#rubber parts manufacturers in usa

Explore tagged Tumblr posts

Text

Custom Molded Rubber Parts Manufacturers in Chennai India USA | K R Industries

#Custom Molded Rubber Parts Manufacturers in Chennai India USA | K R Industries#krindustry#vehiclerubbermanufacturing#manufacturing#rubbermanufacturing#qualityrubbermanufacturingindustryinchennai

2 notes

·

View notes

Text

The Japanese company that owns tire maker Dunlop shuttered a century-old New York factory — and fired 1,500 workers — as it moved manufacturing overseas.

Sumitomo Rubber USA closed down the Dunlop plant located in Tonawanda, near Buffalo, on Nov. 7.

The closure is the latest blow to the western New York area, which, like much of the Rust Belt, has seen its manufacturing sector decimated by companies shifting production overseas in recent decades.

The company said cost controls and investments in the aging facility were not enough to overcome mounting financial losses, according to Cycle News.

“The plant closure is primarily due to overall facility performance within the increasingly competitive international tire market,” Sumitomo said in a statement to the publication.

“This difficult decision follows a multi-year analysis of the company’s financial situation and general market conditions.”

The company said it sought to find a buyer for the facility, which first opened its doors in 1923, but made the decision to shut down the plant when there were no takers.

Local lawmakers blasted the company, which is said to have spent $140 million in modernizing the plant in recent years.

“It appears this decision was made by the Japanese owner’s board without any discussion with local and state officials about the possibility of closure,” Erie County Executive Mark Poloncarz told Cycle News.

“At no point did Sumitomo ask for any additional assistance to remain in operation, despite the fact we have always supported their efforts to succeed here in Erie County with tax incentives and assistance through the Erie County Industrial Development Agency.”

US Rep. Nick Langworthy (R-NY), who represents New York’s 23rd District, which encompasses parts of the Buffalo metro area as well as the southern half of western New York state, said he was “gravely disappointed” by the news.

“I mean, it comes as a shock,” the lawmaker told The Post.

“This is gonna really sting here for our regional economy.”

The Post has sought comment from Sumitomo and Poloncarz.

Dunlop tires are made for passenger cars, trucks, buses and motorcycles. The brand also has sporting goods such as tennis rackets and golf equipment.

The tire brand had been owned by two different companies based on geographic regions. In North America, Europe and Japan, Dunlop tires were manufactured and sold by Ohio-based Goodyear Tire and Rubber Company, which acquired the rights as part of a joint venture with Sumitomo.

In 2015, Sumitomo took full control of Dunlop after the parent company ended its joint venture with Goodyear.

3 notes

·

View notes

Text

anime & game merch and sales post!!!

(genshin impact, jujutsu kaisen, my hero academia, jojo's bizarre adventure)

hi friends! i'm downsizing pre-wedding and i'm selling some merch i bought doubles of, i bought in bundles, i bought to make itabags and never got around to, etc!!! i've sold stuff via tumblr before, but if you are worried: i will use paypal goods and services so you are covered, and i'd be happy to share my vinted/etsy/some other source of feedback with you if you ask in my dms (there's just some sensitive location info so i don't want to share publicly on this post!).

all of this is official merch; either bought through mercari.jp, a japanese shopping service, direct from manufacturers, or the official tmall (in the case of genshin stuff!).

i would prefer to ship within the uk, but i'm happy to ship internationally at your cost!!! shipping costs for the uk and the usa are as follows, ask if you want another country estimate:

UK: £3.30 for Tracked 48 postage USA: £18 for International Tracked; if it ends up being less, I'll refund the difference (it's hard to know for certain without knowing exactly what I'm sending and the weight!), but according to Royal Mail it should be around there!

ok! there's the boring stuff. merch under cut and under headings!!!

Genshin Impact

metal itto keychains! these are HEAVY, honestly, and they're super cute but my itto love simply is not as strong as my love for some other boys and i HAVE to downsize. £8 each, £15 for both

as you can tell i intended to make an itto itabag VFNKJVFN. chibi/emoji buttons, £5 each, £15 for all 4.

itto emoji sticker keychains £6 each, £10 for both!

these ones are bigger buttons than the emoji and are fun and shiny! £6 each, £15 for all 3.

baizhu 2 charm bundle; £10 for both or £6 each.

Miscellaneous genshin stuff; song of broken pines metal keychain, noelle kfc collab badge, a button of ayaka from the clothing collab. £5 and just take them off my hands bdfgvnkjgfnkb.

