#safety machine supplier in india

Explore tagged Tumblr posts

Text

Machine Guards and Safety Fences Manufacturers in India - Sanocs

Machine Guards and safety fences Manufacturers in India

In India, there is a thriving industry dedicated to the manufacturing of machine guards and safety fences, which are essential components in ensuring workplace safety in industrial settings. These manufacturers play a crucial role in providing high-quality and reliable solutions to protect workers, equipment, and surrounding areas from potential hazards

Machine guard and safety fence manufacturers in India prioritize the safety and well-being of individuals operating machinery by producing robust and durable products. They employ advanced technologies and engineering expertise to create guards and fences that effectively mitigate risks associated with moving parts, high temperatures, and hazardous materials.

Recognizing the diverse needs of different industries, these manufacturers offer a wide range of machine guards and safety fences suitable for various applications. Whether it's for manufacturing, construction, automotive, or other sectors, they provide customized solutions tailored to specific machinery and workplace requirements.

Compliance with national and international safety standards is of utmost importance to Indian manufacturers. They conduct thorough testing and quality control processes to ensure that their products meet or exceed industry regulations. By adhering to these standards, they provide assurance to customers that their machine guards and safety fences are reliable and effective.

Indian machine guard and safety fence manufacturers also prioritize customer satisfaction by offering comprehensive support services. They assist with the installation of provide expert advice on safety protocols, and offer guidance on regulatory co guards and fences, Compliance. Additionally, they often emphasize the importance of regular maintenance and inspections to ensure the continued effectiveness of their products.

Through their commitment to innovation and continuous improvement, these manufacturers contribute to the overall safety culture in India's industrial sector. They actively engage in research and development to develop cutting-edge solutions that address emerging safety challenges. By staying abreast of technological advancements, they provide state-of-the-art machine guards and safety fences that enhance workplace safety and productivity.

Moreover, these manufacturers demonstrate their commitment to sustainability by using eco-friendly materials and promoting resource efficiency in their manufacturing processes. This eco-conscious approach aligns with the global trend of responsible manufacturing and ensures a greener and safer future for industries in India.

In conclusion, machine guard and safety fence manufacturers in India are dedicated to producing high-quality solutions that prioritize workplace safety. With their expertise, technological advancements, and commitment to customer satisfaction, they play a vital role in creating safer work environments across diverse industries. Their contributions bolster India's industrial landscape, fostering a culture of safety and protecting the well-being of workers.

Types of Machine safety in India

In India, there are various types of machine safety fencing available to ensure workplace safety in industrial environments. These safety fencing options are designed to create physical barriers and restrict access to hazardous areas, protecting workers from potential risks and accidents. Here are some common types of machine safety fencing used in India:

1.Perimeter Fencing: Perimeter fencing is a common type of safety fencing that surrounds an entire area or perimeter, creating a secure boundary. It prevents unauthorized access and serves as the first line of defense in safeguarding workers from hazardous machinery and equipment.

Welded Wire Mesh Fencing: Welded wire mesh fencing consists of a series of interconnected wires welded together to form a mesh pattern. This type of fencing provides visibility and airflow while ensuring effective protection. It is commonly used in areas where physical barriers are necessary but visibility is still important.

2.Chain Link Fencing: Chain link fencing is a popular choice due to its durability and affordability. It consists of a woven mesh of interlocking metal wires, forming a sturdy barrier. Chain link fencing is often used in industrial settings to enclose specific machinery or hazardous areas, providing both security and visibility.

3.Expanded Metal Fencing: Expanded metal fencing is made by stretching and expanding a metal sheet to create diamond-shaped openings. This type of fencing offers strength and durability while allowing visibility and airflow. It is commonly used in areas where a higher level of protection is required.

Modular Safety Fencing: Modular safety fencing comprises pre-engineered components that can be easily assembled and disassembled as needed. It provides flexibility in configuring the layout and size of the fencing system. Modular safety fencing is often used in industrial environments where machinery and workspaces require frequent reconfiguration.

5.Plexiglass or Polycarbonate Panel Fencing: Plexiglass or polycarbonate panel fencing consists of transparent or translucent panels made from materials such as acrylic or polycarbonate. It provides visibility while acting as a physical barrier against potential hazards. This type of fencing is commonly used in areas where visual monitoring is crucial, such as robotic work cells.

6: Electric Fencing :Electric fencing incorporates electrified wires to deter unauthorised access to hazardous areas. It delivers a non-lethal electric shock when touched . hed, effectively preventing entry. Electric fencing is often used in high-security industrial environments where additional safety measures are required

Advantage of using Machine Guards and safety fences in Industry

These are just a few examples of the types of machine safety fencing available in India. Each type offers specific features and advantages based on the application requirements, level of protection needed, and visibility considerations. It is important to select the appropriate type of safety fencing based on the specific needs and risks present in the industrial environment.

The advantages of using machine guards and safety fences in the industry are numerous:

1.Worker Safety: Machine guards and safety fences provide a physical barrier that protects workers from potential hazards, reducing the risk of injuries and accidents.

2.Accident Prevention: By restricting access to dangerous areas and ensuring proper separation from moving parts, guards and fences help prevent accidents caused by human error or negligence.

3.Compliance with Regulations: Using machine guards and safety fences helps industries comply with safety regulations and standards set by authorities, avoiding legal penalties and promoting a culture of safety.

Equipment Protection: Guards protect machinery from unauthorized access, vandalism, or accidental damage, ensuring the longevity and reliability of the equipment.

4.Increased Productivity: With improved worker safety, employees feel more secure and confident in their work, leading to increased productivity and efficiency.

5.Risk Mitigation: Machine guards and safety fences help identify and mitigate risks associated with operating machinery, reducing the likelihood of costly accidents or disruptions to operations.

6.Employee Morale: Providing a safe working environment demonstrates a commitment to the well-being of employees, boosting morale, job satisfaction, and overall employee engagement.

7.Enhanced Reputation: Industries that prioritize safety through the use of machine guards and safety fences establish a positive reputation for responsible and ethical business practices.

8.Insurance Benefits: Many insurance providers offer reduced premiums or better coverage for companies that implement adequate safety measures, including machine guards and safety fences.

9.Prevention of Unauthorised Access: Machine guards and safety fences restrict access to hazardous areas, preventing unauthorised personnel from entering and reducing the risk of accidents caused by untrained or unqualified individuals.

Overall, the use of machine guards and safety fences in the industry provides a wide range of advantages, including improved worker safety, compliance with regulations, increased productivity, risk mitigation, and protection for both personnel and equipment.

Sanocs Manufacture helps other industries to solve the problem of machinery Fencing in India .

Sanocs manufacture plays a significant role in helping other industries solve the problem of machinery fencing in India. Sanocs, being a specialized manufacturer, offers innovative and tailored solutions for machinery fencing, addressing the specific needs and challenges faced by different industries.

Here are some ways Sanocs manufacture helps other industries in India:

1.Customization: Sanocs manufacturer understands that different industries have unique requirements when it comes to machinery fencing. They provide customised solutions that are designed to fit specific machinery types, workspace layouts, and safety regulations of different industries.

