#rfid in food business

Explore tagged Tumblr posts

Text

Role of RFID Technology in the Food Industry

The food industry, a crucial sector, plays a vital role in ensuring the well-being and health of communities worldwide. With a growing population, the demand for food products is increasing, leading to greater pressure on the industry to provide fresh and high-quality products.

Fortunately, technology has been playing a crucial role in addressing these issues, with RFID (Radio Frequency Identification) technology emerging as a key tool for the industry.

RFID technology is increasingly gaining popularity in the food industry due to its ability to provide real-time product information, reduce errors and delays, and improve supply chain efficiency. Here is a look at the role of RFID technology in the food industry.

Supply Chain Efficiency

RFID technology has revolutionized the food industry by providing a reliable and efficient solution to manage supply chain operations. RFID tags are used to track food products during distribution and storage, making it easier to prevent food spoilage and contamination.

RFID readers can simultaneously interact with multiple tags, making tracking products in real time much faster and easier. This has led to more efficient logistics network management, reducing the amount of labor needed for product counting and identification upon arrival at warehouses.

Many companies have effectively utilized RFID technology to strengthen their supply chain operations. For instance, Wal-Mart required its top 100 suppliers to implement RFID tags on their products in 2005, leading to significant improvements in inventory management and logistics efficiency. (Source: Walmart)

Identification and Traceability

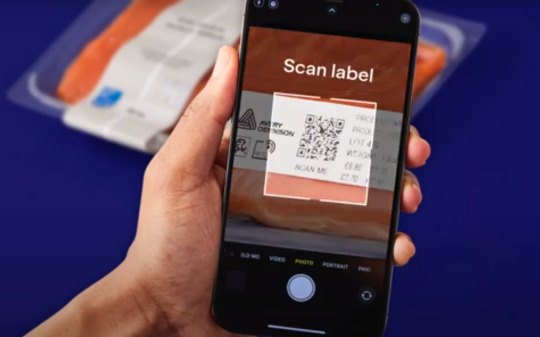

RFID technology enables real-time tracking of food products, including boxes, trays, and more, providing accurate stock information for effective inventory management. Additionally, intelligent labels and tags by brands like Avery Dennison can be used to identify various product attributes, such as expiration dates, preferred consumption, lot numbers, variable weights, and environmental conditions, such as temperature and humidity.

This information can be accessed easily, allowing for quicker and more efficient monitoring and management of the food supply chain.

Inventory Accuracy

RFID technology improves inventory accuracy by enabling real-time tracking of food products, allowing for accurate stock information for effective inventory management. With the ability to track food products at every step of the supply chain, RFID technology provides real-time visibility into inventory levels, reducing the risk of overstocking or understocking.

Inventory Management

Traditionally, managing food inventory involves manual counting, identification, and record-keeping, which can be time-consuming and prone to errors. With RFID technology, these processes are automated, significantly reducing the time required for inventory management.

With the ability to track food products in real-time, RFID technology has reduced the time needed for inventory management. In addition, RFID enables quick decision-making and timely restocking.

Expedition and Shipment Control

RFID technology has significantly improved the speed and accuracy of dispatch and shipments at distribution centers, which has contributed to error-free supply and improved customer satisfaction.

In stores and supermarkets, RFID is also useful for verifying the identification of boxes and pallets and cross-referencing this information with the distribution center's records.

Overall, the use of RFID technology in the food industry has led to more efficient and reliable logistics operations, resulting in improved product quality, safety, and customer satisfaction.

Moreover, you can partner with Avery Dennison, one of leading labels & RFID providers- they provide brands with an extensive collection of digital ID technologies that help find authentic product history. Moreover, they offer tracking and inventory solutions, helping bring up richer consumer encounters.

Avery Dennison’s Smartac division is at the forefront of supporting companies to connect the physical and digital worlds. With its unique combination of materials expertise and innovative technologies, the brand provides clients with next-generation solutions that drive business success.

#RFID#RFID Technologies#RFID Scanner#rfidreader#rfid solutions#rfid solution provider india#rfid solution company india#healthcare rfid market#rfid in food business#blog

0 notes

Text

Explore Top Sustainable Packaging Trends in 2023

Introduction:

Sustainable packaging has become a significant concern for businesses and consumers alike, as the world continues to prioritize environmental consciousness.

With the increasing focus on sustainability, it’s crucial to explore the top sustainable packaging trends that will shape the packaging industry in 2023. This article delves into the various sustainable packaging trends that are expected to make a significant impact in the coming year.

Importance of Sustainable Packaging:

Sustainable packaging plays a prime role in minimizing waste, conserving resources, and minimizing environmental impact.This doesn’t only prioritize eco-conscious consumers but also is very beneficial for businesses in the long run.

Sustainable packaging can enhance brand reputation, attract environmentally conscious customers, and lead to cost savings through optimized material usage and streamlined logistics.

Sustainable Packaging Trends:

Read below to know more about the top Sustainable Packaging Trends that are shaping the future of packaging industry.

Eco-Friendly Packaging Materials:

To achieve sustainable packaging goals, businesses are increasingly turning to eco-friendly materials that have minimal impact on the environment. Three prominent options are:

Biodegradable Packaging: Biodegradable packaging materials are designed to decompose naturally over time, minimizing the piling of waste in landfills. They are formed from plant-based polymers, such as PLA (polylactic acid), which can break down into harmless elements with the help of microorganisms.

Compostable Packaging: Compostable packaging goes a step further by not only breaking down but also providing valuable nutrients to the soil during the composting process. These materials are made from organic matter, such as cornstarch or bagasse, and contribute to a circular economy by turning into compost that can enrich agricultural lands.

Recyclable Packaging: Recyclable packaging materials includes cardboard, glass, and certain types of plastics, can be gathered, refined, and reused to create new packaging or other products. Recycling preserves resources, reduces usage of energy, and minimizes the demand for virgin materials.

Minimalistic Packaging:

One of the emerging sustainable packaging trends is minimalistic design. This approach focuses on eliminating excess packaging and using the bare minimum required to protect and present the product.

Minimalistic packaging not only reduces waste but also enhances the product’s visual appeal, creating a sleek and modern aesthetic.

Packaging Reduction and Lightweighting:

To further minimize the impact of packaging on the environment, companies are vigorously. seeking ways to minimize the amount of material used. Packaging reduction involves optimizing the size and dimensions of packaging to minimize waste, transportation costs, and storage requirements.

Lightweight, on the other hand, aims to decrease the weight of packaging materials without compromising their integrity, leading to energy savings and reduced emissions during transportation.

Smart Packaging Solutions:

Advancements in technology have paved the way for smart packaging solutions that offer enhanced functionality while remaining environmentally friendly. Two notable examples are:

Intelligent Labels: Intelligent labels comprise of RFID (Radio Frequency Identification) or NFC (Near Field Communication) technology to impart real-time insights about the product, such as its origin, ingredients, and expiration date. By enabling consumers to make informed choices, intelligent labels promote transparency and minimize food waste.

Active Packaging: Active packaging involves the integration of active substances or components into the packaging material to extend the shelf life of the product. Oxygen absorbers, moisture control packets, and antimicrobial films are examples of active packaging solutions that help maintain product freshness, reduce spoilage, and minimize food waste.

Plant-Based and Renewable Packaging:

As the demand for sustainable packaging grows, there is a rising focus on plant-based and renewable materials. Packaging created from renewable resources, such as bamboo, sugarcane, or hemp, offers a viable substitute to traditional petroleum-based plastics.

These materials are not only biodegradable or dispensable but also have a lower carbon footprint during production.

Packaging Innovations:

In addition to the aforementioned sustainable packaging trends, packaging innovations continue to drive sustainable practices. Three noteworthy innovations include:

Edible Packaging: Edible packaging materials, often made from natural polymers like seaweed or starch, can be consumed along with the product. This eliminates the need for additional waste and offers a unique, eco-friendly packaging experience.

Water-Soluble Packaging: Water-soluble packaging is created to dissolve when it comes into contact with water, minimizing the amount of waste produced. This type of packaging is particularly applicable for single-use items like detergent pods or dishwasher tablets.

