#solvent cleaning system

Explore tagged Tumblr posts

Text

The Future of Solvent Cleaning Systems: Efficiency, Sustainability, and the Minio 85C

The world of industrial cleaning is constantly evolving, and Solvent Cleaning Systems are no exception. While traditional methods have served their purpose well, the future demands a focus on efficiency, sustainability, and user-friendliness. This blog post will delve into the exciting advancements shaping the solvent cleaning industry and how the innovative Minio 85C from Ecoclean India positions itself at the forefront of this evolution.

Navigating the Evolving Landscape of Solvent Cleaning

Regulatory Pressures and Environmental Concerns:

Environmental regulations are becoming increasingly stringent, driving the development of eco-friendly solvent cleaning solutions. Traditional solvents often contain volatile organic compounds (VOCs) that contribute to air pollution. Manufacturers are seeking alternatives with lower VOC content and improved waste management practices.

Efficiency and Cost-Effectiveness:

In today’s competitive landscape, maximizing production efficiency is crucial. Solvent cleaning systems need to be faster, more precise, and consume less solvent to minimize operational costs. Additionally, advancements in automation and process optimization are streamlining cleaning workflows.

Operator Safety and User Experience:

The safety and well-being of workers are paramount. Modern solvent cleaning systems prioritize operator safety by incorporating features like advanced ventilation systems, leak detection, and user-friendly controls. Additionally, intuitive interfaces and simplified maintenance procedures enhance the overall user experience.

Emerging Trends and Innovations in Solvent Cleaning Technology

1. Bio-Solvents and Sustainable Formulations:

Bio-derived solvents are gaining traction due to their lower environmental impact. These solvents are often made from renewable resources like plant-based oils and offer comparable cleaning performance to traditional options. Additionally, advancements in Solvent Formulations are leading to the creation of high-performance, low-VOC cleaning solutions.

2. Precision Cleaning and Automation:

The future of solvent cleaning lies in precise cleaning techniques. Technologies like Ultrasonic Cleaning and micro-degreasing offer targeted cleaning power, minimizing solvent usage and ensuring critical components are spotless. Furthermore, automation is playing a significant role in streamlining cleaning processes. Robotic systems can handle repetitive tasks, improving consistency and worker safety.

3. Closed-Loop Systems and Solvent Recovery:

Minimizing solvent waste is a key focus. Closed-loop systems allow for the recovery and distillation of used solvent, reducing environmental impact and lowering operational costs. Additionally, advancements in filtration technologies are improving the efficiency of solvent cleaning processes.

4. Data-Driven Cleaning and Predictive Maintenance:

The integration of sensors and data analytics into solvent cleaning systems is fostering a data-driven approach to cleaning. Real-time monitoring of solvent levels, temperature, and cleaning cycles allows for process optimization and predictive maintenance. This can help prevent downtime and ensure consistent Cleaning Performance.

How the Minio 85C Addresses the Future of Solvent Cleaning

The Minio 85C, a revolutionary solvent cleaning system from Ecoclean India, exemplifies the future of solvent cleaning. Here’s how it addresses the key trends we’ve discussed:

Sustainable Cleaning: The Minio 85C is compatible with a wide range of cleaning solvents, including bio-solvents and low-VOC formulations. This allows manufacturers to choose eco-friendly options without compromising cleaning performance.

Efficiency and Automation: The system boasts a compact design with an integrated ultrasonic cleaning stage, ensuring a fast and thorough cleaning process. The user-friendly control panel allows for programmable cleaning cycles, optimizing solvent usage and reducing labor costs.

Operator Safety and User Experience: The Minio 85C prioritizes operator safety with a closed-loop distillation system that minimizes solvent exposure. Additionally, the intuitive interface and easy-to-maintain design enhance the overall user experience.

Data-Driven Cleaning: The Minio 85C can be equipped with optional sensors to monitor solvent levels, temperature, and cleaning cycles. This data can be used to optimize cleaning processes and identify potential maintenance needs.

Conclusion: A Clean Future with the Minio 85C

The future of solvent cleaning is bright, driven by a commitment to efficiency, sustainability, and user safety. The Minio 85C from Ecoclean India embodies these values, offering a versatile, eco-friendly, and user-centric solution for a wide range of cleaning applications. By embracing these advancements, manufacturers can achieve a clean future while maintaining optimal production efficiency.

Visit our website page to learn more about the Minio 85C and how it can revolutionize your solvent cleaning processes: https://ecoclean-india.com/products/minio-85c/

Ecoclean Indiais committed to providing innovative and sustainable solutions for the cleaning industry. Contact us today to discuss your specific cleaning requirements.

1 note

·

View note

Text

"Oh shit, my career!" shouted one of the interns in the bullpen when it becomes obvious immediately what had happened. Yes, Justin. You had now learned a new and uncomfortable truth about working for the Man, and your working life will never be the same again. And it all started because he didn't follow the mandatory security training that every employee needs to click through while half-paying attention.

Yes indeed. In a past life, I was an information-technology security specialist. For those of you in the back who have led worthwhile existences, these words may not make sense to you. Others are not so lucky, and at this moment are rolling their eyes, or looking for the closest exits. We are, or were, the folks who force you to use a password that isn't "password," and stop sending emails containing the company's bank information to Inner Somalia.

Being in information security is a lot like being a regular old computer nerd, except you're also incredibly paranoid. Imagine you live in a house full of vicious, murderous ghosts that only you can see, and all your family members keep doing horror movie cliche shit like leaving the doors open, shaking genie lamps they find in the parking lot, and reciting "Bloody Mary" three times into a bathroom mirror. You gotta keep them safe, which slowly drives you insane over the course of, oh, about your first six weeks of employment. After that, you've basically just given up and are like the hardened firefighters who respond to grisly highway accidents with an encyclopedic knowledge of what kind of solvent cleans what kind of human fluid off the roadway.

Back to Justin: part of our paranoia involved doing elaborate role-playing exercises. Some of our nerds would pretend to be a different kind of nerd, and try to talk themselves into places they didn't belong. The idea is that a horrible criminal or cyberterrorist could also use this rarefied power ("Hi, I'm the guy who is supposed to fix the servers. They're not serving. Please show me where the servers are, and leave me alone with them for several hours") and we needed to figure out who was dumb enough to fall for it. Justin was dumb enough to fall for it.