2.Expertise and Consultation: Sanocs manufacture has a team of experienced professionals who provide expert advice and consultation to industries. They conduct thorough assessments of the workspace, machinery, and potential hazards to offer the most suitable machinery fencing solutions.

3.Compliance with Regulations: Sanocs manufacture ensures that their machinery fencing solutions comply with relevant safety regulations and industry standards in India. They stay up-to-date with the latest regulations, helping industries meet the required safety standards and avoid penalties.

4.Quality and Durability: Sanocs manufacture emphasises the use of high-quality materials and advanced manufacturing techniques to create durable and robust machinery fencing. Their products are designed to withstand the demands of industrial environments, providing long-lasting protection and value for industries.

5.Installation and Support: Sanocs manufacturer offers installation services for their machinery fencing solutions, ensuring proper setup and functionality. They provide ongoing support and maintenance to ensure the continued effectiveness of the fencing systems, addressing any issues or concerns that arise.

6.Cost-effectiveness: Sanocs manufacture understands the importance of cost-effectiveness for industries. They strive to offer machinery fencing solutions that provide optimal safety without compromising the budgetary constraints of businesses.

7.Innovation and Technology: Sanocs manufacture keeps up with the latest advancements in machinery fencing technology. They continuously invest in research and development to offer innovative solutions that address emerging safety challenges and provide enhanced protection.

By providing tailored solutions, expert consultation, compliance with regulations, and quality products, Sanocs manufacture assists other industries in effectively solving the problem of machinery fencing in India. Their expertise and commitment to safety contribute to creating safer work environments and promoting the overall well-being of workers across various industries.

Why choose Us?

Sanocs stands out as a premier choice among machine guards and safety fences manufacturers in India for several reasons.

Firstly, Sanocs offers a highly specialised approach, providing customised solutions tailored to the unique requirements of different industries. Their expertise and consultation services ensure that customers receive the most effective and suitable machinery guarding solutions.

Additionally, Sanocs prioritises quality, using advanced materials and manufacturing techniques to create durable and robust machine guards and safety fences. They maintain compliance with industry standards and regulations, providing peace of mind to customers.

Moreover, Sanocs excels in customer support, offering installation services, ongoing maintenance, and expert guidance on safety protocols. Their commitment to innovation and keeping up with technology trends sets them apart from competitors, ensuring that customers receive cutting-edge solutions for their machinery guarding needs.

For More Information

9879242755

Plot 21, Panchratna Green - Industrial Park, Nr. Pirana Village, Ahmedabad 382425

#Machine Guards and Safety Fences Manufacturers#industrial guarding#machine guarding#industrial machine guarding#safety guards#machine guarding Manufacturers in india#safety guards suppliers in india#guarding equipments dealers in india#imporatance of machine guarding#machine guarding solution#safety machine supplier in india#safety edge supplier in india

0 notes

Text

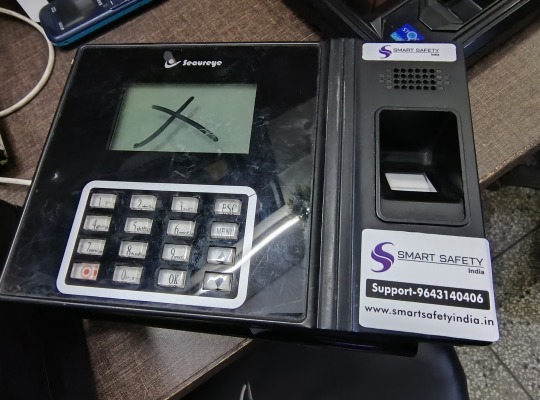

Aadhaar Enabled Biometric Attendance System Delhi,Noida,Gurgaon

Introducing our Aadhaar-Enabled Biometric Attendance System for seamless attendance tracking in Delhi, Noida, and Gurgaon. Ensure accuracy, reduce manual errors, and enhance security with the power of Aadhaar verification. we are providing Aadhaar biometrics for all government organizations & Educational Institutes.

#aadhaarbiometric attendance machine supplier#smart safety india#delhincr#aadhaar#delhi#noida#gurgaon#biometric machine price#biometric attendance machine supplier

0 notes

Text

Rotary 6 Head ROPP Capping Machine

Company Overview: Shiv Shakti Machtech is a Supplier, Exporter, and Manufacturer of Rotary 6 Head ROPP Capping Machine in Ahmedabad, Gujarat, India A Rotary 6 Head ROPP capping machine is an automated system designed to apply ROPP caps to bottles using six rotating capping heads. The rotary mechanism allows for continuous operation and high-speed capping, making it suitable for medium to large-scale production lines. The machine features advanced controls and adjustments to ensure accurate and consistent sealing of bottles. Key Features: Rotary Design: Ensures continuous capping process, enhancing productivity. 6 Head Configuration: Allows simultaneous capping of multiple bottles, maximizing throughput. ROPP Sealing: Provides tamper-evident closure with aluminum caps, ensuring product integrity. Adjustable Speed and Torque: Enables customization according to bottle size and cap type. Stainless Steel Construction: Durable and hygienic material suitable for pharmaceutical and food applications. User-Friendly Interface: Intuitive controls for easy operation and maintenance. Safety Features: Built-in mechanisms for operator safety and operational reliability. Applications: Beverage Industry Pharmaceutical Industry Cosmetic Industry Food Industry Shiv Shakti Machtech is a Rotary 6 Head ROPP Capping Machine in Ahmedabad, Gujarat, India, Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatnam, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar#Chennai#Chhachhrauli

2 notes

·

View notes

Text

One of the top wholesalers, suppliers, and importers of a variety of high-quality Fasteners and Fixing including nuts and bolts, metal screws, machine tools, fastener expansion tubes, heavy-duty anchors, anchors for general fixing, pipe clamps, industrial screws, and other items is Kaizen Metals india Screw India.

Our cutting-edge infrastructure facility located in Jamnagar guarantees standardized product manufacture.

These items, which come in a variety of shapes and sizes, are renowned for their smooth finishes, resistance to corrosion, dimensional precision, and durable construction.

For timely, safe, and secure product delivery to customers, our logistic support specialists leverage a large distribution network.

The superior quality of the things our business creates is the single aspect that supports it, and we never compromise on that in any way.

All of our goods are rigorously tested for their durability and safety. We take steps to ensure that none of our valued customers have ever complained about any of our items.

Our company has achieved an unachievable height that is only attained by a very small number of businesses thanks to our moral business methods and unwavering dedication.

We have been able to provide our clients very consistent and trustworthy items at rock bottom prices because of our extensive experience, thorough understanding of this company range, and the presence of incredibly committed and assiduous employees in our crew.

With the help of a group of knowledgeable, skilled, committed, and diligent individuals, this team approached every assignment with great care. Our staff includes purchasing agents, quality inspectors, packaging specialists, and many more.

These individuals were hired based on their expertise and understanding of their respective fields. Their upbeat demeanor and expert understanding of the field create a productive atmosphere where employees love the work they do. Additionally, this team is periodically refreshed in accordance with the most recent market trends.

#nuts and bolts#metal screw#machine tools#fastener expansion tube#heavy duty anchors#general fixing anchors#pipe clamps#industrial screws#fixings and fasteners#fixings and fastener#screws#bolts#nuts#coach-screws#screw hooks#rivets#cotters#cotter-pins#washers

1 note

·

View note

Text

Did you know? Choosing the right steel grade for #forging? During forging, metal is pressed, pounded, or squeezed under great pressure into high strength elements called forgings.

