#stationary crusher plant

Explore tagged Tumblr posts

Text

Stationary Crusher Plants Unveiled: Exploring Superior Crushing Solutions

Stationary crusher plants represent a cornerstone of efficiency and reliability in the world of crushing operations. Designed to remain in a fixed location, these plants offer a range of benefits that contribute to their widespread use across various industries. In this article, we'll delve into the features and advantages of stationary crusher plants, unveiling the superior crushing solutions they offer.

Understanding Stationary Crusher Plants

Stationary crusher plants are fixed installations that are strategically positioned in quarries, mines, or construction sites to process raw materials into aggregates or other usable materials. Unlike mobile crusher plants, which can be moved from one location to another, stationary crusher plants remain in place throughout their operational lifespan. These plants typically consist of primary, secondary, and tertiary crushers, as well as conveyors, screens, and other auxiliary equipment.

Superior Crushing Efficiency

One of the primary advantages of stationary crusher plants is their superior crushing efficiency. By remaining in a fixed location, these plants are able to process large volumes of raw materials consistently and efficiently. This results in higher throughput rates and increased productivity compared to mobile crushing plants, which may experience downtime during relocation.

Optimal Equipment Configuration

Stationary crusher plants are designed with optimal equipment configuration to ensure efficient and effective crushing operations. Each plant is equipped with primary crushers for initial reduction of raw materials, secondary crushers for further size reduction, and tertiary crushers for final shaping of the product. Additionally, stationary crusher plants may include screening equipment to separate the desired product from oversize or undersize material.

Reliability and Durability

Stationary crusher plants are known for their reliability and durability, making them a trusted choice for long-term crushing operations. Unlike mobile crushers, which are subject to wear and tear from frequent movement, stationary crusher plants remain in place, minimizing the risk of mechanical failures or breakdowns. This reliability ensures uninterrupted production and reduces maintenance requirements, resulting in lower operating costs over time.

Customization and Flexibility

While stationary crusher plants remain in a fixed location, they offer a high degree of customization and flexibility to meet the specific needs of different applications. Manufacturers offer a wide range of stationary crushers with various configurations, capacities, and features to accommodate diverse crushing requirements. This customization allows operators to tailor their coal crusher plant to suit their unique production needs and objectives.

Environmental Considerations

Stationary crusher plants are designed with environmental considerations in mind, incorporating features to minimize their impact on the surrounding environment. Advanced dust suppression systems help control dust emissions during crushing operations, reducing air pollution and protecting the health of workers and nearby communities. Additionally, stationary crusher plants are often equipped with noise-reducing measures to minimize noise pollution in the surrounding area.

Conclusion

Stationary crusher plants offer superior crushing solutions for a wide range of industries, providing efficient, reliable, and customizable crushing operations. With their fixed location, optimal equipment configuration, reliability, durability, and environmental considerations, stationary crusher plants deliver unmatched performance and productivity. Whether used in quarries, mines, or construction sites, these plants play a crucial role in processing raw materials into high-quality aggregates and materials used in various applications. By unveiling the features and advantages of stationary crusher plants, we gain insight into the superior crushing solutions they offer and their significance in the world of crushing operations.

0 notes

Text

#sand washing plant manufacturers in gujarat#roller crusher manufacturers#track mounted mobile crushing and screening plant#mobile crushing and screening suppliers#hsi crusher manufacturers#vibrating screen machine manufacturers india#Stationary & Mobile Crushing & Screening Plant#sand washing machine manufacturers in india#sand washing plant in dhansura#sand washing equipment in gujarat#sand washer suppliers

0 notes

Text

Efficient Crushing Solutions: Understanding the Equipment

In the mining and construction industries, various equipment plays a critical role in ensuring the smooth processing of materials. Among these, a crushing plant, jaw crusher, and crushing screening plant are fundamental components. These systems work together to break down raw materials into usable aggregates, making construction and mining more efficient.

Crushing Plant

A crushing plant is an essential part of material processing in mining and construction. It is designed to crush large stones and minerals into smaller sizes suitable for specific applications, such as road construction or concrete production. Crushing plants combine various machines like feeders, crushers, and screens to create a streamlined production process.

These plants come in fixed or mobile configurations. Fixed crushing plants are ideal for operations requiring high-volume production in a stable location, while mobile units provide flexibility, allowing operations to move closer to raw material sources. The use of crushing plants significantly reduces transportation costs and environmental impact by processing materials onsite.

Modern crushing plants are equipped with advanced technologies like automation and real-time monitoring. Automation allows operators to control and optimize the crushing process efficiently, ensuring consistent output quality. For instance, a well-designed crushing plant, such as those offered by UĞURMAK, integrates advanced features to meet specific project needs.

To learn more about how these plants operate and their benefits, visit the crushing plant section for detailed insights. Whether you need a stationary setup or a mobile solution, understanding the options can help you select the right equipment for your project.

Jaw Crusher

A jaw crusher is a core component in most crushing plants and serves as the primary crushing mechanism. Its primary function is to break down large materials into smaller, manageable pieces that can be further processed by other machines. The jaw crusher achieves this by utilizing two plates: one stationary and one that moves back and forth, compressing the material between them.