If only he had paid attention to the mandatory security quiz that we made him click through, this all could have been avoided. Everything ended up well for him, though. The whole experience made Justin incredibly, violently paranoid, which made him a perfect candidate to become a information technology security specialist. The system works!

349 notes

·

View notes

Note

For a request may I have fluffy smut with Ambulon? He's so cute and deserves all the praise!

His back is warm, wet, against your chest, rumbling under the armor in that way Cybertronians do: like an idling car. The distinct sound of his systems is hard to make out over the drum of solvent over his armor. But the sensation of it sends goosebumps rippling across your skin, arms twining about his shoulders as you press kisses to the nape of his neck cabling. You can already see the flush of heat overtaking Ambulon’s cheekplates, but he presses back, needy, into your embrace. He loves the touch of your flesh upon his sensors despite how abashed he is, too mortified by his own starvation to ask for more. As if begging for sustenance in the midst of ravenous hunger would be worse than dying of need.

Your nimble organic fingers press between the seams of his armor, work warmth into the tense cables overlapping protoform. Years of stress and uncertainty knotting beneath his metal, a strain that would take years to work out. For tonight, it would be enough to work away the stress from the last few hours of his shift. He melts into your touch, back pressing ever firmer to your chest as he allows his shoulders to gradually slope under your loving hands. As if finally aware of his own tension, the tautness of his body begins to ease, his jaw growing slack and upright spinal strut bending under the weight of his own frame, optics long having slipped closed.

Ambulon doesn’t fret or fluster as your hands wander his frame, blissful under your warm touch and the spray of solvent that pounds his open frame. You think he would crumple from the looseness of his cabling if he didn’t have you to ground him. Your fingers find the armor of his hips, the seams of his thigh joints, before your dominant hand cups his interface panel. A gasp stutters from his vocalizer, helm tilted back to rest upon your shoulder. It’s a moment of petting, fingers sliding back and forth upon slick, hot metal, before his panel clicks away to bare his half-pressurized spike and scantly wet valve. He lets out a barely there sigh as you take him in hand, stroking over the smooth segments of his shaft, coaxing him to full pressurization. Ambulon’s servos find purchase on the arm you curled about his midsection, seeking you to ground and hold him steady as he thrusts upward on unsteady pedes.

His helm lolls to the side, cheek pressing into your temple, frame open and wanting. In the quiet of the shower stall, hidden away from the universe, Ambulon unfurls under your hands. You press your lips to his pauldron, stroking him steadily towards overload; your conjunx letting you pull apart his stress tangle by tangle. Your name is but a whisper from his vocalizer as he arches into your touch, transfluid shooting from under the pad of your thumb as it swipes over the sensitive, bulbous head. He lazily picks his helm off your shoulder to lean back and kiss at your hairline, a soft, tired smile stretching his derma. As gentle with you as he is when he’s meticulously cleaning the medbay equipment; steady and placid.

#asks#txt#transformers#reader insert#reader imagine#transformers idw#tf idw#transformers mtmte#tf mtmte#smut#valveplug#ambulon#tf ambulon#idw ambulon#mtmte ambulon

56 notes

·

View notes

Note

i’m taking a construction course which has a module on waste management, so i now know depending on how old the house is, there are a load of different contaminants which could be floating about and have probably ruined the soil (rip fiona’s plants). according to my revision sheet, some of them could be:

- heavy metals (lead pipes, old plumbing, arsenic-treated wood)

- volatile organic compounds like solvents, alcohols, and formaldehyde, (paint thinners, varnishes, wood + wallpaper chemical treatments)

- asbestos (literally everything that needed to be fireproof or insulating, ie tiles, plaster, pipes, insulation, flooring, etc)

- polychlorinated biphenyls which are pollutive but can also affect your immune and reproductive systems (early elec systems, paints and varnishes)

- technically pesticides but i personally doubt they’d be allowed within a ten mile radius of the house

- creosote + wood preservatives, carcinogenic and also toxic to plants, sorry fiona (railway ties, treated beams and floorboards)

- chlorinated solvents (early cleaning products and degreasing agents)

- i cannot overstate the investment of lead all of those kids have heavy metal poisoning in some way. my notes specifically note ‘neurological damage especially in children’

- coal dust and soot (fireplaces)

in conclusion the reason the ruins were still there when jacob arrived was because nobody was investing to remediate a deeply contaminated brownfield site in the middle of nowhere, and it’s a miracle they didn’t die from the toxicity of everything around them before they made it to london

These children are ticking time bombs in more ways than one and they are so incredibly lucky they did not just immediately die anytime they left the loop oh my god

21 notes

·

View notes

Text

What the actual fuck

Manually TLCing fractions from my column w the same solvent system

Def had enough silica, loaded evenly, just. What the fuck why aren't they coming off pure. I specially cleaned the fucking tubes beforehand.

Maybe I need to run on a smaller column??? Was it just broadening peaks too much?? Just, fuck this is like the fifth column

11 notes

·

View notes

Text

EPA bans two cancer-causing chemicals used in everyday products. (Washington Post)

Excerpt from this Washington Post story:

The Environmental Protection Agency on Monday banned two known carcinogens used in a variety of consumer products and industrial settings that can seep into the environment through the soil and waterways.

The new rules, which underscore President Joe Biden’s efforts to enact key protections against harmful chemicals before leaving office, include the complete ban of trichloroethylene — also known as TCE — a substance found in degreasing agents, furniture care and auto repair products. The agency also banned all consumer uses and many commercial uses of perc — also known as perchloroethylene and PCE — an industrial solvent long used in applications such as dry cleaning and auto repair.

“Both of these chemicals have caused too much harm for too long, despite the existence of safer alternatives,” said Jonathan Kalmuss-Katz, a senior attorney at Earthjustice.

The EPA conducted risk analyses last year and found that both substances present unreasonable risk of injury to human health or the environment.

According to the EPA, perc is toxic to the nervous system and the reproductive system and is a persistent environmental pollutant. Multiple organizations — including the National Institute for Occupational Safety and Health and the International Agency for Research on Cancer — have classified the chemical as a probable human carcinogen. Perc can also biodegrade into TCE.

