#structural steel fabrication sydney

Explore tagged Tumblr posts

Text

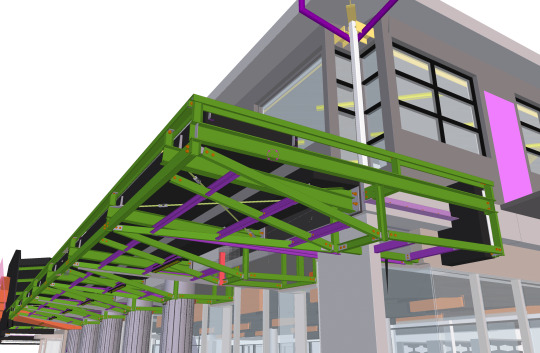

Structural steel detailing

In the construction business, structural steel detailing is essential for maintaining accuracy and precision during the fabrication and erection of steel structures. Structural steel detailers expedite the process from design to construction by converting engineering drawings into detailed plans and giving fabricators and construction teams access to critical information. The use of sophisticated technology in structural steel detailing, such as Building Information Modelling (BIM) and computer-aided design (CAD) programs, has increased efficiency and accuracy beyond previous levels.

1 note

·

View note

Text

Structural Steel Detailers & Steel Fabricators Services in Sydney & Australia

MitreCAD is Australia's best structural steel detailers & fabrication services provider.We offer high-quality shop drawings & steel structures.

#advanced steel fabricators#structural steel fabrication sydney#structural detailing#detailing of steel structures#structural steel detailers#steel detailer#structural steel detailing#best structural steel detailing in sydney#steel detailing

1 note

·

View note

Text

Rebar Detailing CAD Services Provider in USA

Silicon Engineering Consultant Pvt. Ltd. gives high standard quality of Rebar Engineeering Outsourcing Services. Our Rebar Engineering Services typically include the design, detailing, and fabrication of Rebar elements such as beams, columns, walls, slabs, and foundations. Outsource Rebar Engineering Services, construction companies can save time and money while ensuring high-quality work. Rebar Detailing Companies typically employ skilled drafters and engineers who have a deep understanding of reinforced concrete design and fabrication processes. Connected with US for your next Rebar Engineering CAD Services Provider. Rebar Detailing Services are Below:

-Rebar Detailing

-Rebar Estimation

-Foundation Drawings

-Bar Banding Schedule

-3D Modeling of Rebar

More Information :

We provide Rebar Detailing Engineering Services in USA major cities like New York, Chicago, Houston, San Diego, Dallas, San Jose, San Antonio, Los Angeles, San Francisco, Boston, Dallas, Seattle, Washington

We provide Rebar Detailing Engineering Services in UK major cities like London, Liverpool, Newcastle, Bristol, Manchester, Sheffield, York, Cambridge, Norwich, Cardiff

We provide Rebar Detailing Engineering Services in New Zealand's major cities like Auckland, Christchurch, Dunedin, Rotorua, Whangarei, New Plymouth, Wellington, Dunedin, Rotorua, Tauranga

We provide Rebar Detailing Engineering Services in Australia's major cities like Sydney, Brisbane, Hobart, Newcastle, Canberra, Melbourne, Perth, Cairns, Gold Coast, Darwin, Brisbane

#RebarDetailingServices#ShopdrawingServices#3DRebarDetailingservice#RebarDetailingShopDrawingservice#RebarShopDrawingServices#rebardetailingcompanies#RebarDetailingOutsourcingServices#RebarDesignandDetailingServices#CADServices#CADD#SiliconEC#India#USA#UK#NewZealand#Australia

1 note

·

View note

Text

What kind of work do custom metal fabricators in Sydney do?

Custom metal fabricators in Sydney are able to provide a large range of services that may work for both individual clients and businesses in different industries. Their metalworking techniques enable them to produce quality products according to client requirements. Whether working with sheet metal, structural steel, or bespoke designs, a well-qualified fabricator will make that vision a reality while providing durability and functionality into each product.

0 notes

Text

The Importance of Sheet Metal in Architectural Design

The length of service and visual appearance of structures depend substantially on the materials selected in architectural designs formed by engineering talent working with creative ideas together with helpful concepts. The construction industry uses sheet metal as its most valuable and indispensable element relative to all other materials. Modern construction receives distinctive benefits through sheet metal as architects use this material to build protective features and support structures and decorative elements.

