#sandvik cone crusher

Explore tagged Tumblr posts

Text

Unmatched Strength and Reliability of BDI Crusher Parts

In the demanding world of mining and construction, reliable and high-performance crusher parts are crucial for maintaining optimal equipment efficiency and minimizing downtime. BDI Wear Parts stands out as a leading supplier of customized and high-quality crusher parts, offering a comprehensive range that caters to the unique needs of various industries.

What Makes BDI Crusher Parts the Best Choice?

BDI Wear Parts is renowned for its commitment to quality and customer satisfaction. Our products are meticulously crafted to ensure maximum durability and performance, even in the toughest operating conditions. Our focus on innovation and the use of cutting-edge wear technology sets new standards for reliability, efficiency, and productivity. With a one-year warranty against manufacturing defects and 24/7 customer support, BDI Wear Parts is your trusted partner for all your crusher parts Canada needs.

Our Comprehensive Product Range

1. Jaw Crusher Parts

BDI Wear Parts offers a wide array of jaw crusher parts for sale, designed to withstand the rigors of heavy-duty applications. Our jaw plates, crafted from high-quality materials like ZGMn13Cr2 and ZGMn18Cr2, offer outstanding wear resistance and durability. These parts are precisely engineered for an exact fit with a wide range of jaw crusher models, including the widely-used CJ and C series from leading brands. This ensures less downtime, enhanced productivity, and substantial cost savings for our customers.

2. Cone Crusher Parts

For cone crushers, BDI Wear Parts provides an extensive selection of mantles, concaves, and other essential components. Our cone crusher parts for sale are precision-engineered to optimize crushing performance and minimize wear. High-manganese steel and high-chromium iron are among the materials used in our mantles and concaves, ensuring exceptional strength and durability. We offer parts for popular cone crusher series like the H, S, CS, GP, and HP, ensuring compatibility with a wide range of equipment.

3. Impact Parts

BDI Wear Parts also specializes in impact crusher parts, including blow bars, impact plates, and hammer mill hammers. These parts are subject to intense impact and abrasion, making material selection and design crucial. We offer high-chrome and high-manganese steel blow bars, as well as customized materials to suit specific application requirements. Our impact parts are designed to increase productivity, reduce maintenance costs, and extend equipment life.

4. Cutting Edge

The cutting edge of crusher parts for sale, particularly in bucket teeth and jaw plates, is critical to maintaining optimal crushing efficiency. BDI Wear Parts offers cutting edges that are hard-wearing and precision-ground to ensure sharp, consistent performance. These cutting edges are available in various materials, including high-manganese steel, high-chrome iron, and customized alloys, to suit different applications and operating conditions. Regular replacement and maintenance of cutting edges Canada can significantly improve overall crushing performance and reduce machine stress.

ConclusionBDI Wear Parts is your go-to source for high-quality, customized crusher parts. Our comprehensive range of jaw crusher parts, cone crusher parts, impact parts, and cutting edges is designed to meet the unique demands of various industries. Dedicated to innovation, quality, and customer satisfaction, we aim to deliver dependable products that boost productivity and reduce downtime. Whether you require parts for Metso, Sandvik, Terex, or other brands, BDI Wear Parts is your go-to source. Reach out to us today to explore our products and services.

0 notes

Text

Mobile Crushers Market Insights: Comprehensive Global Forecast (2023-2032)

The Global Mobile Crushers Market is projected to witness significant growth, with its value expected to surge from USD 2,789.41 million in 2023 to USD 4,271.97 million by 2032, reflecting a compound annual growth rate of 4.85%.

The mobile crushers market is experiencing significant growth, driven by the increasing demand for efficient, mobile, and flexible crushing solutions in the mining and construction industries. This market expansion is influenced by several factors, including urbanization, the expansion of infrastructure projects, and the need for resource-efficient technologies. As urban areas expand, the demand for raw materials like aggregates for construction increases, pushing the need for equipment that can process these materials directly at the source to minimize transportation costs and environmental impact.

Mobile crushers are favored in settings where fixed installations are impractical or uneconomical, such as remote mining locations or large-scale construction projects that require the frequent relocating of crushing equipment. The versatility and mobility of these crushers allow operators to quickly adapt to changing project needs and site conditions. Technological advancements have also played a crucial role in market growth, with manufacturers integrating features like automation, remote monitoring, and advanced diagnostics into their machines, enhancing both performance and user safety.

Mobile crushers are highly versatile pieces of machinery that are used in the mining and construction industries to break down large rocks, stones, and other materials into smaller, more manageable sizes. Unlike stationary crushing equipment, which remains fixed in one location, mobile crushers can be transported to various sites, making them particularly valuable for projects that require mobility and flexibility. These machines come in various configurations, including jaw crushers, impact crushers, cone crushers, and gyratory crushers, each designed for specific types of materials and crushing processes.

The operation of a mobile crusher involves several stages. Raw materials are first fed into the crusher's hopper, and then moved by a conveyor belt to the crushing mechanism. Depending on the model, the crushing process may involve a single stage or multiple stages, where the materials are reduced to the required sizes through compression, impact, or shear forces. The crushed material is then either directly used on site, transported to another location for further processing, or stockpiled for future use.

More About Report- https://www.credenceresearch.com/report/mobile-crushers-market

Key Player Analysis:

Astec Industries

Thyssenkrupp AG

Terex Corporation

Metso Corporation

Sandvik AB

McCloskey International

Kleemann GmbH

SBM Mineral Processing GmbH

Striker Australia Pty Ltd

Growth Factors:

Urbanization and Infrastructure Development: As global urbanization accelerates, there is a corresponding rise in infrastructure projects, including roads, buildings, and public utilities. Mobile crushers play a crucial role in these projects by providing the necessary raw materials, such as crushed stone and aggregates, directly at the construction sites.

Flexibility and Efficiency: Mobile crushers offer significant flexibility and efficiency advantages over stationary crushers. They can be easily moved between sites, which is particularly valuable in large-scale or remote projects. This mobility reduces material transportation costs and allows for rapid setup and dismantling, aligning well with the variable demands of construction timelines and site locations.

Technological Advancements: Innovations in mobile crusher technology, such as automation, real-time data monitoring, and GPS tracking, have enhanced operational efficiencies, reduced labor costs, and improved safety profiles. These technological enhancements also allow for better resource management and compliance with environmental standards.

Environmental and Regulatory Pressures: Increasing environmental awareness and stricter regulations regarding construction and mining operations have led to greater demand for mobile crushers that are environmentally friendly. These machines often feature reduced emissions, lower noise levels, and better fuel efficiency, making them more acceptable under new environmental standards.

Economic Shifts in Developing Countries: Rapid economic development in countries like China, India, and Brazil has spurred extensive mining activities and construction projects, driving the demand for mobile crushing equipment. The shift towards constructing more infrastructure to support economic growth in these regions continues to boost market prospects.

