#sauce bottle filling machine exporters

Explore tagged Tumblr posts

Text

Soya Sauce Filling Machine Servo-Based

Shiv Shakti Machtech is a Manufacturer, Exporter and Supplier of Soya Sauce Filling Machine Servo-Based across India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Soya sauce is a vital condiment with a global presence, and its precise filling requires advanced machinery to ensure accuracy, efficiency, and hygiene. Shiv Shakti Machtech, a leader in packaging and filling solutions, offers state-of-the-art servo-based soya sauce filling machines. These machines are designed to meet the unique challenges of filling viscous and liquid products with exceptional speed and precision. Other Similar Name of Soya Sauce Filling Machine: Automatic Soya Sauce with Servo Control, Servo-Driven Soya Sauce Bottling Equipment, High-Speed Soya Sauce Filling and Capping Machine, Precision Servo-Based Machine, Fully Automatic Soya Sauce Packaging, Servo-Controlled Liquid Filling Machine, Advanced Soya Sauce Filling System with Servo Technology, Industrial Servo Soya Sauce Dispensing Machine, Customized Soya Sauce Filling Line, Servo-Operated Liquid Filling Machine for Sauces. Types: Automatic Servo-Based Filling Machines Semi-Automatic Filling Machines Multi-Head Filling Machines Inline Filling Machines Customized Filling Machines Features: Servo-based technology ensures accurate volume control for consistent output. Capable of handling various container shapes and sizes. Touchscreen PLC control for easy operation and monitoring. Constructed with food-grade stainless steel for cleanliness and compliance with hygiene standards. Allows customization of filling speeds to match production requirements. Prevents spillage, ensuring a clean and efficient filling process. Optimized systems reduce power consumption while maintaining high performance. What is the filling accuracy of the servo-based filling machine? The machine offers an exceptional filling accuracy of ±1%, ensuring consistent and precise output. Can the machine handle other liquids besides soya sauce? Yes, the machine is versatile and can fill other liquid and semi-liquid products like ketchup, vinegar, oil, and syrups. Is the machine easy to clean and maintain? Absolutely. The hygienic design and easy-to-disassemble parts make cleaning and maintenance simple and quick. Shiv Shakti Machtech is a Manufacturer and Supplier of Filling Machine in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For more information or to request a quote, please reach out to us. Read the full article

#AdvancedSoyaSauceFillingSystemwithServoTechnology#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#AutomaticSoyaSauceFillingMachinewithServoControl#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar

1 note

·

View note

Text

Why Do Condiments Manufacturers Need a Jam Filling Machine?

When it comes to the condiments industry, efficiency and precision are more important than you can imagine. Whether you are producing jams, sauces, or other spreads, maintaining consistent quality while meeting industry demand can be a quite challenge. However, what if we tell you that you don’t need to handle the entire filling process with your bare hands? Instead, you can automate the entire process with an industrial filling machine to speed up your production process and ensure that each jar can be filled with precision while minimizing waste and meeting strict industry standards.

Precision for Consistency

When you are manufacturing condiments like jams, precision should be your topmost concern. The amount of jam in every jar doesn’t just have to be consistent to ensure customer satisfaction; it’s also important to comply with regulatory standards. With a jam-filling machine, you can dispense an exact quantity of product into each container without manual efforts that require unmatched accuracy.

Especially when you are dealing with large volumes of production, a machine-based process ensures that every jar, bottle, or packet contains the exact same amount of product, eliminating human error. So, you don’t just keep your customers happy, you also avoid issues like overfilling, which leads to waste, or underfilling, which might lead to complaints.

Increased Production Speed

In manufacturing, time is money, and a jam-filling machine can drastically speed up the filling process as compared to manual labor. As these machines are built for high-speed operation, they can fill hundreds or even thousands of jars per hour, and help you to scale your production. Imagine trying to manually fill each jar of jam with the same precision, one after the other. Even with a trained workforce, the speed can never match what a machine can achieve. This increased speed allows manufacturers to meet rising market demand without sacrificing quality.

Compliance with Hyiene Standards

In the food industry, hygiene is everything. Jam filling machines are built to meet strict food safety standards because, throughout the filling process, the product remains uncontaminated. Besides, most machines are also made from food-grade stainless steel resistant to corrosion, and they are easy to clean. Condiment manufacturers have to maintain a clean and sterile environment, and a jam-filling machine helps them do just that. The machine’s parts can be easily sanitized, reducing the risk of bacterial contamination—a crucial factor in extending the shelf life of products and ensuring consumer safety.

Conclusion

There’s no denying that an industrial filling machine can be immensely helpful for speeding up your production process and ensuring accuracy. However, in case you are scouring the web for the perfect jam-filling machine, try the FILLOGY® Neo without any second thoughts. Being one of the most versatile and compact machines, it can make it effortless for you to fill all your viscous or liquid condiments flawlessly. The machine has a modular design with subsequent (partial) automation, individual component warranty, and an intelligent use interface where you can record and save the recipes. You can also integrate the automation module with a USB port for data export, and the control unit is compatible with different pumps, drive units, and filling sets, so you can fill different products using just one machine. Fantastic, right?

0 notes

Text

Types of Packaging Machines: A Comprehensive Guide

Introduction

Packaging machines play an essential role in ensuring products are efficiently filled, sealed, labeled, and prepared for distribution. Maharshi Udyog, a prominent manufacturer, exporter, and supplier, offers a diverse range of packaging machines designed to meet various industry needs. This guide explores the different types of packaging machines available, highlighting their features, applications, and benefits.

Precise Bottle Level Filler with Overflow Technology

1.1 Overview

Level Filling Machine Precise Bottle Level Filler with Overflow Technology is designed to fill bottles to a uniform level, ensuring consistency and reducing product wastage.

1.2 Key Features

Uniform Level Filling: Ensures all bottles are filled to the same level.

Overflow Technology: Excess liquid overflows back to the tank, minimizing waste.

High Efficiency: Suitable for high-speed filling operations.

1.3 Applications

Beverage Industry: Filling of water, juices, and soft drinks.

Cosmetic Industry: Filling of lotions and creams.

Household Products: Filling of cleaning agents.

1.4 Benefits

Consistency: Uniform fill levels enhance product appearance and consumer satisfaction.

Waste Reduction: Overflow technology minimizes product loss.

Efficiency: High-speed filling improves productivity.