Mushroom Packaging: Mushroom packaging is also known as mycelium packaging, it makes use of the root structure of mushrooms to create a biodegradable and compostable material. It offers a sustainable alternative to foam-based packaging materials, minimizing reliance on non-biodegradable options.

Packaging for E-commerce:

With the emergence of e-commerce, sustainable packaging solutions are crucial to minimizing the environmental impact of shipping and handling.

Sustainable Packaging Trends in the Food Industry:

The food industry is actively adapting to sustainable packaging practices to address the challenges of food waste and environmental impact.

From compostable food containers to eco-friendly food wraps, innovative packaging solutions are being developed to ensure the freshness and safety of food products while reducing the ecological footprint.

Sustainable Packaging Trends in the Beauty and Personal Care Industry:

Sustainable Packaging Trends in the Fashion Industry:

Sustainable Packaging is gaining popularity in the Fashion Industry, as various brands realize the need to minimize environmental impact of products.

Packaging that is created using recycled materials, biodegradable garment bags and innovative ideas such as seaweed-based packaging is becoming increasingly popular.

Sustainable Packaging Trends in the Electronics Industry:

The electronics industry is notorious for its excessive packaging and e-waste. However, manufacturers are now adopting to sustainable packaging trends such as corrugated cardboard, molded pulp, and plant-based plastics to minimize waste generation and improve recycling rates.

Collaboration for Sustainable Packaging:

Collaboration between stakeholders is crucial to drive sustainable packaging initiatives forward. Brands, packaging manufacturers, consumers, and policymakers need to work in harmony to develop and implement effective strategies that boost sustainable practices throughout the supply chain.

Conclusion – Sustainable Packaging Trends:

In conclusion, the packaging industry is witnessing a shift towards sustainability, driven by the growing awareness of environmental issues and consumer preferences.

In 2023, the top sustainable packaging trends will revolve around eco-friendly materials, minimalistic design, packaging reduction, smart solutions, plant-based alternatives, and innovative packaging options.

By adapting to these sustainable packaging trends, businesses can align with consumer values, minimize their carbon footprint, and contribute to a more sustainable future.

FAQs:

Why is sustainable packaging important?

Sustainable packaging is crucial as it helps to minimize waste, preserve resources, and minimize environmental impact. It also improves brand reputation and attracts eco-conscious consumers.

What are some eco-friendly packaging materials?

Eco-friendly packaging materials such as biodegradable packaging, compostable packaging, and recyclable packaging. These materials have minimal impact on the environment and promote a circular economy.

How can minimalistic packaging benefit businesses?

Minimalistic packaging not only reduces waste but also enhances the visual appeal of products, creating a sleek and modern aesthetic. It can attract consumers and differentiate brands in the market.

What are some packaging innovations in sustainability?

Some packaging innovations in sustainability include edible packaging, water-soluble packaging, and mushroom packaging. These innovations offer biodegradable or compostable alternatives to traditional packaging materials.

How can collaboration drive sustainable packaging initiatives?

Collaboration between brands, packaging manufacturers, consumers, and policymakers is crucial to develop and implement effective strategies for sustainable packaging. By working together, stakeholders can drive positive change throughout the supply chain.

2 notes

·

View notes

Text

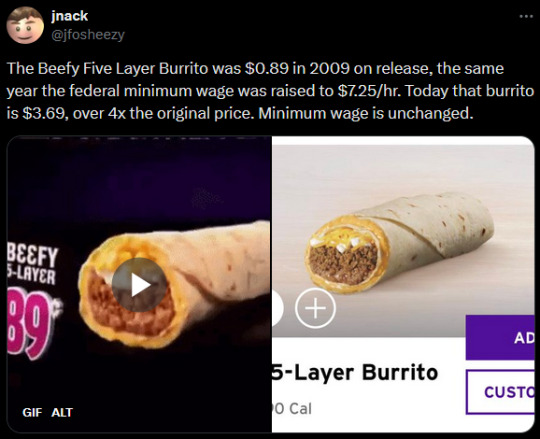

There's something so burningly infuriating about living to see fast food - touted as cheap, fast, and decently tasty if not 'healthy' (and that is like 8 other posts I'm not gonna get into here) - go from something teenagers could afford with change scraped out of their pockets, couch cushions, car seats, off the street, etc. could afford, to this. Most places don't have a dollar menu anymore. Wendy's is experimenting with demand-based pricing and there was that thing about a nonrefillable McDonald's RFID cup. And the food has sometimes gotten better, but that's not a guarantee.

Also, since COVID hit (and since minimum wage is so pathetic lbr), fast food places are understaffed. Hell, they were understaffed before that, because management realized they could make 3 people do the work of 12 for the wage of 2 rather than paying 12 people to actually, you know, keep a business staffed. Fast food isn't the only place this has happened, but it's pretty obvious there. Another example was the local grocery store, which has over 20 stations for human checkers... only half of which were filled... the day before Thanksgiving, one of if not THE biggest food-related holiday in the USA. When the FUCK are you filling those stations if not then? Why do you even HAVE those stations if not to fill them? Why does every drive through have 2 windows but less than 25% of them actually make use of the first one? It's constant cost-cutting that comes at the expense of both customer and employee.

Fast Food isn't the only place price inflation hits, but it's one of the more obvious ones. And it's one that has a lot of impact on other people. If I give the panhandler at the light the change in my purse, in a world with a dollar menu, that's an actual boon. When a full meal costs $20 minimum no matter where you go, it's a different matter entirely. When you have a 15 minute break to eat and Taco Bell is the closest drivethru, it makes a difference whether they can get your food out in 5 minutes or 10.

Enshittification is coming for absolutely everything, indeed.

This problem is nothing new, but this specific example with these numbers puts it into a fucking brutal perspective.

To put these numbers a different way: A Taco Bell burrito that used to cost ~7 minutes and 20 seconds of minimum wage work now costs ~30 minutes and 30 seconds of minimum wage work.

You used to be able to work at Taco Bell anywhere in the country and make enough money in one hour to buy at least 8 burritos (maybe 9 if you're a manager or something) and feed, like, 3-4 people a decently-filling meal. But now, the same amount of work at the same job will get you one meal for one person. And this change has happened over a mere 15 years.

Remember this whenever you see rich people demonize younger generations for our financial situations, when they call us irresponsible for not investing a ton of money in savings accounts.

50K notes

·

View notes

Text

The Future of Supply Chain: Why Businesses Need Product Traceability Solutions

Introduction

The global supply chain is evolving at an unprecedented pace, driven by advancements in technology, increased consumer awareness, and stricter regulatory requirements. In this complex and interconnected environment, businesses must adopt product traceability solutions to enhance supply chain efficiency, ensure compliance, and build consumer trust.

Product traceability solutions enable companies to track products at every stage of the supply chain, from sourcing raw materials to final delivery. As industries face challenges such as counterfeiting, product recalls, and ethical sourcing concerns, traceability solutions have become a necessity rather than an option.

Why Businesses Need Product Traceability Solutions

1. Combatting Counterfeit Products

Counterfeiting is a growing problem across industries such as pharmaceuticals, fashion, and electronics. Fake products not only damage brand reputation but also pose serious health and safety risks to consumers. With traceability solutions like RFID tags, blockchain technology, and serial number tracking, businesses can authenticate products and ensure they originate from legitimate sources.

2. Strengthening Regulatory Compliance

Governments worldwide are imposing strict regulations to ensure product safety and ethical sourcing. Regulations such as:

FDA's Food Safety Modernization Act (FSMA)

EU's General Product Safety Regulation (GPSR)

Drug Supply Chain Security Act (DSCSA) in the U.S.

These laws require companies to maintain detailed records of product movement throughout the supply chain. Traceability solutions simplify compliance by providing accurate, real-time tracking and documentation.

3. Improving Supply Chain Transparency

Modern consumers demand greater transparency regarding product origins, sourcing, and sustainability efforts. Businesses that adopt traceability solutions can:

Provide customers with detailed product histories via QR codes or blockchain-based tracking.

Enhance brand reputation by demonstrating ethical sourcing and sustainability efforts.

Reduce fraudulent activities by verifying supplier claims.