Replacement of Older Equipment: The need to replace or upgrade older crushing equipment with more efficient and environmentally friendly models also contributes to market growth. This replacement cycle is a significant factor, especially in developed markets with strict environmental laws and high labor costs.

Adaptability to Multiple Applications: Mobile crushers are adaptable to a variety of applications, from stone quarries and mining sites to demolition sites and recycling plants. This versatility makes them invaluable across different sectors, enhancing their market demand.

Segments:

Based on Type

Jaw crushers

Impact Crushers

Others

Based on Application

Mining & Quarry

Construction Aggregates

Material Recycling

Others

Market Challenges:

High Initial Investment Costs: Mobile crushers require a substantial initial investment, which can be a barrier for small to medium enterprises (SMEs) and startups. The cost of purchasing and maintaining these machines can deter potential buyers who might otherwise benefit from their use.

Operational Complexity: Operating mobile crushers involves dealing with several complex mechanisms. Proper training and skilled personnel are necessary to ensure efficient and safe operations. This need for specialized labor can increase operational costs and complexity.

Logistical and Transport Issues: Despite their mobility, transporting mobile crushers between sites over large distances can be challenging and costly, especially in regions with inadequate transport infrastructure. The logistical complexity can also involve regulatory compliance regarding oversized loads on public roads.

Maintenance Challenges: Mobile crushers are subjected to extreme wear and tear, especially when used in harsh environments typical of mining and construction sites. Frequent breakdowns and the need for regular maintenance can lead to downtime, affecting productivity and operational costs.

Environmental and Regulatory Compliance: Adhering to stringent environmental regulations is a significant challenge. Mobile crushers must comply with emission standards, noise regulations, and other environmental requirements, which can vary widely by region and over time as policies become stricter.

Browse the full report – https://www.credenceresearch.com/report/mobile-crushers-market

Browse Our Blog : https://www.linkedin.com/pulse/mobile-crushers-market-forecast-analysis-lumef

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

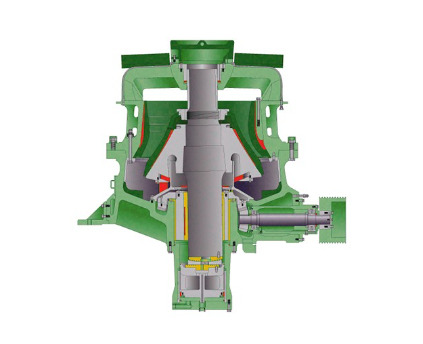

Sandvik Cone Crusher Parts

Sandvik cone crusher is a compressive crusher where feed material is crushed between a fixed concave and a movable mantle. Liners must be changed before they are worn through in order to prevent damage to frame or head. We offer competitive pricing, improved design and excellent service, ensuring you get the best possible return on your investment. We cover a wide range of cone crusher replacement parts for Sandvick cone crusher parts for Hydrocone and Superior Crushers, including the head center, arm shield, burning ring and more.

Read more : https://www.matecmining.com/

0 notes

Text

Global Cone Crusher Market Is Estimated To Witness High Growth Owing To Increasing Demand for Construction and Mining Activities

The global Cone Crusher market is estimated to be valued at US$ 1,599.8 million in 2021 and is expected to exhibit a CAGR of 6.4% over the forecast period 2022-2030, as highlighted in a new report published by Coherent Market Insights. Market Overview: Cone Crusher Market are widely used in the mining and construction industries for crushing various materials such as rocks, ores, and stones. They offer several advantages such as high productivity, excellent particle shape, and low operation costs. The increasing demand for cone crushers can be attributed to the growth in construction and mining activities worldwide. These crushers are used to crush large rocks into smaller aggregates, which are then used in various infrastructure projects. The rising need for infrastructure development, especially in emerging economies, is driving the demand for cone crushers in the market. Market Key Trends: One key trend in the Cone Crusher market is the increasing adoption of automated features in cone crushers. With advancements in technology, manufacturers are integrating various automation features into cone crushers to improve their efficiency and ease of operation. For example, some cone crushers now come with automated control systems that allow operators to adjust the settings remotely. This not only enhances safety but also enables operators to optimize the crusher's performance based on specific requirements. The automation features also help in reducing downtime and improving overall productivity. PEST Analysis: Political: Stable political environments across major economies ensure consistent growth opportunities for the cone crusher market. Economic: Increasing investments in infrastructure development projects and rapid urbanization are driving the demand for cone crushers. Social: Growing population, rising disposable income, and increasing urbanization are fueling the demand for housing and infrastructure, thereby driving the cone crusher market. Technological: Advancements in technology have led to the development of advanced cone crushers with improved efficiency, durability, and automation features. Key Takeaways: 1. The global Cone Crusher market is expected to witness high growth, exhibiting a CAGR of 6.4% over the forecast period. This growth can be attributed to increasing demand for cone crushers in construction and mining activities. 2. Regionally, Asia Pacific is the fastest-growing and dominating region in the cone crusher market. The region is witnessing rapid infrastructure development, especially in emerging economies like India and China, leading to a surge in demand for cone crushers. 3. Key players operating in the global Cone Crusher market include Tesab Engineering Ltd., Terex Corporation, ThyssenKrupp AG, Metso Corporation, FLSmidth & Co. AS, McCloskey Equipment, Keestrack NV, Westpro Machinery Inc., Puzzolana Machinery Fabricators LLP, Astec Industries Inc., and Sandvik AB. In conclusion, the growing demand for cone crushers in the construction and mining industries is expected to drive the growth of the global Cone Crusher market. The adoption of automated features in cone crushers and advancements in technology are further enhancing their efficiency and productivity. Asia Pacific is witnessing significant growth in the market due to rapid infrastructure development in the region. Key players are focusing on technological advancements and strategic collaborations to expand their market presence and gain a competitive edge.

0 notes

Text

Maximising Cone Crusher And Cone Crusher Parts Efficiency

Ensuring successful cone crusher performance may cause main savings of scale to get quarrying facilities There really certainly are a lot of ways in that sandvik cone crusher parts throughput could be successfully optimized. One of the major problems is in keeping the system choke fed throughout performance, because this accentuates the potency of both how rock-on-rock devastating, extends the wear life of manganese parts and makes sure an excellent product shape. A deficiency of feed causes inconstant loading, which also has an effect on the long-term lifetime of inner parts.

Maximising cone-crusher and Cone Crusher Wear Parts efficiency

Ensuring productive cone crusher wear parts performance may deliver important economies of scale for quarrying facilities. There certainly are a number of ways that cone crusher throughput might be optimised.