Preheating the metal to the desired temperature before working it is often (but not always) a part of the method. Forging is a totally different process from casting (or foundry) since the metal used to make forged parts is never melted and poured (as in casting).

The forging process will produce parts that are stronger than those manufactured by the other shaping method. This is often why forgings are nearly always used wherever dependability and human safety are essential. However you will rarely see forgings as they are normally component parts contained within assembled things such as airplanes, cars, tractors, ships, oil drilling instrumentation, engines, missiles and all forms of capital equipment.

Steel is an iron-based alloy with small additions of carbon and other elements that impart improvements in various properties. Steel is among the most useful of metals. It is the metal that has the highest strength per unit cost. There are a wide range of steel compositions as well as a wide range of micro structures that can be produced. These ranges allow a large choice of properties to be achieved within the steel-alloy family.

Properties of Compound Steel: It contains around 1% to 5% of steel that is consolidated with different components. Diverse combination components have remarkable properties and including these components enhance different qualities.

The normal properties of combination steel are Corrosion Resistance, Machinability, Hardenability and Weldability.

Best Steel for Forging: In forging maximum used two steel grades i.e. H13 Tool Steel and DB6 Tool Steel. If you are research company that provide you steel for your forging company the you are at right place.

ViratSpecialSteels – India’s top Largest Supplier, Stockiest, Dealer, Trader Importer and Exporter of H13 Tool Steel and DB6 Tool Steel.

Learn More: https://www.viratsteels.com/h13.html https://www.viratsteels.com/db6.html https://www.db6steel.com/

Any further queries feel free to contact us : Email us: [email protected] or Call us now: +91-98140 21775

We Provide our Special Steels in All Cities in #India:

#ludhiana#india#viratsteels#gurgaon#pune#gurugram#Delhi#Kolkata#Chennai#Bangalore#Hyderabad#Ahmedabad#Pune#Surat#Faridabad#Nashik#Bhiwadi#Jamshedpur#Dehradun#Haridwar#Noida#Rudrapur#Waluj

2 notes

·

View notes

Text

How to Start a Water Bottle Business in India

Starting a water bottle business in India is a promising venture with potential for growth, given the increasing demand for safe drinking water. This guide will walk you through the steps, challenges, and strategies you need to successfully launch a water bottle business in India.

Why Start a Water Bottle Business in India?

The Growing Demand for Packaged Water

India’s population growth and urbanization are driving a substantial increase in demand for bottled water. People are becoming more conscious of water quality and prefer bottled water for convenience, especially in metropolitan areas.

Health and Wellness Trends

Awareness of health and wellness has led to a rise in demand for clean drinking water. As a result, the bottled water industry continues to expand, providing an excellent business opportunity.

Low Initial Investment Opportunities

Compared to other businesses, setting up a water bottling plant can start with a relatively low investment, making it feasible for first-time entrepreneurs.

Market Research and Business Plan

Identifying Your Target Market

Understanding your customer base is crucial. Are you targeting urban consumers, rural areas, or specific commercial clients like hotels and offices?

Analyzing the Competition

Conduct a competitive analysis to identify major players and niche opportunities in the market. This helps you understand pricing, customer preferences, and potential gaps.

Setting Business Goals and Financial Projections

Draft a business plan outlining your objectives, financial projections, and growth strategies. Set realistic goals and estimate costs for production, marketing, and distribution.

Choosing a Business Model

Retail vs. Wholesale Models

Decide if you want to sell directly to consumers or partner with retailers and distributors. Retail models require more customer engagement, while wholesale models often yield larger but less frequent orders.

In-house Bottling vs. Contract Manufacturing

With in-house bottling, you control the entire process, but it requires more investment. Contract manufacturing can save costs but may reduce control over product quality.

Legal Requirements and Certifications

Registering Your Business

Registering your business as a legal entity (such as an LLP, private limited company, or sole proprietorship) is the first step. It’s essential for accessing loans, insurance, and certain business certifications.

FSSAI Certification

An FSSAI license is required for food and beverage businesses in India to ensure your water meets safety standards. It’s a mandatory certificate that signals your compliance with food safety norms.

BIS Certification

The Bureau of Indian Standards (BIS) certification ensures the quality of your water bottles, including the materials and water quality standards.

Additional Permits and Licenses

Check with local authorities for any additional permits, such as environmental clearance, to ensure your bottling plant adheres to government regulations.

Location and Infrastructure

Choosing the Right Location

Choose a location with easy access to your target market and suppliers. Proximity to distribution points reduces transportation costs and enhances product accessibility.

Facility Requirements for Bottling

Your bottling plant should have facilities for purification, bottling, and packaging. Design a layout that supports smooth workflow and compliance with health and safety standards.

Infrastructure for Storage and Transportation

Invest in storage for raw materials and finished products, as well as vehicles or partnerships for product distribution.

Equipment and Machinery

Essential Bottling Equipment

Key machinery includes filling, capping, and labeling machines. Choose machinery that aligns with your production volume and budget.

Water Purification Systems

Install a reliable purification system that meets regulatory standards to ensure water quality. Common methods include reverse osmosis, UV treatment, and ozonation.

Quality Control and Testing Machinery

Quality control ensures your water meets health and safety standards. Invest in testing equipment to monitor water purity, pH levels, and more.

Sourcing Water and Raw Materials

Selecting a Reliable Water Source

A stable water source is vital for production continuity. Ensure your water source complies with regulatory standards and does not deplete local resources.

Packaging Materials (Bottles, Caps, Labels)

Choose durable and eco-friendly materials to improve product appeal and sustainability. Build partnerships with suppliers to ensure a steady supply.

Water Purification and Filtration Process

Common Purification Methods

Effective methods include filtration, reverse osmosis, UV treatment, and mineral adjustment. Choose a combination that best suits your water source and desired product quality.

Maintaining Water Quality Standards

Regularly test your water to maintain consistent quality, as substandard products can harm your brand and lead to regulatory penalties.

Branding and Marketing Strategy

Naming and Logo Design

Your brand name and logo should reflect your mission. Focus on simplicity, cleanliness, and trustworthiness to resonate with customers.

Packaging and Labeling

Label your bottles with essential details like mineral content, source, and certification logos. Visually appealing and informative packaging enhances your brand’s visibility.

Marketing Channels (Digital, Offline)

Leverage digital marketing, social media, and search engine optimization to reach customers online. Offline strategies can include partnerships with retailers, hoardings, and in-store promotions.

Distribution and Sales Channels

Retail Outlets and Supermarkets

Securing placement in retail stores and supermarkets increases your product’s visibility and accessibility to consumers.

Online Platforms

List your products on e-commerce sites and food delivery apps. An online presence expands reach and offers convenience to customers.

Building Partnerships with Distributors

Distributors help expand your reach and manage logistics, especially in areas beyond your direct distribution network.

Pricing Strategy

Competitive Pricing Models

Analyze competitors’ pricing and consider production costs to set a price that attracts customers while ensuring profitability.