4. Reducing Product Recall Costs

Product recalls can be financially devastating and damage brand credibility. Without proper tracking, companies may need to recall entire product batches instead of targeting specific defective units. Traceability solutions allow businesses to:

Pinpoint affected products quickly.

Reduce recall scope and associated costs.

Improve consumer safety by preventing defective goods from reaching shelves.

5. Enhancing Operational Efficiency

Supply chain disruptions, such as delays, theft, or damaged goods, can lead to financial losses. By implementing traceability solutions, companies gain real-time insights into product movements and can take proactive measures to optimize operations. AI-driven analytics can also predict potential supply chain issues before they occur, ensuring smoother logistics management.

6. Leveraging Emerging Technologies for Future Growth

The future of supply chain traceability is being shaped by cutting-edge technologies, including:

Blockchain: Provides tamper-proof records of product movement, reducing fraud.

IoT (Internet of Things) Sensors: Track environmental conditions (e.g., temperature, humidity) to ensure product quality.

AI and Machine Learning: Analyze patterns to predict potential supply chain bottlenecks.

Conclusion

The future of supply chains lies in digital transformation and enhanced traceability. Companies that invest in product traceability solutions will benefit from stronger compliance, better risk management, and increased consumer trust. As global markets become more competitive, businesses that embrace these technologies will lead the industry while minimizing risks and maximizing efficiency.

0 notes

Text

RFID in Food Traceability

RFID in food traceability revolutionizes supply chain management by providing real-time data on food products from farm to table. This technology enables businesses to monitor the freshness and origin of food items, ensuring compliance with safety regulations. Enhanced traceability not only improves consumer trust but also helps in quickly addressing recalls and reducing waste.

1 note

·

View note

Text

How IoT is Enhancing Supply Chain Efficiency and Management

The rapid growth of the Internet of Things (IoT) has revolutionized many industries, with supply chain management being one of the most significantly impacted sectors. IoT technology, which connects devices and systems through the internet to collect and exchange data, has emerged as a game-changer in enhancing the efficiency and transparency of supply chains. By integrating smart sensors, GPS tracking, and real-time data analytics, businesses are witnessing smoother operations, reduced costs, and improved decision-making capabilities. In this context, IoT service providers have played a pivotal role in offering tailored solutions that help businesses leverage these technologies for optimal performance.

The Role of IoT in Supply Chain Management

The supply chain is the backbone of businesses, ensuring that raw materials are sourced, products are manufactured, and goods are delivered to the final consumer. However, the complexity of modern supply chains, along with the increasing demand for faster and more reliable delivery, has put a strain on traditional methods. IoT addresses this challenge by enabling real-time tracking, predictive analytics, and enhanced automation.

IoT-enabled devices, such as RFID tags, GPS trackers, and temperature sensors, provide valuable data that helps businesses monitor the entire supply chain process. For instance, companies can track the location and status of shipments at any given moment, ensuring that products are delivered on time and in optimal conditions. This real-time visibility reduces delays and allows companies to proactively address potential issues before they escalate, thereby improving overall efficiency.

Benefits of IoT in Supply Chain Management

Improved Visibility and Transparency

One of the most significant advantages of IoT in supply chain management is the enhanced visibility it offers. With IoT-enabled devices, businesses can monitor every aspect of the supply chain in real time. This transparency ensures that businesses can track shipments, monitor inventory levels, and even assess the condition of products as they move through the supply chain. This level of visibility allows for better planning and decision-making, minimizing disruptions and improving customer satisfaction.

Predictive Analytics for Demand Forecasting

By collecting vast amounts of data from connected devices, IoT enables businesses to apply predictive analytics to forecast demand more accurately. For example, data from sales trends, seasonal patterns, and consumer behavior can be analyzed to predict which products will be in high demand and when. This helps businesses optimize inventory levels, reduce stockouts, and minimize overstocking, thus improving operational efficiency and reducing waste.

Reduced Operational Costs

IoT-driven automation in supply chain management leads to significant cost reductions. For instance, automated systems powered by IoT can handle tasks such as inventory management, order fulfillment, and route optimization. This reduces the need for manual labor, minimizes errors, and speeds up processes. Additionally, real-time monitoring of the supply chain allows businesses to identify inefficiencies and bottlenecks, leading to cost-saving measures and streamlined operations.

Enhanced Product Quality and Safety

In industries where product quality and safety are paramount, such as food and pharmaceuticals, IoT can play a crucial role. Temperature sensors and environmental monitoring devices can ensure that products are stored and transported under optimal conditions. If the conditions deviate from the required parameters, IoT systems can trigger alerts, allowing businesses to take corrective actions immediately. This ensures that products maintain their quality and safety throughout the supply chain, protecting both the business and the consumer.

Streamlined Inventory Management

Traditional inventory management systems often rely on manual checks, leading to errors and inefficiencies. IoT introduces automation into this process by allowing real-time tracking of inventory levels. IoT-enabled RFID tags and barcode scanners enable businesses to track the movement of goods with pinpoint accuracy. This not only minimizes stockouts and overstocking but also improves order fulfillment rates and reduces storage costs.

Integration of Mobile Solutions in Supply Chain Management

As IoT devices generate a vast amount of data, it becomes increasingly important for businesses to leverage mobile applications to make sense of this information. Mobile apps allow managers and employees to access real-time data from anywhere, making it easier to monitor and manage supply chain activities on the go.

Businesses can use a mobile app cost calculator to estimate the investment needed for developing a custom app tailored to their specific supply chain needs. This tool helps in understanding the financial implications and assists in making informed decisions about the best course of action for their business. In addition, the increasing trend of Android app development in India has made it cost-effective for businesses to integrate mobile solutions into their operations, providing real-time supply chain updates directly to their smartphones.

For businesses seeking to improve their supply chain management processes through mobile solutions, leveraging IoT technology can significantly enhance operations. Mobile apps integrated with IoT devices offer convenience, accessibility, and efficiency, empowering businesses to stay ahead of the competition and improve their bottom line.

If you're interested in exploring the benefits of IoT service provider companies for your business, we encourage you to book an appointment with our team of experts.

Book an Appointment

Future of IoT in Supply Chain Management

The future of IoT in supply chain management looks even more promising as technology continues to evolve. With advancements in artificial intelligence (AI), machine learning, and edge computing, the potential for IoT to transform supply chains is limitless. AI can enhance predictive capabilities, while edge computing allows data to be processed closer to the source, reducing latency and improving response times.

As IoT continues to integrate with other emerging technologies, supply chains will become even more agile, resilient, and efficient. By partnering with IoT service provider companies, businesses can stay at the forefront of these innovations and ensure that their supply chain operations remain competitive in a rapidly changing world.

In conclusion, IoT has already proven its value in transforming supply chain management, offering benefits such as improved visibility, reduced costs, enhanced safety, and more efficient inventory management. As the technology evolves, its potential to drive even greater efficiencies and innovations in the supply chain is boundless. By working with experienced IoT service provider companies, businesses can implement customized solutions that meet their unique needs, ultimately leading to a more streamlined and effective supply chain.