Jaw crushers are known for their efficiency and durability, handling materials like granite, basalt, and other hard rocks. They are particularly favored in industries where strength and reliability are paramount. Additionally, different models and sizes of jaw crushers are available, allowing them to be customized for various operational needs.

These machines can process materials efficiently, reducing the need for repeated crushing and enhancing overall productivity. Operators often pair jaw crushers with screening systems to separate crushed materials based on size, streamlining the workflow.

Crushing Screening Plant

A crushing screening plant combines crushing equipment with screening machinery to create an integrated material processing solution. This setup ensures that raw materials are crushed and sorted efficiently, meeting specific size and quality requirements. The dual function of these plants makes them indispensable in industries like construction, mining, and recycling.

Crushing screening plants are particularly useful for projects involving multiple material types, as they can process and separate various grades simultaneously. They consist of a combination of crushers, screens, conveyors, and sometimes washing systems. These plants are often mobile, making them suitable for operations that require frequent relocation.

Mobile crushing screening plants provide added flexibility, allowing operators to handle materials onsite without the need for extensive infrastructure. These units are also designed to minimize downtime and maintenance, ensuring that operations remain cost-effective.

UĞURMAK offers state-of-the-art crushing screening plants tailored to diverse industry needs. To understand how these systems can optimize your project, visit their crushing screening plant page. Whether you need a mobile or stationary solution, these integrated systems provide unparalleled efficiency and productivity.

0 notes

Text

Key Equipment in Modern Mining Operations

In the construction and mining industries, efficient material processing is essential. Equipment like the crushing plant, jaw crusher, and crushing screening plant play a pivotal role in converting large rocks into smaller, usable materials.

Crushing Plant: Enhancing Aggregate Production

A crushing plant is a comprehensive system designed to break down large rocks and stones into smaller aggregate pieces, essential for construction and various industrial applications. As the first stage in the mineral processing line, it significantly reduces raw material size and prepares it for further processing or direct use. These plants are built to handle heavy-duty operations and come in various configurations, such as stationary and mobile plants.

The configuration of a crushing plant varies based on the specific project and material type. Some setups incorporate several stages, with primary, secondary, and tertiary crushers, while others use single-stage crushers for smaller production needs. The plant's layout often includes conveyors, screens, and storage units, allowing for a well-organized process flow and efficient handling of materials.

An essential benefit of using a crushing plant is the ability to customize the output size, shape, and consistency according to project needs. With adjustable crushers, companies can control the grain size, ensuring the aggregate meets specifications for different applications, from road base to concrete production. Moreover, modern crushing plants incorporate advanced technology that enhances their safety and energy efficiency, reducing operational costs.

In addition, some models are designed with dust suppression systems and noise reduction features, which are especially useful in urban settings where environmental regulations are stringent. These environmental controls not only make operations compliant but also improve working conditions for site personnel.

In summary, crushing plants are integral in material processing, converting large rocks into a reliable aggregate form that serves as a base for construction projects. With the ability to customize production specifications and the use of advanced technology, these plants streamline operations and make construction materials more accessible and affordable.

Jaw Crusher: Powerhouse of Primary Crushing

The jaw crusher is a primary crusher that uses compressive force to break down large materials into smaller sizes, making it ideal for processing various types of rock, ores, and minerals. This type of crusher consists of two plates, or jaws, one fixed and the other moving, which work together to crush materials with high efficiency. Due to its robust design and reliable operation, the jaw crusher is widely used in mining, construction, and recycling industries.

As part of the primary crushing stage, the jaw crusher has a significant impact on the overall efficiency of the production process. By reducing the size of large rocks early on, it simplifies the material handling in subsequent crushing stages. This crusher is built to handle large input sizes and hard materials, making it suitable for operations where high volumes of material are processed. Additionally, jaw crushers are known for their ability to produce a consistent particle size, essential for downstream processes.

One of the major advantages of a jaw crusher is its simple structure, which allows for easy maintenance and operational flexibility. This crusher's high-performance design contributes to reduced downtime, as most maintenance tasks can be carried out with minimal disassembly. Furthermore, some models are equipped with hydraulic settings that enable precise control of output size and quick adjustments to match specific application requirements.

Jaw crushers also have applications beyond mining and construction. In recycling, for instance, they are used to break down concrete, asphalt, and other demolition waste, facilitating the reuse of these materials. This contributes to more sustainable construction practices by minimizing the need for raw material extraction.

Overall, the jaw crusher is indispensable in various industries due to its ability to efficiently crush hard materials and produce uniform output sizes. Its reliable operation and ease of maintenance make it an excellent investment for companies looking to enhance their production capabilities.

Crushing Screening Plant: Combining Versatility and Efficiency

A crushing screening plant combines two essential functions in the aggregate processing industry: crushing and screening. This setup not only breaks down large rocks into smaller pieces but also sorts them into different sizes for diverse applications. It offers a versatile solution for companies that require on-site material processing, making it suitable for both stationary and mobile operations.

