#slitter manufacturer

Explore tagged Tumblr posts

Text

#conpaptex#machine#manufacturers#flexible packaging#packagingmachinery#packaging industry#plastic#plastic slitter rewinder machine#industry#slitter rewinder machine

1 note

·

View note

Text

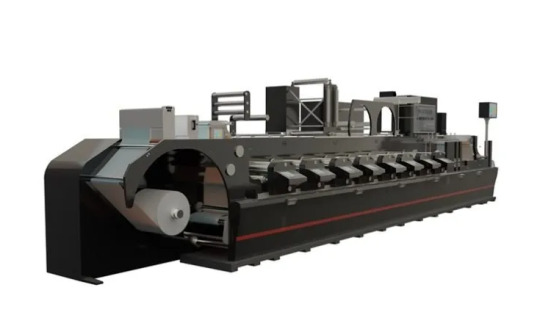

KEW ENGG. & MFG. PVT. LTD., we specialize in manufacturing cutting-edge Heavy Duty Drum Slitter Machine designed to meet diverse industrial requirements. Whether it’s for paper, plastic, textile, or packaging applications, our machines deliver unparalleled precision and durability.

#kewengg#machine#machinery#industry#machinemanufacture#industrial#exporter#supplier#manufacturer#manufacturing#Heavydutydrum#heavyduty#slittermachine#paper industry#papermachinery

2 notes

·

View notes

Text

We manufacture and offer a wide range of Aluminum Foil Slitter that are precisely designed and constructed to meet the standards that effectively meet the requirements of foil cutting.

2 notes

·

View notes

Text

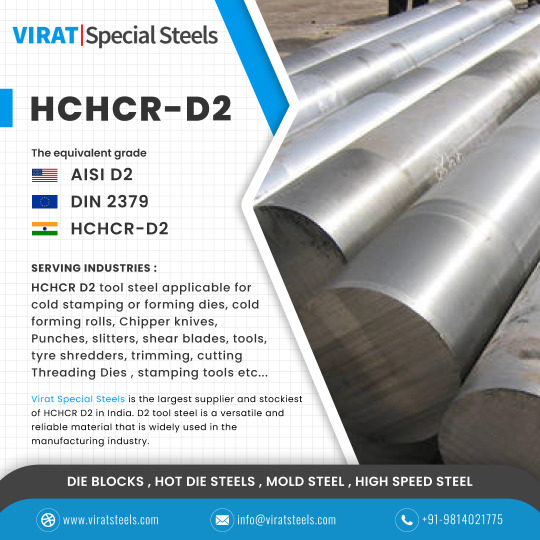

Would you like to purchase HCHCR-D2 steel in #India for your cold work steel industry? Get in touch with us today to place your requirement !

d2steel #d2 #specialsteel #clodworksteel

HCHCR D2 is a type of tool steel that is commonly used in India for making cold stamping or forming dies, cold forming rolls, chipper knives, punches, slitters, shear blades, tools, tire shredders, trimming, cutting threading dies, stamping tools, and more. Virat Special Steels is the largest supplier and stockiest of HCHCR D2 in India.

D2 tool steel is a high-carbon, high-chromium cold work steel. It is a type of tool steel, which means it is primarily used to make cutting and shaping tools such as dies, punches, and molds. D2 tool steel is known for its high wear resistance, toughness, and hardness, making it a popular choice for industrial applications that require durable and reliable tooling. It also has good dimensional stability, meaning it can maintain its shape and size even under high stress and temperature conditions. Overall, D2 tool steel is a versatile and reliable material that is widely used in the manufacturing industry.

Applications: HCHCR D2 tool steel applicable for cold stamping or forming dies, cold forming rolls, Chipper knives, Punches, slitters, shear blades, tools, tyre shredders, trimming, cutting threading dies, stamping tools etc.

Mode of Supply:

ViratSpecialSteels is the largest Supplier & Stockiest of HCHCR D2 in #India. Consult our team who will assist you for HCHCR D2/ DIN 2379/ AISI D2 steel query.

