#soil testing equipment manufacturers

Explore tagged Tumblr posts

Text

Top Civil Engineering Lab Equipment Manufacturers

Civil Engineering Lab Equipment Manufacturers are companies that specialize in designing, manufacturing, and supplying a wide range of equipment and instruments to civil engineering laboratories, research institutions, and educational facilities. These manufacturers cater to the evolving needs of the construction industry, providing innovative solutions to improve the quality and efficiency of infrastructure development projects.

The comprehensive product portfolio of civil engineering lab equipment manufacturers typically includes apparatus for testing and measuring the physical and mechanical properties of construction materials, such as concrete, asphalt, soil, and rock. Some of the common equipment supplied by these manufacturers includes compression testing machines, flexural testing machines, concrete mixers, cement testers, and soil testing equipment.

In addition to providing standard equipment, many civil engineering lab equipment manufacturers also offer customized solutions to meet the specific requirements of their clients. These bespoke solutions can include specialized testing equipment, precision instruments, and software applications designed to streamline laboratory operations and enhance data analysis.

The importance of civil engineering lab equipment manufacturers lies in their ability to provide high-quality, accurate, and reliable equipment that enables researchers, engineers, and students to conduct experiments, gather data, and analyze results with precision and confidence. By doing so, these manufacturers play a vital role in advancing the field of civil engineering, driving innovation, and improving the safety and sustainability of infrastructure projects.

As the construction industry continues to evolve, civil engineering lab equipment manufacturers must stay at the forefront of technological advancements, embracing new materials, techniques, and technologies to remain competitive. This requires significant investments in research and development, as well as collaboration with industry experts, academia, and regulatory bodies to ensure that their products meet the highest standards of quality, safety, and performance.

In conclusion, civil engineering lab equipment manufacturers are essential partners in the pursuit of excellence in infrastructure development, providing the tools and technologies that enable researchers, engineers, and students to push the boundaries of innovation and achievement. By delivering high-quality equipment, customized solutions, and exceptional customer service, these manufacturers play a critical role in shaping the future of the construction industry.

#Civil Engineering Lab Equipment Manufacturers#Lab Equipment Manufacturers#Soil Testing Equipment Manufacturers#Concrete Testing Equipment Manufacturers#Strength Of Material Lab Equipment Manufacturers#Concrete Highway Engineering Lab Equipment Manufacturers#Soil Mechanics Lab Equipment Manufacturers#Survey lab Equipment Manufacturers

0 notes

Text

Who are some prominent soil testing equipment manufacturers?

Several prominent soil testing equipment manufacturers are recognized for their contributions to the field of geotechnical and agricultural research. ELE International is a leading provider, offering a comprehensive range of equipment such as soil mechanics and concrete testing instruments. Humboldt Mfg. Co. is another notable manufacturer, known for its diverse line of soil testing apparatus and construction materials testing equipment. The Gilson Company Inc. specializes in materials testing equipment, including soil testing tools, sieves, and accessories.

Controls Group is an internationally acclaimed manufacturer that provides a wide array of testing equipment for soils, aggregates, and concrete. Matest, based in Italy, is renowned for its high-quality construction material testing equipment, including soil testing instruments.

These manufacturers play a pivotal role in advancing soil science by producing reliable and precise instruments. Researchers, geotechnical engineers, and professionals in agriculture and construction often rely on equipment from these manufacturers to analyze soil properties accurately. The instruments contribute to various tests such as moisture content analysis, particle size distribution, and shear strength assessments, allowing for a comprehensive understanding of soil behavior. The reputation of these manufacturers is often associated with adherence to international standards, continuous innovation, and a commitment to delivering equipment that meets the evolving needs of the scientific and engineering communities.

#soil testing equipment manufacturers#soil testing equipment manufacturer#soil testing#soil testing equipments

0 notes

Text

Reliable lab equipment manufacturer in India

Atico Lab Export reliable lab equipment manufacturer offering high-quality products designed to meet your research needs. Reliable laboratory equipment exporters in india

#lab equipment#manufacturer#supplier#educational lab#engineering lab equipment#tvet lab equipment#africa#biologylabequipment#educational#soil testing lab equipment supplier

0 notes

Text

A lot depends on the soil. It feeds us and helps plants grow. For farming, building, and environmental science, it's important to get accurate soil tests. Professionals can quickly and easily do on-site analyses with portable soil field testing tools, which gives them important information for making decisions. Soil Testing Machines are the tools we need to learn about dirt.

#Soil Testing Machines#Soil Testing Machines Manufacturer#Soil Testing#Testing of Soil#Advance Soil Testing Machines in India#Soil Testing Machine Price#Soil Testing Equipments

0 notes

Text

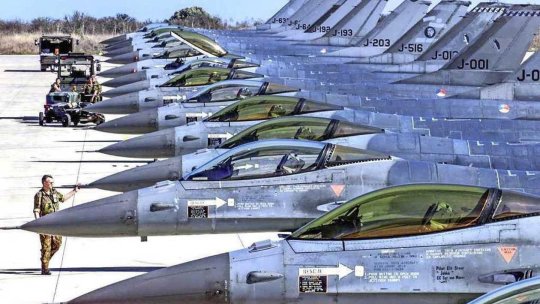

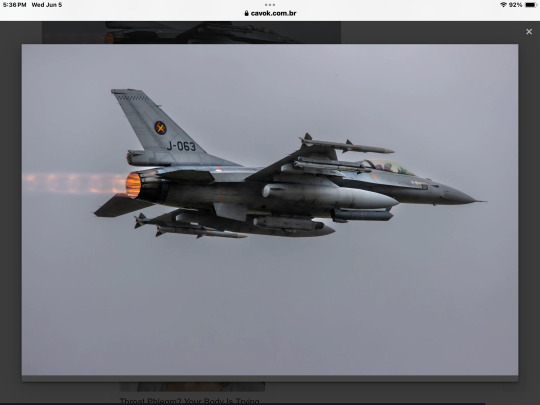

The Netherlands authorizes Ukraine to use donated F-16 fighters to attack targets in Russia

Dutch politicians follow the same decision made by Denmark on the use of the F-16 for attacks within Russian territory.

