#special and custom machines suppliers china

Explore tagged Tumblr posts

Text

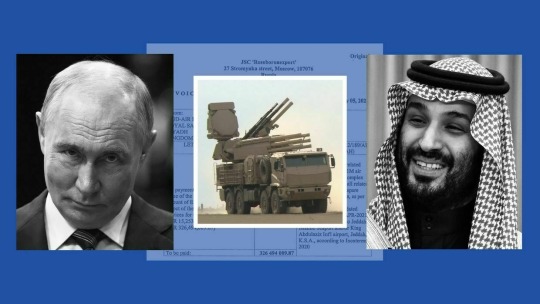

Investigation: How Russia profits from arms exports to Saudi Arabia despite sanctions

Few agreements are shrouded in more secrecy than inter-government arms deals — especially when one of the parties is a global pariah leading a bloody war.

But a recent massive leak of emails and documents has given us an unprecedented glimpse into a particularly secretive transaction.

The leak reveals that Saudi Arabia agreed to pay Russia over 2 billion euros under a contract signed in 2021 involving companies that were repeatedly sanctioned, both before and after Russia’s full-scale invasion of Ukraine.

Saudi Arabia doesn’t appear to have canceled the contract after the invasion started, despite the risk of repercussions from the U.S. — a major supplier of weapons to Saudi Arabia.

Data included in the leak also shows that Russia has continued to sell arms to up to a dozen countries since the start of its invasion of Ukraine, bolstering its defense production and war effort.

Apart from Saudi Arabia, the documents reveal contracts with traditional buyers of Russian weapons, such as India, China, or Algeria, none of which have stopped buying arms from Russia.

The Kyiv Independent, in partnership with OCCRP, obtained a leak containing thousands of internal emails of Roselectronics, a subsidiary of Russia’s state arms giant Rostec.

Arms exports have traditionally been one of Russia’s biggest sources of revenue, although far behind oil and gas. These revenues are now being used to support Russia’s war against Ukraine.

Sanctions imposed after the start of Russia’s full-scale invasion of Ukraine have significantly reduced the country’s arms exports. Still, Russia has managed to continue trade with a dozen countries that have not imposed sanctions on Moscow, making it the world’s third-largest weapons exporter in 2023.

The leak reveals the relentless efforts of Russian arms manufacturers to sustain exports during the war.

Exports help support Russia’s arms industry and fuel its war machine, despite numerous sanctions imposed over its assault on Ukraine. Analysts say the sales also serve as Russia’s “tool of influence,” strengthening its alliances and helping it secure votes at the United Nations. Russia may have even obtained access to Western weapons technologies through its arms sales to Saudi Arabia.

Decoding the secretive Project 82P

Even in internal documentation and letters, Russia maintains some secrecy when it comes to the foreign governments who buy their weapons.

As the leak shows, instead of directly naming the countries that purchase their military products, Russia uses a system that assigns a code to foreign countries, known in Russian as the “All-Russian Classifier of Countries of the World.”

For example, “foreign customer 012” stands for Algeria. In 2022, Russia was going to supply Algeria with its Acacia-E automatic aerospace defense system, according to the leak.

When reporting on deliveries of the Post-3M radio reconnaissance station to Iran in 2021, the letters describe the buyer as “foreign customer 364.”

When mentioning the supply of Polyana-D4M1 command and control system to Egypt, planned for 2025, they code the buyer as “foreign customer 818."

Yet not all the codes are so easy to decipher.

The leak contains a contract encoded in a special way — Project 82P. There is no such country code as “82P,” and the client country isn’t mentioned in almost any of the letters that concerned the project. It appears that this contract was more sensitive than others.

“All the information related to interaction with the foreign customer specified in the contract is subject to restriction,” one of the letters on Project 82P reads. It also says that to keep the details of the contract secret, Russia planned to sign separate confidentiality agreements with the banks involved in the project.

Having analyzed hundreds of letters mentioning Project 82P, the Kyiv Independent can confirm that this code stands for an agreement with Saudi Arabia to supply Pantsir air defense systems. The “82” is a part of the country code for Saudi Arabia (682), and the letter “P” could be referring to the product name — Pantsir.

Within the contract, the Russian side was to supply Saudi Arabia with the Russian Pantsir-S1M system and provide additional services related to it.

The Pantsir is a self-propelled air defense missile and gun system. It can shoot down missiles, airplanes, helicopters, aerial bombs, and drones.

The system itself is a large truck equipped with missiles and anti-aircraft guns, which can be used alone or in battery together with a command post and radar truck.

It recently gained notoriety, as a Russian Pantsir-S battery is alleged to have brought down the Azerbaijan Airlines flight on Dec. 25, killing 38 people.

A view of the crash site where an Azerbaijan Airlines plane with 67 people on board, traveling from Baku, Azerbaijan, to Grozny in Russia’s Chechen Republic crashed near the city of Aktau in Kazakhstan, on Dec. 25, 2024. (Emergency Situations of Kazakhstan/Anadolu via Getty Images)

2 billion euros for Russian military production

While the deal was secret, some evidence surfaced in 2024 that Saudi Arabia obtained Russia’s Pantsir systems.

In February 2024, a photo appeared online showing a man, allegedly a Saudi soldier, posing next to a Pantsir with a training certificate in his hand. At the end of the year, the Saudi Air Defense’s Bulletin listed the Pantsir among its new air defense systems. No other details were provided.

With the leaked Roselectronics emails, the Kyiv Independent can piece together how Saudi Arabia obtained the Russian air defense systems.

The emails reveal not only the high value of the contract but also how Saudi money flows directly to Russian military companies united under the Rostec brand.

According to the leaked documents, Saudi Arabia agreed to pay 2.17 billion euros for the supply of Pantsir batteries, additional equipment and ammunition, and the training of operators.

A battery is a military tactical unit consisting of several pieces of artillery working together. A Pantsir battery usually includes up to six pieces.

According to various references to the contract found in the leaked emails, Saudi Arabia ordered anywhere from six to 10 Pantsir batteries.

Newly revealed details of the Saudi-Russian contract

In more detail, the contract description includes 39 combat vehicles, 10 command post units, nine radio command vehicles, 20 loader vehicles, hundreds of missiles, and tens of thousands of cartridges.

To maintain the Pantsirs, Saudi Arabia also ordered seven repair vehicles, five evacuation trucks, seven fuel servicing trucks, seven storage and transportation vehicles, and other equipment.

They bought various simulators to train the Saudi military and planned three training rounds.

The contract was signed on April 8, 2021, and was expected to last 58 months — that is, until 2026.

The Saudi Defense Ministry made an advance payment of 15% of the contract, or 326 million euros, on Aug. 5, 2021, feeding the Russian military machine with cash just six months before Russia’s full-scale invasion of Ukraine.

Delivery of the first batch of the air defense systems and related equipment was scheduled for the end of 2023.

International trade records found in the ImportGenius database show that at the end of November 2023, Rosoboronexport made two shipments of four units of “new special purpose motor vehicles” to Saudi Arabia. The description is vague but the trademark of the vehicles, the names of Russian shippers and a Saudi consignee, and the cargo delivery point — an air defense base in Jeddah — indicate that the vehicles were supplied under the Pantsir contract.

