#stainless grade 304

Explore tagged Tumblr posts

Text

#stainlesssteel#beststainlesssteel#jindal stainless#ss 304 grade#steel grade 304#stainless steel 304 grade weight chart#ss 304 grade chemical composition#stainless grade 304

0 notes

Text

A Guide To Stainless Steel 304 Pipes

Introduction:

Stainless steel 304 is a type of stainless steel that is widely used in the manufacture of pipes, fittings, and other products. It is an alloy of iron, chromium, and nickel, and is known for its excellent corrosion resistance, strength, and durability.

Advantages of Using Stainless Steel 304 Pipes:

Corrosion resistance: Stainless steel 304 has excellent corrosion resistance in a wide range of environments, including exposure to water, chemicals, and high temperatures. This makes it ideal for use in many applications, including plumbing, water treatment, and food processing.

Strength and durability: Stainless steel 304 is known for its high strength and durability, making it resistant to deformation and damage. This makes it suitable for use in applications where the pipes may be subjected to high levels of stress or pressure.

Non-toxic: Stainless steel 304 is non-toxic and does not leach any harmful chemicals into the materials it comes into contact with. This makes it suitable for use in applications where the pipes may come into contact with food or potable water.

Easy to clean: Stainless Steel 304 Pipe has a smooth, non-porous surface that is resistant to bacteria and other contaminants. This makes it easy to clean and maintain, which is important in applications where hygiene is a concern.

Versatility: Stainless steel 304 is a versatile material that can be used in a wide range of applications, including piping, fittings, and other products. It is available in a variety of sizes and shapes, making it easy to find a product that meets the specific needs of your project.:

Stainless Steel 304 Pipes Are Used In a Wide Range of Applications

Plumbing: Stainless steel 304 pipes are often used in plumbing systems due to their corrosion resistance and durability.

Water treatment: Stainless steel 304 pipes are commonly used in water treatment plants due to their corrosion resistance and ability to withstand high temperatures.

Food processing: Stainless steel 304 pipes are often used in food processing plants due to their non-toxic properties and ability to withstand high temperatures.

Chemical processing: Stainless steel 304 pipes are resistant to corrosion and are often used in chemical processing plants.

Marine applications: Stainless steel 304 pipes are used in marine environments due to their corrosion resistance.

Weight:

Stainless Steel Pipe 304 Grade weight will depend on its size and thickness. As a general rule, the weight of a stainless steel 304 pipe can be calculated by multiplying its length by its wall thickness and then multiplying the result by the density of stainless steel, which is about 8 grams per cubic centimeter.

Conclusion:

Overall, Stainless Steel 304 is a popular choice for use in piping and other applications due to its excellent corrosion resistance, strength, and durability. It is widely used in a variety of industries, including plumbing, water treatment, food processing, chemical processing, and marine applications. I hope this information is helpful! Let me know if you have any other questions.

#Stainless Steel Pipe 304 Grade#Stainless Steel Pipe 304#Stainless Steel Pipe#SS 304 pipes#SS 304 pipe

2 notes

·

View notes

Text

Stainless Steel 304 Coil Price List 2024 Updated

As we step into 2024, the demand for stainless steel products, particularly the 304 stainless steel coil, continues to rise. This alloy, known for its exceptional corrosion resistance, strength, and durability, remains a top choice for various industries, from automotive to construction. At Sonic Steel, we’re committed to providing our customers with the latest and most competitive pricing for stainless steel 304 coils.

Updated 2024 Price List for Stainless Steel 304 Coils

Our updated SS 304 coil price list 2024 reflects the latest trends and market dynamics. Whether you’re looking for bulk orders or smaller quantities, Sonic Steel offers prices that cater to your needs. We understand the importance of timely and accurate pricing, especially in an industry where cost-effectiveness can significantly impact project outcomes.

Why Choose Sonic Steel for Your Stainless Steel 304 Coil Needs?

Sonic Steel has built a reputation for delivering high-quality stainless steel products with unmatched service. Our stainless steel 304 coils are sourced from the best manufacturers and are available in various sizes and thicknesses to meet diverse application requirements. Our commitment to quality and customer satisfaction has made us a preferred supplier in the UAE and beyond.

Applications of Stainless Steel 304 Coils

Stainless steel 304 coils are incredibly versatile. They are used in manufacturing kitchen appliances, chemical containers, architectural paneling, and even in the automotive industry for exhaust manifolds. The alloy’s excellent resistance to rust and oxidation makes it ideal for environments where exposure to corrosive elements is a concern.

For those in need of a reliable supplier, Sonic Steel is here to assist. Explore more about our offerings by visiting our dedicated page on 304 stainless steel coil suppliers.