One of the main advantages of a crushing screening plant is its flexibility. These plants come in various configurations, allowing operators to adjust the setup based on the specific needs of each project. Mobile crushing screening plants are particularly useful in mining and construction sites where the terrain and location change frequently. They offer the convenience of being moved to new sites without requiring extensive disassembly or setup time.

0 notes

Text

The Role and Importance of Crushing Technology in Modern Industry

Efficient material processing is vital in the construction and mining industries. Technological advancements in equipment like crushing plants, jaw crushers, and crushing screening plants have transformed the way raw materials are processed. Each of these components plays a significant role in ensuring streamlined operations, contributing to both productivity and cost efficiency.

Crushing Plant

A crushing plant is an essential component in aggregate production and mining operations. Its primary purpose is to break down large rocks or ore into smaller, more manageable sizes. This is crucial for further processing or direct use in construction and other industries. A modern crushing plant is not just about breaking rocks—it is about ensuring efficiency, safety, and sustainability.

Crushing plants come in various designs, including stationary and mobile setups. They consist of several stages, including primary, secondary, and tertiary crushing, each performing specific tasks. Advanced technology in crushing plants allows operators to automate processes, monitor performance, and minimize environmental impact. For more information, you can explore crushing plant solutions provided by UĞURMAK, a leader in innovative crushing equipment.

The flexibility of crushing plants is a major advantage. Mobile units, for instance, can be relocated to different sites as needed, reducing transportation costs for raw materials. Additionally, these plants are designed to handle different material types, such as granite, limestone, and even recycled materials, providing versatility in operations.

In industries where time is of the essence, the integration of advanced control systems in crushing plants ensures seamless operations. These systems can regulate feeding mechanisms, monitor crushing performance, and ensure timely maintenance, minimizing downtime and maximizing throughput.

Jaw Crusher

At the core of many crushing plants is the jaw crusher, a fundamental piece of equipment known for its robust performance and reliability. Jaw crushers are primarily used for primary crushing, where they break down large rocks into smaller sizes suitable for further processing.

The jaw crusher operates by applying compressive force to materials between two plates, or jaws. One jaw remains stationary while the other moves, creating a powerful crushing motion. This mechanism is highly effective for tough materials like granite and basalt. Jaw crushers are also versatile, capable of handling different material types and sizes, making them indispensable in mining and aggregate production.

Modern jaw crushers incorporate features like hydraulic adjustment systems for ease of use and enhanced safety. These features enable operators to adjust the crusher's settings without halting production, ensuring continuous operation. Additionally, jaw crushers are designed with durability in mind, often featuring wear-resistant materials for longer lifespans. UĞURMAK offers advanced jaw crusher solutions, combining efficiency and innovation to meet industry demands.

The adaptability of jaw crushers is another reason for their popularity. They are used in both stationary and mobile crushing plants, contributing to flexibility in operations. Moreover, the energy efficiency of these machines reduces operational costs, making them an economical choice for businesses.

Environmental considerations are becoming increasingly important in industrial operations, and jaw crushers are no exception. Modern designs focus on minimizing dust and noise emissions, aligning with global sustainability goals. This not only benefits the environment but also enhances workplace safety and compliance with regulations.

Crushing Screening Plant

A crushing screening plant integrates two critical processes: crushing and screening. These plants are designed to handle various material types and sizes, ensuring that finished products meet specific quality standards. The versatility of crushing screening plants makes them a valuable asset in industries ranging from construction to mining.

The screening process is crucial in ensuring that materials are sorted and graded accurately. It eliminates the need for additional processing, saving both time and resources. Advanced crushing screening plants are equipped with state-of-the-art technology, enabling operators to monitor and control each stage of the process. UĞURMAK offers comprehensive solutions for crushing screening plant needs, emphasizing efficiency and precision.

0 notes

Text

Efficient Crushing Solutions: Understanding the Equipment

In the mining and construction industries, various equipment plays a critical role in ensuring the smooth processing of materials. Among these, a crushing plant, jaw crusher, and crushing screening plant are fundamental components. These systems work together to break down raw materials into usable aggregates, making construction and mining more efficient.

Crushing Plant

A crushing plant is an essential part of material processing in mining and construction. It is designed to crush large stones and minerals into smaller sizes suitable for specific applications, such as road construction or concrete production. Crushing plants combine various machines like feeders, crushers, and screens to create a streamlined production process.

These plants come in fixed or mobile configurations. Fixed crushing plants are ideal for operations requiring high-volume production in a stable location, while mobile units provide flexibility, allowing operations to move closer to raw material sources. The use of crushing plants significantly reduces transportation costs and environmental impact by processing materials onsite.

Modern crushing plants are equipped with advanced technologies like automation and real-time monitoring. Automation allows operators to control and optimize the crushing process efficiently, ensuring consistent output quality. For instance, a well-designed crushing plant, such as those offered by UĞURMAK, integrates advanced features to meet specific project needs.