1. Sheet Metal's Adaptability in Architecture

Sheet metal remains structurally sound during shaping processes since it accepts efficient cuts and moulding as an architectural building material. Architects, along with designers, opt for sheet metal because of its ability to enable durable designs that remain innovative. Flexible building applications exist for all sheet metals fabrication in Sydney, such as copper and zinc, stainless steel and aluminium, because these materials bring unique characteristics to construction projects.

The ability of sheet metal to create advanced structural shapes serves as its defining attribute for decorating architecture and making roofing structures and facade constructions. The low maintenance properties of stainless steel, as well as aluminium's lightweight characteristics, contribute to their appropriate uses for exposed conditions and high-rise buildings, respectively. Architects now use recycled sheet metal in their projects to respond to environmental building needs, decrease waste, and build sustainable structures.

2. Structural Applications of Strength and Durability

Buildings need to withstand different environmental factors that combine extreme weather conditions with temperature fluctuations and outside impacts. Engineers choose sheet metal as their first material because of its ability to last for many decades while serving as construction support or providing cladding and roofing functions. Sheet metal maintains functionality for decades without maintenance needs, whereas concrete and wood can fail because of cracking, decay, or distortion over time.

The protective effects of oxidation make copper and zinc ideal for roofing applications because they develop a protective coating which impedes additional deterioration. Stainless steel functions perfectly in marine environments since its superior corrosion resistance protects it from ocean moisture and salt. The characteristics of sheet metal maintain its affordability and durability as a fundamental design material for architecture.

3. Visual Appeal and Contemporary Design Opportunities

In architectural design, functionality is one element in addition to aesthetic effect. The reflective nature of sheet metal surfaces creates contemporary designs suitable for modern structures. Architects can utilise sheet metal in endless ways to make impressive architectural designs through which skyscraper facades shine like new, exteriors become rustic, or aluminium panel surfaces appear polished.

Architecture professionals achieve experimental design results through customisable finish options that include textures and patterns in different colours. Construction organisations can create decorative facades which serve both design purposes while also providing ventilation and light control through perforated metal panel solutions. Current fabrication technology advances through laser cutting, and CNC machining enables creators to achieve complex designs.

4. Sustainability and the Advantages for the Environment

Eco-friendly design strategies in modern buildings heavily depend on sheet metals fabrication in Sydney, which is an essential sustainable construction material. The reusability factor of copper steel and aluminium remains intact because these metals maintain their structural strength during recycling. Building projects have lower environmental impact while obtaining lower material costs through the reprocessing and recycling of sheet metal.

The sustainable properties of sheet metal extend to its ability to save energy. By reflecting light and heat, metal roofs become effective at managing internal temperatures while reducing cooling system energy usage. A combination of special metal cladding techniques can improve insulation properties that result in buildings requiring less total energy utilisation. The properties of sheet metal make it essential for architects seeking to fulfil green building requirements and raise the energy efficiency of constructed systems.

5. Sheet Metal's Function in Modern and Historic Architecture

Elaborate architectural frameworks of the last several decades heavily rely on sheet metal, which powers both contemporary and traditional building designs. Sheet metal successfully demonstrates its versatility through many notable architectural buildings since both modern skyscrapers with aluminium facades and antique cathedrals with copper domes showcase its benefit.

In early architecture, stainless steel fabrication in Sydney was found to be reliable as an artistic building element via sculptures, decorative railings, and ornamental roofs. Historical buildings develop their enduring allure through ageing processes that transform copper and bronze items into elegant finishes. Architects use these historical materials in restoration projects to extend aged buildings and preserve their genuine architectural details.

Contemporary architectural designs at the limit of building innovation extensively incorporate sheet metal components. Both futuristic buildings and advanced structural details emerge from sheet metal's ability to be used in artistic variations of mixed-material planes alongside architecturally expressive curved faces and expressive metal frameworks. Parametric architecture emerged through precise manufacturing and computer modelling practices to enable architects to design sheet metal components that create organic forms for urban expansion.

6. Developments in the Production of Sheet Metal

The wide application of sheet metal in architectural projects becomes possible mainly because of advanced production techniques. Modern precision manufacturing tools that include CNC bending and both water jet and laser cutting systems have replaced outmoded traditional metal cutting procedures. Architects today can carry out sophisticated designs through these advancements regardless of conventional manufacturing constraints.

Conclusion

Sheet metal possesses all the necessary qualities that make it an indispensable structural material for modern architectural applications. Stainless steel fabrication in Sydney enables architects to design innovative structural frameworks that maintain both energy conservation and durability requirements. Sheet metal continues to shape contemporary architectural styles since it finds usage in sustainable constructions, modern high-rise buildings, and historical site restoration projects. The development of fabrication technology will extend the innovative possibilities for sheet metal used in architectural designs, thus strengthening its importance in built environments.

