#reciprocating piston pump

Text

#reciprocating pump#single acting pump#design#diagram#positive displacement pump#piston pump#plunger pump#art#illustration#product design

0 notes

Photo

The old pick-up has been sitting idle long enough, so you suggest a joy ride to ‘blow out the carbs’. My imagination takes a wicked u-turn at the phrasing, even though I know you intend to find a clear stretch of back road and open ‘er up for a couple of miles. I slip into that sheer little tight number, you refer to as my dealbreaker, and not much else besides some tall sandals. I’m waiting for you in the cab, when you finally find the keys. We smile at each other as I elevate one leg above the steering wheel, so you understand my state of mind. I’ve rouged my nipples with cherry chapstick and they peek above the rims of the opaque demi cups as an obvious invitation to be nibbled. You comment on my lack of a visible panty line and I bring your hand between my thighs to verify your suspicions. You kiss me, all tongue and possessive in your intent to blitz my bravado. I ooze in acquiescence as your masterful mouth progresses to the cherry-flavored tips of my full breasts that are already taut and tightened with arousal. I’m soon moaning from the breech below, stirring me deeply with two fingers as you nurse the cherry-ness from the sensitive nubs between your lips.

“Make me cum, baby…”

“What’s the rush, sweetie? We have all afternoon.”

Despite your exquisite torment, you are edging me closer with a pace I obviously crave. I murmur nonsense about the carbs needing to be blown and reciprocation for your own pleasure… There is a moment of hesitation as you stand outside the open door of the truck making me moan and writhe with abandon in the driver’s seat. My agenda finally clicks in your brain and I am finessed into cumming within the next instant. I giggle and gasp hysterically from the exhilarating release and you marvel at the vision of me in the throes of your man-made orgasm. Smothering me with kisses as I recover, the small aftershocks surprise us both. Still in no condition to drive, I maneuver myself over the stick shift to the passenger side and you take the wheel. We head out to a seldom traveled old access highway, while I fiddle and flirt with your fly. You protest half-heartedly as I nuzzle face first in your lap, knowing you are due the gratification for my first satisfaction. You downshift as a familiar car approaches, but I remain focused on my task of freeing you from the confines of your jeans. Not expecting a full stop to exchange brief explanations for your Sunday drive with an old pal, I remain out of sight. I hear him…

“Taking the old girl out for a spin?”

you reply, the

“Perfect day to let all the pistons pump, she deserves to have her carbs blown.”

I have unleashed your twitching to tease the tip with my tongue. The conversation is cut short with a swift farewell as I take you past my lips.

“Aaawh, baby, your timing is…”

“Exquisite?”

I murmur between lavishing the length with a spiraling descent to its hilt.

“This is unsafe… dangerous…”

“Exhilarating?”

I announce as you accelerate and the first backfires are left in the dust as your foot reflexively presses the clutch to upshift to third. I hear the wind in the side window vents reflecting our new speed and take you deeper into my mouth to suckle.

“Aaaaaw, so wrong, jeezus, that’s it, gawd… this is worth… the risk… lord, your mouth…”

By this time, the backfires have subsided, all the pistons are running clean and we are sailing at 70… 80… it’s hard to judge with you halfway down my throat. You’re growling with unbridled bliss at the top of your lungs as you unload all at once. Your foot slips off the accelerator and the old truck slows and sputters to another full stop without the advantage of fuel or the clutch. I have taken one last cleansing lap up and down its girth as your huffing breaths slow to normal. I raise myself to sitting and lick my lips devilishly, much to your amusement, and roll my window down to vent fresh air into the warm roomy cab.

“Hope you enjoyed that as much as I did…”

Your fingers are between my legs again, feeling for the answer… and drippings you seek. You find both and bring the spoils to your lips for tasting. Motioning a ‘chef’s kiss’ you return for another sample, and hum contentedly as you nurse your glistening fingers.

“How did I get so lucky?” You mumble to yourself.

“How are we gonna top that on the ride home?”

I whisper conspiratorially. I eye the revived twitching and note we won’t need to wait long, apparently. You turn over the engine and suggest we drive a bit further out before we head back. The old girl purrs, sounding as pleased as we both feel. Brainstorming a few debauched ideas, revs our own engines to their lusting levels again. You are soon hard again as I compliment your stamina and offer my ongoing slickness from my fingertips to rehydrate your imaginative desires. Several miles more down the empty road we pull over and reach a consensus that there is no need for speed. Having taken that death risk off the table, we agree that ‘slow and steady wins the race’. We’ll take our time and indulge our automotive-sexual fixations one more time today.

“Time to turn her around and let you steer?”

“As long as you’re my co-pilot… lover.”

The details have been hammered out as I crawl into your lap and guide your hardened girth inside of my slick welcoming void. I whimper with delight and clear my head as best I can to focus on the straight road ahead through the bug-specked windshield. Pulling my damp transparent skirt to my waist to give me full range of motion, you caress my hips and belly to feel the goosebumps on my flesh. You rev the engine and thrust deeper to test the comfort and angle of my mount. I squirm slightly to adjust and you groan your approval. I circle the wheel to pull off the shoulder and return back toward our destination. The road is bumpier than I remember… or the shocks need replacing, either way it’s a boon to our engagement. You supply the footwork and finesse the stickshift as I bounce subtly for the gripping friction. Your hip movement adds another dimension each time you change gears, and I request you take me through the sequence several times for purely selfish reasons. For your part, you seem to be still growing as I am stretched from the inside and respond with thrilled complimentary moans. I see our turnoff in the distance and insist we cum together before we arrive.

“I thought you’d never ask… just say when.”

Your fingers add a kneading assist as I double time my bouncing and as we let go simultaneously you can’t help but gun it one last time. The shock and awe of fear adds an unexpected adrenaline and we tear up the track crossing our finish line, roaring with the mutual release. Showing restraint, you pump the brakes softly so the truck rolls to a slow stop after we turn off the main road. I’m breathless, quivering, and you’re somewhat apologetic for leaving teeth marks on my shoulder. Our eyes meet in the rear view mirror for a long while, waiting for the other to reflect confusion… or desire for our new kink.

4 notes

·

View notes

Text

What Is DTH Drilling

DTH drilling, also known as Down-The-Hole drilling, is a technique used in mining, construction, and exploration projects to drill holes in hard rock formations. It is a percussion drilling method that utilizes a pneumatic or hydraulic hammer, often referred to as a DTH hammer, to deliver powerful blows to the drill bit.

Here's how the DTH drilling process typically works:

Rig Setup: A drilling rig is set up at the desired location. The rig consists of a drill string, which includes drill pipes, a DTH hammer, and a drill bit. The rig is positioned vertically or at a suitable angle for the drilling operation.

Hammer Assembly: The DTH hammer is connected to the bottom end of the drill string. The hammer contains a piston that strikes the back of the drill bit, transmitting energy to the bit for breaking the rock.