One of the key issues is that in retaining the system fed during operation, since this accentuates the potency of rock-on-rock devastating, extends the wear life span of manganese components and guarantees a quality product shape. A absence of feed induces inconstant loading, which affects the longterm lifetime of inside components. Too many penalties may confine the room for the rock to expand and could cause high devastating compels, inducing premature damage and wear parts. In addition, if your crusher isn't properly fed this increases recirculating load, impacting on displays or alternative crushers downstream of this circuit, along with decreasing crusher efficacy and total throughput.

Timely oil affects will be vital as the petroleum provides both lubrication and coolingsystem. Making it possible for the crusher to run with oil that is contaminated could decrease bearing and gear life. Oil filters ought to be checked and shifted at the appropriate periods.

The way to obtain contaminants ought to be found and where petroleum flows out, contaminants such as dirt particles and water might get inside. Inspect hydraulic techniques and tag flows for corrective activity in the upcoming maintenance cycle. Thoroughly drain and wash from the inside of the oil tank to get rid of contaminants prior to pruning. The type and status of the lubrication oil is equally critical to effective performance of a telsmith cone crusher parts since the incorrect saver may considerably diminish life. Even a crusher is designed to get the job done with the lube oil from the array of 10°-51°C. The maximum oil temperature is controlled with means of a detector switch in the reservoir return line and in the event the crusher can be employed on a regular basis in cases of heat or cold plus it's a challenge to maintain crusher petroleum while inside the suitable operating scope, it could possibly be necessary to change to synthetic oil. After changing the outer sleeve position, examine the major frame bore to get nicks, burrs, scoring or other damage and make an effort to remove pits using a file or emery cloth. Use a micrometer to measure the bore at the very top, centre and bottom and in each location, check the dimensions in two places ninety ° apart.

The common of all six measurements needs to fall within a decent selection. If large spots cannot be registered down into an acceptable scope the bore will want to get re-machined right into endurance. Check the bore carefully soon right immediately following re-machining to get burrs, particularly in the keyways and grooves. A principal body bore that is worn away from the tolerance constraints need to have the worn spots welded and also the whole bore re-machined to endurance.

If electrical fluctuations are built, or programs will be altered in automated systems, affirm the alarms and interlocks function precisely.

It is cheaper to displace buttons or timers that show up harmed or have been at lousy condition than hazard the cost of a big overhaul.

Record vital machine details like motor ampsand oil temperature and oil pressure in a variety of operating states , which may identify trends and will additionally help to detect problems before they result in expensive downtime or harm.

2 notes

·

View notes

Text

Sandvik Cone Crusher Parts: How To Select And When To Change

Deciding on the right liners and knowing the way to improve them is essential for ideal cone crusher bowl liner effectiveness. Cone Crushers had been grown higher than a hundred years past to present secondary, tertiary and much quaternary materials reduction.

As with other compression crushers, Cone Crushers feature a crushing chamber or pit in which the stone is crushed to some smaller magnitude. The crushing chamber in a metso cone crusher wear parts will be the distance generated between your mantle and also concaves. The mantle and concaves are safeguarded from daily wear with replace able manganese liners.

Choosing the Cone Crusher lining

A variety of liners are available to adapt coarse and fine packs, however that you just choose depends on several things. The most important component in Cone Crusher lining choice may be that the feed. If you intend to discover reliable cone crusher liners, you need to go Qiming Machinery site. It is the best reliable site that aid you great deal for your necessities.

First, you ought to really possess a well-graded feed moving to the crushing chamber. Even a well-graded feed Is Normally thought of :

90-100% passing the closed-side feed opening. Some people look at 80 percent of their open side also and select the smaller of the 2.

40-60% departure the mid point.

0-10% passing the closed-side placing.

You wish to coincide with exactly the full feed gradation, maybe not only the feed dimensions, so that you utilize the entire chamber. It is important to utilize as much of the crushing chamber as possible to find the necessary loss and desirable throughput.

Plant feed size and the outcome from your preceding crushing stage defines your upper feed size, that may provide the most fascia opening. The cavity gap shouldn't be excessively large in relation towards the very best feed measurement. Cavity openings which are much bigger than the feed dimensions lead to badly utilized reduction and liners.

In case the feed measurement is still too small, nearly all the crushing occurs place inside the smallest section of the pit, which means the bottom of the cubes will wear far faster in relation to the very top of their extremities. The generation tends to decrease because of the inadequate reduction ratio. The ability limit of this cone crusher will be exceeded at minimal volume level, and you'll run the probability of inappropriate bearing alignment.

Most of the use on crusher liners does occur shortly until the zone, but this wear will be highlighted in the event the feed is still too small, and you are going to end up with a bowled-out pocket ahead of the parallel zone manner too soon.

About the other hand, in the event the feed size is far too coarse, the feed material will probably keep percolating around the feed launching, inducing the top of these cubes to use out quicker faster. As the feed launching has been invisibly, throughput is reduced and manufacturing declines. The output gradation is going to be coarser, and the product will undoubtedly probably likely be slabby, perhaps maybe not cubical. The volume limit is going to be exceeded at minimum energy attraction.

Recognizing your gradation moving in to the trio cone crusher parts helps you to select the best lining settings needed to attain your creation targets. The perfect lining selection provides you a much better nip and a lot more space to correct different parameters, for example as closed-side setting.

1 note

·

View note

Text

Mobile Crushers Market Insights: Comprehensive Global Forecast (2023-2032)

The Global Mobile Crushers Market is projected to witness significant growth, with its value expected to surge from USD 2,789.41 million in 2023 to USD 4,271.97 million by 2032, reflecting a compound annual growth rate of 4.85%.

The mobile crushers market is experiencing significant growth, driven by the increasing demand for efficient, mobile, and flexible crushing solutions in the mining and construction industries. This market expansion is influenced by several factors, including urbanization, the expansion of infrastructure projects, and the need for resource-efficient technologies. As urban areas expand, the demand for raw materials like aggregates for construction increases, pushing the need for equipment that can process these materials directly at the source to minimize transportation costs and environmental impact.

Mobile crushers are favored in settings where fixed installations are impractical or uneconomical, such as remote mining locations or large-scale construction projects that require the frequent relocating of crushing equipment. The versatility and mobility of these crushers allow operators to quickly adapt to changing project needs and site conditions. Technological advancements have also played a crucial role in market growth, with manufacturers integrating features like automation, remote monitoring, and advanced diagnostics into their machines, enhancing both performance and user safety.

Mobile crushers are highly versatile pieces of machinery that are used in the mining and construction industries to break down large rocks, stones, and other materials into smaller, more manageable sizes. Unlike stationary crushing equipment, which remains fixed in one location, mobile crushers can be transported to various sites, making them particularly valuable for projects that require mobility and flexibility. These machines come in various configurations, including jaw crushers, impact crushers, cone crushers, and gyratory crushers, each designed for specific types of materials and crushing processes.

