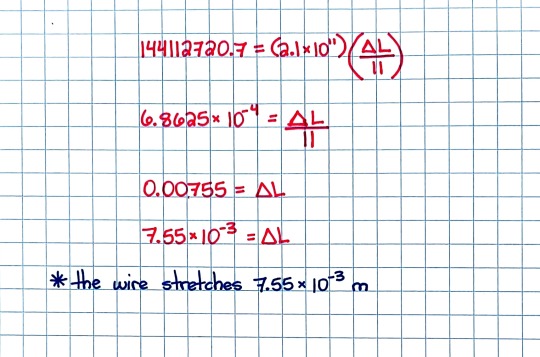

#stretch in youngs modulus

Explore tagged Tumblr posts

Photo

#studyblr#notes#physics#physics notes#physics ex#physics example#young modulus#young's modulus#youngs modulus#calculating stretch#finding stretch#force#force ex#force example#stretch in young's modulus#stretch in youngs modulus#stretch in young modulus

6 notes

·

View notes

Text

[BOTH AINT SHIT] SNIPPET ゜・BLADE, DAN HENG NSFW

they're both my #𝓹𝓻𝓲𝓷𝓬𝓮𝓼𝓼𝓮𝓼 𝓿𝓻𝓸 literally minimal plot I just want to add more background to the roommate au lmao stress, strain: the tale of young modulus and a forlorn physics student (blade) << this is the roommate au go check it out stream B.A.S

HONKAI STAR RAIL MASTERLIST

MASTERLIST ・゜・NAVIGATION

Perhaps he’s just angry with you. Routinely, when his irritation with himself and the world around him reaches a boiling point, it’s then that he chooses to finally pay heed to the eyes ogling at his figure. He’s not stupid: knowing fully that they want to take him to bed, and he won’t refuse when he wants to get out of his head for a while.

There’s something satisfying about your reaction—eyelid just about twitching, a tight grip on your Earl Grey as he waltzes into the kitchen with pyjama pants and not much else—that evokes a grim smirk from him. But these girls just aren’t satisfying him anymore. Soiled, tied-off condoms litter the waste bin in the corner of his room—not proof of his enjoyment, but rather the persistence of the people he’s with to get him off.

You’re just some guy Kafka stuck him with—so why the hell is he thinking of how your body glistened in that heatwave?

There’s something wrong with him.

You notice it too, watching how he brings someone new almost daily with him now—seriously, is this guy trying to get with half the city? He’s lucky it’s summer, but you certainly aren’t.

Of course, you complain at your next gathering with the Trailblazers—drunken condemnations of the man who’s just a prick. You get so frustrated that Stelle practically shoves Dan Heng into you to take you home; he only really loses the reluctant air when you assure him Blade won’t be back until later.

And maybe it’s the whiskey you both consumed—or maybe it’s the lingering memories of the last time he kissed you right after a successful concert, warm and sloppy and dizzying—that slots your lips together once more. He’s pressed beneath you on your bed: back arched as you gently stretch him out with your fingers. Like this, with tears leaking down his eyes and a wobbly smile across his face as the seams of your joined lips gather salt and faint pricks of blood—you can’t help but disregard the door you forgot to close properly.

It could also be the adrenaline—Dan Heng feels so utterly breathless as you pump his weeping cock, getting off to the fact that he’s the one you’re fucking in Blade’s own apartment.

“Don’t—ngh—stop.” Blade freezes when he hears the distinct sound come from your room: hard, fast sounds of tacky skin-against-skin; a wooden bed frame squeaking ever so slightly; and the familiar sound of fucked-out whimpers.

He can’t bring himself to move from where he’s stone-still in the small corridor leading directly from the front door. While breathy and high-pitched, it’s definitely a guy—and that’s not you he’s hearing. His senses are sharp, so he does manage to pick up groans that sound much more like you; and for some reason, the back of his neck prickles with a burning sensation.

His grip on his keys is harsh enough to draw blood—faint, pungent copper wafts up from his palm as he walks past your door to get to his room.

Except, the door’s been left slightly ajar and he takes the opportunity to see exactly who is coaxing your song out from you.

His breath hitches and his red eyes widen at the sight. A lean, muscular back faces him—busy being split apart on your dick. From what he can see, you’re leaning back on the bed: cradling a mop of wavy black hair while his mouth is latched on your chest. He’s bouncing slightly, while your pelvis angles up to meet the plush flesh of his ass with a sickening squelch.

The man pulls back with a pop, and it’s then that Blade glimpses from the side the face he most despises.

Dan Heng.

And…you.

#dan heng#dan heng x reader#res ・゚ writing#slowd1ving#x reader#dan heng x you#astral express#gn reader#male reader#hsr#hsr x reader#honkai star rail x you#honkai star rail#snippet#male character#sub male character#smut#res ・゚ snippet#blade#hsr blade#blade x reader#hsr smut#blade x you

64 notes

·

View notes

Text

What are the Difference between Stress and Strain Curve?

When you are talking about solids and various other materials, it is crucial to understand how these types of materials usually react when a force is applied. This process helps the students identify their strengths, deformations, and various other parameters acting on the objects. And to find these parameters, the stress and strain quantities are important. Here, in this article, we are going to provide a detailed guide about these aspects including how we define stress and strain, their types, and difference between stress and strain. Also let us learn about stress formula and strain formula.

Why is it important to study stress and strain?

It is important to study the stress and strain differences and basics, and stress strain curve, all of which will help in ascertaining the amount of stress or load that a material is capable of handling before it breaks, gets distorted, or stretches. So, the study of stress and strain is all about understanding how and why certain materials are more malleable and can be easily deformed or distorted than others.

What is Stress?

Stress is defined as the force per unit area that is observed by a material when an external force is applied. These external forces are generally uneven heating, permanent deformation, etc. These in turn help students calculate and find the plastic, elastic, and fluid behavior of each material under different forces.

Types of Stress

There are different types of Stress that can be applied to a material, such as

Compressive Stress

When a force acts on a body, it causes a reduction in the volume of the said body, resulting in deformation. This type of stress is referred to as Compressive stress.

Compressive stress leads to material failure that is ultimately caused due to tension. The compressive stress from its application to brittle materials differs from that of ductile materials.

Tensile Stress

When an external force is applied per unit area on a material, and it results in the stretching of the said material, then it is described as Tensile Stress.

Tensile stress leads to elongation of any material due to external stretching force.

What is Strain?

If a body experiences deformation due to the applied external force in a particular direction, it is called strain. Moreover, the strain does not have any dimensions, as it only explains the change in the shape of the object.

Types of Strain

Similar to stress, strain is also differentiated into Compressive Strain and Tensile Strain.

Compressive Strain

Compressive strain is defined as the deformation observed on an object when compressive stress acts on it. And in this type of strain, the length of the material or object generally decreases.

Tensile Strain

The Tensile stress acting on a body or a material that causes the increase in the length of said material is referred to as a tensile strain.

Stress-Strain Curve

This graph explains how stress and strain curve act on a body with respect to each other, as well as the different regions formed on the graph.