Meanwhile, TCE is associated with numerous cancers, including non-Hodgkin’s lymphoma, leukemia, and kidney and liver cancer, and is toxic to the nervous, immune and reproductive systems, even at low levels of exposure.

10 notes

·

View notes

Text

Researchers uncover a rapid, efficient and environmentally friendly method for selective lithium recovery using microwave radiation and a readily biodegradable solvent. A microwave-based process boasts 50% recovery rate in 30 seconds. The "white gold" of clean energy, lithium is a key ingredient in batteries large and small, from those powering phones and laptops to grid-scale energy storage systems. Though relatively abundant, the silvery-white metal could soon be in short supply due to a complex sourcing landscape impacted by the electric vehicle (EV) boom, net-zero goals and geopolitical factors. Valued at over $65 billion in 2023, the lithium-ion battery (LIB) global market is expected to grow by over 23% in the next eight years, likely heightening existing challenges in lithium supply.

Read more.

15 notes

·

View notes

Text

@thebrokenmechanicalpencil

Yeah, I slipped and had to break the scene I had into two… I have the other part half written already so it should be done soon (hopefully)

But this was the scene that’s been spinning around my head and then I got an idea to make everything way more painful. Your welcome. I’m a terrible person.

More Dropmix death trials let’s go.

—

Jeopardy hated silence.

Especially this kind—the kind that settled thick over everything, heavy with tension and the faint, unspoken hum of something unraveling.

The washroom was still damp with steam, condensation clinging to the metal walls. Dropmix had asked to be cleaned up before the call—wanted to look his best, he'd said with a tired sort of pride. Jeopardy hadn’t argued. He’d always be willing to help. And he needed a bit of cleaning anyway and the triplets would want to see him, after all. Not just hear him.

Lyre, Virgo, and Libra had been told about his condition earlier that cycle—Comet and Coo had delivered the news of Dropmix’s impending end gently, but Jeopardy knew it still hit them hard. The small pretenders had been deviated when they heard, and Dropmix had extended the offer to call them in hopes of trying to ease that pain. A video call, something that they hadn’t done in ages.

It wasn’t as simple as dialing in. The triplets had to request access to the Ark’s long-range broadcast system, since personal communications couldn’t support the signal. Ratchet was quick to agree, letting them use the transmitter in the medical bay for privacy.

They scheduled the call right away, during a time when the old medic could get the room cleared.

Jeopardy had managed to dig out their own old long-range broadcaster without too much trouble. And it was already warming up in the other room, the signal link to Earth prepped and waiting. Which had left them with enough time to wash off.

Unfortunately, like most things in Jeopardy’s life, nothing could ever go according to plan.

The universe couldn’t just let him have a good thing—it was taking Dropmix away from him after all, one of the best things that had ever happened to him.

The young mech was currently focused on a stubborn patch of grime tucked deep into a seam near Dropmix’s shoulder, humming quietly to himself—he couldn’t help himself, the lack of music was just as unsettling as before. His fingers worked with care, the cloth soaked in a diluted solvent and warm water, gently scrubbing at the seam. There was no tension or awkwardness between them, they had done this hundreds of times by now.

That’s why Jeopardy felt the shift before he saw it. The subtle way Dropmix spaced out, his movements slowing. He hadn’t thought anything of it though. The medic had learned that Dropmix found the physical contact involved with bathing with another soothing—it was the kind of touch he liked, firm and heavy. So, Jeopardy continued with his work, noting the shift but not addressing it.

Which was his mistake, he should have stopped then.

The larger mech's arm stopped moving. His hand, which had been scrubbing at the plating on his other arm, dropped to his side with a faint metallic clink. Jeopardy casually looked up to Dropmix’s face, expecting to see him relaxed, but was startled to find the old mech glaring—not at him, but at his own arm, like it had done something unforgivable. His expression was blank and furious all at once.

That was when the low growl began.

It rumbled from deep in Dropmix’s chassis, vibrating through the air in a way that made Jeopardy freeze mid-motion. The gladiator hardly ever growled, not without a good reason, and for a brief moment Jeopardy was worried that Dropmix might try to do something with how intensely he gazed at his own arm. The cloth slipped from the young mech’s hand and landed with a soft wet slap against the floor. He opened his mouth to speak—but he was too late.

In a single motion, Dropmix snapped his head toward him, lips pulling back to reveal his teeth that he had filed down ages ago. But the lack of sharpness didn’t matter. He was still a gladiator equipped with a powerful bite force. That hadn’t changed.

Jeopardy didn’t react fast enough. Metal clamped down on his hand with a sickening crunch, as Dropmix’s hands grasped his arm, once clawed digits digging into his shoulder. Pain flared hot and immediate through Jeopardy’s arm. His emergency lights flickered on from the shock—flashes of amber strobing briefly against the walls—before he managed to suppress them, his jaw clenching tightly with effort.

The medic didn’t yell, he couldn’t.

He knew what this was, Dropmix was confused—a symptom of his Cybercrosis. This confusion had been their first sign that something was wrong, an incident similar to this one had altered them to the issue. But last time there had been music to stop the gladiator’s confusion from becoming aggressive. This time there wasn’t.

He stayed still, even as sharp agony laced through his limb. Dropmix’s eyes were unfocused, unseeing—staring straight through him as if he were somewhere else entirely. Despite everything, Jeopardy didn’t pull away. He needed to be calm, take a breath and address this like he would a patient. Calm and collected, he could let his own internal panic and pain prevent him from helping.

Medical programs hummed to life in the back of his processor.

“Dropmix,” he said softly, voice steady despite the tremor in his fingers. “I’m Jeopardy.” Some part of him hoped that the introduction would be enough, but he knew better. He kept his tone deliberate and clear. “I’m a medic. I was helping you wash off.”

“Dropmix, I’m Jeopardy,” an introduction, some part of him hoped that it would be enough to get the other to release his arm. It didn’t. “I’m a medical officer. I was helping you wash off. Are you ready to be done?”

The dark mech didn’t move.