Air or Fluid Supply: Compressed air or drilling fluid (usually water-based) is pumped down the drill string to the hammer. The air or fluid serves multiple purposes, including removing drill cuttings from the hole and providing the necessary force to operate the hammer.

Drilling Operation: When the air or fluid reaches the DTH hammer, it enters the hammer's internal chamber and applies pressure to the piston. The piston reciprocates rapidly, delivering powerful blows to the drill bit. The impact energy fractures the rock, while the cuttings are carried to the surface through the annular space between the drill string and the hole wall.

Hole Advancement: As the drilling progresses, the rig applies downward force to the drill string, allowing the bit to penetrate deeper. The process continues until the desired depth is reached.

DTH drilling offers several advantages, including high drilling efficiency, accurate hole straightness, and the ability to drill in various rock types. It is commonly used in applications such as mining exploration, quarrying, foundation drilling, water well drilling, and geotechnical investigations.

Visit : rotary cum dth drilling rig india to knowmore

4 notes

·

View notes

Text

Selection and Application of Liquid Flowmeter

Reading guide: The liquid volume flowmeter consists of a chamber with a known volume and moving parts. The liquid passing through the flow is calculated by determining the volume of the container and the number of movements of the moving parts. According to the characteristics of liquid volume flowmeter, it can be divided into the following types: waist wheel flowmeter, oval gear flowmeter, scraper flowmeter, double rotor flowmeter, reciprocating piston flowmeter, rotary piston flowmeter, screw flowmeter, etc.

Structure and principle of the liquid volumetric flowmeter calibration device

The liquid accumulation calibration device consists of the quick connector, hydraulic hose, hydraulic filter, standard flowmeter, temperature transformer, pressure transformer, computer system, hydraulic source, etc. The hydraulic oil source also includes a hydraulic oil tank, variable frequency motor, hydraulic variable pump, hydraulic safety valve, and other components. The main features are compact installation, easy use, the same calibration medium, strong movement ability, and the ability to provide hydraulic oil. The working mode of the liquid flow controller is as follows: match through quick connection and replacement, and lead the hydraulic hose into the displaced liquid flow controller calibration device; The hydraulic power converter of the investment department generates clean and stable liquid flow through the hydraulic pump, hydraulic filter, etc. Capture the cumulative flow value determined by the computer system using the calibrated flowmeter and the standard flowmeter, and capture the temperature and pressure on the calibrated flowmeter and the standard flowmeter; The measured value error of calibrated flow is determined by the computer software system.

Main characteristics and application of common liquid flowmeter

Volumetric flowmeter

Volumetric flow meters (also called volume-specific flow values) are general-purpose instruments with the highest accuracy. The measured components can also be divided into the following main features: pitch circle (two rotors), plate flow measurement, oval gear flow measurement, rotary piston flow measurement, circulation flow measurement, etc.

① Advantages: high measurement accuracy; It can be used for measuring high viscosity fluid and simple phase fluid; The instrument does not need external energy to directly record the total flow. It is easy to install without special requirements for front and rear tangent lines.

② Disadvantages: not suitable for high temperature and low temperature; Type of measuring center with limited diameter; Pressure drop; Periodic calibration is required.

③ Application: Volume traffic signs, due to their high-precision measurement in energy, petroleum, medicine, food, chemistry, and other fields, especially raw materials and other fields, must be measured for storage, transfer, and distribution, and used as the basis for a financial settlement, or as a legal indicator of the contract between two tax dealers.

Differential

The differential is one of the most commonly used flowmeter types, which can be divided into diverter flowmeter, Venturi flowmeter, average line current, etc. according to the test piece (inlet instrument). The main features are:

① Advantages: single-phase fluid has a wide range of measurement methods, some mixed fluids; Simple structure, easy maintenance, the long service life of control components and detonators, display equipment produced by different manufacturers, improving economies of scale.

② Disadvantages: general customization accuracy; Large pressure loss (orifice plate, nozzle, etc.) The assembly constraint shall be high, and there shall be enough straight pipelines before and after assembly.

③ Nozzle: When measuring the flow in the closed pipe for the first time, the differential can be used for projects under different conditions where the flow is about 1/4-1/3 of the total flow.

Ultrasonic assistance

The ultrasonic flowmeter can be generally divided into plug-in type, pipe section type, external clamp type, and portable type.

① Advantages: large diameter non-contact measurement, large flow calculation; Pressure loss, no fluid disturbance; Suitable for every liquid, easy to install and maintain.

② Disadvantages: When the measured liquid contains bubbles or noise, the measurement accuracy will be affected; The temperature range of the measured liquid is limited by the heat of the ultrasonic protection and the communication materials between the switch and the line, and the original data for measuring the high temperature of the liquid is incomplete.

③ Application: Ultrasonic velocimeter is often used in petroleum, chemistry, metal, electric power, and other fields, and is often used to measure the emission reduction of gas pipelines in factories, fluids, and work areas.

Turbine speed

Intel Remax accelerated technology plan has been expanded to multiple categories in mass production, and its main features are as follows:

① High precision, usually ± 0.25% r - ± 0.5% r, up to ± 0.25% r - ± 0.5% r; Repeat at most 0.05% r-0.2% r for a short time; Zero contact movement, sturdy and durable.

② Disadvantages: The physical characteristics of the liquid have a great influence on the flow characteristics; Calibration characteristics cannot be saved for a long time.

③ Application. A turbine flow counter is usually used to measure oil, organic liquid, inorganic liquid, and liquid frozen body. The first terminal of the main raw material pipeline is used for commercial calculation of automobile exhaust, gas stations, and light hydropower plants.

Vortex flowmeter

The vortex flowmeter is the latest flowmeter, but it has developed rapidly and has become a common category. Its main characteristics are as follows. ① Advantages: wide application range, liquid, gas, and steam flow measurement can be used; Small pressure loss; Easy installation, simple and durable structure. ② Disadvantages: poor anti-interference ability; Straight pipe section is required before and after installation; The application experience in pulsating flow and multiphase flow is still lacking.

③ Application: Vortex flowmeter has a wide range of applications, usually used in the factory water supply system, and its application will be limited in the case of high viscosity, low flow rate, and small diameter.

General criteria for flowmeter selection and calibration device

Determine the technical requirements for flow measurement and the correctness of the flowmeter, that is, the accuracy requirements for measuring liquid; The flow measurement is repeated, that is, the same measurement is performed multiple times under specific conditions to repeat the same measurement. The expression of flow measurement, that is, whether the flow is mass flow or flow, real-time flow, or cumulative flow. Command and remove the transmission function if necessary. Specifies whether the flow measurement is displayed as a mechanical or electronic title. If the flowmeter does not meet the technical requirements of the measured liquid, measurement errors may also occur.

For the description of the flow calibration liquid calibration device, according to the flow requirements in jgg667-2010:

① The expanded uncertainty of the standard setting should generally not exceed 1/3 of the maximum allowable flow, because the expanded rate of the calibration device is 0.22%.

