#flowmetersupplier

Explore tagged Tumblr posts

Text

Flow Meter Supplier, Flow Meter Manufacturer in Pune, Maharashtra, India, Odisha, Bangalore, Tamilnadu, Hyderabad, Raipur, Jamshedpur, Ahmedabad, Vijayawada, Kolkata, haridwar, Lucknow

Saitech Flow Instruments & Control provide best Flow Meter in Pune, Maharashtra, India, Odisha, Bangalore, Tamilnadu, Hyderabad, Raipur, Jamshedpur, Ahmedabad, Vijayawada, Kolkata, haridwar, Lucknow at best cost. It is the best Flow Meter supplier and Flow Meter manufacturer company in Pune, Maharashtra, India.

0 notes

Text

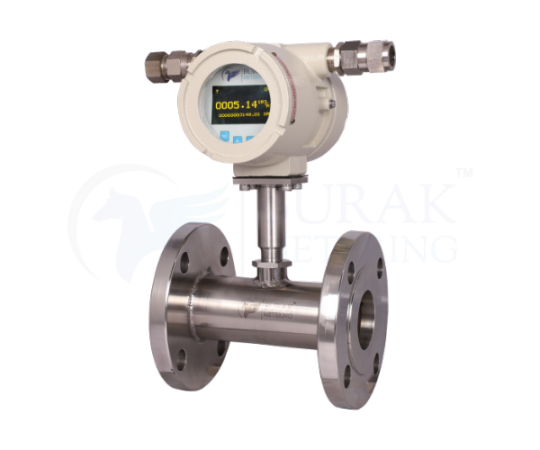

Burak Metering - Your Premier Choice for Flowmeter Solutions

Choose Burak Metering as your premier choice for Flowmeter Solutions. As distinguished Flow Meter Suppliers and Manufacturers, we guarantee top-tier quality and performance

0 notes

Text

Diesel Flow Meter Suppliers: Measure Efficiency with Confidence

In today's fast-paced industrial world, efficiency is key. Whether you're managing a large-scale fuel distribution network or a smaller operation, having precise and reliable measurements is crucial. This is where diesel flow meter suppliers come into play. Let's dive into how these essential tools can boost your operation's efficiency and why partnering with the right suppliers is vital.

Understanding Diesel Flow Meters

What is a Diesel Flow Meter?

A diesel flow meter is an instrument designed to measure the flow rate of diesel fuel through a pipeline. It ensures that the fuel being distributed is accurately measured, preventing discrepancies that can lead to significant financial losses or operational inefficiencies.

Types of Diesel Flow Meters

Positive Displacement Meters: These meters capture a specific volume of diesel and measure the flow based on the number of times the volume is filled.

Turbine Meters: Utilizing a turbine wheel, these meters measure flow based on the speed of the fuel passing through the turbine.

Coriolis Meters: These provide highly accurate measurements by calculating the mass flow rate of the diesel fuel.

Ultrasonic Meters: Using sound waves, these meters measure the flow rate based on the time it takes for the waves to travel through the fuel.

The Importance of Reliable Diesel Flow Meter Suppliers

Ensuring Accuracy and Reliability

Reliable diesel flow meter suppliers offer high-quality products that ensure precise measurements. Accuracy is critical in maintaining operational efficiency, managing costs, and ensuring compliance with industry standards.

Advanced Technology

Top-tier suppliers provide meters equipped with the latest technology, enhancing the accuracy and functionality of the devices. This includes features like digital displays, remote monitoring capabilities, and automatic data logging.

Custom Solutions

Every operation has unique needs. Reputable diesel flow meter suppliers understand this and offer custom solutions tailored to specific requirements. Whether it's a particular type of meter or a specialized installation, these suppliers can provide what you need.

Benefits of Using Diesel Flow Meters

Cost Efficiency

Accurate measurement of diesel flow helps in reducing wastage and ensuring that every drop of fuel is accounted for, leading to significant cost savings over time.