Wholesale vs. Retail Pricing

Offer bulk discounts to wholesalers or retailers for larger orders. Retail prices can be set slightly higher to maximize per-unit profit.

Challenges and How to Overcome Them

Regulatory Challenges

Complying with various regulations can be complex. Stay updated on changes in industry regulations and maintain documentation for all certifications.

Competition from Big Brands

Smaller brands often struggle against established brands. Differentiate by focusing on quality, branding, and targeted marketing to create a unique selling point.

Managing Operational Costs

Monitor expenses carefully and optimize production processes to maintain profitability without compromising on quality.

Sustainability in Water Bottling

Eco-Friendly Packaging

Consider using recycled and biodegradable materials. Eco-friendly packaging not only helps the environment but also appeals to a growing base of eco-conscious customers.

Water Conservation Practices

Implement sustainable practices, such as reusing water where possible and minimizing waste, to conserve resources and reduce operational costs.

Why Choose Canadian Crystalline for Your Mineral Water Plant?

At Canadian Crystalline, we’re proud to be a global leader as a mineral water plant manufacturer, bringing decades of expertise, unmatched quality to the water bottling industry. Our end-to-end solutions cover everything from water purification and bottling to advanced filtration and packaging systems, customized to meet each client’s specific needs.

What Sets Us Apart?

Industry Expertise: With extensive experience in water treatment and bottling, Canadian Crystalline offers solutions backed by proven expertise and innovation.

Advanced Technology: We use the latest technology to ensure efficient and sustainable production, reducing waste and optimizing energy use.

Quality and Compliance: Our systems are built to meet and exceed industry standards, including FSSAI, BIS, and international certifications, so you’re assured of safe, high-quality water production.

Complete Customization: We design and build plants tailored to your unique requirements, whether you’re a small startup or an established brand looking to scale.

Choose Canadian Crystalline to start or upgrade your water bottling business with a trusted partner committed to excellence and customer success. Let’s help you make your mark in the booming mineral water industry!

0 notes

Text

Overview of Anesthesia Machine Suppliers

Anesthesia machines are critical components in modern surgical settings, providing the necessary gases and monitoring capabilities to ensure patient safety and comfort during procedures. The market for these machines is rapidly evolving, driven by technological advancements and an increasing demand for high-quality healthcare. This article explores the key suppliers of anesthesia machines, the market dynamics, and emerging trends within this vital sector.

Key Players in the Anesthesia Machine Market

The global anesthesia machine market is projected to grow significantly, with a valuation of approximately USD 8.84 billion in 2023 and an expected compound annual growth rate (CAGR) of 9.21% over the next five years. Major players in this market include:

- Medtronic

- GE HealthCare

- Philips

- Draeger

- Getinge

- Penlon

- Heyer Medical

These companies are recognized for their innovation and extensive product lines, which cater to various healthcare needs. For example, Medtronic has introduced advanced platforms aimed at enhancing collaboration among healthcare professionals. Draeger remains a leader in high-end models that cater to niche markets, particularly in regions like India where the demand for sophisticated anesthesia solutions is growing.

Market Dynamics

Regional Insights

The anesthesia equipment market is characterized by significant regional variations. North America holds the largest share due to high healthcare expenditure and a growing number of hospitals. The European market follows closely, driven by the adoption of modern medical technologies. Meanwhile, the Asia-Pacific region is expected to witness rapid growth, fueled by rising healthcare awareness and increasing disposable incomes.

Challenges Faced by Suppliers

Despite the promising growth prospects, suppliers face several challenges:

- High Costs: Anesthesia machines are expensive, which can be a barrier for healthcare facilities in regions with limited budgets.

- Regulatory Compliance: Manufacturers must navigate stringent regulations that can complicate market entry for new players.

- Training Needs: The effective operation of anesthesia machines requires skilled professionals, highlighting a gap in training programs in some regions.

Technological Advancements

The landscape of anesthesia machines is marked by relentless technological transformation. Modern machines integrate multiple subsystems that enhance their functionality:

1. Gas Supply Systems: These include pipelines and cylinders that deliver oxygen and anesthetic gases.

2. Flow Measurement: Accurate flowmeters ensure precise gas delivery.

3. Vaporization Systems: Advanced vaporizers mix anesthetic agents effectively.

4. Ventilation Support: Integrated ventilators assist in patient breathing during surgery.

5. Monitoring Systems: Continuous monitoring of vital signs ensures patient safety throughout the procedure.

Recent innovations have also led to the development of compact designs suitable for space-restricted environments, as well as MRI-compatible models that can be safely used in magnetic fields.

Safety Features

Safety is paramount when it comes to anesthesia delivery systems. Modern anesthesia machines are equipped with numerous safety features designed to minimize risks associated with gas delivery and patient monitoring:

- Redundant Systems: These ensure that if one system fails, another can take over seamlessly.

- Automated Checks: Many contemporary machines perform automated pre-use checks to verify functionality before procedures begin.

- User Training: Manufacturers emphasize training for operators to reduce misuse and enhance patient safety.

Future Trends

As the healthcare landscape continues to evolve, several trends are shaping the future of anesthesia machines:

- Integration with Digital Technologies: The incorporation of digital simulation training and telemedicine capabilities is becoming increasingly common among suppliers like GE HealthCare.

- Focus on Patient-Centric Solutions: There is a growing emphasis on devices that not only deliver anesthesia but also provide comprehensive patient monitoring data at the point-of-care.

- Sustainability Efforts: Suppliers are exploring environmentally friendly practices in manufacturing and operation to reduce their carbon footprint.

Conclusion

The anesthesia machine market is poised for significant growth driven by technological advancements and an increasing focus on patient safety. Key suppliers are adapting to changing demands through innovation and strategic partnerships while navigating challenges related to costs and regulatory compliance. As healthcare continues to evolve, so too will the tools that support it, ensuring that anesthesia delivery remains safe, efficient, and effective for all patients undergoing surgical procedures.

0 notes

Text

Nylock Nuts Manufacturer, Supplier & Exporter

What are Nylock Nuts?

Nylock Nuts are specially designed fasteners to avoid loosening under vibration and torque. These are excellent for applications requiring maximum stability and safety. They come with a nylon insert which develops friction against the bolt. Ananka Group is pleased to be one of the top manufacturers, suppliers, and exporters of Nylock Nuts in India. At Ananka Group, we guarantee quality and flexibility to use Nylock Nuts in various sizes, material, and grades that have been designed as per a varied industrial requirement.

Ananka Group is a company with a good name in the fastener industry, especially known for high quality and good customer service. Our Nylock Nuts are manufactured according to international standards, which makes them durable and reliable. We can provide solutions for construction, infrastructure projects, machinery, and other requirements for your needs.

About Nylock Nuts

Nylock Nuts, more commonly referred to as Nylon Insert Lock Nuts, are used in applications where vibration would loosen a nut. Their primary feature is the nylon insert located at the top of the nut, acting as the locking mechanism. As a bolt passes through a nut, the nylon inserts lock firmly on it such that loosening of the nut is minimized.

Applications of Nylock Nuts:

Construction: Used in construction sites where there are high-tension conditions such as bridges, highways, and buildings.

Automotive Industry: They are used in automobiles to provide tight locking of fasteners even on vibration.

Industrial Machinery: Used in machines where continuous motion will cause loose locking of fasteners.