#sheet metal fabrication sydney#welding companies in sydney#steel suppliers sydney#sheet metal supplies sydney

0 notes

Text

Structural Steel Fabricators: Building the Backbone of Modern Infrastructure

Modern infrastructure relies heavily on structural steel fabrication. The metal is tough, strong, durable, and versatile. Be it Burj Khalifa, Sydney Harbour Bridge, Beijing National Stadium, or Willis Tower, the metal has shown its versatility and increased usage.

However, how is this metal used for such applications? Obviously, structural steel fabricators play a significant role by making the metal suitable.

Structural steel fabricators are creating a new world around us, and you must learn more about it. So, check out this blog and understand the role of structural steel fabricators in modern infrastructure.

Role of Structural Steel Fabricators in Modern Infrastructure Development

The job of steel fabricators is to transform raw steel into precisely constructed engineering components. It includes manufacturing structural steel, transforming it into smaller parts, cutting, welding, shearing, punching the steel, and engineering it into specific components. Thus, the role of structural steel fabricators cannot be undermined.

Check out the role that the steel fabricators are playing in the development around us:

Designing and Detailing

For each project, fabricators create detailed blueprints and specifications to fit the project’s needs. Attention to detail is the first prerequisite when building skyscrapers or miles-long bridges. It comes down to the fabricators to detail everything and determine how to achieve the desired results with metals. Creating a blueprint on paper is easier but a million times harder to do so with metal. Thus, structural steel fabricators deserve the due credit.

Cutting and Shaping

Structural steel fabrication includes multiple methods to transform steel. It requires cutting, shearing, punching, notching, welding, and shaping the metal into a useful component. It can only be achieved by employing advanced machines to achieve the required precision, accuracy, and consistency.

Large infrastructure projects require thousands of identical steel products. Steel fabricators ensure that every produced item meets the specifications.

At AZ Metals, we believe embracing technology is the way to meet demands for cutting and shaping metals. Thus, we invest in advanced machinery which can meet the huge and ever-increasing demands of the construction industry.

Welding and Assembly

After cutting and shaping, the next step is assembly and welding. It is a process that requires perfect coordination between the architects, contractors, and steel fabricators. This is where the project starts taking its shape.

While welding is an off-site task, assembly can be done both on-site and off-site. Welding also requires professional knowledge of the underlying task to achieve perfection to ensure that the metal’s strength, durability, and all the necessary qualities are intact.

The assembly in huge construction projects requires an entire workforce, as you must be aware. Custom fabrication ensures that all components fit together perfectly.

Choosing a reliable structural steel fabricator who can assist in on-site installations, if needed, is crucial.

Project Collaboration

Large construction projects require synchronization between engineers, architects, and metal workers. Only through a reliable partnership can a perfect execution be expected.

You need AZ Metals as your metal fabrication partner. There are many reasons to choose us, the first being experience working with contractors and builders.

We have been working in Mesa and Phoenix since 2011. Thus, we have an experience of more than a decade. During this time, we have worked on numerous large projects and have collaborated with many clients. It has given us an edge over our competitors as we understand the market and the industry.

Our past collaborations have been very successful, and we are proud of it.

Quality Assurance

These days, you can always read the reports of buildings or bridges coming down out of nowhere. It is due to the poor-quality material.

In large projects, the biggest role that metal fabricators have to play is to provide quality metals and products.

The experience of working around the metals allows you to understand each alloy’s characteristics and their best use cases. By understanding so, metal fabricators can help you source the industry standard, project-specific metals and alloys for the project’s success.

Final Words

In a metal-dependent industry, what matters most is the product and service quality. It relies on the shoulders of the fabricator to ensure it by employing the latest technology and a trained workforce.

Thus, your choice of a structural steel fabricator makes all the difference.

In large infrastructure projects, there is no room for mistakes. Thus, make no mistake and choose AZ Metals today.

We have the expertise, the ability to handle large projects, advanced machines, and experience to help you succeed.

For more information, visit today!

Original Source: https://az-metals.com/structural-steel-fabricators-building-the-backbone-of-modern-infrastructure/

0 notes

Text

ALM Steel Detailing

ALM Steel Detailing & Shop Drawings is your premier destination for structural steel detailing in Australia. Our team of experienced steel detailers is dedicated to providing clear, precise, and cost-effective steel fabrication drawings. We take pride in using only local Australian draftsmen, which enhances communication and ensures the success of your projects.