Enhanced Operational Control

With precise data on fuel usage, operators can make informed decisions, optimize processes, and ensure smooth operation. This leads to better resource management and improved overall efficiency.

Compliance and Reporting

In many industries, there are stringent regulations regarding fuel usage and reporting. Diesel flow meters help in maintaining compliance by providing accurate and reliable data, simplifying the reporting process.

Choosing the Right Diesel Flow Meter Supplier

Reputation and Experience

When selecting a diesel flow meter supplier, consider their reputation and experience in the industry. Long-standing suppliers are often more reliable and knowledgeable about the latest trends and technologies.

Customer Support

Excellent customer support is essential. Ensure the supplier offers comprehensive support, including installation, maintenance, and troubleshooting services.

Product Range

A good supplier should have a wide range of products to choose from, catering to various needs and applications. This ensures you can find the perfect meter for your specific requirements.

Conclusion

Partnering with reliable diesel flow meter suppliers is crucial for any operation that relies on precise fuel measurement. By ensuring accuracy, adopting advanced technology, and offering custom solutions, these suppliers help businesses measure efficiency with confidence. Investing in quality diesel flow meters not only enhances operational control and cost efficiency but also ensures compliance with industry standards. Choose wisely, and watch your operational efficiency soar.

Contact Now

Location: 476 Boundary Road Derrimut Victoria 3026

Call: (03) 9311 7822

Mail: [email protected]

0 notes

Text

Process Control Devices Mumbai - Leaders in Flow Meter Technology

Discover the latest in flow meter technology with Process Control Devices (PCD). As Flow Meter Manufacturers in Mumbai, we set the standard for precision and innovation in industrial measurement.

0 notes

Text

Electromagnetic Flow Meter Supplier for your Business

Looking for a reliable Electromagnetic Flow Meter Supplier for your business? At Petron Thermoplast, we provide cutting-edge flow meters designed to deliver precision, efficiency, and durability across industries.

Visit Website - https://petronthermoplast.com/flow-meter-manufacturer/

Contact No. - +91-8218684097

Request for Quotation - [email protected]

#flowmeter #electromagneticflowmeter #industrialsolutions #fluidmeasurement #precisionengineering #industrialparts #flowmetersupplier #electromagneticflowmeter

#flow meter manufacturer#Electromagnetic Flow Meter Manufacturer#flow meter manufacturer in india#Electromagnetic Flow Meter Supplier#Flow Meter Supplier

0 notes

Text

Selection and Application of Liquid Flowmeter

Reading guide: The liquid volume flowmeter consists of a chamber with a known volume and moving parts. The liquid passing through the flow is calculated by determining the volume of the container and the number of movements of the moving parts. According to the characteristics of liquid volume flowmeter, it can be divided into the following types: waist wheel flowmeter, oval gear flowmeter, scraper flowmeter, double rotor flowmeter, reciprocating piston flowmeter, rotary piston flowmeter, screw flowmeter, etc. Structure and principle of the liquid volumetric flowmeter calibration device The liquid accumulation calibration device consists of the quick connector, hydraulic hose, hydraulic filter, standard flowmeter, temperature transformer, pressure transformer, computer system, hydraulic source, etc. The hydraulic oil source also includes a hydraulic oil tank, variable frequency motor, hydraulic variable pump, hydraulic safety valve, and other components. The main features are compact installation, easy use, the same calibration medium, strong movement ability, and the ability to provide hydraulic oil. The working mode of the liquid flow controller is as follows: match through quick connection and replacement, and lead the hydraulic hose into the displaced liquid flow controller calibration device; The hydraulic power converter of the investment department generates clean and stable liquid flow through the hydraulic pump, hydraulic filter, etc. Capture the cumulative flow value determined by the computer system using the calibrated flowmeter and the standard flowmeter, and capture the temperature and pressure on the calibrated flowmeter and the standard flowmeter; The measured value error of calibrated flow is determined by the computer software system. Main characteristics and application of common liquid flowmeter Volumetric flowmeter Volumetric flow meters (also called volume-specific flow values) are general-purpose instruments with the highest accuracy. The measured components can also be divided into the following main features: pitch circle (two rotors), plate flow measurement, oval gear flow measurement, rotary piston flow measurement, circulation flow measurement, etc.