The leaked Russian documents also show how many subsidiaries of the Russian arms conglomerate Rostec, which is sanctioned by many countries for its role in the war against Ukraine, benefit from the Pantsir exports.

Here’s how Saudi money moved through the Russian arms holding. The advance payment went from the Saudi Defense Ministry to Rosoboronexport.

This state company, a part of the Rostec conglomerate, acts as an intermediary for all of Russia’s military exports and imports, receives payments, takes a commission for contract management, and subsequently transfers the rest of the money to the contractors.

Following receipt of the advance payment, Rosoboronexport distributed the bulk of the funds to state-owned Russian arms producers — Shipunov Design Bureau, known as the developer of the Pantsir complex, United Instrument Manufacturing Corporation (also known under its Russian acronym, OPK), the managing company of the Roselectronics holding, Sozvezdie Concern, the Scientific Research Institute of Communication and Automated Control Systems (NIISSU), the truck producer KAMAZ’ subsidiary Remdizel and others.

Each entity has a role in the contract. For example, OPK has been appointed as the radio command vehicles supplier, while Sozvezdie Concern and NIISSU are its main co-executors. Russian KAMAZ and its subsidiary Remdizel produce the chassis for the system.

All these companies are currently subject to numerous international sanctions either for their role in the deployment of Russian military technologies on the battlefield in Ukraine or for providing a substantial source of revenue to the Russian government during the war.

Rosoboronexport has also been repeatedly subject to U.S. sanctions within a nonproliferation program against Iran, Syria, and North Korea. The latest Iran-related sanctions were imposed on Rosoboronexport in 2023. Rostec was subject to U.S. sanctions before 2022, including for its connection with Russia’s invasion of Ukraine in 2014 and military cooperation with China.

Sanctions on Rostec companies involved in the production and supply of the Pantsir system. (Lisa Kukharska / The Kyiv Independent)

The transfer of Russian technology to Saudi Arabia

According to the leak, the delivery of Pantsir batteries and additional equipment is only part of the 82P Project.

In addition to the 2-billion-euro contract, the documents describing the project mention a second major part of the cooperation. The contract for it, even three contracts, was not yet signed in the first half of 2022, but was already being discussed.

This includes localizing Russian Pantsir systems production in Saudi Arabia, establishing maintenance centers in the country, and creating a training center.

The future localization of production was Saudi Arabia’s requirement to sign the first contract to supply air defense systems.

A leaked letter titled “Localization Plan” contains a 69-page document entitled Proposal for the Localization of the Pantsir-S1M Complex Production. The proposal includes three localization programs.

The first describes the large-scale assembly of 15 Pantsir batteries in Saudi Arabia.

The second localization program establishes a network of service centers for Pantsir maintenance (five regional and one central repair workshop).

The third program involves building a training center in Jeddah, Saudi Arabia’s second-largest city and “economic capital.” The center would require the construction of a 15,000-square-metre study building.

Although none of the three contracts had been signed during the time period covered by the leak, the leaked documents mentioned that Saudi Arabia was ready to sign the assembling production contract in the second half of 2022.

If the contracts were indeed signed, Russia could receive even more than 2 billion euros from Saudi Arabia over the next few years.

Russia’s war with Ukraine, though, could have affected the fate of any joint Pantsir assembly in Saudi Arabia, as the war has allegedly already affected a couple of other Russian export contracts.

��There was a report that Russia had taken away the shells made for Azerbaijan because it needed them in the war against Ukraine,” Ivan Kirichevsky, an analyst at Defense Express, reported. “Another report indicates that Russian T-90S export tanks intended to be sold to India, Algeria, or Vietnam were also spotted on the battlefield in Ukraine. So there are some doubts as to whether Russians can reach the next stage of the Saudi contract — the organization of joint production. They are now highly dependent on imports of various equipment and electronic components. This may affect co-production arrangements."

A pathway to Western military tech

The Pantsir contract carries with it the risk of Russia becoming familiar with Western technologies through its cooperation with Saudi Arabia. The country is a major buyer of U.S. weaponry and buys arms from South Korea and EU countries, including air defense systems.

“Saudi Arabia is one of the major operators of Patriot systems. Whether the Russians could have gained access to them is a sensitive issue,” said Ivan Kirichevsky, an analyst at Defense Express, a Kyiv-based military think tank. “The U.S. has demonstrated that it is sensitive to the risk of transferring its technology to third parties.”

Kirichevsky cites the example of Turkey. In 2020, four months before the Russian-Saudi agreement was signed, the U.S. slapped sanctions on Turkey over a purchase of the Russian S-400 missile system.

The risk of Russians accessing U.S. technology is high since the Project 82P also includes “integration” services, meaning integrating the Pantsir complex into Saudi Arabia’s command, communications, and intelligence system.

Russia’s President Vladimir Putin and Saudi Crown Prince Mohammed bin Salman hold a meeting in Riyadh, Saudi Arabia, on Dec. 6, 2023. (Sergei Savostyanov / Pool / AFP via Getty Images)

Those services would be performed by Russian specialists, who could obtain access to the existing Saudi arsenal, which is stuffed with U.S. weapons.

Moreover, Russia appeared to have asked for this access.

In October 2021, some six months after signing the contract, Saudi Arabia’s representatives met with the Russian side in Moscow to discuss the execution of Project 82P. The Kyiv Independent found the meeting’s minutes in Russian companies’ emails.

The emails mention an upcoming trip by Russian representatives to Jeddah in Saudi Arabia, scheduled for May 2022. While discussing the meeting, the Russian side requested to visit Saudi air defense facilities — and received consent. They started making preparations for the trip like booking the hotel, car rental, and buying tickets.

The obtained email leak covers the time up until May 2022, the same month when the trip was supposed to take place. While the Kyiv Independent can’t confirm that the trip took place, there was no sign it was canceled either.

The Saudi Defense Ministry did not respond to a written inquiry from the Kyiv Independent.

Why is Russia selling air defense while waging war with Ukraine?

Russia’s efforts show it’s highly interested in selling arms and military technology abroad, despite its massive need for weapons for its war against Ukraine.

According to one of the leaked letters, in June 2022, four months after the start of the full-scale invasion of Ukraine, state arms exporter Rosoboronexport held a three-day meeting with arms manufacturers in St. Petersburg. The event was private, with no public mentions of it.

The topic was promoting Russia’s anti-unmanned aerial vehicle (UAV) equipment “with high export potential.” A Rosoboronexport representative held a presentation on how export sales could be boosted.

Two months later, in August 2022, Rosoboronexport hosted a different event, this time a public one. Its seven-day International Military-Technical Forum aimed to secure new arms sales contracts. It reportedly attracted delegations from 50 countries.

Local media made no secret of Russia’s efforts to interest foreign delegations in a wide range of military products, including tanks, armored vehicles, UAVs and anti-UAVs, air defense systems, rifles, mortars, and fighter aircraft. Similar events were held in 2023 and 2024 and are planned for 2025.

Trying so hard to sell weapons abroad while leading a resource-demanding war may seem like an odd thing to do but there are at least two good reasons for Russia to pursue it: high export revenue and strengthening geopolitical ties.

