industry.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Understanding Lubrication Tools & Accessories: The Key to Efficient Heavy-Duty Machinery Maintenance

When it comes to maintaining heavy-duty machinery, one of the most critical components is proper lubrication. Without the right lubricants and accessories, machinery can quickly wear out, resulting in downtime and costly repairs. This blog will delve into lubrication tools and accessories, highlighting their importance and guiding you to the best lubricants for heavy-duty machines.

What Are Lubrication Tools & Accessories?

Lubrication tools and accessories are devices and products used to apply lubricants to machines and equipment to reduce friction, wear, and heat buildup. These tools are essential in a variety of industries, including manufacturing, construction, and agriculture, where heavy machinery plays a significant role in daily operations.

The range of lubrication tools includes manual grease guns, automatic lubrication systems, oil dispensers, lubrication hoses, and fittings. Each tool has a unique function to ensure the proper distribution of lubricants, ensuring that moving parts are protected and can operate smoothly under heavy workloads.

Why Lubrication is Crucial for Heavy-Duty Machines

Heavy-duty machines, such as excavators, bulldozers, and industrial trucks, face extreme operating conditions. They work in harsh environments, including high-pressure, high-temperature, and high-load scenarios. The components of these machines require adequate lubrication to:

Reduce Friction: Friction is a significant contributor to wear and tear. Proper lubrication helps reduce the friction between moving parts, extending the life of components.

Dissipate Heat: Lubricants act as a heat sink, drawing heat away from the moving parts and preventing overheating.

Prevent Corrosion: Moisture and contaminants can cause corrosion. High-quality lubricants form a protective barrier that helps prevent rust and other forms of corrosion.

Improve Performance: Consistent lubrication enhances the overall performance of machinery by ensuring that parts move freely without unnecessary resistance.

Best Lubricants for Heavy-Duty Machines

Choosing the best lubricants for heavy-duty machinery is crucial for achieving optimal performance and extending the lifespan of the equipment. Here are a few key factors to consider when selecting the best lubricants:

Viscosity: The viscosity of a lubricant is one of the most important characteristics. For heavy-duty machinery, you'll need a lubricant with a high viscosity to withstand the high temperatures and pressures typical in these machines.

Additives: The best lubricants for heavy-duty machines often contain various additives to enhance their performance. These include anti-wear additives, detergents, dispersants, and corrosion inhibitors, all of which provide additional protection.

Temperature Range: Heavy-duty machines often operate in extreme temperatures. Choosing lubricants that perform well under both high and low temperatures is essential to keep the machinery running smoothly.

Synthetic vs. Mineral Oils: Synthetic oils are usually the best choice for heavy-duty machinery. They provide better stability, enhanced performance in extreme conditions, and a longer service life compared to mineral oils.

Popular options for lubricants in heavy-duty applications include:

Multi-purpose Greases: These are ideal for lubricating bearings, gears, and other components in heavy-duty machines. They often contain both synthetic oils and thickening agents to maintain performance over long periods.

High-Performance Engine Oils: Heavy-duty engines require specialized oils that can handle high-stress environments. High-performance engine oils typically contain additives to improve wear protection, oxidation stability, and corrosion resistance.

Hydraulic Oils: Hydraulic systems in heavy-duty machinery need lubricants designed to resist oxidation and foaming. High-quality hydraulic oils also protect against rust and corrosion, ensuring the system remains efficient.

Essential Lubrication Tools for Heavy-Duty Equipment

To apply lubricants effectively, you need the right tools. Below are some of the most essential lubrication tools for maintaining heavy-duty machinery:

Grease Guns: Manual and powered grease guns allow for the precise application of grease to components that require regular lubrication, such as bearings and joints. Automatic grease guns are also available for continuous, hands-free operation.

Oil Pumps and Dispensers: For machinery that requires oil-based lubricants, oil pumps and dispensers can ensure that oil is applied accurately to the right parts without spills or mess.

Automatic Lubrication Systems: These systems are ideal for large machinery fleets or high-maintenance applications. Automatic lubrication systems continuously supply lubricants to various parts of the machine, ensuring consistent lubrication and minimizing downtime.