To learn more about how these plants operate and their benefits, visit the crushing plant section for detailed insights. Whether you need a stationary setup or a mobile solution, understanding the options can help you select the right equipment for your project.

Jaw Crusher

A jaw crusher is a core component in most crushing plants and serves as the primary crushing mechanism. Its primary function is to break down large materials into smaller, manageable pieces that can be further processed by other machines. The jaw crusher achieves this by utilizing two plates: one stationary and one that moves back and forth, compressing the material between them.

Jaw crushers are known for their efficiency and durability, handling materials like granite, basalt, and other hard rocks. They are particularly favored in industries where strength and reliability are paramount. Additionally, different models and sizes of jaw crushers are available, allowing them to be customized for various operational needs.

These machines can process materials efficiently, reducing the need for repeated crushing and enhancing overall productivity. Operators often pair jaw crushers with screening systems to separate crushed materials based on size, streamlining the workflow.

Crushing Screening Plant

A crushing screening plant combines crushing equipment with screening machinery to create an integrated material processing solution. This setup ensures that raw materials are crushed and sorted efficiently, meeting specific size and quality requirements. The dual function of these plants makes them indispensable in industries like construction, mining, and recycling.

Crushing screening plants are particularly useful for projects involving multiple material types, as they can process and separate various grades simultaneously. They consist of a combination of crushers, screens, conveyors, and sometimes washing systems. These plants are often mobile, making them suitable for operations that require frequent relocation.

Mobile crushing screening plants provide added flexibility, allowing operators to handle materials onsite without the need for extensive infrastructure. These units are also designed to minimize downtime and maintenance, ensuring that operations remain cost-effective.

UĞURMAK offers state-of-the-art crushing screening plants tailored to diverse industry needs. To understand how these systems can optimize your project, visit their crushing screening plant page. Whether you need a mobile or stationary solution, these integrated systems provide unparalleled efficiency and productivity.

0 notes

Text

Buy Sand Making Machine at Best Price: A Smart Investment with Jaw Crusher Gold Crush

When looking to invest in equipment for crushing and shaping materials, purchasing the right machinery is crucial. Among the best options in the market are sand making machines, designed to produce high-quality sand for various industries. For businesses looking to buy sand making machine at the best price, Jaw Crusher Gold Crush offers an extensive selection of machines tailored to meet diverse operational requirements. As a leading manufacturer and supplier, Jaw Crusher Gold Crush combines innovation, reliability, and cost-effectiveness to ensure businesses achieve the best return on investment.

Why Buy Sand Making Machine from Jaw Crusher Gold Crush?

A sand making machine is essential in many sectors such as construction, mining, and aggregate production. It is primarily used for shaping materials like granite, limestone, and river rock into fine aggregates that can be used in concrete production, road construction, and other building applications. With Jaw Crusher Gold Crush, you not only get a machine that is designed for high performance but also benefit from their expert customer service and competitive pricing.

By purchasing from Jaw Crusher Gold Crush, customers can expect machines that provide efficiency, reduced maintenance costs, and longer service life. The machines are also engineered to handle high-volume production, ensuring that businesses can scale their operations with ease. Whether you're producing sand for construction or preparing fine aggregates for specialized applications, Jaw Crusher Gold Crush’s sand making machines offer outstanding versatility and durability.

Mobile Stone Crusher Manufacturer: Versatility for Modern Mining Needs

Another significant product line from Jaw Crusher Gold Crush is their mobile stone crushers. These crushers are particularly valuable for mining companies and construction businesses that require portable solutions for material processing. As a prominent mobile stone crusher manufacturer, Jaw Crusher Gold Crush offers highly mobile, flexible, and efficient crushing units that are perfect for on-site operations.

The main advantage of mobile stone crushers is their ability to reduce transportation costs by allowing businesses to crush materials directly at the extraction site. This mobility is particularly useful in remote locations where transporting raw materials to stationary crushing plants can be expensive and time-consuming. By investing in a mobile stone crusher from Jaw Crusher Gold Crush, companies gain operational efficiency, increased productivity, and reduced downtime, leading to substantial cost savings.

Stone Crusher Machine: High-Performance Solutions for Aggregates and Mining

Stone crushers are integral pieces of equipment in the mining, aggregate, and construction industries. They play a vital role in breaking down large rocks into smaller, manageable sizes for further processing. Jaw Crusher Gold Crush specializes in the design and manufacture of high-performance stone crusher machines that ensure superior crushing and screening.

Their machines are built with advanced technology and high-quality components, ensuring maximum efficiency and output. Whether you need jaw crushers, cone crushers, or impact crushers, Jaw Crusher Gold Crush offers a wide range of stone crusher machines suited for different types of materials and applications. These machines are designed to provide exceptional durability and minimal downtime, making them an ideal choice for businesses that need reliable and long-lasting equipment.

Best Vibrating Screen Manufacturer: Enhancing Material Separation

In addition to crushers and sand making machines, Jaw Crusher Gold Crush also excels as one of the best vibrating screen manufacturers. Vibrating screens are essential in the aggregate industry for separating materials by size. These machines help businesses segregate the finer material from larger particles, ensuring that only the right-sized material is processed further.