Learn more: https://www.viratsteels.com/hchcr-d2.html

Any further queries feel free to contact us : Corporate Office, #Gurgaon Administrative Office, #Ludhiana Email: [email protected]. or Call Us: 098140 21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#d2steel#din2379#aisid2#maharashtra#punjab#haryana#delhi#ncr#manufacturing#forging#cold work steel#chipper knives

2 notes

·

View notes

Text

Manufacturer of Flexible Packaging, Paper, Tire-Cord, and Textile Machinery

Krishna Engineering Works is a company based in India that specializes in manufacturing and supplying a wide range of industrial machinery and equipment. The company was established in 1980 and has since become a well-established name in the industry.

Krishna Engineering Works offers a wide range of products including Flexible Packaging, Paper, Tire-Cord, and Textile Machinery, Slitter Rewinder Machines, Coating Machines, and many more. The company's products are widely used in industries like packaging, printing, paper conversion, and textiles.

#Flexible Packaging#Paper#Tire-Cord#Textile Machinery#Textile Processing Machinery#Textile Processing Machine Price#Textile Machine Manufacturer

2 notes

·

View notes

Text

Searching Top 10 Steel Plate Sheets in UAE? Piping Material is a leading Supplier and exporter of Plate in MENA Countries, manufacturing them With the Best quality, price, and shipping cost. You can also purchase several varieties of Steel plate, metal sheet, Carbon sheets, and chamfer steel plates.

steel plate Supplier and metal sheet are very much popular in the construction world. If you think that the term refers to the same thing, a common misconception is its assumed synonymy. While, both of these are critical in any construction undertaking, their respective attributes allow them to be used in different tasks.

It’s important to note the distinctions between these two materials as it can dictate success when undertaking different projects.

Thickness: The distinction in measurement comes first. The distinction in thickness comes into play. Steel plates, which are greater than 4mm thick, are heavier than steel sheets which can go as low as 0.5 mm.

Applications: Cars tend to use steel sheets for their antennas, roofs, and even as car body covers due to how smooth and sleek the finish is. Unlike steel plates which are commonly used for building construction and bridge construction due to the amount of strength and support the structure needs. .Sheet metal which is equal to or exceeds 4mm in thickness is really strong.

Manufacturing Process – Steel sheet is made by processing coil metallic through a roll slitter, which cuts the coil into sheets. Steel plate, however, is made via heating and rolling metal until it will become a flat slab. The slab is then reduce into desired styles and sizes.

Cost – Steel sheet is commonly inexpensive than metal plate, as it requires much less material and processing. Steel plate, on the other hand, is more high priced because of the added thickness and manufacturing procedure. It is straightforward logic, plate has a higher metal content material than sheet.

Strength – Steel plate is normally stronger than steel sheet due to its thickness and durability. It can aid heavier loads and is extra resistant to damage and wear. Steel sheet, alternatively, is greater flexible and may be bent and formed into unique paperwork. 0.5mm for example in all fairness easy to bend by hand. A 6mm thick equivalent would now not be bendable beneath any situations. The image underneath shows a 6mm steel sheet from aspect on.

#Steel Plate Sheet#pipingmaterial#Steel Manufacturing#CompressionFittings#suppliers#SteelIndustry#MetalSupplier

1 note

·

View note

Text

Droid is a leading manufacturer of wet wipes machines, offering a wide range of machines for various applications. From slitters and saturators to folding and packaging machines, Droid has got you covered. With their state-of-the-art technology and expertise, Droid ensures that the wet wipes produced are of the highest quality and meet all necessary safety and hygiene standards.

0 notes

Text

Krishna Engineering Works has a solution that best fits your manufacturing unit or enterprise. Know more about its latest machines from Krishna Engineering Works. Upgrade your paper-making productivity and establish your company as an industry leader in the long term.

heavy duty type slitter drum rewinder machine can process all kinds of paper of any GSM thickness. In our heavy duty series paper slitting rewinding machine, the rewinding diameter can be achieved up to 1200mm.