His eyes didn’t refocus. His grip didn’t loosen. The only thing that changed was the faint tremor starting to ripple through his plating, a subtle quiver that Jeopardy wouldn’t have noticed if he wasn’t close—if his hand wasn’t still trapped in the older mech’s mouth. Dropmix let out another rough growl, though it was quieter, more uncertain.

The medic took another deep breath, trying to keep his own armor from trembling, fighting against the rising panic. Dropmix didn’t mean it, he would never hurt Jeopardy, he was just confused. He needed to help the older mech walk through his thoughts, make sense of his disoriented state.

“You didn’t like it when I touched you there,” Jeopardy spoke softly, each word slow and clear. He needed to keep things as simple and easy to understand as possible. He continued trying to reassure his mentor, “That’s alright. We can do something else now.”

Dropmix still didn’t move for a moment, his eyes slowly moving over Jeopardy’s frame as he processed the words. But his grip loosened, jaw eventually going slack as he pulled away. His large hand didn’t move from the medic’s shoulder, but his fingers didn’t dig into the plating anymore. The gladiator blinked slowly, his expression shifting to something less aggressive and more lost—though clarity didn’t return.

Jeopardy shifted carefully, sucking in a sharp breath as his injured arm protested against the movement. He cradled it against his side, fingers twitching from the aftershock of being crushed. The bite mark was deep. Cracked plating. Joints crushed. Energon smearing over the surface. But nothing unfixable.

His jaw clenched as he fought back a shiver. He knew Dropmix didn’t mean it, but it still hurt. It didn’t stop the way his spark ached with the knowledge that his mentor—the closest thing to a father he knew—had hurt him. Jeopardy sucked in another shaky breath, his uninjured hand gently tapping a soothing rhythm onto his own plating. He weakly nodded. “Yeah, let’s… let’s get dried off now.”

Dropmix didn’t react, he only blinked again slowly, blankly staring down at Jeopardy. The silence that followed was thick. Wrong. The kind of silence that should’ve been filled with the soft lulling of Dropmix’s ever present music. It sat heavy in the air as the gladiator slowly revived his hand from Jeopardy’s shoulder. His vocalizer clicked a few times as his expression twitched—he was struggling to piece together a thought. He seemed to give up on words and nodded instead, a frustrated grunt escaping him.

“You don’t have to speak,” Jeopardy soothed, trying to keep his voice level despite the tremble creeping into his frame. “It’s a bit frustrating for you right now. That’s alright. We can just go sit down.”

Jeopardy reached out again. Carefully. Cautiously. His good hand hovered, then settled just below Dropmix’s elbow. The gesture was slow, telegraphed—meant to be seen, even if Dropmix wasn’t seeing much at all. The gladiator didn’t pull back or react anymore than a low chuff. Jeopardy tried to gently guide the older mech out of the shower.

He didn’t move to follow.

Instead, he looked down at his own hands—still half-curled like they expected to find resistance. He flexed them slowly, watching with mechanical detachment as if they weren’t even his.

Then, abruptly, he let out a low, almost pained whine. His hands shook as he pulled away from Jeopardy’s touch. He backed up one step, then another—until his back thudded into the corner wall of the washroom. He stood there, staring at his own limbs like they were strangers. Like they had betrayed him.

“Don’t,” Jeopardy said quickly, alarm flooding through him as he took a step forward. “Don’t do that. They’re just hands. They made a mistake. That’s all it was.”

Dropmix weakly shook his head, his focus entirely on his hands, slowly turning them over to inspect. He let out a small grunting noise as he did, brows furrowing with concentration. His expression twitched before he finally spoke, voice ragged and hesitant, “My claws? Where did they go?”

Jeopardy swallowed, the lump in his throat thick. His mentor's voice was thick and almost slurred—he was disoriented, beyond confused. It was painful to watch. The medic took a small step forward, hands outstretched like he was approaching a wild animal. Dropmix had gotten rid of his claws before Jeopardy ever got the chance to meet him. Filed them down or ripped them off, Jeopardy didn’t know. But they were gone now, leaving only blunt fingertips behind.

“They’re... gone now,” Jeopardy said softly, trying to keep the pain out of his voice. How would he explain this with confusing or panicking the older mech? Jeopardy’s voice remained gentle as he stepped closer, inch by inch, keeping his movements deliberate. “You had them filed down. You don’t fight anymore.”

Dropmix shook his head once more, a small noise escaping him—one of frustration, of confusion. He shifted slightly, adjusting his balance from one leg to the other, his hands flexing again. The sight of his hands—stripped of their former weaponry—seemed to haunt him in a way that nothing else could. His eyes narrowed and another growl rumbled from his throat. His voice came again, softer, almost as if he were speaking to himself, but more agitated than before. “They’re mine.”

The young medic nodded solemnly, finally close enough to gently grasp the larger hands in his own. Dropmix didn’t protest, his gaze softening as he looked up at Jeopardy, who tried to smile softly. His hand still stung but he could push off the pain until later, until the confusion had passed and the bot before him got to be Dropmix again. Then Jeopardy would let himself break, but until then he needed to b remain steady. “I know. But you didn’t want them anymore.”

For a minute Dropmix was silent, blankly staring at Jeopardy. Then, he chuffed again and leaned forward, forehead pressing against Jeopardy’s own in an affectionate manner. The medic let his eyes close for a moment, allowing himself that brief second to breathe into the contact. His playing trembled as he tried to soothe his own tension and anxiety.

The touch was grounding. Familiar. Dropmix was still there, even if he was buried beneath layers of static and fog. This wasn’t the kind of clarity they used to share, but it was still real. Still his. The gesture—the press of foreheads—meant something, even now.

“I’m here,” Jeopardy whispered, their frames barely apart. “Let’s go sit down.”

Dropmix didn’t speak. He stayed pressed close, quiet and still, and Jeopardy felt a faint hum vibrating through the older mech’s frame. It wasn’t music, not quite, but it was something adjacent—a fragment of melody, an echo of a familiar song. It resonated low in his chassis.

Jeopardy smiled softly, humming along with Dropmix as he slowly guided him out of the washroom. He kept the other’s hands held in his own, dismissing the slickness of Energon and the sting of his injury.

The hallway was dim, quiet save for the hush of the ventilation systems and the steady whisper of their movements. Jeopardy led with slow, deliberate steps, guiding Dropmix toward their living room.