Jujutsu Kaisen

JJK Bandai Banpresto Nanami figure; I accidentally pre-ordered this twice so I need to sell my double! You can see what it looks like out of box here. £15. SOLD

Gojo hotel-key style keychain; £5.

Mahito Pita! charms; I have doubles of them! £6 for both or £4 each.

nanami bundle that i'd rather not split because i am LAZY dfvnjkgfbnkj. 8 x acrylic charms, 2 x buttons and 1 x acrylic stand. £20 for everything. SOLD

My Hero Academia

Endeavour and Pompompurin Sanrio collab merch; £8 for both.

Twice bundle including four buttons and two acrylic charms (two of which are the sanrio collab stuff for him!). £15 for everything.

Toga bundle (realised I forgot the acrylic stand for her which is why it's on its own!). Orb keychain, acrylic stand, two acrylic keychains and four buttons including the Sanrio collab stuff (Toga had Kuromi which is VERY cute!!!). £20 altogether.

shigaraki keychain bundle; one plush orb, three pita! keychains, one rubber keychain and three misc acrylic charms. £20 for everything.

the BIG ONE. there are i THINK 30 assorted shigaraki buttons here that i cannot be bothered to separate; some are from movies, at least one is live action, some are celebration buttons or from exhibitions. they're from a shigaraki itabag i never made. £30 for everything (that evens out to £1 a button!).

shigaraki x gudetama sanrio characters collab bundle. acrylic stand, acrylic keychain and badge. £12 altogether.

Jojo's Bizarre Adventure

prosciutto micro-organisms / tomonui . they ARE official and i love them very much but i do not need five so these two are going to new homes, i hope! i'll lint-roll them before sending bc they're a little fluffy despite just sitting in a box for the better part of a year fgbnkjbgfnkj.

£15 each, or both for £25.

9 notes

·

View notes

Text

The Role of Hydraulic Rubber Press Machine in Revolutionizing Manufacturing in the USA

The Hydraulic Rubber Press Machine is a game-changer in the manufacturing industry, revolutionizing rubber processing in the USA. By applying precise hydraulic pressure, these machines ensure uniform molding, improved quality, and faster production cycles. From automotive parts to industrial seals, the versatility and efficiency of hydraulic presses have significantly enhanced production capabilities, making them indispensable for manufacturers. Investing in this advanced technology not only boosts productivity but also ensures consistent, high-quality rubber products. Embrace the future of manufacturing with the power of the Hydraulic Rubber Press Machine today!

0 notes

Text

0 notes

Text

The Evolution of Shoe Design: From Ancient Times to Modern Trends

Shoe design has come a long way since the dawn of civilization, evolving from simple protective coverings to complex fashion statements that blend functionality and style. Shoes have been an integral part of human culture, reflecting not only technological advancements but also shifts in social norms and fashion trends. In this blog, we'll explore the fascinating journey of shoe design from ancient times to modern trends, showcasing how shoes have transformed and what they signify in today's world.

Ancient Beginnings: The Birth of Footwear

The earliest known shoes date back to around 7000 BCE. Archaeological discoveries in Oregon, USA, reveal that ancient people crafted shoes from plant fibers, animal hides, and leather. These rudimentary shoes were primarily designed for protection and practicality rather than fashion. They served to shield the feet from harsh terrains, sharp objects, and extreme weather conditions. These early shoes were often simple sandals or moccasins, with designs tailored to the specific needs of their environment.

The Influence of Ancient Civilizations

As civilizations progressed, so did the complexity of shoe design. In ancient Egypt, shoes became more elaborate and were often used to denote social status. Sandals made from woven papyrus or leather, adorned with jewels and intricate designs, were a symbol of wealth and power. Similarly, in ancient Greece and Rome, shoes evolved to reflect societal roles and occupations. The Greeks wore sandals with straps that held the foot securely, while the Romans introduced the concept of the “caliga,” a type of military sandal with hobnails for durability.

The Middle Ages: Functionality Meets Fashion

During the Middle Ages, shoe design continued to evolve, influenced by both necessity and the burgeoning fashion sense of the time. Shoes in medieval Europe were characterized by pointed toes, known as "poulaines." These shoes, often made from leather, could be quite long and were sometimes embellished with embroidery. The pointed toe became a symbol of social status, with longer toes denoting higher social rank.