Contact Sonic Steel Today

If you’re looking for the most up-to-date ss 304 coil price list 2024, or have any inquiries regarding our products, don’t hesitate to reach out to Sonic Steel. Our team is ready to provide you with the best solutions tailored to your specific needs.

#ASTM A240 Stainless Steel 304 Coils Supplier#Stainless Steel UNS S30400 Coils Manufacturer#Stainless Steel 304 Coil#UNS S30400 Stainless Steel Coils#304 Stainless Steel Coil Suppliers#SUS 304 Coil#304 full hard Coil Specifications#304 Stainless Steel Coils#SS UNS S30400 Coils Exporter#304 Grade Stainless Steel Price

0 notes

Text

Comparing Different Grades of Stainless Steel: 304 vs. 316 vs. 316L

Stainless metal is generally composed of iron, with at least 10.5% chromium content cloth, which works as a protective oxide layer that prevents corrosion. Different grades of stainless steel vary through their alloy composition, influencing their mechanical properties, corrosion resistance, and packages. When deciding on among 304, 316, and 316L stainless-steel grades, recording their properties is vital for making an informed preference.

Understanding Grade 304 Stainless Steel

Grade 304 is the most common sort of stainless steel and money is owed for more than 50% of the area’s stainless-steel manufacturing. It is also referred to as 18/8 stainless steel because of its composition of 18% chromium and 8% nickel. This composition offers first-rate corrosion resistance and ease of fabrication, making it suitable for a huge type of program.

Key Properties:

Corrosion Resistance: Grade 304 stainless steel gives accurate resistance to quite a few environmental factors and is extensively implemented in applications in which the risk of corrosion is mild.

Mechanical Strength: It has immoderate tensile power, making it appropriate for structural packages.

Weldability: Grade 304 is noted for its ease of welding and forming.

Cost Efficiency: It is much less expensive in contrast to 316 and 316L, making it a rate-effective desire for general-reason packages.

Common Applications of Grade 304:

Kitchen devices (sinks, refrigerators, cooking utensils)

Chemical packing containers

Automotive and aerospace systems

Building facades and architectural trim

Limitations of Grade 304:

While 304 stainless steel is a wonderful all-purpose cloth, it does have boundaries, particularly at the same time as exposed to chloride environments. In such situations, the cloth is prone to pitting and crevice corrosion, decreasing its lifespan.

This leads us to the subsequent grade in our Stainless Steel Grades Comparison: 304 vs. 316 vs. 316L.

Understanding Grade 316 Stainless Steel

Grade 316 stainless steel builds upon the advantages of 304 however enhances its trendy traditional overall performance in greater corrosive environments by means of a long facet of 2-3% molybdenum. This small addition drastically improves its corrosion resistance, particularly in the direction of chlorides and specific commercial solvents.

Key Properties:

Superior Corrosion Resistance: The presence of molybdenum complements resistance to pitting, crevice corrosion, and merciless chemical environments, making it notable for marine and coastal programs.

High-Temperature Resistance: 316 can resist higher temperatures, making it suitable for packages related to warmth publicity.

Versatility: It has a massive shape of applications, from medical devices to marine hardware.

Common Applications of Grade 316:

Marine environments (boat fittings, dock hardware)

Chemical processing and storage tool

Medical implants and surgical equipment

Food and beverage production device

Limitations of Grade 316:

The primary disadvantage of 316 stainless steel is its price. It is higher priced than 304 due to the addition of molybdenum. However, at the same time as superior corrosion resistance is needed, the benefits often outweigh the greater price.

Introduction to Grade 316L Stainless Steel

316L is a low-carbon model of 316 stainless steel. The “L” stands for “low carbon,” which means that it has the most carbon content material of 0.03%. This small exchange makes a large distinction in positive applications.

Key Properties:

Improved Weldability: The decreased carbon content material fabric minimizes carbide precipitation sooner or later of welding, decreasing the risk of corrosion at weld joints.

Corrosion Resistance: While 316 and 316L have similar corrosion resistance, 316L’s lower carbon content material fabric makes it greater suitable for environments wherein welding is worried.

Durability: The mechanical houses of 316L are barely lower than 316, but it gives advanced resistance to sensitization (grain boundary carbide precipitation).

Common Applications of Grade 316L:

Pharmaceutical and scientific industries

Chemical processing environments

Welded systems in marine applications

Oil and gasoline tool

Limitations of Grade 316L:

Although 316L is terrific for welded programs and corrosive environments, it's far typically more expensive than each 304 and 316. Additionally, its mechanical strength is slightly decreased than that of 316, making it a whole lot much less appropriate for excessive-pressure environments.

304 vs. 316 vs. 316L: Detailed Stainless Steel Grades Comparison

Recognize how those grades compare, permits to spoil down their key variations.