Fernando Valduga By Fernando Valduga 06/04/2024 - 08:00 in Military, War Zones

0

Shares

542

Views

Share on Facebook

Share on Twitter

The Netherlands announced that it will allow the Ukrainian Air Force to use the 24 F-16 fighters it will receive by donation to be used in attacks against targets within Russian territory.

The Dutch Minister of Defense, Kajsa Ollongren, confirmed that the Netherlands will not impose limitations on the use of F-16 jets. This decision marks a divergence from Belgium's policy, which limits the use of its donated F-16s.

In an interview with the newspaper Politico at the Shangri-La Dialogue in Singapore, Ollongren said: "There is no [a restriction to the Belgian style]. We are putting into practice the same principle that we apply to all other supplies of capacity, that is, once it is delivered to Ukraine, it is theirs to use." She added that the Netherlands only asks Ukraine to comply with international law and the right to self-defense, as established in the United Nations Charter, ensuring that the jets are used to achieve Ukraine's military objectives in self-defense.

Ollongren and U.S. Secretary of Defense Lloyd Austin were among the senior officials who met with the President of Ukraine, Volodymyr Zelenskyy, at the Singapore conference. Denmark also approved Ukraine's use of F-16s provided by Denmark against military targets on Russian soil. Germany has also indicated that Ukraine can use weapons provided by the West for its defense.

Recently, the U.S. authorized Ukraine to attack Russian territory near Kharkiv using U.S.-suplied weapons, confirmed by President Zelensky's spokesman, Serhii Nykyforov, on May 31. However, Washington continues to restrict the use of long-range weapons for deeper attacks within Russia. President Zelensky has expressed interest in using long-range weapons, such as British-made Storm Shadow missiles, but the United Kingdom has not yet fully authorized their use, possibly awaiting a clear position from the White House. The issue has been discussed twice with UK authorities, but remains dependent on a broader international consensus, particularly the US position.

Tags: Military AviationF-16 Fighting FalconUkraine Air ForceRNLAF - Royal Netherlands Air Force / Royal Dutch Air ForceWar Zones - Russia/Ukraine

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

BRAZILIAN AIR FORCE

For the first time, FAB uses BabyPod incubator for aeromedical evacuation of five-day-old baby

04/06/2024 - 07:00

ILA BERLIN

Airbus reveals stealth Wingman drone concept similar to a fighter

03/06/2024 - 22:26

MILITARY

Finland approves purchase of JASSM-ER cruise missiles for its F-35 fleet

03/06/2024 - 16:00

MILITARY

Textron will manufacture three more T-6C coaches

03/06/2024 - 15:00

MILITARY

VIDEO: Bayraktar TB3 Drone from Turkey completes ski jumping test for aircraft carrier operation

03/06/2024 - 14:00

ARMAMENTS

Kongsberg will supply JSM missiles to the U.S. Air Force through a multimillion-dollar agreement

03/06/2024 - 13:00

21 notes

·

View notes

Text

Chemical Earthing Manufacturer in Noida: Ensuring Electrical Safety

Are you concerned about the safety of your electrical installations and appliances? Do you want to protect them from lightning and electrical faults? If so, then you need to consider installing a chemical earthing system. And if you are based in Noida, Delhi, Gurgaon, and Faridabad then you are in luck because in this area we can provide you with high-quality chemical earthing and reliable products.

In this article, we will discuss everything you need to know about chemical earthing including their products, services, benefits, and more. So, let's get started!

1. Introduction to Chemical Earthing

Chemical earthing is a process of installing a low-resistance electrode in the soil to dissipate the fault current to the ground. This electrode is made of a mixture of conductive compounds, such as bentonite, salt, and charcoal, which are buried in the earth to form a conductive path. When an electrical fault occurs, the current flows through the earthing electrode and dissipates into the thereby protecting the electrical installation and appliances.

2. Why Do You Need Chemical Earthing?

Electrical faults and lightning strikes can cause significant damage to electrical installations and appliances, as well as pose a risk of electrocution and fire hazards. Chemical earthing provides a safe and reliable method of protecting electrical systems and equipment by providing a low-resistance path for the fault current to flow to the ground. This helps to prevent electrical shock, equipment damage, and fire accidents.

4. Advantages of Chemical Earthing

Some of the advantages of chemical earthing include:

Provides a low-resistance path for the fault current to flow to the ground, thereby protecting electrical installations and appliances.

2. Reduces the risk of electrocution, fire hazards, and equipment damage.

3. Ensures reliable and continuous earthing performance in all weather conditions.

4. Requires minimal maintenance and has a long service life.

5. Is cost-effective and easy to install.

In conclusion, chemical earthing is an essential safety measure for any electrical installation or appliance. It provides a reliable and low-resistance path for the fault current to flow to the ground, thereby protecting against electrocution, equipment damage, and fire hazards.