As one of the top vibrating screen suppliers, Jaw Crusher Gold Crush’s products are engineered for high screening efficiency, reducing the risk of oversize or undersize particles in the final output. Their vibrating screens are designed for heavy-duty operations and can handle a wide variety of materials, from sand to gravel to recycled materials.

Best Vibrating Screen Supplier: Ensuring Reliable and Durable Equipment

When it comes to buying vibrating screens, choosing a reliable supplier is paramount. Jaw Crusher Gold Crush is known for being one of the best vibrating screen suppliers, offering machines that are durable, cost-effective, and highly efficient. Their screens come with advanced features such as adjustable vibration frequency, customizable screen sizes, and easy-to-maintain components.

These features ensure that businesses get a product that not only meets but exceeds their expectations in terms of performance and reliability. Whether you're looking for a linear vibrating screen or a circular vibrating screen, Jaw Crusher Gold Crush provides products that offer excellent separation, high capacity, and low maintenance costs, making them a top choice for businesses worldwide.

Conclusion: A One-Stop Solution for Crushing and Screening Needs

With a wide range of high-quality equipment, Jaw Crusher Gold Crush provides businesses with everything they need to excel in the aggregates, mining, and construction sectors. From sand making machines and stone crushers to vibrating screens, Jaw Crusher Gold Crush offers a comprehensive selection of products designed for performance, reliability, and cost-effectiveness.

For companies looking to buy sand making machine at the best price, invest in mobile stone crushers, or purchase top-tier vibrating screens, Jaw Crusher Gold Crush remains a trusted partner. With expert solutions and competitive prices, they continue to set the standard in the industry, helping businesses optimize their operations and achieve greater success.

#buysandmakingmachineatbestprice#mobilestonecrushermanufacturer#buysandmakingmachine#stonecrushermachine#bestvibratingscreenmanufacturer#bestvibratingscreensupplier

0 notes

Text

Selecting the Right Mobile Crusher Plant for Quartz: An In-Depth Guide

Quartz, renowned for its hardness and durability, is a prevalent mineral used in various industries, including construction, electronics, and manufacturing. As quartz deposits are mined and processed, the selection of a suitable crusher plant becomes crucial. In this article, we explore the considerations and factors that guide the selection of a mobile crusher plant for quartz, catering to the needs of different stakeholders involved in quartz processing.

Understanding the Significance of Mobile Crusher Plants for Quartz

Mobile crusher plants offer unparalleled advantages in the processing of quartz deposits, especially in scenarios where mobility, flexibility, and efficiency are paramount. Unlike stationary crusher plants, mobile crushing plant for sale can be easily transported to different sites, facilitating on-the-go processing of quartz materials without compromising productivity or quality.

Factors Influencing the Selection of a Mobile Crusher Plant for Quartz

Choosing the right mobile crusher plant for quartz involves considering various factors, including production requirements, operational constraints, environmental considerations, and budget constraints. Here are the key factors to consider:

1. Production Requirements:

The production requirements dictate the capacity, output size, and throughput of the mobile quartz stone crusher. Contractors must assess the anticipated production volumes and material specifications to ensure that the selected plant can meet the project's demands effectively.

2. Mobility and Site Accessibility:

The mobility of the crusher plant is critical, especially for projects located in remote or challenging terrain. Mobile concrete crusher plants with robust chassis and versatile configurations can navigate through narrow roads, rough terrain, and confined spaces, ensuring accessibility to different quartz deposits and construction sites.

3. Crushing Technology and Equipment:

Different types of mobile crushers, such as jaw crushers, impact crushers, cone crushers, and vertical shaft impactors (VSIs), offer distinct advantages and capabilities for crushing quartz. Contractors must evaluate the crushing technology and equipment features to determine the most suitable option for their specific application requirements.

4. Operational Efficiency and Maintenance:

Operational efficiency and ease of maintenance are essential considerations when selecting a mobile crusher plant for quartz. Contractors should assess the plant's energy efficiency, automation features, and maintenance requirements to minimize downtime, optimize productivity, and reduce operational costs.

5. Environmental Impact and Regulatory Compliance:

Mobile crusher plants must comply with environmental regulations and sustainability standards to minimize their impact on the environment. Contractors should evaluate the plant's emissions, noise levels, and waste management practices to ensure compliance with local regulations and community expectations.

6. Cost Considerations:

Cost considerations, including capital investment, operating expenses, and lifecycle costs, play a significant role in the selection of a mobile crusher plant for quartz. Contractors must assess the total cost of ownership and weigh it against the anticipated benefits and returns to make informed investment decisions.

Conclusion

In conclusion, choosing a mobile crusher plant for quartz requires careful consideration of various factors, including production requirements, mobility, crushing technology, operational efficiency, environmental impact, and cost considerations. By evaluating these factors comprehensively, contractors can select the most suitable mobile crusher plant that meets their project needs effectively.