Corrosion Resistance:

304 Stainless Steel: Good regular corrosion resistance however prone to pitting in chloride environments.

316 Stainless Steel: Superior resistance to pitting and crevice corrosion because of the addition of molybdenum.

316L Stainless Steel: Similar corrosion resistance to 316 however excels in welded applications due to decreased carbide precipitation.

Mechanical Strength:

304 Stainless Steel: High tensile electricity, suitable for structural applications.

316 Stainless Steel: Slightly stronger than 304, supplying higher regular typical overall performance in excessive-strain environments.

316L Stainless Steel: Slightly decreased strength than 316 however with higher resilience in corrosive environments.

Weldability:

304 Stainless Steel: Easily welded and commonplace, however also can be thru corrosion at welded joints if not nicely dealt with.

316 Stainless Steel: Better relevant for immoderate-temperature welding however even though it calls for proper put up-weld treatment.

316L Stainless Steel: Ideal for welding, as its low carbon content material cloth fabric reduces the danger of carbide precipitation.

Cost:

304 Stainless Steel: Most charge-effective opportunity, suitable for cutting-edge-day-reason packages.

316 Stainless Steel: More high priced due to molybdenum, ideal for especially corrosive environments.

316L Stainless Steel: Slightly greater pricey than 316, especially valuable in environments requiring immoderate weldability and corrosion resistance.

Choosing the Right Grade for Your Application

When considering the Stainless Steel Grades Comparison of 304 vs. 316 vs. 316L, deciding on the super grade is based upon elements like surroundings, budget, and unique necessities.

1. General-Purpose Applications:

For duties in which corrosion isn't a massive state of affairs, which encompass kitchen gadgets or fundamental structural additives, 304 is often the remarkable choice. It is rate-powerful and bendy, making it first-rate for non-important packages.

2. Corrosive Environments:

If the environment includes exposure to chlorides, harsh chemical materials, or saltwater, 316 is the recommended grade. Its introduced molybdenum content material fabric presents more appropriate corrosion resistance, making it appropriate for disturbing situations like coastal installations or chemical processing flora.

3. Welded Structures:

For welded structures that require excessive resistance to corrosion, 316L is frequently the popular alternative. Its low carbon content material minimizes the threat of carbide precipitation, ensuring an extended lifespan in environments like pharmaceutical production or meal processing.

Real-World Industry Usage

Companies like Vishal Tube Industries apprehend the importance of selecting the proper stainless steel grade for their applications. Engaged in the production of Stainless Steel Seamless Tubes, Welded Tubes, and U-Tubes, Vishal Tube Industries caters to a big range of industries, from chemical processing to marine engineering.

Their current facilities make sure that they will be able to produce stainless-steel products that meet stringent tremendous necessities. By offering a number of grades, they empower clients to pick out the right fabric for their precise desires. Whether it’s 304 for famous applications or 316L for specialized obligations, Vishal Tube Industries ensures top-terrific answers.

Conclusion

When evaluating Stainless Steel Grades: 304 vs. 316 vs. 316L, it’s clear that every grade has its particular strengths. Grade 304 remains a famous, charge-effective opportunity for fashionable programs. Grade 316 gives advanced corrosion resistance for harsh environments, at the same time as grade 316L gives extra average standard performance in welded systems.

In industries wherein material choice is crucial to conventional overall performance and sturdiness, it’s crucial to understand those variations. By considering factors which include corrosion resistance, mechanical electricity, weldability, and fee, you could decide which stainless steel grade exceptionally fits your undertaking’s requirements.

Vishal Tube Industries, with its willpower to be first-rate and innovative, offers a great shape of stainless steel merchandise to fulfill the numerous desires of worldwide industries. Their expertise in production guarantees that irrespective of which grade you select, you get maintenance of a product that exceeds expectancies.

Understanding the variations among those stainless steel grades not only helps in making a knowledgeable choice but also ensures that your projects have the sturdiness and reliability needed to achieve achievement. Whether you select 304, 316, or 316L, the proper software is the critical issue to maximizing regular fashionable overall performance.

0 notes

Text

Unleash the rugged, strong, durable Stainless Steel Hex Bolts

The best-in-industry manufacturer and even supplier of premium-quality stainless steel hex bolts, ranging from 304, 304L, and 304H. Our foundation is laden with delivering quality products which is a testament to our meticulous manufacturing process and dedication to meeting industry standards. Remarkably known for exceptional strength, durability, and anti-corrode features, which makes Stainless steel hex bolts a crucial component. Across multiple industries, hex bolts have been rigorously used, from construction sites, and distinctively in infrastructure to automobiles and marines industries. The 304 grade is a significator of excellent anti-rust to oxidation and corrosion properties.