The operation of a mobile crusher involves several stages. Raw materials are first fed into the crusher's hopper, and then moved by a conveyor belt to the crushing mechanism. Depending on the model, the crushing process may involve a single stage or multiple stages, where the materials are reduced to the required sizes through compression, impact, or shear forces. The crushed material is then either directly used on site, transported to another location for further processing, or stockpiled for future use.

More About Report- https://www.credenceresearch.com/report/mobile-crushers-market

Key Player Analysis:

Astec Industries

Thyssenkrupp AG

Terex Corporation

Metso Corporation

Sandvik AB

McCloskey International

Kleemann GmbH

SBM Mineral Processing GmbH

Striker Australia Pty Ltd

Growth Factors:

Urbanization and Infrastructure Development: As global urbanization accelerates, there is a corresponding rise in infrastructure projects, including roads, buildings, and public utilities. Mobile crushers play a crucial role in these projects by providing the necessary raw materials, such as crushed stone and aggregates, directly at the construction sites.

Flexibility and Efficiency: Mobile crushers offer significant flexibility and efficiency advantages over stationary crushers. They can be easily moved between sites, which is particularly valuable in large-scale or remote projects. This mobility reduces material transportation costs and allows for rapid setup and dismantling, aligning well with the variable demands of construction timelines and site locations.

Technological Advancements: Innovations in mobile crusher technology, such as automation, real-time data monitoring, and GPS tracking, have enhanced operational efficiencies, reduced labor costs, and improved safety profiles. These technological enhancements also allow for better resource management and compliance with environmental standards.

Environmental and Regulatory Pressures: Increasing environmental awareness and stricter regulations regarding construction and mining operations have led to greater demand for mobile crushers that are environmentally friendly. These machines often feature reduced emissions, lower noise levels, and better fuel efficiency, making them more acceptable under new environmental standards.

Economic Shifts in Developing Countries: Rapid economic development in countries like China, India, and Brazil has spurred extensive mining activities and construction projects, driving the demand for mobile crushing equipment. The shift towards constructing more infrastructure to support economic growth in these regions continues to boost market prospects.

Replacement of Older Equipment: The need to replace or upgrade older crushing equipment with more efficient and environmentally friendly models also contributes to market growth. This replacement cycle is a significant factor, especially in developed markets with strict environmental laws and high labor costs.

Adaptability to Multiple Applications: Mobile crushers are adaptable to a variety of applications, from stone quarries and mining sites to demolition sites and recycling plants. This versatility makes them invaluable across different sectors, enhancing their market demand.

Segments:

Based on Type

Jaw crushers

Impact Crushers

Others

Based on Application

Mining & Quarry

Construction Aggregates

Material Recycling

Others

Market Challenges:

High Initial Investment Costs: Mobile crushers require a substantial initial investment, which can be a barrier for small to medium enterprises (SMEs) and startups. The cost of purchasing and maintaining these machines can deter potential buyers who might otherwise benefit from their use.

Operational Complexity: Operating mobile crushers involves dealing with several complex mechanisms. Proper training and skilled personnel are necessary to ensure efficient and safe operations. This need for specialized labor can increase operational costs and complexity.

Logistical and Transport Issues: Despite their mobility, transporting mobile crushers between sites over large distances can be challenging and costly, especially in regions with inadequate transport infrastructure. The logistical complexity can also involve regulatory compliance regarding oversized loads on public roads.

Maintenance Challenges: Mobile crushers are subjected to extreme wear and tear, especially when used in harsh environments typical of mining and construction sites. Frequent breakdowns and the need for regular maintenance can lead to downtime, affecting productivity and operational costs.

Environmental and Regulatory Compliance: Adhering to stringent environmental regulations is a significant challenge. Mobile crushers must comply with emission standards, noise regulations, and other environmental requirements, which can vary widely by region and over time as policies become stricter.

Browse the full report – https://www.credenceresearch.com/report/mobile-crushers-market

Browse Our Blog : https://www.linkedin.com/pulse/mobile-crushers-market-forecast-analysis-lumef

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Compare Involving Cone Crusher And Also Jaw Crusher

Every one of the heavy duty system manufacturing in China has now resulted in its own development before. You can find lots of significant sorts of machinery produces from the country which has earned credits all around throughout the world. You will find Jaw crushers manufacturers in China, as well because you can find cone crusher manufacturers in China.

These machines are utilized within the sphere of structure, metallurgy, chemical and silicate industry, mining, and road building. This is a no brainer that both these machines, both the jaw crusher along with also the telsmith cone crusher parts locate their usefulness within the crushing procedure.

A layman is ought to make use of the names for all these machines alternatively, but there are many differences in between both machines that are popular. Let's walkthrough a comparative study between the sandvik cone crusher parts as well as the jaw crusher.

Various Form of cone crusher wear parts

A Jaw crusher is composed of 2 limbs - the fixed one and one. The machine can be used to crush larger-sized stones within a movement resembling that of a nut cracker. The crushing process lessens the size of their stones. Even the chute that filters the rocks will be assembled such a way it narrows toward the bottom. This aids in filtering the stones and lets just a particular size of rocks to pass via.

A cone crusher's parts which would be the mended and also the movable cones are like that of the jaw crusher. The big operational difference is the fact that the cone crusher utilizes the cones to grind ores and stones into smaller bits. The input signal is fed between both cones along with the outcome signal is discharged from the release hole at the base of the cones.

Operational difference:

The removable jaw pushes the movable jaw plate while the rigid jaw does exactly the reciprocating rotational movement. So the cloth gets smashed easily.

youtube

A cone crusher, on the flip side, operated to the principle of rotating oscillatory motion. The strain onto the stones behaves when in between your two cones. The two cones do the eccentric moving movement and generate a power strong enough to smash the tough stone. The bending induce, brute pressure and friction force result in a strong force which ultimately breaks down the stones.

Input and output signal :

Even a Jaw crusher is used with the intention of primary crushing. Thus that the rocks fed as enter are obviously a large magnitude. A jaw crusher is able to crush a content at the variety of 125 mm to 1500 mm.

A cone crusher is used for secondary crushing. The enter to the cone crusher is a lot bigger and fragmented compared to that at the jaw crusher. The granularity of these materials that are destroyed from the cone crushers is roughly 35mm to 350 mm. A cone crusher is most beneficial ideal for crushing materials with higher hardness including granite, marble, pebbles, dolomite, rhyolite, and diabase.

Advantages:

Even a Jaw crusher is employed at subjects of of quarrying, mining, recycling, infrastructure, and structure. It plays the primary part within the crushing of huge stones. Some of the Qualities of the Jaw crushers are:

Useful for devastating rough substances.