We are one of the leading chemical earthing manufacturers in Noida, with years of experience and a reputation for excellence. We offer a wide range of chemical earthing solutions, including plate earthing, pipe earthing, Copper Bonded Rods, Copper Bonded Electrode, GI Earthing Electrodes, Lightning Arrester, and Advanced Earthing Compound, to meet the diverse needs of our customers. Our products are made of high-quality materials and undergo rigorous testing to ensure reliability and safety.

So, if you are looking for a trusted and reliable chemical earthing system in Noida, look no further than us. Contact us today to learn more about our products and services and how we can help you protect your electrical installations and appliances.

3 notes

·

View notes

Text

SBJ Nirmal Products: Pioneering Innovation in Rotavator Parts Manufacturing

Agriculture is the backbone of many economies, with mechanization playing a vital role in boosting productivity and sustainability. SBJ Nirmal Products, based in Ludhiana, Punjab, has emerged as a leading manufacturer of high-quality rotavator parts. Renowned for its innovation, durability, and global reach, SBJ Nirmal Products is revolutionizing the agricultural machinery sector.

The Foundation of SBJ Nirmal Products

SBJ Nirmal Products was founded with a clear vision: to provide robust, reliable, and cost-effective rotavator parts that meet the diverse needs of farmers worldwide. Over the years, the company has grown from a regional manufacturer to a globally recognized brand, known for excellence and customer satisfaction.

Comprehensive Product Range

SBJ Nirmal Products offers an extensive range of rotavator parts designed to improve the efficiency and longevity of agricultural equipment. Key products include:

1. Rotavator Blades

Engineered from high-strength steel for superior durability.

Available in various designs to suit different soil conditions.

Optimized for precision cutting and efficient soil tillage.

2. Crown Pinions

Precision-crafted for seamless power transmission.

Heat-treated to enhance wear resistance.

Compatible with a wide range of rotavator models.

3. Stub Axles

Designed for strength and reliability in demanding environments.

Corrosion-resistant materials for extended lifespan.

Tested rigorously to ensure top performance.

4. Gearboxes and Shafts

High-efficiency components for smooth operation.

Built to withstand heavy agricultural workloads.

Reduced maintenance requirements with long service life.

5. Bearings and Seals

Premium materials for low-friction, high-efficiency performance.

Resistant to dust, moisture, and temperature fluctuations.

Enhances the overall durability of rotavator machinery.

Commitment to Quality and Innovation

At SBJ Nirmal Products, quality is non-negotiable. The company employs state-of-the-art manufacturing techniques and rigorous quality control measures to ensure that every product meets international standards.

Key Innovations

Advanced Materials

Use of high-tensile alloys and corrosion-resistant coatings.

Lightweight yet strong materials for improved efficiency.

Precision Engineering

CNC machining for unparalleled accuracy and consistency.

Customization options tailored to specific farming needs.

Eco-Friendly Practices

Sustainable manufacturing processes to reduce environmental impact.

Waste management and recycling initiatives.

Global Presence and Export Strength

SBJ Nirmal Products has a robust international presence, exporting rotavator parts to countries such as Bangladesh, Nepal, Sri Lanka, and beyond. The company’s commitment to quality and customer satisfaction has earned it a strong reputation in global markets.

Factors Behind Global Success

International Quality Standards

ISO certifications and compliance with global regulations.

Consistent product performance across diverse environments.

Efficient Supply Chain

Strong logistics network ensuring timely deliveries.

Partnerships with reliable distributors worldwide.

Competitive Pricing

Affordable products without compromising on quality.

Attractive deals for bulk orders and long-term clients.

Affordable Solutions for Farmers

Understanding the financial challenges faced by farmers, SBJ Nirmal Products offers cost-effective solutions without sacrificing quality. The company’s pricing strategy ensures that even small-scale farmers can access top-notch rotavator parts.

Strategies for Cost Efficiency

Mass production techniques to reduce unit costs.

Direct-to-customer sales models to eliminate intermediaries.

Seasonal discounts and loyalty programs.

Sustainability at the Core

SBJ Nirmal Products is deeply committed to environmental sustainability. The company integrates eco-friendly practices throughout its operations, from production to packaging.

Green Initiatives

Energy-Efficient Manufacturing

Use of renewable energy sources.

Energy-saving equipment and technologies.

Waste Reduction

Recycling programs for metal scraps and industrial waste.

Eco-friendly packaging materials.

Sustainable Supply Chain

Partnering with environmentally conscious suppliers.

Reducing carbon footprint through optimized logistics.

Customer-Centric Approach

SBJ Nirmal Products places customers at the heart of its operations. The company strives to understand and meet the unique needs of its clients, offering personalized solutions and exceptional service.

Comprehensive Customer Support

Technical Assistance: Expert advice on product selection and maintenance.

After-Sales Service: Reliable support for warranty claims and repairs.

Training Programs: Workshops and seminars for farmers and equipment operators.

Why Choose SBJ Nirmal Products?

Expertise: Decades of experience in rotavator parts manufacturing.

Innovation: Continuous R&D for cutting-edge solutions.

Global Reach: Trusted by customers in multiple countries.

Affordability: High-quality products at competitive prices.