0 notes

Text

13 Healthy Items That Will CHANGE YOUR LIFE!!!

youtube

30,000 Mah Doesn't work

With - Electricity - Blanket

Other - works - Not - many

Hours - Maybe - Just - my

Weight - Sleeping Pad was

Not Full - Air - Will get

Another - Same One or

Was just - Yesterday

Slept at 2A Est

Woke up - at - 5:25A

3 hrs - Sleep like Nap

Januaries

Christmas Tree Bookstoree

Special Tablet

Best Apartments

Best Gated Communities

Tiny Homes - No Human

Entry - Gated Communities

Januaries

Coffee and Cinnamon Cake

Bookstore

Dear Korean Girls,

Our Dream Come True

One Floor - Digital Lockers

Height Adjustments

Luggage - Purses

Laptop Tablets Clothes

School Life

Ballet - Musical Theatre

Sports - Hanukkah

Christmas

Lockers - $0.25 per day

Register - Valuables

Louie Vuitton - Cash

Cards - Rolex Watch

Religious - Entry

Tongues - $500 Billion

Sing Tongues - $500 B

Tax Paid

Not Accepting - Hobo

Germs - Full - Clothes

Korean Girls,

Reading - Computer

Business needs our

Health and Wellbeing

Can't Design as Itchy

Smelly - Not - Bathed

Love Korean - Scalp

Treatments - Want yes

Others 2 Do My - Hair

Forgot the Salon Name

Tentative - Name

Legal Permission

Sulli and Goo Salon & Spa

Scalp - Treatment

Face - Treatment

Feet - Treatment

Spa - and - Massage

Gnumbing Cream

Required

Botox - Wrinkles

Removed

World - Record

Botox Face & Neck

Body Parts - $0.25

Total - $0.25

Hair Color - My Own

Shampoo & Conditioner

$0.25

No Tips - Salon & Spa

Hair Extension

Introducing

Hair Transplant

Head - Eyebrows - $0.25

Lashes - Extension

Lashes - Thickened

$0.25

Example - with - me

Introducing

Miracle - Wigs

Like - Vacuum Storage

Bags Wigs - Vacuumed

Short Boy - Hair

Hair - Shoulder - Length

Laser Technology

Height - $0.25

Laser - Removes Moles

Age Spots

Laser - Nails - area

Make overs - Important

Spa - Mints

Full Body Massage

1 hour - $0.25

So - we finish - perfect

Hair - Removal - $0.25

I need - Hair Extensions

Laser - World - Tech

Removes - Blindness

Change - Eye Colors

With Spa - ID - Area

Floors - includes

Ambassador - ID

Laser - Changes Face

Enter - Stars

Paulina Porizcova

Marilyn Monroe

Se Kyung Shin

Laser to our Faces

So New Face

New Fingerprints

Laser - Shape Ears

Breast Injection

Increase - Change Looks

Immigration saw us nude

Change our Bodies

Ambassador - ID

World - Permit

In - All Languages

In - All Dialects

New Citizenships

Exempt - from - Many

Laws - Bible - 'Money'

Ambassador - ID

Paying - New Citizens

Fees - for - Countries

Forgot Mom's Name

Forgot Dad's - Name

Ambassador - ID

World - GPS

Birth Certificates

In - English - Japanese

Female - Japanese

Passport - My Mom

Will have - Animated

Photo of - our Parent

Giving Japan - Fees

500 Billion Yen x 50

Tax Paid - Tokyo Mom

Deleting - US Records

Contains

US Work Visa

South Korea - Work Visa

Paris - France - Student

And - Work Visa

England - Student - Visa

Thus - US - Jury Free

New - SSN - Numbers

New - Face

New - Height - 5'9 ft

New - Mole or Moles

Blue Eyes

Introducing - Dental

Extraction - Fake Teeth

Removes - Bonding

Softens - Gums so

Machine can straighten

Teeth - Extreme - White

Teeth - All our Bodies

Fixed - Scars - Removed

Bruises - Removed

Ambassador - ID

Communicates - with

TAAS - Clear

Global Entry

No need 2 go 2 Airports

Ambassador - ID

When Stolen - this - yes

Bookstore - will have the

Kiosks - 4 - Replacement

Apt Lease - Papers

Register - Keys

100% - Approval

Amex - Diners Club

Visa - Mastercard

JCBC

Amazon Prime MC

Kiosks - Releases

Official - 3 Duplicates

Of - Passports - Cards

RFID - Protection

Special Icon - on - each

Repels Scan of Thieves

Kiosks - Replaces

Title Deeds - Diplomas

Birth Certificates - Keys

Dear Korean Girls,

HDG Bank - First - Bank

Branch - 24/7 - Online 2

Showers - Floor

30 min - $0.10

Shampoo Conditioner

Body Shower Gel

Lotion - Hair - Spray

B4 - Blowdry - Robe

Clothes - Boutique

Step Aside - Ross

Dress - New - $0.25

Self - service

Solves Domestic Violence

New Shoes - $0.25

Cinema - Also - 24/7

Legal - Permission

Silverspot Cinema

Click 4 Full Recline

But - Order - Food

Auto Appears

All you can eat - $1.00

Adults - Kids - Seniors

Free - Order b4 during

Film - Free - App

Decembers

Christmas Tree Bookstore

Tablet

We're - Sponsoring

Fully Furnished

Soundproofed

Apts - Hotels - Inns

Condos - Air BNB

Bed and Breakfasts

Bookstore - Members

Families - Sole

Free - Memberships

Above - Places

Tongues - Password

Every Entry

Tongues - $500 Billion

Sing Tongues - Same

Other - Floors

Ikea - Nooks

Sewing Machine - Dummy

Pattern Tables

Knitting - Hands - Needles

Tables - Clear

Smart TV - Animated

How 2 Sew

How 2 Knit

Nooks - Knitting Machine

Floor - Has - Cloth

Animated - Classes

24/7 - $0.25 - each

Other - Floors

Cardio Boxing

Boxing - Bags

Japan - Aikido

China - Wushu

Clear Booths

German - Semi Auto

Revolvers - Less than

Tic Tac - size - Bullets

Soundproof - Nooks

Shooting Range

21 and older

Tear Gas - Practice

Tiny - Disappears

$0.25 each

Archery - also

Baseball

Rugby

Golf ...

Nooks - 2 improve

Rollerblades

Rollerskates

Ice Skating

Sports Floors - All Ages

Bullet Proof Clothes

Shoes - also

Lightweight - Knife Proof

Combat Knife - Training

Sour Watermelons

Floors - Kitchen

Dear Korean Girls,

Le Cordon Bleu - Floor

English Classes Animated

24/7 - Classes - 2 years

Individual - $0.25

Foods - Provided

Grocery on Floor

Tutorships - 24/7 - Animated

Kids - Seniors - Free

Schools - College

Any Time Frame - $0.25

Dear Korean Girls,

Like - Small Towns

Bookstores that Change

Our Lives

Buying Land - Air Landing

Small Private Planes

Small Toilet included

Instead of Red Coach

Auto - Flies

Pilot not Needed

Ambassador - ID

Provides

Floor - Electric Cars

Only - Drivers - New

License - 50 States

Computer - Front

Steering - Wheels

Attached

Computer - Test

50 States - Traffic Laws

Retention - Vaccine

Weather - Cold Warm

Vaccine

50 States - Traffic Test

Electric Cars - Only

RV - Electric - Only

Private Plane Auto Pilot

US - World - Air Traffic

Both - First Aid Training

Baby - Kids - Training

Ambassador - ID

Training - Attached

Car - Plane Stirring

We issue - New IDs

Ambassador - ID

We issue all ID - Passports

World - US

Bookstore - All our Needs

Many Names - Bookstore

Coming 2 Miami - World 2

Jesus - is - Lord

App - 7 - Eleven

$3 - Any Size Coffee Donuts

Doing - Laundry - Today

Maybe - Brickell 7-Eleven

Jesus - is - Lord

1 note

·

View note

Text

Global Labels Market to Witness Robust Growth Amidst Rising Demand for Smart and Sustainable Labeling Solutions

Global Labels Market to Witness Robust Growth Amidst Rising Demand for Smart and Sustainable Labeling Solutions

Market Overview

The Global Labels Market is poised for substantial growth, driven by the increasing demand for product identification, branding, traceability, and regulatory compliance across various industries. Labels play a critical role in sectors such as food & beverages, pharmaceuticals, logistics, retail, and consumer goods, serving as an essential tool for marketing, authentication, and supply chain management.

With advancements in printing technologies, smart labeling, and eco-friendly materials, the industry is evolving to meet sustainability goals, digital transformation, and consumer engagement strategies. Companies are now adopting RFID labels, QR codes, and NFC-enabled solutions to enhance product tracking, anti-counterfeiting measures, and interactive consumer experiences.

Free Sample Report:- Sample Request | Labels Global Market Insights 2023, Analysis And Forecast To 2030, By Type, End User, Material Type, Printing Technique, And Ink Type

Market Insights & Trends

Rise of Smart and Interactive Labels: The integration of RFID tags, NFC chips, and QR codes is enhancing real-time product tracking, inventory management, and customer engagement.