Stress-Strain Curve constitutes one of the crucial studies and essentially involves the study of elastic properties of materials understood through the relationship between stress and strain, factoring in various loads. In short, any material’s stress-strain curve indicates the relationship between stress and strain. In this curve, the stress and its corresponding strain values are marked.

Let’s understand the stress strain diagram in detail,

The OA line represents the Proportional Limit, as it described the region, where the material or body obeys Hooke’s Law. And this line can help students to calculate Young’s Modulus, using the ratio of stress and strain.

Now, the AB line represents the Elastic Limit of the object, which means that after this point, the body does not retain its original shape or size, when the acting force is removed.

As you can guess, the BC lines describe the Yield Point. Which, when force is applied on the material, then there is complete deformation in the object, which cannot be reversed, even if the force is removed.

D point on the graph is the point beyond which students can observe the complete failure of the object, as it crosses the maximum stress a material can endure. This point is stated as Ultimate Stress Point.

E is the Fracture of Breaking Point, at which students can observe the complete failure of deformation of the object, regardless of the force whether it is applied or removed.

The stress-strain curve typically consists of several distinct regions:

Let us understand stress-strain curve as we try to understand the stress-strain graph better through various regions:

Proportional limit

Elastic Region

Yield point

Stress point

Fracture or breaking point

Elastic Region: In this region, the material deforms elastically in response to applied stress, meaning it returns to its original shape once the stress is removed. The relationship between stress and strain is linear, and this region is characterized by Hooke’s Law, which states that stress is proportional to strain.

Yield Point: Beyond a certain stress threshold known as the yield point, the material begins to deform plastically, meaning it undergoes permanent deformation even after the stress is removed. The yield point marks the transition from elastic to plastic deformation.

Plastic Region: In this region, the material continues to deform plastically with increasing stress, undergoing significant strain without a proportional increase in stress. Plastic deformation is irreversible, and the material’s shape changes permanently.

Ultimate Tensile Strength: The ultimate tensile strength (UTS) is the maximum stress that a material can withstand before failure occurs. It represents the highest point on the stress-strain curve and indicates the material’s resistance to fracture under tension.

Fracture Point: Beyond the ultimate tensile strength, the material experiences a rapid decrease in stress leading to fracture or failure. The fracture point marks the end of the stress-strain curve, indicating the material’s ultimate failure under tension.

Stress-Strain Graph

The stress-strain graph is primarily a representation of the stress-strain curve where plotting is clearly of the curve is shown. It reflects the changes caused to stress vis-à-vis the change in strain. The graphs are reference illustrations for metals in both material sciences as well as manufacturing.

The graph provides design engineers with parameters and inputs much-needed for application design. Also, many mechanical properties such as toughness, yield point, elasticity, strength, strain energy, elongation at load, and many others are understood. Through the graph, one can understand the slope and the axis.

Hooke’s Law

From the above sections, we have learned all about types of stress and strain, and their units, as well as a graphical representation of stress and strain on objects. Now let us talk about Hooke’s law of stress and strain, which plays an important role in helping us understand how stress and strain work on an object when force is applied.

According to this principle, the strain of the material is equal to the applied stress, in the elastic limit region of the said object or material. And it is represented as,

F = –k.x

F = Force

X = Extension of Length

K = Spring Constant

Difference between stress and strain

In physics, stress refers to the force that is acting per unit area of the object, whereas strain depicts the ratio of the change in an object’s dimension to its original dimension. In physical parlance, stress is equivalent to Pressure and its unit is Pascal or psi, or pounds. On the other hand, strain signifies the ratio of change in dimensions to that of the original dimension, therefore has no units of measurement. Strain, however, can be measured by strain gauges.

Stress and strain are related, but are characterized by distinct properties. Stress causes deformation, while strain can be caused by several types of stress, including tension or compression.

Difference between plain stress and plane strain

plane stress happens when the value of normal stress remains zero and the sheer stress which is seen perpendicular to the direction of the applied load is presumed zero. Plane stress is based on assumption and is measured approximately. On the other hand, plane strain is about distortion in the object that is perpendicular to the object’s plane. If plane stress is more of an approximation, then plane strain is more accurate.

Shear stress and shear strain

Shear stress is the stress that is applied parallel to the plane of the object which renders lateral distortion in the object. As far as shear strain is concerned, it reflects the magnitude of lateral strain in terms of tanθ. Shear Strain is shown as tanθ = Lateral Distortion / Perpendicular height.

Stress and strain are fundamental concepts that play a crucial role in understanding the mechanical behavior of materials. The stress-strain curve provides a graphical representation of this relationship, offering insights into the material’s strength, stiffness, and ductility. By studying stress and strain, engineers and scientists can design and analyze structures and materials to ensure their safety, reliability, and performance in real-world applications.

In the above article, we have explained in detail the terms, stress and Strain, how they act, units of stress and strain, types of stress and strain, etc. This will be helpful for students to solve any kind of problems from these chapters or understand other subtopics easily from the next chapters. However, if you are still worried about how to cover many complex topics and chapters in Physics. Then the best solution for you is to join Online Coaching Platforms. Like the Tutoroot platform, which offers cost-effective online interactive classes that come with various amazing benefits for the students. Visit the Tutoroot site to learn more about these benefits.

0 notes

Text

6061 aluminum vs 7075 aluminum

What Is 6061 Aluminum Grade?

Aluminum grade 6061 is one of the most commonly used aluminum alloys. it is the most famous member of the 6000 series of aluminum alloys. Due to the perfect balance of hardness and machinability, 6061 aluminum alloy is referred to as structural aluminum. it is Composed primarily of aluminum(97.9%) and magnesium, silicon, copper, chromium, and a tiny amount of other elements.

What Is 7075 Aluminum Grade?

Aluminum 7075 is a high-strength heat-treatable aluminum alloy used for highly stressed structural parts. it is a member of the 7000 series aluminum alloys. As a primarily zinc-based aluminum alloy, It contains 5.6% zinc, 2.1% magnesium, and 1.2% copper.

Differences Between Aluminum 6061 and 7075

6061 Vs. 7075 Aluminum: Chemical Composition Comparison

Below is a table to show the Chemical Composition of both materials and you will find how each Chemical affects the performance of the materials.

6061 vs. 7075 Aluminum: mechanical properties comparison

A comparison table is below for the mechanical properties of both materials.

Tensile Strength

This property measures a material’s resistance to a longitudinal pulling force. Aluminum 7075 is very good in this aspect, making it ideal for applications where high strength is critical, such as aerospace components.

Yield Strength

Yield strength indicates the point at which a material begins to deform plastically. Aluminum 7075 has a higher yield strength compared to 6061, which means its superior ability to withstand deformation.

Hardness

Hardness means a material’s resistance to surface indentation or abrasion. Aluminum 7075’s hardness is higher than that of aluminum 6061, making it more resistant to wear and damage.

Elongation

Elongation measures how far a material can stretch before breaking. Aluminum 6061 is more ductile in this aspect, meaning it can deform significantly before reaching its breaking point compared to 7075.