Dropmix followed without resistance, his eyes unfocused but not hostile. That fragment of a tune still pulsed faintly through him—off-key and incomplete, but unmistakably his. It was still that familiar soothing lullaby that he would hum when Jeopardy got too caught up in his own mind. The medic returned it, guiding him to the couch and helping him sit down.

He had less than an hour until the family of Pretenders back on earth would try and call. It was entirely possible that Dropmix would recover from the confusion in time for it, the episode may end before they call, but there was no guarantee.

All Jeopardy could do was hope.

#transformers#transformer oc#oc writing#dropmix#jeopardy#Cometeater and his family are mentioned#they are not mine#just these two silly boys#angst#this is angst right?#yeah it is#Dropmix death trials#jeopardy is like 5 seconds away from having another meltdown#but Dropmix needs him so he can’t#not yet#meanwhile the man of the hour is having a crisis over hands#he’s doing great I swear#when I read that amnesia and stuff can happen with Cybercrosis this popped into my head#he’s just going to take a moment to kinda loose it#he’ll be back to normal soon enough#I hope this turned out alright#some parts I don’t like but that’s just how it is#this was also not proofread#enjoy some pain

3 notes

·

View notes

Text

towwn: score a perfect 10 with these natural + nontoxic nail polishes for fall. clean formulas nix harmful chemicals, while offering vibrant, lasting color. we rounded up our favs and asked simcha whitehill, a.k.a. @misspopnails, the go-to nail artist for @elleusa, @marieclairemag + more to spill the polish on her fav autumn trends. 💅

@zoyanailpolish toxin-free + vegan, this leading formula has a chip-resistant finish, but doesn’t have chemicals like parabens or formaldehyde. miss pop says wine is a timeless fall tone, and the anabelle shade is a “standout for its warmth and festive, iridescent sparkle.”

@mooncat mooncat’s eco-packaging & ethical production make it a green fav. (10% of sales help rescue cats!) miss pop says mixed metals are big for fall; we like witch hazel from the fallen collection. “you just can’t go wrong with a metallic mani. it matches every outfit and turns nails into jewelry.”

@nailtopiabeauty nailtopia’s superfood infused–formulas are leaping bunny approved + chip-free for weeks. Per miss pop, the brand’s opaque shades are great for nail art. the color main squeeze is perfect to create hand-painted pumpkin designs.

@cotebeautyofficial cote dries fast + has a gel-like, glossy finish that lasts ~2 weeks. “back from the ‘90s,” miss pop says bright red nails in shades like stiletto are on point for fall. “you can’t go wrong with a classic red nail.”

@habitcosmetics a standout black-owned brand, habit offers shades for all skin tones. using 100% post-consumer plastic packaging + recycled jars, 40% of sales help women + communities of color. “coffee nails are hot,” says miss pop. “all shades, from cream to taupe to caramel, even chocolate french tips and tortoise shell designs.”

@dazzle_dry this nail lacquer system air dries in 5 mins without uv lights and lasts a week+. ingredients are ethically sourced + chemical-free with a low carbon footprint. “fall’s the perfect time for a rich midnight blue,” says miss pop.

@tenoverten tenoverten formulas feature safer solvents, essential oils, vitamin e + aloe to strengthen nails. “light-catching shimmer is a fun layer to add to any color mani,” says miss pop on flashy micro-glitter trend.

8 notes

·

View notes

Note

okay so i did quite a few cleaning/grooming headcanons during the last celibacy week so i figured i’d start it off with some more!

one thing i’ve been debating is how cybertronians clean their plating when my continuity has a completely mechanical cybertron. think about it, most human supplies used to clean cars and/or other machinery is quite soft to avoid scratching or otherwise damaging the exterior plating.

so i have two solutions to this!

number one! the high pressure washer. this is basically just a normal car wash but more widely available to the public and utilised by more than just mecha with transportation altmodes. these showers would provide high powered jets of water that could blast either out of the floors, walls, or ceilings depending on the type of stall. they would probably look similar to gym showers in our world, very utilitarian in design. these would also be outfitted with vents that blast warm air over the plating in order to quickly dry off the user. i imagine these would be common among the labour classes and there would likely be many that are pay to use throughout the city. perhaps expensive ones have oil and solvent bathes that are meant for soaking rather than cleaning.

my secondary solution is metallic fibres. i’m not entirely sure if it would work particularly well but the way i think of it is metal sheets flattened and then cut into extremely fine and flexible wires which can then be woven into something that might be a reasonable approximation of cloth. again i’m not entirely sure if it would work well because with cloth there isn’t the possibility that it could scratch the plating but i think with enough stretching and flattening, one could get a “softer” thread that could be used to make blankets and washcloths. these would likely be kept only for touch ups and smaller jobs since washing the entire frame would take a lot of time doing it by hand, hence the popularity of the above option.

now onto the actual ideas revolving around grooming/cleaning habits.

i think that manual classes are far more likely to develop communal grooming habits than scientific or racing classes. this is very several reasons. for one it’s far easier to get clean faster when there is more than one individual involved and in an industry such as mining or transportation, time is everything. additionally many of these jobs foster a strong sense of community between workers and in a work place where the wash racks are public, trust is crucial in regards to exposing oneself in front of others.

army mecha, like seekers, tanks, and other such warframes also tend to display these communal grooming habits, with seekers in particular displaying intricate and complex rituals of grooming in regards to their wings. of course this varies from individual to individual and just as many mecha prefer to handle cleaning their frames on their own rather than seeking assistance or parting in community activities.

in regards to actual cleaning products i think the manual classes would be supplied with the basics of a wash rack and if their employers are feeling particularly generous, cheap waxes and oils to relax the cables and touch up any plating that may have gotten scuffed or damaged. though many companies do not provide such things due to the prevalence of workers being replaced and/or becoming dirty from their jobs. it’s simply not worth the cost.

those ranked higher in the caste system and who actually receive a paying wage would likely purchase waxes, buffers, and the above mentioned cloths to polish and wax their plating to a shine. even wealthier mecha who have shanix to burn might even buy scented oils, waxes, and extra paint in the event that they want to switch up their scents or paint colours. these bots would most likely include high ranking members of the government, like senators or elected officials, as well as the primes, diplomats, and entertainers.

oOooh inch resting... I do like it when big robots groom and preen each other I think they should do it more often. It makes sense. There's some bits you just can't reach with your own hands, and no one wants grime in the plating seams of their back, or on the back of their wings...