Hex bolts are curated by implementing appropriate industrial measures and needs and most crucially quality control checks are ensured, so that they meet required industry standards. Bolts are applicable in various sizes and specifications, even custom sizes are available. At Flanges Bolts, we understand that each project has unique requirements. That's why we offer tailored solutions to match your specific needs. Our team of experts is always ready to assist with technical support and provide advice on the best products for your application.

With a focus on quality, reliability, and customer satisfaction, Flanges Bolts is your go-to source for stainless steel hex bolts. Explore our range today and experience the difference of working with a trusted industry leader.

0 notes

Text

Guide to Stainless Steel 409: Properties, Composition, and Applications

Introduction

Stainless Steel 409 is a ferritic stainless steel prized for its cost-effectiveness and high-temperature resistance. Unlike grades such as 304, it is not designed for superior corrosion resistance but excels in environments where oxidation and high temperatures are concerns.

Chemical Composition

Chromium (Cr): 10.5-11.75%

Nickel (Ni): ≤0.5%

Carbon (C): ≤0.08%

Manganese (Mn): ≤1.0%

Silicon (Si): ≤1.0%

Phosphorus (P): ≤0.045%

Sulfur (S): ≤0.03%

This composition provides 409 stainless steel with adequate oxidation resistance, particularly in elevated temperatures.

Properties

Corrosion Resistance: Moderate, not as high as grades like 304 or 316.

High-Temperature Resistance: Up to 675°C (1247°F) continuously; 815°C (1499°F) intermittently.

Weldability: Good, suitable for various welding techniques.

Formability: Easily shaped into sheets, plates, and coils.

Applications

Automotive Industry: Exhaust systems, catalytic converters, and mufflers.

Construction: Structural components with moderate corrosion resistance.

Heat Exchangers: Tubes and components for high-temperature use.

Agricultural Equipment: Parts requiring durability and moderate corrosion resistance.

Comparisons with Other Stainless Steels

Stainless Steel 304: Known for its excellent corrosion resistance due to higher chromium (18%) and nickel (8%). More expensive but ideal for food processing, marine applications, and chemical processing.

Alloy Steel SA 387 Grade 11: Used in pressure vessels and industrial boilers, valued for its strength at high temperatures and good corrosion resistance.

SS 430: A ferritic steel with good corrosion resistance, used in automotive trim and appliances.

SS 410: Martensitic steel with high strength, used in cutlery and valves, containing 11.5-13.5% chromium.

SS 347: Austenitic steel with added columbium for enhanced corrosion resistance in high-temperature settings.

Specialty Products

Hardox Plate: Known for wear resistance, used in mining equipment and material handling.

Sheet Lead: Used for radiation shielding and soundproofing, with prices varying by thickness and size.

Stainless Steel 304 Flanges: Connects pipes and equipment with excellent corrosion resistance.

Conclusion

Stainless Steel 409 is a versatile material suited for high-temperature applications and cost-effective solutions. It may not match the corrosion resistance of grades like 304, but it is an excellent choice for specific industrial needs. For more information, visit Bhavya Steel.

#stainless steel 409 sheet plates coils#Stainless 304 Sheets in Pune#stainless steel 304 price#ss304 stainless steel#sa 387 gr 11 in pune#sa387 grade 11 alloy steel#ss 409 sheets plates coils#sa 387 grade 11 sheets#ss 430#ss 410 sheets#ss 410#ss347#hardox plate#sheet lead price#ss410s chemical composition#grades of stainless steel#stainless steel grades#stainless steel 347#ss grades#ss430 chemical composition#stainless steel 304 flanges#lead sheeting price

0 notes

Text

#stainless steel 409 sheet plates coils#Stainless 304 Sheets in Pune#stainless steel 304 price#ss304 stainless steel#sa 387 gr 11 in pune#sa387 grade 11 alloy steel#ss 409 sheets plates coils#sa 387 grade 11 sheets#ss 430#ss 410 sheets#ss 410#ss347#hardox plate#sheet lead price#ss410s chemical composition#grades of stainless steel#stainless steel grades#stainless steel 347#ss grades#ss430 chemical composition#stainless steel 304 flanges#lead sheeting price

0 notes

Text

Calico Metal Alloys LLP is one of the main Manufacturers, Suppliers and Exporters of top notch Duplex 2205, UNS S31803, UNS S32205, UNS S32750, UNS S32760, Duplex 2202, Duplex 2304 pipe, Tube, sheet, plates, Coil, Shim Sheet flanges, fasteners in India at low price.

#ASTM A312 TP 304/304H Stainless Steel#Titanium Grade 1 Pipes & Tubes#Nickel Alloy 200/201#Aluminium Alloy 2014#Copper and Brass Alloys#Duplex Steel 2205#Titanium Alloys#Cobalt Alloys#Silver and Gold Brazing Alloys supplier from Mumbai#India.