The throughput of this jaw crusher is 5-1200 t/h of the input.

Even the Jaw crushers experience minimal movement along with also the impact is longer.

The input is made throughout the closed unwanted settings. This aids in considering the feed content's faculties.

The immense boulders are lower down to a manageable dimension in the jaw crushers.

A cone crusher can be useful for its secondary crushing which is got the outcome of moderate to fine beating. A Few of the features of the cone crusher are:

The variety at the crushing cavity in the cone crushers is equally incredible. It lets you pick the cavity type based on your needs.

The cone crushers with the standard cavity can be employed in surgeries of moderate crushing. The sandvik cone crusher parts using a moderate headed cone is appropriate for fine crushing production as the crushers having a short head cone are employed for ultra-fine devastating.

The cone crushers typically possess a high potential and superior efficiency.

The maintenance and repair charges of these cone crushers usually are low.

There are various differences amongst your Jaw crusher as well as also the cone crusher but each detect high usefulness in crushing procedures. They're used for distinct purposes and also possess amazing meanings.

1 note

·

View note

Text

2 Different Types Of Stone Crushers Routine Maintenance As Well As Powerful Improvement

You will locate two sorts of crushers utilised in mining: jaw crusher, cone crusher. This article mainly introduces the main working theory of those 4 crushersand damage triggers of vulnerable pieces and related alternatives.

Stone-Crushers and crusher wear parts Care and Powerful Improvement

Jaw crusher is useful for (principal crushing) rough and medium crushing of tough stones and stones. The functioning theory of jaw crusher is the fact the belt and belt pulley are driven by the engine, and the movable jaw moves up and down through bizarre shaft.

If moving jaw moves up, the angle involving the toggle plate and the movable jaw Will Become bigger to shove jaw towards fixed jaw and at the same time, substances are squeezed or crushed;

When movable jaw moves down, the angle in between your toggle plate and also the movable jaw will become smaller, and also the movable jaw moves out from the fixed jaw under the act of the pull rod and spring up therefore that the stuff that have been crushed are discharged out of the socket of crushing room.

The Way to protect and maintain jaw plates

Equipment parameters should Suit the materials

Every batch of stuff should be sampled and checked. If you can find really no obvious changes in substances' properties, the parameters of the crusher and metso crusher wear parts needs to be corrected immediately to accommodate to the substances.

The jaw plate Ought to Be fastened regularly

The recently installed chin plate should be fastened carefully. Please make certain that the top layer of the jaw plate contacts with the surface of the machine body steadily.

The materials with very good plasticity these as for example for instance lead plate, cement and plywood mortar may be placed between the two surfaces. The requirement for the removable jaw plate and the fixed jaw plate is that the tooth peak of the jaw plate needs to align using the tooth of another eyebrow plate.

youtube

The materials of this eyebrow plate ought to correspond to stones hardness

For little and medium sized jaw crushers, their chin plates generally employ more compact impact punch. Under such operational conditions, it's more suitable to make use of lean alloy steel which can bring good technical and financial added benefits.

For that large-sized jaw crusher and sandvik crusher wear parts, the huge stones and stones make the mouth plate don seriously. Hence, the high manganese steel may be used whilst the fabric of the jaw plate. As a result of jaw plate is ordinarily formed into a symmetrical symmetrical silhouette, it could be reclined to make use of second.

Cone-crusher

The cone-crusher and crusher wear parts is more ideal for (secondary crushing) moderate and fine crushing of hard or medium-hard ores and rocks. Its operating principle is that the engine compels the bizarre sleeve to rotate with the transmission device, and also the movable cone exerts driven by the bizarre bushing.

The section of this aerodynamic cone near the cone would be the crushing space, and the rocks and ores are repeatedly crushed and affected from the aerodynamic cone as well as the mended cone here.

After the movable cone leaves the segment, the substances that were crushed to the essential particle size are all discharged from the socket of the cone.

The Primary Reasons for the mantle (movable cone) and concave (fixed cone) damages

The ore is overly hard

There are a lot of gems powder and Dampness

Improper feeding Process

The Way to Handle these damages

When purchasing tools, try to inform producer of materials' advice and substance conditions. With the assistance of the expert engineers, most users can decide on the cone crusher that best meets devastating need. Don't forget the hardness of these stones cannot transcend the specified selection of devices.

To get materials with too much wax, the substances should be screened before crushing

For materials having higher moisture, then you should simply take measures such as natural drying or mechanical drying to cut back the dampness (mechanical drying can utilize the corresponding substance sprays, including as river sand drier, gypsum drier, toaster drier, etc.Various dryers can be selected in Fote heavy equipment (FTM), and also for greater dryers' information, remember to refer to.

The chamber may remain a few stuff under some states to guard the devastating space from being damaged by directly calling together with the material, however excessive accumulation may impact the efficiency.

Lower the humidity and viscosity of the substance. It isn't hard to result in adhesion and malocclusion from the crusher once the material's dampness and stick, causing a de crease in crushing capability.

1 note

·

View note

Text

Crushing Equipment Market is Booming Worldwide | Gaining Revolution In Eyes of Global Exposure

Global Crushing Equipment Market Report from AMA Research highlights deep analysis on market characteristics, sizing, estimates and growth by segmentation, regional breakdowns & country along with competitive landscape, players market shares, and strategies that are key in the market. The exploration provides a 360° view and insights, highlighting major outcomes of the industry. These insights help the business decision-makers to formulate better business plans and make informed decisions to improved profitability. In addition, the study helps venture or private players in understanding the companies in more detail to make better informed decisions. Major Players in This Report Include:

Metso (Finland)

Sandvik (Sweden)

IROCK Crusher (United States)

Terex Corporation (United States)

Caterpillar Inc. (United States)

Komatsu Ltd. (Japan)

Joy Global Inc. (United States)

ThyssenKrupp (Germany)

Eagle Crusher Company Inc. (United States)

R.R. EQUIPMENT (United States) Crusher equipment is heavy machinery designed to break the stone into small fragments called aggregates. It may be used to reduce the size or change the form of waste materials so they can be more easily disposed of or recycled or to reduce the size of a solid mix. It holds material that is going to crushed between two parallel or tangent solid surfaces and applies sufficient force to bring the surfaces together to generate enough energy within the material being crushed so that its molecules separate from or change alignment in relation to each other. It has demand in the construction and mining industry due to the low cost of transportation. Crusher equipment manufacturers are focusing to design electric crushers. Market Drivers Increasing Demand from Construction Industry

Development of Construction Industry Worldwide

Market Trend Automation of Crushing Equipment

Demand for Crushing Equipment with Less Carbon Emissions

Opportunities Expansion of Sand Manufacturing Industry Worldwide

Increasing Demand from End-user Industry

Technological Advancements in the Crushing Equipment

Challenges Emissions during the Mining, Screening and Crushing Operations Creates Environmental Issues

