#surface defect inspection

Text

The slightest surface defects are detected

1 note

·

View note

Link

#market research future#surface inspection market#surface inspection market size#surface inspection#defect detection market

0 notes

Text

look. they're dead if they're not on the surface. if they're not, they and everyone else will wish they were. an implosion is the kindest death they could have down there.

here are some things to keep in mind:

the deepest operational depths, meaning the safest depth that a manned crew could, potentially, rescue a submersible, is 300 meters. 980 feet. just under a 1000 feet. classified subs may be able to go deeper but that limit is like maybe 100 feet more. submarines cannot go trawling around sea floors unless they're relatively close to the coast

the titanic is 2.4 miles deep. 3840 meters. 12,600 feet. 12 times the operational depth of even the best naval submarines.

this tourist submersible's greatest operating depth? 13,000 feet. they're already at 96% of their operating depth. there's about a 4% margin before shit goes sideways, in normal circumstances

96 hours of oxygen is what OceanGate has told everyone this submersible has. this unregulated, untested sub. that they made. 96 hours of oxygen is probably being very, very generous.

there's only like a handful of submersibles, in the entire world, that can reach those depths. there's more ROVs that can reach deeper, but what percentage could help pull an entire submersible that can fit five people? their best bet is going to be getting some kind of remotely-operated flotation device attached to the submersible.

descending and ascending in a submersible is an incredibly delicate process that takes careful monitoring and delicate instruments. if they attach the flotation device then they're going to need something to monitor the internal and external pressure of the submersible. expanding gas could create a leak, which would instantly implode the submersible on the way up. not to mention gases and ballast must be monitored to prevent the occupants from getting the Bends, which can be fatal of itself.

all of this going to be made infinitely harder if the submersible is, as some suspect, tangled in the wreckage itself, which presents a hundred more problems such as zero visibility, structural collapse of several thousand tonnes of rusting iron and steel, punctures, etc..

all of this is assuming they are still conscious inside, and even have power. no power? even more difficult.

none of this is including the numerous defects the submersible is suspected of having, such as a CO2 filter. this is all assuming this submersible had zero defects--unlikely, considering their own words on why they didn't wait for inspection.

There is a goddamn reason they send ROVs down to the Titanic. There is a reason it should only be done by non-profit groups. There is a reason there should be oversight from the Navy and Coastguard. There is a reason that any human visitation is a carefully coordinated and monitored effort, where the majority are trained technicians inside the submersible and out. There is a reason that submarine crew and research crews also go through psychological evaluations, go through training to understand what to do in life-threatening situations. All of them, not just one dude at the controls.

Because they understand that, like Mt. Everest, when things go wrong down there, it is so hazardous to even any would-be rescuers that you will be on your own, and you will, almost certainly, die. And they may not even be able to retrieve your body, because that too is life-threatening to rescuers. Frankly, emergencies at the top of Mt. Everest are less dangerous than emergencies at the bottom of the ocean.

The ocean is actively trying to kill you down there. It's safer to visit space right now than it is to visit the bottom of the ocean. People haven't gone down there just to get a looky-loo. People are sent down there because there's certain things that only human eyes and senses can do, when it comes to research.

The deep ocean is not a place for fucking rich tourists to live out their James Cameron fantasies of seeing the prow come out of the darkness like in the movie. Whether you believe it's a gravesite that shouldn't be disturbed at all or not, tourists should not be goddamn down there.

Money won't save you at 12,000 feet at the bottom of the sea, motherfuckers. A divine miracle won't save them. But a miracle of human ingenuity, if there's some merciful force out there, just might.

2K notes

·

View notes

Note

Can you make an asylum patient needy yandere levi ackerman x asylum worker or reporter reader also do you do crossovers if so are you familiar with outlast or the Mount massive asylum

a spoonful of sugar!

yan. asylum patient levi ackerman x fem asylum nurse. reader

+ CW. — au: recon psychiatric hospital, reverse power dynamics, solitary confinement, medical drugging, escapement, morally grey darling, mentions of: mistreatment/abuse of patients, illegal medical procedures; my apologies, i’ve no knowledge on outlast, or asylums for that matter (but the effort is there, trust); not proof-read.

there is something innately unnerving about working so late into the night. it doesn’t help that any remnants of the sun’s presence had since been replaced by the humorless light of the moon, almost mockingly as it shone down on the equally dour and somber asylum. but much to your pleasure, you had been away for the entirety of the day, a blessing for you, but a curse for the recon psychiatric hospital. the asylum without its head nurse may have been left in ruins had you not returned any sooner, all thanks to a particularly high-maintenance patient, one you happened to be on your merry way to see.

delivering medications was child’s play; wonderfully easy, lacking in any form of demanding labor, and so effective. in spite of the fact that you were still quite privy to the more intense and morally questionable procedures performed by the doctors and assisted by the fellow nurses, it wasn’t like you to get your hands dirty. perhaps that is why they always stuck you with the night shift, because it was much simpler and favorable to deal with unconscious patients.

in your dominant hand grasped a singular nonbenzodiazepine pill, colorless and bland, an all white capsule with the only labeling being a letter ‘z,’ engraved on the surface of the medication. it was pinched between your forefinger and thumb, and you were careful as not to be too rough; what would be a sign of poor handling on your part, but you also held an insouciant grip on it to prevent any powdery residue from getting onto your skin. a glass, or rather faux-glass, cup took the empty space of your other hand. a glass half empty with water from two corridors down, courtesy of the leaky faucet from the dingy kitchenette. for once, the water appeared tasteful in the luster of the night, it made you lick your lips when you held the clear glassware up above you as you passed beneath the ceiling lights.

your pace was slowed so as to not allow the water to slosh around too much within its confines, and you made sure the uneven steps on the top floor’s staircase wouldn’t impair neither your ankles, nor fingers. when you had conquered the ascent and found yourself steady on flat ground, you stood motionless and inspected your hand, letting the pill gracelessly fall from your fingertips to the cup of your palm. folding your hand to cover the tablet, you continued down the daunting hallway.

had you not been working at an asylum, you would’ve run for the hills upon seeing such a sight: formidable walls and weak floorboards that creaked under the slightest weight, defectively dismal lighting that was unreliable at its best (constantly flickering) and completely useless at its worst (broken and shattered), and an indefinite silence that would likely cause one to go mad. this was the location deemed as ‘solitary confinement,’ seeing that there was no applicable area for those who deserved such a punishment. the courtyards and other floors were regarded unfit, as it was often frequented by patients and staff alike, and the most suitable section, the basement, was… occupied for more unruly operations.

the latter thought causes a cold shiver to crawl down your spine, and you shake your head with leaden stagnancy to avoid remembering the imagery. thankfully, it doesn’t take long to reach your destination, and you bend down to crouch in front of the door before you. with observant eyes, you gently set the cup down onto the floor, grimacing at how it touches the ground, and you retract your fingers from the body of the glass once the water’s splashes reduce to complete stillness. rising to your feet and straightening your posture, you dig into your pocket, rummaging for the ring of keys set, and looking for the singular key to the top floor’s only inhabited room. you avoid looking into the pathetic excuse of a window, eyes trained to the doorknob; insert, turn right, and pull back. sliding the ring of keys back into your pocket, you take a risky hold of the glass, raising it back up to your level by the rim.

there is absolutely no sense of urgency when you open that door, guiding it with your dominant hand as the inside of the room begins to reveal itself. stepping inside and far enough away from the door’s line of movement, you make eye contact with the patient residing within the recon psychiatric hospital’s loneliest floor, and he does not look happy. your gaze doesn’t shift, locked in place as you feel around for the door, pushing it back with a harsh shove, and only moving once you hear the bolts fasten it closed with an obnoxious slam. you idly meander your way over to the bed, where he is sat, one leg crossed over the other and his hands interlocked atop his knee. he doesn’t look to be someone who requires psychiatric treatment like this, but you’re no fool.