Lubrication Hoses and Fittings: These components help deliver the lubricant from the source to the parts that need it. Durable hoses and well-sealed fittings are essential to prevent leaks and ensure efficient application.

Regular Maintenance: The Role of Lubrication Accessories

Lubrication tools and accessories are not only useful for applying lubricants but also for ensuring their consistent performance. Regular maintenance checks are crucial for heavy-duty machinery, and lubrication accessories, such as filters, reservoirs, and level gauges, play a vital role in monitoring and managing lubrication levels.

Filters: Filters are used to remove contaminants from lubricants, ensuring that only clean lubricant is applied to sensitive machinery parts.

Reservoirs: Proper storage and containment of lubricants are necessary for ensuring that the right quantity is available when needed. Using well-maintained reservoirs ensures that lubrication is always ready for use.

Level Gauges: These accessories help operators monitor the lubricant levels in various parts of the machinery, ensuring that maintenance can be performed at the right intervals.

Conclusion

Lubrication tools and accessories are essential for maintaining the health and efficiency of heavy-duty machinery. Using the best lubricants for heavy-duty machines, combined with the right tools and accessories, can help extend the life of your equipment, improve performance, and reduce costly repairs.

Regular lubrication and maintenance should be part of every operator's routine to ensure that machinery continues to run smoothly under demanding conditions. By investing in high-quality lubricants and accessories, you're not only protecting your equipment but also ensuring that it performs at its best, day after day.

#industrial equipment#groz usa#heavyduty#lubrication#woodworking#hammer#frl combination sets#handtools#tools#grozusa#Lubrication Tools & Accessories#Lubrication Tools#Lubrication Accessories#woodworking hand tools#automotive hand tools#ai tools#automotive tools#writing tool#beauty tools and accessories#electric#howto#record#phone#electronics#bussiness#busservices#tool store#online store#store

0 notes

Text

Building Momentum: Exploring the Latin America Construction Lubricants Market

Market Overview

The Latin America Lubricants Market is projected to grow from an estimated 6.16 billion liters in 2024 to 7.19 billion liters by 2029, reflecting a compound annual growth rate (CAGR) of 3.13% during the forecast period (2024-2029).

Key Market Drivers

Infrastructure Investments: Governments across Latin America are heavily investing in infrastructure projects, driving demand for construction machinery and, subsequently, lubricants.

Urbanization Trends: The rise of urban populations is leading to increased construction activity, particularly in metropolitan areas, amplifying the need for reliable machinery performance.

Technological Advancements: The development of high-performance synthetic lubricants that can withstand extreme operating conditions is gaining traction in the market.

Sustainability Focus: Environmentally friendly lubricants are becoming increasingly popular, aligning with global and regional sustainability initiatives.

Challenges in the Market

While the market presents significant opportunities, challenges such as fluctuating crude oil prices, stringent environmental regulations, and economic uncertainties in certain countries pose hurdles for market players.

Regional Insights

Countries such as Brazil, Mexico, and Argentina are at the forefront of construction lubricant demand, given their large-scale infrastructure projects. Smaller nations in the region are also contributing to market growth as they modernize their infrastructure to support economic activities.

Trends Shaping the Future

Shift to Synthetic Lubricants: As awareness grows about the superior performance and environmental benefits of synthetic lubricants, their adoption is expected to increase.

Digital Transformation: Smart technologies and IoT integration in construction equipment are driving demand for lubricants that cater to advanced machinery.

Focus on Energy Efficiency: Energy-efficient lubricants are becoming a key consideration, aligning with efforts to reduce the carbon footprint of construction projects.

Conclusion

The Latin America Construction Lubricants Market is poised for significant growth, driven by the region's thriving construction sector and evolving industry needs. With a focus on sustainability, innovation, and efficiency, market players are well-positioned to capitalize on the opportunities presented by this dynamic industry.

As Latin America builds its future, construction lubricants will remain an indispensable component in powering progress.