The Middle Ages also saw the introduction of the “clog,” a wooden shoe that provided sturdiness and protection, particularly in rural areas. Clogs were practical and durable, designed to withstand the demands of agrarian life while offering basic protection from the elements.

The Renaissance and Baroque Eras: Artistry and Elegance

The Renaissance period marked a significant shift in shoe design, reflecting the era's emphasis on art and elegance. Shoes during this time were often adorned with intricate embroidery, luxurious fabrics, and ornamental details. Both men and women wore shoes that were designed to complement their elaborate attire, often incorporating elements such as ribbons, lace, and buckles.

The Baroque era continued this trend, with shoes becoming even more ornate. High heels became fashionable for both men and women, reflecting the period's preference for dramatic and extravagant styles. Heels were often made from wood or metal and were sometimes embellished with precious stones or elaborate designs.

The Industrial Revolution: Innovation and Mass Production

The Industrial Revolution brought about significant changes in shoe design and manufacturing. The introduction of machinery revolutionized the production process, allowing for the mass production of shoes. This era saw the advent of new materials such as rubber and synthetic fabrics, which expanded the possibilities for shoe design.

During this time, shoes became more accessible to the general public, with standardized sizes and mass production techniques leading to a more uniform appearance. The development of the "Oxford" shoe, characterized by its closed lacing system, became a staple in men's fashion, while the "ballet flat" emerged as a popular choice for women, combining comfort with style.

The 20th Century: The Birth of Modern Trends

The 20th century was a period of rapid innovation and experimentation in shoe design. The early decades saw the rise of iconic styles such as the Converse Chuck Taylor All-Star, which became a symbol of American youth culture and athletic wear. The 1950s and 60s introduced new materials and designs, including the introduction of the "sneaker" as a fashion statement.

In the 1970s and 80s, high fashion and sportswear began to merge, leading to the creation of designer sneakers and athletic shoes that catered to both performance and style. Brands like Nike and Adidas became household names, and shoe design began to emphasize both functionality and aesthetics.

Contemporary Trends: A Fusion of Fashion and Function

Today, shoe design continues to evolve, driven by both technological advancements and shifting fashion trends. Modern shoes incorporate cutting-edge materials such as memory foam, advanced cushioning systems, and breathable fabrics. The emphasis on comfort and performance is evident in the rise of athletic and casual footwear that seamlessly transitions from the gym to everyday life.

Sustainability has also become a key focus in contemporary shoe design. Many brands are exploring eco-friendly materials, such as recycled plastics and organic cotton, and adopting sustainable production practices. The demand for transparent supply chains and ethical manufacturing processes reflects a growing awareness of environmental and social issues within the fashion industry.

Fashion-forward designs, such as bold color palettes, unconventional silhouettes, and customizable options, continue to push the boundaries of traditional shoe design. Sneakers, once considered purely athletic wear, have become a dominant fashion trend, with limited-edition releases and collaborations driving hype and exclusivity.

Conclusion

The evolution of shoe design is a testament to humanity's ingenuity and adaptability. From the basic protective coverings of ancient times to the sophisticated and diverse footwear of today, shoes have mirrored changes in technology, fashion, and societal values. As we move forward, it will be fascinating to see how future innovations and trends will shape the next chapter in the history of shoe design. Whether you’re a fashion enthusiast, an athlete, or simply someone who appreciates well-crafted footwear, there’s no denying the profound impact shoes have had on our lives and our culture.

0 notes

Text

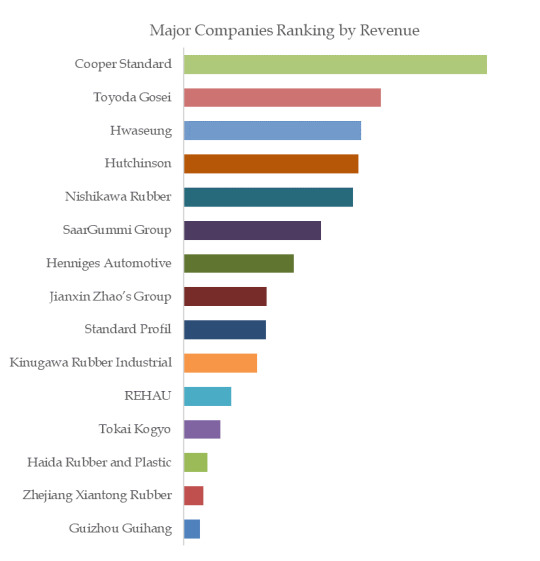

Global Top 15 Companies Accounted for 57% of total Automotive Body Sealing Systems market (QYResearch, 2021)