“i heard you gave dr. zoë quite the scare earlier.” you turn your hand faced up, unfurling your grip and displaying the capsule that continues to sit unperturbed in the cradle of your palm. a sour expression was already present on levi’s face, but at the mention of your peer, his eyebrows furrow and lips tug further into a frown, “where were you?”

taking a small step forward, you gradually traipse closer towards the bed that was pressed into the right corner of the room. he is motionless, even as you near. you dully tilt your head to the side with a quizzical look, it is only until you’re within arms reach does levi unravel from the stiff position, uncrossing his legs and unfolding his arms, “you can’t go terrorizing our psychiatrists and psychologists—”

“where were you?” your face falls at his demanding tone, but that is the least of your concerns once you feel levi’s eager hands on your body. simultaneously, he languidly spreads his legs apart until there is enough room for you to stand in between them; something you fail to take notice of as you’re far too distracted by him grabbing you by your torso, digging his fingers dangerously close to the underside of your breasts, then sliding down and tapping his fingers against the sides of your stomach, squeezing almost playfully, before he ultimately decides to sink his claws into your hips.

abrasively jerking you forward, levi’s arms snake around your waist until his hands meet one another overtop the curve on your lower back. you gasp when he pulls you closer, gaping with distraught panic at the glass of water, which fortunately did not spill, but it had come close. your knees collide with the inner side of his thighs, and you clasp your hand that was holding onto the z-drug to restrain it in place, so as not to lose it. once fully retaining your stability, your eyes dart down to levi, offering him an irked glare and placing the closed fist of your dominant hand on his shoulder, attempting to push him back to provide yourself some space. he doesn’t budge whatsoever, even when you continue your futile efforts in prying him off of you.

“where were you?” he repeats for the third time, but when he asked, levi didn’t sound pushy or domineering, unlike the previous two times, just bemused. your attention finally drops down to him, analytically observing as he gaped up at you. it was almost as if he looked at you with vacant, absentminded eyes with the way he refused to avert his gaze, but his gawking was anything but absentminded. his eyes felt intimate, accompanied by his endearing touches and the close proximity. you felt intimidated to hold this unspoken staring contest, “i, well, i was away.”

levi leans into you, until his head can rest in the crook of your neck. you’re rigid in his hold, refusing to let up your firm posture, only slightly bending to accommodate his height, “where?” you grind your molars together, and although you have the right to leave his questions unanswered, you do respond anyway just to satiate his curiosity, “my presence was requested for an asylum in stohess.”

“and what business do they have that involves you?” levi withdraws away from your neck, only to place his chin in between your collar bones, angling his head to look up at you, “i’ve been requested for a possible transfer, there is a young girl over there, i believe her name is annie… regardless, they think she’ll do better in my care. that’s why i’ve been telling you that you need to treat the other staff nicer.”

levi gives you an incredulous scowl, hands shooting up to cup either side of your face and drawing you closer until you’re nearly forehead to forehead. his eyes are awfully scary when he’s this close, and his voice goes monotonous, “you aren’t going. that’s ridiculous, they need you transferred to help one patient?” he asserts as if he’s the one in charge of that choice, you scoff.

“it’s ridiculous to stay for one patient, levi.” you’re given a break from the leer he was boring practically into your skull as he rolls his eyes, “it’s not your place or mine to finalize this decision. please don’t be difficult, it’s past time you take your medication.” it is both extremely embarrassing and annoying that you have to beg him to do literally anything, considering it only further feeds into his power and control complex when it comes to you.

he’s quiet for a while after that. perhaps not totally out of the ordinary for him, but you can see the gears turning in his head. levi is thinking about something, and whatever it is, it cannot be good. suppressing your unease, you careen backwards, breaking free from his clutch, but not without dipping your clenched hand into his, finally letting go of the pill. levi’s focus is redirected to the little white caplet, and you nudge the glass of water against his other hand. you cross your arms, waiting impatiently, and his eyes briefly flicker towards you before placing the pill in his mouth, mindful as not to accidentally swallow it, before tossing his head back and taking a hefty sip of water. levi raises the empty glass, and you take it from him, practically snatching it out of his hands and kneeling to set it down on the discolored and tarnished floorboards.

when you stand up and dust off your uniform, levi peers at you expectantly. and you let out a defeated sigh, to which levi smiles, “come here.” you instruct him to do so, but it is you coming to him. levi reels you in by the buckle of your apron, causing you to stumble over your own feet. you place both of your hands flat on his shoulders to ground yourself, wordlessly scolding him with a glare, one that only makes his smile grow wider.

you set your middle finger and thumb on the underside of his jaw, pulling it down slack and examining the inside of his mouth. your other hand finds itself on his cheek while you force his head to the left, then to the right, “lift your tongue.” levi obeys, pressing the muscle to the roof of his mouth, you press an index finger down onto his front teeth, causing his head to incline. you’re far too focused on ensuring that he actually consumed the pill to notice levi had gotten increasingly closer to you, and more level as well. levi catches you off guard when he bites down on your finger—

“ow! levi, i— what the hell? why would you do that?” you jump back, cradling the injured appendage in your other hand, mortified at the bite mark it had left on his wake. levi doesn’t give you much time to fully curse him out like you had wished, seizing you by your hips once more and falling back onto the bed, sitting upright with you at his mercy.

you descend with him, landing in a position that has you straddling his lap. the flat of your palm pries at his shoulder and chest, while your other arm is captured by his own hand, unbothered by your feeble endeavors in distancing yourself from him. levi’s other hand slides across the back of your neck, gripping onto your nape with a strict hold before pushing your head forward. his lips are on yours in an instant, letting go of your arm in favor of cruelly pinching your nose. you almost gag, frantically gasping for air, and without hesitation, levi’s tongue bullies its way into your mouth. and through the feeling of his hand tightening around the back of your neck, of his teeth nipping at your lips, of his tongue dominating yours; there is the feeling of a foreign object, and it feels like a pill.

wildly fighting his hold renders you breathless, and this is a fight you cannot win. tears swell in the corners of your bleary eyes, and the urge to cough becomes more eminent. to subdue the desire to hack and wheeze — which would certainly end in you choking — you instinctively swallow back the build up of both yours and levi’s saliva that gathered in the back of your esophagus. levi draws back from the kiss when he sees the lump in your throat bob and disappear, but he makes no move to release you, only relaxing his hands in their place. and it is now that you remember why he was administered to this asylum in the first place.

“i should’ve done this a long time ago…” apart of you wishes that z-drugs were immediately effective, just so you wouldn’t have to be conscious during your struggle against levi— which was, as always, in vain. it must have been due to the lack of air that you could only recount fragments of what happened. you turned your heel to flee, but levi had pinned you to the ground, keeping you in place with a chokehold that was alarming for someone who had been allegedly sedentary during his time in solitude. if your memory served you correctly, the sound of keys jingling and a door being unlocked could be heard; but whether it was in your dreams or in reality is unknown to you.

but that wouldn’t matter, by now, you and levi would be far from the psychiatric institution. it was easy, laughably easy for him. despite the fact it was such a late hour into the early mornings, and that he was carrying an unconscious and seemingly violated woman on his back, no passerby dared to question him. why would they? he was in a guard’s uniform after all, a stolen guard uniform— and thus, all the onlookers had just assumed that levi was kind enough to help an exhausted nurse on a particularly rough night shift get home safely. oh you were going home alright, back to levi’s home beneath the cities above, and how delighted he is now that he’ll be the one taking care of you. at the end of the day, it is what ‘normal,’ lovers do, isn’t it?

#ackerifle#yandere#yandere x reader#yandere attack on titan#yandere aot#yandere aot x reader#yandere levi ackerman#yandere levi ackerman x reader#levi ackerman x reader

175 notes

·

View notes

Text

Roots

Part 1 of Darron and Baeron's Backstory

Link to Part 2

T’zeklochar cast a brief glance toward the vaulted cavern ceiling of Menzoberranzan. A faint red glow rose from somewhere in the middle of the city, signaling that the great stalagmite clock, Narbondel, had only begun its reckoning.

The Matron Mother had had him woken and dragged from bed, in the middle of the night.

“Is there a room somewhere we can put Ryld?” she inquired after he had been essentially jostled through the whole damned house and dropped in front of her throne.

“Couldn't this wait till morning, Breena?” T’zeklochar asked pointedly. He glared at the guards at his elbows (both of whom were smirking females) and got to his feet.