Young’s Modulus(Modulus of Elasticity)

This property defines a material’s stiffness and its ability to return to its original shape after deformation. Both alloys have similar values, but 6061 is slightly more elastic, making it better suited for applications requiring flexibility.

Thermal Conductivity

It means how efficiently a material conducts heat. Aluminum 6061 has higher thermal conductivity, making it suitable for heat dissipation applications like heat sinks.

Electrical Resistivity

This property quantifies a material’s opposition to electrical current flow. 7075 has slightly lower electrical resistivity, making it better for electrical conductivity applications.

Elasticity

Elasticity reflects a material’s ability to deform and regain its original shape under applied stress. Aluminum 6061 has higher elasticity, allowing it to flex more without permanent deformation.

Temperature Resistance

This property indicates how well a material can withstand elevated temperatures. Aluminum 7075 is better in high-temperature environments due to its higher melting point.

Corrosion Resistance

6061 vs. 7075 Aluminum: machinability comparison

CNC Machinability

Aluminum 6061 is easy to machine, and used for producing longer, continuous chips during CNC Aluminum machining. On the other hand, Aluminum 7075 is also machinable, but it generates shorter, segmented chips. so, for CNC machinability, 6061 aluminum will be better.

Weldability

In terms of weldability, Aluminum 6061 is better. It is adaptable to various welding techniques, including TIG and MIG welding with a good result. Although Aluminum 7075 is weldable, it demands more expertise and careful control of welding parameters.

Bending

For bending operations, Aluminum 6061 is highly formable and can be bent to various angles without the risk of cracking or distortion. In contrast, Aluminum 7075 is less ductile and possible to crack during bending.

Sawing

Both alloys can be cut effectively, but Aluminum 6061 is easier to cut. Standard sawing equipment can easily cut 6061, ensuring precise and clean cuts. Aluminum 7075 requires specialized sawing equipment for optimal cutting results.

EDM (Electrical Discharge Machining)

Wire EDM is not commonly used on Aluminum 6061 due to its excellent machinability using conventional methods. For Aluminum 7075, EDM is a viable option, especially in cases demanding high-precision components.

Tool Wear

Tool wear is a key consideration during machining. Aluminum 6061 shows low tool wear. Aluminum 7075, while still machinable has high tool wear due to its high hardness.

Surface Finish

Aluminum 6061 generally delivers a smooth surface finish, making it an excellent choice when aesthetics is important. Aluminum 7075 can also achieve a satisfactory surface finish, but it may require more effort due to its high hardness.

6061 VS 7075 Aluminum: How To Choose?

With the answer to the following three questions, you will know how to choose.

Which One is Stronger: 6061 or 7075 Aluminum?

7075 aluminum alloy has a higher yield strength compared to 6061 aluminum, So it can withstand impacts better than 6061.

Which One is Easier to Machine: 6061 or 7075 Aluminum?

6061 aluminum has lower tensile strength and hardness compared to 7075 aluminum. So, 6061 aluminum is easier to machined and shaped.

Which One is More Cost-Effective?

The raw material cost and machining expenses for 7075 are higher. So Aluminum 6061 is more cost-effective.

When to choose: 6061 or 7075 Aluminum

According to the comparison above, we summarize a when list to help you decide how to choose.

Aluminum 6061 can be considered for use in the following situations:

When parts require a lot of welding process.

When there’s a high demand for corrosion resistance.

When a lower cost is a priority.

7075 aluminum is more suitable for the following situation:

When achieving a high strength-to-weight ratio is needed.

When parts need to withstand high temperatures.

When parts will be subjected to high stress.

When the budget allows for higher material costs.

Conclusion

6061 and 7075 Aluminum alloys are both wonderful in the machining process. if you can not decide well, Contact a professional aluminum machining supplier. KUSLA is a manufacturer of precision aluminum machining in China. Feel free to get in touch with us for your aluminum machining projects.

You may also interested in other comparisons:

Titanium vs Aluminum

this actical was printed from

0 notes

Text

Understanding the Role of Steel’s Modulus of Elasticity in Construction: Insights and Current Pricing

Steel is a cornerstone of modern construction, known for its remarkable strength and versatility. Among the many properties that make steel an essential material, the modulus of elasticity, also known as Young’s modulus, is particularly crucial. This property dictates how much a material will deform under stress, which is vital for the structural integrity of buildings and infrastructure. In this article, we’ll explore the importance of steel’s modulus of elasticity, its application in construction, and how it relates to the use of Tata Tiscon TMT bars. Additionally, we'll examine today’s steel rates and Tata Tiscon's current price list to help you make informed decisions for your projects.

What is the Modulus of Elasticity of Steel? The modulus of elasticity of steel, often referred to as Young's modulus, is a measure of the stiffness of steel. It defines the relationship between stress (force applied) and strain (deformation) in a material. For steel, the modulus of elasticity is typically around 200 GPa (gigapascals). This high modulus indicates that steel is relatively stiff and will deform only slightly under large loads, making it ideal for structural applications.

In practical terms, the modulus of elasticity is crucial when designing structures that need to maintain their shape and support loads without excessive bending or stretching. It ensures that steel components in buildings, bridges, and other structures can withstand the stresses imposed by weight, wind, earthquakes, and other forces without undergoing significant deformation.

The Importance of Modulus of Elasticity in Construction In construction, the modulus of elasticity of steel is a key factor in determining how steel components behave under load. It affects the design of beams, columns, and other structural elements that must resist bending and compression. Engineers use the modulus of elasticity to calculate the amount of deflection a steel component will undergo under a given load, which is essential for ensuring that buildings remain stable and safe.

For example, in high-rise buildings, where steel is used extensively in the framework, the modulus of elasticity helps engineers design structures that can support their own weight plus additional loads.

Tata Tiscon TMT Bars: Combining Strength with Elasticity Tata Tiscon is a leading brand in the production of TMT (Thermo-Mechanically Treated) bars, which are specifically designed to provide high strength and flexibility. TMT bars are essential in reinforcing concrete, providing the necessary tensile strength to prevent cracking and failure under load. The unique combination of strength and ductility in Tata Tiscon TMT bars makes them ideal for use in earthquake-prone regions, where buildings must be able to absorb and dissipate energy without collapsing.

The high modulus of elasticity of steel used in Tata Tiscon TMT bars

ensures that these bars can support heavy loads while maintaining their structural integrity. This makes them a preferred choice for builders and engineers who need reliable materials that can withstand the rigors of modern construction.

Current Tata Tiscon Price List and Today’s Steel Rates As of today, steel prices continue to fluctuate due to various factors, including global demand, raw material costs, and economic conditions. Staying updated with the latest steel rates is crucial for anyone involved in construction, as these prices directly impact project budgets and material procurement.

Tata Tiscon, known for its high-quality TMT bars, offers a comprehensive price list that reflects the current market rates. Whether you're planning a small residential project or a large commercial development, having access to the latest Tata Tiscon price list allows you to make informed purchasing decisions and optimize your budget.

Today’s steel rates vary based on the type and grade of steel, with TMT bars typically priced per kilogram or ton. By monitoring these rates, you can take advantage of favorable pricing trends and ensure that you’re getting the best value for your investment.