#krishnaengineeringworks#machine#manufacturer#machinery#industry#export#supplier#industrial#machinemanufacturer#slitterrewindermachine#heavydutyslitterrewindermachine#slittingrewindingmachine#paperindustry#papermachinery

1 note

·

View note

Text

Webtech Group’s live demonstrations at Printpack 2025

Webtech Group, a leading manufacturer of printing and paper-converting machinery, will showcase its range of machines at Printpack 2025, to be held from 1 to 5 February 2024, at India Expo Centre and Mart in Greater Noida. It show demonstrate the fully servo flexographic printing machine in 450 mm working width, thermal roll slitting rewinding machine with single color online flexo printing, honeycomb paper die cutting machine, and servo-controlled label slitter rewinder machine

Along with the showcased machines, the Webtech team will highlight its entire range of products, including fully servo flexographic printing machines, web offset printing machines, slitting rewinding machines, and die cutting machines at its stand. The team will discuss technological advancements, share insights into the industry’s trajectory, and offer tailored solutions.

Singh emphasized the strategic importance of participating in Printpack 2025. “Printpack provides a vital platform to showcase technological advancements to a global audience and expand our clientele. The exhibition offers invaluable insights into emerging trends and challenges, enabling us to enhance our product offerings and stay ahead of market demands,” he said.

By participating in such exhibitions, Webtech aims to solidify its industry presence while forging new relationships with global clients. “For Printpack 2025, we aim to build on our previous successes by introducing our latest fully servo flexographic printing machine and other innovations. We look forward to engaging with industry leaders and further strengthening our position in the market,” Singh added.

Singh highlighted the evolution of the printing and packaging industry, driven by increasing demand for sustainable and flexible packaging solutions. Key advancements, such as fully servo-driven machines, automation, and eco-friendly substrates, are shaping the future of the industry.

“The printing and packaging sector is experiencing robust growth, with sustainability and precision at its core. We are poised to capitalize on these trends by offering innovative and efficient machinery that addresses challenges such as waste reduction and enhance productivity,” Singh explained.

Webtech International Machineries will be present in hall no 5, stands C19 and C28.

0 notes

Text

A Paper Cutter Rewinder Machine cuts large paper rolls into smaller, much more manageable parts and rewinds them simultaneously; it is machinery that integrates precision-cutting technology together with efficient winding mechanisms to be productive and cut waste to minimum.

Conpaptex's Paper Cutter Rewinder Machine leading the way for the paper, packaging, and printing industries in offering seamless performance.

#conpaptex#paper cutter rewinder machine#paper cutter#slitter rewinder machine#machine#manufacturers#paper industry#paper machinery#paper#machinery

1 note

·

View note

Text

Bopp / Paper Tape Coating Machine

Mohindra is recognized as one of the top manufacturers of Doctoring Slitting Machines in India. Although we are located in Delhi, we supply our wide range of products across the country. We use premium quality raw materials in the production of all our machines. As you may know, the demand for Doctoring Slitting Machines is increasing daily, driven by the rising consumption of paper bags in India. Mohindra Machine stands out as a leading manufacturer of Doctoring Slitting Machines. We are dedicated to producing and supplying these machines to potential customers in the market. The Doctoring Slitting Machine is designed to cut and convert large sheets of paper, foil, and film materials into narrower rolls. These machines consist of three main components: the slitter, unwind, and rewind.

#Bopp paper tape coating machine price#Bopp paper tape coating machine price in india#Bopp paper tape coating machine in india#Bopp paper tape coating machine for sale

1 note

·

View note

Text

Jandu PPM - Printing and Packaging Machines Manufacturer

Jandu Printing and Packaging Machines Company is a professional Slitting and Rewinding Machine manufacturer and supplier in Delhi, India. We are manufacturing an exclusive range of slitter and rewinder machines, which are widely used for cutting and rewinding paper.