As if T'zeklochar hadn't spoken out of turn, Matron Dinbreena carried on, “Somewhere out of the patron's way - where he won't notice. I mean, imagine.”

“How very delicate of you.”

Her eyes were dull from thought, her silver hair loose and trailing down her shoulders to her knees like a curtain. She was preoccupied. About Ryld, of course.

“See that he's found a room.”

It was final. Definite, No room left for contention.

“Yes, Matron Mother,” said T’zeklochar, bowing slightly, all thought of sleep banished with the new task at hand.

Presently, the Weapons Master of House Barriurden crossed the back courtyard, passing the stables housing the lizard mounts. He stepped into the kitchen, then further down into the cellar, and headed for the cubby tucked behind the shelves. The door to the hole slammed against the wall as T’zeklochar threw it open.

The single inhabitant of the cramped cubbyhole sprang up from his bed. “What in the hells – ?!”

“Wake up, pantry boy.” T’zeklochar ordered as Ryld blinked dumbly in the dark. “Whatever paltry possessions you have, gather them and follow me.”

Ryld was a commoner, a kitchen servant tasked with keeping track of the House’s food stores. He was also the newest, albeit unwilling, object of Matron Dinbreena's affections. Her appetite for amorous exploits was unabated even as she saw her third century. No drow could refuse her. Whichever male she chose must submit, under pain of death.

A swarm of bats flitted through the stalactites. Ryld stretched as he quietly followed T'zeklochar to the front of the house. Guards stood in attention as the Weapons Master walked past. The kitchen servant, they paid no mind.

It was difficult not to notice him, however, even T’zeklochar would admit. The drow, at the prime age of a hundred or so, was handsome and tall - tall by drow standards. His build was lean and wiry. His eyes appeared blue in the Underdark, with red pin pricks in their centers. An unfortunate defect, caused no doubt by his forebears interbreeding with surface elves or even humans. And yet, it did not take away from his beauty. The overall effect was one that stirred the blood.

“You think this is some sort of blessing?” T’zeklochar asked the younger drow, who was inspecting his new bedchamber.

Ryld peeled his eyes away from the ornate trimming and gossamer curtains overhanging the bed.

“You're in more peril than you ever were.”

Drow hated and yet thrived on competition. As a rival to the Matron’s consort, he would surely be faced with opposition. The patron would not allow Ryld to sire children by the Matron, and put his own children's ranks at risk.

“You think I asked for this?” snapped Ryld, an assertive fire making the red pin pricks of his eyes more pronounced.

T’zeklochar's frown belied his pleasure. “You'll need more tricks than just batting your eyelashes, if you want to survive now.” He shoved a shortsword into Ryld's hands. “Meet me in the training hall in two hours.”

The empty halls rang with the awful, pained screams of Matron Dinbreena as she labored to bring her and Ryld's child into the world. She had been taken into Lolth's unholy chamber, attended by her clerics and priestesses. All unneeded persons were barred entry, including the father.

Ryld sat trembling where he waited in the stairwell. T'zeklochar, who had become an unlikely friend in the last 10 months, stood leaning on the bannister, smoking on a small pipe. He took pity on the expectant father and passed him the pipe, chuckling as he struggled to put it to his lips.

There came Dinbreena's screams again. “RYLD! WHERE IS HE?! I WANT HIM HERE! RYLD!”

Ryld flew to his feet and up the stairs, followed closely by T'zeklochar. Dinbreena held out her arm as she saw them come through the door.

“Damn you and your spawn,” she hissed as tears streamed down her ashen cheeks. Her grip on Ryld's hand was crushing.

“What's happening? The child has been delivered. Why -?”

The pain was not letting up, even as Liriel, one of Dinbreena's daughters and high priestess of Lolth, carried a squealing child to a stone pedestal.

“There's a second child,” snapped Zardra. “You have twins.”

T’zeklochar stood over the kicking baby, wiping it clean with a blood-soaked towel. Ryld's heart sank as he studied the Weapons Master's expression.

His dark heart uttered a desperate prayer and a bargain. “Please, goddess. If you give me this, I will be your uncomplaining servant.”

Ryld gently set the Matron down on the armchair. She had succumbed to the exhaustion just after the second child arrived.

The children's sobbing had subsided and the chamber grew deathly quiet. Ryld held his breath, looking to T’zeklochar for some hope. His red eyes were empty, his face like stone.

The Weapons Master shook his head, and Ryld felt like he had been gutted.

“Two male children. Cursed day,” muttered Zardra.

Liriel turned to Ryld. “You ought to be executed for your uselessness!” She cast a venomous glance at her newborn brothers, her knuckles white over the handle of her dagger. “Along with these wretched whelps.”

“Look at their eyes!” gasped Evandra. The twins had inherited Ryld’s ice blue eyes, with the red pin pricks glowing bright in the worship chamber.

“Beastly little wretches!” chimed Zardra.

T’zeklochar, who had not left the babies’ side, appeared unbothered, but was slowly easing his hand toward the shortsword at his belt. If any of the priestesses attacked, he was going to defend the little ones.

“Liriel is right,” said Zardra. “This is an omen. We all know what happened to House Do’Urden. We must kill them lest these blue-eyed freaks follow in Drizzt's footsteps.”

Ryld grew cold. Beside him, Matron Dinbreena stirred, and, her voice husky from screaming, addressed her daughters with severity. “If you lay a finger on our children,” she said, “On my honor as Matron Mother, on my honor as the Spider Queen’s servant - I will cut your head off myself.”

A smirk pulled the corner of T’zeklochar’s mouth. Our children. Dinbreena was done for. She had fallen in love with Ryld.

“These children are Noble Drow of House Barriurden. You shall show them the respect they are due.”

Matron Dinbreena retired after nursing her twin boys. She left them in the company of their father, sleeping side by side in a cradle that had held five older sons. The daughters’ cradles were naturally more resplendent, but this one did the job and Ryld was satisfied.

He was still lost in thought when T’zeklochar entered, his hands clasped over something. Ryld admired the sight of the Weapons Master looking into the cradle, how gentle he became in the presence of his children. The way the tension from his broad, muscular back eased as he hummed and cooed at the little ones.

In the purple faerie fire, Ryld saw that T’zeklochar had brought a tarantula for the twins. The fuzzy creature crawled over T’zeklochar's knuckles and settled on Baeron's little chest. The little one stirred, smiled in his sleep, and cuddled the spider closer.

T’zeklochar opened his mouth, and a second tarantula crawled out of hiding. This one he gave to Darron. “Sleep sound in the dark, child,” he purred.

He addressed the father without looking at him. “Do not agree to have Dinbreena's daughters raise your children.”

Ryld scoffed. “I have no intention to. She's allowed me to raise them myself. Being her consort has granted me that favor, I guess.” He watched his boys with his arms crossed. He was steeling himself for what he was about to tell T’zeklochar. “I… I want you to train them, when they come of age.”

The Weapons Master still did not look him in the eye. “You're a madman and a fool,” he simply said.

Indignant, Ryld straightened up. He always had too much cheek for a commoner. It was one of the things that T’zeklochar admired about him. “A fool? My sons will live, if they know how to defend themselves. How am I a fool to know that?”

“Yes.” T'zeklochar nodded, his voice growing louder. “They will live, but not long enough to see 30. The Patron already hates you as it is. Put a sword in either boy's hand, and they will be a greater threat than ever. If they aren't murdered by their siblings, they will be murdered in the Academy.” He gestured wildly to the window. Somewhere out in the city stood Melee Magthere, where fighters were forged. It was a cruel and merciless place whose halls were washed with blood and colonnades polished with screams.

“I cannot protect them there,” T’zeklochar declared. I cannot protect all of you, he thought to himself.

“That's not what I'm asking,” Ryld replied coolly. “I only require that you teach them what they need to know.”

T’zeklochar was adamant. He shook his head. “Give them up for consortship and they may yet survive.”

“So they can be treated like… mere courtesans?” Ryld could not - would not see his sons suffer the same fate.

Ryld. What mother he had was so heartless as to name him “slave” in the drow tongue.

“They will marry into security,” T’zeklochar explained, “They'll be valuable in continuing the bloodline. Is that not enough to placate you?”