The Crushing Equipment market study is being classified by Type (Jaw Crusher, Cone Crusher, Impact Crusher, Gyratory crushers, Compound crusher, Others), Application (Mining, Rock Quarries, Mineral Processing, Recycling, Others), Reduction Ratio (3/1 to 5/1 ratio, 4/1 to 7/1 ratio, Others) Presented By

AMA Research & Media LLP

0 notes

Text

Mobile Crushers and Screeners Market Growth, Size, Analysis, Outlook by Trends, Opportunities and Forecast to 2030

Equipment that is primarily employed in recycling operations, mining operations, and aggregate production is referred to as mobile crushers and screeners. Massive stone blocks are reduced in size using mobile crushers. They may also carry out secondary and tertiary crushing tasks at various mining and construction locations. On the other hand, screeners are used at production sites to flexibly screen various materials. The use of mobile crushers at mining sites eliminates the need for heavy-duty conveyor belts and truck transportation, lowering the overall cost of mining operations.

The Global Mobile Crushers and Screeners Market size is expected to reach $2027.09 Million by 2030, growing at a CAGR of 6.60%.

Mobile screeners and crushers are used in mining operations, aggregates production and mining. Mobile crushers are also used to break stone blocks into many small desirable sizes.

Global Mobile Crushers and Screeners Market: Overview

Screening is the execution of separating one material from another. Mobile screens are cost-effective and mouldable way to screen materials at production sites.

It provides exceptional productivity in smaller aggregate production sites, mining applications and quarrels.

The mobile crushers and screeners market growth is estimated to witness notable growth during the predicted period, owing to increase in mining and construction activities in emerging countries.

Advancement in infrastructure development projects such as dams, airports, railway ballast, expressways, and national highways and construction industry in LAMEA and Asia-Pacific, thrives the global market for mobile crushers and screeners.

Besides, the process of crushing and screening, mobile equipment also helps to reduce material transport cost.

Furthermore, crushing and screening industry faces infrastructure problems such as power shortage, improper roads, rail, and airport links, which limits the market growth in developing countries.

Global Mobile Crushers and Screeners Market- Key Market

Rising construction activities to fuel market growth

With rapid urbanization and economic development, governments of various nations have increased their focus on improving their infrastructural facilities. Favorable incentives and policies associated with the construction of better roads, rail network, and water distributions systems are increasing the adoption of mobile crushers and screens to a large extent.

Moreover, there has been a steep rise in the construction of residential and commercial spaces to accommodate the massively surging populace across the world. This in turn is positively swaying the market dynamics.

Growing significance of environmental recycling to create lucrative opportunities

With rise in pollution levels due to improper waste disposals, there has been an increased need to recycle products like plastics, steel, metal scrap, and components of electronic devices to minimize environmental waste. The surging utilization of these equipment in recycling waste from demolished concrete structures is majorly augmenting the industry outlook.

Request a Free Sample Copy: https://wemarketresearch.com/sample-request/mobile-crushers-and-screeners-market/148/

Segmental Analysis of Global Mobile Crushers and Screeners Market:

Based on Product Type

· MOBILE CRUSHERS

· Cone Crushers

· Jaw Crushers

· Impact Crushers

· MOBILE SCREENERS

· Vibrating

· Gyratory

Based on Solutions

· Aftermarket

· Products

· Based on End-User

· Material Recycling

· Construction

· Mining

· Stone Quarry

· Others

Competitive Landscape:

· Sandvik AB

· Komatsu Ltd.

· Terex Corporation

· Kleemann GmbH

· SBM Mineral processing

· McCloskey International

· Anaconda Equipment Ltd.

· Astec Industries Inc.

· Metso Corporation

· Lipmann Milwaukee Inc.

Major Developments:

In October 2020, Metso Corporation launched two new models to the Lokotrack mobile crushing and screening series, i.e., Lokotrack LT200HPX and Lokotrack LT220GP mobile cone crusher.

Launch models have many new features that are designed to improve efficiency of operations of customers.

Such instances are expected to provide lucrative opportunities to major players for growth of the market.

Major Question answered in the report:

· What is the total value of Global Mobile Crushers and Screeners market?

· What are the key trends of this market?

· Which are the major key players in this market?

Key Takeaway from the report:

· Segmental analysis of mobile screeners and crushers market along with Regional Analysis.

· Deep insight on trends and challenges of Global Mobile Crushers and screeners market.

· The Global Mobile screeners and crushers market valued at $1215.67 Million in 2022, is expected to grow at a CAGR of 6.60%.

For More Details, Visit Our Report Page: https://wemarketresearch.com/reports/mobile-crushers-and-screeners-market/148/

About Us

WE MARKET RESEARCH is an established market analytics and research firm with a domain experience sprawling across different industries. We have been working on multi-county market studies right from our inception. Over the time, from our existence, we have gained laurels for our deep rooted market studies and insightful analysis of different markets.

Our strategic market analysis and capability to comprehend deep cultural, conceptual and social aspects of various tangled markets has helped us make a mark for ourselves in the industry. WE MARKET RESEARCH is a frontrunner in helping numerous companies; both regional and international to successfully achieve their business goals based on our in-depth market analysis. Moreover, we are also capable of devising market strategies that ensure guaranteed customer bases for our clients.

Contact Us:

We Market Research

Phone: +1(929)-450-2887

Email: [email protected]

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound, Reverse engineering services, Mini excavator ,Mini skid steer loader and Electric pallet jack. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Compared with Metso, Sandvik, Symons and Telex OEM wear and parts, we can offer high manganese steel, iron casting, steel casting, bronze machined parts and standard hardware with competitive price, super quality, shortest lead time. Now we have a large number of goods in stock , such as Jaw plate, mantle, concave, liners ,bushings. shaft, Gear& Pinion.,etc

BDI wear and spares co., ltd. assembled with cutting-edge technology and talents. Over 30 years of experience in the industry, we have amassed the knowledge and expertise in aggregating technology and mining machinery to promise you high performance products.

1. Cone crusher wear parts of Metso HP, GP crusher series, Sandvik H2800, H3800, H4800, H6800, H8800 series, Cedar Rapids, KPI-JCI, Nordberg,Symons: 2-7FT, Standard & Shorthead Parts

2. Jaw crusher wear parts , Pionner, Svedala, Cedar Rapids, Heiwitt Robbins, Metso

3. Impact crusher casting blow bar, lining plate , Hartel, Cedar Rapids, Pioneer

4. Gyratory crusher AC linings ,Bushings.

5. Other OEM crusher spare & wear parts like Cedar Rapids, JCI, Telesmith, Trio, Heiwitt Robbins, Svedala, etc.

6. Mini excavator ,Mini skid steer loader and Electric pallet jack

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Benefits of Using A Mini Excavator

Thanks to their versatility and the advanced hydraulics that lend them outsize power, mini excavators are often used in place other construction equipment. They weigh less than full-size excavators and exert less ground pressure. Their compact size allows them to maneuver in places that full-size excavators, backhoes and even skid steer loaders have trouble accessing, making them ideal for small, narrow or congested job sites.