0 notes

Text

Top 7 Reasons Why LIPKA Floor Drains Dominate the Market

https://seolipka.gumroad.com/p/top-7-reasons-why-lipka-floor-drains-dominate-the-market

#floor drain#Lipka#square floor drain#round floor drain#stainless steel#304 grade stainless steel#luxury

0 notes

Text

One of the key properties of stainless steel 304 grade is its corrosion resistance. It is highly resistant to corrosion from most oxidizing acids, organic acids, and chloride solutions, making it suitable for a wide range of applications in various industries, including food and beverage, medical, and chemical processing.

1 note

·

View note

Photo

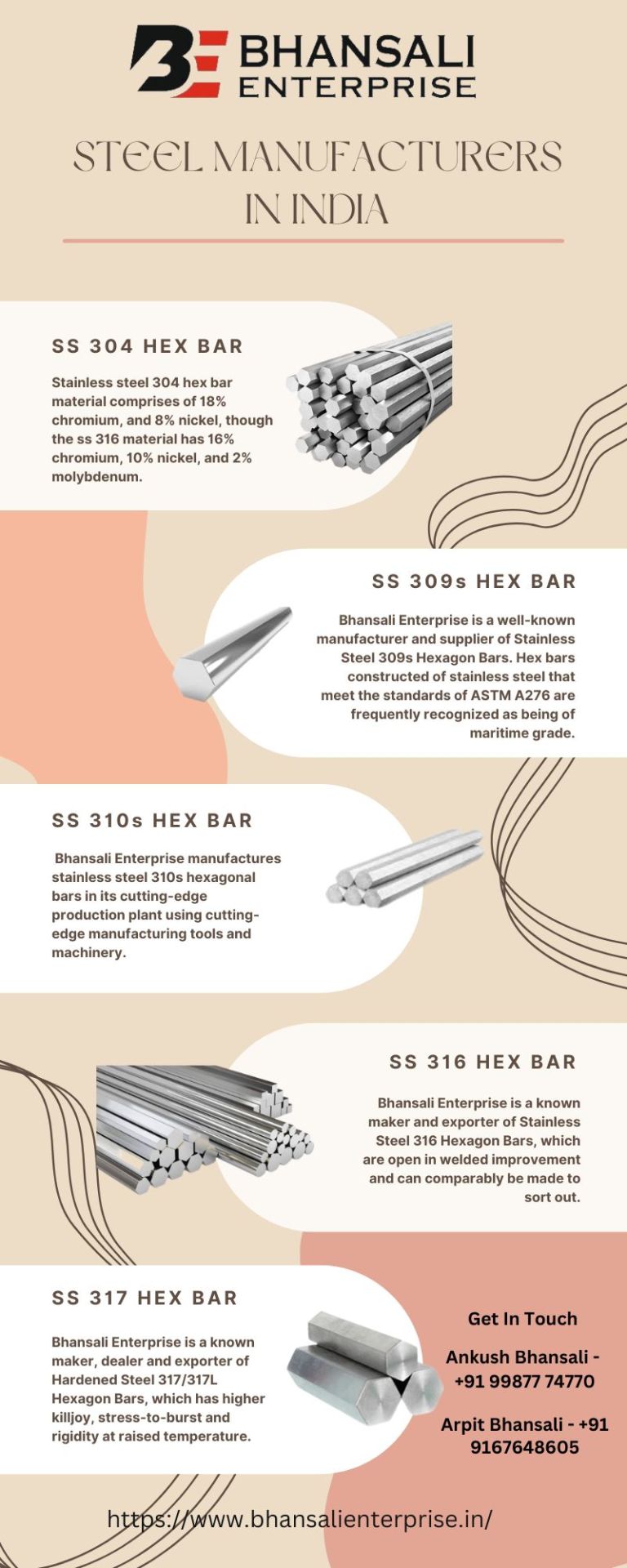

"SS Hex Bars Manufacturers & Exporter."

The Stainless Steel Hex Bars have improved strength and for that reason they are utilized in many applications. The extra strength is because of the mathematical state of the hex bars. On the off chance that the hex bar is made of austenitic treated steel, they have more prominent strength and higher erosion opposing properties. The Stainless Steel Hex Bars can be altered to various shapes and sizes as per the particular necessities. Bhansali Enterprise manufactures ASME SA276 Stainless Steel 309s Hex Bars using state-of-the-art tools and machinery to guarantee complete dimensional accuracy. Customers can choose from a variety of ASTM A276 SS 309s Hexagon Bars at Bhansali Enterprise. We produce 310 stainless steel hexagonal bars that fulfil national and international quality standards using only the best raw materials. Bhansali Enterprise is known in the business for the reliability of the goods we offer. Bhansali Enterprise is a known maker and exporter of Stainless Steel 316 Hexagon Bars, which are open in welded improvement and can comparably be made to sort out. SS 316 Hexagon Bar is utilized in blend process gear; tank trucks; propeller screws, and spent atomic fuel part recuperation. Bhansali Enterprise is a known maker, dealer and exporter of Hardened Steel 317/317L Hexagon Bars, which has higher killjoy, stress-to-burst and rigidity at raised temperature. SS 317 Hex Bars doesn’t respond to warm treatment, which can be additionally solidified by chilly working.