Arms under export contracts are traditionally sold at a higher price than those supplied to the domestic army.

“The policy of arms export contracts is always the same: You sell your products to someone for export at a premium to supply your army at a lower cost,” said Kirichevsky, an analyst at Defense Express. “The price of the 2 billion euros for six Pantsir batteries seems very high, even when it includes additional equipment and training for the military."

Although Russia’s export capacity started crumbling after the start of Russia’s invasion of Ukraine, it remained a significant exporter of military products. The Stockholm International Peace Research Institute (SIPRI) compared data on Russian arms exports for two periods: 2014-2018 and 2019-2023. The institute found that, between those two periods, the volume of Russian arms exports fell by 53%. The number of countries willing to buy Russian arms has also decreased, but 12 countries were still buying Russian weapons in 2023.

Leaked letters show that Rosoboronexport received new export inquiries after Russia’s invasion of Ukraine.

In spring 2022, soon after the world learned about the Russian massacre of civilians in Ukraine’s Bucha and other places, the Russian defense conglomerate received new inquiries from potential clients.

The leaked emails show that Armenia inquired about a possible delivery of the Ranzhir-M1, a command center unit for air defense systems. Meanwhile, Venezuela was interested in Pishchal-Pro and Kupol complexes, the systems that take down unmanned aerial vehicles, or UAVs.

The Kyiv Independent was unable to find confirmation of such deliveries in public sources, or in the customs records available through leaks.

Russia also continued to work on executing contracts signed in previous years. There are no mentions of any contracts canceled by either side after the start of the invasion.

In 2022, Rostec worked on contracts with China, India, Algeria, Egypt, Belarus, and several other countries, all of which continued to receive military supplies from Russia after its full-scale invasion of Ukraine and new sanctions against the Russian defense companies.

Experts say that Russia is motivated to sell its weapons abroad not only by money but by the prospect of establishing or strengthening of geopolitical ties.

“Russia sees arms sales as another tool of statecraft. It’s a tactic,” Anna Borshchevskaya, a senior fellow with the Washington Institute for Near East Policy, says. “It’s not independent of foreign policy, and so arms sales will strengthen bilateral ties between countries on a political level. It’s a tool of influence from the Russian perspective."

According to Agiya Zagrebelska, a Ukrainian sanctions expert and representative of the NGO Economic Security Council of Ukraine, the result of such ties can be seen in the countries' votes at the UN.

Although the allegiance to Russia is not as clear as in the case of Belarus, China, or Iran, Saudi Arabia has abstained from more than half of the UN votes for resolutions on Russia’s war against Ukraine. (See the chart)

How countries buying Russian weapons vote at the UN. (Lisa Kukharska / The Kyiv Independent)

On the one hand, the country voted for the withdrawal of Russian troops from Ukraine. However, it abstained from voting on resolutions on the suspension of Russia’s rights of membership in the Human Rights Council and on remedy and reparation for aggression against Ukraine.

Saudi Arabia has also helped to free foreigners imprisoned by the Russian military and brought together 42 countries in Jeddah to find ways to end the Russian war in Ukraine. It has also allegedly threatened the G7 against seizing Russia’s frozen assets, according to Bloomberg’s sources.

The country has also promised to provide Ukraine with $400 million in humanitarian aid while pledging billions to Russia’s military enterprises.

Yet even with rich clients like Saudi Arabia, the volume of Russia’s arms exports has fallen in recent years.

Due to Western sanctions, it has become both difficult and costly for Russia to import Western equipment and electronic components it still needs for defense production. Some reports also suggest that Russia deployed some of the weapons meant for export to the front line in Ukraine.

This makes Russia an increasingly problematic supplier.

Note from the author:

Hey! This is Alisa Yurchenko, the author of this story. Thank you for reading it.

I spent the past two months reading leaked internal correspondence of Russian state defense companies. The letters were scattered and out of order, so I had to reconstruct their timeline like a jigsaw puzzle.

But it was all worth it. I was glad to reveal how many sanctioned Russian military companies profit from a major arms export deal.

Understanding this is crucial as such deals bolster Russian defense industry and the country’s geopolitical standing — all while Russia is waging a full-scale war.

We are not done with this particular leak, however. We are still analyzing it and will soon share insights about Russia’s efforts to source foreign components for its defense industry.

Please consider supporting the Kyiv Independent by becoming a member or making a one-time donation. It is our readers’ support that makes our work possible. Thank you!

0 notes

Text

BOPP Films Industry Analysis and Forecast 2024-2032: Market Size and Growth Prospects

The global BOPP films market was valued at USD 23.55 billion in 2023. The market is projected to grow from USD 24.76 billion in 2024 to USD 38.40 billion by 2032, exhibiting a CAGR of 5.64% during the forecast period.

Polypropylene, when stretched in machine and transverse directions, results in biaxially oriented polypropylene, also commonly known as BOPP films. As per study, the recyclability of BOPP films, along with its robustness, serves it as a major contributor to lower plastic waste. Moreover, its low-weight reduces the packaging material's overall weight, resulting in cost-effective transportation.

Fortune Business Insights has deep-dived into these inputs in its latest research report titled "BOPP Films Market, 2024–2032".

Request For Sample Report: https://www.fortunebusinessinsights.com/enquiry/sample/bopp-films-market-109631

Segments:

Plain Film’s Superior Properties Over its Counterparts make it Market Leader

By type, the market is profiled into plain, matt, metalized, pearlized, and others. BOPP plain films dominate and secured a substantial 57.26% market share in 2023 with plain film’s flexibility and high tear resistance.

Wraps Segments Tops Market Position with Its Moisture Contravention Function

By product type, the market is classified into wraps, tapes & labels. Food and medical products require packaging with moisture resistance and transparency, placing BOPP wraps at the top owing to its increasing preference.

Food Segment Dominates Market Owing to Mounting Demand from Food Industry

By end use, the market is categorized into food [bakery & confectionary, dairy, meat, poultry & seafood, fruits & vegetables, others], tobacco, medical & pharmaceutical packaging, printing & stationery, beverage, and others. The food segment leads the market as the food and beverage sector witnesses a high demand for BOPP films in secure packaging in transit and on the shelf.

Regionally, the market is studied across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Report Coverage

The research report offers a detailed examination of market trends, notable industry developments, and factors favorable for the market’s growth. Moreover, it includes emerging opportunities and challenges within the market. In addition to the above factors, the report also covers key strategies by market players, their positioning, and technological advancements shaping the market landscape.

Drivers and Restraints

Remarkable Qualities of BOPP Films Increases Demand, Fostering Market Growth

Food suppliers prefer BOPP films for packaging owing to their multiple advantages, including extended shelf life for food products, moisture permeability, and food safety. Manufacturing companies diligently focus on meeting the lifestyle of modern people, which is shifting toward health consciousness by developing high-quality biaxially oriented polypropylene films. These films serve as an exemplary substitute for other packaging films by providing food safety during transit.

However, the BOPP films market growth may be impeded as these films need special processing for certain types of packaging.

