#steel trowel finish

Explore tagged Tumblr posts

Photo

Poolhouse - Modern Pool Example of a mid-sized minimalist backyard stone pool house design

#commercial glazzing#custo roof#steel trowel finish#concrete walls#custom pool fence#glass facade#concrete finish

0 notes

Text

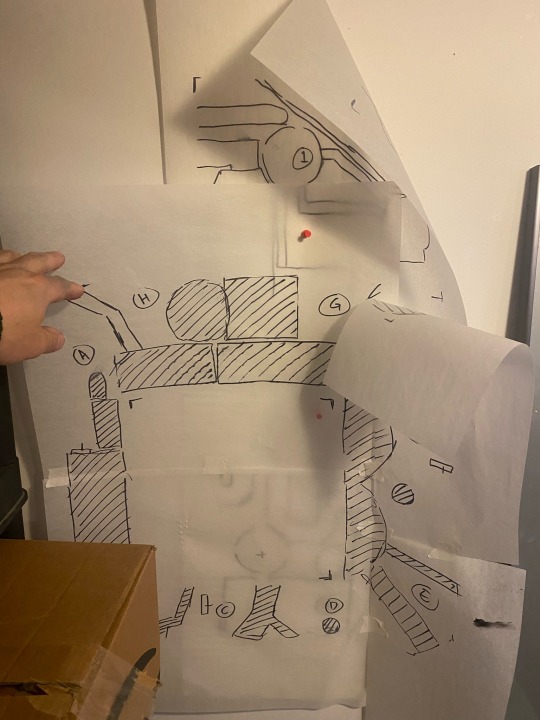

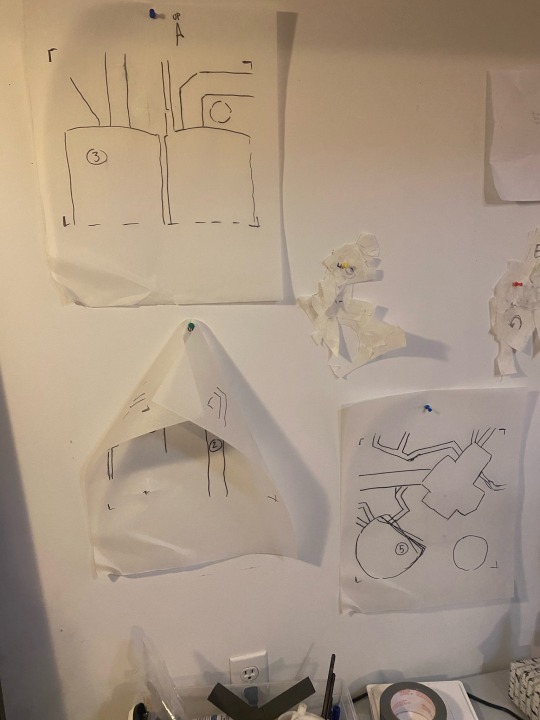

BIOMECH TOWER

I fucked up!! Cost myself hours of work! Big time lessons learnt today!

So I had spent all this time texturing the cryopak cube with spackle, to achieve a concrete-like texture. All good. Then I decided to modpodge the whole thing, thinking (probably correctly) that the powdery crumbly surface would be lousy for attaching large subassemblies to; once that had dried, it was clear that I HAD OBLITERATED THE SPACKLE TEXTURE AND HAD CREATED A GLOSSY SMOOTH CUBE. So mad!!

So I decided to use a different concrete technique to retexture the cube, where you mix equal parts water/pva/flour/black paint. Out of my depth at this point, never done this before. Brush leaving telltale lines, switched to sponge; sponge creates a texture much like the styrofoam I set out to hide in the first place! Switched to 2" drywall trowel, worked better. Now the cube is black and ready for grey base coat tomorrow... this stuff smells awful.

Made a decision that there will be two principal textures on this piece: concrete and steel. The texture/paint process for each is different, so I needed to decide what was what, right now.

It basically goes like this:

The subassemblies are (almost) all to be painted as steel. That means they'll be base coated in black, then a dark brown, then metallic drybrush, then chipping medium (latex masking fluid), then color (if applicable), then weathering work, then varnished.

The cube and the horizontal part of the platform will be concrete. That means black texture mix, then grey base coat, then greyscale layering, then weathering, then varnish.

What I've left out in the above process is considering how to texture/paint the places where these parts intersect. I've never worked on a project with two fundamentally different textures occupying each such large parts of the structure and details. I have time to think about it though; there is a lot of work to be done before this problem needs to be solved.

Right now, I find I only have patience for work that makes big moves towards the completion of this project. That's a problem. As I have mentioned before, I make mistakes when I get impatient. I hope that I will rediscover joy in the tiny details, since there are so many; I do expect the finishing work to take some time. I must remember the Eureka principle and not be afraid to take breaks from the project...

NOTE: I added a couple picture of the way I have decide to record and transpose the markings that I've made on the various subassemblies. I'm just using big old sheets of tracing paper, taped together when necessary, and if I am later in doubt as to what goes where these sheets will help.

What would I sell this thing for? Someone asked me, and since I've never sold a piece before I really had no idea what to say. For some reason I want to say $1350 CAD. If I was honest, I would have trouble selling it for even that much. By the time I'm done, this piece will have consumed literal hundreds of hours of time, across probably 6-8 months (I have a day job).

Anyway this long weekend has been great. Tons of work done, massive progress made.

8 notes

·

View notes

Note

heeeey pspsp id love to hear about your fangan !!! give me all the ch 3 details boss :3

Its been a while sinse I said I'd make a doc huh, well I'm finished with the doc, but I'm not gonna talk about chapter 3 cuz maybe one day this will be an actual thing and I dont wanna give spoilers.

The name of my Fangan is: Danganronpa Deadly Debates (DRDD)

I did not intentionally make it alliterative

Themes

Lies vs Truth

Justice vs Injustice

Actions vs Intentions

Guilt and Shame

Setting

Modern Day America

Campsite

UTOAC (oo - TOKE)

Ultimate Talent Observation and Appreciation Committee

A Committee that chooses 16 talented individuals between the ages of 15 and 25 and makes them Ultimates.

Ultimates are inducted in a public ceremony

A month later, sometime in the fall, each Ultimate receives an invitation from the UTOAC to a talent development event where they can meet their fellow Ultimates and hone their talents.

Characters-

Phoebe Womack

Ultimate Attorney F 18 5’6” DOB Oct 12

She has dark brown straight hair that reaches to her lower back. Her eyes are brown. She wears a blue suit with white underneath and black shoes. Her cuffs are rolled and she has a black belt with a silver buckle. A silver necklace with the libra scales is around her neck and has pear-cut pink tourmaline stud earrings.

Currently still in school, but she is the top of her class. She has an inferiority complex and impostor syndrome.

Benji Eldred

Ultimate Prosecutor M 20 5’11” DOB May 27

He has short, light-brown hair with a cowlick in the front. He has light green eyes He wears rectangle frame glasses. He has a white collared shirt with a light brown leather blazer over top, He wears jeans, which he cuffs with no belt and black socks and brown tennis shoes. He wears a sterling silver band around his right middle finger.

Basically the opposite of Phoebe, he’s extremely confident in his abilities and expects other to respect him at all times because of that. He’s not interested in helping investigate, unless it’s a murder case, and when he does he keeps all his finding to himself.

Hannah Fritzen

Ultimate Florist F 16 5'3" DOB Feb 19

She has brown hair that is braided on both sides of her head and wrapped into space buns. The bun on her left has a pink rose and purple chrysanthemum sticking out of it. Pink eyes. She wears a light red T-shirt, denim overalls, green gardening gloves, and a tool belt with a small garden trowel in it. She has brown boots.

Was depressed, but gardening and flower arangements brought her happiness when she needed it. Comes off as friendly and naive, but she will call out bullshit when she sees it.

Serena Ackerman

Ultimate Judge F 16 5'1” DOB Oct 21

Idk what kind of hair to give her, but she’s wearing one of those black judge’s robes. Blue eyes. She’s native american.

Still in school, but at the top of her class. She seems to be unprofessional and inexperienced, which causes other to become suspicious of who she truly is.