#stainless steel round bar#stainless steel 316l#stainless steel 304#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#steel grades#round bar#polished stainless steel#stainless steel 304 price per kg in delhi#stainless steel manufacturers in india#flange manufacturer in india

0 notes

Text

Everything You Need To Know About Stainless Steel 304 Pipe

stainless steel pipe grade 304 price list Introduction:

Stainless steel pipe grade 304 is a commonly used material in the construction and engineering industries. It is made from an alloy of iron, chromium, and nickel, and is known for its high corrosion resistance and strength. It is often used in the production of pipes, tubes, and other items that require durability and resistance to harsh environments.

There Are Several Advantages to Using Stainless Steel Pipe Grade 304:

Corrosion resistance: The high chromium and nickel content of grade 304 stainless steel makes it resistant to corrosion and rust, even in highly acidic or salty environments.

Strength and durability: Stainless steel grade 304 is known for its high strength and durability, making it suitable for use in a wide range of applications.

Easy to clean: The smooth surface of grade 304 stainless steel makes it easy to clean and maintain, which is important in hygienic environments such as food processing plants.

Non-toxic: Stainless steel grade 304 is non-toxic and does not leach harmful chemicals into the environment, making it suitable for use in the production of food and medical products.

Stainless Steel Pipe Grade 304 has a Wide Range of Applications

Construction: Stainless steel grade 304 is often used in the construction of buildings, bridges, and other structures due to its strength and corrosion resistance.

Automotive: Stainless steel grade 304 is used in the production of exhaust systems and other automotive parts.

Food and beverage: Stainless steel grade 304 is used in the production of food processing equipment, brewing and distillation equipment, and other items that come into contact with food and drink.

Medical: Stainless steel grade 304 is used in the production of medical instruments and equipment due to its corrosion resistance and non-toxic properties.

Conclusion:

In conclusion, stainless steel pipe grade 304 is a versatile and widely-used material in the construction and engineering industries due to its corrosion resistance, strength, and durability. Its non-toxic properties make it suitable for use in the production of food and medical products. While it is more expensive than some other types of steel, its long lifespan and low maintenance costs make it a cost-effective choice in many applications.you can visit thepipingmart for Stainless Steel Pipe Grade 304 Price List.

#stainless steel pipe grade 304 price list#stainless steel pipe grade 304#SS 304 Pipe Price List#SS 304 Pipe Price#SS 304 Pipe

0 notes

Text

Deerma Blender Portable Buah Juicer Wireless 1500mAh 400ml

https://tokopedia.link/di4Q2ora6Jb - https://s.shopee.co.id/1qGZPZcm2m ==================================================== Spesifikasi: Merek: DEERMA Voltase: 220 V Daya / Power: 140 W Material: PCTG (baby bottle material), 304 stainless steel dan PP Dimensi: 308 x 96 x 98 mm Kapasitas Baterai: 1500 mAh Kapasitas: 400 ml Deskripsi Bikin jus pakai blender listrik kini bisa dilakukan di mana saja. Tanpa mesti di dapur dan mencolokan listrik. Xiaomi Deerma solusi bagi Anda yang punya mobilitas tinggi namun tetap ingin memenuhi gaya hidup sehat minum jus yang Anda buat. Gunakan saja blender portable yang bisa Anda masukan ke dalam tas. Tanpa ribet, praktis, mesin yang powerful, baterai isi ulang, dan tentunya terjangkau dari segi harga.

Fitur 2 in 1 Blender and Tumbler Blender ini diranang agar memudahkan Anda langsung meminum jus atau menyimpan hasil juicer ke botol. Nah. blender sudah dilengkapi botol khusus yang juga bagian dari wadah blender itu sendiri. Light Weight and Portable Xiaomi juicer ini memiliki bobot yang ringan dan mudah dibawa. Bahkan, anak umur 4 tahun bisa mengangkat dengan mudah melalui pegangan tali silikon. Taruh saja di mobil ataupun ke dalam tas Anda.

Powerful Juicing Function mata pisau Xiaomi Juicer yang tajam dapat dengan cepat membuat jus, milkshake hingga makanan cepat saji untuk bayi. Kekuatan mesin blender ini layar disandingkan dengan blender konvesional. Sehingga dengan ukuran sekecil ini, Anda bisa mendapatkan hasil jus yang memuaskan.