② Output or. The input line in the equipment used for online identification shall not include redirection between the flowmeter and the equipment designed as a locked cabinet without intermediate circuit.

③ "When the flowmeter is greater than 1.0, the flowmeter and liquid temperature must be measured according to the standard, and the temperature and pressure shall be measured near the standard flowmeter or calibrated flowmeter. Therefore, the liquid flow controller is applicable to the acceptance accuracy standard of Class 1.0 (allowable deviation ± 1.0%) and subsequent fluid calculation.

Conclusion

In the process of liquid flow measurement, a liquid flowmeter is a major measuring tool and has been widely used in metallurgy, pharmacy, paper making, water conservancy, environmental protection, petrochemical, and other fields. In the actual online calibration process, the standard volume method, the standard meter method, and the electrical parameter method are all feasible online calibration methods. However, they all have different use conditions, which requires the staff to constantly summarize and analyze the use of online calibration methods for liquid flow meters, so that the calibration methods can be improved.

Article from: supmeaflow.com

2 notes

·

View notes

Text

What Happens When a Diesel Engine Is Fuelled with Petrol?

Did you ever asked yourself what happens when you fuel a diesel engine with petrol? Or perhaps you have already been a victim of this action and are now suffering the consequences first-hand. Don't blame yourself or your driver, it happens frequently. In either case, combining petrol and diesel in a car can result in headaches and severely harm the engine.

One may imagine that combining petrol and diesel fuel by accident happens frequently, especially in petrol stations with pumps for both fuels located close to one another.

Due to the potentially severe consequences, putting petrol in a diesel engine, considerable attention must be used. Do not start your car if you combine these fuels by mistake. To have the vehicle recovered to a car garage, choose a mechanic by conducting an online search for car garages in Reading. The fuel system must be completely drained and flushed by the mechanic before he can resume driving your car.

What happens when petrol and diesel are combined?

You might have mixed these two fuel types if you own a car and have dealt with fuel for a while. While mixing diesel and petrol fuel is not recommended, there may not be as much of an issue as initially thought.

But how much did you refill, exactly? Will a diesel engine be damaged by a little petrol? Let's investigate.

Effects of petrol in a diesel engine

Early detection of this issue may allow you to prevent serious harm to your engine. On the other hand, if you continue to drive for a long time while using the incorrect or mixed fuel, you could encounter the following problems:

1.No ignition - Neither diesel engines nor petrol engines are built with automatic ignition systems as the fuel must be ignited with a spark. Therefore, there won't be a spark to ignite the petrol when you pour it into a diesel engine. Since both fuels are combined, there will be insufficient ignition to ensure smooth engine performance.

2.Black smoke - Since petrol cannot ignite in a diesel engine as diesel burns at 52 degrees Celsius and petrol at -40 degrees Celsius, respectively, there will be a lot of black smoke. As a result, a sizable amount of fuel will be wasted. Due to the considerable amount of unburned fuel, the exhaust tailpipe will emit a lot of black smoke. This smoke smells awful and will give you a horrible impression. Soot accumulation will cause numerous fuel system sensors to clog if you neglect it for a while. This issue will make an emissions test fail, so check MOT status and have it fixed.

3.Shock wave damage - Both petrol and diesel engines have a number of moving parts, including pushrods, wrist pins, pistons, con rods, camshafts, and crankshafts. These engine components may be damaged by the shock wave from an unexpected ignition. Additionally, it may result in engine knocking. Search online for garages in Reading as soon as you combine petrol and diesel to prevent this from happening, and then have your car recovered so that a mechanic can make the necessary repairs.

4.Fuel system damage - Your fuel pump, injectors, and fuel filters will be damaged if petrol gets into your diesel fuel tank. These make up a diesel fuel system's essential part. To achieve peak performance, you must replace all of the fuel system's components if they are not functioning properly. As was already mentioned, this will cause a MOT test to fail the emissions test. You can conduct an online search for 'check MOT history' if you're curious about if it has ever failed an emissions test.

5.Lack of lubrication - Many people are unaware that petrol is a solvent, and that diesel is a type of 'Oil' that lubricates engine components. As a result, using petrol in a diesel engine will result in inadequate lubrication. If you've ever wondered what occurs when you put petrol in a diesel engine or vehicle, the reason is that there is insufficient lubrication, causing metal to metal contact. Components of reciprocating engines will sustain damage as a result of the metals rubbing against one another.

6.Damage to the engine - If you discover you accidentally filled petrol in a diesel engine in good time, you can still recover your engine before the damages become too severe to fix. However, if you keep on driving for a while, you can wind up ruining the entire engine. And as you are aware, one of the priciest parts of a car is the engine.

#mot history#check mot#check mot history#mot history check#check mot status#mot status#check my mot history#mot history checker#mot testing service

1 note

·

View note

Text

Top Reasons to Choose Danfoss Compressors for Industrial Refrigeration Systems

Danfoss is a global leader in the design and production of energy-efficient solutions, and their compressors are no exception. Danfoss compressors are renowned for their high-quality performance, energy efficiency, and reliability. Widely used in various industries like HVAC, refrigeration, and air conditioning, Danfoss compressors come in different models, sizes, and capacities to meet various cooling and heating needs.

Danfoss compressors are designed to operate efficiently in diverse environments, from small commercial refrigeration systems to large industrial cooling plants. Their advanced technology ensures optimal energy consumption, reducing both costs and environmental impact. One of the key features of Danfoss compressors is their ability to maintain stable performance, even in harsh operating conditions. The Compressors are built with durable materials and undergo rigorous testing, making them highly reliable and long-lasting.

The brand also emphasizes sustainability, focusing on reducing the carbon footprint of their products while providing high-performance solutions for modern refrigeration and air conditioning systems. Their product range includes reciprocating, scroll, and rotary compressors, each designed to provide precise cooling performance for specific applications.

CR36 Compressor

The CR36 compressor is part of a high-performance line of compressors, often used in both commercial and residential refrigeration systems. Known for its efficiency and durability, the CR36 compressor is particularly well-suited for applications where reliable cooling is essential. It features advanced motor technology that ensures quiet and efficient operation, making it a popular choice in settings like supermarkets, restaurants, and cold storage facilities.

One of the key benefits of the CR36 compressor is its compact design. Despite its smaller size, it offers robust cooling power, making it ideal for applications where space is limited but performance cannot be compromised. The compressor's energy efficiency is another significant advantage, helping to reduce operating costs and environmental impact. By delivering consistent cooling with minimal energy consumption, the CR36 compressor stands out as a reliable and sustainable solution for modern refrigeration needs.

Rotary Compressor

Rotary compressors are widely used in air conditioning and refrigeration systems due to their high efficiency and compact design. Unlike reciprocating compressors, which use pistons, rotary compressors utilize a rotating mechanism to compress refrigerant. This design makes rotary compressors smoother and quieter in operation, a crucial factor in applications like residential air conditioning systems where noise reduction is essential.