Viscous/Non-Viscous Liquid Filling Machine

2.1 Overview

Viscous/Non-Viscous Liquid Filling machine is designed for filling both viscous and non-viscous liquids with high accuracy and consistency.

2.2 Key Features

Versatile Filling: Handles a wide range of liquid viscosities.

Servo-Controlled: Ensures precise filling volumes.

Easy Cleaning: Designed for easy disassembly and cleaning.

2.3 Applications

Food Industry: Filling of sauces, oils, and syrups.

Pharmaceutical Industry: Filling of medications and syrups.

Cosmetic Industry: Filling of creams and gels.

2.4 Benefits

Flexibility: Can handle various product viscosities.

Accuracy: Servo control ensures precise filling.

Hygiene: Easy cleaning maintains product purity.

Volumetric Filling Machine

3.1 Overview

The Volumetric Filling Machine is designed to fill products based on volume, ensuring accuracy and efficiency.

3.2 Key Features

Volume-Based Filling: Measures and fills precise volumes.

High Speed: Capable of high-speed filling operations.

Versatility: Suitable for a wide range of products.

3.3 Applications

Food Industry: Filling of sauces, pastes, and liquids.

Cosmetic Industry: Filling of lotions and creams.

Chemical Industry: Filling of solvents and cleaners.

3.4 Benefits

Accuracy: Ensures consistent fill volumes.

Efficiency: High-speed operation increases productivity.

Versatility: Suitable for various product types.

Electronic Liquid Filling Machine

4.1 Overview

The Electronic Liquid Filling Machine utilizes flow meters to ensure precise filling of liquids, enhancing accuracy and control.

4.2 Key Features

Flow Meter Technology: Ensures precise measurement and filling.

Touchscreen Controls: User-friendly interface for easy operation.

High Accuracy: Suitable for critical filling applications.

4.3 Applications

Pharmaceutical Industry: Filling of liquid medications.

Beverage Industry: Filling of drinks and juices.

Chemical Industry: Filling of chemicals and solvents.

4.4 Benefits

Precision: Flow meters ensure accurate fills.

Ease of Use: Touchscreen controls simplify operation.

Reliability: High accuracy reduces product loss.

Automatic Cartonator Machine

5.1 Overview

The Automatic Cartonator Machine is designed to automate the process of packing products into cartons, enhancing packaging efficiency.

5.2 Key Features

Automated Cartoning: Efficiently packs products into cartons.

High Speed: Capable of handling high production volumes.

Versatility: Can handle various product sizes and shapes.

5.3 Applications

Food Industry: Cartoning of packaged foods.

Pharmaceutical Industry: Cartoning of medications.

Cosmetic Industry: Cartoning of beauty products.

5.4 Benefits

Efficiency: Automates the cartoning process, reducing labor costs.

Speed: High-speed operation improves productivity.

Flexibility: Suitable for various products.

Shrink Wrap & Collating Bundling Machine

6.1 Overview

The Shrink Wrap & Collating Bundling Machine is designed to wrap products in shrink film and bundle them together, providing secure and attractive packaging.

6.2 Key Features

Shrink Wrapping: Provides a tight and secure wrap.

Collating: Bundles multiple products together.

Adjustable Settings: Can handle various product sizes.

6.3 Applications

Beverage Industry: Bundling of bottles and cans.

Food Industry: Bundling of packaged foods.

Household Products: Bundling of cleaning supplies.

6.4 Benefits

Security: Ensures products are securely wrapped and bundled.

Appearance: Provides a professional and attractive package.

Versatility: Suitable for various products.

Rotary Screw Capping Machine

7.1 Overview

The Rotary Screw Capping Machine is designed to apply screw caps to bottles efficiently and accurately.

7.2 Key Features

Rotary Capping: High-speed capping operation.

Precision: Ensures caps are applied accurately.

Versatility: Suitable for various cap sizes.

7.3 Applications

Beverage Industry: Capping of bottles and jars.

Pharmaceutical Industry: Capping of medication bottles.

Cosmetic Industry: Capping of beauty product containers.

7.4 Benefits

Speed: High-speed operation improves productivity.

Accuracy: Ensures caps are applied correctly.

Flexibility: Suitable for various cap sizes.

Ropp Capping Machine

8.1 Overview

The Ropp Capping Machine is designed to apply Roll-On Pilfer Proof (ROPP) caps, commonly used in the beverage and pharmaceutical industries.

8.2 Key Features

ROPP Capping: Secure and tamper-evident capping.

High Precision: Ensures accurate capping.

Durability: Designed for heavy-duty use.

8.3 Applications

Beverage Industry: Capping of wine and spirit bottles.

Pharmaceutical Industry: Capping of medication bottles.

Cosmetic Industry: Capping of beauty product containers.

8.4 Benefits

Security: Provides tamper-evident sealing.

Accuracy: Ensures precise capping.

Durability: Built for long-term use.

Linear Capping Machine

9.1 Overview

The Linear Capping Machine is designed for high-speed capping of bottles and containers in a linear motion.

9.2 Key Features

Linear Capping: Efficient and high-speed operation.

Adjustable: Suitable for various cap sizes and types.

Easy Integration: Can be integrated into existing production lines.

9.3 Applications

Beverage Industry: Capping of bottles and cans.

Pharmaceutical Industry: Capping of medication bottles.

Cosmetic Industry: Capping of beauty product containers.

9.4 Benefits

Speed: High-speed operation improves productivity.

Flexibility: Suitable for various cap sizes and types.

Integration: Easy to integrate into existing production lines.

Tablet Capsule Counting And Filling Machine

10.1 Overview

The Tablet Capsule Counting and Filling Machine is designed to count and fill tablets and capsules into bottles accurately.

10.2 Key Features

Accurate Counting: Ensures precise count of tablets and capsules.

High Speed: Capable of handling large volumes.

User-Friendly: Easy to operate and maintain.

10.3 Applications

Pharmaceutical Industry: Counting and filling of tablets and capsules.

Nutraceutical Industry: Counting and filling of vitamins and supplements.

Cosmetic Industry: Counting and filling of beauty supplements.

10.4 Benefits

Accuracy: Ensures precise counting and filling.

Efficiency: High-speed operation improves productivity.

Ease of Use: User-friendly operation and maintenance.

Powder Auger Filling Machine

11.1 Overview

The Powder Auger Filling Machine is designed for filling powdered products into containers with high accuracy.

11.2 Key Features

Auger Filling: Ensures precise filling of powders.