Electrical and Electronics: They are used to lock sensitive components in place.

Benefits of Nylock Nuts:

Prevention of Loosening: The loosening is considerably reduced even after motion under vibrations by Nylock nuts.

Reusable: They can be reused multiple times without compromising their efficiency.

Variety of Materials and Sizes: Available in various sizes and materials, Nylock Nuts can meet the needs of diverse applications.

Nylock Nuts Specifications

Property Specification

Size Range M3 to M48

Material Carbon Steel, Stainless Steel, Brass, and more

Standard Compliance DIN, ISO, ASTM

Surface Finish Zinc Plated, Plain, Hot Dip Galvanized, etc.

Nylock Nuts Materials / Grades

Ananka Group offers Nylock Nuts in multiple materials and grades, each suited to specific applications:

Stainless Steel Nylock Nuts -all stainless steel for excellent corrosion and strength applications- for outdoor and especially marine applications.

Carbon Steel Nylock Nuts - for general applications, strong, tensile strength

Brass Nylock Nuts - ideal to be used in electrical conductive environments

Alloy Steel Nylock Nuts-heat-treated for further strength and wear

Grade of Availability

Grade A - Fine finish and high accuracy for general applications.

Grade B - Medium strength and structural applications.

Grade C - High-strength applications for safety-related conditions

Conclusion

Nylock Nuts are critical in many industries and remain a sure way of holding things together. The creation and use of a nylon insert have made it possible for the nut to have an extended period of holding time even under high vibration environments. Ananka Group offers clients a wide range of different sizes, materials, and grades, making it stand out among the competition from other fields. Whatever the machinery may be, including building and automotive, our Nylock Nuts will give unmatched durability and performance.

Frequently Asked Questions (FAQ)

1. What distinguishes Nylock Nuts from other nuts?

Nylock Nuts have a nylon insert that creates friction between the bolt and the nut preventing the nut from coming loose when the bolt undergoes vibrations. This gives them special value in applications where stability and security are essential.

2. Are Nylock Nuts reusable?

Nylock Nuts may be used many times, but with every re-use, the nylon insert loses some of its efficiency. When critical application usage is involved, it's always best to replace them after each time they're disassembled.

3. Are Nylock Nuts resistant to corrosion?

Yes, particularly if the material is of corrosion-resistant metal like stainless steel or if a protective finish including zinc plating is included. This is dependent upon the material and the environment in which they are placed.

4. Where can I find Nylock Nuts of various sizes and grades?

Ananka Group offers Nylock Nuts in many sizes, materials, and grades to meet industrial demands for industrial applications. Contact us to discuss your requirements and our team will assist you in finding the perfect solution.

5. What are the standard specifications for Nylock Nuts?Material type and standards compliance such as DIN, ISO, and ASTM may also be included in the standard sizes for Nylock Nuts.

0 notes

Text

Partition Walls Manufacturers, Suppliers and Dealers in India -Sanocs

Partition Walls Manufacturers, Suppliers and Dealers in India - Sanocs

Sanocs stands as a premier name among Partition Walls Manufacturers, Suppliers, and Dealers in India, renowned for delivering top-notch products and solutions across diverse industries. As a leading Partition Walls Suppliers, and Dealers in India, we pride ourselves on our commitment to quality, innovation, and customer satisfaction.

Our range of partition walls is designed to cater to the unique needs of modern workplaces, commercial spaces, and industrial facilities. With a focus on functionality, durability, and aesthetics, As a leading partition wall manufacturer, we utilize premium materials and advanced manufacturing techniques in crafting our partition walls, guaranteeing superior performance and durability.

As a trusted Partition Walls Manufacturer in India, Sanocs offers a comprehensive range of partition wall solutions to meet various requirements. Whether you need partitions for office spaces, conference rooms, retail outlets, or healthcare facilities, we have the expertise and capabilities to deliver customized solutions tailored to your specific needs.

In addition to manufacturing, Sanocs also serves as a reliable supplier and dealer of partition walls, providing seamless access to our high-quality products across India. Our extensive network of distributors ensures timely delivery and installation, allowing customers to enhance their spaces with ease and convenience.

At Sanocs, we understand the importance of providing value-added solutions that enhance productivity, privacy, and aesthetics in commercial and industrial settings. That's why our partition walls are not only functional but also customizable to complement the design aesthetics of any space.

As a trusted Partition Walls supplier in India, Sanocs is committed to exceeding customer expectations by delivering superior products, exceptional service, and cost-effective solutions. Whether you're looking to create collaborative work environments, separate functional areas, or enhance privacy, Sanocs has the expertise and resources to meet your needs.

In conclusion, Sanocs emerges as a leading Partition Walls Manufacturer, Supplier, and Dealer in India, offering high-quality products and solutions to enhance the functionality and aesthetics of various spaces. With our commitment to quality, innovation, and customer satisfaction, we strive to be your preferred partner for all your partition wall needs.

For More Information

9879242755

Plot 21, Panchratna Green - Industrial Park, Nr. Pirana Village, Ahmedabad 382425

#Partition Walls Manufacturer#Partition Walls supplier in india#industrial guarding#industrial machine guarding#safety gurds#machine guarding Manufacturers in india#Safety inte machine safety guards supplier in india#guarding equipments dealers in india#imporatance of machine guarding#machine guarding solution#safety machine supplier in india#safety edge supplier in india

0 notes

Text

Today, Smart Safety India repaired and installed many biometric attendance machines for clients. we have 5 years of experience as technical engineers that repair any brand biometric devices. so if any requirements for biometric repair and support then contact us.

Call Us:-96431 40406

#biometric attendance machine supplier#biometicrepairservice#biometicinstalltion#biometric machine price#smart safety india

0 notes

Text

Understanding Types and Uses of Stainless Steel Fasteners

Ananka Fasteners is the leading Top-quality Stainless Steel Fasteners Manufacturer in India. Highest quality fasteners are supplied by us to several industries worldwide. A vast array of forms, sizes, and dimensions are available for fasteners. To accommodate specific customer needs, they can also be altered. We are also a leading custom fastener manufacturer in India.

SS Fasteners are used to connect or secure a range of things. In several industries, such as building, manufacturing, transportation, and home goods, they are essential components. Fasteners prevent pieces from moving or separating and provide mechanical strength and integrity to integrated structures.

Types of Fasteners:

Screws:

Wood Screws: With a coarse thread and a sharp point for effortless penetration, these screws are made specifically for use in wood applications.

Machine Screws: Available in a range of sizes and materials, machine screws are usually used with nuts or tapped holes.

Self-Tapping Screws: These screws don't require pre-drilling because they have a sharp point and form their own threads as they penetrate the material.

Bolts:

Hex bolts: Easily identified by their full threads and hexagonal heads, these bolts are frequently utilised in structural and building applications.

Bolts for Carriage: Carriage bolts, which have square necks and round heads, are frequently used in wood applications where one side of the wood needs to be smooth.

Nuts:

Hex bolts: These bolts are easily recognized by their hexagonal heads and full threads, and they are widely used in building and structural applications.

Lock Nuts:

Lock nuts are available in a variety of styles, including serrated and nylon-insert, and are made to withstand loosening from vibrations..