“And if your boy was alive, would you do the same?” Ryld snapped.

The words were out before Ryld could stop himself. When he saw the look of hurt on the Weapons Master's face, he knew he had gone too far.

T’zeklochar was Matron Dinbreena's consort once. He'd sired a child. A third son.

He didn't even get a chance to hold the boy before Liriel plunged her dagger into his tiny heart. A sacrifice to appease the goddess, Lolth.

Recovering, T'zeklochar replied, “If he had been allowed to live? Yes.”

He held Darron's foot and placed a tender kiss on his heel. He passed Ryld on his way to the door, and without so much as a warning, he grabbed him by the throat and shoved him against the wall.

The impact knocked the wind out of Ryld. His breath did not return now that he and T’zeklochar were a lip's distance from each other.

“If you ever mention my boy again,” T’zeklochar whispered, his voice soft as silk. “I'll kill you.”

He dropped Ryld to his feet and headed out the door.

“I need you.”

T’zeklochar froze.

“I cannot do this alone,” Ryld begged. “These boys need to be strong. You must teach them.”

“Have it your way. It won't be easy. It will break them.”

“I know.”

---

A/N: not me posting this because it got too long 🤡

There will be more.

#oc lore#character backstory#dnd oc#dnd au#drow oc#t'zeklochar#ryld#dinbreena#darron#baeron#twins au#drow twins#bluecoolr.txt

27 notes

·

View notes

Text

Like Real People Do

C/W: theoretically, nothing; mentions eating of crystals, mentions of sleep deprivation (due to travelling)

A/n: HAPPY BIRTHDAY OLD MAN 🎉🎉🎉

Word count: 932 words.

The moonlight enters through the open window, the howling winds echoing through the quiet room. It sweeps away the disorder, the spirits, and anything else that dares to disturb him. A lone figure sits in the corner, a small chest full of treasure and oddities sit in front of him, awaiting his judgment.

He picks up another, carefully inspecting it with his eyes. It shines bright and gleams, yet there is a crack just barely inconceivable on the inside. It will not suffice. It is weak, it is impure. It will become unstable if he uses it. He clicks his tongue and opens his maw, and bites down hard with teeth sharp like swords. Crunch! A bottomless pit and a long, serpentine tongue clean up the remains, leaving behind no trace of imperfection on his lips. He sighs at the warmth that envelops him momentarily, his hunger satiated, yet it is proof of another failure.

He resists the urge to yawn or rub his eyes as he picks up another gem. Another defect. Crunch. Hours pass by, but there is no sign of anything remotely close to what he's looking for. His continuous failure wears him down each time, muscles taut as he grips the table with his gloved hands.

Countless nights spent awake, days spent travelling, bargaining and searching with aching feet and a restless mind. His face was haunted by shadows, and his hands twitched at his sides. Days spent inside cramped, barely-lit spaces, stomach empty as the sea in the west. Days spent alone without the comfort of anything or anyone but his own gnawing thoughts.

He closes his eyes and breathes deeply through his nose, counting one, two, three, until he lets out his breath slowly. Aching bones creaking as he reaches for another crystal, mind wondering why he's even making this much effort in the first place. Why he's always thinking of a certain redhead, why does he always want the best for the kingdom, even if it wasn't his land?

His eyes dart to the glass casing behind him. To the crown that has sat on top of many leaders' heads. The same crown that he is trying to design for this land's future, the Crown Prince Diavolo. The man who will soon rise to the throne and take over the kingdom. The man that Lucifer will be forever grateful to for he accepted him and his son, who are deemed traitors in their homeland, into their territory. Who risked another war just to make them feel safe, dressed them, fed them and treated them like his own people. He will not forget the kindness in those golden eyes, the kindness that warms his aching heart and comforted his weary body. He lets out a shaky breath, forcing his eyes to clear of the memories.

A twinkle catches his eye, as the moon's light hits the crystalline surface, and he squints his eyes at the sight. He picks up the red gem, turning it around in his fingers and bringing it closer to the light to take a look. He hums in thought as he continues to analyze it. It has a good physical structure and does not have any cracks anywhere. It holds a small amount of magic that is barely useful but seems to be able to hold more than it looks. It has a nice bright colour, the same shade as the ones embedded in the crown behind him. His eyes start to glow.

He flicks his wrist, and tendrils of black ichor reach out from underneath his sleeve and float up. They follow his wordless command, encircling the small rock and seeping into it until the black swirls inside like smoke.He watches as the colour refuses to fade, and the surface provides no resistance or pressure. He waits for a different reaction, his mind tracing back to the time he felt too assured and was bested by a stupid delay. Minutes pass and still, it does not break nor does it produce any strange sounds. The existing magic within the crystal does not die but co-exists with his own. It is perfect.

He sighs, deep and weary as he stands, up walking over to his bookshelf and picking up a glass case to put the crystal inside for safekeeping. He closes his eyes, taking a moment to rest a little as he allows himself to bathe under the moonlight. He opens his eyes and turns around, just now noticing how dark the room is as he stretches his limbs. He turns and leaves the room to find comfort and inform his liege of his accomplishment.

Walking down the hallways, Lucifer tries to conceal his excited steps, wouldn't want any of the servants or him to see him walking to the future king's room at night. Lucifer arrives, a sigh leaving his lips as he tries to collect himself before rapping his knuckles in the wood. He gets no answer. He knocks again and softly calls out but still, no answer. He tries the door but it is locked. His mind wanders as he looks down and notices a piece of paper at his shoes with his name on it. Picking it up, he recognized the king's neat handwriting.

Fixing the glasses on his nose, Lucifer opened the letter and read the contents. He sighs, rolling his eyes. Of course he'd be there at this time, he thought. He pocketed the paper and went back to his room, grabbing a cloak to don and walking down the palace halls, a destination in mind.

A/n: this took way too long because i couldn't find motivation and time to continue the illustration until recently! (For context, I started the drawing on February and only finished it now😔). But happy birthday once again to the most arrogant bastard I've ever known in fiction! <3 If not for you, I may not have even considered playing om, haha!

Also, this is part of an au I'm trying to cook (keyword try since I'm not very good at cooking) (also the au's temp name is Morning Glory) and I'm planning a Diavolo companion piece to this (I already started on the sketch) so fingers crossed that college won't eat me up before I could finish that for Dia's bday!

#obey me#obey me lucifer#obey me diavolo#dialuci#my stuff#fanart#morning glory au#also im gonna try to post this to ao3 w the pic#but im gonna have to learn how to insert pics there without having to upload the pic somewhere else#obey me morning glory au

14 notes

·

View notes

Text

Preventing Defects and Imperfections in Welded Joints

Welding is a critical process used across industries to join metals in the construction of buildings, bridges, automobiles, aircraft, pipelines and many other structures. However, welding is not a perfect process and various types of defects can occur, both internally and externally in the welded metal. These welding defects are imperfections that deviate from acceptable tolerances, weakening the joint and potentially leading to catastrophic failures. Understanding the common types of welding defects, their causes, and preventive measures is crucial for ensuring the integrity and reliability of welded structures. In this article, we will explore the major categories of welding defects, delve into specific defect types, examine their causes, and discuss strategies for preventing their occurrence.

