#sintered parts manufacturer

Explore tagged Tumblr posts

Text

What's The Differences Between SLA and SLS in Rapid Prototyping?

Rapid Prototyping(RP) is a manufacturing technology that quickly generates models or parts. There are more than ten different processes, such as stereolithography (SLA), laminated object manufacturing (LOM), selective laser sintering (SLS), fused deposition modeling (FDM), solid ground curing (SGC), three dimensional printing (3DP_Binder Jetting), ballistic particle manufacturing (BPM), etc. Among them, SLA is the earliest and most widely used technology, accounting for about 70% of all rapid prototyping equipment.

Today we'll discuss the differences between SLA and SLS from four aspects.

The principle of SLA: use laser of a specific wavelength to solidify the resin.

The material of SLA is the category of resin.

The characteristics of SLA:

1. Stereolithography is the earliest rapid prototyping process, with high maturity and time-tested. 2. The prototype is made directly from the CAD digital model, with fast processing speed, short production cycle, and no need for cutting tools and molds. 3. It can process prototypes and molds with complex structures or difficult to form using traditional means. 4. Make CAD digital models intuitive and reduce the cost of error repair. 5. Provide samples for experiments can verify and check the results of computer simulation calculations. 6. It can be operated online and remotely controlled, which is conducive to production automation.

The disadvantages of SLA:

1. The SLA system is expensive to build, use and maintain. 2. The SLA system is a precision device that operates liquids and has strict requirements on the working environment. 3. Most molded parts are made of resin, which has limited strength, rigidity and heat resistance, and is not conducive to long-term storage.

The principle of SLS: heat the powder sintered to near melting point of the material and then add laser energy to sinter it.

The material of SLS is nylon and various materials and mixed materials.

The characteristics of SLS:

1. A variety of materials can be used. In principle, this method can use any powder material that reduces viscosity when heated, and can produce any shape through materials or various types of coated particles containing binders to meet different needs. 2. The manufacturing process is relatively simple. Since a variety of materials can be used, the selective laser sintering process can directly produce complex-shaped prototypes, cavity mold three-dimensional components or parts and tools according to the raw materials used. 3. No support structure is required. The overhanging layers that appear during the lamination process can be supported directly by the unsintered powder. 4. High material utilization rate. Since the process does not require a support structure, most of the powders used in the SLS process are relatively cheap, so the cost of the SLS model is relatively low. 5. Short production cycle. It only takes a few hours to dozens of hours from CAD design to the completion of parts processing. The entire production process is digitalized and can be modified and manufactured at any time. This feature makes it particularly suitable for the development of new products. 6. Combined with traditional process methods, it can realize functions such as rapid die casting, rapid molding and small batch manufacturing, injecting new vitality into traditional manufacturing methods. 7. Wide application. Due to the diversity of molding materials, the SLS process is suitable for a variety of application fields, such as prototype design verification, mold master, precision casting investment, casting shell and core, etc.

The disadvantages of SLS:

1. Rough surface. Since the raw material of SLS process are in powder form, the prototype is built by melting the powder layer by layer through heating. Therefore, strictly speaking, the surface quality of the prototype is not good enough as in powder form. 2. Polymer materials or powder particles generally emit odorous gases during laser sintering and melting. 3. Sometimes more complicated auxiliary processes are required. SLS technology varies depending on the materials used, and sometimes more complicated auxiliary processes are required, such as preheating the raw materials for a long time, cleaning the surface powder of the model after the modeling is completed, etc.

The advantage of RP prototype is its rapidity, but it is mainly formed by stacking technology, so RP prototype is generally relatively rough, and has centain requirements on the wall thickness of the product. For example, if the wall thickness is too thin, it cannot be produced.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#rp#sla#sls#3d printing#3d printed#additive manufacturing#stereolithography#selective laser sintering#fdm#fdm 3d printing

1 note

·

View note

Text

ALCAZAR TOWNHOMES. SOLANA COURT. §320,000.00 MONTHLY.

This isn’t her home. Her home is Kurojima Island, where she wakes up to the sounds of birds chirping, the rhythmic creak of a wooden well pump drawing crystal water from deep beneath the cliffs, and the cool morning breeze rustling the thickets of black pines and yellow-leafed trees by her window. Fumiko simply refers to her townhouse as a resthouse. A place that offers her reprieve from her near-24-hour job at YAMI Radio. By morning, she’s the iconoclastic, nepotist radio DJ talking about worldly things with worldly people, keeping on the line what’s left of the Del Bosque-Shibata loyalists. But by night—secret phrases upon phrases to alert the kagehito of the latest open bounties, with prices going as high as §8,000,000.00 for the quiet deaths of decision-makers. It’s only ever her mixing console and its soft, glass-like clicks through the night—hell, that’s more like home to her. Her townhouse is by no means drab. It’s a dream to live in by all normal accounts. But unfortunately, she’s no homebody. She only chose this over the Orchid Hotel so as to brandish the illusion of a quasi-socialite who’s a part of society… but not really. She stays in the expensive townhouse to let people know she’s untouchable. Visible, but untouchable. Its furnishings are manufactured, what with her mother hiring a decorator on her behalf to make it appear as though Fumiko has the perfect eye to populate traditional interiors. The tapestry on her living room wall? From the Marisella Art House archives, generously donated. A powder room with a sink made of sintered stone? Painstakingly chiseled by their forgers. The marble countertops in her kitchen? Sourced by Luciana Arrazola herself. Everything looks (and is) well-curated. It all perfectly fits the bill of Fumiko Shibata, the only member of the Shibata family who dares to let people hear the sound of her voice. And if that’s what she’d wanted, she’d have no problem with it. There’s one thing that doesn’t look like it fits. On display—encased in glass with a mahogany frame and laid down like an artifact, not something hung on a wall—a pair of swords. Glinting and gleaming, and ultimately, incredibly jarring to the otherwise pleasant and chic air of her ‘home.’ It’s the only thing that’s hers.

5 notes

·

View notes

Photo

3D printing near net shape parts with no post-processing

Carnegie Mellon University Professor Rahul Panat, and his team, were developing a new type of 3D printed Brain-Computer Interface (or BCI) device where custom micropillars capture the communication signals from neurons when they stumbled upon an unexpected problem: the micropillars in the array bent during sintering. These BCI devices, now called "CMU Arrays," stack millions of metal nanoparticles in 3D space and then sinter, i.e., fuse them together.

In a rather dramatic illustration, a time-lapse film from their experiment, the silver micropillars opened in a highly coordinated fashion like a blooming flower during the 12-hour sintering process to 150-300 °C. This phenomenon was completely unexpected as sintering theory predicts no permanent distortion, even under variable temperatures.

Panat led an interdisciplinary team of researchers from Carnegie Mellon and Washington State University on a quest to not only determine why there was such a distortion, but to more importantly, find a way to control it. In fact, if controlled, the research would lead to world's first illustration of sintering as mechanism of "4D printing," a relatively new discipline within additive Manufacturing (AM) where 3D printed objects are transformed into another shape using sources like heat, water, or other environmental stimuli.

Read more.

#Materials Science#Science#3D printing#Nanoparticles#Sintering#Nanotechnology#4D printing#Additive manufacturing#Carnegie Mellon

14 notes

·

View notes

Text

3D Printing Services UAE: Inoventive 3D Leading the Future of Additive Manufacturing

3D Printing Services UAE - 3D printing has revolutionized manufacturing, prototyping, and design across various industries, making it an indispensable technology in today’s world. The UAE, known for its innovation and forward-thinking approach, has embraced this technology with open arms. Among the leading providers of 3D printing services in the UAE, Inoventive 3D stands out as the premier choice, offering cutting-edge solutions for businesses and individuals alike.

Why Choose Inoventive 3D for 3D Printing Services in UAE?