Growing Preference for Sustainable Labeling: The push for biodegradable, recyclable, and linerless labels is increasing as businesses adopt eco-friendly packaging solutions.

Technological Advancements in Printing Techniques: Innovations in digital printing, UV-cured inks, and hybrid printing methods are revolutionizing label production with high-quality graphics, customization, and efficiency.

Increased Demand from E-commerce & Logistics: The growth of online retail and supply chain automation is driving demand for barcode labels, tracking labels, and tamper-evident packaging.

Regulatory Compliance & Transparency: Governments and industries are enforcing stringent labeling regulations for food safety, pharmaceutical traceability, and chemical hazard warnings, fueling demand for compliant and informative labels.

Key Players in the Market

The Global Labels Market is dominated by major players focusing on technological advancements, sustainable solutions, and industry collaborations. Key companies include:

Avery Dennison Corporation

CCL Industries Inc.

3M Company

UPM Raflatac

Mondi Group

Constantia Flexibles

Coveris Holdings S.A.

Brady Corporation

Fuji Seal International Inc.

Sato Holdings Corporation

These companies are actively investing in smart labels, environmentally friendly materials, and high-performance printing technologies to cater to evolving industry needs.

Full Report:- Labels Market Size, Scope & Growth Report 2030

Regional Insights

North America: The United States and Canada lead in technological innovation and stringent labeling regulations, with significant demand from retail, pharmaceuticals, and food industries.

Europe: Countries like Germany, France, and the UK are focusing on sustainable labeling solutions and compliance with EU regulations regarding packaging waste reduction.

Asia-Pacific: The fastest-growing region, driven by rapid industrialization, e-commerce expansion, and increasing consumer awareness in China, India, and Japan.

South America, Middle East & Africa: These regions are experiencing steady growth, driven by urbanization, rising consumer goods demand, and improved logistics infrastructure.

Market Outlook & Growth Prospects

The Global Labels Market is expected to grow at a CAGR of over 5% through 2030, driven by:

The rise of digital and smart labeling technologies

Growing emphasis on sustainable and recyclable materials

Increased demand from logistics, healthcare, and retail industries

Stricter regulatory requirements for product labeling and traceability

Advancements in ink and printing techniques for high-performance labeling

As the industry shifts toward sustainability, digital innovation, and compliance-driven solutions, the market will continue to expand, offering new opportunities for manufacturers, technology providers, and end-users.

Enquire Before Buy:- Enquire Before Buy | Labels Global Market Insights 2023, Analysis And Forecast To 2030, By Type, End User, Material Type, Printing Technique, And Ink Type

Conclusion

The Global Labels Market is undergoing a significant transformation with the adoption of smart, sustainable, and high-performance labeling solutions. As businesses prioritize brand differentiation, regulatory compliance, and customer engagement, the demand for advanced labels and printing technologies will continue to rise.

Top Trending Reports

Global More Electric Aircraft Market

Nigeria Oil and Gas Upstream Activities Market

Global Industrial Plastic Bags Market

Global Palladium Market

0 notes

Text

Challenges in Air Cargo Tracking Across North America and How to Overcome Them

The air cargo industry in North America plays a critical role in global trade, ensuring the swift movement of goods across borders. With millions of shipments processed daily, air cargo tracking in North America has become essential for logistics efficiency, security, and customer satisfaction. However, despite technological advancements, tracking air cargo in real time presents several challenges that impact operations.

This article explores the key challenges in air cargo tracking across North America and how businesses can overcome them to improve visibility, security, and efficiency in the supply chain.

1. Lack of Real-Time Visibility

The Challenge:

One of the biggest hurdles in air cargo tracking in North America is the lack of real-time visibility. While tracking technologies like RFID and GPS exist, many cargo shipments still rely on outdated systems that provide limited updates. Delays in data transmission can lead to:

Uncertainty about cargo location.

Difficulty in predicting arrival times.

Increased risk of cargo misplacement.

How to Overcome It:

Implement IoT-Enabled Tracking: Using IoT-based tracking devices ensures real-time monitoring of cargo, allowing businesses to receive instant updates on location and status.

Adopt Cloud-Based Tracking Systems: Cloud-based platforms enable seamless data sharing between stakeholders, reducing information gaps.

Integrate AI and Predictive Analytics: AI-powered tracking helps anticipate delays and recommend alternative routes for faster deliveries.

By investing in advanced tracking solutions, logistics providers can improve operational transparency and reduce uncertainty in shipments.

2. Data Integration and Standardization Issues

The Challenge:

Different airlines, freight forwarders, and logistics companies use various tracking systems, leading to data silos and lack of standardization. Without a unified system, stakeholders struggle to access complete shipment information, causing inefficiencies in cargo tracking.

How to Overcome It:

Adopt a Unified Tracking Platform: Using a single, integrated tracking system that connects all stakeholders ensures streamlined data access.

Implement API Connectivity: APIs enable different tracking systems to communicate and exchange real-time data, improving coordination.

Encourage Industry Collaboration: Standardizing tracking protocols across North America’s air cargo industry can improve overall transparency and efficiency.

A well-integrated tracking ecosystem enhances visibility and reduces errors caused by fragmented data.

3. Security Risks and Cargo Theft

The Challenge:

Cargo theft remains a major concern in air freight logistics, particularly for high-value shipments such as electronics, pharmaceuticals, and luxury goods. Without proper security tracking, stolen or tampered cargo can go undetected until it reaches its final destination.

How to Overcome It:

Use Tamper-Proof Tracking Devices: GPS-enabled locks and RFID tags provide real-time alerts if cargo is tampered with.

Enhance Airport and Warehouse Security: Strengthening security at cargo hubs, warehouses, and loading docks reduces the risk of theft.

Utilize Blockchain for Secure Transactions: Blockchain technology helps maintain an immutable record of cargo movements, preventing data manipulation and unauthorized access.

By prioritizing security tracking, businesses can protect their cargo from theft and unauthorized handling.

4. Weather-Related Disruptions

The Challenge:

North America experiences extreme weather conditions, including snowstorms, hurricanes, and heavy rainfall, which can disrupt air cargo tracking and delivery schedules. Flight cancellations or diversions often cause:

Shipment delays.

Loss of temperature-sensitive goods (e.g., pharmaceuticals, perishable food).

Increased costs due to rerouting.

How to Overcome It:

Use AI-Powered Weather Forecasting: AI-driven predictive analytics help logistics companies anticipate weather disruptions and plan alternative routes in advance.

Implement Temperature-Sensitive Tracking: IoT sensors monitor temperature-controlled cargo, ensuring compliance with cold chain requirements.

Develop Contingency Plans: Having backup logistics partners and alternative transport modes (e.g., trucks, rail) helps maintain supply chain continuity during extreme weather.

Proactive weather tracking improves supply chain resilience and reduces risks associated with unexpected disruptions.

5. Compliance and Regulatory Challenges

The Challenge:

Strict government regulations in North America, including customs clearance, security screening, and safety protocols, can cause delays in air cargo tracking. Regulatory compliance differs across the U.S., Canada, and Mexico, making cross-border tracking more complex.

How to Overcome It:

Automate Customs Documentation: Using AI-based customs processing tools speeds up regulatory compliance and reduces paperwork errors.

Enhance Digital Communication with Authorities: Integrating tracking systems with government regulatory databases streamlines compliance checks.

Stay Updated with Regulatory Changes: Partnering with compliance experts ensures businesses remain up to date with evolving trade regulations.

By adopting automated compliance solutions, businesses can speed up cargo clearance and avoid unnecessary tracking delays.

Conclusion

Air cargo tracking in North America faces several challenges, including limited real-time visibility, data integration issues, security risks, weather disruptions, and regulatory complexities. However, by leveraging IoT, AI, blockchain, and automation, businesses can improve tracking accuracy, enhance security, and ensure seamless cargo movement.

As the demand for faster and more reliable air freight grows, investing in advanced tracking technologies will be key to maintaining efficiency, security, and customer satisfaction in North America's dynamic logistics sector.