Types of Welding Defects

Welding defects can be broadly classified into two main categories:

External defects: Discontinuities that are visible on the surface of the weld metal

Internal defects: Imperfections that occur within the weld metal and are not readily visible

External Welding Defects

Some of the most common external welding defects include:

Cracks: Fractures that form in the weld metal or heat-affected zone due to thermal stresses, hydrogen embrittlement, or solidification shrinkage

Undercut: A groove-like defect along the edges of the weld bead, reducing the cross-sectional area and weakening the joint

Overlap: Excessive weld metal that flows onto the base material without proper fusion

Spatter: Small droplets of molten metal that solidify on the base material or surrounding area, affecting aesthetics and requiring additional cleaning

Internal Welding Defects

Internal welding defects are not readily visible and often require advanced inspection techniques to detect. Some common internal defects are:

Porosity: Gas bubbles or cavities that form within the weld bead due to trapped gas during solidification

Slag inclusion: Retention of solid materials, metallic or non-metallic, within the weld metal

Lack of fusion: Insufficient bonding between the base material and weld metal or between successive weld beads

Incomplete penetration: The weld does not fully extend through the thickness of the base material, leaving a gap or void

Causes of Welding Defects

Several factors can contribute to the formation of welding defects:

Poor welding technique: Incorrect welding parameters, improper electrode angle, or inadequate travel speed

Incorrect welding parameters: Unsuitable voltage, current, or wire feed speed settings

Contamination: Presence of impurities such as oil, grease, rust, or moisture on the base metal or filler material

Inadequate shielding gas coverage: Insufficient or improper shielding gas flow, leading to atmospheric contamination

Improper joint preparation: Incorrect joint design, poor fit-up, or inadequate cleaning of the joint surfaces

Preventing Welding Defects

To minimize the occurrence of welding defects and ensure high-quality welds, several preventive measures can be implemented:

Proper Welding Technique

Maintain the correct electrode angle and travel speed

Adjust welding parameters based on the material thickness and joint configuration

Ensure proper weld bead placement and overlap

Material Preparation

Thoroughly clean the base metal and filler material to remove contaminants

Ensure proper joint preparation, including beveling and fit-up

Preheat the base metal when required to reduce thermal stresses

Shielding Gas Management

Use the appropriate shielding gas composition and flow rate for the specific welding process and material

Regularly check and maintain the gas delivery system to prevent leaks or contamination

Ensure adequate gas coverage, especially in windy or drafty environments

Equipment Maintenance and Calibration

Regularly inspect and maintain welding equipment to ensure proper functioning

Calibrate welding machines and monitoring devices to maintain accurate settings

Replace worn or damaged components, such as contact tips and gas nozzles

Welder Training and Qualification

Provide comprehensive training to welders on proper techniques, parameter selection, and defect prevention

Ensure welders are qualified and certified according to relevant standards and codes

Encourage continuous learning and skill development through ongoing training and education

Implementing Quality Control Measures

Establish and follow welding procedures and specifications

Conduct visual inspections and non-destructive testing (NDT) to detect and evaluate defects

Implement corrective actions and process improvements based on defect analysis and root cause identification

Detecting and Correcting Welding Defects

Despite preventive measures, welding defects may still occur. Early detection and appropriate corrective actions are essential to maintain the integrity of welded structures. Some common methods for detecting and correcting welding defects include:

Visual Inspection

Examine the weld surface for visible defects such as cracks, undercut, overlap, or spatter

Use magnifying lenses or borescopes for closer inspection of hard-to-reach areas

Document and evaluate the severity of defects based on acceptance criteria

Non-Destructive Testing (NDT)

Employ NDT techniques such as radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), or dye penetrant testing (PT) to detect internal defects

Interpret NDT results and determine the acceptability of defects based on applicable standards and specifications

Perform additional testing or sectioning for further evaluation if necessary

Corrective Actions

Remove defects by grinding, chipping, or gouging, ensuring complete removal of the defective material

Re-weld the affected area using proper techniques and parameters

Perform post-weld heat treatment (PWHT) when required to relieve residual stresses and improve mechanical properties

Re-inspect the repaired area to confirm the effectiveness of the corrective action

Advancements in Welding Technology

Welding technology continues to evolve, with advancements aimed at improving weld quality, productivity, and safety. Some notable developments include:

Automated welding processes: Robotic welding systems and computer-controlled welding machines enhance precision, consistency, and efficiency, reducing human error and variability.

Advanced welding consumables: New filler materials with improved mechanical properties, corrosion resistance, and weldability enable welding of challenging materials and in demanding environments.

Real-time monitoring and control systems: Sensors, data acquisition systems, and machine learning algorithms enable real-time monitoring of welding parameters, defect detection, and process optimization, leading to improved weld quality and reduced rework.

Conclusion

Preventing defects and imperfections in welded joints is crucial for ensuring the structural integrity, safety, and reliability of welded components across various industries. By understanding the common types of welding defects, their causes, and implementing effective preventive measures, welding professionals can significantly reduce the occurrence of defects and achieve high-quality welds.

3 notes

·

View notes

Text

How to Choose the Right Plywood for Your Project

Selecting the right plywood for your project can make a significant difference in the outcome. With a variety of types, grades, and sizes available, it’s essential to understand what to look for to ensure you get the best results. In this blog, we’ll guide you through the process of choosing the right plywood for your needs. Plus, we’ll show you why Bhawani Plywood is your go-to source for top-quality plywood.

Understanding Plywood Grades

Plywood is graded based on its quality and waterproof level , and knowing these grades can help you make an informed decision.

BWP-Grade Plywood : This is the highest quality plywood, Which is boiling water proof best for places like chennai which are near sea . It’s ideal for projects requiring a long life, such as cabinetry and furniture.

BWR-Grade Plywood : Slightly lower in quality than BWP-grade, BWR-grade plywood has a little less life than BWP . But can be used for furniture which are not often in contact with water.

COMMERCIAL-Grade Plywood : The lowest grade, with several imperfections and lowest level of water that is moisture resistence . It’s best used for structural purposes where appearance isn’t a priority or temporary furnitures. It is also called as MR grade

Types of Plywood

Different types of plywood are designed for specific applications. Here are some common types:

1. Softwood Plywood : Made from softwood species like pine, fir, or spruce, this type is often used for construction and industrial purposes.

2. Hardwood Plywood : Made from hardwood species like oak, maple, or birch, this type is ideal for furniture, cabinetry, and high-quality interior finishes.

3. Marine Plywood : Specially treated to resist moisture, marine plywood is perfect for outdoor projects, boat building, and areas exposed to high humidity.

Key Factors to Consider

When choosing the right plywood for your project, consider the following factors:

1. Application : Determine where and how the plywood will be used. Structural applications require strong, thick plywood, while decorative uses benefit from high-quality veneers.

2. Exposure to Elements : For outdoor or high-moisture areas, choose BWP or marine-grade plywood to prevent damage.

3. Budget : Higher-grade plywood costs more but provides a better finish and longevity. Balance your budget with the quality required for your project.

4. Thickness : The thickness of plywood affects its strength and stability. Ensure you select a thickness appropriate for the load and stress it will endure.

Tips for Selecting Plywood

Here are some expert tips to help you select the right plywood:

1. Inspect the quality : Look for smooth, even surfaces with minimal defects. High-quality face ensures a better finish.

2. Check the Core: The core layers should be consistent and free from gaps. This affects the strength and durability of the plywood.

3. Consider the Weight : Heavier plywood indicates a higher density, which can be beneficial for structural applications but might be overkill for decorative uses.

Why Buy Plywood from Bhawani Plywoods

At Bhawani Plywood, we are committed to providing the highest quality plywood for all your project needs. Here’s why you should choose us:

- Quality : We offer plywood of kitply which is our most trusted partner for plywood with good support for any issue.

- Expert Advice : Our knowledge and experience can help you select the best plywood for your specific needs.

- Competitive Prices : We provide top-quality plywood at competitive prices to fit your budget.

- Convenience : Shop online at Bhawani Plywood or visit our store for a hassle-free shopping experience.

Conclusion

Choosing the right plywood is crucial for the success of your project. By understanding plywood grades, types, and key factors to consider, you can make an informed decision that ensures the best results.

Ready to get started on your next project? Visit Bhawani Plywood for the best selection of high-quality plywood. Our team is here to help you find exactly what you need to bring your project to life. Shop with us today and see the difference quality plywood can make!

2 notes

·

View notes

Text

Titanium ring/Titanium forging ring (Titanium forgings)

1. Brand: TA1, TA2, TA9, TA10, TC4, TC11/GR1, GR2, GR5, GR12

2, titanium ring/titanium forging ring (titanium forging) surface

The surface is clean and smooth, without peeling, porosity, cracks and other defects.

Three, titanium ring/titanium forging ring (titanium forgings) implementation standards

National standard: GB/T 16598-2013, GB/T2965-2007.

Us standard: ASTM B381, ASTM F67, ASTMF136, ASTM4928.

Fourth, titanium ring/titanium forging ring (titanium forgings) inspection

Destructive testing: physical properties testing, hardness testing, chemical composition testing, metallographic testing.