With numerous 3D printing companies available, it’s crucial to choose a provider that offers high-quality services, reliability, and competitive pricing. Inoventive 3D has established itself as the leader in 3D printing services in UAE due to several key factors:

1. State-of-the-Art 3D Printing Technology

Inoventive 3D utilizes the latest advancements in 3D printing technology, including SLA (Stereolithography), SLS (Selective Laser Sintering), FDM (Fused Deposition Modeling), and Multi-Material 3D Printing. This allows them to produce high-quality prints with exceptional precision and durability.

2. Customized 3D Printing Solutions

Every project is unique, and Inoventive 3D understands this better than anyone. Whether you need architectural models, industrial prototypes, customized medical implants, or creative designs, their team offers tailored solutions to meet your specific needs.

3. Fast Turnaround Time

Time is a critical factor in industries such as construction, manufacturing, and product development. Inoventive 3D ensures rapid production of 3D-printed models and prototypes, reducing lead times and helping businesses speed up their processes.

4. Affordable and Cost-Effective Services

3D printing can be expensive, especially for large-scale projects. However, Inoventive 3D offers some of the most competitive prices in the UAE, making high-quality 3D printing accessible for startups, businesses, and individuals alike.

5. Diverse Material Options

Material selection plays a crucial role in 3D printing, affecting the final product’s durability, flexibility, and aesthetic appeal. Inoventive 3D provides a wide range of material options, including resins, plastics, metals, and composites, to cater to different project requirements.

Industries Benefiting from Inoventive 3D's Services

1. Architecture & Construction

Architectural firms and real estate developers rely on 3D-printed scale models to visualize projects before construction begins. Inoventive 3D’s expertise in architectural 3D printing allows clients to present detailed and accurate models that enhance project planning and approvals.

2. Automotive & Manufacturing

Prototyping is crucial in the automotive and manufacturing industries. Inoventive 3D provides functional prototypes, spare parts, and production tools, allowing businesses to streamline their design and manufacturing processes.

3. Healthcare & Medical Applications

From prosthetics to customized medical implants, Inoventive 3D is at the forefront of medical 3D printing in the UAE. Their ability to create precise, patient-specific models has improved the efficiency of medical treatments and surgeries.

4. Education & Research

Universities and research institutions use 3D printing for educational purposes, creating detailed models for engineering, medicine, and architectural studies. Inoventive 3D supports STEM education by offering high-quality 3D printing services to schools and universities in the UAE.

5. Advertising & Marketing

The marketing industry has embraced 3D printing for custom signage, promotional materials, and 3D-printed billboards. Inoventive 3D has helped numerous brands create eye-catching, one-of-a-kind advertising materials that stand out in a competitive market.

The Future of 3D Printing in UAE

The UAE has always been at the forefront of adopting new technologies, and 3D printing is no exception. With government initiatives like Dubai 3D Printing Strategy, which aims to integrate 3D printing into major industries, the future looks bright for additive manufacturing in the region. Inoventive 3D is actively contributing to this vision by expanding its capabilities and pushing the boundaries of innovation.

For anyone looking for top-tier 3D printing services in UAE, Inoventive 3D remains the best choice. Their expertise in high-quality printing, fast turnaround times, competitive pricing, and industry-specific solutions makes them a trusted partner for businesses, professionals, and individuals. Whether you need a prototype, a functional part, or a large-scale architectural model, Inoventive 3D delivers excellence with every print.

If you are looking for the best 3D printing solutions in the UAE, contact Inoventive 3D today and bring your ideas to life with precision and innovation. Please feel free to contact us for any further assistance. Call/WhatsApp: +971 52 595 9616 | TOLL FREE: 800 535353 | Email: [email protected] | https://inoventive.com/

#3d printing#3d printing dubai#model making dubai#architectural scale models#3dprinting#rapid prototyping#3d model#scale models#industrial scale models#architecture

0 notes

Text

3D Printing Plastics: $3.4B by 2033 🖨️🔬

3D Printing High-Performance Plastic Market is set for remarkable growth, expanding from $1.2 billion in 2023 to $3.4 billion by 2033 at a CAGR of 10.5%! 📈🔥 These advanced polymers — such as PEEK, PEI, and PPSU — are revolutionizing industries by offering lightweight, durable, and heat-resistant components.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS21079 &utm_source=SnehaPatil&utm_medium=Article

Key Growth Drivers & Market Trends

🔹 PEEK Leads the Market (38% Share): Ideal for aerospace & medical implants due to its exceptional strength & biocompatibility. 🛩️🏥 🔹 PPSU (27%) & Polycarbonate (20%): Gaining traction in automotive & electronics for their impact resistance & versatility. 🚗⚙️ 🔹 Fused Deposition Modeling (FDM) & Selective Laser Sintering (SLS): Dominating 3D printing technologies for high-performance plastics. ⚙️🖨️ 🔹 Growing Demand for Sustainability: 🌱♻️ Companies are exploring bio-based & recyclable thermoplastics for eco-friendly production.

Regional Insights & Market Leaders

📍 North America leads, driven by technological advancements & strong industry presence. 🇺🇸💡 📍 Europe follows, focusing on sustainable manufacturing & innovation. 🇪🇺🌍 📍 Asia-Pacific poised for rapid growth, with China & India driving industrial adoption. 🇨🇳🇮🇳🚀

🏆 Top Players: Stratasys Ltd., 3D Systems Corporation, Arkema Group are pioneering innovations in high-performance 3D printing materials. 🏅💡

Future Outlook & Challenges

📊 R&D investments to accelerate, pushing the boundaries of customized, high-performance 3D-printed parts! 🔬⚡ ⚠️ Challenges: High material costs & process optimization hurdles need to be tackled for widespread adoption.

💡 How do you see 3D printing reshaping industries? Drop your insights below! 👇

#3DPrinting #AdditiveManufacturing #HighPerformancePlastics #PEEK #FDM #SLS #Polycarbonate #SustainableManufacturing #AerospaceTech #AutomotiveInnovation #Medical3DPrinting #IndustrialPrinting #AdvancedMaterials #DigitalManufacturing #Innovation

0 notes

Text

3D Printing and Scanning Services in Bangalore: Revolutionizing the Additive Industry

Introduction

Bangalore, often referred to as the "Silicon Valley of India," has been at the forefront of technological advancements in various industries. One of the most rapidly growing sectors in the city is the additive manufacturing industry, encompassing 3D printing services and 3D scanning services. These services are transforming industries such as healthcare, automotive, aerospace, architecture, and product design by offering cost-effective, precise, and innovative solutions.

In this blog, we will explore the significance of 3D printing services in Bangalore and 3D scanning services in Bangalore, their applications, and how they are shaping the future of manufacturing and design.

The Rise of 3D Printing Services in Bangalore

3D printing, also known as additive manufacturing, is a revolutionary technology that enables the creation of three-dimensional objects by layering materials based on a digital model. Over the past decade, Bangalore has emerged as a hub for 3D printing services, with numerous startups and established firms offering cutting-edge solutions.

Why is 3D Printing Gaining Popularity in Bangalore?

Technological Advancements: Bangalore’s strong IT and R&D ecosystem has fueled innovations in 3D printing, making it more accessible and efficient.

Cost-Effective Prototyping: Startups and businesses leverage 3D printing to create prototypes at a fraction of the cost of traditional manufacturing.

Customization & Rapid Production: Industries such as healthcare and fashion benefit from the ability to produce customized products quickly.

Sustainable Manufacturing: 3D printing reduces material waste, making it an environmentally friendly alternative to conventional methods.

Applications of 3D Printing in Bangalore

1. Healthcare & Medical

Custom prosthetics, dental implants, and anatomical models for surgical planning.

Bio-printing of tissues and organs for medical research.

2. Automotive & Aerospace

Rapid prototyping of components and lightweight parts for enhanced efficiency.

Reduction in production costs and lead times for vehicle and aircraft manufacturing.

3. Architecture & Real Estate

Creation of scaled models for visualization and design approval.

3D printing of construction materials for sustainable buildings.