Nadia Harman

Ultimate Sailor F 17 5'8" DOB Apr 1

Blue hair and a white sailor’s uniform and hat with blue neckerchief. Cyan Eyes

Left her home when she was young and lives with an older widowed gentleman by the sea. She’s humble but boisterous, often to an excessive amount where others don’t want to be around her.

Walter Caulfield

Ultimate Antarctic Researcher M 16 5'6" DOB Dec 19

He has medium-length subtle purple hair and light grey eyes. He wears a grey ushanka with the flaps tied on top. He has an unzipped brown winter coat lined with light brown fur. Underneath he has a grey shirt with some sort of design. He’s got grey fingerless mittens and jeans with steel-toed brown winter boots. He has darker skin.

He’s not pompous, but he is a very selfish person. As an only child he never had to share or be nice to a sibling and he was often not reprimanded for his behavior and now he’s paying the social price.

Naomi Akabane

Ultimate Fashion Model F 19 6'0" DOB Mar 3

She has a curly dark blue/purple pixie cut and light blue and gold hoop earrings. Her shirt is a custom-tailored red sweater with this texture that covers her mouth and nose. It has full-length sleeves and round cutouts around her waist. She has Black leggings and Ugg-like boots with fur at the top. She also has the same kind of (Boa?) that Yoruko Kabuya from SDRA2 has, just smaller at the top. Has a rose quartz crystal pendant necklace Also has some sort of bracelets IDK what kind though.

She Believes that make-up is terrible and that only fashion models are true models. Overly cautious about her appearance. She is very consistant with eating a health diet and getting exercise.

Ryder Seabrooke

Ultimate Food Critic M 18 5'7" DOB Jun 26

Not a clue what he is wearing or what he looks like.

He is reserved and observant, he tends not to get in the way, but when he is excited, he can’t hide that fact.

Alannah Otis

Ultimate Crime Scene Investigator F 21 5'5" DOB Feb 23

She’s wearing one of those white investigation hazmat suits with the hood down and no face mask. The Sleeves are rolled up to her elbows, but she is wearing blue gloves. The suit goes down to her ankles and she has her normal shoes on. (IDK what shoes, eyes, hair, or accessories to give her.)

Due to her work she has become desensitized to death and comes off as cold and emotionless. She is very smart though and doesn’t ted to miss details

Wyatt “Wyrqa” Kaiser

Ultimate Graffiti Artist M 16 5'4" DOB Nov 25

Medium-length blonde hair with red tips. Green Eyes His left ear has two silver loop earrings on the lobe and an industrial. On his right, he has a loop on the lobe and two bands on his upper cartilage. He has a green sweatshirt with some sort of colorful design and ripped black jeans. All his clothing has spraypaint all over it. He wears a white painter’s mask constantly.

He’s combative, stubborn, and a delinquent. He prefers to work alone, and that’s where he gets his best art done. He is really creative and expressive, but he tends to let his emotions get the best of him.

Keiko Shimura

Ultimate Chemist F 15 5'0" DOB Sept 6

Light blue medium-length bobbed hair She is normally blind, but she wears an oculus-like headset over her eyes that allows her to see. The from has blue pixelated eyes that change based on emotion. She has a white lab coat. I think I want to have her wear a belt on the outside of her lab coat around her waist, but I’m not sure that would look good or not. Her nails are painted rainbow.

Born in Japan and only speaks Japanese, she is very meak and anxious. She is basically a voluntary outcast, not wanting to have people notice her.

Stellan Bjorn

Ultimate Bounty Hunter M 22 6'3" DOB Aug 16

Not a clue what he is wearing or what he looks like, but I do know I want him to have a black choker and gold ring bands on every finger except the thumbs. Light red eyes and decent muscles (not like sakura, gonta, or nekomaru though.) (More like mondo.)

Intimidating but actually super friendly and sociable. Prefers to talk to others rather than be alone, but when angered he can become very intense and frightening.

Olivia Sakaguchi

Ultimate Translator F 17 5'7" DOB Jul 4

I have a very specific for how I want her hair to look and I’m not sure if it will come across well in writing, but I’ll try my best. Black hair. On her left side, (our right when facing her head on) has a bun stuck together with a zanzi hair pin vertically but at the top some hairs are sticking out. On her right (Our left) it is a braid sticking straight downwards with an orange hair tie. She is half Cameroonian and half Japanese, but her skin is very dark and she has very dark hair. (basically unless she told you, you wouldn’t know she is any part Japanese. It is important to her character lore.) She wears a shirt like the one below, only it is more of a dark tan, like a color around Hex #A08155-ish, and the sleeves are rolled up to her elbows. She has a medium-small brown backpack that she wears over her right shoulder and it hangs down and you can see it to her side. She wears khaki pants with a brown belt. The ends are cuffed and she wears Black boots. She has black circular rimmed glasses and hazel eyes. (can you tell I’ve thought the most over her design?)

Shes Very interested in linguistics and would rather focus on her studies than partake in activities. A very good teacher. Surprisingly patient. Serious personality, doesn’t make jokes.

Rhyse Whitaker

Ultimate Costume Designer M 17 5'10" DOB Jan 17

Brown hair. His outfit is eclectic and chaotic on purpose. He wears a gold-colored aluminum crown, a blue superhero cape, black fingerless biker gloves, spurred cowboy boots, white collared shirt with pink and white pawprint patterned tie, and red and white plaid patterned pajama pants. In one of his sprites he puts on glasses that have a fake mustache on the bottom, and on another he puts on springy-slinkie googly eye glasses. Blue eyes.

Goofy and jokey. Likes to have a lot of fun. Tends to not realize the tone of situations and makes jokes at the wrong time. Gets platonically attached really easily.

Abel Mortimar

Ultimate Angler M 17 5'8" DOB Jul 9

Not a clue what he is wearing or what he looks like

Really chill almost all the time, doesn’t get upset very often. Sometimes comes off as uncaring.

Izaac Wolfe

Ultimate Veterinarian M 19 5'6" DOB Dec 26

IDK hair. White doctors coat with dogbone logo on pocket and blue scrubs shirt underneath. Dark grey pants and blue shoes. His right eye Brown, his left eye grey.

Personable and relatable. Seems to be a normal guy, but he is keenly interested in macabre subjects like horror and death. Not to an overly concerning degree. (Like Veronika Grebenshchikova from DRDT is) doesn’t like to be uninformed.

If you want to draw any of these characters go ahead, just be sure to tag me in the finished product.

I’m not going to go into details about the cases but I can tell you the motives for chapters 2-4

General Plot-

Chapter 2

Secrets: Each participant is given another participant’s secret at random. In 2 days the contents of each secret will be revealed. The next day who recieved each secret. The next day who each secret is for. The last day the secrets will be revealed to the public. The deads’ secrets are not in the mix but will still be revealed with everyone else’s.

Chapter 3

Personal Weapons: Each participant is given a unique and personalized weapon to aid in murder. The four deceased participants’ weapons were placed in the storage shed and are accessible to everyone. The details of each participant’s weapons are not publicly disclosed and are left to each participant’s discretion as to whether or not they choose to reveal their weapon.

Chapter 4

BDA time limit: 24 hours after a murder occurs, if the BDA is not set off, the murderer will automatically win and everyone else will be executed.

I have not thought of the motives for chapters 1 or 5

1 note

·

View note

Text

With a focus on customer satisfaction and high-quality results

A Concrete driveway installation is a significant home improvement project that can greatly enhance the curb appeal and functionality of your property. Concrete driveways are highly valued for their durability, low maintenance, and ability to withstand harsh weather conditions, making them an ideal choice for homeowners seeking a long-lasting solution.

In this blog, we will dive into the steps, considerations, and benefits of Concrete driveway installation, covering everything from preparation to finishing touches. Whether you’re replacing an old driveway or installing a new one, understanding the process is crucial to achieving a smooth and durable surface that complements your home's aesthetic.

Planning and Design

The first step in installing a concrete driveway is careful planning. Before any work begins, it's essential to determine the size and shape of the driveway to ensure it fits the layout of your property. Considerations include the slope for drainage, the width for vehicles, and whether additional features like curbing, borders, or decorative elements will be incorporated. At this stage, it's also important to check with local zoning regulations for any permits or codes that may apply.