Conclusion: The Synergy Between Steel’s Elasticity and Cost-Effective Construction Understanding the modulus of elasticity of steel and its impact on construction is vital for designing safe, durable, and efficient structures. Tata Tiscon TMT bars exemplify the ideal balance between strength and flexibility, making them a top choice for reinforcing concrete in a wide range of construction projects.

By staying informed about today’s steel rates and Tata Tiscon's current price list, builders and contractors can make smarter, more cost-effective decisions. Whether you're purchasing materials online or through traditional suppliers, knowing the value and capabilities of the steel you choose will ensure the success and longevity of your projects

0 notes

Text

Odor For Interior Materials-MS 300-34 AT Kiyo R&D Center and Laboratory

Understanding the Importance of Tensile Testing at Kiyo R&D Center and Laboratory in Chennai Chitlapakkam

Introduction

In materials science, understanding the mechanical properties of materials is essential for ensuring their performance and durability. Tensile testing is a fundamental method used to determine these properties. At Kiyo R&D Center and Laboratory in Chennai Chitlapakkam, we offer specialized tensile testing services to help manufacturers evaluate the strength and elasticity of their materials.

What is Tensile Testing?

Tensile testing involves stretching a material until it breaks to measure its response to stress. This test provides valuable data on the material’s tensile strength, yield strength, elongation, and Young’s modulus, which are critical for assessing its suitability for various applications.

Methodology of Tensile Testing

Sample Preparation: Materials are prepared in standard shapes and sizes for testing.

Mounting: Samples are securely mounted in the testing machine.

Stretching: The machine applies a controlled force to stretch the sample.

Data Collection: The material’s response to the applied force is recorded.

Analysis: The data is analyzed to determine the material’s mechanical properties.

Benefits of Tensile Testing

Material Characterization: Provides detailed information about the material’s mechanical properties.

Quality Control: Ensures materials meet specified performance standards.

Product Development: Assists in selecting appropriate materials for specific applications.

Compliance: Helps manufacturers comply with industry standards and regulations.

Why Choose Kiyo R&D Center and Laboratory?

At Kiyo R&D Center and Laboratory, we are committed to delivering precise and reliable tensile testing services. Our advanced facilities in Chennai Chitlapakkam are equipped with the latest technology, and our team of experts ensures the highest standards of testing accuracy. By choosing us, you gain access to:

Expert Knowledge: Our team has extensive experience in tensile testing.

State-of-the-Art Equipment: We use advanced machinery for accurate testing.

Customized Solutions: Tailored services to meet your specific testing needs.

Comprehensive Reporting: Detailed analysis and reporting for informed decision-making.

Conclusion

Tensile testing is a vital process for evaluating the mechanical properties of materials. At Kiyo R&D Center and Laboratory, we offer comprehensive tensile testing services to help you ensure the quality and performance of your materials. Contact us today to learn more about our tensile testing capabilities and how we can support your material testing needs.

For More Info About Odor For Interior Materials — MS 300–34, Kiyo R&D Center and Laboratory, Kiyorndlabs.com, Test Method of Odor For Interior Materials — MS300–34, Hyundai Kia MS 300–34 Interior Fragrance, Top Laboratory Testing For Chemicals in Chennai, Top Laboratory Testing Services in Chennai, NABL Certified Laboratory in India | Material Testing Lab India

0 notes

Text

Tensile Testing Machine Manufacturer in India

A tensile tester or tensile testing machine is used to determine the strength and deformationbehavior of a material up to the point of fracture. It is used to find out how strong a material is and also how much it can be stretched before it breaks. This test method is used to determine yield strength, ultimate tensile strength, ductility, strain hardening characteristics, Young's modulus and Poisson's ratio. To perform a tensile test, an operator will load a specimen into the two specimen grips of the machine. After loading the specimen, the operator selects the correct rate of movement for the material type. The tester then pulls the specimen apart until failure. The data obtained by tensile testing ensures the integrity and safety of materials, components and products. It helps manufacturers to ensure the quality of their final product and are fit-for-purpose.

For more details clicks here - https://www.indiantradebird.com/product/tensile-testing-machine-

0 notes

Text

🌱 solid materials 🌱

hooke’s law

with a material, applying a force extends / compresses it. the larger the force, the larger the extension.

F= kx [ Force (N) = spring constant x extension (m) ]

the extension is the change in length from the unloaded material, and the spring constant is the stiffness of the material.

hooke’s law states that the force applied is directly proportional to the extension of the material until the limit of proportionality is exceeded.

the limit of proportionality is the point where hooke’s law is no longer obeyed. it’s often the same as the elastic limit.

F-x graphs

on a graph of F-x, the gradient = k. when a material is deformed, it stores elastic strain energy, which is equal to the area underneath the graph, which would be a straight line graph.

E(p) = 1/2 Fx or E(p) = 1/2 kx^2

this only occurs when the material is still obeying hooke’s law and deforming elastically.

elastic strain energy is the ability of the material to do work to regain its original shape after elastic deformation.

elastic deformation is when a material will still return to its original shape once the load is removed. all work done to stretch the object is stored as E(p)

for plastic deformation, the area between loading and unloading lines is equal to the work done to deform the material. energy put into the system breaks the bonds between atoms, which is then dissipated as heat energy.

materials that are stretched beyond their elastic limit will not return through the origin on F-x graphs, but the unload and load lines will be parallel, as their stiffness is constant.

the area between the two lines is the work done to deform the material.

stress and strain

stress σ (Pa) = F/A

strain ε = x / L [extension / original length]

as strain is a ratio of two lengths, it has no units

young modulus or E is a description of the stiffness of the material, but isn’t the actual stiffness value (that’s the spring constant! i was really confused about it). it’s usually BIIG numbers (like x10^9)

E (Pa) = σ/ε so E=Fx/AL

stress-strain graphs:

the elastic limit is the final point at which the material can be unloaded and still return to its original shape.

the yield point is where the material does no longer behave elastically.

ultimate tensile strength is the maximum stress a material can take, and going beyond that point results in the material breaking (breaking stress).

the area underneath a stress-strain graph is equal to the energy stored per unit volume (energy density). this is sometimes called a hysteresis loop.

the area within a hysteresis loop on stress-strain graphs is the energy per unit volume (energy density) transferred to the internal energy of the material.

0 notes

Text

https://en.wikipedia.org/wiki/Bulk_modulus

Other moduli describe the material's response (strain) to other kinds of stress: the shear modulus describes the response to shear stress, and Young's modulus describes the response to normal (lengthwise stretching) stress. For a fluid, only the bulk modulus is meaningful. For a complex anisotropic solid such as wood or paper, these three moduli do not contain enough information to describe its behaviour, and one must use the full generalized Hooke's law. The reciprocal of the bulk modulus at fixed temperature is called the isothermal compressibility.

so fluids only have bulk modulus which makes sense

according to the wikipedia article on the shear modulus the relationship between the Young's modulus E, the Poisson's ratio ν, bulk modulus K and the shear modulus G is

so I guess I need the poisson's ratio and either bulk or young's modulus?

is the elastic modulus of a material enough to characterize its acoustic properties?