For a detailed overview and more insights, you can refer to the full market research report by Mordor Intelligence: https://www.mordorintelligence.com/industry-reports/latin-america-lubricants-market

#Latin America Construction Lubricants Market#Latin America Construction Lubricants Market Size#Latin America Construction Lubricants Market Share#Latin America Construction Lubricants Market Trends

0 notes

Text

Alpha Olefin Market: A Look at Global Growth and Regional Insights

The global alpha olefin market was valued at approximately USD 10.42 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This market growth is primarily driven by the increasing demand for polyethylene, which is one of the most widely used plastics in various industries, including packaging, consumer goods, and industrial processes. The versatility and demand for polyethylene are expected to significantly boost the alpha olefin market, as alpha olefins are crucial raw materials used in the production of polyethylene and other synthetic materials.

Polyethylene is used extensively in packaging applications, ranging from plastic films and containers to bottles and bags. In addition, it plays a key role in various industrial processes, such as in the production of automotive parts, construction materials, and medical supplies. Its widespread use across different sectors is expected to drive a continuous demand for alpha olefins, which are essential in polyethylene production.

The most common method of alpha olefin production is the oligomerization of ethylene, where ethylene molecules are linked to form larger compounds. This process is the predominant method used globally to produce alpha olefins, resulting in the creation of products with even-numbered carbon chains, typically ranging from C4 to C30+. These products are crucial in the production of various derivatives like polyethylene, synthetic lubricants, detergent alcohols, and plasticizers.

In addition to the growing demand for polyethylene, oil drilling activities in the United States have emerged as a significant contributor to the market growth. The U.S. has witnessed a substantial increase in oil drilling activities, particularly in major oil-rich regions such as the Permian Basin in Texas and New Mexico, the Bakken Formation in North Dakota, and the Eagle Ford Shale in Texas. These regions are characterized by high oil production rates, which have, in turn, enhanced the availability of ethylene, a critical raw material for the production of alpha olefins.

Gather more insights about the market drivers, restrains and growth of the Alpha Olefin Market

Regional Insights

North America Alpha Olefin Market

North America led the global alpha olefin market with a revenue share of 39.3% in 2023, largely due to the surge in shale gas production in the U.S., which has significantly boosted ethylene production. Since ethylene is the primary feedstock for producing alpha olefins, this increase in production directly impacts the alpha olefin market. Furthermore, ongoing oil exploration activities in the Gulf of Mexico are expected to contribute further to market growth, as these activities increase the availability of hydrocarbons used in the production of ethylene and other key petrochemicals. Additionally, crude oil production in Canada is anticipated to further support the growth of alpha olefins in the region, as Canada is a major player in the global petrochemical market.

U.S. Alpha Olefin Market Trends

In the U.S., the alpha olefin market is primarily driven by the demands of the packaging sector, which requires vast quantities of polyethylene and other polymer products made from alpha olefins. Additionally, advances in polymer technology have contributed to the growing use of alpha olefins in high-performance plastics. The market is dominated by large, well-established players such as Chevron Phillips Chemical Co., The Dow Chemical Company, and ExxonMobil, who are heavily involved in the production and development of alpha olefins. These companies contribute significantly to the market’s expansion through innovation, large-scale production, and strategic investments in ethylene production capabilities.

Europe Alpha Olefin Market Trends

Europe holds the second-largest share of the alpha olefin market in 2023. The region is witnessing steady growth, driven by a focus on sustainable production methods and a rising demand for bio-based alpha olefins. As the demand for specialty chemicals and performance products continues to grow, the need for high-quality alpha olefins to meet these requirements is increasing. Germany, one of the leading players in the European market, is known for its emphasis on technological innovation and sustainability. The country has a strong presence of companies like Shell plc, which plays a crucial role in driving the development and production of alpha olefins. The demand for synthetic lubricants, plasticizers, and cosmetics is also contributing to the growth of the alpha olefin market in Germany, which is a hub for chemical innovations.

In the UK, the alpha olefin market is supported by demand from various sectors, including coatings, paper, pharmaceuticals, cosmetics, and the automotive industry. The easy availability of raw materials and the presence of abundant natural resources in the region are expected to further fuel market growth.