Mobile crusher plants offer unparalleled advantages in quartz processing, enabling contractors to enhance productivity, flexibility, and sustainability in their operations. As the demand for quartz products continues to rise, the selection of the right mobile crusher plant becomes increasingly critical for achieving operational success and delivering high-quality quartz materials for diverse applications. Embracing mobile crusher technology empowers contractors to overcome logistical challenges, optimize production processes, and capitalize on opportunities in the dynamic quartz processing industry.

0 notes

Text

Best Stone Crusher Plant

Craftsmencrusher stands at the forefront of excellence in the realm of stone crusher plants, boasting the title of the best in the industry. With a commitment to innovation, quality, and customer satisfaction, Craftsmencrusher's stone crusher plants represent the pinnacle of engineering and design. Each plant is meticulously crafted to deliver superior performance, durability, and efficiency, catering to the diverse needs of clients in the mining, construction, and aggregate industries. Equipped with cutting-edge technology and precision-engineered components, Craftsmencrusher's plants are capable of crushing a wide range of materials with ease, from hard granite to abrasive quartzite, ensuring optimal productivity and minimal downtime. Beyond their exceptional performance, Craftsmencrusher prioritizes safety and environmental responsibility, implementing robust safety measures and eco-friendly practices throughout the design and operation of their plants. Whether it's a stationary jaw crusher plant for primary crushing or a portable impact crusher plant for on-the-go applications, Craftsmencrusher offers a comprehensive range of solutions tailored to meet the specific requirements of each project. Backed by a team of experienced engineers and dedicated support staff, Craftsmencrusher provides unparalleled service and support, guiding clients through every step of the process, from initial consultation to installation and beyond. With their unwavering commitment to excellence and a track record of delivering exceptional results, Craftsmencrusher has earned the trust and admiration of clients worldwide, solidifying their reputation as the best choice for stone crusher plants. Whether tackling large-scale construction projects or smaller-scale ventures, clients can rely on Craftsmencrusher to deliver reliable, high-performance solutions that exceed expectations and stand the test of time.

0 notes

Text

Crushing Expectations: Analyzing the Mobile Crushers and Screeners Market

In the ever-evolving landscape of construction and mining industries, mobile crushers and screeners have become indispensable tools, revolutionizing the way materials are processed and sorted on-site. These versatile machines offer efficient solutions for crushing, screening, and separating various materials, from aggregates and ores to demolition waste and recycled materials. In this article, we delve into the mobile crushers and screeners market, exploring its significance, trends, and impact on industry dynamics.

Mobile crushers and screeners are specialized equipment designed to facilitate the crushing, screening, and sorting of materials directly at the job site, eliminating the need for costly transportation of raw materials to centralized processing facilities. This on-site processing capability offers numerous benefits, including reduced transportation costs, faster project completion times, and increased operational flexibility.

One of the primary applications of mobile crushers and screeners is in the construction and demolition (C&D) industry, where they are used to crush and screen materials such as concrete, asphalt, and bricks, as well as to separate and recycle aggregates for reuse in new construction projects. By processing materials on-site, mobile crushers and screeners help contractors minimize waste, reduce environmental impact, and meet sustainability goals by promoting the circular economy principles of reduce, reuse, and recycle.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS24836

Moreover, mobile crushers and screeners find extensive use in the mining and quarrying sector, where they are deployed to crush and screen various ores, minerals, and aggregates for further processing and refinement. These machines enable mining operations to optimize production efficiency, improve ore recovery rates, and reduce operational costs by eliminating the need for expensive stationary crushing and screening plants.

In recent years, technological advancements have driven innovation in the mobile crushers and screeners market, leading to the development of more efficient, durable, and versatile machines. Manufacturers are investing in research and development to enhance machine performance, reliability, and safety features, as well as to integrate advanced technologies such as automation, telematics, and remote monitoring systems for real-time equipment tracking and diagnostics.

Furthermore, there is a growing emphasis on sustainability and environmental responsibility within the mobile crushers and screeners market, with manufacturers and operators increasingly focused on reducing emissions, improving fuel efficiency, and minimizing environmental impact. Electric-powered and hybrid mobile crushers and screeners are gaining traction as viable alternatives to diesel-powered machines, offering lower operating costs, reduced noise levels, and zero emissions during operation.

Additionally, the COVID-19 pandemic has accelerated the adoption of mobile crushers and screeners, as companies seek to minimize workforce exposure and adhere to social distancing guidelines while maintaining productivity and efficiency on job sites. The portability and versatility of mobile crushers and screeners have made them indispensable tools for remote and temporary construction projects, disaster relief efforts, and infrastructure development initiatives worldwide.

In conclusion, mobile crushers and screeners have emerged as indispensable assets in the construction, mining, and quarrying industries, offering efficient solutions for on-site material processing and sorting. With ongoing technological advancements, increasing emphasis on sustainability, and evolving industry dynamics, the mobile crushers and screeners market is poised for continued growth and innovation. By embracing innovation, sustainability, and adaptability, stakeholders in the mobile crushers and screeners market can meet the evolving needs of their customers and drive positive change in the industries they serve.