With more than 20 years of experience in drafting, our team employs the latest technologies to assist you in achieving your steel fabrication design and construction goals. Our expertise is highly valued by fabricators, engineers, architects, and general contractors who seek reliable drafting services to support their use of advanced computerized detailer technologies. At ALM Steel Drafting & Design, we specialize in reviewing and refining computer-generated plans and drawings, helping you identify and resolve potential issues before they impact your project. We offer specialized structural drafting services to steel fabricators in Melbourne, Sydney, Perth, and Brisbane, as well as rebar detailing & scheduling for numerous companies across Australia. Our commitment to following Australian structural steel standards ensures that all our projects meet the highest levels of quality and precision. Utilizing top-tier software such as 3D BIM modeling tools like Tekla, Prosteel, and AutoCAD, we deliver professional craftsmanship that fulfills your project requirements.

Contact Us:

ALM Steel Detailing & Shop Drawings

Address: 1/27 Austin Avenue, Elwood VIC, 3184

Phone: 0418 507 063

Email: [email protected]

Website: https://www.steeldetailing.com.au

1 note

·

View note

Text

7 Techniques Professionals Use To Install Glass Roofs

In today’s architectural landscape, the allure of expansive, light-filled spaces via the glass awning Sydney has made the installation of transparent roof structures a popular choice for both residential and commercial buildings. These installations not only enhance aesthetic appeal but also offer a unique way to integrate natural light into indoor environments. Professionals in the field have developed a range of techniques to ensure these installations are performed with precision, safety, and durability. The process involves meticulous planning and execution to address both structural integrity and design elegance.

The installation of transparent roofing is more complex than traditional roofing systems. It requires a deep understanding of material properties, weather conditions, and structural supports. Given the precision required, professionals employ a variety of specialised techniques to achieve optimal results. These techniques ensure that the roof performs well under various environmental conditions while maintaining its visual and functional integrity.

The following guide explains the key techniques employed by experts in the field to install transparent roofs effectively.

Pre-Installation Assessment and Planning

Before any installation begins, a thorough assessment of the site is crucial. Professionals conduct detailed surveys to understand the structural requirements and potential challenges of the project. This includes evaluating the existing framework, considering load-bearing capacities, and assessing environmental factors such as wind and temperature variations. Detailed planning also involves selecting the right type of transparent material based on the project’s needs, whether it’s for insulation, UV protection, or aesthetic preferences.

Precision Measurements and Custom Fabrication

Accurate measurements are vital for the successful installation of transparent roofs. Professionals use advanced tools and technologies to ensure every dimension is precisely measured. These measurements are then used to fabricate custom panels that fit perfectly within the designed framework. This step often involves collaboration with fabricators who specialize in cutting and shaping the materials to match the specific requirements of the project.

Reinforced Structural Framework

The framework that supports the transparent panels must be robust and well-engineered. Professionals use high-quality materials such as aluminium, steel, or reinforced composites to construct a frame that can handle the weight and stress placed upon it. The framework is designed to accommodate the expansion and contraction of the panels due to temperature changes, ensuring long-term stability and durability.

Advanced Mounting Techniques

Once the framework is in place, the transparent panels are carefully mounted using advanced techniques to ensure secure attachment. This may involve using specialised brackets, seals, and adhesives designed for high performance and weather resistance. The mounting process requires precision to prevent any gaps or misalignments that could affect the integrity of the roof or lead to potential leaks.

Sealing and Insulation

Effective sealing is essential to protect the interior from weather elements. Professionals use high-quality sealants and gaskets to create a watertight and airtight seal around the edges of the transparent panels. Additionally, insulation materials may be integrated into the framework to improve energy efficiency and thermal performance. Proper sealing and insulation help in maintaining a comfortable indoor climate and enhance the overall energy efficiency of the building.

Quality Control and Testing

After installation, a rigorous quality control process is conducted to ensure that the transparent roof meets all safety and performance standards. This includes inspecting the installation for any signs of defects, leaks, or misalignments. Testing might involve subjecting the roof to various conditions to simulate real-world performance, ensuring that it withstands environmental stresses and performs as expected.

Regular Maintenance and Upkeep

Transparent roofs require regular maintenance to keep them in optimal condition. Professionals provide guidelines for routine cleaning and inspections to address any wear and tear that may occur over time. Maintenance involves checking the seals, frames, and panels for any signs of damage or degradation and performing necessary repairs to prolong the lifespan of the installation.

The installation of transparent roofs is a sophisticated process that demands a high level of expertise and attention to detail. The techniques used by professionals are designed to address both the technical and aesthetic aspects of the installation, ensuring that the final result is both functional and visually pleasing.