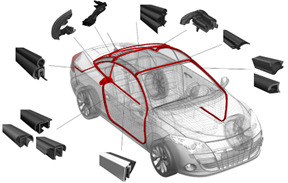

Body sealing system is commonly made of EPDM rubber and PVC, a thermoplastic elastomer (TPE) mix of plastic and rubber, and a thermoplastic olefin (TPO) polymer/filler blend. The goal of body sealing system is to prevent rain and water from entering entirely or partially and accomplishes this by either returning or rerouting water. A secondary goal of body sealing system is to keep interior air in, thus saving energy on heating and air conditioning.

The automotive body sealing system means the edges of a vehicle's windshield, windows, doors and trunk lid, etc. Automobile Sealing System strip is usually made into a hollow sponge foam tube.

According to the new market research report “Global Automotive Body Sealing Systems Market Report 2023-2029”, published by QYResearch, the global Automotive Body Sealing Systems market size is projected to reach USD 25.95 billion by 2029, at a CAGR of 13.3% during the forecast period.

Figure. Global Automotive Body Sealing Systems Market Size (US$ Million), 2018-2029

Figure. Global Automotive Body Sealing Systems Top 15 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Automotive Body Sealing Systems include Cooper Standard, Toyoda Gosei, Hwaseung, Hutchinson, Nishikawa Rubber, SaarGummi Group, Henniges Automotive, Jianxin Zhao’s Group, Standard Profil, Kinugawa Rubber Industrial, etc. In 2021, the global top five players had a share approximately 57.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Plastics Manufacturing Austin USA

Plastics Manufacturing Austin offers the best plastic molding services to our customers; we are a single-source manufacturer of high-performance engineering plastic, rubber, and metal products. We have a 40,000-square-foot foot facility located in Stafford, TX we provide services like plastic injection molding, insert molding, compression molding, vacuum forming, etc. We offer our customers post-injection molding operations and assembly; we are ready to work with our customers to integrate the plastic part assembly into the total molded part process which helps to cut the cost down. Our secondary assembly option includes prototyping, drilling, and tapping, packing & distribution, over-molding, etc.

0 notes

Text

Top Silicone Rubber Extrusion Manufacturers In The USA

Extrusions made of silicone rubber are a flexible and vital part of many different industries. Our products have exceptional heat resistance, flexibility, and durability, which makes them perfect for a wide range of uses, including construction materials and medical devices. Selecting the best silicone rubber extrusion manufacturer is essential to guaranteeing the effectiveness and caliber of your finished product. This blog post explores the top silicone rubber extrusion manufacturers in USA. We'll delve into their capabilities, areas of expertise, and what sets them apart.

Read More: https://www.customrubber-extrusion.com/knowledge-base/top-silicone-rubber-extrusion-manufacturers-in-the-usa

0 notes

Text

K R Industries have Wide Range of competency in the Supplies and Manufacture of Industrial Automotive Rubber Products Manufacturers in USA & India, Get Automotive Molded (Moulded) Rubber Parts from us. Enquire us for any requirements.

0 notes

Text

API Globe Valve Manufacturer

SVR Global is the leading API globe valve manufacturer in USA and supplies top notch quality valves in various oil and gas industries, chemical industries in Chicago, New York and Houston. API stands for American Petroleum Institute. API Globe valves are operated to control the flow of fluids in the system. They are usually used for throttling the flow apart from controlling as well. These valves have a stem which moves up and down to control the flow of fluids & a disc and seat that is attached to the body of the valve. Globe valves are the best among other valves for controlling and regulating the flow of fluids. These valves are bi-directional which means they can move in either direction inside the valve. The fluid flow in globe valves is highest when its disc is raised. They are operated manually and automatically. Parts: •Body: The body of an API globe valve is a shell that houses all the internal parts of the valve. •Bonnet: The bonnet is a cover that sits on top of the valve body and provides access to the internal parts of the valve. It is usually bolted to the valve body and can be removed for maintenance or repair. •Disc: The disc, also known as the plug or the disk, is a movable component that regulates the flow of fluid through the valve. It can be moved up or down by the valve stem to open or close the valve. •Stem: The stem is a threaded rod that connects the valve disc to the valve handwheel or actuator. It is used to control the position of the valve disc and regulate the flow of fluid. •Seat: The seat is a sealing surface that is in contact with the valve disc to provide a tight shut-off. It is usually made of a resilient material such as rubber, , or metal. •Packing: The packing is a set of seals that prevent leakage of fluid through the valve stem. It is typically made of graphite or other flexible materials. •Gland: The gland is a component that compresses the packing material around the valve stem to provide a tight seal. It is usually made of metal.