4. Product Design & Engineering

Iterative prototyping for product development and functional testing.

On-demand manufacturing of customized consumer goods.

With the increasing demand for 3D printing services in Bangalore, service providers are expanding their capabilities to include SLA (Stereolithography), SLS (Selective Laser Sintering), FDM (Fused Deposition Modeling), and DMLS (Direct Metal Laser Sintering) technologies to cater to diverse industry requirements.

The Role of 3D Scanning Services in Bangalore

Alongside 3D printing, 3D scanning technology is playing a crucial role in industries that require precision and digital replication of physical objects. 3D scanning services in Bangalore are widely used for reverse engineering, quality inspection, and digital archiving.

What is 3D Scanning?

3D scanning is a process of capturing the shape and dimensions of an object using laser or structured light technology to create a digital 3D model. This data can be used for various applications, including quality control, CAD modeling, and digital twin creation.

Benefits of 3D Scanning Services in Bangalore

High Precision & Accuracy: Captures intricate details of objects with exceptional accuracy, essential for industries like aerospace and healthcare.

Time-Saving & Cost-Effective: Reduces manual measurement errors and accelerates the design and manufacturing process.

Reverse Engineering: Enables the recreation of legacy parts that lack CAD documentation.

Customization & Personalization: Facilitates the design of personalized medical implants, consumer products, and automotive parts.

Industries Utilizing 3D Scanning in Bangalore

1. Manufacturing & Engineering

Quality control and inspection of manufactured parts.

Reverse engineering to improve and reproduce legacy parts.

2. Healthcare & Biomechanics

Creation of personalized orthotics, prosthetics, and dental implants.

Digital modeling of human anatomy for medical research and training.

3. Art & Heritage Preservation

Digital restoration of historical artifacts and sculptures.

Virtual museums and AR/VR applications for cultural heritage conservation.

4. Education & Research

Enhanced learning through 3D models and virtual simulations.

Research in biomechanics, material science, and industrial design.

Leading 3D Printing and Scanning Service Providers in Bangalore

The 3D printing and 3D scanning service in Bangalore is thriving, with numerous companies offering specialized solutions. Some of the leading providers include:

Think3D: One of India’s top 3D printing and scanning service providers.

Intech Additive Solutions: Specializing in metal 3D printing and additive manufacturing.

Morphing Machines: Offering high-precision 3D scanning and reverse engineering.

Bangalore 3D: A local service provider offering rapid prototyping and product design solutions.

Fabheads: Focuses on composite 3D printing for aerospace and defense applications.

These companies cater to businesses of all sizes, from startups to large enterprises, providing customized solutions for their manufacturing and design needs.

The Future of Additive Manufacturing in Bangalore

The future of 3D printing and scanning services in Bangalore looks promising, driven by continuous advancements in technology and increased adoption across various industries. Some key trends to watch out for include:

Advancements in Metal 3D Printing: More industries, especially aerospace and automotive, will adopt metal 3D printing for high-performance parts.

AI and Automation Integration: AI-powered 3D scanning and printing will enhance precision, reduce material waste, and streamline workflows.

Sustainable Materials & Eco-Friendly Manufacturing: The shift towards biodegradable and recyclable materials in 3D printing will reduce environmental impact.

On-Demand & Distributed Manufacturing: Localized production through 3D printing hubs will minimize supply chain dependencies.

Medical Innovations: From bioprinting tissues to creating fully functional implants, 3D printing in healthcare will witness exponential growth.

Conclusion

The 3D printing and scanning industry in Bangalore is set to revolutionize the way products are designed, developed, and manufactured. Whether you're a startup looking for rapid prototyping or an enterprise seeking high-precision engineering solutions, 3D printing services in Bangalore and 3D scanning services in Bangalore offer unparalleled benefits.

With technological advancements, reduced costs, and increased accessibility, the adoption of additive manufacturing will continue to grow, solidifying Bangalore’s position as a leading hub for innovation and industrial transformation.

If you're looking to integrate 3D printing or 3D scanning into your business operations, now is the perfect time to explore the endless possibilities that these cutting-edge technologies offer.

Have you tried 3D printing or scanning services in Bangalore? Share your experiences in the comments below! 🚀

#Metal 3D printing in Bangalore#Additive Manufacturing in Bangalore#Additive Manufacturing Companies in Bangalore#3D Printing Service in Bangalore#3D Scanning Services in Bangalore#3D Scanning And Design in Bangalore#Best Trumpf TruPrint 1000 Metal 3D Printer#Best Trumpf TruPrint 2000 Metal 3D Printer#Best Trumpf TruPrint 3000 Metal 3D Printer#Best Trumpf TruPrint 5000 Metal 3D Printer

0 notes

Text

3D printing technology has been part of the discussion for at least a couple of decades, and about ten years ago the first 3D printer was designed and released. This machines have amazing capabilities and can print almost everything from hardware and toys to food and housing. Today, 3D printers occupy relatively small niches and are mainly used to print product prototypes, custom phone cases, detailed toys and figurines, various cosplay materials, figures for board games (Warhammer 40000, for instance), etc. And after hearing about astonishing 3D printers capacities, you decided to buy one or just planning to use this technology to print some product or simply want to know more about 3D printers, then this article is for you. Today, we unveil the curtain of what stands behind additive manufacturing and introduce you to ten things which are necessary to know before dealing with three-dimensional printing. 1. Different Types Of 3D Printers Use Different Technology Modern market is full of a variety of 3D printers with diverse specifications and requirements that work under different technologies. Let's discuss three the most common approaches to additive manufacturing. Fused Deposition Modeling (FDM) It's the most popular 3D printing process which works on a principle of placing material layer by layer. FDM printers use a thermoplastic or metal spool of filaments and apply heating to release the filament of a material to put down layers that echoing the shape of the model. Fused Filament Fabrication (FFF) is also a widely used term that literally means the very same method of 3D printing and was invented by the RepRap initiative in order to patent and legally used this technology. It's also known as Plastic Jet Printing (PJP). FDM printers are universally available and considered to be relatively not high priced. Stereolithography (SLA) Such printers involve using photosensitive liquid substances as a basic material and work with ultraviolet light in order to release molecules and link them together, forming a solid 3D object. Stereolithography is also called Optical Fabrication or Rapid Prototyping. It's suitable for prototyping, creating models or patterns since SLA is distinguished by the amazing precision of all the details. On the other hand, it allows using a very narrow range of possible materials and is unsuitable for printing organic and metal. Moreover, stereolithography printers are at least twice more expensive than FDM ones and a bit more difficult to found. Selective Laser Sintering (SLS) SLS is slightly different from SLA printing technique in choosing the basic working material which in turn leads to the use of other 3D printing technology. SLS printers engage a laser as a source of power that is focused on a specific place in space according to the 3D model parameters. Such printers work with powder materials, mainly metals, and use a laser to melt the powder and bind its molecules into a solid model. This technology is mainly used to print metal objects. The choice of technology depends on a desirable material and the amount of funds that you are willing to spend on manufacturing. Besides, despite the fact that 3D printing features high details accuracy, some devices in more or less degree do not allow you to print fine details. That's why before choosing a 3D printer for further purchasing or printing, you should consider the points made above. Let's pay a bit more attention to the prices and materials used to print objects. 2. Printers Can Cost As Much As Your House This point will be mainly interesting for the ones who are going to buy a 3D printer or just interested in its pricing policy. Well, the prices of three-dimensional printers depend, for the most part, on a quality of the end-product. Generally, professional and the most expensive ones can produce the higher-quality objects and their price mainly starts from $2,000. However, the price also depends on the type of raw material and the printing technology.