Preparation

Proper site preparation is key to ensuring the longevity of your concrete driveway. This phase involves removing the old driveway (if applicable), clearing the area of debris, and excavating the soil to the required depth. A solid foundation of gravel or crushed stone is typically laid down to promote drainage and prevent cracking. Compaction of the soil ensures the driveway will remain stable over time.

Forming and Reinforcement

Once the base is prepared, the next step is to build forms around the perimeter of the driveway. These forms serve as molds to shape the concrete as it cures. Steel reinforcement bars (rebar) or wire mesh are often placed within the forms to provide additional strength to the concrete, preventing cracks from forming under pressure.

Pouring and Finishing

The concrete mix is then poured into the forms, and it’s carefully leveled and smoothed using specialized tools. For a durable and smooth finish, the concrete is troweled, and any air bubbles are removed. Depending on your design preference, you can opt for a standard gray finish, or you can add color, texture, or patterns to enhance the aesthetic appeal of your driveway.

Curing

After the concrete has been poured and finished, it needs time to cure properly. Curing is the process where the concrete hardens and gains strength, typically taking around 7 days for initial curing. During this period, it’s crucial to keep the surface moist to prevent cracking and ensure the concrete sets evenly.

Sealing

After the concrete has fully cured, sealing the driveway helps protect it from stains, weathering, and the elements. A high-quality concrete sealant not only improves the longevity of the driveway but can also enhance its color and finish. Sealants come in various types, including acrylic, polyurethane, and epoxy, depending on the desired finish and level of protection.

Maintenance and Care

One of the major advantages of concrete driveways is their low maintenance requirements. However, occasional maintenance will help keep the driveway looking its best. Regular cleaning, periodic sealing, and repairing small cracks as they appear will extend the lifespan of your driveway and keep it looking fresh for years.

Benefits of Concrete driveway installation:

Durability: Concrete is one of the longest-lasting materials, capable of withstanding the weight of vehicles and the wear and tear of daily use.

Low Maintenance: Concrete requires minimal upkeep compared to other materials like asphalt or gravel, saving you time and money in the long run.

Customization: Concrete driveways can be customized with a variety of finishes, colors, and patterns to complement your home’s design.

Increased Property Value: A well-installed concrete driveway can increase the resale value of your home, making it a worthwhile investment.

Weather Resistance: Concrete driveways are resistant to damage from UV rays, rain, snow, and extreme temperatures.

Conclusion

Investing in Concrete driveway installation is a smart decision for homeowners looking to add value and functionality to their property. While the installation process may seem complex, working with a professional contractor can ensure that your driveway is built to last. With proper care and maintenance, your concrete driveway will provide years of reliable service, enhancing the overall appearance and value of your home.

1 note

·

View note

Text

Venetian Plaster Application in Los Angeles

Venetian plaster is a centuries-old decorative technique that originated in Italy, primarily used in grand Venetian palaces and aristocratic homes. Composed primarily of slaked lime and marble dust, this plastering technique is prized for its deep, glossy finish that resembles polished stone or marble. The process involves the application of multiple layers, resulting in a smooth, reflective surface that can transform any space.

In Los Angeles, Venetian plaster has gained popularity as homeowners seek ways to blend European elegance with modern design. It is commonly used in living rooms, kitchens, bedrooms, and even bathrooms, where it lends a sophisticated, artistic look. The flexibility of Venetian plaster, which can be customized to fit any aesthetic, makes it a favorite among LA’s interior designers and property owners looking to elevate their interiors.

The Process of Venetian Plaster Application in Los Angeles

Achieving the perfect Venetian plaster finish requires expertise, precision, and patience. For those seeking the highest quality Venetian plaster application in Los Angeles, it’s essential to understand the steps involved in the process. Each phase builds upon the last to create a beautiful, seamless finish that complements the city’s chic and diverse architectural styles.

The process begins with the preparation of the wall. Walls must be cleaned, sanded, and repaired to ensure a smooth foundation for the plaster. Applying a primer is crucial, as it helps the plaster adhere better to the wall and ensures an even application. Following the primer, the first layer of plaster is applied, usually in a base coat that provides the foundation for the multiple layers to follow.

Once the base layer is dry, additional coats are meticulously applied, with each layer smoothed and polished to bring out the rich, velvety texture unique to Venetian plaster. Professional artisans often use steel trowels or spatulas to create the distinctive sheen and depth, resulting in a finish that can range from soft and matte to highly polished and reflective. Each step in the application is an art form, requiring skill and a deep understanding of the medium.

Benefits of Venetian Plaster for Interior Design in Los Angeles

With a unique aesthetic that cannot be replicated by other wall finishes, Venetian plaster offers several benefits. Its timeless appeal makes it a worthy investment for homeowners in Los Angeles, where innovative design and trendsetting styles are always in demand.

One of the standout benefits of Venetian plaster is its durability. When properly applied, Venetian plaster can last for decades, maintaining its beauty with minimal maintenance. Unlike traditional paint, which can chip or fade over time, this finish ages gracefully, developing a natural patina that enhances its allure. In Los Angeles, where the weather can be harsh, this durability makes Venetian plaster an excellent choice for both residential and commercial properties.

The plaster is also highly resistant to mold and mildew, making it suitable for humid environments like bathrooms or kitchens. Its natural breathability prevents moisture buildup, which not only adds to its longevity but also creates a healthier indoor environment.

For those looking to create unique and luxurious interiors, the versatility of Venetian plaster cannot be overstated. It can be tinted with pigments to match any color palette, allowing homeowners to achieve the perfect shade and style to complement their decor. In Los Angeles, decorative wall painting is a popular way to personalize spaces, and Venetian plaster is an ideal medium for adding artistic flair.

The Role of Los Angeles Decorative Wall Painting in Modern Interiors

The concept of Los Angeles decorative wall painting has evolved over the years, moving beyond simple paint colors to include a variety of textures, finishes, and artistic techniques. Venetian plaster is at the forefront of this movement, offering a highly customizable option for those looking to make a statement with their interiors.

Decorative wall painting in Los Angeles often involves combining different textures and techniques to create visually striking effects. Venetian plaster, with its luxurious texture, complements other decorative finishes beautifully. It can be paired with metallic accents, stucco finishes, or custom murals, allowing homeowners to create spaces that reflect their individual style and taste.

In modern interiors, Venetian plaster can be used to highlight architectural features such as columns, fireplaces, or accent walls. In addition to adding elegance and sophistication, it provides a focal point that draws the eye and enhances the room’s overall design. The combination of Venetian plaster and decorative wall painting techniques enables homeowners and designers to achieve a truly unique aesthetic that is both timeless and contemporary.

Why Choose Professional Venetian Plaster Services in Los Angeles?

While DIY options are available, achieving a flawless Venetian plaster finish requires the skill of a trained professional. For those in Los Angeles seeking quality Venetian plaster application, hiring an experienced artisan is essential to ensure a lasting and beautiful result. Professionals understand the intricate process of layering, smoothing, and polishing the plaster to bring out its signature luster and depth.

Professional plaster artists in Los Angeles are well-versed in creating custom textures and effects tailored to each client’s taste. From high-gloss finishes that exude luxury to soft, matte looks that offer understated elegance, a skilled artisan can bring any vision to life. Additionally, a professional ensures that the plaster is applied correctly, which is key to maximizing its longevity and resilience.

The Lasting Appeal of Venetian Plaster in Los Angeles

Venetian plaster has carved a special niche in the world of Los Angeles interior design. Its timeless elegance, coupled with its adaptability to modern aesthetics, makes it a preferred choice for those looking to enhance their living spaces. The demand for Los Angeles decorative wall painting continues to grow, and Venetian plaster stands out as a sophisticated option that brings depth, beauty, and artistry to any room.

Whether you’re renovating a single room or designing an entire home, the inclusion of Venetian plaster can elevate your interior to a level of sophistication that few other materials can achieve. The process may be intricate, but the end result—a beautifully polished, luxurious wall finish—is well worth the effort.

0 notes

Text

Top 5 Must-Have Plastering Tools for Perfect Finishes

When it comes to achieving smooth and flawless plaster finishes, the right tools can make all the difference. Plastering is an art that requires skill and precision, and having the right plastering tools at your disposal can elevate your work from good to exceptional. Whether you’re a seasoned professional or a DIY enthusiast, understanding which tools are essential will help you achieve the best results in your plastering projects. In this article, we will explore the top five must-have plastering tools that every plasterer should have in their toolkit.