Benefits of using a mini excavator include the following:

1.Small and compact, yet powerful

2.Compact swing for tight work spaces.

3.Useful in less than ideal terrain

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

sandvik crusher parts

sandvik crusher parts

matech solutions crusher spare and wear parts are designed for sandvik crusher parts cone and jaw crusher models.

Various parts in the series have improved safety features and extended operational life. In addition to crusher spares and wears,

We offer all the required services for Sandvik crushers. we provide a one-stop-shop also for your Sandvik cone and jaw crushers.

High quality parts design using our know-how.

Enhanced parts offer improved safety, easier maintenance for reduced downtime and longer life.

Warranty and quality based

Fast delivery from stock for the most common and needed parts.

When you are interested in buying parts or want to know more about them, please send us an inquiry by filling out the contact form at the end of the page.

Visit: https://matecsolutions.com/index.php/product/vsi-crusher-parts/

0 notes

Text

Stone Crushing Equipment Market Trends, Global Industry Analysis 2021, Size, Share, Competitive Landscape, and COVID-19 Pandemic Presenting Future Opportunities 2027

The recently Published Report titled Stone Crushing Equipment Market Trends, Global Industry Analysis 2021, Size, Share, Competitive Landscape, and COVID-19 Pandemic Presenting Future Opportunities 2027 by Axel Reports offers a comprehensive picture of the market from the global view point as well as a descriptive analysis with detailed segmentation, complete research and development history, latest news, offering a forecast and statistic in terms of revenue during the forecast period from 2021-2027. The report covers a comprehensive analysis of key segments, recent trends, competitive landscape, and key factors playing a substantial role in the market are detailed in the report. The report helps vendors and manufacturers to understand the change in the market dynamics over the years.

Get Sample Copy of this Report with the Latest Market Trend and COVID-19 Impact: https://axelreports.com/request-sample/116222

By Market Players: Metso Sandvik Terex Mark & Wedell Mormak Equipment Ltd Screen Machine Industries Shanghai Shibang Machinery (SBM) Zhejiang Shuangjin Machinery Holdings IROCK Crushers Minyu Machinery Stedman Machine Company Bico Braun International Gujarat Apollo Industries Limited McCloskey International Tesab Engineering Torsa Machines Limited By Type Jaw Crushers Roller Crushers Cone Crushers By Application Mining Quarrying Recycling Other

NOTE: Consumer behaviour has changed within all sectors of the society amid the COVID-19 pandemic. Industries on the other hand will have to restructure their strategies in order to adjust with the changing market requirements. This report offers you an analysis of the COVID-19 impact on the Stone Crushing Equipment market and will help you in strategising your business as per the new industry norms.

Report offers: 1. Insights into the intact market structure, scope, profitability, and potential. 2. Precise assessment of market size, share, demand, and sales volume. 3. Authentic estimations for revenue generation and Stone Crushing Equipment Market development. 4. Thorough study of Stone Crushing Equipment Market companies including organizational and financial status. 5. Perception of crucial market segments including, forecast study. 6. Acumen of upcoming opportunities and potential threats and risks in the market.

The report diversifies the global geographical expanse of the market into five prominent regions as:

North America (United States, Canada and Mexico)

Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe)

Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia)

South America (Brazil, Argentina, Colombia, and Rest of South America)

Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

Key Elements Discussed In The Report: The report then discusses important dynamics on the business drivers that have a major impact on the performance are given in the report. The business drivers are important to the business operations and financial results of the industry. All the drivers are determined in the research study using market analysis. The report is comprehensive coverage of the existing and potential markets along with their assessment of their competitive position in the changing market scenario. It scrutinizes in-depth global market trends and outlook coupled with the factors driving the global Stone Crushing Equipment market, as well as those hindering it.

Get Up to 30% Discount on the first purchase of this report @ https://axelreports.com/request-discount/116222

Moreover, the report throws light on the pinpoint analysis of global Stone Crushing Equipment market dynamics. It also measures the sustainable trends and platforms which are the basic roots behind the market growth. With the help of SWOT and Porter’s five analysis, the market has been deeply analyzed. Consumer behavior is assessed with respect to current and upcoming trends. The report takes a detailed note of the major industrial events in past years. These events include several operational business decisions, innovations, mergers, collaborations, major investments, etc.

Customization of the Report: This report can be customized to meet the client’s requirements. Please connect with our sales team ( [email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +18488639402 to share your research requirements.

ABOUT Axel Reports:

Axel Reports has the most comprehensive collection of market research products and services available on the web. We deliver reports from virtually all major publications and refresh our list regularly to provide you with immediate online access to the world’s most extensive and up-to-date archive of professional insights into global markets, companies, goods, and patterns.

Contact: Axel Reports Akansha G (Knowledge Partner) Office No- P 221 Pune, Maharashtra 411060 Phone: US +18488639402 Web: https://axelreports.com/

0 notes

Text

Global and Regional Stone Crushing Equipment Industry Status and Prospects Professional Market Research Report Standard Version 2021-2027

The global Stone Crushing Equipment market was valued at 3853.8 Million USD in 2020 and will grow with a CAGR of 4.7% from 2020 to 2027, based on our Researcher newly published report.

The prime objective of this report is to provide the insights on the post COVID-19 impact which will help market players in this field evaluate their business approaches. Also, this report covers market segmentation by major market verdors, types, applications/end users and geography(North America, East Asia, Europe, South Asia, Southeast Asia, Middle East, Africa, Oceania, South America).

By Market Verdors:

Download FREE Sample of this Report @ https://www.grandresearchstore.com/report-sample/global-regional-stone-crushing-equipment-2021-2027-194

Metso

Sandvik

Terex

Mark & Wedell

Mormak Equipment Ltd

Screen Machine Industries

Shanghai Shibang Machinery (SBM)

Zhejiang Shuangjin Machinery Holdings

IROCK Crushers

Minyu Machinery

Stedman Machine Company

Bico Braun International

Gujarat Apollo Industries Limited

McCloskey International

Tesab Engineering

Torsa Machines Limited

By Types:

Jaw Crushers

Roller Crushers

Cone Crushers

By Applications:

Mining

Quarrying

Recycling

Key Indicators Analysed

Market Players & Competitor Analysis: The report covers the key players of the industry including Company Profile, Product Specifications, Production Capacity/Sales, Revenue, Price and Gross Margin 2016-2027 & Sales with a thorough analysis of the market?s competitive landscape and detailed information on vendors and comprehensive details of factors that will challenge the growth of major market vendors.