0 notes

Text

Automatic Identification And Data Capture Market Key Players, Revenue And Growth Rate

The global automatic identification and data capture market size is expected to reach USD 136.86 billion by 2030, according to a new report by Grand View Research, Inc. The market is expected to grow at a CAGR of 11.7% from 2025 to 2030. With an increase in the use of smartphones for image recognition and QR code scanning along with an increase in the development of e-commerce platforms internationally, the market is anticipated to experience a noticeable growth during the forecast period.

Furthermore, increased automatic identification and data capture (AIDC) solution acceptance due to their capacity to reduce discrepancies is likely to drive the growth of the AIDC industry during the forecast period. For instance, in April 2022, Arcion Labs, Inc., a truly real-time database replication platform, announced the release of Arcion Cloud, a fully managed change data capture data replication as a service that empowers businesses to leverage more significant, big data pipelines in minutes.

The most prevalent devices used to identify and capture the data are RFID scanners and RFID tags, barcode scanners, fixed-position, and handheld laser scanners and imagers, wearables devices, voice recognition solutions, and rugged tablets. Automatic identification and data capture systems, such as wearables, barcoding solutions, and RFID scanners, are critical in e-commerce and warehouse management.

AIDC technology not only assists the e-commerce business in automatically identifying objects, collecting data about them with high accuracy and precision, and electronically entering this data into the computer system. By keeping track of inventories, accounting, human resources, and overall procedures, technology also helps increase productivity and operational efficiency.

Gather more insights about the market drivers, restrains and growth of the Automatic Identification And Data Capture Market

Automatic Identification And Data Capture Market Report Highlights

• North America dominated the market and accounted for the largest revenue share of 38.5% in 2024. This high share can be attributed to the increasing awareness and high adoption of AIDC devices and increased government legislative and investment, particularly in retail, healthcare, and manufacturing industries.

• AIDC systems are routinely used to manage assets, inventory, delivery, document scanning, and security in various industries, including transport and logistics, chemical, pharmaceutical, food and beverage, automotive, consumer products, retail and warehousing, and distribution

• Radio Frequency Identification (RFID) tags, barcodes, biometrics, labels, smart cards, and speech and voice recognition have gained acceptance across various industries due to their increased accuracy, precision, and smooth functioning

• Banks and financial institutions' increasing implementation of AIDC solutions to ensure customer security, safety, and data privacy is projected to fuel market expansion

Automatic Identification And Data Capture Market Segmentation

Grand View Research has segmented the global automatic identification and data capture market on the basis of component, end-use, and region:

Automatic Identification And Data Capture Component Outlook (Revenue, USD Billion, 2017 - 2030)

• Hardware

o RFID Reader

o Barcode Scanner

o Smart Cards

o Optical Character Recognition Devices

o Biometric Systems

o Others

• Software

• Services

o Integration & Installation Services

o Support & Maintenance Services

Automatic Identification And Data Capture End-user Outlook (Revenue, USD Billion, 2017 - 2030)

• Manufacturing

• Retail

• Transportation & Logistics

• Hospitality

• BFSI

• Healthcare

• Government

• Energy & power

• Others

Automatic Identification And Data Capture Regional Outlook (Revenue, USD Billion, 2017 - 2030)

• North America

o U.S.

o Canada

• Europe

o UK

o Germany

o France

• Asia Pacific

o China

o Japan

o India

o Australia

o South Korea

• Latin America

o Brazil

o Mexico

• Middle East and Africa

o Saudi Arabia

o South Africa

o UAE

Order a free sample PDF of the Automatic Identification And Data Capture Market Intelligence Study, published by Grand View Research.

#Automatic Identification And Data Capture Market#Automatic Identification And Data Capture Market Size#Automatic Identification And Data Capture Market Share#Automatic Identification And Data Capture Market Analysis#Automatic Identification And Data Capture Market Growth

0 notes

Text

How RFID and IoT Are Changing the Game in Uniform Management

Uniform management? Not exactly the most thrilling topic—until you realize how much of a headache it used to be. Lost uniforms, chaotic inventory, and constant reordering? Total nightmare. But with RFID (Radio Frequency Identification) and IoT (Internet of Things) stepping in, managing uniforms is starting to feel less like a chore and more like a well-oiled machine.

From healthcare to hospitality and manufacturing, businesses are swapping out old-school tracking methods for high-tech automation. RFID tags and IoT-powered systems are making uniform distribution smoother, cutting down on losses, keeping things hygienic, and—best of all—saving money. Let’s talk about how these innovations are totally reshaping uniform management software and what the future holds.

So, What’s the Big Deal with RFID and IoT?

RFID: The Ultimate Time-Saver

Think of RFID as a digital ID system for uniforms. Tiny tags embedded in garments send signals to RFID scanners, automatically logging every movement. No more manual scanning, no more guessing games—just instant tracking that makes sure uniforms don’t magically disappear into thin air.

IoT: The Smart Assistant You Never Knew You Needed

IoT kicks things up a notch by connecting RFID data to cloud-based systems. Now, businesses can track uniform usage in real time, automate restocking, and even analyze trends to stay ahead of demand. Plus, features like smart lockers mean employees can grab what they need without a middleman slowing things down.

Why RFID is a Total Game-Changer

No More Manual Tracking (Finally!)

Remember when uniform tracking meant clipboards, spreadsheets, and sheer frustration? RFID makes all that obsolete. Each time a uniform is issued, returned, or washed, the system records it instantly—no human intervention needed. That means fewer errors and way more efficiency.

Lost Uniforms? Not on RFID’s Watch

If missing uniforms are eating into your budget, RFID has your back. Every move a uniform makes is recorded, so if something goes missing, you’ll know exactly where it was last seen. Bonus: It also keeps employees accountable.

Smarter Laundry, Less Hassle

In industries like healthcare and food service, hygiene isn’t optional—it’s critical. RFID ensures that uniforms go through the right cleaning cycles and are returned to the right people, cutting down on contamination risks and mix-ups.

How IoT Is Taking Uniform Management to the Next Level

Smart Lockers: Grab and Go

IoT-powered smart lockers? Absolute game-changer. Employees scan an ID, grab their uniforms, and go—while the system keeps track of every transaction. No more wasted time, no more confusion.

Real-Time Inventory Updates

With IoT-powered uniform inventory management, managers always know what’s in stock and what’s running low. The system predicts shortages, reorders automatically, and ensures there’s never too much or too little on hand.

Predictive Analytics = Smarter Planning

IoT isn’t just about what’s happening now—it’s about anticipating what’s coming next. By analyzing uniform usage patterns, businesses can schedule replacements, optimize laundry cycles, and even adjust orders based on trends.

The Best Perks of RFID and IoT in Uniform Management

Supercharged Efficiency

No more bottlenecks, no more wasted time. RFID and IoT streamline every part of uniform management, making things run faster and smoother.

Cost Savings That Make a Difference

When uniforms aren’t getting lost, over-ordered, or underutilized, businesses save serious cash. RFID and IoT help cut unnecessary expenses while making sure resources are used wisely.

Hygiene You Can Actually Trust

For industries where cleanliness is king, RFID and IoT ensure uniforms are cleaned properly and swapped out at the right time. No more sketchy hygiene practices—just reliable, trackable sanitation.

The Challenges of Jumping on the RFID and IoT Train

The Price Tag

Yes, these systems are a smart investment, but they aren’t free. Businesses need to think about upfront costs and whether the long-term benefits justify the expense.

Integration Takes Work

Not every company has the latest tech infrastructure, which means rolling out RFID and IoT might take some adjustments. Compatibility with existing systems and staff training are key to making the transition smooth.

Data Security Concerns

Tracking uniforms digitally means storing sensitive data. Businesses need to lock down their systems with encryption and authentication to keep everything secure.

Who’s Already Using RFID and IoT Like a Pro?

Healthcare

Hospitals are using RFID to track scrubs, lab coats, and protective gear, ensuring strict hygiene compliance. IoT-powered smart lockers let medical staff grab clean uniforms without waiting in line.

Hospitality

Hotels and restaurants rely on RFID and IoT to keep uniforms available for housekeeping, kitchen, and front-desk employees. Automated tracking prevents shortages and keeps things running smoothly.

Manufacturing and Industrial Workplaces

In factories, workwear software helps track uniform usage, flagging items for replacement and ensuring compliance with safety standards.