FDM printers are the easiest to find at the market and use at home or in a small office. In general, the lower the price is the more limitations the printer has in terms of the size of final object and materials involved. But, if you don't want to spend a lot of money and prefer to purchase a relatively cheap printer as an introductory device, you can easily find a small printer that will cost you about $100. Nevertheless, the 3D printing technology gains more and more popularity among consumers, and thanks to that prices on 3D printers went down while the printing quality enhances. In addition, do remember that printing devices don't come along with the materials used in a printing process. These components should be purchased or collected separately according to printer and model requirements. 3. There Aren't So Many Materials Fit For 3D Printers Despite the fact that innovators found a way to think-out-of-the-box and print chocolate and pasta, today the devices available for customers have a comparatively narrow range of materials to use. Most popular models involve FDM technology and use different thermoplastics to print solid objects. We would like to examine plastic as an example, so you can see what dangers await you at this step. One of two most popular materials is Poly Lactic Acid (PLA). This material is derived from corn starch and possesses good temperature characteristics (can be cooled or heated quickly). PLA is eco-friendly and presented in solid and translucent colors. This material is perfect for newbies to deal with. However, since it possesses low melting characteristics, the output can contort under high temperatures. Besides, it's not the best options for models that have joints or moving parts. The second material we would like to mention is Acrylonitrile Butadiene Styrene (ABS), a petroleum-based thermoplastic that became popular thanks to its flexibility and durability. Moreover, ABS won't likely be deformed under heat because it's resistant to high temperatures. Furthermore, it can be used to produce a solid object with interlocking parts. On the other hand, at the output, ABS-based models take longer to cool after printing. It's obligatory to know decide on a suitable material before buying a printer or choosing one for future printing. Some printers can work with a range of materials, some, on the other hand, accept only one type. 4 Nozzles Size Is Important When it comes to preferred filament size, it's really up to the printer specifications, 3D model quality, and personal preferences. Most printers go with 1.75 mm filament size, however, 3 mm is also quite common and more tolerant with hardware shortcomings. But you need more force to push 3mm filament into the hot end. The nozzle size affects the horizontal resolution of the print. The most popular nozzle diameters are 0.34 mm and 0.4 mm. Each size is better in some situations. For example, if you need to print the 3D object fast, it's better to choose bigger nozzle since it reduces the overall number of layers thanks to thicker string. Smaller nozzles, on the other hand, ensures the smoother finish of the final prototype. 5 3D Modeling For Different 3D Printers Has Its Peculiarities It's possible to create a 3D model in a wide range of software both free and commercial like Maya, 3ds max or Zbrush. Besides, as you already know the type of raw material is also important and affects the modeling process. When it comes to 3D modeling, you should pay attention to many details and limitations. For instance, take into consideration printer type, printing technology, and physical qualities of the raw material. This also means that you should create a 3D model with physically correct characteristics. If you are not familiar with modeling processes and material guidebooks, you should better entrust this work to professionals who are experienced in 3D modeling for 3D printing. Just provide them with all necessary information about printer type and model,

material that you are going to use while printing and the outlines of the overall idea (sketches, pictures, photos). 6. STL Is A Universal File Format For All Printers The name of .STL file extension does not come from stereolithography printing technique. It stands for Standard Triangle Language and became a worldwide format supported by all 3D printers. Basically, the term 'Standard Triangle Language' means expansion of the modeled object into triangles in three-dimensional coordinates. STL file is required in order to print any 3D model. This file with full information about the model can be uploaded, recognized and proceeded by the printer in a matter of seconds if everything is done according to industry standards. The printer inspects the information received from the STL file and places the pin of the printer which moves along X, Y and Z axes in order to create an object layer by layer to the appropriate point in space according to the model coordinates. In addition, professionals don't recommend to exceed the 100MB file size. 7. You Should Have A Special Software Even if you make everything right with a 3D modeling and compile the correct STL file of the model, you will still need an appropriate software installed. Such programs known as 'slicing software' will explain the printer how to produce the model you uploaded on the language it understands. This software provides exhaustive information about the number of layers, the solid parts of the prototype and hollows, and also the starting position of the print bed. Some companies produce printers that have an inbuilt slicing software or such program come along with the printer. For other printers, you should choose the right software on your own or consult with a community what the best choice is. 8. Different Printers Provide Different Print Quality This point should be noted by the ones who are going to buy a printer or looking for a 3D printing services. Printing quality is one more point that should concern you in three-dimensional printers. To receive a high-quality prototype, you should take into account resolution and printing speed. Print resolution indicates to the level of detail that printer can ensure. The smaller this parameter is, the more detailed object you can create. Print speed refers to the speed of extruder movements. Generally, printers with high print speed characteristics print faster than others. Moreover, there are other factors that may affect the print quality, for instance, slow down the print speed or change the output. These elements can include the material characteristics (some materials cool slower that can cause deformation or blur the details) or default settings when a change of speed is required and printer reacts by acceleration to higher speed and vice verse. Eventually, the best way to judge about the print quality of a specific printer is to carefully examine the final output. If you are going to buy the printer, you should better Google some images and photos of a final product. If you're just looking for the printing services, consult the representatives and look at company portfolio to determine the most suitable printer. 9. 3D Printers Require Careful Care To Prevent Safety Issues Three-dimensional printers as any other manufacturing devices are fraught with specific safety problems to which you should pay special attention. When it comes to working with any 3D printer, precautions must be taken to avoid accidents. For this reason, before purchasing the printer examine all available instructions and possible problems that may arise and follow the rules of operation. We prepared a small brief description about some notable issues. One of the most important things you should pay attention to is high temperatures of materials you are working with. Due to the fact that a majority of 'domestic' printers work with heated plastic, some external parts of the printer can get extremely hot. For instance, print bed, extruders and the plastic itself.

These parts can be a cause of dangerous burns in cases when you aren't careful. Most large printers have an inbuilt protective glass around the print area, however, many small ones have an open area. That's why with that type of 3D printers, you should take extra precautions. Moreover, 3D printers require a well-ventilated space due to the fact that during the printing process some printers accumulate fumes, especially when ABS plastic has been taken as a raw material. There is no much research about the impact of these fumes on general health and there is no final option on that matter. Still, it's better to protect personal health and safety by taking extra precautions. In addition, the plastic you use can be dangerous for your well-being and welfare. Think about it, 3D printing industry has reached the point when three-dimensional printers are used to create many household hardware and kitchenware, in particular. The two most popular thermoplastics mentioned in this article Poly Lactic Acid and Acrylonitrile Butadiene Styrene are considered to be safe, however, it's only in case they are of a good quality. If you buy a substandard plastic no matter on purpose or accidentally, this material can include additives that may be unsafe. Another problem is that most printers work under FDM technology and can produce the items with not smooth enough surface that is a perfect condition for collection of bacteria. In some cases, this problem can be solved by coating an item, however, it's still not completely safe to use printed kitchenware. 10. The Technology Is Everywhere We guess it's not a secret for everyone that 3D printing industry is a field for investment. The world considers three-dimensional printing as the future of manufacturing and even humanity. Thirty years ago people didn't even think about having printed hardware, but now it's everywhere. The majority of 3D printers use plastic or metal material to produce items, but it's also possible to use a generous amount of other primary products, including food. Such devices are capable of creating almost every dish from cookie to pizza. These machines use fresh components that were prepared just before printing. 3D printers is also an area of interest of a Health Care industry. For example, this technology can be used in prosthetics to create custom prostheses that will be individual and fix perfectly for a specific patient and in surgery to conduct operations that now seem impossible. Moreover, humanity organized a housing initiatives in order to provide poor families with relatively cheap houses in countries like China and Netherlands. Besides, in areas where natural disasters have happened, such as a tornado or earthquake, and people lost their homes, such shelters will be a perfect option. In addition, Science and Education are particularly interested in implementation of 3D-printed models and print devices in order to improve educational and research process. 3D printing apps are recommended for children as a part of their study process. Finally, 3D printing can play a significant role in further space exploration, for example in long-term space missions as a part of a spaceship 3D printer can produce and replace the damaged or lost part of the ship according to the design sent from the control center. Although 3D printers aren't very common like PCs, people can observe an express grow in the technology and quantity of devices itself. Many industry experts name 3D printing industry one of the most perspective trends for the upcoming years. While it's easy to predict the areas where 3D printers will become a usual device or a part of a process, some industries are still keeping themselves aloof and probably wait for some kind of a revolution to include 3D printers in their techniques. 3D printers have all chances to revolutionize manufacturing (actually, they have already started doing this) and become one of the most important inventions of a human being. Victor Terekhovskyi is a marketing specialist at Program-Ace.