Adjustable Settings: Suitable for various container sizes.

Easy Cleaning: Designed for easy disassembly and cleaning.

11.3 Applications

Food Industry: Filling of spices, flour, and protein powders.

Pharmaceutical Industry: Filling of powdered medications.

Cosmetic Industry: Filling of powdered beauty products.

11.4 Benefits

Accuracy: Ensures precise filling of powders.

Flexibility: Suitable for various container sizes.

Hygiene: Easy cleaning maintains product purity.

Automatic Mini Flow Wrap Machine

12.1 Overview

The Automatic Mini Flow Wrap Machine is designed for wrapping small products in flow wrap film, providing secure and attractive packaging.

12.2 Key Features

Flow Wrapping: Provides tight and secure wrap.

Compact Design: Suitable for limited spaces.

High Speed: Capable of high-speed wrapping operations.

12.3 Applications

Food Industry: Wrapping of small snacks and candies.

Cosmetic Industry: Wrapping of small beauty products.

Pharmaceutical Industry: Wrapping of small medication packs.

12.4 Benefits

Security: Ensures products are securely wrapped.

Appearance: Provides professional and attractive packaging.

Efficiency: High-speed operation improves productivity.

Automatic Flow Wrap Machine

13.1 Overview

The Automatic Flow Wrap Machine is designed for wrapping products in flow wrap film, providing secure and attractive packaging.

13.2 Key Features

Flow Wrapping: Provides tight and secure wrap.

Adjustable Settings: Suitable for various product sizes.

High Speed: Capable of high-speed wrapping operations.

13.3 Applications

Food Industry: Wrapping of snacks, bars, and baked goods.

Cosmetic Industry: Wrapping of beauty products.

Pharmaceutical Industry: Wrapping of medication packs.

13.4 Benefits

Security: Ensures products are securely wrapped.

Appearance: Provides professional and attractive packaging.

Efficiency: High-speed operation improves productivity.

Bottle Unscrambler Machine

14.1 Overview

The Bottle Unscrambler Machine is designed to organize and orient bottles for subsequent filling and labeling processes.

14.2 Key Features

Automatic Orientation: Organizes and orients bottles efficiently.

High Speed: Capable of handling large volumes.

Versatility: Suitable for various bottle sizes and shapes.

14.3 Applications

Beverage Industry: Unscrambling of bottles for filling and labeling.

Pharmaceutical Industry: Unscrambling of medication bottles.

Cosmetic Industry: Unscrambling of beauty product containers.

14.4 Benefits

Efficiency: Automates the unscrambling process, reducing labor costs.

Speed: High-speed operation improves productivity.

Flexibility: Suitable for various bottle sizes and shapes.

Rotary Bottle Unscrambler Machine

15.1 Overview

The Rotary Bottle Unscrambler Machine is designed to organize and orient bottles in a rotary motion, preparing them for subsequent processes.

15.2 Key Features

Rotary Orientation: Efficiently organizes and orients bottles.

High Speed: Capable of handling large volumes.

Versatility: Suitable for various bottle sizes and shapes.

15.3 Applications

Beverage Industry: Unscrambling of bottles for filling and labeling.

Pharmaceutical Industry: Unscrambling of medication bottles.

Cosmetic Industry: Unscrambling of beauty product containers.

15.4 Benefits

Efficiency: Automates the unscrambling process, reducing labor costs.

Speed: High-speed operation improves productivity.

Flexibility: Suitable for various bottle sizes and shapes.

Counter Rewinder Unit

16.1 Overview

The Counter Rewinder Unit is designed to count and rewind labels, ensuring accurate label counts and organization.

16.2 Key Features

Label Counting: Ensures accurate count of labels.

Rewinding: Organizes labels for easy use.

User-Friendly: Easy to operate and maintain.

16.3 Applications

Labeling Industry: Counting and rewinding of labels for various applications.

Printing Industry: Counting and rewinding of printed labels.

Packaging Industry: Counting and rewinding of packaging labels.

16.4 Benefits

Accuracy: Ensures precise label counts.

Organization: Organizes labels for easy use.

Efficiency: Automates the counting and rewinding process, reducing labor costs.

Counter Rewinder Unit With Label Applicator

17.1 Overview

The Counter Rewinder Unit with Label Applicator is designed to count, rewind, and apply labels, providing an all-in-one solution.

17.2 Key Features

Label Counting: Ensures accurate count of labels.

Rewinding: Organizes labels for easy use.

Label Application: Applies labels efficiently.

17.3 Applications

Labeling Industry: Counting, rewinding, and applying labels for various applications.

Printing Industry: Counting, rewinding, and applying printed labels.

Packaging Industry: Counting, rewinding, and applying packaging labels.

17.4 Benefits

All-in-One Solution: Combines counting, rewinding, and applying labels.

Efficiency: Automates multiple processes, reducing labor costs.

Accuracy: Ensures precise label counts and application.

Conclusion

Packaging machines are vital to ensuring efficient, accurate, and secure product packaging. Maharshi Udyog's range of packaging machines offers solutions for various industries, enhancing productivity and product presentation. By understanding the features and benefits of each type of packaging machine, businesses can make informed decisions to optimize their packaging processes and improve overall efficiency.

FAQs About Packaging Machines

What factors should be considered when choosing a packaging machine?

When choosing a packaging machine, consider factors such as the type of product, production speed, accuracy, ease of integration, and maintenance requirements. Additionally, assess the specific packaging needs of your industry and product type.

How does a precise bottle level filler with overflow technology work?

A precise bottle level filler with overflow technology ensures that each bottle is filled to the same level. Excess liquid overflows back into the tank, minimizing waste and ensuring consistency.

What are the benefits of using a volumetric filling machine?

Volumetric filling machines offer precise filling based on volume, ensuring accuracy and efficiency. They are versatile and can handle various products, making them ideal for different industries.

Can shrink wrap & collating bundling machines handle different product sizes?

Yes, shrink wrap & collating bundling machines are adjustable and can handle various product sizes, providing secure and attractive packaging for different products.

What maintenance is required for packaging machines?