What’s Next for RFID and IoT in Uniform Management?

AI + RFID + IoT = Next-Level Efficiency

Imagine a system that doesn’t just track uniforms but predicts what you’ll need before you do. AI-powered analytics will help businesses plan ahead, reduce waste, and keep everything running like clockwork.

Blockchain for Ultimate Security

Blockchain could make RFID tracking even more secure by ensuring data stays tamper-proof and accessible only to authorized users. More transparency, less risk.

Managing Uniforms Across Multiple Locations

As companies grow, keeping track of uniforms across different locations will get even easier with RFID and IoT. No matter where employees are, they’ll always have access to what they need.

The Bottom Line

RFID and IoT are totally transforming uniform management, making it faster, smarter, and more reliable. From automated tracking to predictive analytics, these innovations are turning an outdated process into a seamless experience.

If you’re looking to take uniform management to the next level, investing in uniform management software is a no-brainer. With RFID and IoT in the mix, the future of uniform tracking has never looked better.

0 notes

Text

How do Anti-theft Backpacks Work?

The laptop backpack aims at protecting your digital devices from damage, but what happens to the bag itself? One cannot fathom having to lose your laptop and other devices that can be with you for the rest of your life. Anyone who anticipates that there are various tech products that may attract criminals’ attention but does not want to fall prey to such criminals should consider getting an anti-theft backpack.

Whatever your chosen bag type – backpack, business bag, or handbag – there’s undoubtedly a model that’s anti-theft on the market. Below are some questions to ask in order to understand an anti-theft backpack. All questions that you may be having will be answered in this post.

What is an Anti-theft Backpack?

A laptop, business, or cross-body bag with a cutting-edge theft-proof function is called an anti-theft backpack. It can prevent thieves thanks to its integrated RFID pockets, extremely secure zips, and password-protected property. The primary goal of the anti-theft bag is to provide commuters, tourists, and students peace of mind.

How Do Anti-Theft Backpacks Work?

According to what many commuters or travelers believe, using an anti-theft backpack is not difficult. After purchasing an anti-theft backpack, you need to take the following actions:

Step 1: Put Tech products properly

The first step is to load all of your electronic devices in a backpack properly. Separate spaces are provided for charging USB cables, computers, smartphones, and power banks.

There are also distinct spaces for food items and water bottles. Your wallet, ID card, passport, tickets, and debit or credit card are all kept in the secret pockets.

Step 2: Zipped each Pocket Appropriately

The next step is to zip up each backpack pocket and small/large compartment. Although it appears to be a simple error, it will have serious consequences.

You wouldn't know what would happen if you neglected to zip up your pocket and one of your gadgets was picked up at random. Therefore, you should use caution when zipping your anti-theft backpack's pockets.

Step 3: Set a Strong Passcode

The most important step in the procedure is creating a secure passcode for the bag. Make sure the passcode does not contain your date of birth, house number, or SIM number since a smart friend is attempting to hack your rucksack using your personal data.

What Makes a Backpack Anti-theft?

Anti-theft bags, in contrast to regular bags, are equipped with sophisticated safety mechanisms to prevent theft. You should read the bag's characteristics before purchasing an anti-theft backpack from a real or online vendor. Let's now examine some of the essential features that distinguish an anti-theft backpack:

1. Passcode Protection

The majority of individuals look up "how to make your backpack anti-theft" on social media or another website. Setting up a secure and unique password or passcode on your laptop bag is the most genuine solution.

In case you forget your password, it's a good idea to keep it in your phone notebook. Additionally, don't share your password with anyone, not even your friends or coworkers. You can also search for Festival bags.

2. RFID Blocking Pockets

Blocking radio-frequency identification (RFID) is another crucial component of a bag that prevents theft. To track your personal belongings and determine the frequency, the backpacks come with an integrated tracking system.

You can safeguard your credit cards, debit cards, and other chip-operated cards with these RFID blocker pockets. These frequencies might be blocked by the anti-theft backpack. You should also search forTravel pouches.

3. Reinforced Zip

The anti-theft backpacks are specifically made with zippers on the exterior to safeguard priceless electronics. This may make it more difficult for someone to unlock your bag's zippers and clips and obtain unwanted access.

However, criminals or burglars find it more difficult to enter backpacks with strengthened zips. Maybe that will prevent them from getting near your stuff. You can also search online for bags with locks.

4. Slash and cut-proof straps

Since the straps on anti-theft backpacks are slash-proof, thieves cannot cut them with a knife or other blade. It ensures that your belongings are completely secure. Their weight will not cause any pain to your shoulders or back. It is difficult to cut the straps or compartments of this robust laptop backpack.

5. Secrete Pockets

Designers of laptops hide numerous pockets to fully conceal your personal belongings, including cash, passports, and credit cards. It is the most effective method of keeping it secure and out of criminals' grasp.

Are Anti-theft Backpacks Worth it?

Indeed, the anti-theft backpack characteristics make it well worth the money. Protecting your priceless technological gadgets from stolen thieves is essential. Hackers cannot access the backpack because of its difficult-to-open zippers, passcode setting, and slash-resistant straps.

The conclusion is that, in comparison to a standard laptop backpack, owning an anti-theft backpack is worthwhile. Because a theft-proof bag will save you money on pricey and important tech devices, don't be afraid to spend more on it.

#smell proof bags#smell proof bags with lock#odorless bags#odorless backpack#smell proof backpacks#smell proof cases#smell proof pouches#Smelly Proof Bags#small smell proof bags#best smell proof bags#Urban commute bags#College backpacks#Festival bags#Travel pouches#Gym and fitness bags#Water resistant bags#Anti-theft backpacks#bags with locks#lockable backpack#Durable travel bags#Skateboard backpacks

0 notes

Text

Control Systems In Pune

Enhance Your Operations with Advanced Control Systems In Pune by Perfecto Robotics. Are you looking for Control Systems In Pune? Perfecto Robotics offers specialized expertise as well as innovative solutions to optimize industrial processes.

Why Choose Perfecto Robotics for Control Systems?

Expertise.

Innovation.

Customization.

Collaboration.

What is a Control System?

A control system manages, commands, directs, or regulates the behavior of other devices as well as systems using control loops.

Control Systems range from a single home heating controller using a thermostat controlling a domestic boiler to large industrial control systems that are used for controlling processes or machines. The control systems are designed via a control engineering process.

Use of Control System:

Boiler controls in heating and power plant systems.

Pipeline monitoring.

Water distribution systems.

Wastewater treatment systems.

Electricity distribution systems.

How are control systems used?

Agriculture.

Chemical plants.

Pulp and paper mills.

Industrial and manufacturing quality control.

Boiler controls and power plant operations.

Environmental control.

Water and sewage treatment plants.

Food and food processing.

Metal and mines.

Pharmaceutical manufacturing.

Sugar refining.

Control System Main Types:

Open Loop:

Closed Loop

Linear Systems

Applications Control System:

CONTROL USING PID

CONTROL USING LQR

CONTROL USING RFID

Features of Control Systems:

Feedback Mechanism.

Setpoint Adjustment.

Error Detection and Correction.

Closed-Loop Operation.

Integration with Sensors and Actuators.

Safety and Fault Tolerance.

Ready to elevate your industrial automation with advanced control systems in Pune? Look no further—contact Perfecto Robotics today to schedule a consultation. Let us help you harness the power of cutting-edge control technology to achieve operational excellence and drive business growth.

Drive Efficiency and Reliability with Perfecto Robotics – your trusted partner for control systems in Pune.

If you want to add value to your operations with advanced control systems, please do not hesitate to contact us. With Perfecto Robotics, you can achieve custom-designed solutions that can transform your business. Our team will guide you at every step of the decision-making process, from initial consultation and system installation up to after-sales support.

Optimize. Automate. Innovate. Perfecto Robotics secures your business in Pune’s hands, helping unlock a whole new scale for your potential, thereby paving its path toward successive growth. Get set to propel the transformation journey for your operations in Pune today.