2 notes

·

View notes

Text

Investigation 13: Elasticity – Danjuro Tobita

It’s almost the Christmas holidays as I write this, as well as being exactly halfway through December. Hopefully during the holidays we can catch back up to schedule, so this should be the last upload that isn’t on time. Let’s not dwell on it. Shall we?

Danjuro Tobita, better known as Gentle Criminal, has the quirk of elasticity. This allows him to make anything he touches elastic (in the sense of property, rather than material). I only learned when researching this quirk that his name is in fact a pun of the quirk in Japanese, where the standard Japanese kanji for ‘elasticity’ also translates as ‘gentleman’. This has nothing to do with the investigation, I just thought it was a cool fact.

The first problem we run into is that elasticity isn’t a set property at the molecular level. Different materials are elastic for different reasons, mostly due to the different ways the atoms and molecules within the substance are bonded together. For example, rubber is elastic because of its complex interlinked polymers that align when stretched. Most other substances deform elastically due to uniform deformation of their atomic structure. Which brings us to our second problem…

Nothing is perfectly elastic. Rubber and other elastomers are ‘elastic’ up to a point (around 10x their original length), but other materials can only deform slightly before they become plastic. Plasticity, in opposition to elasticity, is the property of a substance that retains its new shape when deformed, while elastic materials return to their original shape.

These two factors together make the effects of Gentle’s quirk highly irregular. To explain them, we first have to look at elasticity in more depth. So-called ‘perfect elasticity’ is described by Hooke’s Law, which states the force required to stretch or extend a material is directly proportional to the distance it is to be stretched or extended. This means to compress a spring to a quarter its length, one must apply twice the force required to halve its length, and so forth. This is (practically) true for all materials to a point. After that point, known as the yield point, the material stops being perfectly elastic, and begins deforming plastically. There are other stages between this and the material breaking, but these are unnecessary to discuss since no material that has been affected by the quirk has ever reached its yield point.

Let’s begin, as always, with the largest use of the quirk, here being the material that underwent the largest force and still remained elastic. The answer would of course be the air trampolines that redirected Izuku’s pellet of air[1], but the physics behind this interaction is possibly the most gratuitous and bloody murder of sense in the anime. I usually shy away from criticising the anime on its science, primarily because it’s a work of fiction about superheroes, but also because its purpose is a source of entertainment, and I bring the burden of applying science to it upon myself. In this instance however, I am allowing myself a small fracture in my usual composure to discuss why this scene is absolutely nonsensical.

Firstly, Izuku cannot create a bullet of air. To flick his finger is to create a pressure wave that spreads out from the point of creation at the speed of sound. No faster, no slower. If the finger is to move at a supersonic speed, the resultant pressure wave would create a sonic boom, and still travel at only the speed of light, still in a dissipating wave. Due to the properties of waves, their amplitude decreases with the square of the distance from the source. Thus Deku’s blast wave would not need aiming, and would also be barely a light breeze at such a distance as it is used.

Additionally, and most grievously, Gentle cannot create trampolines of air in the air. This is for the simple (yet often misquoted) fact of Newton’s Third Law. The classic, profound, smart-guy quip version is “every action has an equal opposite reaction”, but this is most likely only because the full answer is far more bloated. The law is in fact “when body A exerts a force on body B, body B exerts a force on body A that is of equal magnitude, opposite direction, identical type, and in the same line, as the force of body A on body B”. Quite a mouthful, but there’s a lot of subtle and important detail missing from the first, I’m sure you’ll agree. The problem here is that the created trampoline must exert a large force of Gentle to cause such acceleration (see Newton’s Second Law of Motion), and thus Gentle exerts a force on the trampoline, that causes an accelerate in the same proportion to the acceleration of Gentle as the ratios of their respective masses. Since air is a lot less dense than Gentle, and his quirk does not appear to add mass to a system, the trampoline would be accelerated backwards considerably fast before Gentle could gain any significant acceleration. It would be like trying to push yourself backwards by punching a balloon. Sure, the balloon is elastic, but it does not have enough mass to exert the required force. The only way this could work is if the trampolines were connected to the earth (thus the mass of the system is increased), but the only way this could occur is via more elasticated air. This does not happen because a) it is not seen – the elasticated air becomes slightly opaque (possibly a stylistic effect to show the action of the quirk) and there are no opaque structures visible, just a single floating disc, and b) these structures would be elasticated, and thus the system would be too flexible to exert such force over such distance.

Right, after that little rant, lets get back to the matter at hand. During the fight with Gentle and Deku there is a scene within a construction site that gives a lot of valuable information. This comes in the form of gratuitous quirk use, as well as an explicit statement of the quirk’s features: it cannot be turned off at will, and instead fades over time. This is odd when compared to almost all other quirks (if you need any examples, every other quirk investigated save one can be both activated and deactivated at will) and so it is likely it ties into the mechanism of the quirk’s action.

The scene contains two key uses of elasticity. Firstly, multiple steel girders are made elastic, and secondly a crane arm is made elastic. The former is useful because it is used by Gentle for movement, so the force on it and thus a lower limit for the yield point can be garnered. The second is useful because it showcases the flexibility of elasticated materials by how much the crane arm bends.

The steel beam bends about 1m each side of its equilibrium, which seems to be relatively unaffected by the quirk. The beam seems around 10m long, but thankfully the beams look like Universal Beams, which have standardised measurements including each type’s flange thickness, root radius, and most importantly, mass by metre and elastic modulus in each axis. Unfortunately there are almost 100 types, each of subtly different dimensions and properties. After downloading a spreadsheet and sifting through all types, I can confidently say the distinction does not matter, as the differences are all within the margin of error that arises upon attempts to measure the on-screen girder.

Let’s start with some maths. There’s no escaping it, and this time it’s back with a vengeance. Assuming the girder bends to approximate an arc (a section of a circle’s circumference) we can use some geometry to figure out the length of the original and stretched girders, and thus how much longer the latter is than the former. The unstretched we already know is around 10m long, and the centre bends ~1.5m from equilibrium. Since the ends are fixed, we know the chord subtending the arc is 10m long, and the distance bent (1.5m) is the distance between the arc and the centre of the chord. I won’t bore you with the details, but it turns out that the steel only increases length by 60cm, or one 60th its original length.

There isn’t much clear data on how elastic metals are (illustrated by the fact that a cursory search of “how far do metals stretch” gets 10 results in before some very different and nsfw questions come up instead, no points for guessing what they are) but there is an incredibly useful dataset courtesy of engineering toolbox, containing the ultimate tensile strength, yield strength or Young’s Modulus of almost every material you can think of. I’m not sure which engineer would need to compare the elasticity of compact and spongy bone, but I’m sure some day I’ll be glad the entry is there. For now we’ll look at the structural steel values, and thankfully all three are available. Let’s take a moment to discuss what they mean.