It is an R&D company that provides a full circle of IT services located in Kharkov, Ukraine. Our team specializes in development of 2D/3D games and apps, custom web solutions and mobile applications. The qualified experts of Program-Ace combine a unique experience in complex web systems and 3D related fields.

0 notes

Text

Automated 3d Printing Market set to hit $315.6 billion by 2035, as per recent research by DataString Consulting

Higher trends within Automated 3d Printing applications including aerospace, automotive, healthcare and consumer goods; and other key wide areas like aerospace and automotive are expected to push the market to $315.6 billion by 2035 from $1.7 billion of 2023.

Automated 3D printing allows for the creation of lightweight parts like those used in engines and aircraft structures Companies such, as Boeing and GE Aerospace utilize this technology to improve design versatility and lower production expenses. The car industry leverages automated 3D printing for creating prototypes and specialized parts while improving production processes and supply chain efficiency; companies such as BMW and Ford are, at the forefront of utilizing this technology to speed up product design cycles and enhance operations.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/automated-3d-printing-market-research-report

3 D printing automation is leading the path, towards automated manufacturing plants by combining robotics and artificial intelligence to boost productivity.

Industry Leadership and Strategies

The Automated 3d Printing market within top 3 demand hubs including U.S., Germany and China, is characterized by intense competition, with a number of leading players such as GE Additive, Stratasys, Materialise, 3D Systems, HP, EOS, SLM Solutions, Desktop Metal, Formlabs, Protolabs, Carbon Inc and Markforged. Below table summarize the strategies employed by these players within the eco-system.

Leading Providers

Provider Strategies

GE Additive, EOS

Advanced lightweight component manufacturing

Stratasys, HP

Prototyping and on-demand part production

Materialise, Formlabs

Customized implants and precision devices

Desktop Metal, Carbon Inc.

Rapid prototyping and mass customization

This market is expected to expand substantially between 2024 and 2030, supported by market drivers such as growing demand for customization, technological advancements, and cost reduction in manufacturing.

Regional Analysis

The Automated 3D Printing market in this area is thriving thanks to technological progress and a high demand from the aerospace and automotive industries with companies such as GE Additive and Stratasys, at the forefront of innovation.

Research Study analyse the global Automated 3d Printing market in detail and covers industry insights & opportunities at Technology (Stereolithography, Fused Deposition Modeling, Selective Laser Sintering), Component (Hardware, Software, Services) and Application (Aerospace, Automotive, Healthcare, Consumer Goods) for more than 20 countries.

About DataString Consulting

DataString Consulting assist companies in strategy formulations & roadmap creation including TAM expansion, revenue diversification strategies and venturing into new markets; by offering in depth insights into developing trends and competitor landscapes as well as customer demographics. Our customized & direct strategies, filters industry noises into new opportunities; and reduces the effective connect time between products and its market niche.

DataString Consulting offers complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. Our Industry experts and data aggregators continuously track & monitor high growth segments within more than 15 industries and 60 sub-industries.

0 notes

Text

3D Printing for Prototyping and Art: Unlock Your Creative Potential

Introduction: 3D printing has revolutionized the way we design and create. Whether you’re a designer refining your product prototype or an artist exploring new forms of expression, 3D printing lets you bring your ideas to life faster and more freely than ever before. It’s a game-changer that opens up endless possibilities—whether you’re pushing the limits of innovation or diving into intricate, one-of-a-kind art.

What is 3D Printing?

At its core, 3D printing (or additive manufacturing) builds objects layer by layer from a digital file. Unlike traditional methods that cut away material, 3D printing adds material, creating shapes and structures that were once impossible to achieve. Here are some of the key technologies you’ll encounter:

FDM (Fused Deposition Modeling): Great for budget-friendly prototypes. It extrudes plastic filament layer by layer.

SLA (Stereolithography): Offers stunning detail with a smooth finish, ideal for high-quality prototypes and art pieces.

SLS (Selective Laser Sintering): Perfect for creating strong, functional parts by using a laser to fuse powdered material.

Applications:

Prototyping: 3D printing speeds up product development by allowing you to quickly prototype, test, and refine your designs—helping you move from concept to production in record time.

Art: Artists are embracing 3D printing to craft complex, interactive sculptures that push the boundaries of traditional art. The freedom to create without limits is transforming the artistic landscape.

Challenges to Consider:

While the technology is incredibly powerful, there are a few things to keep in mind:

Print Quality: Factors like material type, printer calibration, and even room temperature can affect the final print quality.

Material Options: Though there are more options than ever, 3D printing materials are still somewhat limited compared to traditional manufacturing. But with ongoing research, the possibilities are constantly expanding.

Getting Started with 3D Printing:

Choose the Right Printer:

FDM: Affordable and versatile, great for basic prototypes.

SLA: Offers exceptional detail and a smooth finish, perfect for high-quality models.

SLS: Ideal for creating durable, functional parts.

Master 3D Modeling: Learn how to use design software to bring your ideas to life. Whether it’s Fusion 360 for engineering, Blender for artistic work, or ZBrush for sculpting, mastering the right tools will elevate your creations.

Optimize Your Designs:

Avoid overhangs and make sure your walls are thick enough for strength.

Design with the print orientation in mind to reduce material waste and improve print efficiency.

Select Your Materials: Choose based on your project’s needs—PLA and ABS for sturdy models, or flexible filaments for parts that need to bend and stretch.

Prepare Your Files: Use slicer software like Cura or PrusaSlicer to convert your 3D model into a printer-ready file.

Print & Post-Process: After printing, remove support structures, sand rough edges, and add a paint finish if needed to bring your object to life.

Advanced Techniques to Try:

Multi-Material Printing: Combine materials for parts that have different properties—like flexible hinges and rigid support structures in the same piece.

Generative Design: Use AI to create complex, organic shapes that optimize strength and functionality.

Large-Scale Printing: Need bigger objects? Split your design into sections and print them separately to assemble later.

Bioprinting: Explore the future of medicine with 3D printing using living cells.

4D Printing: Create objects that change shape or function over time, responding to heat, moisture, or other stimuli.

Common Pitfalls to Avoid:

Material Settings: Each material has specific requirements. Always adjust your printer’s settings accordingly.

Forget About Supports: Don’t skip adding supports for complex shapes—your printer won’t magically print them without help.

Printer Maintenance: Keep your printer in top shape with regular calibration and care to prevent issues.

Rushing the Process: 3D printing takes time. Be patient and avoid speeding up the process—it will pay off in better results.

FAQs:

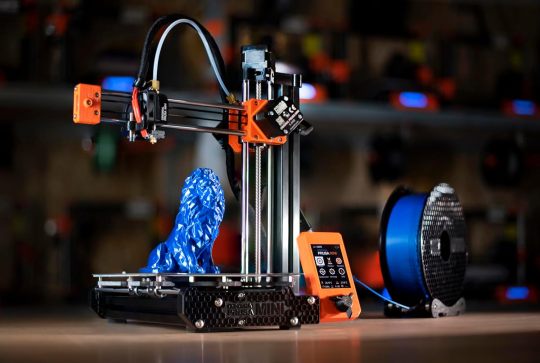

What's the best 3D printer for beginners? The Creality Ender 3 and Prusa i3 MK3S+ are great options for getting started. They’re affordable and highly customizable.

How much does it cost to start? Entry-level 3D printers usually start around $200–$300, with additional material costs depending on your projects.

Can 3D printing be used for mass production? While it’s perfect for rapid prototyping and custom items, 3D printing is also expanding into small-batch production.