Global and Regional Market Analysis: The report includes Global & Regional market status and outlook 2016-2027. Further the report provides break down details about each region & countries covered in the report. Identifying its sales, sales volume & revenue forecast. With detailed analysis by types and applications.

Market Trends: Market key trends which include Increased Competition and Continuous Innovations.

Opportunities and Drivers: Identifying the Growing Demands and New Technology

Porters Five Force Analysis: The report provides with the state of competition in industry depending on five basic forces: threat of new entrants, bargaining power of suppliers, bargaining power of buyers, threat of substitute products or services, and existing industry rivalry.

Key Reasons to Purchase

To gain insightful analyses of the market and have comprehensive understanding of the global market and its commercial landscape.

Assess the production processes, major issues, and solutions to mitigate the development risk.

To understand the most affecting driving and restraining forces in the market and its impact in the global market.

Learn about the market strategies that are being adopted by leading respective organizations.

To understand the future outlook and prospects for the market.

Besides the standard structure reports, we also provide custom research according to specific requirements.

Get the Complete Report & TOC @ https://www.grandresearchstore.com/manufacturing-and-construction/global-regional-stone-crushing-equipment-2021-2027-194

Table of content

Chapter 1 Industry Overview 1.1 Definition 1.2 Assumptions 1.3 Research Scope 1.4 Market Analysis by Regions 1.4.1 North America Market States and Outlook (2022-2027) 1.4.2 East Asia Market States and Outlook (2022-2027) 1.4.3 Europe Market States and Outlook (2022-2027) 1.4.4 South Asia Market States and Outlook (2022-2027) 1.4.5 Southeast Asia Market States and Outlook (2022-2027) 1.4.6 Middle East Market States and Outlook (2022-2027) 1.4.7 Africa Market States and Outlook (2022-2027) 1.4.8 Oceania Market States and Outlook (2022-2027) 1.4.9 South America Market States and Outlook (2022-2027) 1.5 Global Stone Crushing Equipment Market Size Analysis from 2022 to 2027 1.5.1 Global Stone Crushing Equipment Market Size Analysis from 2022 to 2027 by Consumption Volume 1.5.2 Global Stone Crushing Equipment Market Size Analysis from 2022 to 2027 by Value 1.5.3 Global Stone Crushing Equipment Price Trends Analysis from 2022 to 2027 1.6 COVID-19 Outbreak: Stone Crushing Equipment Industry Impact Chapter 2 Global Stone Crushing Equipment Competition by Types, Applications, and Top Regions and Countries 2.1 Global Stone Crushing Equipment (Volume and Value) by Type 2.1.1 Global Stone Crushing Equipment Consumption and Market Share by Type (2016-2021) 2.1.2 Global Stone Crushing Equipment Revenue and Market Share by Type (2016-2021) 2.2 Global Stone Crushing Equipment (Volume and Value) by Appl

CONTACT US: 276 5th Avenue, New York , NY 10001,United States International: (+1) 646 781 7170 / +91 8087042414 Follow Us On linkedin :- https://www.linkedin.com/company/grand-research-store/

0 notes

Text

Mobile Crushers and Screeners Market Revenue Analysis, Company Revenue Share,

Global Mobile Crushers and Screeners Market has valued US$ 2.8Bn in 2017, and is expected to reach US$ 4.1Bn by 2026, at CAGR of 4.88% during forecast period. The mobile crusher and screener equipment are the machinery used for crushing and processing stones and minerals mostly stationary crushing and screening equipment are mounted on a mobile wheeled or tracked platform. The mobile equipment is transported to the work site where they can manoeuvre within the site to crush and screen the aggregate.

Some major drivers of mobile crushers and screeners market are a requirement of less space, easy installation, high efficiency, convenient mobility and high production capacity. Also, the elimination of the requirement for additional transportation solutions helps in saving a significant amount of capital. The continuous increase of construction and mining industry especially in the countries such as China, the U.S, Australia, India and Brazil is boosting the market for mobile crushers and screeners. Durability and reliability are the key factors restraining the mobile crushers and screeners market.

For more info, Get PDF at:https://www.trendsmarketresearch.com/report/sample/6069

A quarry is dominating the mobile crushers and screeners market during the forecast period. The fastest increasing application sector for mobile crushers and screeners is the construction industry. The increase in infrastructure development in the industrial, commercial and residential sector in the Asia-Pacific region drives the growth.

Mobile crushers accounted for a majority share of around 70% in 2017 and are expected to maintain its dominant position over the analysis period. The equipment’s rise in an application in material recycling sector further contributes to the market growth. The mobile crushers segment is further split into jaw crushers, impact crushers, cone crushers, and others. Jaw crushers were the most dominant type mainly owing to their high application in the primary crushing of aggregates.

Region-wise, Asia-Pacific is the most dominant regional market for mobile crushers and screeners globally during the forecast period. Asia-Pacific region is expected to be the fastest growing regional market due to an increase in infrastructure development in countries such as China, India, and Japan. Growth in urbanization in the region has forced governments in these countries to invest in several infrastructure projects for instance construction of bridges, flyover, and railroads, which help the market growth in the construction segment.

Key players operating in global mobile crusher and screener market, Komatsu Ltd., Sandvik AB, Terex Corporation, SBM Mineral processing, Kleemann GmbH, McCloskey International, Anaconda Equipment Ltd., Metso Corporation, Astec Industries Inc., and Lipmann Milwaukee, Inc., Atlas Copco Corp, CDE Global, RUBBLE MASTER HMH GmbH, IROCK Crushes, SBM Mineral Processing GmbH. Scope of the Global Mobile Crushers and Screeners Market Global Mobile Crushers and Screeners Market, by Machinery Type Mobile Crushers Screeners

Global Mobile Crushers and Screeners Market, by Equipment Usages New Used

You can Buy This Report from Here @ https://www.trendsmarketresearch.com/checkout/6069/Single

Global Mobile Crushers and Screeners Market, by End user Quarry Extraction Construction Mining & Others

Global Mobile Crushers and Screeners Market, by Region North America Europe Asia Pacific Middle East and Africa South America

Get Discount on This Report: https://www.trendsmarketresearch.com/report/discount/6069

Key players operating in Global Mobile Crusher and Screener Market Komatsu Ltd. Sandvik AB Terex Corporation SBM Mineral processing Kleemann GmbH McCloskey International Anaconda Equipment Ltd. Metso Corporation Astec Industries Inc. Lipmann Milwaukee, Inc. Atlas Copco Corp CDE Global RUBBLE MASTER HMH GmbH IROCK Crushes SBM Mineral Processing GmbH.

0 notes