Jandu PPM offers highly versatile Roll To Sheet Cutting Machine and centre drum slitting and rewinding machines suitable for slitting plastic films, paper, and metal foils. This machine comes with slitting.

Contact Jandu Printing and Packaging Machines

Company: Jandu PPM

Call: +91-9811100842, 9811510842

Address: 25/18, Gali No.6, Master Mohalla Libaspur, Delhi-110042

#SlittingandRewindingMachine#SlitterandRewinderMachine#CentreDrumSlittingAndRewindingMachine#ReelToSheetCuttingMachine#RollToSheetCuttingMachine#JanduPPM

1 note

·

View note

Text

Jandu PPM - Slitting and Rewinding Machine Manufacturer

Jandu Printing and Packaging Machines Company is a leading Slitting and Rewinding Machine manufacturer and offers an exclusive range of slitter and rewinder machines, which are widely used for cutting and rewinding paper. Key Features of Slitting and Rewinding Machines Latest in Design Good Performance Simple in Operating Easy Maintenance High Speed Contact for Slitter and Rewinder…

0 notes

Photo

Are you looking for HCHCR-D2 steel? Looking HCHCR-D2 steel for your Cold Work Steel Industries? #d2steel #d2 #specialsteel #clodworksteel

HCHCR D2 is a type of tool steel that is commonly used in India for making cold stamping or forming dies, cold forming rolls, chipper knives, punches, slitters, shear blades, tools, tyre shredders, trimming, cutting threading dies, stamping tools, and more. Virat Special Steels is the largest supplier and stockiest of HCHCR D2 in India.

D2 Steel Consolidates maximum wear resistance, great durability, exceptional front line maintenance and treating resistance. 12 % ledeburitic chromium steel. It can be nitride after special heat treatment. It can be utilized as threading rolls and dies, icy trimming, cutting and stamping tools for sheet thickness's up to 6 mm, accuracy cutting instruments for sheet thicknesses up to 12 mm.

D2 tool steel is a high-carbon, high-chromium cold work steel. It is a type of tool steel, which means it is primarily used to make cutting and shaping tools such as dies, punches, and molds. D2 tool steel is known for its high wear resistance, toughness, and hardness, making it a popular choice for industrial applications that require durable and reliable tooling. It also has good dimensional stability, meaning it can maintain its shape and size even under high stress and temperature conditions. Overall, D2 tool steel is a versatile and reliable material that is widely used in the manufacturing industry.

Applications: HCHCR D2 tool steel applicable for cold stamping or forming dies, cold forming rolls, Chipper knives, Punches, slitters, shear blades, tools, tyre shredders, trimming, cutting threading dies, stamping tools etc.

Mode of Supply: Virat Special Steels is the largest Supplier & Stockiest of HCHCR D2 in #India.Consult our team who will assist you for HCHCR D2/ DIN 2379/ AISI D2 steel query.

Learn more: https://www.viratsteels.com/hchcr-d2.html

Any further queries feel free to contact us : Corporate Office, #Gurgaon Administrative Office, #Ludhiana Email: [email protected]. or Call Us: 098140 21775

#metalworking#metallurgy#iso9001#engineering#steel#db6steel#toolsteel#toolsteelsupplier#viratsteels#viratsteelsindia#d2#d2steel#makeinindia#forging#quality#india#ludhiana#gurugram#pune#maharashtra#punjab#haryana#delhi#delhincr