Rotary compressors are known for their energy efficiency and ability to maintain stable performance over long periods. They are particularly effective in small to medium-sized cooling systems, such as window air conditioners, heat pumps, and refrigerators. The simplicity of their design also leads to fewer moving parts, reducing wear and tear and extending the life of the compressor. Rotary compressors are an excellent choice for those looking for an efficient, low-maintenance solution for their cooling needs.

Compressor Refrigeration Pvt. Ltd.

Compressor Refrigeration Pvt. Ltd. is a leading player in the refrigeration and air conditioning industry, offering a wide range of high-quality compressors to meet various industrial and commercial needs. The company specializes in providing energy-efficient and reliable Compressor solutions, ensuring that customers receive top-notch performance and long-lasting products.

Their product lineup includes rotary, reciprocating, and scroll compressors, each designed to meet the specific requirements of different applications. Compressor Refrigeration Pvt. Ltd. is known for its commitment to innovation and sustainability, continuously improving its products to offer more energy-efficient and environmentally friendly solutions. Whether it's for industrial cooling systems or commercial refrigeration, Compressor Refrigeration Pvt. Ltd. delivers products that combine performance, durability, and cost-effectiveness.

The company's focus on customer satisfaction, combined with its expertise in the field, has made it a trusted name in the industry. Their compressors are widely used in supermarkets, cold storage facilities, HVAC systems, and industrial refrigeration units, where reliable cooling is a critical requirement.

Make More Information about on this : https://crtechnologys.com/about-us

0 notes

Text

Asia Pacific Industrial Pumps Market Growth, Size, Report by 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Asia Pacific Industrial Pumps Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the Asia Pacific Industrial Pumps Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Asia Pacific Industrial Pumps Market?

The Asia Pacific industrial pumps market was valued at US$ 24.2 Billion in 2023 and is expected to register a CAGR of 4.9% over the forecast period and reach US$ 37.2 Bn in 2032.

What are Asia Pacific Industrial Pumps?

Industrial pumps are machines used to transport fluids, including water, chemicals, oil, and slurry, across various industrial processes. They are essential in industries such as manufacturing, oil and gas, chemical processing, and water treatment, enabling the smooth flow of liquids to support different operations. Available in several types, like centrifugal, positive displacement, and diaphragm pumps, each is designed for specific tasks based on the fluid’s viscosity, required flow rate, and pressure. These pumps are vital for ensuring efficient, safe, and reliable performance in industrial environments.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2436

What are the growth prospects and trends in the Asia Pacific Industrial Pumps industry?

The Asia Pacific industrial pumps market growth is driven by various factors and trends. The industrial pumps market in the Asia Pacific region is seeing strong growth, propelled by rapid industrialization, infrastructure expansion, and increasing demand from industries such as water and wastewater management, oil and gas, chemicals, and power generation. Countries like China, India, and Japan are investing heavily in manufacturing and energy projects, driving the need for reliable and efficient pumping solutions. There is also a growing focus on energy-efficient and advanced pumps as industries seek to lower operational costs and improve productivity. Government efforts to enhance water infrastructure and adhere to environmental regulations are further contributing to the market's growth. Hence, all these factors contribute to Asia Pacific industrial pumps market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Centrifugal Pump

Displacement Pumps

Reciprocating

Rotary

Peristaltic

Piston Pumps

Others

By Material

Stainless Steel

Bronze

Plastic

Others

By Drive Mechanism

Engine Driven

Electric Driven

By Application

Water Treatment

Irrigation Systems

Slurry Handling

Others

By End Use

Oil & Gas

Chemicals

Power Generation

Mining

Construction

Water and Wastewater Treatment

Others

Who are the key players operating in the industry?

The report covers the major market players including:

Schneider Electric

Tata Power Solar Systems Ltd.

Eaton

Solex Energy Limited

Boston Solar

ETAP

GE Vernova

ABB

S&C Electric Company

View Full Report: https://www.reportsandinsights.com/report/Asia Pacific Industrial Pumps-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Asia Pacific Industrial Pumps Market share#Asia Pacific Industrial Pumps Market size#Asia Pacific Industrial Pumps Market trends

0 notes

Text

North And Latin America Water Pumps Market is Estimated to Witness High Growth owing to Rising Construction Activities

The North and Latin America water pumps market consists of various product segments including centrifugal pumps, rotary pumps and reciprocating pumps. Centrifugal pumps function on the principle of centrifugal force to transport water from a low-pressure system to a high-pressure system. They are ideal for large flow rate applications like commercial HVAC systems, agriculture and wastewater treatment. Rotary pumps use a roller or sliding vane to push water from the inlet to the outlet. They are energy efficient and commonly used for hydraulic applications. Reciprocating pumps utilize a plunger or piston to transport water in a linear back-and-forth motion. They are suitable for high-pressure applications like boiler feed water and desalination. The water pumps find extensive usage in industrial, municipal, agriculture and residential sectors for applications like irrigation, drainage, filtration, dosing and liquid transfer.

North and Latin America water pumps market is estimated to be valued at US$ 12.72 Bn in 2024 and is expected to exhibit a CAGR of 4.7% over the forecast period from 2024 to 2031.

Key Takeaways

Key players operating in the North and Latin America water pumps are KSB AG, Ruhrpumpen Group, Flowserve Corporation, Kirloskar Brothers Limited, Sulzer AG, Xylem Inc., Ebara Corporation, Wilo SE, GRUNDFOS, and The Weir Group PLC.

The market provides significant opportunities in sectors like construction, agriculture, irrigation, wastewater treatment and power generation. Rising investments in infrastructure projects are fueling the demand for water pumps.

North And Latin America Water Pumps Market Demand are expanding to Latin American countries like Brazil, Mexico and Argentina through acquisitions, partnerships and distribution agreements to take advantage of opportunities in the growing regional market.

Market drivers

The main driver for the growth of North and Latin America water pumps market is the rising construction activities in the residential, commercial and industrial sectors. There is rising expenditure on construction of buildings, roads, bridges and other infrastructure which involves extensive usage of water pumps. The development of water supply and wastewater treatment infrastructure is another key factor driving the market growth.

PEST Analysis

Political: The regulations for water pumps vary in different countries across North America and Latin America. There are regulations regarding the efficiency and safety of pumps.

Economic: The economic growth and investment in industries like agriculture, mining will drive the demand for water pumps in the region. Repair and replacement of aging infrastructure also boosts market growth.

Social: Access to clean water is increasing in the region. Population growth and urbanization requires efficient water distribution which supports market growth.

Technological: Advances in material, design and variable frequency drives has improved pump efficiency. Integration of IoT enables remote monitoring of pumps.

Geographical regions with high market concentration

The United States accounts for the largest North And Latin America Water Pumps Market Size And Trends backed by investments in irrigation and water supply projects. Mexico, Canada and major countries in Central and South America also contribute significantly to the regional market.