Regular maintenance for packaging machines includes cleaning, checking and replacing worn parts, calibrating sensors, and ensuring proper lubrication. Periodic inspections and preventive maintenance help maintain optimal performance and extend the machine’s lifespan.

youtube

0 notes

Text

Automatic Bottle Air Jet Cleaning Machine in Bhutan

Company Overview: Laxmi Pharma Equipment is a prominent Manufacturer, Supplier, and Exporter of Automatic Bottle Air Jet Cleaning Machine in Bhutan. An Automatic Bottle Air Jet Cleaning Machine is a specialized piece of equipment used to clean bottles before they are filled with products. This machine uses high-pressure air jets to remove dust, debris, and other contaminants from the inside of the bottles, ensuring they are clean and ready for the filling process. Technical Specifications: Cleaning Method: High-pressure air jets. Capacity: Several hundred to thousands of bottles per hour, depending on the model. Bottle Sizes: Adjustable for different sizes and shapes. Material: Stainless steel construction. Power Supply: Standard industrial power (specifications vary). Dimensions: Compact design. Weight: Robust yet manageable for installation and relocation. Advantages: Improved Product Quality: Ensures bottles are free from contaminants. Increased Efficiency: High-speed cleaning reduces production time and increases throughput. Cost-Effective: Reduces the need for manual cleaning labor. Versatility: Adjustable settings for various bottle types and sizes. Durability: Stainless steel construction for long-lasting performance and corrosion resistance. Applications: Pharmaceutical Industry: Ensures bottles are contaminant-free before filling with medicines. Beverage Industry: Cleans bottles for water, juices, soft drinks, and alcoholic beverages. Cosmetics Industry: Prepares bottles for perfumes, lotions, and other cosmetic products. Food Processing: Cleans bottles for sauces, oils, and other food products. Laxmi Pharma Equipment is Automatic Bottle Air Jet Cleaning Machine in Bhutan Including Bumthang, Chhukha, Chirang, Daga, Gasa, Geylegphug, Ha, Lhuntshi, Mongar, Paro, Pemagatsel, Punakha, Samchi, Samdrup Jongkhar, Shemgang, Tashigang, Tashi Yangtse, Thimphu, Tongsa, Wangdi Phodrang, Thimphu, Phuntsholing, Paro, Geylegphug, Samdrup Jongkhar, Wangdue Phodrang, Punakha, Jakar, Samtse, Shali, Mongar, Trashigang, Laya, Trashi Yangtse, Trongsa, Nganglam, Zhemgang, Damphu, Daphu, Daga, Tsirang, Haa, Sarpang. If you have any questions or require further information, please feel free to contact us. View product Read the full article

0 notes

Text

Bottle & Liquid Filling Machines Inline Filling Methods

The Series 10 VFFS filling head provides the perfect configuration when built-in with a vertical-form-fill-seal bagging system. The sleeved mount permits rotation of the filling head for ease of tooling /hopper removal. An OEM version of the Series 10 filling head which could be integrated with horizontal and vertical-form-fill-seal machines and other OEM equipment. Typical Bulk Feed Option could possibly be from overhead IBC/bulk bin through horizontal cross-feed auger. Modern packaging machines have to be nimble and versatile – they want to find a way to fill quite so much of containers regarding shapes and sizes.

The machine has an electronic photo-cell in order to management the cutting point as per printed mark. It is built on a thick and heavy forged steel frame for maximum torsional rigidity and mounted on wheels. With the help of our state-of-the-art infrastructure unit, we're able to manufacture, export and supply superior high quality Automatic Pouch Packing Machine-High Speed for Snack.

The following info will assist you in choosing the most effective powder filling machine or powder filler to satisfy their budgetary needs and shopper expectations. We will go over everything you need to find out about powder filling machines. Please discover enclosed a self explanatory package contains worth schedule technical information filling and packaging machines for the provision of the identical. However, if you wish to have extra info regarding packaging machines please don’t hesitate to call us. We provide computerized liquid & paste filling & packaging machine, which is used in packaging of pure liquid as nicely as paste products with specially fitted injection pump.

APACKS producers a complete line offilling machinesas nicely ascapping machinesto deal with completely different ranges of container sizes, fill weight or quantity, and product sorts. No matter what you liquid filling problem could additionally be APACKS has machine solutions for all types of liquids and almost filling and packaging machines all industry functions. Inline Filling Systems big selection of liquid filling machines, includes cleansing, filling, capping, conveyors and accumulation gear. ATS Engineering sturdy liquid fill equipment for a variety of functions.

The demand for fruit yogurt has created the need for fruit yogurt filling and packaging machines. To start, there are quite a few elements to consider when selecting a liquid filling machine, together with overflow, gravity, pistons, and pumps, and choosing the proper machine additionally is determined by your goals. They’re perfect for small-scale manufacturing, laboratory use, and different conditions where an exterior energy supply isn’t available or reliable. To maintain the stainless-steel floor of the liquid filling machine bright and clean, by no means scratch it with a pointy or onerous edge instrument. They fill containers with sauces, juice concentrates, and jams. Offer secure, ergonomic grip with multi-prong design for controlling, positioning and tightening.

This kind of machine runs for 24Hours without break to finish the necessities. Inspections of your pouch filling machine ought filling and packaging machines to be accomplished on a frequent basis. The bottle filling machine must be inspected frequently.

You may also be able to be taught what’s the important thing issue deciding the standard as well as good pricing. With the event of internet and logistics, now it’s getting easier and easier to buy from the manufacturer instantly, regardless it's going to take more time to review the machinery via the website. We would like to help you and be good cooperator in China for your automated packing equipment in your factory.

Accutek Auger Fillers are properly suited to the filling of dry merchandise, powders, granules, or seeds. The Accutek All Electric Servo Driven Filler (E-SPF) is a piston filler that accurately delivers a measured quantity of product to each container. This machine may be geared up with nitrogen fuel filling gadget is on the market to be added on for allowing the oxygen present in product to be controlled within fewer than 2%. This machine may also be outfitted with perforating device for steady package output. The packaging system adopts a palm-type sealing mechanism, so that the appearance of the output package is neat, the sealing is tight, and there are no material clamping or pinhole potentialities.