0 notes

Text

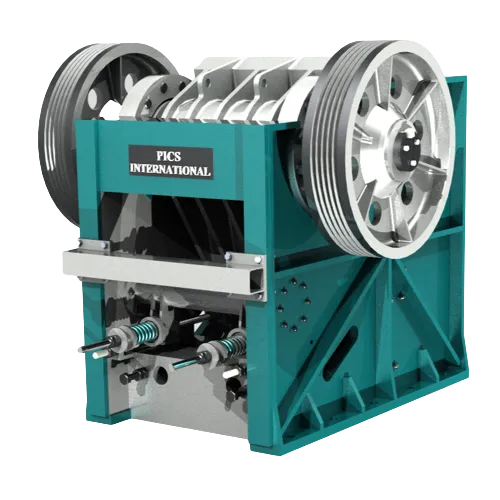

Pics International We Engineer, We Manufacture, We Deliver..... Worldwide

Picson Construction Equipments Pvt. Ltd.

PICS INTERNATIONAL is a leading global engineering and manufacturing unit engaged in supplying cutting-edge crushing and screening equipment for applications in mining, quarrying, and infrastructure projects, Construction and Demolition and waste recycling.

We have more than three decades of experience in supplying a robust range of crushing, screening and washing equipment, including varying sizes of stationary and mobile jaw, cone and impact crushers; heavy duty screens and mobile plants for recycling construction and demolition waste. These high-quality industrial equipments ensures a fine and precise performance promises an end result which is nothing less than the best.

Our Quality Products

1.CRUSHER

2.IMPACTORS

3.WASHING SYSYTEM

4.SCREENS

5.FEEDERS

6.MIXING

OUR PRODUCTS

1.Single Toggle Jaw Crusher

2 Double Toggle Jaw Crusher

3 Cone Crusher HC Series

4 Cone Crusher GC Series

Our Products

Crusher

Sand Making Machine

C & D Waste Recycling Plant

Washing System

Semi Mobile Series

Applications

Quarrying & Aggregate

Sand Processing

C & D Waste Recycling

Mining

Industrial Sand

Supports

Parts

Service

Operator Training

Dealer Portal

Manuals

Get In Touch

986, 986/1, Near Getco Substation, GIDC, Por Ramangamdi, Por, Vadodara - 391243, Gujarat, India.

9081777945

https://www.picsinternational.com/

#Stone Crusher#Cone Crusher#Jaw Crusher#C&D Waste#C&D Waste Recycling#C&D Waste Recycling Plant#C&D Waste Recycling Plant Manufacturer#C&D Waste Recycling Plant Manufacturer in India#Construction & Demolition Waste Recycling#Construction & Demolition Waste#Stone Crusher Manufacturers

0 notes

Photo

#india's best industrial product dealers #best industrial material dealers#special offers for industrial products #savewater #happynewyear2023 #PlantTreesSaveEarthIn a typical jaw crusher, two outer bearings located on either side of the main frame support an eccentric shaft, while two inner bearings support a movable jaw. These are commonly known as “Pitman” bearings. The reciprocating motion of the shaft moves the Pitman against a second, stationary jaw.Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations.A jaw crusher is a large piece of equipment that's used in mine and ore processing plants to crush rocks. The equipment was first introduced back in inventor Eli Whitey Black who primarily developed machinery used for crushing stone

0 notes

Video

tumblr

stationary stone crusher plant which can be with jaw impact crusher plant and jaw cone crusher plant, capacity from 20-1200 t/h, with max input size around 1100mm. widely used in quarry, mining, road, building, bridgt industries. DM me if you are interested.

1 note

·

View note

Text

STONE CRUSHER PLANT | 60TPH Stone Crushing Plant - Royal Techno India

R Techno is the leading Stone Crusher Manufacturer and supplier in India. We provide heavy-duty and best-quality stone crusher plants, Stone Crusher machines all over India.

Visit now: https://www.royaltechnoindia.com/products/stationary-mobile-crushing-screening-plant

#Stationary & Mobile Crushing & Screening Plant#stone crusher plant#stone crusher plant in gujarat#stone crusher plant in india#stone crusher#royal stone crusher#roller crusher#60TPH Stone Crushing Plant#best-quality stone crusher plants#Stone Crusher Manufacturer

0 notes

Text

Jaw Crusher Gold Crush: Leading the Way in Stone Crushing and Sand Making Solutions

In the competitive landscape of the construction and mining industry, the need for reliable machinery is paramount. Among the key players in this sector is Jaw Crusher Gold Crush, a prominent jaw crusher manufacturer based in India. Known for its commitment to quality and innovation, the company has established itself as a provider of the best jaw crusher solutions, catering to a diverse range of applications.

Jaw Crusher Gold Crush specializes in manufacturing high-performance jaw crushers that deliver exceptional crushing efficiency. These machines are designed to handle various materials, including hard stones, ores, and aggregates. The company focuses on providing a robust and durable product, ensuring that each stone crusher machine operates seamlessly under challenging conditions. Their crushers are not only efficient but also easy to maintain, significantly reducing downtime and operational costs for users.