Washers:

Flat Washers: Distributing the load and creating a smooth surface, flat washers are positioned beneath nuts or bolt heads.

Spring washers: These washers are designed like springs and provide tension to stop vibration-induced loosening.

Anchors:

Concrete anchors: These anchors, which come in a variety of designs such as wedge and sleeve anchors, are used to fasten objects to concrete surfaces.

Drywall anchors: Made of lightweight materials, drywall anchors offer support for gypsum board and other similar materials.

Applications:

Aerospace:

Specialised fasteners are necessary for the assembly of aircraft and spacecraft because aerospace applications require accuracy and dependability.

Woodworking:

Fasteners, such as wood screws, are essential to woodworking projects because they provide a stable connection between wooden parts.

Construction:

In order to give buildings and bridges the strength and stability they require, bolts and nuts are widely used in structural applications.

Automotive Industry:

Fasteners, such as bolts and screws, are essential for assuring dependability and safety when assembling different car parts.

Stainless Steel Fasteners Manufacturer are used in heat exchangers, instrumentation, and other applications because of our extensive industry experience in sourcing, manufacturing, and exporting. In difficult environments, they are often employed for delicate functions. All applications, whether they are seawater, nuclear, offshore (petrochemical and buoyancy), pumps, valves, or other, require exceptional service and dependability.

For more details:

Web site : anankafasteners.com

Product Source: SS Fasteners Supplier in India

#Stainless SteelFastenersManufacturerinIndia#StainlessSteelFastenersManufacturer#StainlessSteelFasteners

1 note

·

View note

Text

Automotive NVH Materials Market 2030 - In-Depth Analysis on Size, Trends & Prominent Key Players

The global market for automotive noise, vibration, and harshness (NVH) materials was estimated at USD 9.84 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2030. One of the primary drivers of growth in the NVH materials market is the increased global production and use of heavy commercial vehicles across various end-use industries. These vehicles generate noise and vibrations due to both structure-borne and airborne sources, which can diminish passenger comfort and reduce vehicle longevity. Automotive NVH materials help to mitigate these issues, enhancing ride quality and overall passenger experience. This has created a strong demand for NVH materials in the automotive industry as manufacturers strive to improve the comfort and durability of their vehicles.

The focus on managing acoustic properties, vibration, and harshness in both passenger and commercial vehicles has increased among automotive manufacturers. This focus on NVH control is essential not only for enhancing passenger comfort but also for improving fuel economy and cabin sound levels, which boosts the durability of vehicle components. Changes in consumer preferences toward vehicles with better acoustic management and comfort are expected to further drive the demand for NVH materials in the automotive industry. Additionally, the increasing adoption of active noise control systems in cars, which cater to consumer demands for quieter and safer rides, along with evolving regulatory standards, are further fueling growth in the automotive NVH materials market.

The value chain in the NVH materials market includes suppliers of raw materials, manufacturers, converters, distributors, and end-users. Converters play a pivotal role, transforming raw materials into final products such as foam laminates and molded rubber components that reduce noise and vibration. Manufacturers may either sell NVH materials directly to consumers through their own brands or supply them to third-party distributors and dealers.

Gather more insights about the market drivers, restrains and growth of the Automotive NVH Materials Market

Regional Insights:

Asia Pacific Automotive NVH Materials Market Trends

Asia Pacific dominated the automotive NVH materials market in 2022, accounting for about 47% of total market revenue. Emerging economies in the region, including India, China, and Indonesia, have witnessed rapid economic growth, driven by industrialization, urbanization, and population growth. As living standards in these countries rise, the demand for enhanced ride quality, comfort, and safety in vehicles has increased. Growing disposable incomes have led to a preference for vehicles that offer better acoustic insulation and overall comfort, spurring demand for NVH materials in the region.

China

China, the world's largest automobile producer, has experienced significant urbanization and industrial growth, fueling a demand for personal vehicles. The trend of rural-to-urban migration in China, coupled with higher disposable incomes, has bolstered the demand for passenger cars, which in turn drives the demand for automotive NVH materials.

North America Automotive NVH Materials Market Trends

In North America, the automotive industry saw a production increase of about 5% over recent years. The region benefits from the presence of key domestic automotive manufacturers, which are influenced by strict fuel economy regulations. These regulations necessitate the use of NVH materials to optimize vehicle performance. North America’s abundant supply of raw materials, such as engineering plastics and rubber, further supports the growth of the NVH materials market.

Browse through Grand View Research's Category Advanced Interior Materials Industry Research Reports.

The global machine tools market size was estimated at USD 97,927.5 million in 2024 and is and is projected to grow at a CAGR of 7.0% from 2025 to 2030.

The global scissor lift market size was valued at USD 3.43 billion in 2024 and is expected to grow at a CAGR of 7.1% from 2025 to 2030.

Key Companies & Market Share Insights

The global NVH materials market is highly competitive due to the presence of numerous sellers and the potential for differentiation in product types and prices. Key players in the market focus on innovation and custom application development to remain competitive. Customized materials, tailored to meet specific noise and vibration reduction requirements, are becoming a key strategy for leading companies. Additionally, mergers and acquisitions are common among industry players seeking to broaden their product portfolios and enhance NVH performance, thus securing a competitive advantage.

By investing in innovative NVH solutions and pursuing strategic acquisitions, companies aim to meet evolving customer needs while addressing regulatory requirements and market demands for quieter, safer, and more comfortable vehicles.

Key Automotive NVH Materials Companies

Creative Foam Corporation

BRC Rubber & Plastics Inc.

Wolverine Advanced Materials

ElringKlinger AG

Hoosier Gasket Corporation

Industry Products Co.

Interface Performance Materials

Hematite

Plastomer Corporation

Rogers Foam Corporation

Swift��Components Corp

Unique Fabricating Inc.

Avery Dennison

KKT Holding GmbH

Nicholson Sealing Technologies Ltd.

KOPP GmbH & Co. KG

Janesville Acoustics

Order a free sample PDF of the Automotive NVH Materials Market Intelligence Study, published by Grand View Research.

0 notes

Text

Automotive NVH Materials Market Comprehensive Analysis and Future Estimations by 2030

The global market for automotive noise, vibration, and harshness (NVH) materials was estimated at USD 9.84 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2030. One of the primary drivers of growth in the NVH materials market is the increased global production and use of heavy commercial vehicles across various end-use industries. These vehicles generate noise and vibrations due to both structure-borne and airborne sources, which can diminish passenger comfort and reduce vehicle longevity. Automotive NVH materials help to mitigate these issues, enhancing ride quality and overall passenger experience. This has created a strong demand for NVH materials in the automotive industry as manufacturers strive to improve the comfort and durability of their vehicles.

The focus on managing acoustic properties, vibration, and harshness in both passenger and commercial vehicles has increased among automotive manufacturers. This focus on NVH control is essential not only for enhancing passenger comfort but also for improving fuel economy and cabin sound levels, which boosts the durability of vehicle components. Changes in consumer preferences toward vehicles with better acoustic management and comfort are expected to further drive the demand for NVH materials in the automotive industry. Additionally, the increasing adoption of active noise control systems in cars, which cater to consumer demands for quieter and safer rides, along with evolving regulatory standards, are further fueling growth in the automotive NVH materials market.