0 notes

Link

'Packwell' is one of the leading manufacturer of automatic liquid filling machine.We provide best quality of sauce bottle filling machine and supplies in India,Bangladesh,Jordon, Dubai,Kenya,Sri-lanka.For more details visit packwell machinery

#sauce bottle filling machine#sauce bottle filling machine manufacturers#sauce bottle filling machine exporters#sauce bottle filling machine manufacturer in ahmedabad-gujarat#sauce bottle filling machine supplies it across globe

1 note

·

View note

Text

Milk Packing Machine Manufacturers in Ernakulam

Milk Packing Machine Manufacturers in Ernakulam

We are the famous Milk Packing Machine Manufacturers in Ernakulam. The Milk Packing Machine Manufacturers in Ernakulam of countless things which consolidate pickle filling machines, pickle squeezing machines, tea customized pocket squeezing machines, tea packaging pockets machine cost, flavors filling machines, and dates Squeezing Machines. Ketchup Packing Machine Manufacturers in Ernakulam is expected for filling the little measure of powders in sachets moulded from the virgin/covered material. The resting unit is a drill filler machine with an exceptionally arranged screw/Funnel that exactly delivers the powder in the outlining sachet. Our seal part and the thing discharge are synchronized to give the most raised speed and accuracy. 3 and 4 side seal models are moreover open on request. Remarkable component, exceptionally planned for the things which ought to be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Ernakulam and filling machines are associated with the connector so that the machine can be used as a pocket filling machine additionally as it will, in general, be mounted on the conveyor zed system for filling bottles. Simple-to-use microcontroller/PLC-based controller helps with defining various limits for the machines including the weight, half/full cutting, Pouch grouping, etc.

Pickles are a huge reinforcement of food and it is sold in the market in pockets and packages. Milk Packing Machine Manufacturers in Ernakulam of pickles use the pickle squeezing machine in their plant to make the most well-known approach to filling and squeezing pickles basic and simple. Machines offer a chance to buy these machines in both modified and self-loader structures. If you are a maker or supplier of pickles, capitalize on this entryway and get the machine for Milk Packing Machine Manufacturers in Ernakulam. The machine is driven by pneumatic power. It fills pickles in pockets and a while later seals and packs it. The squeezing of pickles is done under clean conditions to avoid debasement in the pickles so it is a safeguarded strategy.

The pickle squeezing machine is made of tempered steel and it has significant solid areas for an energetic turn of events. It is a top-quality machine with a long assistance life. This is the inspiration driving why it is involved by the exporter of Pickle Packing Machine Manufacturers in Ernakulam. It is doable to change the machine as indicated by the prerequisites of clients. The action and use of the squeezing machine are fundamental and straightforward. It has a very fine culmination. Since the machine uses a very low impact, it gets a reasonable setup on the energy bills.

Milk Packing Machine Manufacturers in Ernakulamhttps://sampackindia.com/milk-packing-machine-manufacturers-in-ernakulam/

0 notes

Text

Milk Packing Machine Manufacturers in Bangalore

Milk Packing Machine Manufacturers in Bangalore

We are the famous Milk Packing Machine Manufacturers in Bangalore. The Milk Packing Machine Manufacturers in Bangalore of countless things which consolidate pickle filling machines, pickle squeezing machines, tea customized pocket Squeezing Machines, tea packaging pockets machine cost, flavors filling machines, and dates Squeezing Machines. Ketchup Packing Machine Manufacturers in Bangalore is expected for filling the little measure of powders in sachets molded from virgin/covered material. The resting unit is a drill filler machine with an exceptionally arranged screw/Funnel that exactly delivers the powder in the outlining sachet. Our seal part and the thing discharge are synchronized to give the most raised speed and accuracy. 3 and 4 side seal models are moreover open on request. Remarkable component, exceptionally planned for the things which ought to be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Bangalore and filling machines are associated with the connector so that the machine can be used as a pocket filling machine additionally as it will, in general, be mounted on the conveyor zed system for filling bottles. Simple-to-use microcontroller/PLC-based controller helps with defining various limits for the machines including the weight, half/full cutting, Pouch grouping, etc.

Pickles are a huge reinforcement of food and it is sold in the market in pockets and packages. Milk Packing Machine Manufacturers in Bangalore of pickles use the pickle squeezing machine in their plant to make the most well-known approach to filling and squeezing pickles basic and simple. Machines offer a chance to buy these machines in both modified and self-loader structures. If you are a maker or supplier of pickles, capitalize on this entryway and get the machine for Milk Packing Machine Manufacturers in Bangalore. The machine is driven by pneumatic power. It fills pickles in pockets and a while later seals and packs them. The squeezing of pickles is done under clean conditions to avoid debasement in the pickles so it is a safeguarded strategy.

The pickle Squeezing Machine is made of tempered steel and it has significant solid areas for an energetic turn of events. It is a top-quality machine with a long assistance life. This is the inspiration driving why it is involved by the exporter of Pickle Packing Machine Manufacturers in Bangalore. It is doable to change the machine as indicated by the prerequisites of clients. The action and use of the squeezing machine are fundamental and straightforward. It has a very fine culmination. Since the machine uses a very low impact, it gets a reasonable setup on the energy bills.

Keywords: Vegetable cutting Machine Manufacturers in Bangalore, Pickle Packing Machine Manufacturers in Bangalore, Milk Packing Machine Manufacturers in Bangalore, Ketchup Packing Machine Manufacturers in Bangalore, Tomato sauce Packing Machine Manufacturers in Bangalore

0 notes

Text

Milk Packing Machine Manufacturers in Ernakulam-sampackindia

Milk Packing Machine Manufacturers in Ernakulam-sampackindia

We are the famous Milk Packing Machine Manufacturers in Ernakulam. The Milk Packing Machine Manufacturers in Ernakulam of countless things which consolidate pickle filling machines, pickle squeezing machines, tea customized pocket squeezing machines, tea packaging pockets machine cost, flavors filling machines, and dates Squeezing Machines. Ketchup Packing Machine Manufacturers in Ernakulam is expected for filling the little measure of powders in sachets moulded from the virgin/covered material. The resting unit is a drill filler machine with an exceptionally arranged screw/Funnel that exactly delivers the powder in the outlining sachet. Our seal part and the thing discharge are synchronized to give the most raised speed and accuracy. 3 and 4 side seal models are moreover open on request. Remarkable component, exceptionally planned for the things which ought to be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Ernakulam and filling machines are associated with the connector so that the machine can be used as a pocket filling machine additionally as it will, in general, be mounted on the conveyor zed system for filling bottles. Simple-to-use microcontroller/PLC-based controller helps with defining various limits for the machines including the weight, half/full cutting, Pouch grouping, etc.