Sustainability: Eco-friendly practices for a greener future.

Customer Focus: Dedicated support and personalized services.

Conclusion

SBJ Nirmal Products is more than just a manufacturer; it’s a trusted partner for farmers and agricultural businesses worldwide. With a focus on quality, innovation, and sustainability, the company is shaping the future of agricultural machinery. As SBJ Nirmal Products continues to grow and evolve, it remains committed to supporting the global farming community with top-notch rotavator parts and exceptional service.

#agriculture#sbj nirmal#rotavator parts manufacturer#sbj#farming#agricultural machinery parts#sbj nirmal products#rotavator#high-quality rotavator parts#agricultural equipment

0 notes

Text

What are the business opportunities for a Civil Engineer?

A Civil Engineer has numerous business opportunities, leveraging their expertise in construction, infrastructure, and project management. Here are some of the top business ideas:

1. Construction Company

Start a general contracting or specialized construction business for residential, commercial, or infrastructure projects.

Services: Building construction, roads, bridges, real estate development.

2. Structural Consultancy

Provide structural design, analysis, and consultancy for buildings and infrastructure.

Clients: Architects, builders, government projects.

3. Interior & Renovation Services

Offer renovation, remodeling, and interior design solutions for homes and offices.

Focus on sustainable and smart home solutions.

4. Precast Concrete Products Business

Manufacture precast concrete slabs, blocks, pipes, fencing, or ready-mix concrete for the construction industry.

5. Surveying & Land Development Services

Provide land surveying, plot demarcation, GIS mapping, and site development consulting.

6. Waterproofing & Insulation Services

Specialize in waterproofing buildings, basements, and terraces using modern techniques.

7. Green Building & Sustainable Construction

Offer eco-friendly, energy-efficient construction using sustainable materials.

Work with companies focusing on LEED certification and green buildings.

8. Real Estate Development & Investment

Build or invest in residential/commercial real estate projects.

Develop townships, gated communities, or industrial parks.

9. Road Construction & Infrastructure Development

Take up government or private contracts for roads, highways, drainage, and bridges.

10. Civil Engineering Software & Training

Provide AutoCAD, Revit, STAAD Pro, and project management training for students and professionals.

Develop or sell construction ERP & project management software.

11. Modular Construction & Prefabricated Homes

Start a business in modular housing solutions, offering fast and affordable construction alternatives.

12. Construction Equipment Rental

Rent out heavy machinery like cranes, JCBs, and concrete mixers to builders and contractors.

13. Smart City & Infrastructure Solutions

Work on urban development projects, smart city infrastructure, and waste management systems.

14. Demolition & Excavation Services

Offer services for building demolition, excavation, and site preparation.

15. Testing & Quality Control Lab

Set up a materials testing lab for soil, concrete, and steel quality assessment.

Why Civil Engineers Should Start a Business?

✅ Growing construction industry with high demand for specialized services. ✅ Government infrastructure projects, smart cities, and real estate boom. ✅ Opportunities in sustainable and tech-driven construction.

Sagar Institute of Research & Technology (SIRT) offers a B.Tech in Civil Engineering, providing students with the skills and knowledge needed to excel in the construction and infrastructure industry.

Why Choose B.Tech in Civil Engineering at SIRT?

✅ Comprehensive Curriculum – Covers structural engineering, construction technology, geotechnical engineering, and environmental engineering. ✅ State-of-the-Art Labs – Advanced labs for material testing, surveying, hydraulics, and CAD designing. ✅ Industry-Oriented Training – Exposure to real-world projects, site visits, and internships. ✅ Placement Assistance – Career opportunities in top construction firms, government sectors, and private industries. ✅ Entrepreneurship Support – Guidance for students interested in starting their own civil engineering business.

#civil engineering#civil engineer#b.tech in civil engineering#Construction Company#sirt bhopal#Career opportunities#business opportunities#engineering college bhopal

0 notes

Text

Modern Lab Technologies for Resource Extraction and Processing

Himlaborreactiv is a recognized leader in Ukraine, specializing in equipping laboratories across key industrial sectors. The company provides state-of-the-art laboratory solutions for the oil and gas industry, energy sector, mining and metallurgy, mechanical engineering, chemical production, and construction. By offering high-quality equipment and advanced technologies, Himlaborreactiv supports businesses in maintaining precision, efficiency, and compliance with international standards.

Comprehensive Laboratory Solutions for Industries

Modern industrial laboratories require specialized equipment to conduct accurate analyses, quality control, and research. Himlaborreactiv supplies cutting-edge instruments and technologies that enhance productivity, safety, and regulatory compliance.

Oil and Gas Industry

The oil and gas sector relies on precise laboratory analysis for fuel quality testing, petrochemical research, and environmental assessments. Himlaborreactiv offers advanced analytical instruments for refining processes, ensuring compliance with industry regulations and improving product efficiency.

Energy Sector

Energy production demands continuous monitoring and testing of fuels, emissions, and materials. Himlaborreactiv supplies laboratory equipment for power plants, renewable energy facilities, and research institutions, helping them optimize efficiency and sustainability.

Mining and Metallurgy

Laboratory analysis is essential for assessing mineral composition, metal quality, and material properties in mining and metallurgy. Himlaborreactiv provides specialized solutions for ore testing, metallurgical research, and process optimization, ensuring superior product quality and performance.