Regional Insights

Asia Pacific Holds Leadership Position with the Region’s Rising Economy

Asia Pacific leads by capturing the largest BOPP films market share and secured a market capital of USD 9.03 billion in 2023. The surging population and rising economic growth in Japan, India, and China create a positive outlook for the market over the coming years.

Europe stands in second position, following Asia Pacific, powered by the presence of prominent companies producing tobacco and an escalating number of tobacco users.

Ask For Customization: https://www.fortunebusinessinsights.com/enquiry/ask-for-customization/bopp-films-market-109631

Competitive Landscape

Key Companies Aim to Increase Consumer Base through Innovations

The highly competitive market houses industry giants, including SRF Limited, CCL Industries, and Taghleef Industries, among many others. Client pool expansion and development of cutting-edge technology to make advancements in BOPP films are predominantly centered on market leaders.

Key Industry Development

August 2023: Mitsui Chemicals Tohcello, Toppan, and Mitsui Chemicals unveiled joint pilot testing for horizontal recycling of flexible packaging film to establish operational infrastructure and technologies for recycling flexible packaging materials.

List of Major Players Profiled in the Report:

Taghleef Industries (UAE)

SRF Limited (India)

TORAY INDUSTRIES, INC. (U.S.)

ObenGroup (Peru)

UFlex Limited (India)

NAN YA PLASTICS CORPORATION (Taiwan)

Polyplex (India)

Jindal Poly Films Limited (India)

CCL Industries (Canada)

FUTAMURA CHEMICAL CO., LTD. (Japan)

Cosmo Films (India)

Amcor plc (Switzerland)

0 notes

Text

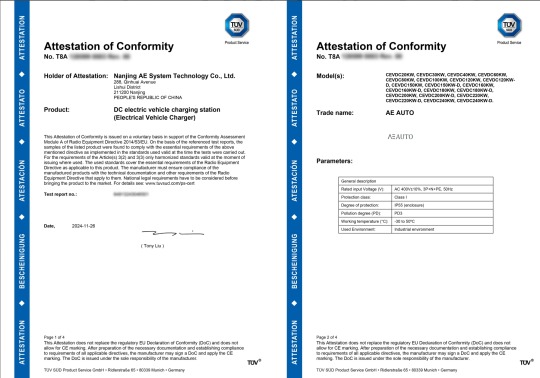

AEAUTO successfully unlocked the TUV certificate

TUV testing (Technischer überwachüngs-Verein) means Technical Inspection Association in English . TUV testing is similar to China's Technical Quality Supervision Bureau. In the early days of its establishment, each state had an independent TUV organization. Still, the difference is that each state's TUV is an independent third-party organization rather than a government organization, but it undertakes many state-authorized tasks. With mergers and acquisitions, by 2008, the largest in Germany was TUV SUD, and the second largest was TUV Rheinland. Currently, TUV organizations in mainland China generally refer to TUV SUD or TUV Rheinland.

The TUV certification body's authority is very high in the field of electronic appliances and components. It is widely recognized by customers in various countries, especially in Europe and the United States. Therefore, it has gained a high degree of recognition and is able to carry out TUV's CE, mark, CB, GS, and other certifications.

What is TUV certification?

The TUV mark is a safety certification mark specially customized by Germany's TUV for component products, which is widely accepted in Germany and Europe. At the same time, when applying for the TUV mark, enterprises can apply for the CB certificate together, thereby obtaining certificates from other countries through conversion.

Moreover, after the product passes the certification, Germany's TUV will recommend these products to rectifier manufacturers who come to inquire about qualified component suppliers; in the whole machine certification process, all components with the TUV mark are exempt from inspection.

Moreover, after the products pass the certification, Germany's TUV will recommend these products to rectifier manufacturers who come to inquire about qualified component suppliers; during the whole machine certification process, all components that have obtained the TUV mark are exempt from inspection.

TUV certification scope

Consulting services for certification of radio and communication products

Product testing: short-range wireless equipment, wireless LAN, GSM, CDMA, DECT, Bluetooth, PMR, micro equipment, PLG, modem, ISDN, ADSL, xDSL, communication network equipment, etc

Test radio communication equipment according to ETSI standards, FCC standards of the United States, and standards of other countries such as Australia, Singapore, and Japan

Information circular on spectrum permitted in Europe

Electromagnetic compatibility test

Electrical Safety and Health Protection Test (SAR Assessment)

Test the compatibility and quality of analog and digital terminal equipment

On-site or public training and seminars on radio and communication equipment

Testing for restricted substances

Light industrial product testing

Reliability test

Guide testing and certification of automotive products.

TUV certification agency is highly authoritative in the field of electronic appliances and components and is well recognized by customers in various countries, especially in Europe and the United States, so it has gained a high degree of recognition.

At the same time, Nanjing AE System has also passed the CE system certification, which is a rigorous and authoritative certification system established by the European Union for many key indicators such as product safety, health, and environmental protection. CE certification has extremely high recognition and credibility. Once a product successfully obtains this certification mark, it is equivalent to having a "pass" to travel freely in Europe and even many regions around the world that recognize this certification. It can effectively demonstrate that the product meets international cutting-edge standards and specifications, has excellent quality, and is safe and reliable. AEAUTO's successful certification once again proves that the products manufactured by our company meet international electrical safety standards, providing strong support for further expansion of the international market.

AEAUTO has always regarded product quality and efficient service as the lifeline of the enterprise. Through advanced product technology and continuous improvement of management level, it ensures that the products reach higher standards than the same industry. The successful acquisition of TUV and CE certification is not only a high recognition of AEAUTO's quality management but also a full proof of its technical strength and innovation ability.

In the future, AEAUTO will continue to increase investment in scientific research, continuously improve its product innovation capabilities, and continue to provide customers with higher quality, safer, and more reliable products.

0 notes

Text

Screw Suppliers in India: Building a Global Reputation

India has emerged as a significant player in the global screw manufacturing and supply industry, thanks to its skilled workforce, advanced production technologies, and competitive pricing. Indian screw suppliers cater to a wide range of industries, including automotive, construction, electronics, and aerospace, offering products that meet international quality standards. With a focus on precision engineering, durability, and customization, Indian suppliers have earned the trust of clients worldwide. Government initiatives like Make in India and incentives for exports have further fueled the sector’s growth. By adopting sustainable practices and embracing innovation, Indian screw suppliers are solidifying their position in global markets, proving themselves as reliable partners for industrial and commercial needs.

Why Choose Indian Screw Suppliers?

Screw suppliers in India offer a wide range of fasteners that cater to industries like automotive, construction, electronics, and machinery. Known for their cost efficiency, Indian suppliers leverage local raw materials and skilled labor to provide high-quality screws at competitive prices. Additionally, Indian suppliers are adapting to global standards with ISO-certified manufacturing processes, making them a preferred choice for domestic and international clients.

Types of Screws Offered by Indian Suppliers

Machine Screws: Commonly used in industrial applications.

Wood Screws: Ideal for carpentry and woodworking.

Self-Tapping Screws: For sheet metal and plastic.

Hex Screws: Designed for heavy-duty machinery.

Specialty Screws: Custom-designed screws tailored for specific industries.