Rechargeable Battery Dengan konsep wireless alias tanpa kabel, blender ini sudah dibekali baterai charger. Sheingga Anda bisa mengisi ulang baterainya selama di perjalanan, misalnya menggunakan power bank ataupun car charger.

Easy Operation Pengoperasian Xiaomi juicer ini cukup menekan tombol power yang tersedia dan kemudian menunggu beberapa saat untuk mendapatkan jus segar dan sehat.

Safe Material with Food Grade Material Xiaomi juicer ini ramah lingkungan sehingga aman dan tidak berbahaya bagi kesehatan termasuk bayi Anda.

Isi Kemasan 1 x Deerma Blender Portable Buah Juicer Wireless 1500mAh 400ml 1 x Tutup Botol 1 x Kabel USB 1 x Brush 1 x Panduan Penggunaan ==================================================== https://s.shopee.co.id/9ezi7T2NcG https://tokopedia.link/vfg3UqLVZzb

#kantong belanja#tas belanja#tokopedia#anggaran belanja#keranjang belanja#toko online#ecommerce#shopping#shopee#shoppers#mixer#blender#blender portable#online shopping#shop small#small business#store#online store

21 notes

·

View notes

Note

Question for Tom, how do you deal with the internal pressure? The A272 has a slightly protruding ring section inside, near the base. It digs into the underside of the penis causing bruising.

I wear the largest size ring and everything is comfortable when flaccid, toilet trips can be a little uncomfortable but nothing worth complaining about.

Nocturnal erections however cause me severe pain and injury and as a result I’ve stopped wearing it at night. I’ve tried using lotion but it’s not enough. I’m slightly “thicker” than average so that may have something to do with it; I was just wondering if you had the same issue, if so any advice would be appreciated.

The A272 (and A271) are comprised of a section of curved, grade 304 stainless tube (approx 33mm inner diameter), and a cage tip welded to one end, and a welded ring with a "boss" that attaches to the cuff ring. The rings at both ends are about the same diameter as the tube, and held in place by several spot welds.

I noticed that the rings at the end of the tube had a slight offset from the tube itself, so I polished mine with some find emery, and finished it with several more grades of Scotchbrite pads. However, keep in mind that these cages are selling for less than $20 USD, so the assembly is probably not super tightly controlled. Your cage may be offset a bit more, or the tack welds may be in a spot that rubs your skin.

If you are at all handy, try noting where on the cage the high spot or rough spot may be located, and then blend in that spot with some fine emery paper, and then use some finer polishing cloths to smooth it out. Our skin is surprisingly sensitive to picking up little imperfections.

172 notes

·

View notes

Text

SS 304 Blind Flange | Best Deals at Lowest Price

SS 304 Blind Flanges are an essential component for sealing off pipelines and preventing the flow of liquids or gases in various industrial systems. Known for their exceptional corrosion resistance, strength, and durability, SS 304 Blind Flanges are widely used in industries like oil and gas, chemical processing, water treatment, and more. Finding the best deals at the lowest price for SS 304 Blind Flanges is key to optimizing your operational costs while maintaining the quality and performance you need.

In this article, we'll explore the benefits of SS 304 Blind Flanges, their industrial applications, and how you can find the best deals online.

Why Choose SS 304 Blind Flange?

SS 304, a grade of stainless steel, is one of the most popular and versatile alloys used in various industrial components, including flanges. It contains 18% chromium and 8% nickel, which makes it highly resistant to corrosion, even in harsh environments where moisture, chemicals, and high temperatures are present. Here’s why SS 304 Blind Flanges stand out as a top choice for industrial use:

1. Exceptional Corrosion Resistance: One of the main reasons why SS 304 Blind Flanges are favored across multiple industries is their corrosion resistance. The chromium content in the stainless steel creates a passive oxide layer on the surface of the flange, preventing it from rusting. This makes it ideal for use in environments exposed to moisture, chemicals, or high humidity.

2. High Durability and Strength: SS 304 Blind Flanges are known for their strength and ability to withstand high pressures and temperatures. Whether you're dealing with high-pressure pipelines or industrial systems that operate in extreme temperatures, SS 304 Blind Flanges provide the durability needed to keep your systems running smoothly.

3. Low Maintenance: Because of their corrosion resistance and strength, SS 304 Blind Flanges require minimal maintenance, which reduces the need for frequent replacements or repairs. This makes them a cost-effective solution for industrial applications where reliability and long-term performance are essential.

4. Easy Installation: SS 304 Blind Flanges are designed for easy installation, making them a convenient option for industrial systems that need to be sealed off temporarily or permanently. They can be quickly bolted into place, ensuring a tight seal that prevents leakage or contamination.