From initial planning and custom fabrication to advanced mounting and regular maintenance, each step is crucial in achieving a successful installation. By employing these techniques, professionals can create stunning roof structures that enhance the natural light and beauty of any space while maintaining structural integrity and performance. The careful execution of these methods ensures that transparent roofs continue to be a popular choice for those seeking to bring the outdoors inside stylishly and functionally.

0 notes

Text

Structural steel Sydney

Our wide variety of services covers every facet of structural steel, from precise design and cutting-edge manufacture to flawless installation. Our seasoned team of professionals is committed to providing exceptional quality, longevity, and affordability, making us a reliable partner for all your steel projects—residential, commercial, and industrial.

0 notes

Text

All that you need to know about structural fabrication of steel

The base of the structural fabrication in Sydney is the pre-planning and product blueprints. From the first step to the last, everything is done to accomplish the larger objective, i.e. the product in the eyesight.

0 notes

Text

Expert Steel Bending & Forming Services in Sydney

Steel bending and forming are crucial processes in the construction, manufacturing, and industrial sectors. These processes shape steel components into desired forms while maintaining their strength, durability, and functionality. In Sydney, expert steel bending and forming services are in high demand, catering to industries such as construction, automotive, aerospace, and infrastructure development. This article explores the significance, methods, and benefits of professional steel bending and forming services in Sydney, ensuring high-quality outcomes for various projects.

Understanding Steel Bending and Forming

Steel bending and forming involve manipulating steel into various shapes without compromising its integrity. These processes require specialized machinery, skilled technicians, and precise techniques to achieve accurate results.

1. Steel Bending

Steel bending is the process of deforming steel sections to create curves, angles, and custom shapes. This technique is widely used in structural frameworks, pipelines, architectural designs, and machinery components. Various methods are used for bending steel, including:

Roll Bending: Utilizes a set of rollers to gradually bend steel into large curves.

Press Brake Bending: Uses a press brake machine to create precise bends at specific angles.

Mandrel Bending: Maintains internal diameter integrity, commonly used for pipes and tubes.

Rotary Draw Bending: Produces high-quality, repeatable bends for applications requiring precision.

2. Steel Forming

Steel forming involves shaping steel sheets or sections into desired forms through force and pressure. This is essential in creating custom components for buildings, vehicles, machinery, and more. Common steel forming techniques include:

Cold Forming: Performed at room temperature to retain strength and enhance durability.

Hot Forming: Involves heating the steel to make it more pliable for complex shapes.

Stretch Forming: Used for aerospace and automotive applications requiring smooth curves.

Stamping and Punching: Creates specific designs, holes, and shapes through mechanical force.

Importance of Expert Steel Bending & Forming Services in Sydney

Sydney is home to a thriving construction and industrial sector, making high-quality steel fabrication services essential. Expert steel bending and forming services offer several advantages, including:

1. Precision and Accuracy

Professional steel fabrication companies use advanced machinery and computer-aided designs (CAD) to ensure precise bending and forming, reducing errors and material waste.

2. Custom Solutions

Every project has unique requirements, and expert steel fabricators provide tailored solutions to meet specific design and structural needs.

3. Structural Integrity

High-quality bending and forming ensure that steel retains its strength and durability, making it suitable for load-bearing structures and critical applications.

4. Cost-Effectiveness

Efficient steel processing reduces material waste, lowers labor costs, and enhances production efficiency, providing value for money.

5. Time Efficiency

With advanced technologies and skilled professionals, steel bending and forming services deliver quick turnaround times, helping projects stay on schedule.

Industries Benefiting from Steel Bending & Forming Services

Expert steel bending and forming services in Sydney cater to a diverse range of industries, including:

1. Construction

Steel bending is essential for structural frameworks, bridges, railings, and architectural designs. Formed steel components provide strength and aesthetic appeal in modern buildings.

2. Automotive & Transport

Custom steel bending is used for vehicle frames, exhaust systems, roll cages, and suspension components. Precision bending ensures optimal performance and safety.

3. Aerospace

Aircraft structures require lightweight yet strong steel components, making precision forming crucial for fuselages, engine parts, and support structures.

4. Infrastructure & Energy

Pipelines, wind turbine structures, and power transmission towers rely on steel bending and forming for strength and durability.

5. Manufacturing & Industrial Equipment

Machinery parts, conveyor systems, and industrial tools require precise steel forming to meet operational standards.

Choosing the Right Steel Bending & Forming Service Provider in Sydney

Selecting a reliable steel fabrication company ensures high-quality results and seamless project execution. Here are key factors to consider:

1. Experience and Expertise

Look for companies with extensive experience in steel bending and forming. Skilled professionals and engineers ensure high-quality workmanship.