1. Trowel

The trowel is arguably the most important tool for plastering. Available in various shapes and sizes, it allows for the application and smoothing of plaster onto walls and ceilings. A stainless steel trowel is preferred for its durability and resistance to rust. A flexible trowel can help achieve finer finishes, while a larger trowel is useful for covering more extensive areas quickly. Mastering the use of a trowel will greatly enhance your plastering technique, allowing you to create the perfect base for painting or decorating.

2. Hawk

The hawk is a flat, square platform with a handle on the bottom, used for holding plaster as you work. It allows for a more efficient application process by keeping the plaster within easy reach, minimizing the number of trips to your mixing area. Using a hawk also helps ensure that you maintain a consistent amount of plaster on your trowel, which is crucial for achieving even coats. A well-crafted hawk made from lightweight material can make a significant difference in the comfort and speed of your plastering tasks.

3. Plastering Float

A plastering float is essential for smoothing out the surface of your plaster after it has been applied. It helps to remove any imperfections and creates a uniform finish. There are different types of floats, such as those made from rubber or foam, which can create varying textures on the surface. A float can also be used to apply a final coat of plaster, ensuring that your work has a professional look. Choosing the right float for your plastering style will enhance your final results.

4. Corner Trowel

For those hard-to-reach areas, a corner trowel is an indispensable tool. This specialized trowel is designed to help you create sharp, clean corners in your plastering work, which is essential for a polished finish. It allows you to maneuver easily around edges without damaging the surrounding areas. Using a corner trowel will not only improve the quality of your plastering but also save time by reducing the need for touch-ups in these tricky spots.

Conclusion

Investing in the right plastering tools is key to achieving professional-grade finishes in your plastering projects. A trowel, hawk, plastering float, and corner trowel are must-haves for anyone looking to create smooth, flawless surfaces. By equipping yourself with these essential plastering tools, you can enhance your skills and achieve the perfect finishes that will impress clients and guests alike. Remember, the right tools not only improve your work quality but also make the plastering process more enjoyable and efficient.

1 note

·

View note

Text

Concrete Pourer: Essential Guide for Successful Concrete Projects

Concrete pouring is a critical aspect of construction that requires precision, expertise, and careful planning. A concrete pourer plays a crucial role in ensuring that concrete is placed correctly and finishes to the highest quality. This guide provides a comprehensive overview of the role of a concrete pourer, the pouring process, best practices, career insights, and more.

Understanding the Role of a Concrete Pourer

What is a Concrete Pourer?

A concrete pourer is a skilled professional responsible for placing and finishing concrete in construction projects. This role involves various tasks, from preparing the site and mixing the concrete to pouring it into forms and ensuring it sets correctly. Concrete pourers must work closely with other construction workers, such as concrete finishers and site supervisors, to achieve the desired results.

Key Skills and Qualifications of a Concrete Pourer

To excel in concrete pouring, several skills and qualifications are essential:

Technical Skills: Knowledge of concrete mix designs, curing methods, and finishing techniques.

Physical Stamina: Ability to handle the physical demands of the job, including lifting heavy materials and working in various weather conditions.

Attention to Detail: Precision in measuring and placing concrete to avoid defects and ensure quality.

Certifications: Depending on the region, certifications or licenses may be required, such as those related to safety and equipment operation.

Importance of a Concrete Pourer in Construction

The success of a construction project heavily relies on the expertise of a concrete pourer. Proper concrete pouring ensures structural integrity, durability, and aesthetic quality. An experienced concrete pourer helps prevent issues such as cracks, uneven surfaces, or poor adhesion, contributing to the overall success of the project.

The Concrete Pouring Process

Steps Involved in Concrete Pouring

Site Preparation: The site must be cleaned and properly prepared to receive concrete. This includes setting up forms, reinforcing steel if needed, and ensuring the area is level and free of debris.

Mixing Concrete: The concrete mix must be prepared according to the specifications of the project. This involves combining cement, sand, gravel, and water in the correct proportions.

Pouring Concrete: The concrete is poured into the prepared forms using tools such as hoses or chutes. The pourer must ensure even distribution and avoid segregation of the mix.

Finishing: After pouring, the concrete surface is leveled and smoothed using trowels or other finishing tools. Techniques such as floating and edging may be used to achieve the desired finish.

Curing: Proper curing is essential to ensure that the concrete achieves its full strength and durability. This involves keeping the concrete moist and at the right temperature for a specified period.

Equipment Used by Concrete Pourers

Concrete pourers use various tools and machinery to complete their tasks:

Concrete Mixers: For preparing the concrete mix on-site.

Concrete Pumps: To transport concrete from the mixer to the pour site, especially in large or difficult-to-reach areas.

Trowels and Floats: For finishing the surface of the concrete.

Vibrators: To remove air bubbles and ensure proper compaction of the concrete.

Common Challenges and Solutions

Concrete pouring presents several challenges, including:

Weather Conditions: Extreme temperatures can affect the curing process. Solutions include using additives to adjust the setting time or covering the concrete to protect it from the elements.

Formwork Issues: Poorly constructed forms can lead to defects. Ensuring that forms are correctly installed and secured can prevent problems.

Mix Quality: Variations in the concrete mix can cause issues. Properly mixing and testing the concrete before use helps ensure consistency.

Best Practices for Concrete Pouring

Preparation for a Concrete Pour

Successful concrete pouring starts with thorough preparation:

Site Inspection: Check the site for any issues that might affect the pour, such as drainage problems or obstructions.

Formwork Setup: Ensure that forms are properly aligned, secured, and free of gaps.

Material Readiness: Verify that all materials, including concrete, reinforcing steel, and tools, are ready and in good condition.

Techniques for Ensuring Quality

To achieve a high-quality finish:

Proper Placement: Pour concrete in a continuous flow to avoid cold joints and ensure uniformity.

Effective Finishing: Use appropriate finishing techniques to achieve the desired surface texture and smoothness.

Curing: Follow recommended curing practices to maintain moisture and temperature, which helps the concrete reach its maximum strength.

Post-Pour Care and Maintenance

After pouring, it's crucial to:

Monitor Curing: Check that the curing process is proceeding as planned and adjust as needed.

Inspect for Defects: Look for any signs of issues, such as cracks or uneven surfaces, and address them promptly.

Clean Equipment: Properly clean and maintain equipment to ensure its longevity and performance for future projects.

Career Insights for Concrete Pourers

Career Path and Opportunities

A career as a concrete pourer offers various opportunities for advancement:

Specialization: Gaining expertise in specific types of concrete work, such as decorative concrete or high-strength mixes.

Supervisory Roles: Moving into supervisory or management positions within construction companies.

Training and Mentoring: Sharing knowledge and skills with new concrete pourers or working as a trainer.

Training and Education

Aspiring concrete pourers should consider:

Vocational Training: Enrolling in vocational courses or apprenticeships that focus on concrete work and construction techniques.

Certifications: Obtaining certifications related to concrete technology, safety, and equipment operation.

On-the-Job Experience: Gaining hands-on experience through internships or entry-level positions in the construction industry.

Day in the Life of a Concrete Pourer

A typical workday involves:

Early Start: Arriving early to prepare the site and equipment for the day’s work.

Site Coordination: Working with other team members to ensure smooth operations and address any issues.

Concrete Pouring: Handling the pouring, finishing, and curing of concrete as per project specifications.

End-of-Day Tasks: Cleaning equipment, reviewing the day’s work, and preparing for the next phase of the project.

Innovations and Trends in Concrete Pouring

Technological Advancements

Recent innovations include:

Automated Concrete Mixers: Enhancing precision and consistency in mixing.

Advanced Pumping Equipment: New technologies that improve efficiency and reduce downtime.

Digital Monitoring: Using sensors and software to monitor concrete placement and curing conditions.

Sustainable Practices in Concrete Pouring

Modern concrete pouring practices are increasingly focused on sustainability:

Eco-Friendly Materials: Incorporating recycled materials and reducing the carbon footprint of concrete.

Efficient Resource Use: Optimizing material use and minimizing waste.