Is 3D printing safe? Yes, as long as you use proper ventilation and follow safety guidelines, it’s safe for home use.

Key Takeaways:

3D printing opens up a world of possibilities, whether you’re designing innovative prototypes or creating detailed works of art. By mastering the basics—design, material selection, and post-processing—you’ll be able to produce high-quality prints and push the boundaries of your creativity. Keep experimenting, refining your skills, and watching as your designs come to life in ways you never imagined.

Ready to get started? Let’s bring your ideas to life with 3D printing. Whether you’re prototyping or creating stunning art, we have the tools and expertise to help you succeed. Explore our printers, materials, and support to take your creations to the next level.

1 note

·

View note

Text

A Deep Dive into the Aerospace 3D Printing Market: Insights and Analysis

The global aerospace 3D printing market size is anticipated to reach USD 11.38 billion by 2030 and is projected to grow at a CAGR of 20.6% from 2024 to 2030, according to a new report by Grand View Research, Inc. The increasing adoption of additive manufacturing for tooling, fixtures, and other support equipment in aerospace manufacturing facilities is driving the market growth. While aerospace components are the primary focus of additive manufacturing applications, there is also significant demand for 3D-printed tooling and fixtures used in assembly, testing, and maintenance operations. 3D-printed jigs, fixtures, and molds offer advantages such as rapid production, design flexibility, and cost-effectiveness compared to traditional machining methods.

The economic fallout from COVID-19 resulted in budget cuts and reduced investment in research and development across the aerospace industry. Many companies were forced to prioritize immediate cost-saving measures over long-term innovation initiatives, leading to a slowdown in the pace of technological advancement in 3D printing and related areas. As a result, aerospace manufacturers faced challenges in adopting the latest advancements in additive manufacturing technology, limiting their ability to optimize production processes, improve component performance, and enhance competitiveness in the global market.

The growing trend toward space exploration and satellite deployment is driving demand for lightweight, high-performance components for space missions. 3D printing technology offers unique advantages for producing space-ready components, such as complex geometries, lightweight structures, and customized designs tailored to specific mission requirements. This capability enables aerospace companies to overcome the constraints of traditional manufacturing methods and develop innovative solutions for space exploration, satellite propulsion, and other space-related applications.

Gather more insights about the market drivers, restrains and growth of the Aerospace 3D Printing Market

Aerospace 3D Printing Market Report Highlights

• Based on component, the hardware segment led the market with the largest revenue share of 63.6% in 2023 and is expected to grow at the fastest CAGR over the forecast period. The need for rapid prototyping and production agility is accelerating the adoption of 3D printing technology in the aerospace hardware segment

• Based on technology, the direct metal laser sintering (DMLS) segment is expected to grow at the fastest CAGR over the forecast period. Advancements in DMLS technology, such as improved laser power, finer powder materials, and enhanced process control, are expanding its capabilities and driving further adoption in the aerospace sector

• Based on application, the prototyping segment led the market with the largest revenue share of 54.8% in 2023. The demand for customized and highly intricate aerospace components necessitates the use of 3D printing for prototyping purposes

• Based on material, the polymer segment is expected to grow at a significant CAGR over the forecast period. The development of aerospace-grade polymer materials with enhanced mechanical properties and fire-retardant characteristics further drives the adoption of polymer 3D printing in aerospace manufacturing

• Based on end-product, the aircraft segment led the market with the largest revenue share of 58.6% in 2023. The growing demand for fuel efficiency and sustainability drives aircraft manufacturers to adopt 3D printing for developing aerodynamic components and structural parts

• In March 2024, GE Aerospace, the aerospace and aviation division of General Electric (GE), a US-based energy multinational, announced an investment of more than USD 650 million towards enhancing its worldwide manufacturing facilities and supply chain in 2024. This substantial investment aims to facilitate the expansion of production for its LEAP engines, utilizing 3D printing technology. In addition, the funds will support the full-scale manufacturing of GE9X engines, distinguished by their incorporation of over 300 3D-printed components. These engines are tailored for use in Boeing 777X aircraft

Aerospace 3D Printing Market Segmentation

Grand View Research has segmented the global aerospace 3D printing market report based on component, technology, application, material, and end-product:

Aerospace 3D Printing Component Outlook (Revenue, USD Million, 2017 - 2030)

• Hardware

• Software

• Services

o Design Software

o Inspection Software

o Printer Software

o Scanning Software

Aerospace 3D Printing Technology Outlook (Revenue, USD Million, 2017 - 2030)

• Selective Laser Melting (SLM)

• Electron Beam Melting (EBM)

• Direct Metal Laser Sintering (DMLS)

• Stereolithography (SLA)

• Others

Aerospace 3D Printing Application Outlook (Revenue, USD Million, 2017 - 2030)

• Prototyping

• Tooling

• Functional Parts

Aerospace 3D Printing Material Outlook (Revenue, USD Million, 2017 - 2030)

• Metal

• Polymer (Plastic)

• Composite

Aerospace 3D Printing End-Product Outlook (Revenue, USD Million, 2017 - 2030)

• Aircraft

• Unmanned Aerial Vehicles (UAVs)

• Spacecraft

Aerospace 3D Printing Regional Outlook (Revenue, USD Million, 2017 - 2030)

• North America

o U.S.

o Canada

• Europe

o UK

o Germany

o France

• Asia Pacific

o China

o Japan

o India

o South Korea

o Australia

• Latin America

o Brazil

o Mexico

• Middle East & Africa

o UAE

o KSA

o South Africa

Order a free sample PDF of the Aerospace 3D Printing Market Intelligence Study, published by Grand View Research.

#Aerospace 3D Printing Market#Aerospace 3D Printing Market Size#Aerospace 3D Printing Market Share#Aerospace 3D Printing Market Analysis#Aerospace 3D Printing Market Growth

0 notes

Text

Tomorrow’s Reality: The Exciting Evolution and Future of 3D Printing Technology

3Ding

Tomorrow’s Reality: The Exciting Evolution and Future of 3D Printing Technology 3D Printers

With its roots tracing back to the 1980s, 3D printing, also known as additive manufacturing, has seen significant advancements in recent decades. From creating simple plastic prototypes to producing complex, functional parts, the technology continues to evolve rapidly. As we look forward to the future of 3D printing, it’s evident that this innovative technology is on the precipice of revolutionizing various sectors globally.

Next-Level Materials: One of the most thrilling areas of development in 3D printing is in the realm of materials. While the technology initially relied on a limited selection of plastics, modern 3D printers can now work with an array of substances, including metals, ceramics, and even biological materials. As research continues, we can expect 3D printers capable of handling increasingly diverse and sophisticated materials, leading to broader applications and greater adoption.

Advanced 3D Bioprinting: In the medical field, 3D printing has shown immense potential. Bioprinting, or the 3D printing of biological tissues and organs, is making significant strides. Though still in its nascent stages, the progress suggests a future where organ shortages could be a thing of the past, with custom-printed organs tailored to individual patients’ needs becoming a reality.

Rapid Production and Mass Customization: The advancements in 3D printing speed and scalability promise to challenge traditional manufacturing methods. With techniques such as High-Speed Sintering (HSS) and Continuous Liquid Interface Production (CLIP), we’re inching closer to the goal of high-speed, high-volume 3D printing. This development will enable mass customization – the production of personalized products on a large scale – revolutionizing sectors from automotive to consumer goods.

Enhanced Software and AI Integration: The future of 3D printing also lies in the integration of advanced software and Artificial Intelligence (AI). These tools can help streamline the design process, improve the quality of prints, and even predict and correct errors before they occur. As AI algorithms continue to learn and adapt, their integration with 3D printing technology will likely become more refined, leading to even more precise and efficient manufacturing.

Sustainability: As global attention towards sustainability grows, 3D printing could play a crucial role in reducing waste and promoting circular economies. By nature, additive manufacturing produces less waste than traditional, subtractive methods. As technology advances, we can expect further developments geared towards enhancing its environmental sustainability.