Young’s Modulus is the ratio of stress against strain, and has a fixed value for each material. Stress is the force per unit of cross-sectional area applied to the material, and the strain is the stretched length sure to such stress over the original strength. Yield strength is the minimum stress required to deform the material plastically, and ultimate tensile strength is the stress required to snap the material. Structural Steel has a Young’s Modulus of 200, so for every 200 MN of force per square metre of cross-sectional area, the beam will double in length. Sadly, these simple calculations are only applicable when the force and extension lie on the same line. In our case, the deformation is complex, non-shear, and therefore cannot be described at an angle relative to the force. In this case, we must apply the terrifyingly named Euler-Bernoulli Beam Theory. It contains some fittingly terrifying equations, included variable functions based on beam material, and second derivatives against two separate nested variables. However, in our scenario, the beam is supported at both ends (known as a simply supported beam) and we’ll assume it is uniform in density, elasticity, etc. Therefore we get an equation that looks like this: σmax = ymax F L / (4 I) where σmax is maximum stress at a given point, ymax is the distance from the point to the neutral axis, F is the force applied to the centre of the beam, L is double the length of the beam, and I is the ‘area moment of inertia of the cross section’. I have almost no idea what that last one means, but thankfully I managed to find an equation for it given different dimensions of a symmetrical I-shaped cross-section. There are two pieces of bad news. 1, it looks like this: Iy = (a^3 h / 12) + (b^3 / 12) (H - h), and 2, we now need to play a game of universal-beam ‘Guess Who’ to gain the correct dimensions.

The beam in the anime seems to be less than 500mm in depth, so that removes 47 possible types. Less than 500mm in width sadly doesn’t remove any more. However, we do know the beam is roughly larger than 150mm, since it larger than Deku’s hand span, which removes another 23. Averaging the rest gives us some dimensions we can use as an approximation of the beam. Thankfully, there exists a table of standard UK I beam dimensions and their respective area moment of inertia of the cross section. Comparing our values to the closest standard gives a value of 7440. Plugging this into the max strain equation, we find the maximum strain on the beam to be 0.79N per square metre. A strangely low number that says to me something must be wrong. The problem is we don’t know the value of F, and since I just used Gentle’s weight the formula treats the beam as incredibly flexible, since it bent so much under such little load. This is a problem, only solved by using a formula involving the Young’s Modulus E of the beam rather than F. Such a formula is even more complex than those already seen, and is at such a level that I cannot understand how to apply it to the above scenario. Indeed, this post is already much over its due posting date at time of writing, and we have not talked at all about the quirk’s mechanism. Beam theory being as complicated as it is, and having spent now a good few days failing to apply it, I believe it is best we approach the problem from a different angle.

It’s safe to say the metal becomes not just more elastic, but more flexible, when the quirk takes effect. It takes a very large force to bend metal to the extent shown, and that metal would snap or at least bend plastically before that point is reached (sadly I cannot say which would occur). Therefore something about the molecular structure of the metal must change.

As previously discussed, metals and polymers bend differently at the molecular level, and this is because their very structures are different. Metal atoms bond by delocalising their outer electrons, creating positively charged ions attracted to a sea of negatively charged delocalised electrons. This is why metals shine – the electron sea is incredibly smooth, sub atomically so. Polymers bond via covalent bonds and inter-molecular bonds, creating discrete polymers that weakly attract each other. Gentle’s quirk must somehow make both these structures, and others, elastic in the same fashion.

The first answer is to weaken the inter-molecular forces within the structures, allowing polymers/molecules/any base elements to more easily move past each other within the material. Sadly, this just makes the material more ductile, which is the ease with which the material can be elongated via tensile force. To make something more elastic, the forces holing the molecules together must be made, for want of a better word, springier. Essentially, they must be able to act over a longer distance in order to pull the material back into shape after deformation. To do this simply would be to make the bonds stronger, but this would also make the material less flexible and denser. Instead, the force must somehow be spread across some distance profile, maintaining its magnitude at the standard distance of molecules from each other, but fall off slower as distance increases. The way to do this while retaining the other featured of the material is essentially fictional, and would even break thermodynamics (again) by being able to increase the Helmholtz Free Energy within a closed system. Since we’re now changing the mechanism by with one of the four fundamental forces of the universe functions, we can suppose the quirk changes the quirk in such a way ass to create perfectly elastic materials, since they already seem to have ridiculously high yield points.

Supposing this is the case, the question immediately arises – so what? The answer is that perfectly elastic materials have immense uses within many scientific circles. If a material returns to exactly the same state after deformation as it was in before, then it has the same energy. This means any object that hits it rebounds with the same kinetic energy as it started with, a phenomenon known fittingly as a perfectly elastic collision. Every other collision loses energy as heat, save for collisions that stretch the term for physics reasons, such as two orbiting objects. In our case purely elastic collisions have as many uses as elastic materials do, and possibly more. To have any material possible suddenly, even though temporarily, gain perfect elasticity will have material scientists drooling, and although I do not have the intelligence to think of any novel applications of such, asking one of them would I’m sure give you myriad answers.

Another fun application is heat-proofing. A material becomes liquid when the inter-molecular forces are partially overcome by kinetic energy, and gasses when the forces are broken completely. Since these forces are unlimited in distance, the objects would never be able to become gaseous, and would have very high cohesion (surface tension) when liquid. I’m again not sure of the applications of this, but it is cool nonetheless.

To conclude, Gentle Criminal’s quirk affects any material he touches, and changes the effect of the electrostatic forces within it, making them act across any distance, with a slight reduction in magnitude with distance. This works by having the force pull the molecules together from any distance, until they become close enough to be repelled by the electrostatic repulsion of the atoms. Any force applied may overcome the electrostatics for a distance, but will never cause yielding.

[1] Season 4 episode 85: School Festival Start!!

I hope you enjoyed this investigation! It’s almost Christmas as I post this, and as I’m sure you’re aware this post should have ben released on the 1st. I’m also sure you’re aware this has become a trend, and I’m sure you know reasons behind it. It is therefore with a heavy heart I announce we will be taking a hiatus for an undefined length of time. We have decided it is better to write a few posts as backup and prepare for posting, rather than desperately writing posts weeks after they’re due and apologising. We don’t have an idea of when we will be back, but we will. In the mean time, go have a Merry Christmas/Happy Holidays, and a happy new year. We’ll see you some time in 2021.