Non-destructive testing: ultrasonic testing, penetration testing, appearance testing.

5. Titanium ring/titanium forging ring (titanium forgings) Specifications:

Customized processing according to specifications and dimensions

Six, titanium ring/titanium forging ring (titanium forging) performance and process

Smelting forging, grinding, CNC, flaw detection

2 notes

·

View notes

Text

An encounter with a siren

The waters were unforgiving to the poor woman in the boat, almost tipping the small vessel several times with each blow the wind made.

The person's name was Bianca Fujitsu, a poor woman in her early 20's who went fishing to sustain herself. No children, no husband and no other family members: she was alone. The last one standing and fighting to live, refusing to accept death. She hated the fact that she was now in an unknown enviroment, due to the storm.

Well, until she felt the waters getting colder. She realized, a bit too late, that she was near Antarctica. A place where only two mer species lived and hunted: Orca- and Leopard seal mers. The two most fearsome predators that humans tried to avoid.

Unfortunately, she knew that it would be impossible, as these predators of Antarctica were excellent trackers. What had she done to deserve such a cruel fate? Not to mention that she could not even speak. A birth defect she had grown used to until now.

Tired, scared, hungry and weak was all she felt. Her grip loosened on the wood that kept her afloat, and she splashed in the water as adrenaline pumped into her veins. It all but did her any good, as she began to sink, her arm sticking out of the water before disappearing under the surface.

Unbeknownst to her, a siren heard her splashing.

She sank, vision blurry and air escaping past her lips.

A dark mass headed towards her.

She couldn't make out what it was, as her eyes fully closed and she fell unconscious.

---

His pink-red eyelights focused on her small form sinking, expression blank. He gripped her waist with one hand, her small figure perfectly fit in his. He went to the surface, and inspected her. Thick jacket that was now soaked, hazel brown hair, thick pants and black shoes. He saw her lips turn blue, and knew that she was cold or began getting hypothermia.

His jaws slowly opened, revealing a pink-red ecto tongue. Saliva connected from sharp tooth to sharp tooth and on the tongue, jaws widening to fit her completely inside his maw. He carefully guided her into his maw, using his ecto tongue to prevent his canines from cutting her.

After gently getting her inside, he closed his maw and waited a few seconds before tilting his head. He swallowed, and that one gulp got her waist deep in his throat. A second gulp and only her hands were free from his throat. He took a deep breath, placing his hand on his throat and swallowed again, tracing her small form all the way to his stomach. He made a small sound, before diving under the waves. He would wait and ask her questions later. After all: Leopard seal siren was a curious, dangerous and intelligent being that sent fear through many.

These are my oc's: Leo and his Frisk(Bianca). These characters strictly need my permission to be used. Anyways, thank you for reading!

9 notes

·

View notes

Text

What is PCB Assembly ?

PCB Assembly manufacturer - Hitech Circuits Co., Limited

It’s the step in the manufacturing process in which you populate a blank board with the electronic components needed to make it into a functional printed circuit board. It’s these components that make a board into the circuit that enables an electronic product to function. PCB assembly typically takes place via one of two processes:

1. Surface-mount technology

SMT: SMT stands for “Surface Mount Technology“. The SMT components are very small sizes and comes in various packages like 0201, 0402, 0603, 1608 packages for resistors and capacitors. Similarly for Integrated circuits ICs we have SOIC, TSSOP, QFP and BGA.

The SMT components assembly is very difficult for human hands and can be time taking process so it is mostly done by automated pick and place machine.

2. Through-hole manufacturing

THT: THT stands for “Through hole Technology”. The components with leads and wires, like resistors, capacitors, inductors, PDIP ICs, transformers, transistors, IGBTs, MOSFETS are example.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

Printed Circuit Board Assembly Techniques

There are only two common PCBA techniques available for use by a PCB designer. The methods are:

1. Automated PCB Assembly Techniques

Generally, this technique employs the use of state of the art machines, which are fully automatic. For example, the surface mount components are worth positioning with the aid of an automated pick and place machine.

Again, reflow soldering is commonly for surface mount components usually done in a reflow oven. An automated solder stencil is also used to apply the solder paste on the PCB.

Finally, high tech inspection machines are used to confirm and check the quality of the PCBA. Some of which include: Automated optical inspection machine (AOI), X-ray inspection machines, etc.

Above all, due to the precise monitoring, control of soldering, no human input and versatile machines.

This technique ensures utmost efficiency, output consistencies, and limits defects.

2. Manual PCB Assembly Techniques

This method is favorite for use with through-hole parts, which needs manual placement on the board. Besides, with these through-hole parts, it’s advisable you use wave soldering. Note that in the through- hole assembly process, you need to place the components and electronics on the PCB.

After that, you use wave soldering to solder the leads. Typically, you will need an individual to insert a component into a marked PTH. Once done, transfer the PCB to the next station where the next person will be on standby tasked with fixing another part.

What are the Benefits of SMT PCB Assembly?

SMT assembly provides many benefits and some of them are as follows:

It can be used to incorporate small components.

In SMT, the components can be placed on both sides of the board.

It assures high component densities.

Fewer holes need to be drilled for surface mounting than through-hole.

It require low initial costs and time for setting up the mass production.

SMT is the simpler and faster-automated assembly when compared to through-hole.

Errors regarding the component placement can be easily rectified.

Surface mount PCBs feature strong joints, which can easily withstand vibrations.

What are the techniques used in Surface Mount Technology?

There are several techniques for the reflow process. After applying the solder paste or a flux mixture on the board and after placing the components, the boards are conveyed to a reflow soldering oven. The techniques used for reflowing soldering include infrared lamps, hot gas convection, fluorocarbon liquids with a high boiling point, and so on.

What are the different testing methods used in SMT PCB Assembly?

Hitech Circuits as the PCB assembly manufacturer, we perform the following testing and inspection to ensure the quality of surface mount PCBs.

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

What type of files or documents should I send for SMT PCB Assembly?

Gerber Files: The file contains all details of physical board layers including solder masks, copper layers, drill data, legends, and so on.

Bill of Materials (BOM): This contains information on the list of items needed for the PCB manufacturing and the instructions of manufacturing.

Pick and Place File: This file contains information on all components to be used in the PCB design and their rotation and X-Y coordinates.

The whole process of PCB Assembly

1. Bare board loader machine

The first step in the PCB assembly is to arrange the bare boards on the rack, and the machine will automatically send the boards one by one into the SMT assembly line.

2. Printing solder paste

When PCB on the SMT production line, firstly, we have to print solder paste on it, and the solder paste will be printed on the pads of the PCB. These solder pastes will be melt and solder the electronic parts to the circuit board when it passes through the high-temperature reflow oven.

In addition, when testing new products, some people will use film board/adhesive cardboard instead of solder paste, which can increase the efficiency for adjusting the SMT machines.

3. Solder paste inspection machine(SPI)

Since the quality of solder paste printing is related to the quality of welding of subsequent parts, some SMT factories will use optical machine to check the quality of solder paste after printed the solder paste in order to ensure stable quality. If there any poorly printed solder paste board, we will wash off the solder paste on it and reprint, or remove the excess solder paste if there is redundant solder paste on it.

4. High speed SMT machine

Usually, we will put some small electronic parts (such as small resistors, capacitors, and inductors) to be printed on the circuit board first, and these parts will be slightly stuck by the solder paste just printed on the circuit board, so even if the speed of printing is very fast and the parts on the board will not fall away. But large parts are not suitable for use in such high speed SMT machines, which will slow down the speed of small parts assembly. And the parts will be shifted from the original position due to the rapid movement of the board.

5. Universal SMT machine

Universal SMT machine is also known as "slow machine", it will be assembled some large electronic components, such as BGA IC, connectors, etc., these parts need more accurate positions, so the alignment is very important. Use a camera to take a picture to confirm the position of the parts, so the speed is much slower than High speed SMT machine we taked before. Due to the size of the components here, not all of them are packed in tape and reel, and some may be packed in trays or tubes. But if you want the SMT machine to recognize the trays or tube-shaped packaging materials, you must configure an additional machine.