Conclusion: From innovative materials to AI integration, the future of 3D printing is teeming with exciting possibilities. The technology is poised to enhance current manufacturing practices and revolutionize them entirely. As we continue to push the boundaries of what’s possible with 3D printing, the only certainty is that this technology holds a promising, transformative role in our collective future.

READ MORE ON OUR WEBSITE

3Ding Reddx Technologies Pvt Ltd K5, 7th Street, Ambattur Industrial Estate, Chennai - 600058

#3d blog#3d printing#3d printing in chennai#3d printers#3ding#3d printing service in chennai#3d printing services

1 note

·

View note

Text

Additive Manufacturing Market Analysis, Growth Factors and Competitive Strategies by Forecast 2034

Additive manufacturing (AM), commonly known as 3D printing, is a transformative approach to industrial production that enables the creation of lightweight, complex designs directly from digital models. It is increasingly used across industries like aerospace, automotive, healthcare, and consumer goods due to its ability to reduce waste, lower production costs, and shorten manufacturing times.

According to projections, the additive manufacturing market would grow linearly and reach a valuation of USD 17.23 billion by 2023. With a compound annual growth rate (CAGR) of 21.65% from 2024 to 2033, it is anticipated to have increased to USD 84.87 billion by that time.

Get a Sample Copy of Report, Click Here: https://wemarketresearch.com/reports/request-free-sample-pdf/additive-manufacturing-market/1376

Key Drivers

Technological Advancements: Innovations in 3D printing materials and techniques, such as metal and bio-based printing, are fueling growth.

Adoption Across Industries: Applications in aerospace, healthcare, automotive, and consumer goods are expanding rapidly.

Sustainability Goals: Additive manufacturing reduces waste and optimizes material usage, aligning with global sustainability efforts.

Challenges

High initial investment costs for equipment and training.

Limitations in material properties and product size for certain applications.

Regulatory hurdles in industries like healthcare and aerospace.

Applications Across Industries

Aerospace and Defense Additive manufacturing is extensively used to produce lightweight and complex parts, reducing fuel consumption and improving performance.

Healthcare Customized medical devices, implants, and prosthetics are transforming patient care. Bio-printing for tissues and organs is an emerging field.

Automotive Automotive manufacturers leverage 3D printing for prototyping, tooling, and even end-use parts, reducing lead times and costs.

Consumer Goods The ability to personalize products such as footwear, jewelry, and electronics is driving adoption in the consumer market.

Construction Large-scale 3D printing is being utilized to construct buildings and infrastructure more efficiently and sustainably.

Key companies profiled in this research study are,

Stratasys, Ltd.;

Materialise NV;

EnvisionTec, Inc.;

3D Systems, Inc.;

GE Additive;

Autodesk Inc.;

Made In Space;

Canon Inc.;

Voxeljet AG.

Additive Manufacturing Market Segmentation,

By Technology:

Stereolithography (SLA)

Fused Deposition Modeling (FDM)

Selective Laser Sintering (SLS)

Direct Metal Laser Sintering (DMLS)

Others (Binder Jetting, Electron Beam Melting, etc.)

By Material:

Polymers

Metals

Ceramics

Others (Composites, Biomaterials, etc.)

By Application:

Prototyping

Production

Tooling

By Industry:

Aerospace

Automotive

Healthcare (particularly for dental and orthopedic implants)

Consumer Goods

Defense

Additive Manufacturing Market Regional Analysis:

North America: Dominates the market due to high adoption of AM technologies in industries like aerospace and healthcare.

Europe: Strong growth due to government initiatives and industrial adoption.

Asia-Pacific: Emerging as a significant market with increased investment in industrial 3D printing in countries like China, Japan, and South Korea.

Conclusion:

The additive manufacturing market is poised for transformative growth, offering unparalleled opportunities across industries. As technology evolves and adoption increases, this sector is expected to redefine traditional manufacturing processes, paving the way for a more sustainable and efficient industrial future.

0 notes

Text

Sharpedge Technologies | Decoding Manufacturing Productivity

Cutting Tools in Industry 4.0: Breaking through Performance Barriers

Table of Contents Charting the Evolution of Cutting Tools Responding to Process Challenges Conclusion: Productivity or Price Cutting tools are central to machining processes for making industrial machinery, watch components, and car and aircraft parts. Given this diverse applicability, they are in high demand and the subject of significant innovation. Comprising saws, reamers, drills, chasers, cutters, end mills, boring tools, honing tools, combination tools, and gear-cutting tools, the scope and quality of industrial cutting tools is a constant test for innovators. Accordingly, they have focused on improving tool durability, speed, and precision, with tool geometry and application-specific design also in focus.

Newer materials like cermet and polycrystalline diamonds (PCD) are stronger and more durable than the previously preferred High-Speed Steel (HSS) and Cemented Carbide. Creating the coatings that amplify tool strength leverages processes like Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD). Adopting Industry 4.0 methods such as Artificial Intelligence (AI) and the Internet of Things (IoT) has resulted in greater efficiency, cost reductions, and increased tool longevity. Additive manufacturing can usher in novelly designed tools. Equally, digitalization has enabled encompassing sustainability in tool design and manufacturing.

Charting the Evolution of Cutting Tools The development of carbide cutting tools, now spanning a century, offers vital clues to the expectations from newer technologies. The invention of cemented carbide was a significant milestone in the search for tool-grade materials with the ideal levels of hardness and toughness. Characteristics of tool-grade materials include versatile applicability – they can cut through most metals and metallic alloys and better withstand heat and wear. Some of the breakthrough high-performance materials used for making industrial cutting tools as an improvement on cemented carbide include:

Cermet, which is a sintered alloy of Titanium Carbide and Titanium Nitride Coated carbides, wherein the strength of the carbide cutting tool is augmented using a film of diamond, diamond-like carbon (DLC), or aluminum layered using CVD or PVD. Polycrystalline Cubic Boron Nitride (PCBN), whose advantages include extreme heat resistance and hardness The evolution of these materials is also a response to the application and the work material. For instance, PCD cutting tools are suitable for working on non-ferrous materials like high-silicon aluminum. The advent of carbon composites with laminated structures like Carbon Fiber Reinforced Polymer (CFRP) has also encouraged further research into tool materials. Developers have also investigated changing the tool geometry – for example, the shape and angle of the cutting edge – for milling or drilling into advanced materials precisely. Additive manufacturing, which involves fashioning 3D-printed cutting tool parts from metal powders, teases the possibility of imaginatively shaping cutting tools with greater complexity.

Responding to Process Challenges The wear and tear of cutting tools necessitates frequent repair or replacement. Tools with replaceable cutting tips, called indexable tools, help lower costs and simplify maintenance. The machining scale also matters; micro-drilling tools address reliability issues when machining small parts. On another front, metalworking fluids are invariably required to lower friction and preserve the tool but pose risks to workers’ health and safety. Altering tool composition or design has minimized the use of these fluids.

Metalworking fluids are invariably required to extend tool life

The heavy use and regular changing of cutting tools raise questions regarding their sustainable use. Using optimized materials that break down less easily reduces the tool replacement frequency. In this regard, AI-enabled sustainable manufacturing approaches like automating the selection of tooling materials, facilitating predictive maintenance, and leveraging sensors to detect tool damage can positively impact the entire cutting tool lifecycle from production to deployment and disposal or reuse. Improving the tools’ energy efficiency is also a step forward from a sustainability perspective.

Conclusion: Productivity or Price Despite the ever-growing demand and the continuous development of more productive and longer-lasting cutting tools, the market remains price-differentiated. Crucially, expenditure on cutting tools amounts to only 2-3% of the total production cost. Cutting tools manufacturers have a significant opportunity to evangelize high-tech cutting tools that more rapidly produce better-finished, higher-quality machine parts and yet do not massively increase tooling costs. The shift to custom-designed complex cutting tools can also push manufacturers to take a productivity-first stance when equipping their assembly lines.