2 notes

·

View notes

Text

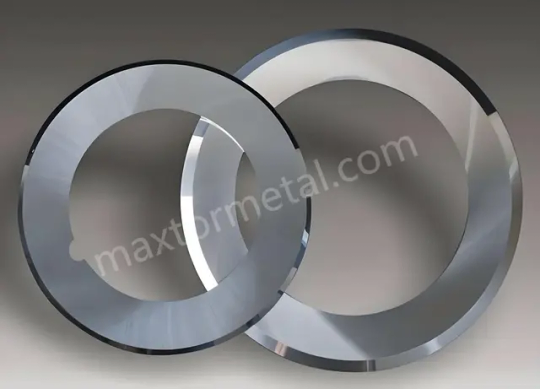

How to Maximize Slitter Blade Sharpness for Superior Cutting Performance

Summary

Maintaining the sharpness of a slitter blade is essential for achieving precise cuts, minimizing downtime, and improving operational efficiency. This article explores why sharpness retention matters, factors affecting blade longevity, advanced techniques for durability, and best practices for maintenance, ensuring your cutting tools perform at their best.

Introduction

In industrial applications, precision cutting is the cornerstone of efficiency and quality. The slitter blade, a critical component in industries like paper, metal, and plastic processing, must remain sharp to perform effectively. Dull blades lead to uneven cuts, wasted material, and costly downtime. This article delves into the technologies and strategies to retain the sharpness of slitting tools, helping you optimize performance and reduce costs.

By understanding the factors influencing blade sharpness and adopting advanced techniques, you can ensure your operations run smoothly. Let’s explore how you can keep your slitter blades sharp and effective for longer periods.

Why Sharpness Retention Matters for Slitter Blades

Sharpness plays a critical role in ensuring the efficiency and precision of industrial cutting processes. Whether you are cutting thin plastic films, thick metal sheets, or delicate paper rolls, maintaining a sharp edge on your slitter blade is essential. Let’s examine the specific impacts dull blades have on your operations:

1. Uneven Cuts

Dull blades fail to create clean, consistent edges, which can compromise the quality of the final product. For example, in the paper industry, jagged edges can lead to product rejection, affecting customer satisfaction and brand reputation. According to industry reports, manufacturers using dull blades experience up to 15% more defective products than those using well-maintained cutting tools.

2. Material Waste

Poor sharpness often results in inaccurate cuts, generating excess material waste. In industries handling expensive raw materials like aluminum or specialty polymers, this waste can represent significant financial losses. A study in a metal processing plant found that switching to precision-sharpened slitting knives reduced scrap rates by 25%, saving approximately $100,000 annually.

3. Increased Wear on Equipment

Using a dull blade requires more force to achieve the same cuts, which puts undue stress on machinery. Over time, this can lead to faster wear and tear on mechanical components, increasing maintenance costs and the risk of equipment failure. Preventive maintenance through blade sharpness retention can lower machine repair expenses by 20%.

4. Downtime for Maintenance

Frequent blade sharpening or replacement interrupts production schedules, resulting in costly downtime. In high-volume production environments, even an hour of unscheduled maintenance can translate into thousands of dollars in lost revenue. Maintaining sharper blades significantly extends service intervals, keeping your operations running smoothly.

The Competitive Edge

Maintaining sharp blades is more than just a technical necessity—it’s a strategic advantage. Companies that invest in blade sharpness retention report up to 30% better operational efficiency, giving them an edge in competitive markets.

Keep reading to explore the factors affecting sharpness and how to address them.

Key Factors Affecting Slitter Blade Sharpness

1. Blade Material

Blade composition significantly affects sharpness retention. High-grade alloys such as M2 tool steel, tungsten carbide, and ceramic composites offer excellent hardness and durability. A coated slitting blade can last twice as long as an uncoated one under similar conditions. For example, tungsten carbide-coated blades can withstand up to 500,000 cuts before requiring sharpening, compared to just 250,000 for standard steel.

2. Cutting Environment

The type of material being processed greatly influences blade wear. Harder materials like steel generate more friction and heat, which can quickly degrade blade edges. Additionally, cutting plastics or rubber often produces sticky residues that dull blades faster if not cleaned properly. Addressing these environmental factors with proper lubrication and cleaning can extend blade life by up to 40%.