Mechanical Engineering

Manufacturers in mechanical engineering require laboratory testing to evaluate material strength, durability, and resistance. Himlaborreactiv delivers high-precision instruments for mechanical testing, helping companies improve product reliability and safety.

Chemical Industry

The chemical sector relies on laboratory equipment for research, quality control, and process monitoring. Himlaborreactiv supplies analytical solutions that enable precise chemical composition analysis, ensuring compliance with safety and industry standards.

Construction Industry

Construction materials must undergo rigorous testing to meet regulatory requirements. Himlaborreactiv offers laboratory instruments for testing concrete, soil, and building materials, helping construction companies guarantee durability and safety.

Why Choose Himlaborreactiv?

Wide Range of Equipment – Comprehensive solutions for industrial laboratories.

Advanced Technologies – Cutting-edge instruments from leading global manufacturers.

Expert Support – Professional consultations and technical assistance.

High Quality Standards – Reliable and accurate equipment ensuring compliance with industry regulations.

Conclusion

Himlaborreactiv is a trusted partner for industrial laboratories, providing essential equipment for testing, research, and quality control. By serving key sectors such as oil and gas, energy, metallurgy, mechanical engineering, chemical production, and construction, the company helps Ukrainian enterprises enhance efficiency, innovation, and competitiveness.

0 notes

Text

Cutting-Edge Equipment for Pharmaceutical and Medical Research

HIMLABORREAKTIV is a leading company in Ukraine, offering comprehensive solutions for industry-specific laboratories. With years of experience, we specialize in providing high-quality equipment and services to meet the diverse needs of laboratories in a wide range of sectors, including pharmaceutical, medical, agricultural, food, chemical industries, as well as the mining and metallurgy, machine engineering, oil and gas, and quality control sectors.

At HIMLABORREAKTIV, we understand the importance of reliable and accurate laboratory instruments for industries that rely on precision and compliance. Whether you are involved in scientific research, product testing, or quality assurance, we offer everything your laboratory requires to operate efficiently and meet industry standards.

A Wide Range of Laboratory Solutions

Our product range is designed to cover all your laboratory needs across various industries. From high-tech testing equipment to everyday laboratory essentials, HIMLABORREAKTIV provides solutions for:

Pharmaceutical Laboratories: We offer a broad selection of pharmaceutical-grade equipment, reagents, and analytical instruments necessary for the production and quality control of medicines. These products are designed to help pharmaceutical laboratories maintain compliance with rigorous industry standards and regulations.

Medical Laboratories: From diagnostic equipment to clinical tools, we provide everything needed for medical laboratories to conduct precise tests and analyses, supporting accurate diagnosis and patient care.

Agricultural Laboratories: Our laboratory solutions for agriculture include soil and water testing equipment, plant analysis tools, and devices designed to optimize agricultural processes and promote sustainable farming practices.

Food Industry Laboratories: We offer testing equipment to ensure food safety and quality. Our products help monitor factors such as moisture content, texture, and microbiological safety, enabling food manufacturers to comply with regulatory standards.

Chemical Industry Laboratories: HIMLABORREAKTIV provides reliable instruments for testing chemical properties, including materials analysis, chemical reaction studies, and safe chemical handling.

Mining and Metallurgy Laboratories: Our mining and metallurgy laboratory equipment is designed for material testing, mineral analysis, and metal quality control, essential for maintaining high standards in these industries.

Machine Engineering Laboratories: We supply equipment for testing materials in machine engineering, such as hardness testers and stress analyzers, ensuring that machine components meet durability and performance requirements.

Oil and Gas Laboratories: HIMLABORREAKTIV offers specialized tools for testing petroleum, gas analysis, and monitoring oilfield operations, supporting safety and efficiency in the oil and gas industry.

Quality Control Laboratories: Our extensive range of laboratory tools and testing devices ensures that products meet industry-specific quality standards, allowing manufacturers to carry out thorough quality control and testing procedures.

Why Choose HIMLABORREAKTIV?

Comprehensive Selection: With a vast array of laboratory equipment from leading manufacturers, HIMLABORREAKTIV offers all the tools and solutions required for a variety of industries, all available in one convenient online store.

Largest Laboratory Equipment Supplier in Ukraine: As the largest supplier of laboratory equipment in Ukraine, we provide customers with access to the most advanced, reliable, and efficient solutions on the market.

Easy-to-Navigate Online Store: The HIMLABORREAKTIV website is designed to ensure a seamless shopping experience. Users can easily browse, select, and purchase products from the comfort of their offices or laboratories.

Top-Quality Products: Our commitment to providing only the highest quality laboratory equipment ensures that every product we offer meets the strictest industry standards, delivering reliable and accurate results for your lab.

Expert Support and Consultation: We offer professional consultation and customer support to guide you in choosing the right products for your laboratory’s specific needs. Our team is dedicated to ensuring your satisfaction and success.

Conclusion

HIMLABORREAKTIV is committed to providing comprehensive, industry-specific laboratory solutions to a wide range of sectors. Our online store, shop.hlr.ua, offers a vast selection of high-quality equipment for pharmaceutical, medical, agricultural, food, chemical, mining, metallurgy, machine engineering, oil and gas, and quality control laboratories.

Visit shop.hlr.ua today to find the best laboratory solutions that meet your industry's needs. With HIMLABORREAKTIV, you can be confident that your laboratory will be equipped with the latest technology and tools to ensure efficiency, accuracy, and compliance.