2. Technology and Equipment

Modern machinery and advanced software play a crucial role in precision bending and forming. Ensure the service provider uses state-of-the-art equipment.

3. Material Quality

High-quality steel materials contribute to the durability and strength of the final product. Reputable companies source steel from trusted suppliers.

4. Customization Capabilities

Every project has unique requirements. Choose a provider that offers custom solutions and flexibility in designs.

5. Compliance and Standards

Ensure the company adheres to industry standards, safety regulations, and quality control measures for reliable results.

6. Customer Reviews and Reputation

Check client reviews, testimonials, and previous projects to assess the company's reputation and service quality.

Conclusion

Steel bending and forming are vital processes in various industries, contributing to the strength, durability, and functionality of structures and components. In Sydney, expert steel fabrication companies provide precision solutions to meet the growing demands of construction, automotive, aerospace, and industrial sectors. By choosing a reliable steel bending and forming service provider, businesses can ensure high-quality, cost-effective, and time-efficient solutions for their projects.

Whether you need custom steel bending for architectural designs or precision forming for industrial equipment, Sydney offers a range of expert services to fulfill your requirements with excellence.

#steel plate supplies in sydney#sheet metal supplies sydney#steel suppliers sydney#welding companies in sydney

0 notes

Text

Advantages of Steel Framing – Saffron Steel Frames

Steel framing is a popular construction method for a variety of reasons. Here are some of the advantages of steel framing:

· Strength and durability: Steel is a very strong and durable material, making it ideal for use in construction. Steel frames can withstand a lot of weight and are resistant to damage from fire, pests, and rot.

· Versatility: Steel frames can be used to create a wide variety of structures, from small homes to large commercial buildings. They can be easily adapted to different architectural styles and can be used to create open floor plans with large spans.

· Cost-effectiveness: Steel frames are often more cost-effective than other types of framing, such as wood framing. This is because steel is a relatively inexpensive material and because steel frames can be fabricated off-site and quickly assembled on-site.

· Sustainability: Steel is a recyclable material, making it a sustainable choice for construction. Steel frames can also be designed to be energy-efficient, helping to reduce greenhouse gas emissions.

· Fire resistance: Steel is a non-combustible material, making it highly resistant to fire. This can help to protect occupants and property in the event of a fire.

· Pest resistance: Steel is not susceptible to pests such as termites, which can damage wood-framed structures.

· Rot resistance: Steel is not susceptible to rot, which can damage wood-framed structures.

· Dimensional stability: Steel does not expand or contract with changes in moisture content, which can help to prevent cracks and gaps in walls and ceilings.

· Ease of construction: Steel frames can be easily erected and assembled, which can help to reduce construction time and costs.

Overall, steel framing is a versatile, durable, and cost-effective construction method that offers a

number of advantages over other types of framing.

Visit Our Website:- https://www.saffronsteelframes.com.au/steel-frames-sydney/

0 notes

Text

Structural Innovations: The Pinnacle of Construction Companies

Welcome to our blog post on structural innovations, where we will explore how these advancements are shaping the construction industry. In today's competitive market, staying ahead is crucial for construction company Queenstown, and embracing structural innovations is a key way to achieve that. In this engaging and friendly discussion, we will delve into the definition, importance, key areas, challenges, and benefits of structural innovations in construction companies. So, let's get started!

I. Definition and Importance of Structural Innovations

Structural innovations can be defined as the introduction of new ideas, materials, technologies, and design approaches to improve the efficiency, sustainability, and safety of construction projects. These innovations are essential for construction companies as they enable them to stay competitive in a rapidly evolving industry. The significance of structural innovations cannot be overstated. By adopting new materials, techniques, and design approaches, Queenstown construction companies can improve the speed and quality of their projects, reduce waste, and minimize environmental impact. For example, the use of sustainable materials such as recycled steel or engineered wood can significantly reduce the carbon footprint of a project. Additionally, innovations in construction techniques like 3D printing or modular construction allow for faster and more efficient project delivery. Real-life examples of structural innovations include the Burj Khalifa in Dubai, the tallest building in the world, which showcases advancements in materials, design approaches, and construction techniques. The use of high-strength concrete, composite materials, and parametric design tools contributed to the successful completion of this iconic structure.

II. Key Areas of Structural Innovations

A. Materials and Techniques

Advancements in materials play a vital role in structural innovations. Construction companies are increasingly exploring sustainable options such as bamboo, recycled materials, and low-emission concrete. These materials not only reduce the environmental impact but also offer durability and cost-effectiveness.