Industry: •Electric power industries •Oil and gas industries •Petroleum industries •water and wastewater industries •Marine Industries •Construction Industries •Mining industries Applications: •Oil and gas industry - for controlling the flow of fluids, gases, and steam. •Chemical industry - for resisting corrosive chemicals and high-pressure environments. •Power plants - for controlling the flow of steam and water in high-pressure and high-temperature. •Water treatment plants - for regulating water flow and pressure. •Petrochemical industry - for regulating the flow of petrochemicals and gases. •Marine industry - for regulating the flow of seawater and fluids. •Mining industry - for regulating the flow of water and slurries in mining operations. •Fire protection systems - for controlling the flow of water or other fire suppression agents in case of a fire. •Aerospace industry - for regulating the flow of fluids, gases, and propellants in aerospace applications. •Biotechnology industry - for regulating the flow of gases and liquids in bioreactors and fermentation systems. •Pulp and paper industry - for regulating the flow of chemicals and fluids in pulp and paper production processes. •Wastewater treatment plants - for regulating the flow and pressure of wastewater and sludge in treatment processes.

Advantages

•Excellent throttling capabilities •Simple to use and clean the valve •Can also work as a stop-check valve •Quick and a safe shutdown •Durable throughout its life span •It has a Non-rotating stem •The seats of these valves are very easy to resurface. •Safe to use and dependable as well

SVR Global, the API globe valve manufacturer in USA provides top-notch quality valves which are not only durable and strong but also comes at pocket-friendly prices. Description: Body material: Cast Iron, Cast steel [A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91] Class: 150 – 2500; PN10 – PN 450 Size: DN 10 – DN 1200 Ends: Butt weld, Flanged, threaded, socket weld Operations: Hand-wheel operated, Pneumatic actuated, Electric actuated, Gear operated

Visit our website for more information- https://svrglobal.net/products/api-globe-valve/

0 notes

Text

Perfect Fit High Quality Rubber Molded Parts Manufacturers In The Usa

The world of manufacturing relies heavily on precision and quality. In the realm of rubber components, finding reliable Rubber Molded Parts Manufacturers is crucial for businesses that depend on these versatile parts. From gaskets and grommets to intricate seals and industrial components, rubber molded products play a vital role in countless applications.

0 notes

Text

0 notes

Text

Mark Singer: The Pioneering Visionary Behind The Gorilla Glue Company

Glues, Adhesives, and Sealants are substances used to hold and attach surfaces. They can be used for Craft, DIY, Repairs, Construction, and other industrial purposes and needs. Whatever you need to fix, build, stick, create, bond, and seal – these sticky glues, adhesives, and sealants are the solution. These gummy and goey stuff are made of Silicones, Silane-Modified Polymers, Polyurethanes, Methacrylates, Cyanoacrylates, Epoxies, Butyl Rubber, or Elastomers.

Incredibly stronger glues, adhesives, and sealants are used mostly in the manufacturing innovation and industrial sectors as they can be very harmful during simple craft and repair work. Having the substance of higher strength fall on any bare bodily part can prove to be detrimental and needs to be addressed immediately. The versatility of these tacky and viscous substances is more sustainable in the amount of materials used to just get the job done. Different types and kinds of materials can be bonded and sealed by glues, adhesives, and sealants without the use of extra materials for additional support. Many companies, brands labels, and organizations make their patented sticky composite and market them, which would rake in huge profits if their quality is good and gets the job done as advertised.

Therefore in this article, we will be talking about one such company founded by Mark Singer in the manufacturing industry. An American woodworker found a type of glue that was Danish manufactured, being used in Indonesia. After asking the manufacturer for the glue to modify its composition a little, Mark bought and acquired the Northern American rights for the same. He went back to his country and built The Gorilla Glue Company in 1994, whose mission is – “to make products that deliver impressive results”.