The value chain in the NVH materials market includes suppliers of raw materials, manufacturers, converters, distributors, and end-users. Converters play a pivotal role, transforming raw materials into final products such as foam laminates and molded rubber components that reduce noise and vibration. Manufacturers may either sell NVH materials directly to consumers through their own brands or supply them to third-party distributors and dealers.

Gather more insights about the market drivers, restrains and growth of the Automotive NVH Materials Market

Regional Insights:

Asia Pacific Automotive NVH Materials Market Trends

Asia Pacific dominated the automotive NVH materials market in 2022, accounting for about 47% of total market revenue. Emerging economies in the region, including India, China, and Indonesia, have witnessed rapid economic growth, driven by industrialization, urbanization, and population growth. As living standards in these countries rise, the demand for enhanced ride quality, comfort, and safety in vehicles has increased. Growing disposable incomes have led to a preference for vehicles that offer better acoustic insulation and overall comfort, spurring demand for NVH materials in the region.

China

China, the world's largest automobile producer, has experienced significant urbanization and industrial growth, fueling a demand for personal vehicles. The trend of rural-to-urban migration in China, coupled with higher disposable incomes, has bolstered the demand for passenger cars, which in turn drives the demand for automotive NVH materials.

North America Automotive NVH Materials Market Trends

In North America, the automotive industry saw a production increase of about 5% over recent years. The region benefits from the presence of key domestic automotive manufacturers, which are influenced by strict fuel economy regulations. These regulations necessitate the use of NVH materials to optimize vehicle performance. North America’s abundant supply of raw materials, such as engineering plastics and rubber, further supports the growth of the NVH materials market.

Browse through Grand View Research's Category Advanced Interior Materials Industry Research Reports.

The global machine tools market size was estimated at USD 97,927.5 million in 2024 and is and is projected to grow at a CAGR of 7.0% from 2025 to 2030.

The global scissor lift market size was valued at USD 3.43 billion in 2024 and is expected to grow at a CAGR of 7.1% from 2025 to 2030.

Key Companies & Market Share Insights

The global NVH materials market is highly competitive due to the presence of numerous sellers and the potential for differentiation in product types and prices. Key players in the market focus on innovation and custom application development to remain competitive. Customized materials, tailored to meet specific noise and vibration reduction requirements, are becoming a key strategy for leading companies. Additionally, mergers and acquisitions are common among industry players seeking to broaden their product portfolios and enhance NVH performance, thus securing a competitive advantage.

By investing in innovative NVH solutions and pursuing strategic acquisitions, companies aim to meet evolving customer needs while addressing regulatory requirements and market demands for quieter, safer, and more comfortable vehicles.

Key Automotive NVH Materials Companies

Creative Foam Corporation

BRC Rubber & Plastics Inc.

Wolverine Advanced Materials

ElringKlinger AG

Hoosier Gasket Corporation

Industry Products Co.

Interface Performance Materials

Hematite

Plastomer Corporation

Rogers Foam Corporation

Swift Components Corp

Unique Fabricating Inc.

Avery Dennison

KKT Holding GmbH

Nicholson Sealing Technologies Ltd.

KOPP GmbH & Co. KG

Janesville Acoustics

Order a free sample PDF of the Automotive NVH Materials Market Intelligence Study, published by Grand View Research.

0 notes

Text

Laser Engraving and Cutting Machine in Maharashtra

Success Technologies is a Manufacturer, and Supplier of Laser Engraving and Cutting Machine in Maharashtra, India. Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. Our Laser Engraving & Cutting Machine is a versatile, high-performance device designed to deliver precision engraving and efficient cutting capabilities. Ideal for a wide range of industrial, commercial, and creative applications, this machine is perfect for crafting intricate designs, personalizing products, and cutting various materials. It offers exceptional accuracy, speed, and durability, making it a reliable choice for diverse needs. Features: High Precision Performance Wide Material Compatibility Adjustable Power and Speed Robust and Durable Construction Compact and Space-Saving Design Easy Maintenance and Longevity Applications: Prototyping and Model Making: Ideal for creating prototypes, models, and detailed product designs. Woodworking: Perfect for engraving and cutting wood for furniture, signage, and décor. Trophies and Awards: Used for creating custom trophies, plaques, and awards. Art and Craft: Enables intricate designs for artists and crafters. Custom Products and Gifts: Personalizes a variety of products, from gifts to promotional items. What materials can laser engraving and cutting machines work with? Laser machines can work on materials such as wood, acrylic, metal, glass, leather, fabric, rubber, plastics, and even certain types of stone. Different machines are suited to specific materials based on the type of laser. Are laser cutting and engraving machines safe to use? Yes, most modern machines come with safety enclosures, ventilation systems, and other safety features. However, it’s essential to follow operating guidelines to ensure safe use, especially when working with materials that produce fumes. Success Technologies is a Manufacturer, and Supplier of Laser Engraving and Cutting Machine in Maharashtra, India Including Mumbai, Pune, Nagpur, Thane, Pimpri-Chinchwad, Nashik, Kalyan-Dombivli, Vasai-Virar, Aurangabad, Navi Mumbai, Solapur, Mira-Bhayandar, Bhiwandi-Nizampur, Jalgaon, Amravati, Nanded-Waghala, Kolhapur, Ulhasnagar, Sangli-Miraj-Kupwad, Malegaon, Akola, Latur, Dhule, Ahmednagar, Chandrapur, Parbhani, Ichalkaranji, Jalna, Ambarnath, Bhusawal, Panvel, Badlapur, Beed, Gondia, Satara, Barshi, Yavatmal, Achalpur, Osmanabad, Nandurbar, Wardha, Udgir, Hinganghat. For detailed information or inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Achalpur#Ahmedabad#Ahmednagar#Akola#Ambarnath#Amravati#Aurangabad#Badlapur#Barshi#Beed#Bhiwandi-Nizampur#Bhusawal#Chandrapur#Dhule#Exporter#ExporterofLaserEngravingandCuttingMachine#Gondia#Gujarat#Hinganghat#Ichalkaranji#India#Jalgaon#Jalna#Kalyan-Dombivli#Kolhapur#LaserEngravingandCuttingMachine#LaserEngravingandCuttingMachineinAhmedabad#LaserEngravingandCuttingMachineinIndia#LaserEngravingandCuttingMachineinMaharashtra#Latur

0 notes

Text

Alloy Steel WP91 Buttweld Fittings Suppliers In India

Alloy Steel WP91 Buttweld Fittings Manufacturers In India,Supplier In India ,Stockists In India,Exporter In India

Introduction:- Alloy Steel WP91 Buttweld Fittings Manufacturers In India

Alloy Steel WP91 Buttweld Fittings Manufacturers in India are critical suppliers of high-quality piping components designed for applications that require exceptional strength, durability, and resistance to high temperatures and pressures. These manufacturers produce WP91 buttweld fittings made from P91 alloy steel, a chromium-molybdenum steel known for its excellent mechanical properties, including high tensile strength, corrosion resistance, and ability to withstand extreme temperature conditions.

India has a rapidly growing industrial landscape, with significant demand for high-performance materials in sectors such as power generation, petrochemical, oil and gas, chemical processing, and construction. The demand for WP91 alloy steel buttweld fittings has grown as these industries require reliable piping solutions that can endure the rigors of high-pressure steam systems, high-temperature applications, and corrosive environments.