0 notes

Text

Sofa Cleaning,

Sofa Cleaning,

Sofa Cleaning: Tips and Techniques for a Fresh, Hygienic Home

A sofa is often the centerpiece of a living room, offering comfort and style while serving as the perfect spot for relaxation. However, over time, sofas accumulate dirt, stains, dust, and even allergens. Regular cleaning is essential not just for aesthetics, but for maintaining a hygienic environment in your home. Whether your sofa is upholstered with fabric, leather, or synthetic materials, each type requires specific care. Here’s a comprehensive guide to cleaning your sofa and keeping it looking brand new.

1. Regular Dusting and Vacuuming

To maintain a clean sofa, start with regular dusting and vacuuming. Dust can accumulate quickly on fabric and leather surfaces, and vacuuming will help remove dirt and debris from the fabric or cushions. Be sure to use an upholstery attachment or a soft brush to reach into the crevices where dirt tends to collect, like seams and folds.

2. Spot Cleaning Stains

Accidents happen, and when they do, it’s important to act fast. Blot spills immediately with a clean cloth to absorb as much liquid as possible. Avoid rubbing, as this can push the stain deeper into the fabric. For common stains, such as coffee, wine, or food spills, use a mild detergent mixed with warm water. Dab the solution onto the stained area, then blot with a clean cloth until the stain lifts. Always check the manufacturer’s care instructions before applying any cleaning solution to ensure it’s safe for your sofa material.

3. Fabric Sofa Cleaning

Fabric sofas tend to trap dust, pet hair, and stains. To clean fabric upholstery, consider using an upholstery cleaner specifically designed for fabric. Start by testing the cleaner in an inconspicuous area to ensure it doesn't cause discoloration. Use a sponge or cloth to apply the cleaner and scrub gently to lift dirt. After cleaning, you can use a fabric refresher to eliminate odors. Additionally, using a fabric protector can help keep your sofa looking clean for longer.

4. Leather Sofa Cleaning

Leather sofas require a more delicate cleaning process to avoid damage. Use a soft cloth to wipe down the surface and remove dust. For deeper cleaning, mix a mild soap (like dish soap) with water, and use a damp cloth to gently clean the leather. Make sure to avoid soaking the leather. Afterward, apply a leather conditioner to keep the material soft and supple, preventing it from drying out and cracking.

5. Steam Cleaning for Deep Cleaning

If your sofa needs a deep clean, a steam cleaner can be a great tool. Steam cleaning helps eliminate deep-seated dirt, germs, and allergens, especially in fabric upholstery. Be sure to follow the manufacturer's instructions and avoid using excessive steam, as too much moisture can damage your sofa. Steam cleaning is an excellent option for fabric sofas but should be avoided on leather unless it's specifically designed for it.

6. Odor Removal

To keep your sofa smelling fresh, deodorize it regularly. Baking soda is a natural and effective deodorizer. Sprinkle a generous amount of baking soda over the fabric, let it sit for about 15 minutes, and then vacuum it up. For leather sofas, a mixture of water and white vinegar can help neutralize odors. Always make sure the sofa is dry before sitting on it again.

7. Protecting Your Sofa

Preventing stains and dirt buildup is easier than removing them later. Consider using slipcovers to protect your sofa from spills and dirt, especially if you have children or pets. Slipcovers are easy to remove and wash, providing an additional layer of protection. Additionally, consider applying a fabric protector to repel stains and prevent dust buildup.

8. Professional Sofa Cleaning

If your sofa is heavily soiled or has stubborn stains that you can’t remove, it may be worth investing in professional cleaning services. Professional cleaners have the equipment and expertise to deep-clean sofas without causing damage. They can also treat specific issues like pet odors or tough stains that require specialized treatment.

9. Maintaining Sofa Hygiene

To ensure your sofa stays fresh and clean over time, incorporate these habits into your routine:

Keep pets off the furniture to avoid fur buildup.

Regularly rotate cushions to ensure even wear.

Use throw blankets or pillow covers to protect the upholstery.

Conclusion

A clean sofa not only adds to the aesthetic appeal of your living room but also promotes a healthier environment. With regular cleaning, spot treatments, and occasional professional services, you can keep your sofa in pristine condition for years to come. Take time to understand your sofa’s material and use the appropriate cleaning methods to maintain its look and longevity.

4o mini

O

0 notes

Text

The Impact of Wastewater Testing on UAE's Agricultural and Industrial Sectors | +971 554747210

In the United Arab Emirates (UAE), water scarcity is a significant challenge due to its arid climate and limited freshwater resources. To address this issue, the reuse of treated wastewater has become an essential component of sustainable development, particularly in the agricultural and industrial sectors. Wastewater testing plays a crucial role in ensuring that recycled water meets safety and quality standards, enabling its safe application in various industries. This blog explores the transformative impact of wastewater testing on the UAE's agricultural and industrial sectors.

Understanding Wastewater Testing

Wastewater testing involves analyzing water discharged from residential, industrial, or agricultural sources to determine its chemical, physical, and biological composition. Key parameters tested include:

Chemical Oxygen Demand (COD): Measures organic pollutants.

Biochemical Oxygen Demand (BOD): Indicates the amount of biodegradable organic matter.

Nutrient Levels: Analyzes nitrogen and phosphorus content.

Heavy Metals and Toxins: Detects harmful contaminants.

Pathogens: Ensures microbial safety.