Green Building Standards: Adhering to standards that promote environmental responsibility in construction.

Future Trends and Predictions

Looking ahead, the concrete pouring industry may see:

Increased Automation: Greater use of robotic systems and automated machinery.

Enhanced Sustainability: Further innovations in eco-friendly materials and practices.

Advanced Training: More sophisticated training programs incorporating new technologies and methods.

Tips for Hiring a Concrete Pourer

What to Look for in a Concrete Pourer

When hiring a concrete pourer, consider:

Experience: Look for a pourer with relevant experience in similar projects.

Certifications: Ensure they have the necessary certifications and training.

Reputation: Check references and reviews from previous clients.

Questions to Ask Potential Candidates

Important questions include:

Experience with Specific Projects: Inquire about their experience with the type of project you are undertaking.

Approach to Quality Control: Ask how they ensure the quality and durability of their work.

Problem-Solving Skills: Discuss how they handle common challenges and unexpected issues.

Evaluating Quotes and Proposals

To make an informed decision:

Compare Quotes: Review quotes from multiple candidates to understand cost and value.

Assess Proposals: Look for detailed proposals that outline the scope of work, timelines, and materials used.

Consider Value: Evaluate the overall value, including the pourer’s expertise and the quality of their work.

Conclusion

A concrete pourer plays a vital role in the success of construction projects by ensuring that concrete is poured and finished to the highest standards. Understanding their role, the pouring process, and best practices can help achieve quality results. With the right skills, training, and adherence to best practices, concrete pourers contribute significantly to the durability and aesthetic appeal of construction projects.

0 notes

Text

Expert Tips from a Concrete Flooring Contractor in Idaho Falls

Concrete flooring has become an increasingly popular choice for homeowners, DIY enthusiasts, and interior designers. Its durability, versatility, and aesthetic appeal make it an excellent option for various spaces, from garages to living rooms. But achieving the perfect concrete floor requires expertise, and who better to provide that than a seasoned concrete flooring contractor in Idaho Falls? Here are some expert tips to help you get started.

Proper Site Preparation

One of the key elements of a successful concrete floor is proper site preparation. This step is crucial for ensuring the longevity and quality of your concrete floor.

Why is Site Preparation Important?

Proper site preparation sets the foundation for a durable concrete floor. Neglecting this step can lead to issues like cracking, uneven surfaces, and poor drainage.

Tips for Proper Site Preparation

Clear the Area: Remove any debris, plants, or old concrete from the site.

Level the Ground: Use a shovel or a mechanical grader to level the ground. Uneven ground can result in an uneven concrete surface.

Compact the Soil: Compact the soil to ensure stability. You can use a hand tamper or a plate compactor for this task.

Install a Gravel Base: Lay down a layer of gravel to improve drainage and provide a stable base for the concrete.

Choosing the Right Type of Concrete

Not all concrete is created equal. Different types of concrete are suited for different projects.

Types of Concrete and Their Uses

Standard Concrete: Ideal for most residential flooring projects.

High-Strength Concrete: Best for heavy-duty areas like driveways and industrial floors.

Stamped Concrete: Perfect for decorative purposes, offering a range of patterns and textures.

Polished Concrete: Provides a sleek, shiny finish suitable for modern interiors.

Choosing the Right Concrete for Your Project

Consider the specific needs of your project. For example, if you're installing a concrete floor in your garage, high-strength concrete might be the best option due to its durability.

Understanding Concrete Sealers

Concrete sealers play a vital role in maintaining the longevity of your floors. They protect the concrete from stains, moisture, and wear and tear.

Importance of Sealers

Sealers act as a protective barrier, preventing water, oil, and other contaminants from penetrating the concrete. They also enhance the appearance of your floors by adding a glossy or matte finish.

Types of Concrete Sealers

Acrylic Sealers: Quick-drying and easy to apply, suitable for indoor and outdoor use.

Epoxy Sealers: Highly durable, ideal for high-traffic areas.

Polyurethane Sealers: Offer excellent protection but require more time to apply and cure.

Achieving a Smooth and Level Finish

A smooth, level finish is essential for both the appearance and functionality of your concrete floor.

Step-by-Step Guidance

Pour the Concrete: Ensure an even pour to avoid air pockets.

Screed the Surface: Use a screed board to level the concrete.

Float the Surface: Use a bull float to smooth the surface and push down any aggregate.

Trowel the Surface: For a polished finish, use a steel trowel.

Cure the Concrete: Cover the concrete with a curing compound to retain moisture and prevent cracking.

Common Mistakes to Avoid

Pouring too much concrete at once.

Not using a level to check the surface.

Skipping the curing process.

Incorporating Decorative Elements

Concrete floors don't have to be plain and boring. Adding decorative elements can enhance their aesthetic appeal.

Ideas for Decorative Elements

Staining: Adds color to your concrete floor.

Stamping: Creates patterns and textures that mimic natural stone or tile.

Scoring: Involves cutting shallow lines to create geometric designs.

Inlays: Embedding materials like tiles or stones into the concrete.

When to Incorporate Decorative Elements

The best time to add decorative elements is during the initial pouring and finishing stages. This ensures they are well-integrated into the concrete.

Conclusion

Creating the perfect concrete floor involves several steps, from proper site preparation to choosing the right type of concrete and incorporating decorative elements. Each step plays a crucial role in ensuring the durability, functionality, and aesthetic appeal of your floor. By following these expert tips from a concrete flooring contractor in Idaho Falls, you can achieve a beautiful and long-lasting concrete floor.

0 notes

Text

Advanced Plastering Tools for Professional Results 🚀

Mastering the art of plastering requires both skill and the right tools. Whether you’re tackling a large commercial project or a small home renovation, the correct plastering tools will help you achieve a professional finish every time.

1. The Ultimate Plastering Trowel Collection ��️

Investing in a high-quality set of trowels is essential for any plasterer. From standard finishing trowels to specialized corner trowels, each tool has a specific function that contributes to the overall finish. For a smooth and even application, opt for stainless steel trowels with a comfortable grip.

2. Power Mixers: Save Time, Increase Efficiency ⚡

Hand-mixing plaster can be time-consuming and inconsistent. A power mixer ensures a uniform mix, saving you time and effort. With adjustable speed settings, power mixers provide greater control over the plaster's consistency, leading to better application results.

3. Plastering Floats: Essential for Smooth Finishes 💎

Floats come in various materials, including plastic, wood, and magnesium. Each type is suited for different stages of the plastering process. A plastic float is excellent for final smoothing, while a magnesium float is ideal for the initial leveling of plaster.

4. Measuring Tools: Precision Matters 📏

Accuracy is key in plastering. Laser levels, tape measures, and spirit levels are crucial for ensuring your work is straight and even. Proper measuring tools help avoid costly mistakes and ensure a professional-grade finish.

5. Specialty Tools: Elevate Your Craft 🎯

For advanced plastering tasks, specialty tools like texture rollers, corner beads, and joint knives are indispensable. These tools allow you to create unique textures and details, adding a touch of artistry to your work.

Shop the Best at PlasteringSupplies.com.au

At plasteringsupplies.com.au, we provide advanced plastering tools for professionals who demand the best. Our tools are designed to help you work faster, more efficiently, and with better results.

Let's Connect! 📞

Have questions about our products? Our team is here to help you find the perfect tools for your next project.

📧 Email: [email protected] 📞 Phone: 123-456-7890 🌐 Visit: plasteringsupplies.com.au

0 notes

Photo

Make it floorwise For a Fantastic LVT Installation

With everything needed to start off a fantastic LVT floor, floorwise makes it easy and affordable to deliver customers a high-quality installation.

Luxury vinyl is flooring’s growth area with homes and businesses both embracing the product’s easy living nature. Yet, as any experienced floor installer will know, making sure you give a high quality LVT installation is not so easy and takes time, effort and expertise. Fortunately, with floorwise at your side you can be confident that your skills and expertise will be matched by tools, installation and finishing products that provide quality and floorwise’s famous value.

Quality tools are essential part of making the installation run as smoothly as possible. floorwise distributors across the UK, Ireland and Europe carry a comprehensive range of tools from the world’s best manufacturers. Including surface preparation tools such as the Flex Power Stripper, Long handled scrapers, screeding and adhesive trowels, primer and aeration rollers, pin levellers and stirring stations, LVT laying equipment such as the large plank design cutter, LVT cutters, and small pressure and heavy duty 75kg rollers; there’s a tool for every job.