This diversity ensures Indian suppliers can meet the needs of various sectors, making them versatile and reliable partners.

Regions Leading Screw Supply in India

Ludhiana: Known as a hub for fastener manufacturing, producing high-quality screws and bolts.

Pune and Mumbai: Emerging as centers for automotive fasteners.

Delhi-NCR: Specializes in industrial and construction fasteners.

Chennai and Bengaluru: Key exporters of precision screws for the technology and electronics industries.

These regions not only cater to domestic markets but also serve as significant exporters to countries across Europe, the Americas, and the Middle East.

Technological Advancements in Screw Manufacturing and Supply

CNC Machining: For high precision and uniformity.

Heat Treatment: Ensuring screws meet strength and durability standards.

Surface Coating Techniques: Providing corrosion resistance and enhanced aesthetics.

Automation: Improving efficiency and reducing lead times.

By integrating these technologies, Indian suppliers ensure their products meet international standards, catering to diverse industrial requirements.

Challenges Faced by Screw Suppliers in India

Rising Raw Material Costs: Fluctuations in steel prices directly impact production costs.

Global Competition: Competing with countries like China, which dominate the fastener market.

Skilled Labor Shortage: The need for a workforce trained in advanced manufacturing techniques.

Logistical Barriers: Delays in supply chains affecting delivery schedules.

Addressing these issues through innovation and government support is essential for the industry's sustained growth.

Opportunities for Screw Suppliers in India

The increasing demand for screws in industries like renewable energy, aerospace, and infrastructure development offers significant opportunities. Government initiatives like Make in India and the focus on local sourcing present further growth avenues. Additionally, the rising preference for sustainable and recyclable materials opens doors for eco-friendly screw production.

Export markets also provide tremendous potential. With India gaining recognition for its quality products, suppliers can expand their reach globally, especially in regions seeking cost-effective alternatives to European and Chinese manufacturers.

How to Choose the Best Screw Supplier in India?

Certifications and Standards Compliance: Look for suppliers adhering to ISO and other international standards.

Product Range: Ensure the supplier offers screws suited to your industry’s specific needs.

Customization Options: Check if they can design and produce specialty screws.

Reputation and Experience: Research reviews and track records of suppliers.

Delivery Timelines and Logistics: Ensure they can meet your deadlines efficiently.

A thorough evaluation will help you identify a reliable partner for your screw requirements.

Conclusion

Screw suppliers in India are becoming global leaders due to their ability to provide high-quality, cost-effective solutions across industries. With advancements in technology, increasing demand from domestic and export markets, and support from government policies, the industry is poised for significant growth. However, overcoming challenges like raw material costs and global competition is critical to unlocking the sector’s full potential. By focusing on quality, innovation, and sustainability, screw suppliers in India can secure a stronger foothold in the global market and continue contributing to India's industrial growth.

0 notes

Text

HYB64 Steel-Based Copper Alloy Bearing

The steel-based copper-alloy bearing is produced by compounding the rolled tin bronze and other alloy plates in a steel or cast die cavity with a special process. It has the abrasion resistance of copper alloy and high mechanical strength of steel. Compared with traditional copper pieces, it can reduce more than 25% cost. So, it is widely applied in the sliding pairs of various machines and mechanical equipment.

The processing of this series of products is customized as per the drawings.

0 notes

Text

Granulator

Role of Pelletizer Pelletizer is a kind of machine equipment, its main role is to powder, granular, infiltrating liquid, and some other materials are processed into different sizes of granular materials. Specifically, the granulator can extrude powdery raw materials into granules, and can also press granular raw materials into different sizes of granules. This not only improves the utilization rate of the material, but also improves its flowability, reduces the dosage, increases the stability, and so on.

0 notes

Text

Increasing production and reducing costs with Smartjet

Facing intense competition and the need to maintain high-quality yarn production, Wugang Longshan Textile Technology Co. Ltd. partnered with Rieter to implement the innovative Smartjet power nozzle technology for their automatic winding machine Autoconer X5. This upgrade boosted machine efficiency by up to 3%, reduced operator workload and cut conversion costs, enabling Wugang Longshan Textile Co. Ltd. to strengthen their market position.

Rieter’s customer, Wugang Longshan Textile Technology Co. Ltd., located in Pingdingshan, Henan, China, operates with a substantial capacity of 360 000 spindles. Founded in 1988, it is a leading supplier of high-quality yarn in the market. Wugang Longshan Textile Technology Co. Ltd. is a subsidiary of Wugang Yinglong Group which has a total capacity of 700 000 spindles and specializes in producing compact cotton yarn in a yarn count range of Ne 32 to Ne 80, with an annual output of 60 000 tons of weaving and knitting yarn. Their average yarn count is Ne 45, and they consume around 70 000 tons of cotton annually. Additionally, they operate 2 160 rotor spinning units.

Coping with challenging market dynamics

In the face of intense competition and declining yarn prices, Wugang Longshan Textile Technology Co. Ltd. was looking for upgrades and conversions to reduce operational costs. They aim to be cost competitive without compromising on yarn quality.

Increased machine efficiency lowers conversion costs

Rieter’s after-sales team worked closely with Wugang Longshan Textile Technology Co. Ltd. to understand their specific challenges and needs. In March 2024, the Rieter team installed Smartjet conversions on three winding machines Autoconer X5. This upgrade included introducing additional parts to enhance machine performance. The installation of the first batch of Smartjet power nozzles on the existing doffer unit significantly reduced downtime and the frequency of red lights on the machines. Smartjet functions as a search device, improving the success rate of upper yarn end manually searches by 51%. This technology supports the suction nozzle in picking up upper yarn ends that would otherwise be missed. The increased efficiency in yarn end searches translates directly to higher machine efficiency and reduced downtime. Impressed with the initial results, Wugang Longshan Textile Technology Co. Ltd. ordered the Smartjet upgrade for another ten Autoconer X5.

Smartjet helps improve yarn production and reduce labor cost

The Smartjet nozzles had a profound impact on the efficiency, productivity and labor cost of Wugang Longshan Textile’s operations:

Machine efficiency rose from 80% to 83%, translating to an increase in production to 21 kg per machine per eight-hour shift.

Annual yarn production expanded by 20 790 kg.

The demand for manual yarn searching was reduced by 51%, significantly lowering the operators’ workload.

Operators were able to manage one additional winding machine, thereby reducing labor costs.

The energy cost per kilogram of yarn was reduced due to increased efficiency.

With the Smartjet nozzle upgrade, not only did production increase, but the need for manual intervention was greatly diminished too. This allowed operators to handle more winding machines simultaneously, effectively lowering labor costs. Additionally, the increased production efficiency led to a reduction in energy consumption per kilogram of yarn produced. These improvements in turn lowered conversion costs which made the customer cost competitive.

”The Smartjet nozzle strengthens our market position significantly. It helps reduce operator workload and conversion costs while increasing yarn production. The retrofit of the Smartjet power nozzle on the doffer has been a game-changer for our operations, enhancing our productivity and reducing overall costs. Wang Ping, Chief Engineer at Wugang Yinglong Group.”