#bnha#boku no hero academia#mha#my hero academia#gentle criminal#danjuro tobita#tobita danjuro#quirk investigation#bnha analysis

3 notes

·

View notes

Text

stress-strain iteration of Hooke’s Law for spring-like systems

k is determined by the spring’s physical characteristics

spring constant k is a measure of spring’s stiffness – k increases as spring becomes harder to stretch

i.e., as k increases, F(spring)’s magnitude increases and pushes against non-equilibrium movement

k is directly proportional to the spring’s thickness and inversely proportional to the spring’s length

thus, k ≈ (some constant) • A / L where A is cross-sectional area and L is un-stretched length

(some constant) = Young’s Modulus (Y) in units of N/m^2, dependent on material and physical state

Y(rubber) = 5e6 N/m^2 | Y(steel) = 2e11 N/m^2

to compare Y’s of two different springs, one needs information about A and L upon which Y and k are dependent

relation between k, spring’s physical characteristics, and F(spring)

when substituted into F(spring) = -kx → F(spring) = – (Y • A/L) • ∆x

since L is the length of the un-stretched spring, x = 0 when spring’s length = L and ∆x is the same as ∆L

thus, F(spring) = – (Y • A/L) • ∆L, where ∆L is especially used in lieu of ∆x in biological sciences

tensile stress and strain

more applicable variation on Hooke’s Law, F(spring) = – (Y • A/L) • ∆L, that emphasizes proportionality and reactionary character of spring system

the percent stretch ∆L/L is known as the tensile strain of the spring in direct proportional reaction, by a factor of Y, to the tensile stress = F(spring) / A

tensile strain • Y modulus = tensile stress, where tensile stress is the force exerted by each portion of the cross section area and tensile strain is the stretch

or stress is proportional to strain via Y modulus

strain cannot occur without some stress, i.e., strain is the spring’s reaction to the force stressor

on the other hand, stress force can be applied over an area without changing an object’s length, so stress can happen without reactionary strain depending on the system’s properties

volume stress and strain

3D objects have tensile stress and strain analogous to F/A = Y(∆L/L) in 2D, but in 3D volume dimensions rather than 2D length dimensions

F/A = -B (∆V / V), where B is the bulk modulus constant like Y, and V is initial or equilibrium uncompressed volume that is analogous to L

larger B modulus is harder to compress than smaller B modulus

shear stress and strain

applies to F that is exerted tangentially to object’s surface, which can cause object to twist

same Hooke’s law, but for objects that deform and exhibit shear strain from exertion of a tangentially shear stress

F/A = -S (x/h) for two surfaces being sheared in a system

h is the initial or equilibrium distance between two sheared surfaces of the system (i.e., the height of a rectangular block), analogous to L or V

x is the displacement between the two sheared surfaces, analogous to ∆L or ∆V

large S modulus constant is harder to shear than small S modulus

diagram summary of all Hooke’s Law iterations

from Dr. Savanna Starko’s notes, 10/29/2020

elasticity and fracture

∆L, V, x are reversible if applied F and reactionary strain are relatively small

however, if F/strain are too large, system components will tear and deformation of system may be permanent

stress and strain are linearly proportional when both are within certain magnitude range, known as elastic regime, where strain deformation ∆(whatever L, V, or x is relevant) is reversible

at a certain upper threshold, strain deformation becomes irreversible and stress v. strain is no longer linear; region beyond upper threshold is known as plastic regime

within plastic regime, yield strength is tensile stress value that system can take before failure, or fracturing/breakage of system components

ultimate strength is the maximum yield strength before failure and breaking strength is that which pushes the system to failure

4 notes

·

View notes

Text

How to buy a Martin acoustic guitar

Rookie buyers or people with GAS(Guitar Acquisition Syndrome),

I’ll dive right in. Martins are costly. This blog aims to steer you in the right direction to make an informed decision.

1. Know your woods ;)

https://www.youtube.com/watch?v=IhyMhPt04Ag

Probably the only video you will ever need to watch ^

2. Know the name

<Size> - <Ornamentation>

Example : Model D-28 means Dreadnought sized 28 series family.

In increasing order of size : 0 --> 00 --> 000 or OM --> D --> M --> J

And in general, higher the number, fancier it is.

Further reading : https://www.maurysmusic.com/maury_s_blog/view/153146/naming_a_martin_guitar

http://onemanz.com/guitar/reviews/acoustic-guitars/martin/model-designation/

3. The Tone :

FICTION : In general, denser the wood warmer the sound.

FACT : Elastomechanical and anatomical properties depend on several factors such as natural oils, how dry the wood is, which tree was it etc. which explains why maple and ebony are so bright, even though they are MUCH denser than Mahogany.

SUBTLETY : When talking of wood acoustics, denser implies closely grained(which doesn’t necessarily mean heavier)

https://www.soundunlimited.co.uk/blogs/articles/guitar_tone_woods

4. Physics 101 :

An acoustic guitar generates its sound in the following way: -When the strings on a guitar vibrate, they transmit their vibrations to the saddle. -The saddle transmits its vibrations to the soundboard. -The soundboard and body amplify the sound. -The sound comes out through the sound hole. Most important mechanical properties that govern the choice of wood are : Young’s Modulus Density Stability with humidity variation Heat bendability Janka Hardness

Braces in a guitar limit the soundboard’s deflection and control how the vibration is subdivided.

Soundboard is guitar’s primary sound radiating surface.

Back and Sides can be “live” (secondary vibrating surface) or “non-live” (acoustically immaterial)

Necks are composite structure comprising the neck, fingerboard and truss rod.Neck wood needs to be stable under load and humidity variations. For that reason, neck and fretboard wood should not have highly dissimilar coefficients. Fretboard woods are usually high density and high stiffness to achieve hardness, abrasion resistance and ability to hold a fret.

Bridge transfers a strings vibrations to the fret.

When the string is tuned, the stress due to tension causes it to get longer and thinner, much as our waist does when we stretch our hands high in the air. The ratio between the elongated “waist” and the “waist” at rest is called the Poisson Ratio.

Young’s Modulus for Strings :

Linear Region: string stretches, then recovers. Plastic Region: string stretches permanently; time to re-tune before you sound bad. Failure: string breaks, concert's over, crowd demands refund; groupies leave, career ends.

Young’s modulus for tonewoods :

R is Sound Radiation Coefficient, E is Young’s Modulus in Pascals, ρ is the density.

Per above formula, loudness of the top increases with stiffness, and decreases with density. The loudest wood tops, such as Sitka Spruce, are lightweight and stiff. Denser woods often used for necks are stronger but not as loud. Basically, woods simply absorb certain frequencies - - Mahogany(has the warmest sound I’ve heard with unreal sustain) absorbs the brighter frequencies while Maple(bright sounding) absorbs the warmer spectrum.

https://www.youtube.com/watch?v=edNwW5BOuIA https://www.youtube.com/watch?v=DxD6aeNEzt4 https://www.youtube.com/watch?v=LYBMmuNW7Sc https://www.youtube.com/watch?v=XsublaCXtlE https://www.premierguitar.com/articles/Sucking_the_Sap_From_Tonewoods http://guitarworks.thestrandbergs.com/2014/12/28/the-impact-of-wood-choice-in-an-electric-guitar/

#How to buy a Martin acoustic guitar#martinguitars#martin#buying guitar#acousticguitar#acoustic guitar#martin guitar

1 note

·

View note

Text

Effects of high loading by eccentric triceps surae training on Achilles tendon properties in humans.

Maximum isometric force had increased by 49% and tendon CSA by 17% ! Tendons can change their cross sectional area, if you load them.

Here I show lateral forefoot loading in a heel raise, and a medial forefoot loading in heel raise. This has to be part of the discovery process outlined below.