17 notes

·

View notes

Text

The Benefits of Using a Solvent Cleaning System for Industrial Applications

In the industrial world, maintaining clean equipment is critical for ensuring efficient operation, minimizing downtime, and producing high-quality products. Traditional cleaning methods, like water-based solutions, can be ineffective for removing stubborn contaminants like grease, oil, and machining fluids. This is where Solvent Cleaning Systems come into play.

Why Choose Solvent Cleaning Systems?

Solvent Cleaning Systems offer a multitude of benefits for industrial applications, making them a superior choice over traditional methods. Here’s a closer look at some of the key advantages:

Superior Cleaning Performance: Solvents are highly effective at dissolving and removing a wide range of industrial contaminants, including grease, oil, fluxes, adhesives, and more. They can reach into tight spaces and intricate components, ensuring a thorough and consistent clean.

Reduced Costs: While the initial investment in a solvent cleaning system might be higher, it can lead to significant cost savings in the long run. Solvent recovery systems, a feature of many modern units, allow for the reuse of solvents, minimizing waste and reducing the need for frequent solvent purchases.

Increased Efficiency:Solvent cleaning systems are known for their fast cleaning cycles. Parts can be quickly cleaned and dried, minimizing downtime and allowing for a more efficient production process.

Versatility: Solvent cleaning systems can be used on a variety of materials, including metals, plastics, and glass, making them a suitable solution for a wide range of industrial applications.

Environmentally Friendly Options: Modern solvent cleaning systems are designed with features that minimize solvent emissions and promote responsible waste disposal. When used properly, they can be an environmentally friendly cleaning solution.

Introducing the Minio 85C: A Powerful Solution for Your Industrial Cleaning Needs

If you’re looking for a high-performance solvent cleaning system for your industrial applications, then look no further than the Minio 85C, available atEcoclean India.

The Minio 85C boasts several features that make it a perfect choice for industrial environments:

Compact Design: This space-saving unit is ideal for workshops and production lines where floor space is limited.

Ultrasonic Cleaning Option: The Minio 85C can be equipped with ultrasonic technology, which provides an extra level of cleaning power for heavily soiled components.

Distillation System: The built-in distillation system allows for the continuous recycling of solvent, minimizing waste and reducing solvent costs.

User-Friendly Controls: The easy-to-use control panel simplifies operation and ensures consistent cleaning results.

Safety Features: The Minio 85C prioritizes safety with features like level controls, leak sensors, and fire protection systems.

Invest in a Cleaner, More Efficient Future

By incorporating a solvent cleaning system like the Minio 85C into your operation, you can experience a multitude of benefits, including improved cleaning quality, reduced costs, and increased production efficiency.

Ecoclean India is a leading provider of industrial cleaning solutions, and we are here to help you choose the right system for your specific needs. Contact us today to learn more about the Minio 85C and how it can revolutionize your industrial cleaning process.

0 notes

Text

youtube

The Psychological and Physical Perks of Houseplants

A Tranquil Ambiance for Mind and Body

The inclusion of greenery in your home or office can create a serene and calming environment. Studies have shown that interacting with indoor plants can reduce psychological and physiological stress. In fact, according to research published in the Journal of Physiological Anthropology, active interaction with indoor plants can reduce stress, specifically by suppressing sympathetic nervous system activity and click here diastolic blood pressure, and by promoting comfortable, soothed, and natural feelings.

Boosting Productivity and Happiness at Work

Incorporating plants into office spaces has been linked to increased employee satisfaction and productivity. A study by the University of Exeter found that employees' productivity jumped by 15% when workplaces were filled with just a few houseplants, as workers felt more engaged and better able to concentrate.

Healing Power in Healthcare Settings

The presence of plants in hospital rooms can expedite patient recovery. A study from Kansas State University revealed that viewing plants during recovery from surgery led to a significant improvement in physiologic responses as evidenced by lower systolic blood pressure, and lower ratings of pain, anxiety, and fatigue as compared to patients without plants in their rooms.

Educational Benefits for Students

Classrooms that incorporate plants into their environment can see a positive impact on student performance. Research indicates that students demonstrate 70% greater attentiveness when they're taught in rooms containing plants. Additionally, they're more likely to attend class and are more satisfied with their education.

Enhancing Air Quality and Breathing Comfort

Symbiotic Breathing

Plants and humans engage in a natural exchange: humans breathe in oxygen and exhale carbon dioxide, while plants absorb carbon dioxide and release oxygen. This complementary relationship is especially beneficial indoors, where air circulation may be limited. Certain plants, like orchids and succulents, continue to produce oxygen at night, making them ideal for bedrooms to maintain air quality even during sleep.

Air Purification

NASA's Clean Air Study has identified a range of indoor plants that can detoxify air from harmful chemicals such as trichloroethylene, benzene, and formaldehyde. These toxins can be found in everyday materials like paints, solvents, and cigarette smoke. Plants like the peace lily and snake plant not only absorb these toxins but also improve overall air quality.

Humidity Regulation

Through the process of transpiration, plants release moisture vapor, which increases humidity indoors. This can be particularly beneficial during dry months, reducing the incidence of respiratory distress, dry skin, and colds. Grouping several plants together can create a microclimate that further enhances this effect.

2 notes

·

View notes

Text

Did not go as planned (Collage roommate Sneaker TF Story) PART 3 (a new Beginning)

Years have passed, and the pile of worn sneakers in the corner has grown considerably. One day, Tyler stands in front of his wardrobe, contemplating the mountain of shoes. "This is getting out of hand," he mutters to himself. He retrieves his football bag from the floor, still carrying the scent of countless practices, games, and locker rooms. He starts to fill it with the worn sneakers, and as I find myself being lifted and placed into the bag, a wave of nostalgia washes over me. I sense the presence of all the other sneakers, each with their own history, their own scent, their own connection to Tyler. Tyler zips up the bag and hoists it over his shoulder. "Time to give them a second life," he says, almost as if he's talking to us. For a moment, I wonder where we're going. A thrift store? A recycling center? Somewhere else? Either way, I find myself excited about this next chapter. The bag sways as Tyler walks, each step he takes a reminder of all the steps he's taken in each of us. Finally, Tyler stops walking. He unzips the bag and starts to pull us out one by one. It turns out he's at a local charity where worn but usable items are refurbished and given to those in need. As I get lifted out of the bag and placed into a new pile, I can't help but feel a sense of rebirth. I may no longer serve Tyler, but I can serve someone else, carry someone else's dreams and steps.