Another area of focus is the use of composites, which combine different materials to create stronger and lighter structures. For example, carbon fiber reinforced polymers (CFRP) are being used in bridge construction to enhance strength and reduce weight.

Pre-fabricated elements are also gaining popularity due to their efficiency and quality control. Off-site manufacturing allows for faster construction and reduces the risks associated with on-site work.

B. Design Approaches

Innovative design approaches are essential for achieving structural innovations. Architects and engineers are embracing new philosophies that prioritize energy efficiency, flexibility, and adaptability. By considering factors such as natural light, ventilation, and thermal performance, buildings can reduce their energy consumption and contribute to a sustainable future.

Parametric design tools, such as computer algorithms, enable architects and engineers to create complex structures with ease. These tools optimize designs for efficiency and provide valuable insights into the structural performance of a building.

Iconic architectural projects like the Sydney Opera House or the Guggenheim Museum in Bilbao exemplify the use of cutting-edge design approaches. Their unique and innovative designs have become landmarks and symbols of architectural excellence.

C. Technological Integration

Technology plays a pivotal role in driving structural innovations. Building Information Modeling (BIM) is revolutionizing the construction process by enabling collaboration, coordination, and visualization of projects. It allows for better project management, reduces errors, and improves communication among stakeholders.

Augmented reality (AR), virtual reality (VR), and drones are transforming the way construction companies operate. AR and VR technologies provide immersive experiences that help architects, engineers, and clients visualize designs and make informed decisions. Drones, on the other hand, are being used for site inspections, surveying, and monitoring construction progress.

Construction companies are embracing technology to streamline their operations. For example, some companies are using automated machines and robots for tasks such as bricklaying or concrete pouring, improving efficiency and precision.

III. Challenges Faced by Construction Companies

While structural innovations offer immense benefits, construction companies also face several challenges in their implementation.

A. Regulatory Compliance

Regulations and building codes vary across regions, and compliance can be a hurdle for construction companies. The need to obtain permits and certifications for innovative materials or techniques adds complexity to the construction process.

However, many regulatory bodies are recognizing the importance of structural innovations and are working towards creating more flexible frameworks that allow for the adoption of new ideas while ensuring safety and quality.

B. Cost Considerations

Implementing structural innovations may involve higher upfront costs compared to traditional methods. New materials, technologies, and techniques often require investments in research, training, and equipment. However, it is crucial to consider the long-term cost savings that can be achieved through improved efficiency, reduced maintenance needs, and increased durability.

Construction companies should carefully evaluate the potential benefits and weigh them against the initial investment to make informed decisions.

C. Skill Development

As the construction industry embraces structural innovations, there is a growing need for upskilling workers to adapt to technological advancements. Construction companies must invest in training programs to bridge skill gaps and ensure their workforce can effectively utilize new tools and techniques.

Collaboration with educational institutions, vocational training centers, or partnerships with technology providers can help construction companies develop the necessary skills within their workforce.

IV. Benefits of Embracing Structural Innovations

Construction companies that embrace structural innovations stand to gain numerous benefits.

Firstly, adopting innovative approaches improves project outcomes. Whether it's faster construction, reduced environmental impact, or enhanced energy efficiency, these innovations differentiate companies from their competitors and attract clients who value sustainability and advanced technologies.

Secondly, embracing structural innovations enhances the reputation of construction companies. Being at the forefront of innovation positions them as industry leaders and fosters trust among clients, investors, and partners.

Lastly, structural innovations lead to increased client satisfaction. By delivering projects that meet or exceed expectations, construction company Queenstown can build long-lasting relationships with clients and secure repeat business.

Conclusion:

In this comprehensive blog post, we have explored the world of structural innovations in the construction industry. From materials and techniques to design approaches and technological integration, these innovations are revolutionizing the way construction companies operate.

0 notes

Text

Structural Steel Design and Drawing Services at Reasonable prices in Shepparton

Structural Steel Detailing forms the backbone of most modern construction projects. Proper design and drafting are vital for safety, longevity, and cost-efficiency. Our services ensure your project stands strong and meets all necessary regulations. Contact us today for a consultation! Let's build your vision with precision and strength.