0 notes

Text

Customized PV photovoltaic accessories quenched T-shaped square head bolts (can be threaded)

This quenched T-shaped square head bolts is a fastener model specially designed for photovoltaic industry. It is mainly used for connecting and fixing photovoltaic brackets, solar panels and other components, providing strong and stable fastening for projects. The production of this bolt requires advanced machines and high manufacturing technology. Our equipment and processes are dedicated to manufacturing the products meet our customers requirements. We provide customized services for the size, shape, appearance, grade, surface treatment, etc. of bolts. Please feel free to contact us if you need it.

0 notes

Text

1100D 11 SBR foil aluminium foil laminated

Zhejiang Shengdannu New Materials Technology Co.,Ltd. is a professional manufacturer specializing in technical textile field. With 20 years export experience and researches on the new material field for all textile field. We started research on textile for industry on 2018. Based on a group of 10 technical people with 2 years research, we are now aimed on reinforcing textile materials for films and boards. Company imported Laid Scrim machine from German which can produce more than 60000 square-meter scrim every day with single or double layer lamination optionally.

As 1100D 11 SBR foil aluminium foil laminated scrims Suppliers and custom Company, our main products include glass fiber and high strength polyester fiber laid scrim with 1*1 -3*3 /cm mesh. Single and double sides lamination with PVC tarpaulin, aluminium foil, PET foil, polyester non-woven fabric and glass fiber non-woven fabric. Those product widely used for indoor and outdoor waterproof system, thermal isolation system, road construction, agricultural shed, PVC flooring, cement board reinforcement and etc.,

Telphone +86-13255848688

Phone +86 15067365510

Fax +86-0574-62401821

E-Mail [email protected]

Address No18 Hongqi East Road, Maqiao Street, Haining, Zhejiang, China

0 notes

Text

Here are some laser engraver suppliers and manufacturers:

Trotec Laser: Offers high-end laser machines for precise engraving, marking, and cutting. With over 25 years of experience, they develop innovative, comprehensive laser systems. Their laser machines, powerful software, and high-quality materials are perfectly matched.

Linxuan Laser: With more than 18 years of experience in the laser industry, it is one of the top industrial laser marking/carving machine manufacturers in China. They provide customized laser marking + carving solutions with cost-effectiveness, potentially saving up to 10%-20% on costs.

HGLASER: A pioneer and leader in China's laser industrial applications and one of the world's leading laser equipment and intelligent manufacturing solution providers. They offer a variety of laser cutting systems, laser welding systems, laser marking series, laser texture complete equipment, laser heat treatment systems, laser drilling machines, and various support equipment, special laser processing equipment, and plasma cutting equipment, as well as the construction of automatic production lines and intelligent factory solutions.

Epilog Laser: Provides laser engraving, cutting, and marking machine systems. Their product line includes Fusion Maker Lasers, Fusion Edge Lasers, Fusion Pro Lasers, and Fusion Galvo Lasers.

Made-in-China.com: Offers a directory of laser engraver manufacturers, suppliers, and factories, including Zhejiang Shengli Laser Technology Co., Ltd., Shanghai Yuehua Laser Technology Co., Ltd., Guangdong Guangwei Laser Technology Co., Ltd., and more.

Argus Laser: A professional laser solution provider since 1998. They offer advanced high-speed laser equipment for cutting, engraving, and industrial marking.

These laser engraver suppliers offer a range of laser engraving machines in different models and specifications suitable for various materials and application scenarios. You can choose the appropriate laser engraver suppliers and machine model based on your specific needs and budget.

0 notes

Text

Printing And Packaging Cutting Machine

With the rapid development of the printing and packaging industry, the demand for high-quality, high-efficiency and diversified cutting processing has been increasing. With the advantages of high automation, high precision and high efficiency, cutting machines are playing an increasingly important role in the printing and packaging industry.

0 notes

Text

China Fiber Laser Cutting Machine Manufacturer & Factory

15 years of experience in laser equipment production and manufacturing, serving 1000+ customers, specializing in the production of laser cutting machines, laser pipe cutting machines, laser cleaning machines, laser welding machines and other products. The professional design and R&D team can provide OEM and ODM services to provide you with the most affordable price.

1 note

·

View note

Text

Unbeatable Prices on Electric Forklifts: Shop Now

Unbeatable Prices on Electric Forklifts: Shop Now

In the competitive world of industrial operations, efficiency and cost-effectiveness are paramount. As companies strive to enhance productivity and reduce operational costs, the demand for electric forklifts has surged. These eco-friendly machines offer numerous advantages over traditional internal combustion engine (ICE) forklifts, making them a smart investment for modern businesses. And now, with unbeatable prices on electric forklifts available, there has never been a better time to upgrade your fleet. This article explores the benefits of electric forklifts and why you should take advantage of these exceptional deals.

The Advantages of Electric Forklifts Environmental Sustainability

Electric forklifts are powered by rechargeable batteries, producing zero emissions during operation. This makes them an environmentally friendly option compared to diesel or gasoline-powered forklifts. By choosing electric forklifts, companies can reduce their carbon footprint and contribute to a cleaner, healthier environment. This commitment to sustainability can also enhance a company's reputation and appeal to eco-conscious customers and stakeholders. ForkLift pallet truck | China Manufacturer Trade Price on Materials Handling electric pallet truck PT 16L Li Sale Buy Online Trade Importer of | FORKLIFT Cost Savings

While the initial purchase price of electric forklifts may be higher than ICE forklifts, the long-term cost savings are significant. Electric forklifts have lower operating costs because electricity is generally cheaper than diesel or gasoline. Additionally, electric forklifts require less maintenance due to fewer moving parts, eliminating the need for oil changes, spark plug replacements, and other engine-related services. These savings can add up quickly, providing a substantial return on investment.

Improved Indoor Air Quality

Electric forklifts do not produce exhaust emissions, making them ideal for indoor use. This improves indoor air quality, creating a healthier work environment for employees. In industries such as food and beverage, pharmaceuticals, and warehousing, maintaining clean air is crucial for both employee health and product integrity.

Quiet Operation

Electric forklifts operate more quietly than their ICE counterparts, reducing noise pollution in the workplace. This quieter operation enhances the work environment, allowing employees to communicate more effectively and reducing overall stress levels.

Enhanced Performance

Modern electric forklifts are equipped with advanced technology that enhances performance and efficiency. Features such as regenerative braking, advanced battery management systems, and precise control systems contribute to smoother and more efficient operation. These technological advancements make electric forklifts a reliable choice for various applications, from warehouse operations to outdoor tasks.

Unbeatable Prices on Electric Forklifts With the growing demand for sustainable solutions, many manufacturers and dealers are offering unbeatable prices on electric forklifts. These special deals and promotions make it more affordable than ever to invest in these eco-friendly machines. Here are some tips for finding the best deals on electric forklifts:

Research Suppliers

Start by researching reputable suppliers and manufacturers that offer electric forklifts. Look for companies with a track record of providing quality products and excellent customer service. Reading reviews and seeking recommendations can help you find reliable suppliers.

Compare Prices

Take the time to compare prices from different suppliers. Look for special promotions, discounts, and financing options that can make the purchase more affordable. Be sure to consider the total cost of ownership, including maintenance and operating costs, when comparing prices.