In addition to jaw crushers, Jaw Crusher Gold Crush also produces high-quality sand making machines in Indore. These machines are essential for producing sand from stones and are widely used in the construction industry for concrete production. The innovative technology employed in their sand making machines ensures the production of high-quality sand that meets industry standards, contributing to superior construction quality.

As a stone crusher machine manufacturer, Jaw Crusher Gold Crush emphasizes the importance of a quality stone crusher plant. The company offers a comprehensive range of stone crushing solutions that are tailored to meet the specific needs of its clients. From stationary plants to mobile configurations, their products are designed to maximize output while minimizing operational challenges. The focus on quality materials and precise engineering ensures that their plants deliver optimal performance and longevity.

Moreover, Jaw Crusher Gold Crush stands out as a mobile stone crusher manufacturer. The growing demand for mobility in construction projects has led the company to innovate and develop portable crushing solutions. These mobile crushers offer flexibility and convenience, allowing users to easily transport equipment to different job sites while maintaining efficiency in operations.

In summary, Jaw Crusher Gold Crush is a leading name in the stone crushing industry, recognized for its quality and innovative solutions. Whether you are in need of the best jaw crusher, a reliable sand making machine in Indore, or a comprehensive stone crusher plant, Jaw Crusher Gold Crush has the expertise and equipment to meet your requirements. With a focus on customer satisfaction and technological advancement, they continue to set benchmarks in the industry, helping businesses thrive in a competitive market.

#jaw crusher manufacturer#best jaw crusher#sand making machine in Indore#stone crusher machine manufacturer#quality stone crusher plant#mobile stone crusher manufacturer

0 notes

Text

Conquer Any Terrain: The Unparalleled Mobility of a Mobile Crushing Plant

In the world of heavy machinery, the mobile crushing plant stands out as a beacon of versatility and mobility. This ingenious piece of equipment can traverse the most challenging terrains, making it an essential asset for any construction or mining project. Why settle for anything less when you can conquer any landscape? The mobile crushing & screening plant not only epitomizes efficiency but also offers a level of operational freedom that stationary crushers simply can't match.

Unmatched Versatility

Multiple Crushing Options

The mobile crushing plant is a marvel of modern engineering. It is designed to handle a variety of crushing tasks, from processing natural rock and recycled materials to mining applications. Equipped with interchangeable crushing units, this plant can switch between jaw crushers, cone crushers, and impact crushers in a matter of hours. This versatility means that operators can adapt to different project requirements without the need for multiple machines. Why limit yourself to one type of crusher when you can have them all?

Flexible Configurations

One of the standout features of the mobile crushing plant is its ability to be configured in numerous ways. Whether you need a compact setup for urban construction sites or a more extensive arrangement for large-scale mining operations, this plant can be tailored to meet your specific needs. The modular design allows for easy adjustments and expansions, ensuring that you always have the right setup for the job at hand. Flexibility is key in today's fast-paced construction environment, and the mobile crushing plant delivers it in spades.

Operational Efficiency

On-Site Mobility

Imagine a machine that can move seamlessly from one part of the job site to another, eliminating the need for costly and time-consuming material transport. The AIMIX crushing plant offers exactly that. With its robust tracks and powerful engines, it can traverse rough terrain, steep inclines, and even muddy conditions without breaking a sweat. This on-site mobility not only speeds up the crushing process but also reduces operational costs by minimizing the need for additional transport equipment. Efficiency and mobility go hand in hand with this exceptional machine.

Quick Setup and Teardown

Time is money, and the mobile crushing plant understands this better than any other piece of equipment. Its design allows for rapid setup and teardown, meaning you can have it operational in a fraction of the time it takes to install a stationary crusher. This quick turnaround is particularly beneficial for projects with tight deadlines or those that require frequent relocation. Why waste time on cumbersome installations when you can have a fully operational crushing plant up and running in no time?

Cost-Effectiveness

Reduced Transportation Costs

The cost of transporting raw materials to a stationary crusher can be exorbitant. With a mobile crushing plant, these costs are significantly reduced. The plant can be moved directly to the material source, whether it's a quarry, demolition site, or mining operation. This on-site processing not only saves money on transport but also reduces the environmental impact associated with long-haul trucking. It's a win-win situation for both your wallet and the planet.

Lower Maintenance Expenses

Maintenance is a necessary evil in the world of heavy machinery, but the mobile crushing plant makes it a little less painful. Its design incorporates easy-access points for routine maintenance tasks, reducing the time and effort required to keep it in top condition. Additionally, the plant's modular components can be replaced or upgraded without significant downtime. Lower maintenance expenses mean more money in your pocket and less time worrying about equipment failures.

The mobile crushing plant is a game-changer for any construction, mining, or recycling project. Its unparalleled mobility, unmatched versatility, and operational efficiency make it an invaluable asset in any challenging terrain. Why limit yourself to stationary crushers when you can have a machine that adapts to your needs and conquers any landscape with ease? Invest in a mobile crushing plant and experience the future of efficient, flexible, and cost-effective crushing operations.

0 notes