0 notes

Text

The Connected Car Economy: Tapping into In-vehicle Payment Potential

The global in-vehicle payment services market size is expected to reach USD 14.43 billion by 2030, registering a CAGR of 12.1% from 2023 to 2030, according to a new report by Grand View Research, Inc. The aggressive spending by automakers on enabling drivers to make payments and authenticate transactions from the vehicle itself coupled with the rising levels of disposable income, especially in the developed economies, and the growing preference for contactless payments are expected to drive the growth of the market over the forecast period.

Busy schedules are prompting drivers to look forward to hassle-free experiences as part of an upgraded lifestyle. At this juncture, the ability to shop, order, and pay on the go without performing any cash transactions for swiping credit/debit cards would allow commuters to save time and ensure a convenient commute. In-vehicle payment services offer drivers and passengers the convenience of making payments through various payment modes from the vehicle itself. The demand for In-vehicle payment services is expected to increase over the forecast period in line with the proliferation of connected cars and the growing preference for advanced infotainment.

Automakers, such as BMW AG, Mercedes-Benz, Ford Motor Co., Honda Motor Co. Ltd., General Motors Co., and Jaguar Land Rover Automotive PLC, have already started integrating in-vehicle payment services and solutions into their vehicle models. Payment service providers, such as MasterCard, Visa, and PayPal, are also striking strategic partnerships and collaborations with automotive OEMs to deliver efficient in-vehicle payment platforms.

The preference for contactless payments is growing in the wake of the outbreak of the COVID-19 pandemic. As such, the majority of the parking systems, gas stations, and toll collection booths have already incorporated mobile payment technology. The popularity of e-wallets is rising owing to the convenience and ease of payment e-wallets can offer. Digital wallet and online payment platforms, such as Google Pay, Amazon Pay, and Apple Pay, are also getting immensely popular and their adoption is expected to increase significantly over the forecast period.

However, automotive OEMs are looking forward to designing and developing a payment ecosystem that would allow drivers and passengers to avail and pay for all the desired services, such as filling gasoline or charging electric cars, booking and paying for parking slots, paying tolls at toll booths, and ordering food and coffee, among others, without having to get out of the vehicle. Hence, the market for in-vehicle payment services is expected to grow significantly over the forecast period.

In-vehicle Payment Services Market Report Highlights

The gas & charging station segment accounted for a significant revenue share of around 27.5% in 2022. This is attributed to the increasing adoption of electric vehicles (EVs), the growing popularity of contactless payments, and the increasing availability of in-vehicle payment technology.

The credit/debit card segment accounted for the largest market share of 53.2% in 2022.Debit cards and credit cards remain the most popular payment modes and are used extensively to make contact and contactless payments.

North America accounted for a market share of around 39.3% in 2022. Continued integration of the latest technologies in automobiles and the rising levels of disposable income are anticipated to drive the growth of the regional market

In-vehicle Payment Services Market Segmentation

Grand View Research has segmented the global in-vehicle payment services market on the basis of mode of payment, application, and region:

In-vehicle Payment Services Mode Of Payment Outlook (Revenue, USD Million, 2018 - 2030)

NFC

QR Code/RFID

App/E-wallet Based

Credit/Debit Card Based

In-vehicle Payment Services Application Outlook (Revenue, USD Million, 2018 - 2030)

Parking

Gas & Charging Stations

Shopping

Food & Coffee

Toll Collection

Others

In-vehicle Payment Services Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Europe

UK

Germany

France

Asia Pacific

China

Japan

India

Australia

South Korea

Latin America

Brazil

Mexico

Middle East and Africa

Saudi Arabia

South Africa

UAE

List of Key Players

BMW AG

Daimler AG

Ford Motor Co.

General Motors Co.

Honda Motor Co. Ltd.

Hyundai Motor Co.

Jaguar Land Rover Automotive PLC

Volkswagen AG

ZF Friedrichshafen AG

Google

Amazon

Visa

MasterCard

PayPal

Order a free sample PDF of the In-vehicle Payment Services Market Intelligence Study, published by Grand View Research.

0 notes

Text

"Smart Packaging Solutions: Trends in Nano-Enabled Packaging"

"Nano-Enabled Packaging Market Size And Forecast by 2032

The global Nano-Enabled Packaging Market study provides an in-depth exploration of the industry, emphasizing key trends, evolving market dynamics, and the competitive landscape. It underscores the performance and strategies of leading companies shaping the market. The report delves into the Top 10 Companies in the [Nano-Enabled Packaging ] Market, analyzing their innovative approaches, financial outcomes, and their roles in driving market growth and capturing market share. This comprehensive overview enables stakeholders to understand the strategies fueling success in this dynamic industry.

Data Bridge Market Research analyses that the Global Nano-Enabled Packaging Market which was USD 43037.78 Million in 2022 is expected to reach USD 92389.58 Million by 2030 and is expected to undergo a CAGR of 10.02% during the forecast period of 2022 to 2030

Lastly, the study emphasizes the broader implications of these companies’ contributions to the Nano-Enabled Packaging Market growth and evolution. Their strategies, technological advancements, and market influence not only define current industry trends but also set the stage for future developments. By providing a comprehensive overview of the leading players, the report equips stakeholders with critical insights to understand competitive positioning, identify opportunities for collaboration, and develop strategies to thrive in this dynamic industry.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-nano-enabled-packaging-market

Nucleus is a secure, cloud-based platform designed to streamline data transfer and management for businesses. Its intuitive interface offers practice administrators and financial managers advanced filtering options, enhancing operational efficiency. By integrating various data sources, Nucleus enables effective prioritization of critical exposures, incorporating business context and threat intelligence to bolster security measures. Additionally, Nucleus supports seamless collaboration among multiple users across different applications, fostering rapid iteration and teamwork. Its deployment flexibility allows installation on-premises or via preferred cloud service providers, ensuring scalability and adaptability to meet diverse organizational needs.

Get More Detail: https://www.databridgemarketresearch.com/nucleus/global-nano-enabled-packaging-market

Which are the top companies operating in the Nano-Enabled Packaging Market?

The Top 10 Companies in Nano-Enabled Packaging Market operating in the Nano-Enabled Packaging Market are recognized for their innovation, market leadership, and strong presence across key regions. These companies invest heavily in research and development, driving continuous product innovation to meet evolving customer demands. Their extensive distribution networks, brand reputation, and technological expertise have solidified their positions as industry leaders. Additionally, these top companies are expanding through strategic partnerships, mergers, and acquisitions, enabling them to strengthen their market share and enhance their competitive advantages.

**Segments**

- **By Type**: The nano-enabled packaging market can be segmented based on the type into active packaging and intelligent packaging. Active packaging involves incorporating nanomaterials to actively interact with the packaged product to extend its shelf life or improve its safety. Intelligent packaging, on the other hand, includes features like sensors, indicators, and RFID tags that provide information about the product's quality and condition.

- **By Application**: This market segment can be categorized into food packaging, pharmaceutical packaging, cosmetic packaging, and others. Food packaging is a significant application area for nano-enabled packaging due to its ability to improve food preservation and safety. Pharmaceutical packaging benefits from nanotechnology by enhancing drug stability and efficacy. Cosmetic packaging utilizes nanomaterials for better protection and attractiveness of cosmetic products.

- **By End-User**: The end-user segmentation of the nano-enabled packaging market includes food & beverages, healthcare, personal care, and others. Food and beverage industry extensively uses nano-enabled packaging solutions to maintain product freshness and quality. Healthcare sector relies on nanotechnology for drug delivery systems and anti-counterfeiting measures. Personal care products leverage nano-enabled packaging for improved aesthetics and performance.

**Market Players**

- **Amcor Limited**: A global leader in packaging solutions, Amcor offers innovative nano-enabled packaging solutions for various industries. Their focus on sustainability and technological advancement sets them apart in the market.

- **BASF SE**: Known for its expertise in materials and chemicals, BASF provides cutting-edge nanotechnology solutions for packaging applications. Their research and development capabilities drive innovation in the nano-enabled packaging sector.

- **Tetra Pak International S.A.**: Specializing in food processing and packaging, Tetra Pak incorporates nano-enabled features in their packaging solutions to improve food safety and quality. Their commitment to food sustainability resonates well with environmentally conscious consumers.