Asia Pacific Alpha Olefin Market Trends

The Asia Pacific region is expected to witness significant growth in the alpha olefin market from 2024 to 2030. This growth is attributed to the increasing demand from the packaging industry, rapid industrialization, and the expansion of the automotive sector. The region is also seeing significant investments in research and development (R&D), focusing on the development of specialty chemicals, which are increasingly being used in a wide range of applications.

In China, the alpha olefin market is growing due to the strong presence of domestic companies like Sinopec and PetroChina, who play a pivotal role in producing alpha olefins. The industrial expansion in China, particularly in the polyethylene and detergent alcohols sectors, has led to a growing need for high-quality alpha olefins. As China's industrial and manufacturing sectors continue to expand, the demand for alpha olefins is expected to rise further, making it one of the most significant contributors to the global market.

The Indian alpha olefin market is also growing, primarily due to the increasing demand for polyethylene and rising consumption in the automobile sector. However, the market faces challenges such as the high costs of raw materials and manufacturing processes, which could be a barrier to more widespread growth. Despite these challenges, India is expected to remain a key player in the alpha olefin market.

Central & South America Alpha Olefin Market Trends

The Central and South American market for alpha olefins is expected to experience significant growth from 2024 to 2030. The market is supported by the abundant availability of raw materials, particularly ethylene, and the presence of major industry players such as Braskem and Petrobras. The focus on renewable and environmentally friendly solutions is shaping market trends in the region, as more companies seek to integrate sustainable practices into their operations.

In Brazil, the market for alpha olefins is driven by the country's focus on sustainable growth, with a growing need for specialty chemicals and plasticizers. Major producers like Braskem are concentrating on developing high-quality alpha olefins to meet the diverse needs of the Brazilian market. Additionally, the growing demand for synthetic lubricants and adhesives in various sectors, including automotive and construction, is further supporting the market's growth in Brazil.

Middle East & Africa Alpha Olefin Market Trends

The Middle East and Africa (MEA) region is poised to see significant growth in the alpha olefin market during the forecast period. The region's strong petrochemical industry, combined with efforts to diversify its economy, is contributing to market expansion. Strategic investments in advanced polymer technologies and the development of innovative production methods are also key drivers of the region's growth.

In Saudi Arabia, the market is experiencing significant growth due to the country's vast natural resources and the prominent role of key players like SABIC. The increasing demand for alpha olefins in industries such as oil and gas and petrochemicals is a significant driver for the region's market. Furthermore, Saudi Arabia's efforts to enhance its chemical and petrochemical manufacturing capabilities are expected to lead to a rising demand for alpha olefins, further strengthening the market in the region.

Browse through Grand View Research's Organic Chemicals Industry Research Reports.

• The global isobutanol market size was valued at USD 1.28 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% from 2024 to 2030.

• The global pentaerythritol market size was valued at USD 2.80 billion in 2023 and is expected to grow at a CAGR of 43.2% from 2024 to 2030.

Key Alpha Olefin Company Insights

Companies in the alpha olefin industry are focusing heavily on the development of new products and building long-term partnerships with raw material suppliers. These strategic efforts are aimed at driving growth in the market, with key factors contributing to success including the range of products offered, competitive pricing strategies, and advanced manufacturing technologies. As the demand for alpha olefins continues to rise, many companies—especially large international players—are investing significantly in research and development (R&D). They are also working to innovate and adopt sustainable production methods to stay ahead of competition and meet regulatory requirements for environmental sustainability. In addition, to capitalize on emerging opportunities, these companies are expanding their presence by establishing production facilities in developing countries, where market potential is rapidly growing.

Several key players in the alpha olefin market include:

1. Chevron Phillips Chemical Company LLC

Chevron Phillips Chemical is a leading global chemical company that offers a comprehensive product range. This includes aromatics, drilling specialties, olefins, performance pipe, polyethylene, and specialty chemicals. Within its product portfolio, the company also produces alpha olefins, which are integral to many of the industries the company serves. Chevron Phillips is known for its strong technological capabilities and large-scale production of high-quality alpha olefins, particularly in the normal alpha olefin segment. The company’s research and development efforts continue to support its leadership position in the market, focusing on developing new applications and more efficient manufacturing processes.

2. Evonik Industries AG