5. Versatile Use Across Industries: SS 304 Blind Flanges are used in a wide range of industries, from oil and gas to food processing and water treatment. Their versatility makes them a reliable choice for various applications, ensuring that they meet the needs of different industrial environments.

Applications of SS 304 Blind Flanges

SS 304 Blind Flanges are used in several industries for their ability to seal off piping systems. Common applications include:

Oil and Gas Pipelines: SS 304 Blind Flanges are used to close off pipeline sections during repairs, testing, or maintenance. Their corrosion resistance makes them suitable for handling hydrocarbons and other chemicals typically found in the oil and gas industry.

Chemical Processing Plants: In chemical plants, where pipelines carry corrosive fluids, SS 304 Blind Flanges are a reliable option for sealing pipes during system shutoffs or maintenance periods. They prevent leaks and ensure the integrity of the system.

Water Treatment Facilities: In water treatment plants, SS 304 Blind Flanges are used to block off sections of water pipelines, ensuring that the water remains uncontaminated and the system remains functional during maintenance.

Marine Industry: The saltwater environment can be particularly corrosive, but SS 304 Blind Flanges are resistant to seawater corrosion. This makes them ideal for use in shipbuilding, offshore platforms, and other marine-related industries.

Food and Beverage Industry: The non-reactive properties of SS 304 make it a preferred material in industries that require high hygiene standards, such as food processing and beverage production. SS 304 Blind Flanges ensure a safe, clean, and durable seal in these environments.

Tips for Finding the Best Deals on SS 304 Blind Flanges

Finding SS 304 Blind Flanges at the lowest price doesn't mean compromising on quality. With a bit of research and strategy, you can secure the best deals on high-quality flanges. Here are a few tips to help you get the most value for your money:

1. Compare Prices from Multiple Suppliers: To find the best deals, it's important to compare prices from several suppliers. With the availability of online platforms, you can easily compare pricing, shipping options, and customer reviews. Be sure to check if the supplier offers any promotions or discounts that could further lower the price.

2. Look for Bulk Purchase Discounts: If your project requires a large number of SS 304 Blind Flanges, buying in bulk can significantly reduce the cost per unit. Many suppliers offer discounts on bulk purchases, which can help you save money in the long run, especially for large-scale projects.

3. Check for Seasonal Promotions: Some suppliers offer seasonal discounts, promotional offers, or clearance sales. These can be a great opportunity to buy SS 304 Blind Flanges at reduced prices. Keep an eye on major online marketplaces and industrial suppliers for these kinds of offers.

4. Verify Product Quality and Certifications: While getting a good deal is important, ensuring product quality is equally crucial. Make sure the SS 304 Blind Flanges you’re purchasing meet international standards such as ASTM, ASME, or DIN certifications. This ensures that the product has been manufactured to meet rigorous quality control and safety standards.

5. Negotiate with Suppliers: Don't hesitate to negotiate with suppliers, especially if you’re placing a large order or planning a long-term partnership. Many suppliers are willing to offer discounts or better pricing for repeat business, so it’s worth asking for a better deal.

Advantages of Buying SS 304 Blind Flanges Online

Purchasing SS 304 Blind Flanges online offers several benefits:

Convenience: Online platforms make it easy to browse, compare, and purchase products from the comfort of your office or home. You can explore a wide range of suppliers, products, and prices in just a few clicks.

Wide Selection: Online suppliers often offer a greater variety of SS 304 Blind Flanges in different sizes and specifications, ensuring that you find the exact product to meet your requirements.

Fast Shipping: Many online suppliers provide fast delivery options, ensuring that you receive your SS 304 Blind Flanges when you need them, helping to keep your project on schedule.

Customer Reviews: Reading reviews from other customers can give you insight into the quality of the product and the reliability of the supplier, helping you make an informed decision before making a purchase.

#SS304BlindFlange#BestDealsFlanges#LowestPriceFlange#StainlessSteelFlange#IndustrialFlanges#BuyNow#CorrosionResistantFlange#OilAndGasFlange#WaterTreatmentFlange#PipelineSolutions#BulkOrderFlanges#ChemicalProcessingFlange

6 notes

·

View notes

Text

#stainless steel 409 sheet plates coils#Stainless 304 Sheets in Pune#stainless steel 304 price#ss304 stainless steel#sa 387 gr 11 in pune#sa387 grade 11 alloy steel#ss 409 sheets plates coils#sa 387 grade 11 sheets#ss 430#ss 410 sheets#ss 410#ss347#hardox plate#sheet lead price#ss410s chemical composition#grades of stainless steel#stainless steel grades#stainless steel 347#ss grades#ss430 chemical composition#stainless steel 304 flanges#lead sheeting price

0 notes