Sharpedge Technologies offers state-of-the-art cutting tools solutions for a wide range of industries applications in collaboration with the world-leading manufacturers. To learn more, call us at +91-9822194710 or email [email protected]. You can also connect with us on LinkedIn.

0 notes

Text

3D Printing Stainless Steel Market: Emerging Trends, Innovations, and Key Insights for 2024 and Beyond

The 3D printing stainless steel market is poised for significant growth in 2024 and beyond, driven by continuous technological advancements, evolving industry needs, and emerging trends across various sectors. This innovative manufacturing method, also known as additive manufacturing, is revolutionizing the production of stainless steel parts by offering greater design flexibility, efficiency, and customization. As we move into 2024, several key trends, innovations, and insights are expected to shape the trajectory of the market.

Emerging Trends in 3D Printing Stainless Steel

Increased Adoption in Aerospace and Automotive Industries Aerospace and automotive sectors are leading the charge in adopting 3D printing stainless steel due to the technology's ability to produce lightweight, high-performance parts that can withstand extreme conditions. In aerospace, the focus is on creating complex, high-strength components that reduce weight and improve fuel efficiency. In the automotive industry, 3D printing is being used to create customized, high-performance parts that meet stringent safety and durability standards. As both industries increasingly emphasize efficiency and innovation, the demand for stainless steel 3D printed parts is expected to rise.

Customization and Personalization The ability to produce customized, made-to-order parts is one of the most significant advantages of 3D printing. Stainless steel's strength, durability, and corrosion resistance make it an ideal material for custom applications in industries such as healthcare, defense, and manufacturing. In the healthcare sector, 3D printed stainless steel implants and surgical tools are tailored to meet the specific needs of individual patients, enhancing outcomes and reducing recovery times. The demand for bespoke components is also expanding in defense and industrial sectors, where specialized, high-performance parts are required.

Sustainability and Waste Reduction Sustainability is becoming a top priority for manufacturers across industries, and 3D printing offers a solution by significantly reducing material waste. Traditional manufacturing methods, such as casting and machining, produce considerable waste during production. In contrast, 3D printing builds parts layer by layer, minimizing material use and allowing for more precise production. Additionally, there is a growing trend toward using recycled stainless steel powder in the 3D printing process, further reducing environmental impact. As industries increasingly focus on reducing their carbon footprint, the demand for sustainable manufacturing methods like 3D printing will continue to grow.

Innovations Shaping the Market

Advanced 3D Printing Techniques Technological innovations in 3D printing techniques are driving the evolution of the stainless steel market. For example, the development of metal laser sintering (MLS) and direct energy deposition (DED) techniques has significantly improved the quality and speed of stainless steel 3D printing. These methods allow for greater control over material deposition, leading to parts with superior mechanical properties, surface finishes, and dimensional accuracy. Moreover, hybrid manufacturing systems that combine 3D printing with traditional subtractive processes are becoming more popular, enabling manufacturers to produce parts with enhanced precision and reduced production times.

Faster Printing Speeds Speed is a critical factor in industrial manufacturing, and 3D printing technology has seen advancements in print speeds that significantly reduce production times. Innovations in hardware and software are allowing manufacturers to produce stainless steel parts more quickly and efficiently. For example, some 3D printers now feature faster laser scanning and more efficient material deposition systems, allowing for faster build times without compromising quality. As a result, the speed of 3D printing is becoming comparable to traditional manufacturing methods, making it more competitive for mass production.

Improved Material Properties Another key area of innovation is the enhancement of the material properties of 3D printed stainless steel. Ongoing research and development efforts are focused on improving the mechanical properties of 3D printed stainless steel parts, such as their strength, corrosion resistance, and heat resistance. These improvements enable 3D printed stainless steel to be used in more demanding applications, such as in high-temperature environments or for components that are exposed to corrosive elements. The development of new alloys and composite materials specifically designed for 3D printing is also expanding the range of applications for stainless steel.

Key Insights for 2024 and Beyond

Increased Integration with Industry 4.0 As industries embrace the Fourth Industrial Revolution (Industry 4.0), 3D printing stainless steel is increasingly being integrated with other advanced technologies such as automation, artificial intelligence (AI), and the Internet of Things (IoT). The combination of these technologies enhances the efficiency, precision, and scalability of 3D printing processes. In the future, 3D printers may be able to self-monitor and adjust parameters in real-time, improving production quality and reducing the risk of errors. The integration with AI and IoT will also enable manufacturers to optimize production schedules and reduce downtime.

Expanding Use in Healthcare The healthcare sector is expected to remain a significant driver of growth for the 3D printing stainless steel market. The technology’s ability to create highly customized and precise medical implants, prosthetics, and surgical tools is transforming the healthcare industry. Stainless steel's biocompatibility and strength make it a preferred material for implants, particularly in orthopedic and dental applications. As the healthcare industry continues to embrace personalized medicine, the demand for 3D printed stainless steel components is likely to increase.

Market Fragmentation and Emerging Players The 3D printing stainless steel market is witnessing increased fragmentation, with more players entering the space, offering specialized solutions. While large companies dominate the industry, smaller, specialized players are focusing on niche applications, creating opportunities for innovation and tailored solutions. These emerging players may be able to meet the needs of specific industries or regions by offering cost-effective solutions, customized services, or specialized alloys.

Regulatory Considerations As 3D printing in industries like aerospace, automotive, and healthcare continues to grow, regulatory frameworks are expected to evolve. Manufacturers will need to ensure that their 3D printed stainless steel parts comply with stringent industry standards, including safety, durability, and quality controls. Regulatory bodies are likely to establish guidelines for the use of additive manufacturing to ensure consistency and reliability across the industry.

Conclusion

The 3D printing stainless steel market is on the verge of a transformative shift, with emerging trends, technological innovations, and evolving industry needs shaping its future. As advancements continue in speed, material properties, and customization, the market is expected to expand rapidly across industries such as aerospace, automotive, healthcare, and manufacturing. The increasing demand for sustainable and cost-effective production methods, coupled with the ability to create highly personalized parts, makes 3D printing a key technology to watch in 2024 and beyond.

Request Sample PDF Report: https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NjE5&RD=3D-Printing-Stainless-Steel-Market-Report

#3DPrintingStainlessSteelMarket#3DPrintingStainlessSteelMarketInsights#3DPrintingStainlessSteelMarketTrends#3DPrintingStainlessSteelMarketForecast#3DPrintingStainlessSteelMarketOpportunities#3DPrintingStainlessSteelMarketGrowth

0 notes

Text

The Rise of Additive Manufacturing in Bangalore: A Hub for Metal 3D Printing, Scanning, and Design

Bangalore, India's leading technology and manufacturing hub, is rapidly emerging as a center for additive manufacturing. The city's advanced industrial ecosystem, combined with cutting-edge research and development, has fueled the growth of metal 3D printing, 3D scanning services, and 3D design.

From aerospace and automotive to healthcare and consumer products, businesses are leveraging 3D printing services in Bangalore to enhance product development, reduce costs, and improve efficiency. The growing number of additive manufacturing companies in Bangalore further strengthens its position as a leader in next-generation manufacturing technologies.

This article explores the key aspects of metal 3D printing, additive manufacturing, 3D scanning, and design services in Bangalore, highlighting their impact on various industries.

Metal 3D Printing in Bangalore: Transforming Manufacturing

1. What is Metal 3D Printing?

Metal 3D printing, also known as Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM), is a technology that builds metal parts layer by layer using powdered metal alloys. This process allows manufacturers to produce complex metal components with high precision and minimal material waste.

2. Industries Benefiting from Metal 3D Printing

Aerospace & Defense: Lightweight, high-strength metal components for aircraft and satellites.

Automotive & Motorsports: Custom engine parts, heat exchangers, and structural components.