As I adjust to the new surroundings, Tyler turns to leave. "Take care of them. They've been good to me," he tells the volunteer, smiling. And just like that, he's gone, leaving me and the others behind for our second life. Yet even as he walks away, a part of him remains with each of us—memories woven into fabric, history imprinted onto soles. Even as I prepare for my new journey, I know I'll always be a part of Tyler's story, just as he will always be a part of mine.

As I'm placed on a workbench along with the other sneakers, I can't help but feel a sense of anticipation. The charity staff really take their mission to heart, giving each of us worn-out sneakers a new lease on life. First comes the cleaning process. I've never experienced anything like it. Powerful yet gentle solvents wash away the accumulated grime, and brushes scrub into crevices I'd forgotten existed. I start to feel lighter, refreshed. The next stage is the polishing, and as I'm buffed and shined, I can see a transformation taking place. What were once signs of wear and age are now marks of character; I've gone from worn-out to vintage. Special equipment reinforces my weakened soles, patches up my frayed fabric, and revitalizes my faded colors. The smell of Tyler still lingers faintly within me, but it's now mixed with a clean, almost new aroma. One by one, each of us gets tagged and entered into the charity system, marked for a new chapter. And as I consider the future, I can't help but feel optimistic. We, all 20 pairs that once belonged to Tyler, will soon be gracing the feet of teenagers and young adults who turn to the charity for support. Each of us will become a part of new stories, new lives. As I'm placed on a shelf with other revitalized sneakers, waiting for someone to choose me, I find myself thinking about what comes next. Whose life will I be a part of? What new adventures await? While I'll always cherish my time with Tyler, I can't help but feel eager for what lies ahead.

Did not go as planned (Collage roommate Sneaker TF Story) PART 4 (Alex)

As Alex slips his foot into me, I immediately sense the difference between him and Tyler. Alex's socks are clearly worn, much more so than Tyler's ever were, and I can tell his family has had to prioritize other needs over new clothing. But as he laces me up, there's an unmistakable feeling of joy and satisfaction emanating from him. His mother watches, clearly relieved to find good-quality sneakers for her son at such a symbolic price. The staff at the charity store, seeing the family's genuine need, go the extra mile to make sure they have everything they need, from clothing to household items. All sold at minimal cost, giving the family a sense of ownership while still helping them in their time of need. "Mom, look, they fit perfectly!" Alex exclaims, taking a few steps to test me out. His mother smiles, her eyes shining with a mix of relief and gratitude.

"Looks like we've found your new sneakers," she says, confirming what I already sensed: I've found my new owner. As we leave the charity store, I can't help but feel a sense of purpose rejuvenated within me. While Tyler's college journey had its own excitement, the path ahead with Alex feels just as significant, albeit in a different way. Alex and his family head home, and the moment we step through their front door, he eagerly puts me on again. This time, I'm paired with another one of his worn socks, but I don't mind. I know that in no time, I'll grow to love the unique scent and feel of being Alex's sneakers just as much as I loved being Tyler's.

From the moment I became Alex's go-to pair of sneakers, I notice the meticulous care with which both he and his mother treat their belongings. For them, every item holds value because they don't know when they'll be able to replace it. Unlike Tyler, who had the luxury of multiple options and frequent replacements, Alex wears me every day—to school, to play, to run errands with his mom. I become well-acquainted with every type of terrain, from asphalt to dirt paths to linoleum floors. The wear and tear is inevitable, of course, but Alex and his mother do their best to mitigate it. They clean me regularly, wiping away the day's grime and occasionally applying a little polish to keep me looking presentable. I can tell that they're trying to extend my lifespan as much as possible. Over time, I adapt to the unique demands of being Alex's only pair of sneakers. I find myself not just becoming a part of his life but a necessity, a constant in a world that doesn't offer him many. The soles of my fabric may wear thin, and my laces may fray, but the sense of purpose I feel only grows stronger.

As Alex's everyday sneakers, I quickly become attuned to the rhythm of his life—a life much more demanding than Tyler's. Each day after school, Alex heads to the small grocery store where he works, and I can sense the fatigue setting in as he stands for hours, stocking shelves and managing inventory. I do my best to offer support, cushioning his steps and absorbing the strain of long hours on his feet. He hardly has any free time; what little he does have is often spent taking care of his siblings or helping his mother with chores. And yet, despite the challenges and worries that fill his days, Alex never complains. His resilience impresses upon me a deep sense of admiration and respect.The wear and tear on me becomes more apparent as the weeks roll by. The soles start to thin, the fabric bears the marks of long days and hard work, and my inner padding becomes increasingly compressed. Yet, Alex and his mother continue their regimen of care, cleaning and polishing me regularly, doing their best to keep me functional for as long as possible. Every step Alex takes in me feels weighted with responsibility and tinged with hope. I find a new form of honor in being the support system for someone who has to be strong not just for himself, but for his family as well. While I can't change the circumstances of Alex's life, I can offer him the small comfort and reliability that comes with a good pair of sneakers. In this way, I do my best to help him, to absorb the shocks and stresses of his busy, challenging life. Though I'm just a pair of shoes, I feel like I'm contributing something meaningful to Alex's world, even if he doesn't know it. As I feel myself adapting to the unique demands of being his one and only pair, I find that the value and importance of my role have never been clearer. In Alex's world, where each day brings new challenges, being a reliable pair of sneakers is more than just a function—it's a privilege.