About Mark Singer – Founder of The Gorilla Glue Company:

The pioneering and trailblazing visionary who founded The Gorilla Glue Company is Mark Singer. A woodworker who has been working with wood and its related tools and types of equipment is all too familiar with how the adhesive technology of glues, adhesives, and sealants work. Woodworking, designing, and making furniture was a tedious activity for Mark. He says – “Practice, patience, proper tools, good lighting, reading glasses, and technique are all really helpful.”

Between the late 1989s and early 1990s, Mark Singer traveled from America to Bandung, Indonesia to visit a furniture factory there. He found that the workers used a type of glue unknown to Mark, on Teak furniture. The glue was made in Germany, specifically Danish manufactured. Seeing how the market was rising and how in-demand the glue was with customers, Mark went back to his country with sample bottles of the same.

“Strong enough for the toughest jobs on planet Earth” – Tagline of The Gorilla Glue Company.

On arriving back home, he tested the glue on the furniture at his workshop. He found that this glue worked on not only Teak wood but also on metals, ceramics, plastics, stones, and much more. He immediately envisioned a product that is of high quality and a brand that people would love and find to be incredibly helpful. Therefore, he approached the Danish manufacturer of the glue and asked to modify its composition a little. After this, he bought and acquired the Northern American rights for the same and brought it to America. Here, Mark started his brand building and chose the brand logo, name, and products in 1994 and launched the business that same year.

About The Gorilla Glue Company:

The Gorilla Glue Company was founded by Mark Singer, in the year 1994. It is a manufacturing company that makes waterproof glues, adhesives, and sealants for a variety of purposes in a factory established in Cincinnati, Ohio, USA. Currently, the business is family-operated by the Ragland Family. Mark Singer sold The Gorilla Glue Company to the family in the year 1999 – after which the business growth took to the skies. Mark continued to focus on his woodworking and furniture-making career thereafter.

The company manages the patented brands of – Gorilla Glue, Gorilla Tape, O’Keeffe’s, and Lutz Tool. Later after the expansion of the company due to its immediate surge in high demand and prices, Gorilla Super Glue Impact-Tough Formula, Gorilla Construction Adhesive, Gorilla Wood Glue, and Gorilla Epoxy were the other brands created and included in the manufacturing line among many other premium products.

Vision Statement – “We believe in high-quality products and choose to only put the Gorilla logo on products that meet rigorous development standards.”

Building brands that people would love and manufacturing products that they would find to be incredibly helpful, the company believes that they do this for the people they care about – “The Gorilla Way”. The Gorilla Glue Company is an all-purpose adhesive substance used for many purposes, such as – Craftwork, DIY and Builders, Repairs and Construction, and Moving and Storage purposes.

The company is headed towards sustainability efforts with the vision to have future generations still using the brand’s products. A success story, this company is a proud member of the How2Recycle Program – a smarter labeling system that recycles for Americans and Canadians, operates in local areas, has store drop-off facilities, and compostable initiatives as well. Recognized as one of the top places to work for 13 continuous years, The Gorilla Glue Company is all set gearing up for future ventures and expanding its market with more innovative and creative, sticky products.

Visit More : https://thebusinessmagnate.com/mark-singer-the-pioneering-visionary-behind-the-gorilla-glue-company/

0 notes

Text

Global Top 15 Companies Accounted for 39% of total Waterproof Fabrics market (QYResearch, 2021)

Waterproof fabrics are fabrics that are inherently, or have been treated to become, resistant to penetration by water and wetting. They are usually natural or synthetic fabrics that are laminated to or coated with a waterproofing material such as rubber, polyvinyl chloride (PVC), polyurethane (PU), silicone elastomer, fluoropolymers, and wax.

In this report we focus on raw membrane material.

According to the new market research report “Global Waterproof Fabrics Market Report 2023-2029”, published by QYResearch, the global Waterproof Fabrics market size is projected to reach USD 2.12 billion by 2029, at a CAGR of 3.9% during the forecast period.

Figure. Global Waterproof Fabrics Market Size (US$ Million), 2018-2029

Figure. Global Waterproof Fabrics Top 15 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Waterproof Fabrics include Gore, Performax, Toray Industries, Polartec Neoshell, Swmintl, Sympatex, DSM, Carrington Textiles, Derekduck, Porelle Membranes, etc. In 2021, the global top five players had a share approximately 39.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Link

Check out this listing I just added to my Poshmark closet: Boombah Mens Dart USA Clandestine Turf Shoes Size 9.5.

0 notes