Explore Trade-In Programs

Some suppliers offer trade-in programs that allow you to trade in your old equipment for a discount on new electric forklifts. This can be a cost-effective way to upgrade your fleet and take advantage of the latest technology.

Negotiate

Don’t be afraid to negotiate with suppliers to get the best possible deal. Many companies are willing to offer additional discounts or incentives to secure a sale, so be sure to explore your options and ask for the best price.

Conclusion Investing in electric forklifts is a strategic move that can enhance your operational efficiency, reduce costs, and contribute to a more sustainable future. With unbeatable prices on electric forklifts available, now is the perfect time to upgrade your fleet and take advantage of these exceptional deals. By choosing electric forklifts, you can enjoy the numerous benefits they offer and position your business for long-term success.

0 notes

Text

How Chatbots are Revolutionizing Customer Experience in Exponential Growth Trends

The chatbot market has seen tremendous growth in recent years driven by need for enhanced customer support services. Chatbots provide round-the-clock customer support across websites and social media platforms through conversational interactions. Chatbots are powered by advanced technologies like artificial intelligence and natural language processing to understand customer queries, resolve issues and provide timely assistance. They are designed to emulate human conversations through voice and text to effectively address customer needs. Global chatbot market is estimated to be valued at US$ 1.2 Billion in 2024 and is expected to exhibit a CAGR of 25% over the forecast period 2024-2029. The market offers immense opportunities for businesses to automate repetitive support tasks and customer queries. This significantly reduces overhead costs and allows organizations to re-allocate resources to more strategic priorities. Chatbots also help boost customer satisfaction by resolving issues instantly without long wait times. Key Takeaways Key players: Key players operating in the chatbot market are Anthropic, International Business Machines Corporation (IBM), Nuance Communications, eGain Corporation, Artificial Solutions, Creative Virtual, Next IT Corporation, CX Company, and Speaktoit. Growing demand in the market - The demand for chatbots is growing steadily due to benefits like reduced operating costs, improved customer experience and around-the-clock support. Businesses are increasingly adopting chatbots for customer care, sales and marketing to engage customers proactively. Global expansion of market- Several major chatbot developers have expanded their geographical footprint to cater to the burgeoning demand globally. They are focusing on emerging markets like Asia Pacific and Latin America which offer huge untapped growth potential for conversational AI technology. Market Key Trends One of the key trends observed in the Chatbot Market Growth is the shift towards more specialized and domain-focused solutions. Earlier, chatbot development focused on creating one-size-fits-all platforms. However, as businesses recognize the importance of deep domain expertise, specialized chatbots are being developed for functions like e-commerce, healthcare, banking, travel and hospitality. These understand business nuances better and deliver superior experience. As technology evolves further, domain-focused solutions will play a greater role in driving business outcomes.

Porter's Analysis Threat of new entrants: Low capital requirement but high technical barrier to entry due to intense IP protection from major players. Bargaining power of buyers: Chatbots being used for various services and personal assistance, buyers have medium to high bargaining power to negotiate on pricing and functionality. Bargaining power of suppliers: Major technology providers have high bargaining power being the solution providers and can influence pricing and profit margins. Threat of new substitutes: Alternate technologies like voice AI poses potential threat but chatbot being uniquely positioned for text conversations have less threat currently. Competitive rivalry: Intense competition among global and local players to acquire more customers. Major players focusing on expanding capabilities to edge out competition. Geographical Regions: North America accounted for the largest share of over 35% of global chatbot market in terms value in 2018 led by high tech adoption and massive investments from technology giants in the region. Asia Pacific region is expected to be the fastest growing regional market for chatbots majorly attributed to proliferation of messaging apps in countries like China, India along with government support and investments for AI development.

Get more insights on Chatbot Market

Discover the Report for More Insights, Tailored to Your Language

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Coherent Market Insights#Chatbot Market#Chatbot#AI Chatbot#Conversational AI#Virtual Assistant#Natural Language Processing#Machine Learning#Customer Service Bot#Chatbot Technology#Automated Responses#NLP

0 notes

Text

Freight Forwarder China to Mexico: Helping a Client Solve Complex Shipping Issues

Freight Forwarder China to Mexico: Helping a Client Solve Complex Shipping Issues

Recently, I took on a special task: helping my client Jack ship a batch of goods from Shanghai to the Port of Manzanillo in Mexico. Jack is the head of a U.S.-based trading company that specializes in selling Chinese-made home goods to the North American market. This time, the shipment involved a large quantity of furniture components that would be assembled in Mexico before being distributed.

Jack told me, “Alice, this shipment consists of 100 boxes, weighing about 2.8 tons in total, with a volume of 20 cubic meters. It absolutely needs to reach Mexico within two weeks, or our assembly plant will have to stop production.” I knew this meant the shipping had to be smooth and efficient, or it would cause significant losses for the client.

“No problem, Jack,” I reassured him. “I’ll arrange the best freight forwarder China to Mexico plan, and I’ll make sure the goods reach their destination as quickly as possible.”

“This time, we need to make sure all the documents are accurate and that the customs clearance goes smoothly,” Jack emphasized. As an experienced freight forwarder China to Mexico, Sunny Worldwide Logistics not only offers shipping services but also helps clients handle the complicated parts, especially customs and paperwork.

First, I contacted the supplier to confirm the shipping schedule and details of the goods. Since the shipment included wooden furniture components, I had to make sure all the necessary documents were ready in advance—detailed product descriptions, certificates of origin, and all relevant inspection and quarantine paperwork. After multiple communications with the supplier, we ensured that all the documents were correct.

At the same time, I provided Jack with some advice on the customs clearance process in Mexico. Our company is very familiar with Mexico’s customs procedures and tax regulations, and we can usually complete clearance 1-2 days faster than other companies. This is a big advantage we offer as a freight forwarder China to Mexico.

Once the documents were ready, I secured space on the vessel and informed Jack about the estimated transit time. Due to recent capacity constraints, some shipping lanes were experiencing delays, so I prepared multiple backup options for him. This way, if one route got delayed, we could quickly switch to another without impacting the delivery time.

The next day, Jack called me, “Alice, I might need your help with something. Our partner factory in Mexico needs some special machine parts, but our supplier there can’t deliver them on time. I know this isn’t part of your service, but is there any chance you could help us find a supplier in China and ship the parts along with the furniture?”

Having been a freight forwarder China to Mexico for 26 years, I often receive these types of extra requests from clients. At Sunny Worldwide Logistics, we’re known for offering extra services without charging additional fees. If a client needs something, we always do our best to help. I quickly found a suitable machine parts supplier through our network, purchased the items, and arranged for them to be shipped together with the furniture components.

Two days later, the goods were successfully loaded onto the vessel. Before the shipment left, I made sure to remind Jack, “If anything comes up during transit, we’ll let you know immediately. I’ll also track the shipment every day to make sure the customs clearance goes smoothly once it arrives.”

After the goods left China, I stayed in constant communication with the shipping line and our customs agents in Mexico to make sure everything was going as planned. Jack was very happy with our detailed arrangements as a freight forwarder China to Mexico. “You’ve really saved us this time,” he said. “Not only did you handle the shipping perfectly, but you also helped us get those crucial machine parts. That saved us so much time.”