Accurate wastewater testing ensures compliance with UAE regulations and facilitates the safe reuse of treated water.

Wastewater Testing in the Agricultural Sector

1. Enhancing Irrigation Practices

In the UAE, agriculture accounts for a significant portion of water consumption. By using treated wastewater for irrigation, the agricultural sector can:

Reduce Freshwater Demand: Minimize reliance on scarce freshwater resources.

Provide Nutrient-Rich Water: Recycled water often contains beneficial nutrients like nitrogen and phosphorus, reducing the need for chemical fertilizers.

Support Desert Agriculture: Treated wastewater enables the cultivation of crops in arid regions, promoting food security.

2. Ensuring Soil and Crop Safety

Regular wastewater testing is essential to prevent contamination of soil and crops with harmful substances. Testing ensures that:

Heavy Metals: Levels remain within permissible limits to avoid toxicity.

Pathogens: Are eliminated, safeguarding human health and preventing the spread of diseases.

Salinity: Is managed to protect soil fertility and crop yield.

3. Regulatory Compliance

The UAE government has established stringent guidelines for using treated wastewater in agriculture. Compliance with these standards is verified through comprehensive testing, ensuring:

Public health protection.

Environmental sustainability.

Alignment with the UAE's national water strategy.

Wastewater Testing in the Industrial Sector

1. Optimizing Water Reuse

Industries in the UAE, particularly manufacturing, petrochemicals, and construction, generate substantial amounts of wastewater. By treating and reusing this water, businesses can:

Lower Operational Costs: Reduce freshwater procurement and wastewater discharge expenses.

Conserve Natural Resources: Minimize the depletion of groundwater reserves.

Improve Sustainability: Align with the UAE's vision for a circular economy.

2. Protecting Equipment and Processes

Poor-quality water can damage industrial equipment and disrupt processes. Wastewater testing ensures:

Corrosion Prevention: By monitoring pH and dissolved solids.

Efficient Treatment Systems: Optimized performance of reverse osmosis and other filtration technologies.

Compliance with Standards: Meeting sector-specific water quality requirements.

3. Mitigating Environmental Impact

Industries are subject to environmental regulations to prevent pollution. Wastewater testing helps companies:

Avoid Fines: By complying with discharge limits.

Monitor Pollutants: Detect harmful chemicals like hydrocarbons and heavy metals.

Achieve Sustainability Goals: Reduce ecological footprints.

The Role of Advanced Technologies in Wastewater Testing

Advancements in technology have revolutionized wastewater testing, making it more accurate, efficient, and cost-effective. Key innovations include:

Real-Time Monitoring: Internet of Things (IoT) devices for continuous water quality analysis.

Spectroscopic Techniques: Advanced methods for detecting trace contaminants.

AI-Driven Insights: Machine learning algorithms for predictive analysis and process optimization.

These technologies enhance the reliability of wastewater testing, enabling better decision-making in agriculture and industry.

Regulatory Framework for Wastewater Reuse in UAE

The UAE government has implemented comprehensive policies to regulate wastewater treatment and reuse. Key regulations include:

Federal Law No. 24 of 1999: Governing environmental protection and pollution control.

Municipal Guidelines: Issued by local authorities for treated water quality.

National Water Strategy 2036: Emphasizing the importance of wastewater reuse.

Wastewater testing labs play a pivotal role in helping businesses and agricultural entities adhere to these regulations.

Benefits of Wastewater Testing for UAE's Economy and Environment

1. Economic Advantages

Cost Savings: Lower expenses for water procurement and wastewater disposal.

Resource Efficiency: Maximize the utility of available water resources.

Industry Growth: Enable sustainable expansion of water-intensive sectors.

2. Environmental Benefits

Reduced Pollution: Minimize the release of untreated wastewater into natural ecosystems.

Water Conservation: Protect precious freshwater reserves for future generations.

Biodiversity Preservation: Prevent contamination of habitats and aquatic life.

How to Choose a Wastewater Testing Lab in UAE

Selecting the right lab is critical to ensure reliable results. Consider the following:

Accreditation: ISO 17025 certification for quality assurance.

Technology: Use of advanced testing equipment.

Expertise: Experience in agricultural and industrial wastewater testing.

Turnaround Time: Prompt reporting of results.

Regulatory Knowledge: Familiarity with UAE guidelines and standards.

Conclusion

Waste water testing is a cornerstone of sustainable water management in the UAE. By ensuring the safe reuse of treated wastewater, it supports agricultural productivity, industrial efficiency, and environmental conservation. Advanced testing methods, coupled with adherence to regulations, enable the UAE to tackle water scarcity challenges while fostering economic and ecological sustainability.

As the demand for treated wastewater grows, investing in reliable testing practices will remain crucial for achieving the UAE's vision of a greener, more sustainable future.

#waste water testing#waste water testing lab#water testing#water testing lab#testing lab near me#testing lab uae

0 notes

Text

#soil testing equipment manufacturers#soil testing equipment#soil testing manufacturers#soil testing lab equipment#lab equipment#soil testing equipments#soil testing#soil ph

0 notes

Text

Soil Testing Equipment Importance

Soil testing is a fundamental aspect of agriculture, construction and environmental sciences that offers insights into soil composition, fertility and suitability for various applications. Accuracy and reliability depend heavily on the equipment.