Fastest growing region

Central and South America are projected to experience strong growth during the forecast period due to ongoing infrastructure projects, economic development and improving access to water and sanitation facilities across the region. Countries like Brazil, Colombia and Peru are expected to drive the future demand.

Get More Insights On, North and Latin America Water Pumps

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#North and Latin America Water Pumps Market Demand#North and Latin America Water Pumps Market Size#North and Latin America Water Pumps Market Trends#North and Latin America Water Pumps#North and Latin America Water Pumps Market

0 notes

Text

Air Compressor Equipment & Services in Los Angeles, California

OUR COMMITMENT

YOUR TRUSTED COMPRESSED AIR SOLUTIONS PROVIDER IN LOS ANGELES, CALIFORNIA

At Pattons CA, we take pride in being your premier partner for all your compressed air needs in Los Angeles, CA. With years of experience in the air compressor industry, we offer a comprehensive range of top-quality air compressor products, unrivaled services, and OEM and after-market parts to ensure your operations run seamlessly and efficiently.

Based in Cerritos, California, the Pattons CA team provides compressed air solutions and services to all of Southern California. Our team members are experts in identifying cost saving opportunities for your compressed air system. So, whether you need a routine service or looking to upgrade your compressed air system, Pattons CA is here for you.

CONTACT US

OUR COMPRESSED AIR PRODUCTS

Discover a diverse selection of quality air compressors, vacuum & blowers, compressed air dryers, condensate management equipment, and more! Pattons of California offers compressed air system products that are engineered to deliver unparalleled performance. Our compressed air products are designed to meet the demands of various industries such as food and beverage, aerospace, automotive, textile, and electronics.

Compressed air is vital to the operations of facilities. That is why Pattons CA partners with CAGI certified brands such as ELGi Air Compressors, Champion Air Compressors, BEKO Compressed Air Dyers to ensure our customers can purchase with confidence and have reliable and trusted compressed air solutions.

Explore our offerings of air compressors, compressed air dryers, compressed air piping, vacuum pumps, filtration, nitrogen generators and more!

Air Compressor Products

PCA has a wide range of reliable, high quality, energy-efficient & low maintenance air compressors. You can count on us for all your compressed air needs.READ MORE

Compressed Air Dryers

When it comes to keeping your compressed air system free from contamination, You'll need Air dryers. At PCA, we can recommend best dryer products that meet your unique specifications.READ MORE

Compressed Air Piping

PCA offers compressed air piping for all applications including stainless steel, aluminum and more! We can install your new pipes on-site in a fast and professional manner.READ MORE

When it comes to selecting the compressed air equipment there are many factors to consider. There are many different air compressor technologies including rotary screw, reciprocating/piston, centrifugal. Size and application of compressed air is also important to consider. Our team works closely with you to determine the right equipment for your specific needs. Reach out to the Pattons of California team to help you make the best decision for your operation. We offer complimentary system assessments to help you determine the best air compressor equipment for your business.Request Free Assessment

PROVIDING QUALITY AIR COMPRESSOR SERVICES IN LOS ANGELES, CA

At Pattons CA, we specialize in providing top-notch air compressor services in Los Angeles, CA, and the surrounding areas. With over 70 years of experience in the industry, we are dedicated to delivering prompt and cost-effective compressed air services

Pattons of California services all major brand compressors including ELGi, Atlas Copco, Ingersoll Rand, Kaeser, Gardner Denver, and Quincy compressors! We keep OEM and aftermarket parts and equipment in stock at our Cerritos, CA warehouse so we can quickly address your needs.

Don't let air compressor problems disrupt your business.Contact Pattons of California for reliable air compressor services in Los Angeles, CA. Our team is ready to assist you.

CONTACT ADDRESS

Pattons of California LLC

16312 Bloomfield Ave,

Cerritos, CA 90703

EMAIL

CALL US

562 229 0955

Read More

#elgi air compressor dealers#Air compressor distributor los angeles#Air compressor parts in los angeles#Air compressor distributor california#Elgi air compressor dealers in los angeles#Air compressor dealers in los angeles#Air compressor dealers in california#zeks air dryer

0 notes

Text

How Can Positive Displacement Pumps Enhance Water Services?

Introduction

Positive displacement pumps are an essential component in various industries, particularly in water services. They operate on a simple principle: they move a fixed amount of fluid through a system with each cycle. This reliable and consistent method of fluid transfer makes them an excellent choice for applications requiring precise flow control. But what exactly makes these pumps so effective for water services, and why should you consider them for your needs? This article delves into the functionality, benefits, and specific applications of positive displacement pumps for water services.

How Do Positive Displacement Pumps Work?

Types of Positive Displacement Pumps

Positive displacement pumps can be categorized into two main types: reciprocating pumps and rotary pumps.

Reciprocating Pumps: These pumps use a back-and-forth motion to move fluid. They include piston, diaphragm, and plunger pumps.

Rotary Pumps: These pumps use a rotating mechanism to transfer fluid. Common types include gear, screw, and vane pumps.

Each type of pump is designed to handle different kinds of fluids and applications, offering versatility and efficiency.

Advantages of Positive Displacement Pumps in Water Services

Consistent Flow Rate

One of the most significant advantages of positive displacement pumps is their ability to deliver a consistent flow rate regardless of pressure changes within the system. This characteristic is crucial for water services, where maintaining a steady supply is essential.

High Efficiency

Positive displacement pumps are known for their high efficiency. They can handle high-viscosity fluids and operate effectively at varying pressures. This efficiency translates to lower energy consumption and operational costs, making them a cost-effective solution for water services.

Handling Various Fluids

These pumps are capable of handling a wide range of fluids, including those with high solid content. This capability is particularly useful in water treatment plants where the fluid often contains suspended solids and debris.

Applications in Water Services

Water Treatment Plants

In water treatment plants, positive displacement pumps are used to transfer chemicals, slurries, and other fluids with high solid content. Their ability to handle abrasive and corrosive fluids makes them ideal for this application.

Municipal Water Supply

Municipal water supply systems rely on these pumps for their ability to provide a consistent and reliable flow of water. Whether it's pumping water from a reservoir or distributing it through the city's pipelines, positive displacement pumps ensure that the water supply remains uninterrupted.

Industrial Water Services

In industrial settings, positive displacement pumps are used for cooling, washing, and other water-related processes. Their efficiency and reliability make them a preferred choice for industries looking to optimize their water usage.

Key Considerations When Choosing a Positive Displacement Pump

Fluid Characteristics

When selecting a pump, it's essential to consider the characteristics of the fluid being pumped. Factors such as viscosity, temperature, and solid content can affect the pump's performance and longevity.

Pressure Requirements

Understanding the pressure requirements of your system is crucial. Positive displacement pumps are well-suited for high-pressure applications, but it's important to choose a pump that matches your system's specifications.

Maintenance and Durability

Positive displacement pumps are generally low-maintenance, but regular inspection and maintenance are necessary to ensure optimal performance. Choosing a pump made from durable materials can also extend its lifespan and reduce maintenance costs.