Part 3/4 of 7

32 notes

·

View notes

Text

Do you ever just feel a machine in your hands, feel the *motion* as you manually run it through its paces, the cool metal burning against your hands as you tenderly handle it, feel the mechanisms slide against each other in perfect harmony as you make sure it’s working- until it isn’t, a tiny imperfection in your perfect system, so you take it- take *her* apart to find the bug on your sculpture of steel and machined iron, and then destroy it, destroy what dares ruin your perfect set, and then return her to perfection? Bathing it in lubricant and solvent, then feeling as you not only cleaned and bathed her, but improved her, waiting- itching for you to use her again…

Or are you normal

#I wrote this about a gun I was cleaning#guess it technically works for robot gfs too#robot gf#robot girl#firearms

39 notes

·

View notes

Text

Fire Safety Training: A Comprehensive Guide

Introduction to Fire Safety

Fire safety training is essential for ensuring the safety and well-being of individuals in any environment. Whether in the workplace, at home, or in public spaces, understanding the principles of fire safety can prevent accidents, save lives, and protect property. This guide provides a comprehensive overview of fire safety training, including key concepts, prevention strategies, and emergency procedures.

Understanding Fire and Its Hazards

The Fire Triangle

The fire triangle is a simple model used to understand the components necessary for a fire to ignite and sustain. It consists of three elements:

Heat: The energy source that initiates and sustains the combustion process.

Fuel: Any combustible material (e.g., wood, paper, fabric, flammable liquids).

Oxygen: The element that supports combustion, typically found in the air.

To prevent fires, it is essential to control or eliminate one or more of these elements.

Classes of Fire

Fires are categorized into different classes based on the type of fuel involved:

Class A: Fires involving ordinary combustibles such as wood, paper, and cloth.

Class B: Fires involving flammable liquids like gasoline, oil, and solvents.

Class C: Fires involving electrical equipment.

Class D: Fires involving combustible metals such as magnesium and titanium.

Class K: Fires involving cooking oils and fats.

Fire Prevention Strategies

Preventing fires requires a proactive approach that includes good housekeeping, proper storage, and adherence to safety protocols.

Housekeeping

Keep workspaces clean and free of clutter.

Dispose of waste materials regularly.

Ensure that emergency exits and pathways are unobstructed.

Electrical Safety

Regularly inspect electrical equipment and wiring.

Avoid overloading electrical outlets and circuits.

Use surge protectors and circuit breakers.

Storage of Flammable Materials

Store flammable liquids in approved containers and cabinets.

Keep flammable materials away from heat sources.

Label all hazardous materials clearly.

Workplace Design and Maintenance

Install and maintain fire doors and barriers.

Ensure that fire detection and suppression systems are operational.

Conduct regular fire drills and safety inspections.

Fire Detection and Alarm Systems

Effective fire detection and alarm systems are critical for early warning and prompt response.

Types of Fire Detectors

Smoke Detectors: Detect the presence of smoke particles in the air.

Heat Detectors: Trigger an alarm when they sense a significant increase in temperature.

Flame Detectors: Identify the presence of flames through infrared or ultraviolet sensors.

Alarm Systems

Ensure that alarm systems are audible and visible throughout the premises.

Test alarm systems regularly to ensure functionality.

Firefighting Equipment

Proper firefighting equipment and training on its use are essential for controlling and extinguishing fires.

Portable Fire Extinguishers

Types and Uses: Understand the different types of fire extinguishers (e.g., water, foam, CO2, dry chemical) and their appropriate uses.

Operation: Follow the PASS method (Pull, Aim, Squeeze, Sweep) to use a fire extinguisher effectively.

Fire Hoses and Hydrants

Ensure that fire hoses and hydrants are easily accessible and in good working condition.

Sprinkler Systems

Regularly inspect and maintain sprinkler systems to ensure they are operational.

Emergency Procedures

Having clear and well-practiced emergency procedures can save lives during a fire.

Evacuation Plans

Develop and communicate a detailed evacuation plan.

Identify multiple evacuation routes and exits.

Ensure that all employees are familiar with the evacuation plan.

Emergency Exits and Routes

Keep emergency exits and routes clearly marked and unobstructed.

Install emergency lighting to guide occupants during an evacuation.

Assembly Points

Designate safe assembly points away from the building.

Conduct headcounts to ensure all occupants are accounted for.

Role of Fire Wardens

Appoint fire wardens to assist with evacuation and ensure that all areas are cleared.

Provide fire wardens with specialized training.

Conclusion

Fire safety training is a crucial aspect of ensuring safety in any environment. By understanding fire hazards, implementing prevention strategies, and being prepared with the right equipment and emergency procedures, individuals and organizations can significantly reduce the risk of fire-related incidents. Regular training and drills are essential to keep everyone prepared and aware of the best practices for fire safety.

#fire safety#fire fighting training#fire fighters#fire extinguisher#safety#health and safety#education#training#trending

2 notes

·

View notes

Text

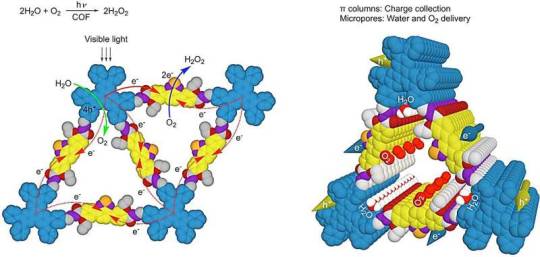

Researchers develop novel method to photosynthesize hydrogen peroxide using water and air

Researchers at the National University of Singapore (NUS) have developed a microporous covalent organic framework with dense donor–acceptor lattices and engineered linkages for the efficient and clean production of hydrogen peroxide (H2O2) through the photosynthesis process with water and air. Traditional industrial production of H2O2 via the anthraquinone process using hydrogen and oxygen is highly energy-intensive. This approach employs toxic solvents and expensive noble-metal catalysts and generates substantial waste from side reactions. In contrast, photocatalytic production of H2O2 from oxygen and water offers an energy-efficient, mild, and clean route. Most importantly, it addresses the common drawbacks of existing photocatalytic systems, such as low activity, heavy use of additional alcohol sacrificial donors, and the necessity for pure oxygen gas input.

Read more.

#Materials Science#Science#Hydrogen peroxide#Materials synthesis#Covalent organic framework#COF#National University of Singapore

14 notes

·

View notes