#soil testing lab#soil testing lab equipment#soil testing lab equipment manufacturer#soil testing lab equipment supplier

0 notes

Text

The soil testing lab in India, which is outfitted with Heico soil testing equipment, delivers precise and trustworthy analysis, allowing farmers to understand the actual status of their soil and make educated decisions to improve crop productivity.

#soil testing lab#soil testing machine#soil testing lab in India#testing on soil#soil testing equipment#soil testing tools#soil testing machine price#soil testing equipment price#soil testing machine suppliers#soil testing equipment manufacturer

0 notes

Text

The Importance of Rajasthan Lime in Soil Stabilization | Key Benefits & Insights

Soil stabilization is a crucial process in construction and agriculture, ensuring durability and fertility. Among the many materials used for this purpose, lime stands out for its efficiency and cost-effectiveness. This article explores The Importance of Rajasthan Lime in Soil Stabilization, with insights into the contributions of Lime Manufacturers in Jodhpur, hydrated lime manufacturers in Jodhpur, and Reliable Lime Exporters in India.

1. What is Soil Stabilization?

Soil stabilization involves altering soil properties to enhance strength, durability, and load-bearing capacity. Lime is commonly used for this process due to its ability to react with clay and other soil components, forming stable compounds.

Benefits of Soil Stabilization with Lime:

Increases soil strength

Reduces plasticity and shrinkage

Improves water resistance

Enhances load-bearing capacity

2. Why Rajasthan Lime?

Rajasthan, known for its rich limestone reserves, is a leading producer of high-quality lime. Lime Manufacturers in Jodhpur leverage these resources to provide products ideal for soil stabilization.

Key Features of Rajasthan Lime:

High purity and consistency

Suitable for various soil types

Eco-friendly and cost-effective

3. Role of Lime Manufacturers in Jodhpur

a. Ensuring Quality Standards

Lime Manufacturers in Jodhpur are committed to producing lime that meets stringent quality standards. Their products are tested for purity, reactivity, and particle size, ensuring optimal performance in soil stabilization projects.

b. Advanced Production Techniques

Modern manufacturing processes ensure consistent quality and efficient production, making Jodhpur a hub for reliable lime products.

c. Supporting Infrastructure Projects

From road construction to building foundations, manufacturers in Jodhpur supply lime for large-scale infrastructure projects across India.

4. Hydrated Lime Manufacturers in Jodhpur

a. What is Hydrated Lime?

Hydrated lime, also known as calcium hydroxide, is a refined form of lime. It is widely used in soil stabilization due to its quick reactivity and ease of application.

b. Contributions to Soil Stabilization

Hydrated lime manufacturers in Jodhpur focus on producing high-grade hydrated lime suitable for:

Treating expansive clay soils

Enhancing soil compaction

Preventing soil erosion

c. Applications in Agriculture

Hydrated lime is also used to balance soil pH, improving fertility and crop yields. This dual-purpose use highlights its importance in both construction and agriculture.

5. Reliable Lime Exporters in India

a. Meeting Global Demand

Reliable Lime Exporters in India play a crucial role in promoting Rajasthan’s lime products internationally. They ensure that lime meets the quality and environmental standards of importing countries.

b. Efficient Logistics

Exporters streamline the supply chain, ensuring timely delivery to global markets. This strengthens Rajasthan’s position as a leader in lime production.

c. Competitive Edge

Rajasthan’s lime products, known for their purity and performance, are preferred by international buyers, boosting export potential.

6. The Lime Stabilization Process

a. Preparation

Identify soil type and required lime quantity.

Choose between quicklime and hydrated lime based on project needs.

b. Application

Spread lime evenly over the soil surface.

Use mechanical equipment to mix lime with soil thoroughly.

c. Curing

Allow time for chemical reactions to stabilize the soil.

Test the stabilized soil for strength and durability.

7. Environmental Benefits of Lime Stabilization

a. Reducing Construction Waste

Lime stabilization allows the reuse of marginal soils, reducing the need for soil replacement and minimizing construction waste.

b. Lowering Carbon Footprint

Using locally produced lime from Rajasthan reduces transportation emissions, contributing to eco-friendly construction practices.

c. Sustainable Agriculture

Hydrated lime improves soil health, promoting sustainable farming practices in India and beyond.

8. Challenges in Lime Production and Supply

a. Regulatory Compliance

Strict environmental and mining regulations require manufacturers and exporters to adopt sustainable practices.

b. Transportation Issues

Ensuring timely delivery of lime products to remote areas can be challenging, requiring efficient logistics and infrastructure.

c. Market Competition

Rajasthan faces competition from other lime-producing regions, necessitating continuous innovation and quality improvement.

9. Future Prospects

a. Rising Demand for Infrastructure

The growing need for infrastructure development in India and abroad is expected to drive demand for lime.

b. Focus on Sustainability

Rajasthan’s lime industry is adopting eco-friendly practices, ensuring long-term growth and global acceptance.

c. Expanding Export Markets

With the support of Reliable Lime Exporters in India, Rajasthan’s lime products are gaining recognition in international markets.

10. Conclusion

The Importance of Rajasthan Lime in Soil Stabilization cannot be overstated. From enhancing soil strength to promoting sustainable agriculture, lime plays a vital role in India’s development. The contributions of Lime Manufacturers in Jodhpur, hydrated lime manufacturers in Jodhpur, and Reliable Lime Exporters in India are central to ensuring a steady supply of high-quality lime. By addressing challenges and embracing innovation, Rajasthan’s lime industry is poised for continued success.

0 notes