Although problems can arise during shipping, our team is experienced and quick to react in emergencies. We always strive to provide the best support for our clients. Jack’s order was time-sensitive, but thanks to our careful planning and efforts, everything went smoothly in the end.

As a professional international freight forwarder, Sunny Worldwide Logistics always puts the client’s needs first. We don’t just offer shipping solutions; we also help clients with other tasks so they can focus on their core business. Want to know more about me? Check out my diary!

0 notes

Text

The Shift to Overseas Clothing Manufacturing: A Comprehensive Overview

The trend of American clothing companies manufacturing their apparel overseas has become increasingly prevalent in recent decades. This shift is driven by a complex interplay of economic, logistical, and strategic factors that make overseas production more appealing than domestic manufacturing. Below, we delve into the key reasons behind this trend and explore the implications for various segments of the clothing industry, including custom clothing manufacturers, women’s clothing manufacturers, and kids’ clothing manufacturers.

1. Cost Efficiency and Economies of Scale

a. Lower Production Costs

One of the primary reasons American clothing companies opt to work with overseas clothing manufacturers is cost efficiency. Countries such as China, Bangladesh, Vietnam, and India offer significantly lower labor costs compared to the United States. This wage disparity allows manufacturers to produce apparel at a fraction of the cost, which is crucial for companies aiming to keep prices competitive.

Labor Costs: Lower wages in overseas factories reduce overall production expenses.

Material Costs: Bulk purchasing of raw materials in manufacturing hubs can also lead to reduced material costs.

b. Economies of Scale

Overseas clothing manufacturers often benefit from large-scale operations that enable them to achieve economies of scale. High-volume production not only reduces per-unit costs but also provides the ability to reinvest savings into further cost reductions.

Mass Production: Large production runs can lead to lower costs per unit.

Operational Efficiency: Streamlined production processes improve cost-efficiency.

2. Access to Advanced Manufacturing Technologies

a. Technological Expertise

Many overseas manufacturers are equipped with state-of-the-art technology and advanced manufacturing processes. Countries like China and South Korea are known for their investment in high-tech machinery and automation, which enhances production capabilities.

High-Tech Machinery: Automated machines and advanced textile technologies improve production efficiency.

Innovation: Continuous upgrades in technology help in producing high-quality garments.

b. Specialized Facilities

Some overseas manufacturers have specialized facilities that cater to specific types of apparel, such as sportswear, high-fashion, or technical textiles. This specialization allows for more precise and efficient production processes.

Custom Clothing Manufacturer: Advanced facilities can handle complex custom designs and high-quality prints.

Women's Clothing Manufacturer: Specialized production lines focus on current fashion trends and high-quality standards.

3. Supply Chain and Logistics Advantages

a. Integrated Supply Chains

Overseas manufacturers often operate within well-established supply chains that include fabric suppliers, accessory manufacturers, and logistics providers. This integration simplifies the production process and reduces lead times.

Vertical Integration: Many overseas factories handle everything from fabric sourcing to final garment production.

Streamlined Logistics: Efficient supply chain management minimizes delays and lowers costs.

b. Flexibility in Production

Overseas clothing manufacturers are often more flexible in terms of production schedules and order sizes. This flexibility allows for quicker adaptation to market demands and changing trends.

Responsive Production: Ability to quickly adjust production volumes in response to market fluctuations.

Reduced Lead Times: Faster turnaround times for new collections and trends.

4. Market Demand and Globalization

a. Global Market Reach

As American clothing companies increasingly target international markets, manufacturing overseas allows them to be closer to these global consumers. This geographic proximity helps in catering to regional preferences and reducing shipping costs for international orders.

International Demand: Manufacturing in or near target markets can reduce shipping times and costs.

Cultural Adaptation: Local production can be tailored to meet regional fashion preferences.

b. Competitive Pricing

To remain competitive in a global market, American companies need to offer affordable pricing. Overseas manufacturing provides a way to achieve lower production costs, which can be passed on to consumers in the form of lower prices.

Price Competitiveness: Reduced production costs help maintain lower retail prices.

Market Positioning: Competitive pricing can attract price-sensitive customers.

5. Labor and Working Conditions

a. Labor Costs vs. Standards

In the quest for lower costs, some American companies may prioritize labor cost savings over working conditions. This has led to criticism and the need for ethical sourcing practices.

Labor Standards: There are concerns about working conditions and fair wages in some overseas manufacturing locations.

Ethical Sourcing: Many companies are working to ensure that their overseas suppliers adhere to ethical labor practices.

b. Domestic Labor Costs

Domestic manufacturing in the U.S. often involves higher labor costs due to stricter labor laws, higher wages, and benefits. This makes it challenging for companies to compete with lower-priced imports.

Higher Wages: Domestic manufacturing is constrained by higher labor costs.

Regulatory Compliance: U.S. labor laws enforce higher standards for worker rights and benefits.

6. Customization and Specialized Manufacturing

a. Custom Clothing Manufacturers

For businesses focusing on custom clothing, overseas manufacturers often offer a wider range of customization options at lower costs. This includes everything from custom prints and embroidery to unique garment designs.

Custom Printing: Advanced techniques and equipment enable a variety of custom printing options.

Design Flexibility: Ability to accommodate complex and diverse design requests.

b. Women’s and Kids’ Clothing Manufacturers

Manufacturers specializing in women’s and kids’ clothing overseas often have extensive experience and facilities dedicated to these specific markets. This specialization ensures that products meet the quality and design standards expected by consumers.

Women’s Clothing Manufacturer: Focus on the latest trends and high-quality materials for women’s fashion.

Kids’ Clothing Manufacturer: Emphasis on safety, comfort, and durability for children’s apparel.

7. Challenges and Considerations

a. Quality Control and Communication

While overseas manufacturing offers many benefits, it also presents challenges, such as maintaining consistent quality and managing communication across different time zones and languages.

Quality Assurance: Ensuring that overseas manufacturers meet quality standards requires rigorous oversight and inspections.

Communication Barriers: Time zone differences and language barriers can complicate coordination.

b. Ethical and Environmental Concerns

There is growing scrutiny over the environmental impact and ethical practices of overseas manufacturing. Companies must address concerns related to sustainability and labor practices to maintain consumer trust.

Sustainability: Many companies are investing in sustainable practices and materials.

Ethical Manufacturing: Ensuring that suppliers adhere to fair labor practices and environmental regulations.

Conclusion

The decision to manufacture clothing overseas is influenced by a variety of factors including cost efficiency, technological advancements, and supply chain benefits. American clothing companies leverage overseas manufacturing to achieve lower production costs, access advanced technologies, and respond to global market demands. However, this shift also presents challenges related to quality control, ethical practices, and environmental impact. As the industry continues to evolve, balancing cost benefits with ethical considerations and sustainability will be crucial for maintaining a competitive edge in the global market.

Whether you are a custom clothing manufacturer, a women’s clothing manufacturer, or a kids’ clothing manufacturer, understanding these dynamics is essential for navigating the complexities of international apparel production and ensuring success in the global marketplace.

1 note

·

View note