Conclusion

Positive displacement pumps offer numerous advantages for water services, from their consistent flow rates and high efficiency to their ability to handle various fluids. Whether you're managing a municipal water supply, operating a water treatment plant, or utilizing water in an industrial setting, these pumps provide a reliable and cost-effective solution.

If you are interested in learning more about how positive displacement pumps for water services can benefit your operations, don't hesitate to contact us. Our team of experts is ready to help you find the perfect solution for your needs.

For more information or to discuss your specific requirements, please contact us. We look forward to helping you optimize your water services with the right positive displacement pump.

0 notes

Text

China offer VALVE CONTROL FLOW G761-3005B for turbine generator

"China offer VALVE CONTROL FLOW G761-3005B for turbine generator

Is YOYIK for the use of turbine units of the power plant supporting professional models of products. YOYIK main generator accessories, generator sets of accessories. For decades, the company relies on advanced technology, technology, materials and scientific management to improve the stability and reliability of the pump, for hundreds of thermal power plants, hydropower stations, cement plants, coal gangue power plants, metallurgical companies, steel and other overhaul , Technical transformation to provide a reasonable and excellent equipment selection, construction planning, installation commissioning, after-sales service, such as perfect complete service, won the power industry industry wide acclaim.

Yoyik can offer many spare parts for power plants as below:

DF-VALVE CONTROL FLOW G761-3005B-DF

Solenoid valve Z2804076

Fluoro Rubber O-Ring OR0311308

sealing ring HB4-56J8-124

high pressure hydraulic pump power pack station 65AY5010 centrifugal pump stainless steel CZ80-250A pump screw HSNH80-27 mechanical rubber seal 10014CH1-5008 transfer pump vane F3V201S8S1C11 globe throttle check valve LJC40C-1.6P dc centrifugal pump 65-250B pump hydraulic power 40AY35X11 vacuum pumps 125LY-35-8 oil transfer electric pump Y160M-2/11KW/IP44 Accumulator bladder LP40 screw pump working ACF090N5ITBP single screw pump HSND280-54 sealing oil Re-Circulating pump HSNH280-43Z dc vane pump F3-V10-1S6S-10-20 three screw pump HSNH440 turbine AC lube pump 125LY-40-B globe throttle check valve KJC25C-4.0P high pressure oil pump 80LY-80-B electric hydraulic oil power pump 80AY506

oil pump cost 50YW25-33

seal sleeve lock nut FK5C32AM-03-02

Manual pressure regulating valve EXCELON B72G-2GK-QD3-RMN

hydraulic pump motor 65AY100

piston pump parts M03EA10VSO45DFR1/31RVPA12

coupling cushion 30-WS

Accumulator NXQ-AB-25-31.5

centrifugal pump types 100-80-125A

Regulating valve KS100ZXNO016 DN100 PN16

vacuum hand pump 125LY-32-B

piston vacuum pump A10VSO100DFR1/32R

vacuum oil pump P-1607

globe valve J1F1.6P-25

VALVE CONTROL FLOW G761-3005B

EH oil pump PV29-2R50C00

screw pump diagram HSND280-43NZ

Vacuum pump 30WS

vacuum pump ac A10VS0100DR/31R-PPA12NOO

radial piston pump hydraulic PVH98QIC-RSF-1S-10-C25-31

gear pump hydraulic 80AY100

pump centrifugal DFB100-80-230

oil pump replacement 80AYP60

mechanical seal for pump 8b1d

reciprocating piston pump PVH074R01AA(AB)10A250000002001AB0

axial piston variable pump PVH98Q1C-RSF-1S-10-C25-31

mechanical face seal BGM37G/50R-G9

reciprocating pump 80AY50*9

mechanical seal for pump BGM37G/50R-G9

RUBBER BLADDER NXQA-25/31.5-L-EH

accumulator NXAQ-10/31.5-L

mian trip solenoid valve 8YVHP trip solenoid valve

turbine OPC solenoid valve HQ16.80Z

rotary vane vacuum pump F3-V10-IS6S-IC-20

rotary vacuum pump P-1761-1

screw pump working principle ACF 090N4 1RBP

Mechanical control valve 224.32.9.1/1X

centrifugal pump DFB80-80-240

butterfly valve K65DSF4PB3

dc screw pump SMH120-42W1Q1

OPC solenoid valve ZD.02.008

dc screw pump HSND280-46

rotary vacuum pump P-1937A

electric transfer oil pump DLZB820-R64A-01

ASTSolenoid valve HQ16.16Z-2

BALL BEARING SINGLE ROW RADIAL DEEP GROOVE NO.6202

Check valve 216C15

liquid ring vacuum pump HSNH660-40NZ

vacuum pump 222v SK-831

electric centrifugal pump head 50-250-007

servo valve J761-002

VALVE CONTROL FLOW G761-3005B

DFYLSYC-2024-7-15-A

"

0 notes

Text

How to choose the right piston air compressor? (Belt Drive or Direct Drive)

Irrespective of the technology, choosing the right compressor for your application is very critical. This will optimise the performance and save money in terms of energy, maintenance and service.

With piston compressors, there are two alternatives – belt drive and direct drive. To make the right choice for your compressed air needs, it is important to understand the difference between the two.

Understanding the requirement

The requirement for any given application will play a big role while deciding on the type of the piston compressor - belt drive or direct drive.

The factors to be considered are as follows:

Pressure and Flow

Duty Cycle and duration of use

Environment

Maintenance

Energy efficiency

The Technology

Belt driven reciprocating compressors are conventional machines, proven for their durability in intermittent usage patterns over the years. On the other hand, direct drive machines are quieter, compact and suit a higher duty cycle with proven reliability when compared to a belt drive.

Please do note that both differ in terms of the “use case” they fit into.

Belt Drive Reciprocating Air Compressor

A belt drive reciprocating air compressor has a belt that connects the motor and the pump. When the motor runs, the belt transfers the power through pulleys to run the pump.

The energy and maintenance costs of these machines are comparatively higher, owing to the transmission system and higher number of touchpoints.

This is why, a periodic check of the pulley’s alignment and the belt tension is required. Improper alignment will impact the motor’s load pattern, thereby increasing the energy cost. This can also result in belt failure due to excessive tension.

Direct Drive Reciprocating Air Compressor

A direct drive reciprocating air compressor has a crankshaft that is directly connected to the motor, thereby eliminating transmission losses.

Energy Efficient: Since the crankshaft is directly connected to the motor, there is no need to replace the conventional belt drive. As a result, the loss in energy due to the transmission is eradicated.

Minimum Maintenance Cost: Direct drive air compressors have fewer components than belt drive compressors. This is why, they do not require as many part replacements resulting from wear-and-tear.

Lesser Noise: Elimination of belts and pulleys makes the direct drive operate “quietly” as compared to its belt drive counterpart. This is why, they are generally better for environments where noise emissions have to be kept low, such as indoors or residential neighbourhoods.