Pickles are a huge reinforcement of food and it is sold in the market in pockets and packages. Milk Packing Machine Manufacturers in Ernakulam of pickles use the pickle squeezing machine in their plant to make the most well-known approach to filling and squeezing pickles basic and simple. Machines offer a chance to buy these machines in both modified and self-loader structures. If you are a maker or supplier of pickles, capitalize on this entryway and get the machine for Milk Packing Machine Manufacturers in Ernakulam. The machine is driven by pneumatic power. It fills pickles in pockets and a while later seals and packs it. The squeezing of pickles is done under clean conditions to avoid debasement in the pickles so it is a safeguarded strategy.

The pickle squeezing machine is made of tempered steel and it has significant solid areas for an energetic turn of events. It is a top-quality machine with a long assistance life. This is the inspiration driving why it is involved by the exporter of Pickle Packing Machine Manufacturers in Ernakulam. It is doable to change the machine as indicated by the prerequisites of clients. The action and use of the squeezing machine are fundamental and straightforward. It has a very fine culmination. Since the machine uses a very low impact, it gets a reasonable setup on the energy bills.

Milk Packing Machine Manufacturers in Ernakulam-https://sampackindia.com/milk-packing-machine-manufacturers-in-ernakulam/

0 notes

Text

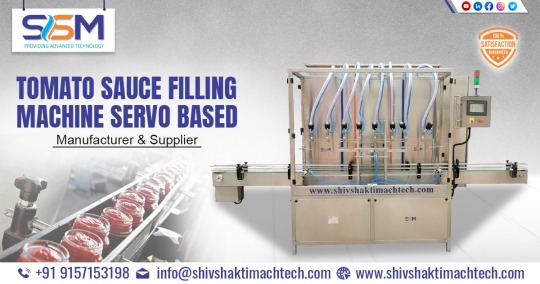

Tomato Sauce Filling Machine Servo Based

Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Tomato Sauce Filling Machine Servo Based across India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Shiv Shakti Machtech is a leading manufacturer and supplier of high-performance Servo-Based Tomato Sauce Filling Machines, designed to meet the precise filling requirements of the food processing industry. Our machines deliver accuracy, speed, and hygiene, making them ideal for small to large-scale production lines. Similar Sauce Bottle Filling Technology Machinery: Tomato Sauce Filling Machine, Ketchup Filling Machine, Automatic Tomato Sauce Servo Filling Machine, Automatic Sauce Tin Can Filling and Sealing Machine, Tomato Sauce Packing Machine, Automatic Liquid Filling Machine – Servo Based, Automatic Hot Tomato Sauce Filling Machine, Servo Automatic Sauce Filling Machin, Tomato Sauce Packaging Equipment, Tomato Sauce Bottling Machine Types of Tomato Sauce Filling Machines: Single-Head Servo Filling Machine Multi-Head Servo Filling Machine Automatic Servo-Based Filling Machine Semi-Automatic Filling Machine Custom Configurations Features: Servo Motor Technology: Ensures precision in filling volumes. Stainless Steel Construction: Durable and easy to clean, ensuring compliance with food-grade standards. Touchscreen Control Panel: Offers user-friendly operation and programmable settings. Adjustable Filling Nozzles: Accommodates various bottle sizes and shapes. Anti-Drip Mechanism: Prevents spillage and waste. High-Speed Operation: Enhances productivity for large-scale operations. What types of containers can this machine handle? Our machines can fill glass bottles, plastic jars, pouches, and even sachets. How accurate is the filling process? The servo-based design ensures high accuracy, typically within ±1% of the desired volume. Can this machine handle different viscosities? Yes, it is designed to handle various viscosities, from thin liquids to thick sauces. Is the machine suitable for small-scale production? We offer semi-automatic and single-head models that are perfect for small-scale operations. Shiv Shakti Machtech is a Supplier of Tomato Sauce Filling Machine Servo Based in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For more information or to request a quote, please reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar#Chennai#Chitradurga

1 note

·

View note

Text

Milk Packing Machine Manufacturers in Ernakulam

Milk Packing Machine Manufacturers in Ernakulam

We are the famous Milk Packing Machine Manufacturers in Ernakulam. The Milk Packing Machine Manufacturers in Ernakulam of countless things which consolidate pickle filling machines, pickle squeezing machines, tea customized pocket squeezing machines, tea packaging pockets machine cost, flavors filling machines, and dates Squeezing Machines. Ketchup Packing Machine Manufacturers in Ernakulam is expected for filling the little measure of powders in sachets moulded from the virgin/covered material. The resting unit is a drill filler machine with an exceptionally arranged screw/Funnel that exactly delivers the powder in the outlining sachet. Our seal part and the thing discharge are synchronized to give the most raised speed and accuracy. 3 and 4 side seal models are moreover open on request. Remarkable component, exceptionally planned for the things which ought to be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Ernakulam and filling machines are associated with the connector so that the machine can be used as a pocket filling machine additionally as it will, in general, be mounted on the conveyor zed system for filling bottles. Simple-to-use microcontroller/PLC-based controller helps with defining various limits for the machines including the weight, half/full cutting, Pouch grouping, etc.

Pickles are a huge reinforcement of food and it is sold in the market in pockets and packages. Milk Packing Machine Manufacturers in Ernakulam of pickles use the pickle squeezing machine in their plant to make the most well-known approach to filling and squeezing pickles basic and simple. Machines offer a chance to buy these machines in both modified and self-loader structures. If you are a maker or supplier of pickles, capitalize on this entryway and get the machine for Milk Packing Machine Manufacturers in Ernakulam. The machine is driven by pneumatic power. It fills pickles in pockets and a while later seals and packs it. The squeezing of pickles is done under clean conditions to avoid debasement in the pickles so it is a safeguarded strategy.

The pickle squeezing machine is made of tempered steel and it has significant solid areas for an energetic turn of events. It is a top-quality machine with a long assistance life. This is the inspiration driving why it is involved by the exporter of Pickle Packing Machine Manufacturers in Ernakulam. It is doable to change the machine as indicated by the prerequisites of clients. The action and use of the squeezing machine are fundamental and straightforward. It has a very fine culmination. Since the machine uses a very low impact, it gets a reasonable setup on the energy bills.

0 notes

Text

Gravimetric Filling Machines

Processors profit from preserved product integrity and look along with correct portions and a major reduction in labor. These Semi Automatic Volumetric Liquid Filling Machines are manufactured from excessive grade quality material and are easily out there at very affordable worth in market. These machines are appropriate for spherical or flat form bottles or vials. Our machines have output of most 20 Products per minute depending on nature of liquids, neck diameter or vial/bottle and fill volume. Ashirwad Enterprises is considered one of the celebrated companies of the business, to engage in proffering Automatic Sharbat Filling Machine. Made available in quite a few specs, these efficient methods supply inbuilt safety against over current, voltage fluctuation and quick circuit automated speed control system.