Generally, traditional SMT machines are using the principle of suction to move electronic parts, and in order to place the parts successfully, and there must be the flat surface on these electronic components for the suction nozzle of the SMT machine to absorb. However, for some electronic parts don’t have a flat surface for these machines, and it is necessary to order special nozzles for these special-shaped parts, or add a flat tape on the parts, or wear a flat cap for thees electronic parts.

6. Manual parts or visual inspection

After assembled all parts by the high speed SMT machine or Universal SMT machine and before going through the high-temperature reflow oven, and we will set up a visual inspection station here and to pick out the deviation parts or missing components boards etc., because we have to use a soldering iron to repair if there are still defectives boards after passing the high-temperature oven, which will affect the quality of the product and will also increase the cost. in addition, for some larger electronic parts or traditional DIP parts or some special reasons cannot be processed by the SMT machine before, they will be manually placed on pcb here.

7. Reflow oven

The purpose of reflow oven is to melt the solder paste and form a non-metallic compound on the component feet and the circuit board, that means to solder electronic components on the circuit board. The temperature rise and fall curves often affect the soldering quality of the entire circuit board. According to the characteristics of the solder materials, usually the reflow oven will set the preheating zone, soaking zone, reflow zone, and cooling zone to achieve the best soldering effect.

For example, the melting point for SAC305 solder paste with lead-free is about 217°C, which means that the temperature of the reflow oven must be higher than the melting points to remelt the solder paste. What's more, the maximum temperature in the reflow furnace should not exceed 250°C, otherwise many parts will be deformed or melted because they cannot withstand such a high temperature.

Basically, after the pcb passed through the reflow oven, the assembly for the entire circuit board is almost complete. If there are hand-soldered parts, we need to transfer to DIP process, and then we have to check the quality after reflow oven by QC department.

8. Automatic optical inspection(AOI)

The main purpose of setting up AOI is because some high density boards can’t be process the following ICT test, so we used AOI inspection to replace it. But even using AOI inspections, there still have the blind spots for such checking, for example, the solder pads under the components cannot be checked by AOI. At present, it can only check whether the parts have side standing issue, missing parts, displacement, polarity direction, solder bridges, lack of soldering etc., but cannot checking the BGA solderability, resistance value, capacitance value, inductance value and other components quality, so far AOI inspection can’t completely replace ICT test.

Therefore, there is still some risk if only AOI inspection is used to replace ICT testing, but ICT test is also not 100% make sure the good quality, we suggest these two ways can be combined with together to make sure the good quality.

9. PCB unloader machine

After the board is fully assembled, it will be retracted to the unloder machine, which has been designed to allow the SMT machine to automatically pick and place the board without damaging the quality for PCB.

10. Visual inspection for finished products

Normally there will be a visual inspection area in our SMT production line whether there is an AOI station or not, and it will help to check if there are any defectives after completed assembled the pcbs. If there is an AOI station, it can reduce the visual inspection worker on our SMT line, and to reduce the potential cost, and because it is still necessary to check some places that cannot be judged by AOI, many SMT factories will provide the mainly visual inspection templates at this station, which is convenient for visual inspection worker to inspect some key parts and polarity for components.

11. DIP process

DIP process is a very important process in the whole PCBA processing, and the processing quality will directly affect the functional for PCBA boards, so it is necessary to pay more attention to the DIP process. There are many preliminary preparations for DIP process. The basic process is to re-process the electronic components first, like to cut the extra pins for some DIP components, our staff received the components according to the BOM list, and will check whether the material part numbers and specifications are correct or not, and performs pre-production pre-processing according to the PCBA samples. The steps are: Use various related equipment (automatic capacitor pins cutting machine, jumper bending machine, diode and triode automatic forming machine, automatic belt forming machine and other machines) for processing.

12. ICT test

Printed Circuit board open/short circuit test (ICT, In-Circuit Test), The purpose of ICT test is mainly to test whether the components and circuits on the printed circuit board are open or short issues. It can also measure the basic characteristics of most components, such as resistance, capacitance, and inductance values to judge whether the functions of these parts are damaged, wrong parts or missing parts etc. after passing through the high-temperature reflow oven.

ICT test machines are divided into advanced and basic machines. The basic ICT test machines are generally called MDA (Manufacturing Defect Analyzer). It’s just to measure the basic characteristics of electronic components and judge open and short circuits issue we talked above.

In addition to all the functions of the basic ICT test machines, for advanced ICT test machine can also test the whole PCBA by using power, start to testing the PCBA boards by setting the program in the test machine. The advantage is that it can simulate the function of the printed circuit board under the actual power-on condition, this test can partly replace the following functional test machine (Function Test). But the cost for the test fixture of this advanced ICT test can probably buy a car, it’s too expensive and we suggest it can be used in mass production products.

13. PCBA function test

Functional testing is to make up for the ICT test, because ICT only tests the open and short circuits on the the PCBA board, and other functions such as BGA and other fuctions are not tested, so it is necessary to use a functional testing machine to test all functions on the whole PCBA board.

14. Cutting board (assembly board de-panel)

Normally, printed circuit boards will be produced in panel, and it will be assembled to increase the efficiency of SMT production. It means several single boards in one panel, such as two-in-one, four-in-one etc. After finished all the pcb assembly process, it needs to be cut into single boards, and for some printed circuit boards with only single boards also need to cut off some redundant board edges.

There are several ways to cut the printed circuit board. You can design the V-cut using the blade cutting machine (Scoring) or directly manually break off the board (not recommended). For more high density circuit boards, it will be used the professional splitting machine or the router to split the board without any damage the electronic components and printed circuit boards, but the cost and working hours will be a little longer.

Why Choose Hitech Circuits PCB Assembly Manufacturer for Your PCB Assembly Projects?

There are several PCB manufacturers specializing in PCB assemblyservices. However, Hitech Circuits PCB Assembly stands out owing to the following:

Assistance in Material Procurement:

Technically, in PCB assembly services, the quality of parts is the responsibility of the OEM; however, we ease your job by assisting you to make the right selection. We can help you procure all your parts of the same type own a single part number, thanks to our supply chain and vendor network as well as experience. This saves time and cost that goes in ordering single parts as you plan.

Testing procedures:

We are very focused on quality and thus implement stringent testing procedures at each stage of the assembly and after completion.

Fast Turnaround Times:

Our well-equipped facility and the right tools enable us to complete your requirements well before time, and without compromising on the quality or functioning of the PCBs. For simple designs we revert in 24 to 48 hours.

Cost Effectiveness:

While PCB assembly is a cost-effective alternative, we go a step further and assure that the parts you list are of a good quality and suitable for your requirement. Also, you can control the part flow and replenish them as needed. This eliminates the need to buy extra stock and store it.

Quick Quote:

We offer a quick quote based on your BOM. All you need is a detailed BOM, Gerber files, your application requirement sheet, and quantity.

We’re not one to stand still, which is why we use the latest equipment and the finest minds to create your PCB projects. We’re constantly keeping our finger on the pulse of the latest trends. And as a result, we know how to deliver the highest standards of PCB assembly to meet all your requirements.

Our dedicated, friendly customer service team also means that we support you every step of the way. Offering our expert guidance to ensure a complete PCB project that you’re happy with.

Contact us today

No matter what your printed circuit board assemblyneeds are, we always aim to deliver efficient, dependable solutions. For more information about our services, do not hesitate to get in touch with us today for a no-obligation quote

2 notes

·

View notes

Text

Intsoft Tech machine vision inspection equipment, vial appearance information detection

#print inspection system#defect detection in manufacturing#acquire image#machine vision integrator ohio#surface inspection systems

1 note

·

View note

Text

The Role of MSERW Pipe in the Oil and Gas Industry: Applications and Challenges

Introduction

In the oil and gas industry, the transportation of fluids and gases over long distances is crucial. To ensure the safe and efficient movement of these resources, various types of pipes are utilized. One such pipe that plays a vital role in the industry is the MSERW pipe. In this blog, we will explore the applications and challenges associated with MSERW pipes and highlight the importance of finding a reliable MSERW pipe distributor, dealer, supplier, and provider in Gujarat.