Compact: As the drive and driven are integrated, the compact arrangement of the machine is an added advantage.

Belt drive or direct drive – What to choose?

If you use compressed air for longer hours and want to keep your energy costs low, then a direct drive model, such as ELGi’s LD Series, is the right choice. In addition to the inherent benefits of the direct drive technology, the LD series also offers more superior value additions such as:

Higher energy efficiency: Apart from ensuring savings due to elimination of transmission losses, ELGi’s direct drive compressors offer

best-in-class flow as compared to any piston compressor in the market, thereby offering higher flow per HP

Eco friendly and minimum maintenance cost: ELGi’s direct drive compressors are assured with the lowest oil fill requirement

Silent: The noise levels of such systems are close to screw compressors

Compact: These piston compressors can fit anywhere with proper ventilation

Flexible: They have a duplex system, which supports varying industry demand, especially in the 10 and 15 HP variants

Reliable: ELGi’s proven parts and robust materials ensure reliability. What’s more, they are backed by ELGi’s Pan India Service support

#aircompressorindia#air compressors#oilfreecompressors#aircompressorsmanufacturers#piston air compressors india#air compressors manufacturers#aircompressoraccessoriesindia#oilfreescrewcompressors#pistoncompressors

0 notes

Text

High Pressure Pumps: Powering Critical Industrial Processes

High pressure pumps are essential tools across various industries, providing the necessary force to move fluids at high pressures. These pumps are designed to handle demanding applications, offering robust performance and reliability. In this blog, we will delve into the features, benefits, and applications of high pressure pumps, with a focus on the premium solutions provided by Raah International.

Understanding High Pressure Pumps

High pressure pumps are designed to move fluids at high pressures, typically exceeding 800 psi (55 bar). These pumps are critical in applications that require the transfer of liquids over long distances or the delivery of fluids at high pressures for specific processes.

Key Features of High Pressure Pumps

Robust Construction:

Made from durable materials such as stainless steel and high-grade alloys to withstand extreme pressures and harsh environments.

High Efficiency:

Engineered to operate efficiently, reducing energy consumption while delivering high performance.

Precision Engineering:

Designed with tight tolerances to ensure accurate and consistent fluid delivery.

Corrosion Resistance:

Constructed with materials that resist corrosion, extending the pump's lifespan and ensuring reliable operation in corrosive environments.

Versatility:

Capable of handling a wide range of fluids, including water, chemicals, and oils, making them suitable for diverse applications.

Types of High Pressure Pumps

Reciprocating High Pressure Pumps:

Features: Utilize a piston or plunger to move fluids, capable of generating very high pressures.

Applications: Ideal for applications such as hydrostatic testing, high-pressure cleaning, and chemical injection.

Centrifugal High Pressure Pumps:

Features: Use a rotating impeller to move fluids, suitable for continuous high-pressure applications.

Applications: Commonly used in boiler feed, reverse osmosis, and high-pressure water supply systems.

Hydraulic High Pressure Pumps:

Features: Employ hydraulic fluid to generate high pressures, offering precise control and high efficiency.

Applications: Used in industrial hydraulic systems, machinery, and equipment testing.

Diaphragm High Pressure Pumps:

Features: Utilize a flexible diaphragm to move fluids, ensuring leak-free operation.

Applications: Suitable for handling aggressive and corrosive fluids in chemical processing and water treatment.

Benefits of Using High Pressure Pumps

Enhanced Performance:

Provide the necessary force to move fluids at high pressures, essential for many industrial processes.

Energy Efficiency:

Designed to operate efficiently, reducing energy costs and improving overall system efficiency.

Durability and Reliability:

Built to withstand extreme conditions, ensuring long-lasting performance and minimal downtime.

Versatile Applications:

Suitable for a wide range of industries, from water treatment and oil and gas to manufacturing and agriculture.

Precision and Control:

Offer precise fluid control, essential for processes that require accurate pressure and flow rates.

Applications of High Pressure Pumps

Water Treatment:

Used in reverse osmosis systems, filtration, and high-pressure cleaning to ensure clean and safe water supply.

Oil and Gas Industry:

Employed in drilling operations, hydraulic fracturing, and chemical injection to enhance production and processing.

Manufacturing:

Used in processes such as cutting, cleaning, and pressure testing to ensure product quality and integrity.

Agriculture:

Essential for irrigation systems, pesticide application, and fertigation to improve crop yield and efficiency.

Automotive and Aerospace:

Utilized in component testing, fuel injection systems, and high-pressure washing to maintain performance and safety standards.

Raah International’s High Pressure Pump Solutions

Raah International offers a comprehensive range of high pressure pumps designed to meet the demanding needs of various industries. Their products are characterized by:

Advanced Technology: Incorporating the latest innovations to ensure superior performance, precision, and durability.

Robust Construction: Engineered for long-lasting reliability in demanding environments.

Custom Solutions: Providing tailored pump solutions to meet specific operational requirements and industry standards.

For more detailed information on Raah International’s high pressure pump offerings and to explore a range of products tailored to your specific needs, visit High Pressure Pump page.

0 notes

Text

Types of Oil Pressure Pumps: From Gear Pumps to Vane Pumps and Beyond

Oil pressure pumps are a critical component in various mechanical systems, from automotive engines to industrial machinery. These pumps are responsible for circulating oil throughout the system, ensuring proper lubrication, cooling, and hydraulic pressure. Over the years, several types of oil pressure pumps have been developed, each with its own unique design and functionality. In this blog, we'll explore some of the most common types of oil pressure pumps, from traditional gear pumps to modern vane pumps and beyond.

Gear Pumps: Gear pumps are among the oldest and most widely used types of oil pressure pumps. They consist of two intermeshing gears – a driving gear and a driven gear – housed within a casing. As the gears rotate, they create a suction force that draws oil into the pump and then forces it out under pressure. Gear pumps are known for their simplicity, reliability, and relatively low cost. However, they are also prone to noise and vibration, and their efficiency can be affected by variations in oil viscosity.

Gerotor Pumps: Gerotor pumps are a variation of gear pumps that utilize an eccentrically mounted inner rotor and an outer rotor with internal teeth. As the inner rotor rotates, it meshes with the teeth of the outer rotor, creating chambers that vary in size and volume. This variation in chamber size generates the pumping action, drawing oil into the pump and then expelling it under pressure. Gerotor pumps offer improved efficiency and smoother operation compared to traditional gear pumps, making them popular in automotive and industrial applications.

Vane Pumps: Vane pumps are another common type of oil pressure pump that operates on the principle of positive displacement. They consist of a rotor with multiple vanes that are housed within a cylindrical casing. As the rotor rotates, centrifugal force pushes the vanes outward, creating chambers that vary in volume. Oil is drawn into these chambers as they expand and then expelled under pressure as they contract. Vane pumps are known for their quiet operation, high efficiency, and ability to handle a wide range of viscosities. They are commonly used in hydraulic systems and power steering applications.