Packaging is a crucial component in customer decision-making and serves as a conduit between the manufacturer and the buyer. As a end result, the food packaging trade is doubtless considered one of the key industries seeing appreciable market enlargement. The food packaging business makes a major contribution to employment, gross value-added, and industrial funding. Various macroeconomic causes such as rising middle-class revenue ranges, more shopper consciousness, and rising demand for processed and packaged foods all contribute to market development throughout the forecast period. We are engaged in manufacturing and exporting a extensive range of SemiAutomatic Liquid Filling Machine. Our supplied range is manufactured using highest quality raw materials and advanced expertise.

The machine is supplied with a mechanism that ensures that the appropriate quantity of powder is dispensed into the container. Powder filling machines are commonly used in the meals, pharmaceutical, and chemical industries to fill containers with all kinds of powders. A volumetric cup filler machine is a tool often volumetric filler machine used in powdery merchandise and ensures that each container receives an correct dose of whatever substance is being poured. This machine is meant to fill cups precisely and precisely, ensuring that your items are properly packaged and meet FDA tips.

Volumetric Filling Systems are based on a self-priming cylinder. A piston moves inside the cyclinder, and the diameter and size of the stroke are measured, figuring volumetric filler machine out the filling volume. Be used for filling with particulate matter sauce, paste, liquid, Shampoo, liquid soap and other materials.

Be used for filling with particulate matter sauce,paste,liquid and different materials. Equipped with filling quantity adjusting device knob, quantitative filling and filling speed can be manually controlled. Our position in the market is instantly attributable to our precisely designed Hand Operated Cream And Paste Filling Machine. The contact components volumetric filler machine material is made from 304 stainless steel or 316 stainless steel as per the customer’s requirement and utility. • Machine may be provided with Height adjustable nozzles for variable products .

Such as,milk,soybean milk, fruit juice,beverage,ice drink, soy sauce, vinegar and wine, It makes use of single lay film PE as packaging supplies. It can automatically sterilized by ultraviolet radiation,bag molding, print the code, precisely fill, seal and cut at one time. This collection has been long-tested and its performance enjoys a very excessive reputation from our purchasers that this series is easyt to function and run smoothly with low failure fee. Cream Filling Machineis use for pharma, cosmetic, meals industries and so forth. Cream filling machine are in two sort of mannequin, one is totally computerized cream filling and second is semi computerized cream filling machine. Cream filling machine is use for bottle, jar & pouch filling additionally.

Such as, milk,soybean milk, fruit juice,beverage,ice drink, soy sauce, vinegar and wine, It uses single lay film PE as packaging supplies. As one of the leading entity of this area, we're engrossed in offering supreme quality Automatic Liquid Filling Machine. The provided machine’s cowl manufactured using chrome steel alloy with a mirror polish. Also, the fundamental unit consists of SS conveyor belt with further half of HPAC motor and A.C aviator for conveyor velocity. It has simple volume setting with the eccentric screw and filling meeting is the diving kind with no dripping problem. Apart from this, the machine can be bought from us at business leading charges.

We are instrumental in designing and creating an in depth number of Drum Filling that analogs to widest business requirements and norms. Shampoo, Adhesive, Paint, Resin, Distemper, Oil, Honey, catch up, Handwash, Chatni, Semi liquid many more liquid merchandise. Tooth Paste, Cosmetic lotions, Pickles with small pieces, Adhesives, Jams & high Viscous products. The tube holding Cup is manufactured utilizing quality stainless steel of grade 304. We are one of many main manufacturers and suppliers of European/American normal Process equipment at unmatched Indian rates.

Features on theTP-401includes a straightforward to make use of contact screen panel andPLC managed, easy maintenance and the potential to add additional features like thermal date coding for variable information required on the sachets. As an advancement in sachet form, fill, and seal solutions, theTP-401provides sturdy driving systems powered byservo motors, Auger dosing for powders, cup dosing for granules, solids and piston stress for liquids and pasty products. The Filling Machine is manufactured or developed accordance with GMP standards.The construction is manufactured from MS cladded with SS 304.Rigid vibration free development for bother free efficiency.SS Elegantly matt finished physique. Diving nozzle gadget.Minimum change overtime, from one measurement to another bottle or fill size.

The vibratory weigh filling machine is a superb choice for those corporations who're looking for a approach to boost their manufacturing line. The powder filling machine is excellent and helpful if you should fill small to massive containers with powder. According to the functions or kinds of Volumetric Liquid Filling Machine, Volumetric Liquid Filling Machine may be categorised into many types. Be honest about your volume and select the Volumetric Liquid Filling Machine that is designed for the wants of your business. Nozzles can set to be above bottle mouth or bottom up, synchronizing with liquid level to get rid of bubbling of foamy liquids.

0 notes

Link

'Packwell' is one of the leading manufacturer of automatic liquid filling machine.We provide best quality of sauce bottle filling machine and supplies in India,Bangladesh,Jordon, Dubai,Kenya,Sri-lanka.visit packwellmachinery.com

#sauce bottle filling machine#sauce bottle filling machine manufacturers#sauce bottle filling machine exporters

0 notes

Text

Pickle Packing Machine Manufacturers in Ernakulam

Pickle Packing Machine Manufacturers in Ernakulam

We are the popular Pickle Packing Machine Manufacturers in Ernakulam. The Milk Packing Machine Manufacturers in Ernakulam of a large number of items which incorporate pickle filling machine, pickle pressing machine, tea programmed pocket pressing machines, tea bundling pockets machine cost, flavors filling machine and dates pressing machine. Ketchup Packing Machine Manufacturers in Ernakulam is intended for filling little amount of powders in sachets shaped from the virgin/covered material. The napping unit is a drill filler machine with uniquely planned screw/Funnel precisely releases the powder in the framing sachet. Our seal component and the item release is synchronized to give the most elevated speed and precision. 3 and 4 side seal models are likewise accessible on demand. Extraordinary element, extraordinarily intended for the items which should be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Ernakulam and filling machines are connected with the connector so that machine can be utilized as pocket filling machine also as it tends to be mounted on the conveyor zed framework for filling bottles. Easy to utilize microcontroller/PLC based regulator assists with setting different boundaries for the machines including the weight, half/full cutting, Pouch bunching and so on.