Every installer knows that an LVT installation will only ever be as good as the subfloor and so good preparation is key. Failure to ensure a smooth, flat and well-prepared substrate will compromise the installation in terms of appearance and potential failure. With the new products in the Pro-Screed line, floorwise is giving installers everything they need to prepare a floor to the exacting tolerances needed.

For a great problem-solver and time-saver, Pro-Screed Ultra is rapid setting smoothing and levelling compound that it is capable of receiving LVT floors in just three-hours. It can also be poured over old adhesive residue and DPMs and no priming is required on most subfloors. For subfloors that need a little more work, Pro-Screed Xtra is fibre-reinforced for extra strength and flexibility. It’s also moisture tolerant so can be used above or beneath DPMs. Just like Pro-Screed Ultra, Xtra has an install time of just three-hours, making it a true all-rounder.

With Dura for value and Feather for patch repairs, as well as the best-selling and award-winning Pro-Screed Gold, the Pro-Screed range can tackle all subfloor preparation requirements before laying an LVT floor.

When it comes to the job of sticking down, floorwise distributors offer a host of branded adhesive solutions for the job. With floorwise cartridge adhesives and sealants to help seal around the edges of LVT installations you can assured of right adhesive for the job.

For click based installations, a suitable underlay beneath the LVT floor can help to combat worries about noise between floors or in the room. However, choose an underlay that’s too thick and the floor’s joints may well be compromised causing creaking, squeaking and eventual failure. The floorwise Acoustica range includes a variety of solutions that can help to improve sound quality while also supporting the floor.

While much of the focus in ensuring a lasting installation occurring beneath the floor where efforts are never seen, there’s no doubt that what goes on top will make a statement about of the quality of workmanship and attention to detail elsewhere. Fortunately, with the recently updated Zenith and Max Reflections ranges, it’s easier than ever to achieve that fantastic finishing touch and the perfect match to door furniture, switches and sockets.

Installers can now choose Reflections in the new Brushed Black and Brushed Space Grey finishes, alongside the existing Brushed Steel Nickel and Chrome. The extended Zenith range also includes Black and Space Grey, alongside the best-selling matt silver and matt gold finishes. Many profiles are also available in oak, dark walnut and grey oak wood effects. Both collections feature a wide range of task-specific profiles.

In commercial projects such as offices, where LVT may be used in complex, curved layouts joining other flooring materials such as carpet tiles, floorwise range of flexible PVC provides more flexibility in transitioning from one area to another. Along with 22 colours, the range gives the ability to manage more transitions and effectively delineate areas using colours, or to match flooring more closely.

With everything needed for a high-quality LVT installation from the subfloor to finishing, floorwise is the only name you need for the start of a fantastic floor.

For further information on these and other great flooring products contact Floorwise on 01509 673974, visit www.floorwise.co.uk or email [email protected]

0 notes

Text

A Guide to External Finishes and Render Options for UK Residents

The application of external finishes to a residential property serves two primary functions:

It shields the building's wall from weather-induced damage, such as the impact of rainfall.

It enhances the visual appeal of the property, adding a pleasing aesthetic touch.

Categories of External finishes and Renders

Cement Render

Acrylic render, a popular choice in contemporary home construction, is typically applied as a thin finishing layer to elevate the property's visual appeal. During its production, small fibres are included to ensure a durable finish and to resist cracking once the material has been applied to the building. The use of silicone in the process extends the lifespan of the product and endows it with self-cleaning capabilities.

Cement Render

Cement, mixed on-site for rendering, generally involves three or four application layers on the building facade, with the top coat polished to a glossy finish. While the materials used to produce the cement are relatively inexpensive, the labour involved can be costly. This type of render typically requires regular repainting to retain its aesthetic allure.

Lime Render

Available in multiple formats like lime putties or bagged hydraulic limes, lime render is somewhat more challenging to apply and slightly pricier than alternatives like Portland cement. Lime render also necessitates on-site mixing.

Monocouche Render

Sold in bags for mixing with water, monocouche render is usually applied manually with a trowel or sprayed onto the wall surface. This render comes pre-coloured in a variety of shades, includes a weatherproofing layer, and contains additives that minimise the likelihood of cracking. The material is also self-cleaning. Although the materials for monocouche render can be costly, the ease of application reduces labour costs and eliminates the need for subsequent painting.

Polymer Render

Polymer render is sold pre-mixed in diverse colours, based on either white cement or lime. The production process includes the addition of polymers and other plastic-based products to reduce the propensity for cracking, thereby enhancing the finish's lifespan.Types of External Cladding

Timber Cladding

Timber cladding is popular for its natural aesthetic appeal, particularly for residential properties. It mimics the traditional timber frame style and adds a charming touch to any building exterior.

Benefits of Timber Cladding:

Easy installation: Timber's lightweight nature facilitates rapid installation by labourers, reducing construction costs.

Energy efficiency: Timber's low thermal conductivity compared to steel and concrete reduces the building's energy consumption for heating and cooling, making it a cost-effective choice.

Eco-friendly: Unlike many construction materials, timber is a renewable and 100% recyclable resource, making it a truly green building option.

Versatility: Timber can be trimmed to any shape to meet clients' demands and is available in diverse patterns.

Durability: With proper and regular maintenance, timber cladding can last for years. The manufacturing process often enhances its durability and fire resistance. Certain timber species, such as Western Red Cedar or Douglas fir, have a naturally longer lifespan than other types of wood.

Concrete Cladding

Concrete cladding, often seen in commercial buildings, comes in the form of cladded tiles. These tiles, although durable and requiring minimal annual maintenance, are limited in shape variety and require longer installation times, leading to higher labour costs.

Fibre Cement Cladding

This cladding sheet, a low-cost blend of cellular fibre, compressed sand, water, and cement, is straightforward to install and available in a range of colours and effects. It arrives from the factory already painted or stained and needs minimal annual cleaning, with no need for repainting or restaining.

Metal Cladding

Commonly used in commercial buildings like business parks and offices, metal cladding comes in various forms, all easily customisable to client specifications. Steel cladding, robust, low-maintenance, and visually appealing, is a popular choice for commercial purposes. However, it can be costly, making it less favourable on a tight budget, and offers poor thermal insulation. Aluminium cladding, on the other hand, is affordable, low-maintenance, and easy to install but can appear cheap if poorly designed and is prone to damage. Like steel, aluminium also delivers subpar thermal insulation performance.

Stone Cladding

Stone cladding is a favourite for residential buildings, offering a natural aesthetic and sometimes combined with another exterior finish or render for added depth. This material is an excellent insulator and incredibly durable, capable of withstanding years of weathering. Stone cladding can be an expensive choice in terms of installation and maintenance, but if budget constraints are not an issue, it's a worthy option due to the myriad benefits it provides.

Vinyl Cladding or Vinyl Siding

Primarily designed for residential exteriors, vinyl cladding comes in various colours and patterns and is cost-effective due to its insulating properties, reducing the heating and cooling costs. While it requires little to no maintenance and can resist harsh weather conditions, the colour may fade over time, requiring replacement every 5-7 years. A significant downside is that this material can mask issues like dampness, facilitating mould growth, and can release harmful toxins when exposed to high temperatures, posing an environmental risk.

Weatherboard Cladding

Frequently used on residential properties, weatherboard cladding can be implemented with a variety of materials like fibre cement and UPVC in numerous colours and effects. This highly durable cladding method can be applied to many substrates but requires comprehensive annual maintenance for optimal conditions.

0 notes

Text

Transform Your Kitchen: A Guide to Backsplash Installation

A kitchen backsplash is more than just a protective barrier for your walls. It’s a design element that can transform your kitchen, adding color, texture, and personality. Whether you’re remodeling your entire kitchen or just looking to update its look, installing a new backsplash is a project that can make a significant impact without breaking the bank. Here's a comprehensive guide to kitchen backsplash installation.

Choosing Your Backsplash Material

The first step in your backsplash project is selecting the right material. There are numerous options available, each with its own set of benefits:

Ceramic and Porcelain Tiles: These are popular choices due to their affordability, ease of cleaning, and wide range of styles and colors.