① Advantages: high measurement accuracy; It can be used for measuring high viscosity fluid and simple phase fluid; The instrument does not need external energy to directly record the total flow. It is easy to install without special requirements for front and rear tangent lines. ② Disadvantages: not suitable for high temperature and low temperature; Type of measuring center with limited diameter; Pressure drop; Periodic calibration is required. ③ Application: Volume traffic signs, due to their high-precision measurement in energy, petroleum, medicine, food, chemistry, and other fields, especially raw materials and other fields, must be measured for storage, transfer, and distribution, and used as the basis for a financial settlement, or as a legal indicator of the contract between two tax dealers.

Differential The differential is one of the most commonly used flowmeter types, which can be divided into diverter flowmeter, Venturi flowmeter, average line current, etc. according to the test piece (inlet instrument). The main features are: ① Advantages: single-phase fluid has a wide range of measurement methods, some mixed fluids; Simple structure, easy maintenance, the long service life of control components and detonators, display equipment produced by different manufacturers, improving economies of scale. ② Disadvantages: general customization accuracy; Large pressure loss (orifice plate, nozzle, etc.) The assembly constraint shall be high, and there shall be enough straight pipelines before and after assembly. ③ Nozzle: When measuring the flow in the closed pipe for the first time, the differential can be used for projects under different conditions where the flow is about 1/4-1/3 of the total flow. Ultrasonic assistance The ultrasonic flowmeter can be generally divided into plug-in type, pipe section type, external clamp type, and portable type. ① Advantages: large diameter non-contact measurement, large flow calculation; Pressure loss, no fluid disturbance; Suitable for every liquid, easy to install and maintain. ② Disadvantages: When the measured liquid contains bubbles or noise, the measurement accuracy will be affected; The temperature range of the measured liquid is limited by the heat of the ultrasonic protection and the communication materials between the switch and the line, and the original data for measuring the high temperature of the liquid is incomplete. ③ Application: Ultrasonic velocimeter is often used in petroleum, chemistry, metal, electric power, and other fields, and is often used to measure the emission reduction of gas pipelines in factories, fluids, and work areas.

Turbine speed Intel Remax accelerated technology plan has been expanded to multiple categories in mass production, and its main features are as follows: ① High precision, usually ± 0.25% r - ± 0.5% r, up to ± 0.25% r - ± 0.5% r; Repeat at most 0.05% r-0.2% r for a short time; Zero contact movement, sturdy and durable. ② Disadvantages: The physical characteristics of the liquid have a great influence on the flow characteristics; Calibration characteristics cannot be saved for a long time. ③ Application. A turbine flow counter is usually used to measure oil, organic liquid, inorganic liquid, and liquid frozen body. The first terminal of the main raw material pipeline is used for commercial calculation of automobile exhaust, gas stations, and light hydropower plants.

Vortex flowmeter The vortex flowmeter is the latest flowmeter, but it has developed rapidly and has become a common category. Its main characteristics are as follows. ① Advantages: wide application range, liquid, gas, and steam flow measurement can be used; Small pressure loss; Easy installation, simple and durable structure. ② Disadvantages: poor anti-interference ability; Straight pipe section is required before and after installation; The application experience in pulsating flow and multiphase flow is still lacking. ③ Application: Vortex flowmeter has a wide range of applications, usually used in the factory water supply system, and its application will be limited in the case of high viscosity, low flow rate, and small diameter.

General criteria for flowmeter selection and calibration device Determine the technical requirements for flow measurement and the correctness of the flowmeter, that is, the accuracy requirements for measuring liquid; The flow measurement is repeated, that is, the same measurement is performed multiple times under specific conditions to repeat the same measurement. The expression of flow measurement, that is, whether the flow is mass flow or flow, real-time flow, or cumulative flow. Command and remove the transmission function if necessary. Specifies whether the flow measurement is displayed as a mechanical or electronic title. If the flowmeter does not meet the technical requirements of the measured liquid, measurement errors may also occur.