Pickles are a significant backup of food and it is sold in the market in pockets and bundles. The Pickle Packing Machine Manufacturers in Ernakulam of pickles utilize the Pickle Packing Machine in their plant to make the most common way of filling and pressing pickles simple and easy. Machines offer an opportunity to purchase these machines in both programmed and self-loader forms. In the event that you are a producer or provider of pickles, make the most of this open door and get the machine for Pickle Packing Machine Manufacturers in Ernakulam. The machine is driven by a pneumatic power. It fills pickles in pockets and afterward seals and packs it. The pressing of pickles is finished under clean circumstances to stay away from defilement in the pickles so it is a protected method.

The Pickle Packing Machine is made of tempered steel and it has major areas of strength for a vigorous development. It is a top quality machine with a long help life. This is the motivation behind why it is involved by the exporter of Pickle Packing Machine Manufacturers in Ernakulam. It is feasible to tweak the machine according to the requirements of clients. The activity and utilization of the pressing machine are basic and simple. It has an extremely fine completion. Since the machine utilizes an extremely low influence, it gets a good deal on the energy bills.

Pickle Packing Machine Manufacturers in Ernakulamhttps://sampackindia.com/pickle-packing-machine-manufacturers-in-ernakulam/

0 notes

Text

Pickle Packing Machine Manufacturers in Bangalore

Pickle Packing Machine Manufacturers in Bangalore

We are the popular Pickle Packing Machine Manufacturers in Bangalore. The Milk Packing Machine Manufacturers in Bangalore of a large number of items which incorporate pickle filling machine, pickle pressing machine, tea programmed pocket pressing machines, tea bundling pockets machine cost, flavors filling machine and dates Pressing Machine. Ketchup Packing Machine Manufacturers in Bangalore is intended for filling little amount of powders in sachets shaped from the virgin/covered material. The napping unit is a drill Filler Machine with uniquely planned screw/Funnel precisely releases the powder in the framing sachet. Our seal component and the item release is synchronized to give the most elevated speed and precision. 3 and 4 side seal models are likewise accessible on demand. Extraordinary element, extraordinarily intended for the items which should be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Bangalore and filling machines are connected with the connector so that machine can be utilized as pocket filling machine also as it tends to be mounted on the conveyor zed framework for filling bottles. Easy to utilize microcontroller/PLC based regulator assists with setting different boundaries for the machines including the weight, half/full cutting, Pouch bunching and so on.

Pickles are a significant backup of food and it is sold in the market in pockets and bundles. The Pickle Packing Machine Manufacturers in Bangalore of pickles utilize the Pickle Packing Machine in their plant to make the most common way of filling and pressing pickles simple and easy. Machines offer an opportunity to purchase these machines in both programmed and self-loader forms. In the event that you are a producer or provider of pickles, make the most of this open door and get the machine for Pickle Packing Machine Manufacturers in Bangalore. The machine is driven by a pneumatic power. It fills pickles in pockets and afterward seals and packs it. The pressing of pickles is finished under clean circumstances to stay away from defilement in the pickles so it is a protected method.

The Pickle Packing Machine is made of tempered steel and it has major areas of strength for a vigorous development. It is a top quality machine with a long help life. This is the motivation behind why it is involved by the exporter of Pickle Packing Machine Manufacturers in Bangalore. It is feasible to tweak the machine according to the requirements of clients. The activity and utilization of the pressing machine are basic and simple. It has an extremely fine completion. Since the machine utilizes an extremely low influence, it gets a good deal on the energy bills.

Keywords: Vegetable cutting Machine Manufacturers in Bangalore, Pickle Packing Machine Manufacturers in Bangalore, Milk Packing Machine Manufacturers in Bangalore, Ketchup Packing Machine Manufacturers in Bangalore, Tomato sauce Packing Machine Manufacturers in Bangalore

0 notes

Text

Pickle Packing Machine Manufacturers in Ernakulam-sampackindia

Pickle Packing Machine Manufacturers in Ernakulam-sampackindia

We are the popular Pickle Packing Machine Manufacturers in Ernakulam. The Milk Packing Machine Manufacturers in Ernakulam of a large number of items which incorporate pickle filling machine, pickle pressing machine, tea programmed pocket pressing machines, tea bundling pockets machine cost, flavors filling machine and dates pressing machine. Ketchup Packing Machine Manufacturers in Ernakulam is intended for filling little amount of powders in sachets shaped from the virgin/covered material. The napping unit is a drill filler machine with uniquely planned screw/Funnel precisely releases the powder in the framing sachet. Our seal component and the item release is synchronized to give the most elevated speed and precision. 3 and 4 side seal models are likewise accessible on demand. Extraordinary element, extraordinarily intended for the items which should be filled in little sachet/pockets as well as in bottles. Tomato sauce Packing Machine Manufacturers in Ernakulam and filling machines are connected with the connector so that machine can be utilized as pocket filling machine also as it tends to be mounted on the conveyor zed framework for filling bottles. Easy to utilize microcontroller/PLC based regulator assists with setting different boundaries for the machines including the weight, half/full cutting, Pouch bunching and so on.

Pickles are a significant backup of food and it is sold in the market in pockets and bundles. The Pickle Packing Machine Manufacturers in Ernakulam of pickles utilize the Pickle Packing Machine in their plant to make the most common way of filling and pressing pickles simple and easy. Machines offer an opportunity to purchase these machines in both programmed and self-loader forms. In the event that you are a producer or provider of pickles, make the most of this open door and get the machine for Pickle Packing Machine Manufacturers in Ernakulam. The machine is driven by a pneumatic power. It fills pickles in pockets and afterward seals and packs it. The pressing of pickles is finished under clean circumstances to stay away from defilement in the pickles so it is a protected method.

The Pickle Packing Machine is made of tempered steel and it has major areas of strength for a vigorous development. It is a top quality machine with a long help life. This is the motivation behind why it is involved by the exporter of Pickle Packing Machine Manufacturers in Ernakulam. It is feasible to tweak the machine according to the requirements of clients. The activity and utilization of the pressing machine are basic and simple. It has an extremely fine completion. Since the machine utilizes an extremely low influence, it gets a good deal on the energy bills.

Pickle Packing Machine Manufacturers in Ernakulam-https://sampackindia.com/pickle-packing-machine-manufacturers-in-ernakulam/

0 notes