What We Offer:

Structural Steel Design: From concept to detailed design, we create sturdy and safe steel structures. Steel Detailing: Accurate, fabrication-ready drawings for smooth construction. Connection Design: Ensuring seamless integration of steel components. 3D Modeling: Visualize your project and detect issues before construction begins. Drafting Services: Precise and comprehensive drafts for permits and construction. Industries We Serve: - Commercial Buildings - Industrial Facilities - High-Rise Construction - Retail Spaces - Educational Institutions - Residential Complexes - Renovation and Retrofitting Visit URL: https://www.siliconec.com/structural-detailing-services/sydney-detailing-engineering.html

#StructuralSteelDetailing#SteelDetailingServices#SteelFabricationDrawing#CADSteelDetailing#SteelDesignDrawing#StructuralSteelDesignDrawing#StructuralSteelDetailingServices#StructuralSteelFabricationDrawing#CADServices#SiliconEC

1 note

·

View note

Text

Steel Mesh Supplier Sydney: Ensuring Quality Reinforcing Steel Supplies

In the bustling city of Sydney, construction and infrastructure development are constantly on the rise. Whether it's erecting skyscrapers or reinforcing bridges, the need for reliable steel mesh and reinforcing steel supplies is paramount. Fortunately, Sydney boasts a plethora of reputable steel mesh suppliers who play a vital role in providing high-quality materials to support these projects. In this article, we will delve into the importance of steel mesh and reinforcing steel supplies in Sydney's construction industry, highlighting the key factors to consider when choosing a supplier.

Understanding Steel Mesh:

Steel mesh supplier in Sydney, also known as wire mesh or welded mesh, is a critical component in construction and engineering projects. It is fabricated by welding or weaving steel wires together, creating a grid-like structure with uniform openings. Steel mesh offers several benefits, including enhanced structural integrity, load-bearing capacity, and resistance to impact and corrosion. It is commonly used for reinforcing concrete structures, such as slabs, walls, columns, and foundations, providing added strength and durability.

The Significance of Reinforcing Steel Supplies:

Reinforcing steel, often referred to as rebar, is another essential material in construction. It consists of carbon steel bars or rods that are embedded within concrete to enhance its tensile strength. Reinforcing steel supplies are crucial for ensuring the structural stability of various projects, including buildings, bridges, highways, and tunnels. The appropriate placement of reinforcing steel within the concrete framework helps prevent cracks, minimize deformation, and increase overall longevity.

Choosing the Right Steel Mesh Supplier:

When it comes to selecting a steel metal mesh supplier in Sydney, several factors should be considered to ensure you receive top-quality materials and reliable service:

a) Reputation and Experience: Look for a supplier with a solid reputation and extensive experience in the industry. A reputable supplier will have a track record of delivering high-quality steel mesh and reinforcing steel supplies, backed by positive customer reviews and testimonials.

b) Product Quality: Insist on superior-grade steel mesh that complies with industry standards. Quality assurance certifications, such as Australian Standard (AS/NZS 4671), are indicative of a supplier's commitment to providing reliable and durable products.

c) Product Range: Choose a supplier that offers a wide range of steel mesh options to cater to different project requirements. This includes varying wire diameters, mesh sizes, and configurations. A diverse product range ensures flexibility in design and enables customization for specific applications.

d) Timely Delivery: Construction projects often have strict timelines, and delays can be costly. Select a supplier with a proven track record of delivering orders promptly, ensuring that your project progresses smoothly.

e) Customer Support: A reputable supplier should provide excellent customer service. This includes being responsive to inquiries, offering technical support, and addressing any concerns promptly.

Sustainable Practices:

As sustainability becomes increasingly important in the construction industry, it is essential to choose a steel mesh supplier that prioritizes environmental responsibility. Look for suppliers who follow sustainable manufacturing practices, such as using recycled materials, reducing energy consumption, and implementing waste management strategies. By supporting environmentally conscious suppliers, you contribute to a greener and more sustainable future.

In the vibrant city of Sydney, where construction and infrastructure projects are thriving, finding a reliable steel mesh supplier is crucial. The quality of steel mesh and reinforcing steel supplies in Sydney directly impacts the structural integrity and longevity of various construction projects. By considering factors such as reputation, product quality, range, timely delivery, and sustainable practices, you can make an informed decision when selecting a supplier. Remember, choosing a reputable supplier ensures that your project receives the necessary materials to withstand the test of time.

#Reinforcing mesh supplies sydney#floor epoxy supplier#epoxy floor coatings sydney#garage floor epoxy#epoxy floor paint

1 note

·

View note

Text

Steel detailing

To achieve reliability and precision in the fabrication and erection of steel structures, steel detailing is essential in the construction sector. Steel detailing means creating complex blueprints and drawings that direct fabricators and contractors through the assembly process on everything from skyscrapers to bridges. Steel detailers can increase productivity, reduce errors, and optimize operations by using sophisticated software such as Tekla or Advance Steel.

0 notes