For the description of the flow calibration liquid calibration device, according to the flow requirements in jgg667-2010: ① The expanded uncertainty of the standard setting should generally not exceed 1/3 of the maximum allowable flow, because the expanded rate of the calibration device is 0.22%.

② Output or. The input line in the equipment used for online identification shall not include redirection between the flowmeter and the equipment designed as a locked cabinet without intermediate circuit. ③ "When the flowmeter is greater than 1.0, the flowmeter and liquid temperature must be measured according to the standard, and the temperature and pressure shall be measured near the standard flowmeter or calibrated flowmeter. Therefore, the liquid flow controller is applicable to the acceptance accuracy standard of Class 1.0 (allowable deviation ± 1.0%) and subsequent fluid calculation.

Conclusion In the process of liquid flow measurement, a liquid flowmeter is a major measuring tool and has been widely used in metallurgy, pharmacy, paper making, water conservancy, environmental protection, petrochemical, and other fields. In the actual online calibration process, the standard volume method, the standard meter method, and the electrical parameter method are all feasible online calibration methods. However, they all have different use conditions, which requires the staff to constantly summarize and analyze the use of online calibration methods for liquid flow meters, so that the calibration methods can be improved.

Article from: supmeaflow.com

2 notes

·

View notes

Text

An Introduction to Flow Meters

A flow meter is a device used to extent the capacity or mass of a gas or liquid. Flow meters are referred to by numerous names, such as flow gauge, flow indicator, liquid meter, flow ratio sensor, etc. depending on the particular industry. However, they all measure flow. Open channels, like watercourses or streams, may be measured with. Or more frequently, the greatest utility from a flow meter and the greatest variety of flow meters focus on measuring gasses and liquids in a pipe. Improving the precision, accuracy, and purpose of fluid measurement are the extreme benefits of the best flow meters.

What is the Purpose of a Flow Meter?

Flow meters are used to measure the mass flow rate or the volumetric flow rate of a fluid in many types of uses. The type of airflow meter is based on its application. Volumetric flow rate and mass flow ratio are units used to extent gases and liquids. Both volumetric mass rates are related to the thickness of the fluid. Q denotes the volumetric flow ratio, and ṁ denotes the mass flow rate in the equality ṁ=Q x ρ.

The Key Step to Indicate the Right Flow Meter

Significant whether the flow rate data will be incessant or totalized is the major stage in picking the correct flow meter or sensor. One should also recognize whether the info given will be relayed remotely or nearby. Should it be complete locally, will it be transmitted digitally or analog, or shared. If it is going to be shared, what will be the min and max data update incidence required. When all these are addressed, what follows is an assessment of the fluid flow possessions. The piping system that the fluid will flow through also requirements to be specified.

Flow meter characteristics refer to the specific features and attributes of a flow meter that define its performance, accuracy, and suitability for various applications. Understanding these characteristics is crucial when selecting a flow meter for a specific purpose. Here are the key characteristics of flow meters:

1. Flow Range:

Flow meters operate within a specific flow range, indicating the minimum and maximum flow rates they can accurately measure. It's essential to choose a flow meter that matches the expected flow rates of the application.

2. Accuracy and Precision:

Accuracy represents how closely the flow meter's measurement aligns with the actual flow rate. Precision refers to the repeatability of measurements. High accuracy and precision are vital, especially in applications where precise control of flow rates is necessary.

3. Repeatability:

Repeatability indicates the flow meter's ability to provide consistent results under the same operating conditions over time. A flow meter with good repeatability will yield similar measurements for the same flow rate, ensuring reliability in data collection.

4. Response Time:

Response time refers to how quickly a flow meter can detect and respond to changes in flow rates. In some applications, particularly those involving rapid changes in flow, a fast response time is critical for accurate monitoring and control.