3. Maintenance Practices

Inadequate blade maintenance is a major factor in premature dulling. For instance, incorrect sharpening angles can weaken the blade edge, while poor cleaning techniques may leave residues that accelerate wear. Implementing systematic maintenance schedules helps ensure consistent blade performance.

4. Innovative Blade Design

Advanced blade designs optimize edge geometry for specific applications. For example, beveled edges reduce cutting resistance and friction, improving durability. Laser-precision manufacturing techniques can achieve tolerances as fine as 0.001mm, creating sharper, more reliable blades.

Advanced Techniques to Prolong Slitter Blade Sharpness

1. Coating Technologies

Special coatings protect blade surfaces from wear and corrosion. For example, titanium nitride coatings increase surface hardness, allowing blades to retain sharpness 50% longer in high-speed operations. Similarly, diamond-like carbon coatings reduce friction, lowering operational temperatures and improving edge retention.

2. Cryogenic Treatment

Cryogenic processing aligns the internal structure of metals, enhancing their hardness and resistance to wear. Studies show that cryogenically treated industrial cutting tools last 30% longer than untreated blades in heavy-duty environments.

3. Precision Grinding and Sharpening

Grinding machines capable of maintaining a consistent edge angle ensure that the blade delivers smooth, precise cuts. Automated sharpening systems eliminate human error, providing consistent results that increase blade longevity by up to 20%.

4. Custom Blade Design

Tailored blade solutions enhance performance for specific applications. For example, rotary knives designed for textile cutting may feature serrated edges to minimize wear while ensuring clean cuts. Custom designs reduce maintenance frequency and improve process efficiency.

Maintenance Best Practices to Retain Blade Sharpness

Routine care and attention can drastically extend the lifespan of your slitting knives.

1. Routine Inspections

Perform regular checks for visible damage, including nicks, burrs, or uneven wear. An inspection log helps identify patterns and predict when blades require sharpening or replacement.

2. Proper Cleaning

Use non-abrasive tools and solvents to remove residues after each use. For example, a specialty blade-cleaning solution can reduce buildup by 50%, minimizing the risk of dulling.

3. Lubrication

Choose a lubricant that matches the cutting environment. For example, water-based lubricants are effective for heat-sensitive applications, while oil-based options are ideal for heavy-duty metal cutting. Proper lubrication reduces friction, extending blade life by 15%-25%.

4. Correct Storage

Preventing physical damage during storage is crucial. Blades should be kept in dry, temperature-controlled environments, and protective covers should always be used.

5. Operator Training

Ensure operators understand proper blade handling techniques, such as avoiding direct contact with edges and correctly aligning blades during installation. Trained staff are less likely to cause accidental damage, reducing blade replacements by up to 10%.

By adopting these best practices, you can ensure peak performance from your cutting tools.

How Our Slitter Blades Stand Out in Sharpness Retention

At [Your Company Name], we prioritize precision and durability in every slitter blade we manufacture. Here’s why our products excel:

Superior Materials: Our blades are crafted from premium alloys and coated with cutting-edge technologies to ensure unmatched sharpness retention.

Advanced Manufacturing: We use precision grinding and laser cutting to create blades tailored to your specific needs.

Proven Performance: Our blades have helped clients reduce downtime by 40% and improve product quality consistently.

Client Testimonial:

“We switched to Metal’s industrial cutting tools, and the difference was night and day. Less waste, smoother cuts, and longer blade life!” – Operations Manager, Packaging Industry

Our commitment to quality ensures that your cutting operations remain seamless and efficient.

Contact us today to learn how we can optimize your cutting processes.

Conclusion and Call to Action

Sharpness retention is the cornerstone of efficient and cost-effective cutting operations. By understanding the factors that affect slitter blade performance, leveraging advanced technologies, and following best maintenance practices, you can enhance blade durability and reduce operational costs.

Ready to upgrade your cutting tools? Discover how our advanced solutions can revolutionize your operations. Custom Industrial Blades Manufacturer in China and Custom Industrial Blades Supplier in China. Contact us today!

1 note

·

View note