WP91 buttweld fittings are indispensable in critical infrastructure projects such as thermal power plants, refineries, and chemical plants, where the integrity and reliability of piping systems are paramount to maintaining safety and efficiency.

Product Overview:-

Alloy Steel WP91 Buttweld Fittings epitomize strength, durability, and corrosion resistance within industrial piping systems. Manufactured and supplied by Shasan Piping Solution, a trusted name in the industry, these fittings are meticulously designed to meet the stringent requirements of diverse applications. The unique composition of the alloy imparts enhanced resistance to high temperatures and corrosive environments, making Alloy Steel WP91 Buttweld Fittings a reliable choice for critical operations.

Shasan Piping Solution has solidified its position as a key player in the manufacturing and supply of Alloy Steel WP91 Buttweld Fittings. With an unwavering commitment to quality and innovation, the company has earned a stellar reputation for delivering products that adhere to international standards. Shasan Piping Solution's state-of-the-art facilities ensure precision manufacturing, and their team of experts focuses on providing tailored solutions to meet the specific needs of diverse industries.

Specifications:-

Specifications

:

ASTM A234 / ASME SA234

Size

:

1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated)

Standards

:

ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Thickness

:

Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

Type

:

Seamless / Welded / Fabricated

Benefits:-

Exceptional Weldability: Alloy Steel WP91 Buttweld Fittings from Shasan Piping Solution boast exceptional weldability, facilitating easy and secure installations in various piping systems.

Robust Mechanical Properties: The fittings exhibit robust mechanical properties, making them well-suited for high-pressure applications in industries such as oil and gas, power generation, and chemical processing.

Free-Machining Attributes: Shasan Piping Solution emphasizes the free-machining attributes of these fittings, contributing to efficient fabrication processes and ensuring seamless integration into complex industrial setups.

These fittings find applications across a spectrum of industries, including oil and gas, where they play a crucial role in the construction and maintenance of pipelines. In the power generation sector, Alloy Steel WP91 Buttweld Fittings contribute significantly to power plant infrastructure. Their corrosion resistance makes them an ideal choice for chemical processing plants, ensuring the safe transport of corrosive substances. With Shasan Piping Solution's unwavering dedication to quality, Alloy Steel WP91 Buttweld Fittings stand as a testament to reliability and performance in the most demanding industrial environments.

Conclusions:-

WP91 Buttweld Fittings are crucial in maintaining the integrity of high-performance piping systems that must withstand extreme temperatures, pressures, and mechanical stress. Their robust design and superior properties make them a popular choice for industries requiring advanced materials for safety, efficiency, and longevity.

Email Id:[email protected]

Contact Number:-88797-09191

0 notes

Text

Stainless Steel 309 Plates Manufacturers in India

Stainless Steel 309 Sheets are extensively valued for their first rate oxidation resistance and immoderate-temperature electricity, making them an excellent preference for applications withinside the petrochemical, electricity generation, and aerospace sectors. As foremost manufacturers, suppliers, stockists, and exporters of Stainless Steel 309 Sheets, we`re dedicated to supplying a product that meets the stringent desires of various industries. Stainless Steel 309, an austenitic chromium-nickel alloy, is engineered to keep structural integrity at immoderate temperatures as a lot as 1100°C (2012°F). The immoderate chromium content, complemented thru manner of approach of nickel, enhances the alloy's oxidation resistance, efficiently preventing scaling and presenting excellent protection in the direction of thermal fatigue and stress corrosion cracking Stainless Steel 309 Plates are extensively valued for his or her first rate oxidation resistance and excessive-temperature electricity, making them best to be used in petrochemical, energy generation, and aerospace industries.

As main manufacturers, suppliers, stockists, and exporters of Stainless Steel 309 Plates, we're proud to provide a product that meets the rigorous necessities of diverse business sectors. Stainless Steel 309, an austenitic chromium-nickel steel, is engineered to face up to excessive temperatures as much as 1100°C (2012°F) whilst keeping its structural integrity. Its advanced oxidation resistance is mostly because of its excessive chromium content, blended with nickel, which complements resistance to scaling and gives first rate safety towards thermal fatigue and pressure corrosion cracking.

Our Stainless Steel 309 Plates are to be had in more than one forms, which include hot-rolled, cold-rolled, and forged, catering to various programs. These plates are regarded for his or her first rate weldability and machinability, making fabrication and set up straightforward. With a strong composition of 25% chromium and 12% nickel, SS 309 plates offer excellent oxidation and corrosion resistance, making them best for excessive-temperature programs including furnace parts, warmness exchangers, and chemical processing equipment. The alloy`s balance and electricity at extended temperatures additionally make it appropriate for fueloline turbine additives and different disturbing environments in which sturdiness and reliability are essential.

Our dedication to fine is pondered in our rigorous fine manage approaches and adherence to global standards, which include ASTM A240, ASME SA240, and EN 10088-2. We make sure that our Stainless Steel 309 Plates are produced with unique dimensional tolerances, floor finish, and mechanical properties, tailor-made to fulfill our customers' particular desires. Available in diverse thicknesses, widths, and lengths, our plates may be custom designed for particular venture necessities. We additionally provide value-introduced services, which include cutting, polishing, and machining, to offer complete answers for our clients.

Characteristics of 309 Stainless Steel Plates

Chemical equivalence Oxidation, corrosion, and abrasion resistance Resistance to crevice, pressure, and pitting cracking High temperature balance Excellent weldability, formability, and machinability Robust finish High sturdiness

With an established global export network, we ensure timely and reliable delivery of Stainless Steel 309 Plates worldwide. Our commitment to customer satisfaction is reflected in our extensive inventory, competitive pricing, and exceptional customer support. Whether you need standard sizes or custom solutions, our expert team is dedicated to delivering top-quality stainless steel products with the utmost precision and professionalism. Trust us as your reliable partner for Stainless Steel 309 Plates, and experience unmatched quality, reliability, and service for every project.

Specification/grades of 309 Stainless Steel sheets

Standards of 309 Stainless Steel Sheets

Standards: ASTM A240 / ASME SA240

Width: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Thickness: 4mm-100mm

Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Surface Finish: 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, hairline, sand blast, Brush, etching, Hot rolled coil (HR), Cold rolled coil (CR), SATIN (Met with Plastic Coated), etc

Hardness: Soft, Hard, Half Hard, Quarter Hard, Spring Hard, etc.

Form: Coils, Foils, Rolls, Plain Coil, Shim Coil, strips, Flats, Blank (Circle), Ring (Flange), etc.

Applications of 309 Stainless Steel Sheets

Off-Shore Oil Drilling Companies

Power Generation

Petrochemicals

Gas Processing

Specialty Chemicals

Pharmaceuticals

Pharmaceutical Equipment

Chemical Equipment

Sea Water Equipment

Heat Exchangers

Condensers

Pulp and Paper Industry and So on.

#Stainless Steel 309 Sheets Manufacturers in India#Stainless Steel 309 Sheets Suppliers in India#Stainless Steel 309 Sheets Stockists in India#Stainless Steel 309 Sheets Exporters in India

0 notes