Isometrics are useful, they have their place. In a recent podcast to load up here in the future, we discuss the place and time to use isometrics, isotonics, eccentrics and concentrics. One of the goals in a tendinopathy is to restore the tendon stiffness. Isometrics are a safe way to load the muscle tendon complex without engaging a movement that might have to go through a painful arc of movement. With isometrics here is neurologic over-spill into the painful arc without having to actually go there. The key seems to be load. More load seems to get most people further along. Remember, the tendon is often problematic because it is inflamed and cannot provide a stiffness across its expanse. Heavy isometric loading seems to be a huge key for most cases. But, we have to say it here, not everyone fits this mold. Some tendons, in some people, will respond better to eccentrics, and strangely enough, some cases like stretching (perhaps because this is a subset of an eccentric it seems or because there is a range of motion issue in the joint that is a subset of the problem). Now the literature suggests that stretching is foolish, but each case is unique all in its own way, and finding what works for a client is their medicine, regardless of what the literature and research says. Finding the right load for a given tendon and a right frequency of loading and duration of loading is also case by case specific. Part of finding the right loading position is a discovery process as well, as noted in the photos above. Finding the fascicles you want to load, and the ones you do not want to load (painful) can be a challenging discovery process for you and your client. Finding the right slice of the pie to load, and the ones not to load takes experimentation. When it is the achilles complex, finding the safe However, if one is looking for a rough template to build from, brief, often, heavy pain free loads is a good template recipe to start with.

Here, in this Geremia et al article, "ultrasound was used to determine Achilles tendon cross-sectional area (CSA), length and elongation as a function of plantar flexion torque during voluntary plantar flexion." They discovered that, "At the end of the training program, maximum isometric force had increased by 49% and tendon CSA by 17%, but tendon length, maximal tendon elongation and maximal strain were unchanged. Hence, tendon stiffness had increased by 82%, and so had Young’s modulus, by 86%.

Effects of high loading by eccentric triceps surae training on Achilles tendon properties in humans. Jeam Marcel Geremia, Bruno Manfredini Baroni, Maarten Frank Bobbert, Rodrigo Rico Bini, Fabio Juner Lanferdini, Marco Aurélio Vaz European Journal of Applied Physiology August 2018, Volume 118, Issue 8, pp 1725–1736

2 notes

·

View notes

Text

What is the Stress-Strain Curve?

Stress is defined as the force per unit area that is observed by a material when an external force is applied. These external forces are generally uneven heating, permanent deformation, etc. These in turn help students calculate and find the plastic, elastic, and fluid behaviour of each material under different forces.

Types of Stress

There are different types of Stress that can be applied to a material, such as

Compressive Stress

When a force acts on a body, it causes a reduction in the volume of the said body, resulting in deformation. This type of stress is referred to as Compressive stress.

Compressive stress leads to material failure that is ultimately caused due to tension. The compressive stress from its application to brittle materials differs from that of ductile materials.

Tensile Stress

When an external force is applied per unit area on a material, and it results in the stretching of the said material, then it is described as Tensile Stress.

Tensile stress leads to elongation of any material due to external stretching force.

What is Strain?

If a body experiences deformation due to the applied external force in a particular direction, it is called strain. Moreover, the strain does not have any dimensions, as it only explains the change in the shape of the object.

Types of Strain

Similar to stress, strain is also differentiated into Compressive Strain and Tensile Strain.

Compressive Strain

Compressive strain is defined as the deformation observed on an object when compressive stress acts on it. And in this type of strain, the length of the material or object generally decreases.

Tensile Strain

The Tensile stress acting on a body or a material that causes the increase in the length of said material is referred to as a tensile strain.

Stress-Strain Curve

This graph explains how stress and strain curves act on a body with respect to each other, as well as the different regions formed on the graph.

Stress-Strain Curve constitutes one of the crucial studies and essentially involves the study of elastic properties of materials understood through the relationship between stress and strain, factoring in various loads. In short, any material’s stress-strain curve indicates the relationship between stress and strain. In this curve, the stress and its corresponding strain values are marked.

Let’s understand the stress strain diagram in detail,

The OA line represents the Proportional Limit, as it described the region, where the material or body obeys Hooke’s Law. And this line can help students to calculate Young’s Modulus, using the ratio of stress and strain.

Now, the AB line represents the Elastic Limit of the object, which means that after this point, the body does not retain its original shape or size, when the acting force is removed.

As you can guess, the BC lines describe the Yield Point. Which, when force is applied on the material, then there is complete deformation in the object, which cannot be reversed, even if the force is removed.

D point on the graph is the point beyond which students can observe the complete failure of the object, as it crosses the maximum stress a material can endure. This point is stated as Ultimate Stress Point.

E is the Fracture of Breaking Point, at which students can observe the complete failure of deformation of the object, regardless of the force whether it is applied or removed.

Stress-Strain Graph

The stress-strain graph is primarily a representation of the stress-strain curve where plotting is clearly of the curve is shown. It reflects the changes caused to stress vis-à-vis the change in strain. The graphs are reference illustrations for metals in both material sciences as well as manufacturing.

The graph provides design engineers with parameters and inputs much-needed for application design. Also, many mechanical properties such as toughness, yield point, elasticity, strength, strain energy, elongation at load, and many others are understood. Through the graph, one can understand the slope and the axis.

Stress and strain are fundamental concepts that play a crucial role in understanding the mechanical behavior of materials. The stress-strain curve provides a graphical representation of this relationship, offering insights into the material’s strength, stiffness, and ductility. By studying stress and strain, engineers and scientists can design and analyze structures and materials to ensure their safety, reliability, and performance in real-world applications.

However, if you are still worried about how to cover many complex topics and chapters in Physics. Then the best solution for you is to join Online Coaching Platforms. Like the Tutoroot platform, which offers cost-effective online interactive classes that come with various amazing benefits for the students. Visit the Tutoroot site to learn more about these benefits.

0 notes

Text

85. An iron rod of length 2m and cross section area of , stretched by 0.5 mm, when a mass of 250 kg is hung from its lower end. Young's modulus of the iron rod is

85. An iron rod of length 2m and cross section area of , stretched by 0.5 mm, when a mass of 250 kg is hung from its lower end. Young’s modulus of the iron rod is

(a) 19.6×1010 N/m2 (b) 19.6×1015 N/m2 (c) 19.6×1018 N/m2 (d) 19.6×1020 N/m2 Answera-a

View On WordPress

0 notes

Text

Tensile Testing Machine Manufacturer and Suppliers in India

The greatest prices on Tensile Testing Machine can be found at Indian Trade Bird. A tensile tester, also known as a pull tester or univeral testing machine, is an electromechanical test system that applies a tensile force to a material to determine the tensile strength and deformation behavior until break. It is used to find out how strong a material is and also how much it can be stretched before it breaks. This test method is used to determine yield strength, ultimate tensile strength, ductility, strain hardening characteristics, Young's modulus and Poisson's ratio. A tensile membrane structure is most often used as a roof, as they can economically and attractively span large distances. Tensile membrane structures may also be used as complete buildings, with a few common applications being sports facilities, warehousing and storage buildings, and exhibition venues.

For more details clicks here - https://www.indiantradebird.com/product/tensile-testing-machine-

0 notes