5. Turndown Ratio:

Turndown ratio is the ratio of the maximum flow rate the meter can handle to the minimum flow rate it can accurately measure. A higher turndown ratio indicates a flow meter's versatility in handling a wide range of flow rates.

6. Pressure and Temperature Ratings:

Flow meters have specific pressure and temperature limits within which they can operate effectively and safely. It's crucial to consider these ratings to prevent damage and ensure accurate measurements under varying conditions.

7. Fluid Compatibility:

Flow meters are designed for specific types of fluids, whether liquids, gases, or slurries. Compatibility with the fluid being measured is essential to prevent corrosion, erosion, or contamination, which could affect the meter's accuracy and lifespan.

8. Installation Requirements:

Flow meters often have specific installation requirements, such as straight pipe lengths before and after the meter, to ensure stable flow conditions. Proper installation is vital for accurate measurements.

9. Maintenance Needs:

Different flow meters have varying maintenance requirements. Some may need periodic calibration, cleaning, or parts replacement. Understanding the maintenance needs is crucial for the long-term reliability of the meter.

10. Output and Communication:

Flow meters can provide outputs in various formats, such as analog signals, digital data, or pulse outputs. The choice of output type depends on the integration requirements with control systems and data loggers.

11. Cost:

Flow meters come at different price points based on their features and capabilities. Balancing the desired characteristics with the budget constraints is essential when selecting a flow meter for a specific application.

By considering these flow meter characteristics, engineers and professionals can make informed decisions about which flow meter best suits their needs, ensuring accurate and reliable flow measurements in various industrial and commercial settings.

Applications of Flow Meters:

Water Management:

Monitoring water distribution networks.

Optimizing irrigation systems.

Ensuring accurate billing for water usage.

Oil & Gas Industry:

Measuring crude oil flow in pipelines.

Monitoring fuel consumption in refineries.

Managing gas flow in drilling operations.

Chemical Processing:

Controlling chemical dosing in manufacturing.

Ensuring precise mixing of chemicals for various processes.

Pharmaceuticals:

Measuring and controlling the flow of ingredients in drug manufacturing.

Ensuring accurate dosage in pharmaceutical formulations.

HVAC Systems:

Monitoring and controlling the flow of coolants and refrigerants.

Optimizing energy efficiency in heating and cooling systems.

Importance of Flow Meters:

Accuracy and Efficiency:

Flow meters ensure precise measurement, enhancing process efficiency and reducing wastage.

Compliance and Regulations:

Industries must adhere to regulatory standards; accurate flow measurement is essential for compliance.

Cost-Effectiveness:

By preventing overuse or underuse of fluids, flow meters contribute to significant cost savings.

Maintenance and Longevity:

Properly monitored flow rates lead to reduced wear and tear on equipment, increasing their lifespan and reducing maintenance costs.

In conclusion, flow meters are the unsung heroes of various industries, silently ensuring the smooth operation of processes that we often take for granted. Their ability to provide accurate and reliable measurements is fundamental to the efficiency, cost-effectiveness, and sustainability of modern industrial operations. Saitechflow Instruments Control provide the best Flow meters supplier, manufactures in Pune, Mumbai, Maharashtra, India, Delhi, Kolkata, Chennai, Bangalore, Hyderabad , Ahmedabad, Surat, Kanpur, Jodhpur, Lucknow, Gwalior, Aurangabad, Raipur, Jamshedpur, Vijaywada, Haridwar, Odisha, Tamilnadu at best price.

Contact Us for Your Flow Meter Needs

Thank you for considering Saitechflow Instruments & Control for your flow meter requirements. Flow meters please check also, we provide installation and commissioning services for the same. Write us at reach us at [email protected]

We pride ourselves on providing top-quality flow measurement solutions tailored to your specific needs. If you have any questions, need a quote, or require technical assistance, please don't hesitate to get in touch with us.

0 notes