Understanding MSERW Pipe

MSERW stands for Mild Steel Electric Resistance Welded. MSERW pipes are constructed using low-carbon steel, which is known for its strength, durability, and resistance to corrosion. These pipes are manufactured by forming flat steel plates into cylindrical shapes and then welding the edges together using electric resistance welding techniques.

Applications of MSERW Pipe in the Oil and Gas Industry

Transporting Oil and Gas:

MSERW pipes are extensively used for the transportation of oil and gas products. These pipes provide a cost-effective solution for delivering crude oil, natural gas, and refined petroleum products from extraction sites to refineries, storage facilities, and distribution networks. Their ability to withstand high pressure and temperature variations makes them an ideal choice for long-distance oil and gas pipelines.

Offshore Drilling Operations

The oil and gas industry heavily relies on offshore drilling for exploration and production activities. MSERW pipes are commonly employed in the construction of subsea pipelines and risers. These pipes offer excellent structural integrity and are resistant to harsh environmental conditions, making them suitable for deepwater drilling applications.

Oil and Gas Processing Plants

Within oil and gas processing plants, MSERW pipes are utilized for various purposes. They are often used in the construction of storage tanks, separators, heat exchangers, and other equipment required for the processing and refining of crude oil and natural gas. MSERW pipes' versatility and reliability ensure the smooth operation of these critical facilities.

Challenges Associated with MSERW Pipe

While MSERW pipes have numerous advantages, they also face some challenges in the oil and gas industry. It is essential to be aware of these challenges and take appropriate measures to mitigate them:

Corrosion and Erosion

One of the primary concerns with MSERW pipes is their susceptibility to corrosion and erosion. Exposure to corrosive substances and abrasive particles in the oil and gas flow can lead to degradation of the pipe's surface, reducing its lifespan. Regular inspections, protective coatings, and cathodic protection systems are implemented to minimize the impact of corrosion and erosion.

Weld Quality and Integrity

The integrity of the welded joints in MSERW pipes is crucial for their performance. Weld defects such as porosity, cracks, and lack of fusion can compromise the strength and reliability of the pipe. Quality control measures during manufacturing and rigorous inspection procedures help ensure that welds meet industry standards and specifications.

Finding a Reliable MSERW Pipe Distributor in Gujarat

To address the growing demand for MSERW pipes in Gujarat's oil and gas industry, it is essential to collaborate with a trustworthy MSERW pipe distributor, dealer, supplier, and provider. The following factors should be considered while choosing the right partner:

Quality Assurance: Look for a distributor that sources MSERW pipes from reputable manufacturers who adhere to stringent quality control procedures and industry standards.

Product Range: Ensure that the distributor offers a wide range of MSERW pipe sizes, grades, and specifications to cater to various project requirements.

Timely Delivery: Reliability in terms of on-time delivery is crucial to avoid project delays. Choose a distributor with a track record of timely and efficient order fulfillment

#MSERW Pipe Distributor in Gujarat#MSERW Pipe dealer in Gujarat#MSERW Pipe Supplier in Gujarat#MSERW Pipe Provider in Gujarat

7 notes

·

View notes

Note

On your store, what does the small surface defect mean???

some of the charms with epoxy coating that makes the front rounded was touched before they fully hardened during production, which unfortunately left little dents or scratches in it. they're visible on inspection and touch, but doesnt ruin the design (which is sandwiched between 2 pieces of acrylic so it will never get scratched).

#i talked to the manufacturer about it and theyll do better about the epoxy coating 😔#so hopefully in the future i won't have any more like this 😭#i had to toss several bc some had defects too big#so i have even less stock to put back up 😔

46 notes

·

View notes

Text

Types of cracks in a car windshield

There are several types of cracks that can occur in a car windshield. Here are some common types:

Bull's Eye: A bull's eye crack is a circular or semi-circular crack with a cone-shaped point of impact. It resembles a target's bull's eye and is typically caused by a direct impact from a rock or other object. This type of crack can range in size and may have concentric circles around the impact point.

Star Break: A star break crack is characterized by several short cracks radiating outward from the impact point, resembling a star. It is usually caused by a medium-sized object striking the windshield and can expand over time if not repaired promptly.

Combination Break: A combination break is a combination of different crack types, such as bull's eye and star break, occurring in close proximity. It may have features of multiple cracks, making the damage more complex.

Half-Moon or Partial Bull's Eye: A half-moon crack is similar to a bull's eye but lacks the circular shape. It appears as a semi-circular or crescent-shaped crack, often caused by a smaller object hitting the windshield.

Crack Chip: A crack chip is a small, shallow crack on the surface of the windshield caused by a minor impact. It is typically less severe than other types of cracks and may not expand as easily.

Stress Crack: Unlike impact-induced cracks, stress cracks develop due to internal or external stress factors. They typically appear as single, straight lines running across the windshield. Extreme temperature changes, structural issues, or manufacturing defects can lead to stress cracks.

It's important to note that these are general descriptions, and the appearance and severity of cracks can vary. If you notice any crack on your car windshield, it's advisable to have it inspected by a professional as soon as possible. Prompt windshield repair or replacement, if necessary, can help maintain the structural integrity and visibility of the windshield while ensuring your safety on the road.

Contact National Auto Glass today for the best windshield repair in Brampton.

https://www.nationalautoglass.ca/

2 notes

·

View notes

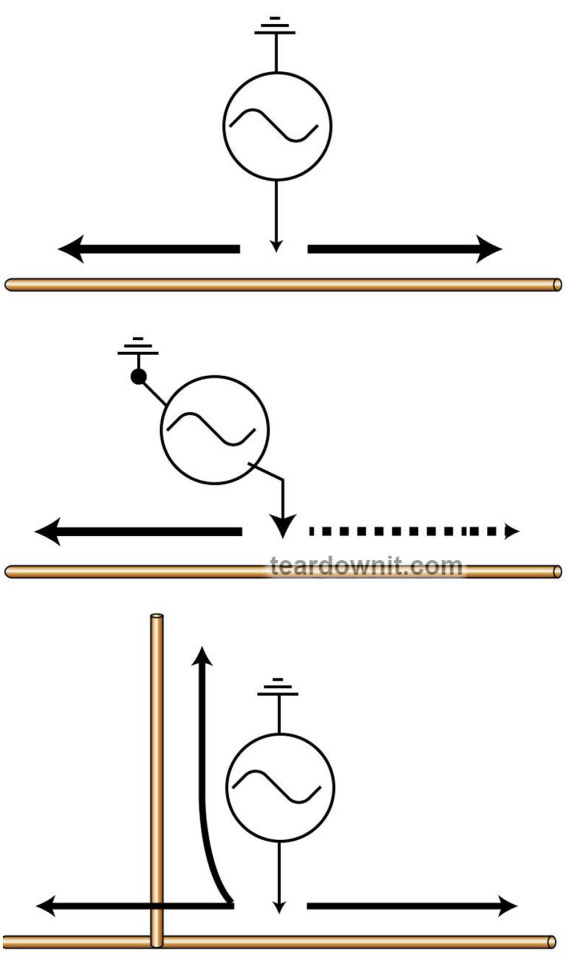

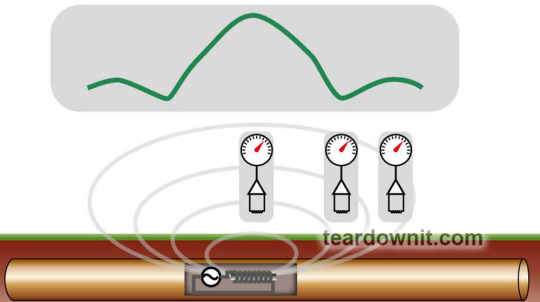

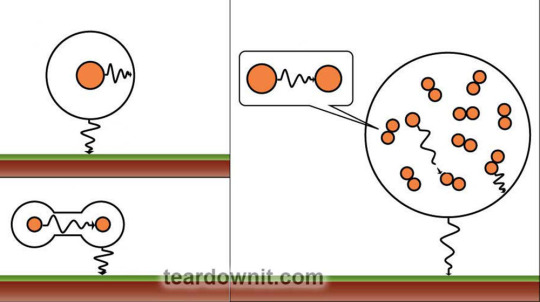

Text

Cable locator: features of cable tracing and identification