Glass Tiles: These provide a modern, sleek look and are available in various colors and finishes. They can make a small kitchen feel larger and brighter.

Natural Stone: Materials like marble, granite, and travertine add a luxurious touch to your kitchen. However, they require more maintenance and can be more expensive.

Metal Tiles: Stainless steel, copper, and aluminum backsplashes are durable and add an industrial vibe to your kitchen.

Peel-and-Stick Tiles: These are a great option for DIY enthusiasts or renters. They’re easy to install and remove, though they may not be as durable as other materials.

Preparing Your Workspace

Before you start the installation process, you need to prepare your workspace. Clear the countertops, remove any outlet covers, and make sure the wall surface is clean, dry, and smooth. If the wall has any imperfections, sand them down or fill them in to ensure the tiles adhere properly.

Measuring and Planning

Accurate measurements are crucial for a successful backsplash installation. Measure the area you plan to cover, accounting for any outlets or windows. Plan your tile layout by dry-fitting the tiles on the countertop to see how they will look on the wall. This will help you determine the best starting point and avoid small slivers of tiles at the edges.

Cutting the Tiles

Cutting tiles to fit around outlets, windows, or edges is often the most challenging part of the installation process. Use a tile cutter or wet saw for clean, precise cuts. Measure and mark the tiles carefully before cutting to ensure they fit perfectly into your layout.

Applying Adhesive

For most tile installations, a thin-set mortar is the adhesive of choice. Apply the mortar to the wall using a notched trowel, working in small sections to prevent it from drying out before you can place the tiles. Press each tile firmly into the mortar, using spacers to maintain consistent gaps between them.

Installing the Tiles

Start installing the tiles from the bottom center of the wall and work your way outwards. This ensures that any cut tiles are at the edges, where they are less noticeable. Check your work frequently with a level to ensure the tiles are straight and even.

Grouting and Finishing

Once the tiles are set and the adhesive has dried (usually 24 hours), it’s time to apply the grout. Mix the grout according to the manufacturer’s instructions and apply it with a grout float, pressing it into the spaces between the tiles. Wipe away excess grout with a damp sponge, being careful not to remove too much from the joints. After the grout has cured, apply a grout sealer to protect it from stains and moisture.

Final Touches

Replace the outlet covers, caulk the edges where the backsplash meets the countertop and cabinets, and clean the tiles thoroughly. Step back and admire your handiwork—your Kitchen Backsplash Installation Service now has a fresh, new look!

0 notes

Text

Expert Tips for High-Quality FM2 Concrete Floor Finishing

At Midas Concrete Floor Solutions, we specialize in FM2 concrete floor treatments, recognized for their high tolerance, flatness, and durability. In this blog, we discuss the FM2 techniques and processes that ensure a top-quality concrete finish.

Understanding FM2 Concrete Flooring

FM2, as defined by TR34 4th Edition under the Concrete Society, sets guidelines for the structural design of ground flooring, particularly in industrial environments like warehouses and manufacturing plants, where precision is critical.

Benefits of Proper Floor Finishing

Durability: FM2 finishing enhances floor longevity and resistance to wear.

Safety: Smooth, even surfaces reduce accidents and improve efficiency.

Maintenance: Quality finishes make floors easier to clean and maintain.

Aesthetics: A well-finished floor enhances the facility's appearance.

Key Techniques to Achieve FM2 Floor Finishing

1. Subgrade Preparation Compaction: Ensures a dense subgrade to support the concrete slab.

Moisture Barrier: Prevents water vapor from causing curling and cracking.

Levelling: Laser-guided technology ensures precise subgrade leveling.

2. Formwork & Reinforcement

Formwork: Precisely installed to define slab shape and maintain levelness.

Reinforcement: Steel rebar or mesh strengthens the slab and prevents cracks.

3. Concrete Placement

Mix Design: High-quality concrete mix ensures workability and strength.

Pouring: Controlled placement to prevent segregation and ensure homogeneity.

4. Levelling and Screeding

Laser Screeding: Precisely levels concrete for FM2 standards.

Hand Screeding: Used where laser screeds aren't applicable, handled by skilled craftsmen.

5. Power Floating and Troweling

Power Floating: Smooths and consolidates the concrete surface.

Power Troweling: Creates a dense, durable surface with multiple passes.

6. Curing

Moisture Retention: Uses curing compounds or water-retention techniques.

Curing Time: Ensures a minimum of 10 days to achieve maximum strength and durability.

7. Joint Placement and Sealing

Saw Cutting: Creates control joints to prevent shrinkage cracking.

Sealing: Uses polyurethane sealant to reduce dirt and moisture infiltration.

Conclusion: Achieving a high-quality FM2 finish requires expert design, implementation, and a deep understanding of concrete behavior. At Midas Concrete Floor Solutions, we are committed to delivering floors that meet the highest standards of flatness, levelness, and durability, ensuring the best industrial flooring solutions for our clients.

1 note

·

View note

Text

Expert Solutions for Durable Concrete Patio Construction | Flatwork Construction Services

When it comes to building a solid foundation or creating aesthetically pleasing outdoor spaces, flatwork construction services are crucial. Among the various applications, concrete patio construction stands out as a popular choice for homeowners and businesses seeking a functional and stylish outdoor area. In this article, we will explore the significance of flatwork construction services and delve into the specifics of concrete patio construction.

What Are Flatwork Construction Services?

Flatwork construction refers to the process of pouring and finishing concrete to create flat surfaces, such as floors, driveways, and patios. This type of construction is essential for ensuring that surfaces are level, stable, and capable of withstanding regular use. Flatwork construction services involve several key tasks:

Site Preparation: Proper site preparation is fundamental. It includes grading the land, ensuring proper drainage, and removing any debris or vegetation.

Formwork Installation: Forms are used to shape the concrete as it sets. They are constructed from wood or metal and must be carefully set up to ensure accurate dimensions.

Concrete Pouring and Finishing: The concrete mix is poured into the prepared forms and then finished to achieve a smooth and level surface. This step may involve techniques such as troweling or broom finishing, depending on the desired texture.

Curing: Curing is the process of maintaining the moisture of the concrete to ensure it reaches its full strength. Proper curing is essential for the durability of the finished surface.

Concrete Patio Construction: Enhancing Your Outdoor Space

Concrete patios are a versatile and durable option for creating outdoor living spaces. They offer a range of benefits that make them an attractive choice for many homeowners. Here’s why concrete patio construction is worth considering:

Durability: Concrete is renowned for its strength and longevity. A well-constructed concrete patio can withstand heavy use and harsh weather conditions, making it a reliable choice for outdoor spaces.

Low Maintenance: Unlike other materials, concrete requires minimal maintenance. Regular cleaning and occasional sealing are usually sufficient to keep your patio looking great.

Customization Options: Concrete patios can be customized to suit various styles and preferences. Options such as stamped concrete, colored finishes, and decorative patterns allow homeowners to achieve the desired look and feel.

Cost-Effectiveness: Compared to some other patio materials, concrete is often more cost-effective. Its durability and low maintenance requirements contribute to long-term savings.

Versatility: Concrete can be shaped and finished to create various designs, including traditional, modern, and even rustic styles. This versatility allows homeowners to match their patio to the overall aesthetic of their property.

The Flatwork Construction Process for Concrete Patios

The process of constructing a concrete patio involves several steps:

Design and Planning: Work with a contractor to design the patio layout and select materials. Consider factors such as size, shape, and any additional features like built-in seating or planters.

Site Preparation: The area where the patio will be installed is excavated and leveled. Proper drainage is ensured to prevent water pooling.

Formwork and Reinforcement: Forms are set up to define the patio’s shape. Reinforcement, such as steel rebar or wire mesh, is placed within the forms to enhance the concrete’s strength.

Pouring and Finishing: Concrete is mixed and poured into the forms. After pouring, the surface is finished to achieve the desired texture. Techniques like stamping or troweling may be used for added visual appeal.

Curing and Sealing: The patio is cured to allow the concrete to set and achieve its maximum strength. Once cured, a sealant may be applied to protect the surface and enhance its appearance.