Piston Pumps: Piston pumps are a more complex type of oil pressure pump that utilizes reciprocating pistons to generate hydraulic pressure. These pumps typically consist of a cylinder block with multiple pistons arranged in a radial or axial configuration. As the pistons move back and forth within their cylinders, they draw oil into the pump on the intake stroke and then expel it under pressure on the discharge stroke. Piston pumps offer high efficiency, precise control, and the ability to generate high pressures, making them ideal for demanding hydraulic applications such as heavy machinery and construction equipment.

Screw Pumps: Screw pumps, also known as rotary screw pumps, utilize intermeshing screws to generate hydraulic pressure. These pumps consist of two or more helical rotors that rotate within a close-fitting housing. As the rotors turn, they trap and compress oil between the screw threads and the pump casing, forcing it through the pump and out under pressure. Screw pumps offer smooth, pulsation-free flow, high efficiency, and the ability to handle high-viscosity fluids. They are commonly used in industrial applications such as oil and gas processing, chemical manufacturing, and marine propulsion systems.

Centrifugal Pumps: While centrifugal pumps are more commonly associated with water and fluid transfer applications, they can also be used as oil pressure pumps in certain systems. Centrifugal pumps rely on the principle of centrifugal force to generate hydraulic pressure. They consist of a rotating impeller housed within a volute casing. As the impeller rotates, it imparts kinetic energy to the fluid, causing it to move radially outward and increase in pressure. Centrifugal pumps are known for their simplicity, reliability, and ability to handle large flow rates. They are often used in oil cooling systems, lubrication systems, and hydraulic power units.

In conclusion, oil pressure pumps play a crucial role in ensuring the proper functioning of various mechanical systems. From traditional gear pumps to modern vane pumps, piston pumps, screw pumps, and centrifugal pumps, there are several types of oil pressure pumps available, each with its own unique design and characteristics. By understanding the differences between these pump types, engineers and designers can select the most suitable pump for their specific application, ensuring optimal performance, reliability, and efficiency.

0 notes

Text

0 notes

Text

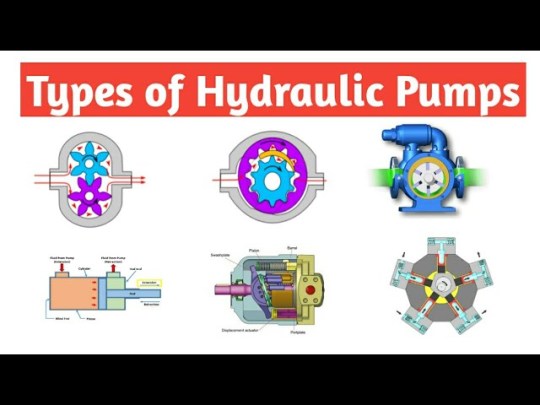

Top Types of Hydraulic Pumps and Their Various Applications

Hydraulic systems are essential components of various industries, providing the power needed to perform a wide range of tasks. At the heart of these systems are hydraulic pumps, which play a crucial role in generating the necessary fluid power.

In this blog, we'll explore the top types of hydraulic pumps and their diverse applications, shedding light on their functionality and significance in different settings.

Understanding Hydraulic Pumps

Before delving into the specific types of hydraulic pumps, it's important to understand their fundamental purpose. Hydraulic pumps are mechanical devices designed to generate flow and provide power to hydraulic systems.

They convert mechanical energy into hydraulic energy by pressurising hydraulic fluid. This pressurised fluid is then utilised to perform various tasks, making hydraulic pumps integral components of a wide array of applications.

Types of Hydraulic Pumps

1. Gear Pumps

Gear pumps are one of the most common types of hydraulic pumps. They operate using the intermeshing of gears to pump fluid.

With their simple design and ability to handle a wide range of viscosities, gear pumps are widely used in applications such as automotive power steering systems, forklifts, and construction equipment.

2. Vane Pumps

Vane pumps utilise vanes to push fluid through the pump. These pumps are known for their quiet operation and ability to handle low-to-medium pressure applications.

They find extensive use in industrial and mobile hydraulic systems, as well as in aerospace and automotive applications.

3. Piston Pumps

Piston pumps use reciprocating pistons to pressurise fluid. They are capable of handling high-pressure applications and are often used in heavy machinery, hydraulic presses, and other industrial equipment where high power density is required.

4. Radial Piston Pumps

Radial piston pumps consist of a set of pistons arranged radially around a drive shaft. These pumps are known for their high efficiency and are commonly employed in high-pressure hydraulic systems, including those used in plastic injection moulding machines, hydraulic presses, and marine equipment.

5. Axial Piston Pumps

Axial piston pumps feature pistons arranged in a circular array within a cylinder block. They are widely utilised in various hydraulic systems, including industrial machinery, agricultural equipment, and construction machinery, thanks to their ability to handle high pressure and provide efficient performance.

Applications of Hydraulic Pumps

Industrial Machinery

In the industrial sector, hydraulic pumps play a critical role in powering heavy machinery such as presses, extruders, and injection moulding machines.

The high pressure and power density provided by piston pumps and radial piston pumps make them well-suited for these demanding applications.

Construction Equipment

Construction and earthmoving equipment rely heavily on hydraulic pumps to provide the power needed for tasks such as lifting, lowering, and manoeuvring heavy loads. Gear pumps and vane pumps are commonly used in hydraulic systems within excavators, dump trucks, and cranes.

Aerospace and Automotive Systems

Vane pumps are often employed in aerospace and automotive applications where quiet operation and efficient fluid handling are essential. These pumps are utilised in aircraft hydraulic systems, as well as in power steering and automatic transmission systems in automobiles.

Agriculture

In the agricultural sector, hydraulic pumps are integral to the operation of various equipment, including tractors, harvesters, and irrigation systems. Axial piston pumps are well-suited for these applications due to their ability to handle high pressure and provide reliable performance in demanding agricultural environments.

Marine Equipment

Radial piston pumps are commonly used in marine hydraulic systems to power steering, winches, and other equipment on ships and offshore platforms. Their high efficiency and ability to handle high-pressure applications make them ideal for these marine applications.

Conclusion

Hydraulic pumps are indispensable components of hydraulic systems across diverse industries. Understanding the various types of hydraulic pumps and their applications is crucial for selecting the right pump for specific tasks and ensuring efficient and reliable operation.

By exploring the functionality and significance of hydraulic pumps, we gain a deeper appreciation for the pivotal role they play in powering a wide range of machinery and equipment.

As we've seen, the versatility and performance of hydraulic pumps make them essential for achieving powerful and precise hydraulic operations across numerous applications. Whether in industrial settings, construction sites, aerospace and automotive systems, agriculture, or marine environments, hydraulic pumps continue to drive innovation and efficiency in hydraulic power systems.

Source URL: https://hydraulicpumpsau.blogspot.com/2024/04/top-types-of-hydraulic-pumps-and-their.html

0 notes