Choosing the Right Contractor

Selecting the right contractor for your flatwork construction services and concrete patio construction is essential for achieving the best results. Look for contractors with:

Experience: Choose a contractor with a proven track record in flatwork construction and patio installation.

Reputation: Check reviews and ask for references to ensure the contractor has a positive reputation.

Expertise: Ensure the contractor has the skills and knowledge required to handle your specific project needs.

Clear Communication: A good contractor will communicate clearly and keep you informed throughout the construction process.

Conclusion

Flatwork construction services are integral to creating stable and functional surfaces, with concrete patio construction being a prime example of their application. By Material Masters Concrete understanding the benefits and process of concrete patios, you can make informed decisions to enhance your outdoor space. For top-notch flatwork construction services and expert concrete patio installation, consider partnering with a reputable contractor who can deliver exceptional results and transform your vision into reality.

#concrete services#concrete work#flatworks concrete#backyard patio#artwork#concrete project#concrete services company#concrete flatwork#backyard concrete projects

0 notes

Text

Understanding the Process: A Guide to Shotcreting Services

Introduction

Shotcreting, also known as sprayed concrete, has revolutionized the construction industry by providing an efficient, durable, and versatile method for concrete application. This guide aims to give a comprehensive understanding of the shotcreting process, its benefits, and its applications in various construction projects.

What is Shotcreting?

Shotcreting involves spraying concrete at high velocity onto a surface. It can be applied using two primary methods: the dry-mix process and the wet-mix process. This technique is particularly advantageous for creating complex shapes, reinforcing structures, and working in challenging environments where traditional concrete application may be impractical.

The Shotcreting Process

Preparation:

Surface Cleaning: Ensure the surface to be shotcreted is clean, free of loose material, and properly moistened.

Reinforcement Setup: Install any required reinforcement, such as steel bars or mesh, to provide additional structural integrity.

Dry-Mix Process:

Mixing: Cement and aggregates are mixed dry.

Conveying: The dry mix is conveyed through a hose using compressed air.

Hydration: Water is added at the nozzle as the dry mix is sprayed onto the surface.

Wet-Mix Process:

Mixing: Cement, aggregates, and water are mixed to form a concrete slurry.

Pumping: The wet mix is pumped through a hose to the nozzle.

Spraying: The concrete is sprayed onto the surface using compressed air.

Application:

Spraying: The concrete is sprayed in layers, with the nozzle operator controlling the flow and direction.

Compaction: The force of the spray compacts the concrete, ensuring a dense and strong layer.

Finishing: The surface can be finished using trowels or other tools to achieve the desired texture.

Curing:

Moisture Retention: Keep the shotcreted surface moist to ensure proper curing and prevent cracking.

Curing Time: Allow sufficient time for the concrete to cure and reach its full strength.

Benefits of Shotcreting Services

Versatility: Ideal for various applications, including slopes, tunnels, retaining walls, and architectural features.

Efficiency: Faster application compared to traditional concrete pouring, reducing construction time.

Strength and Durability: High-velocity application compacts the concrete, resulting in a dense and durable layer.

Minimal Formwork: Reduces the need for extensive formwork, saving time and material costs.

Adaptability: Suitable for difficult-to-reach areas and complex shapes where traditional methods are impractical.

Applications of Shotcreting

Slope Stabilization: Used to reinforce and stabilize slopes and embankments, preventing erosion and landslides.

Tunneling: Essential in tunnel construction for providing initial and final linings, ensuring stability and safety.

Retaining Walls: Effective for constructing and reinforcing retaining walls, offering structural support and longevity.

Repair and Rehabilitation: Ideal for repairing damaged concrete structures, such as bridges and parking garages, by providing a new layer of concrete.

Architectural and Decorative: Used to create intricate designs and shapes for architectural and decorative purposes.

Choosing a Shotcreting Service Provider

Experience and Expertise: Look for providers with a proven track record and expertise in shotcreting projects similar to yours.

Quality of Equipment: Ensure they use modern, well-maintained equipment to guarantee efficient and high-quality application.

Skilled Workforce: The skill and experience of the nozzle operators and crew significantly impact the quality of the shotcrete application.

Safety Standards: Verify that the provider adheres to strict safety standards and practices to ensure the safety of both workers and the project site.

Customer Reviews and References: Check reviews and ask for references to gauge the provider's reliability and quality of work.

Conclusion

Shotcreting services offer a versatile, efficient, and durable solution for a wide range of construction applications. Understanding the shotcreting process and its benefits can help you make informed decisions for your construction projects. By choosing a reputable shotcreting service provider, you can ensure high-quality results that meet your project's specific needs and requirements.

0 notes

Text

POOL CONSTRUCTION PROCESS

The most common cause of frustration during the construction process is not knowing what to expect. We hope the information provided will help you understand the steps necessary to build an in ground swimming pool.

After the final design has been approved by the client, a 2 dimensional scaled plan is created for engineering and made available to use for submittal to homeowners associations. Building permits are obtained from the engineered plan. Custom Pools Las Vegas

Working from the scaled plan, the finished grade is established and the outline of the pool and location of the steps and benches are marked and spray painted on the ground. The superintendent will check the layout for accuracy. The homeowner will see the placement of the pool on the property and minor adjustments can be made without too much difficulty.

Laguna utilizes specialized crews for each phase of the construction process, the first being the excavators.

The equipment is brought in, the pool and trenches for plumbing are dug, mounds are formed in the location of steps and the excess dirt is hauled off by dump trucks. Occasionally problem soil is encountered, such as solid rock or caliche, which requires special equipment to remove. This is referred to as a “hard dig” and additional charges may result. The homeowner is notified if a hard dig is necessary.

PVC pipe and conduit are installed and connected to the new pool equipment which is placed on a concrete pad by the plumbing crew. The entire system is pressurized and checked for leaks and repairs are made if necessary.

Reinforced steel or “rebar” is placed in a grid like pattern with tie wires according to the detailed structural calculations throughout the pool and on top of the steps by the steel crew.

Electricians will install niches and electrical conduit for the underwater lighting. They are also responsible for bonding all metal within 5’ of the water’s edge by connecting a copper wire. This is similar to grounding.

At this point, pre-gunite inspections are scheduled and upon approval, the pool is ready for the shotcrete crew to be scheduled.

Gunite or shotcrete is pneumatically sprayed filling all of the voids to form the shell of the pool, then troweled to a smooth finish. This process is completed in a single day. The following day, the homeowner must spray the shotcrete thoroughly with water 2-3 times per day for 1 week. This ensures the concrete will cure properly and reach full strength integrity. It is normal for water to collect at the bottom of the pool while curing.

The tile crew begins by applying tile to the waterline and possibly steps, seats or raised walls depending on the plan. Then they install the coping around the rim of the pool providing a finished edge that prevents water from getting behind the pool shell.

The area surrounding the pool is cleaned and prepared by the deck crew. Forms are placed around the edges according to the plan. Concrete is poured and troweled to drain water away from the pool coping and into deck drains. The wet cement must not be walked on for at least 24 hours and children and pets should be kept clear of the area for at least 36 hours. The concrete is allowed to cure for approximately 1 week before the spray deck material is applied. Clean up around the pool and yard are completed.

Codes have been enacted to prevent children unsupervised access to the pool area. These safety barriers are required which is the homeowner’s responsibility, although Laguna can assist in bringing the residence to compliance. Current barrier codes can be viewed by following this link (insert link or PDF). Once safety barriers are in place, the pre-plaster inspection is scheduled. Someone must be available for the inspector to check the safety barriers inside the home. Upon approval, the interior finish (plaster, quartz or pebble) is scheduled. Pool Builder Las Vegas

The plaster crew applies a 1/2 “ thick layer of finish material that adheres to the shotcrete surface and trowels it smooth. Immediately following plaster, water begins filling the pool. The pool can take 24-48 hours to fill and the water is not to be turned off (or moved to the spa) until it reaches halfway up the waterline tile. Once the pool is full, a superintendent will start up the equipment.

A final inspection (if required) is scheduled and the homeowner must contact Southwest Gas to connect to the meter. This does not cost extra but only the homeowner can make the request.

A walk through of the property and an orientation of the equipment are performed with the homeowner and a superintendent and then you’re ready to start enjoying your new Laguna pool!!

0 notes