#rapid mixer granular

Explore tagged Tumblr posts

Text

SOP for Rapid Mixer Granular

1.0OBJECTIVE To lay down the standard cleaning and operation procedure for Rapid mixer granulator 150 L.2.0SCOPE This SOP describes the cleaning and operation of Rapid mixer granulator 150 L with co-mill installed in production department at EquipmentMakeModel / CapacityEquipment IDRapid mixer granulator 150 LSSPMSigma Gran / 150 LPRD/E0043.0RESPONSIBILITY 3.1Production…

View On WordPress

0 notes

Text

youtube

Rapid Mixer Granulator RMG Machine

The goals of the Rapid Mixer Granulator RMG Machine (High Shear Mixer), which includes the Pharma RMG machine, are to reduce processing times, provide more uniform and homogenous granular mixing at lower operating costs, and, most importantly, maintain enhanced sanitary compliance with cGMP standards. For cGMP compliance, all contact parts are constructed from FDA-approved materials or stainless steel 316L.

Granulator and Rapid Mixer created for maximum efficiency. cGMP compliance, with a focus on validating clearance. The Rapid Mixer Granulator is engineered to yield superior mixing and uniform granules while reducing operational expenses and boosting output. Improved mixing and closed granule size control result in higher tableting speeds, better quality, and fewer rejections. As a manufacturer of quick mixer granulators, we go to great lengths to construct sturdy, high-quality equipment.

0 notes

Text

Ribbon Blender Supplier in Rajasthan

Amma En-fab Is a leading Provided Ribbon Blender Supplier in Rajasthan, India. Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India. Amma En-fab’s Ribbon Blender is a high-speed, high-capacity batch mixer designed for the homogeneous blending of dry, free-flowing solids. The blender features a U-shaped horizontal trough with a specially designed double helical ribbon agitator rotating within. Ribbon blenders utilize a proven agitator construction that provides a triple mixing action, ensuring fast and efficient blending. The dimensions and configuration of the ribbons are carefully balanced to facilitate material movement within the container, avoiding dead spots and enabling rapid product discharge. Features: Multiple working volumes and capacities available. Made from stainless steel and carbon steel. Ribbon agitator designed for center discharge. Suitable for a wide range of batch sizes, from 10% of the rated capacity. Designed for both atmospheric and vacuum operation. Equipped with a centrally located flush bottom discharge valve. Stuffing boxes with easily disassembled housings and pure Teflon gland packing. Polished stainless steel surfaces to desired standards. Exterior non-stainless surfaces painted with enamel paint. What materials can a ribbon blender mix? Ribbon blenders are highly versatile and can mix dry powders, granular materials, pastes, and some liquids. They are used in food, pharmaceuticals, chemicals, and many other industries. How does the ribbon blender improve mixing efficiency? The double ribbon design moves the materials in opposite directions, creating a continuous and homogeneous mixing action, which ensures quick and uniform blending. Amma En-fab Is a leading Ribbon Blender Supplier in Rajasthan, India Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur. Feel free to contact us for more information and inquiries. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alwar#Anupgarh#Balotra#Banswara#Baran#Barmer#Beaware#Bharatpur#Bhilwara#Bikaner#Bundi#Chittorgarh#Churu#Dausa#Deeg#Dholpur#Didwalna-Kuchaman#Dudu#Dungarpur#Exporter#ExporterofRibbonBlender#Ganganagar#GangapurCity#Gujarat#Hanumangarh#India#Jaipur#Jaisalmer

0 notes

Text

Organic fertilizer is an important fertilizer source in modern agricultural production, and its production effect is directly related to soil fertility and crop yield. Selecting the right raw materials and optimizing the production process is the key to improving the quality of organic fertilizer.

First of all, the raw material selection of organic fertilizer should be based on the organic matter content, nutrient composition and microbial activity of the raw material. Common high-quality raw materials include animal manure, municipal sludge, domestic waste, sugar filter mud, wine lees, bean residue, straw, etc. After proper treatment and fermentation, these raw materials can be converted into nutrient-rich organic fertilizers.

In an organic Fertilizer Production Line, the Fertilizer Granulating Production Line is a key link in the formation of granular fertilizer. The granulation process not only improves the physical properties of fertilizer, but also helps to improve the application efficiency of fertilizer. For example, Fertilizer Granules Compaction Machine and Flat-Die Pellet Machine are commonly used granulation machines, which make raw materials into particles by extrusion, and these particles have good forming effect and high strength.

In order to further improve the quality of organic fertilizer, Windrow Compost Turning Machine plays an important role in the fermentation process. This equipment improves the fermentation efficiency by turning the compost, improving the ventilation conditions and promoting the rapid decomposition of organic materials.

In the production of organic fertilizers, the use of fertilizer shredders (such as Cage Crusher) is also essential. The pulverizer crushes the bulk organic material into the right size to facilitate subsequent mixing and granulation processes.

Finally, in order to ensure the uniformity of organic fertilizers and improve production efficiency, fertilizer mixers (such as the Horizontal Ribbon Mixer) and fertilizer Screening machines (such as the Rotary Screening Machine) are also indispensable equipment on the production line. Mixers are used for uniform mixing of raw materials, while sifters are used to separate fertilizer particles of different sizes to ensure consistency and quality of the final product.

Through scientific and reasonable raw material selection and production process optimization, it can not only improve the quality of organic fertilizer, but also contribute to the sustainable development of agriculture.

#Fertilizer Granules Compaction Machine#Flat-Die Pellet Machine#Cage Crusher#Horizontal Ribbon Mixer#Rotary Screening Machine

0 notes

Text

Cost-Effective Bolted Steel Tanks as EGSB Reactor and Wastewater Tanks

Cost-Effective Bolted Steel Tanks as EGSB Reactor and Wastewater Tanks

As the leading bolted steel tanks manufacturer, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) offers innovative solutions for wastewater treatment processes, including the use of bolted steel tanks as EGSB reactors (Expanded Granular Sludge Bed) and wastewater tanks. Our cost-effective storage solutions are designed to meet the high demands of industrial and municipal wastewater treatment systems worldwide.

Why Bolted Steel Tanks for EGSB Reactors?

EGSB reactors are advanced anaerobic wastewater treatment systems known for their high efficiency in treating wastewater with high organic loads. These reactors rely on the granular sludge bed to digest organic material and generate biogas as a byproduct. The design and material used for these reactors are critical to their performance, making bolted steel tanks the optimal choice for use as EGSB reactors.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Key Benefits of Bolted Steel EGSB Reactors:

Corrosion Resistance: The bolted steel tanks used in EGSB reactors are coated with Glass-Fused-to-Steel (GFS) technology, offering unmatched resistance to corrosion. This is crucial in the anaerobic digestion process, where the presence of biogas, chemicals, and wastewater requires durable materials that can withstand aggressive conditions.

Cost Efficiency: Center Enamel's bolted steel tanks provide a cost-effective solution compared to traditional concrete tanks. Their modular design allows for quick installation, which reduces labor costs and shortens project timelines. Additionally, the low maintenance requirements of GFS-coated tanks further enhance their cost efficiency over time.

High Capacity and Flexibility: The bolted design of these tanks enables flexible configurations, allowing for a wide range of capacities and sizes to meet the specific needs of any wastewater treatment project. Whether for small-scale plants or large municipal wastewater facilities, our EGSB reactors can be customized to fit any application.

Rapid Installation: The prefabricated bolted design of our EGSB reactors ensures that the tanks can be quickly assembled on-site with minimal equipment. This allows for rapid deployment, making our tanks ideal for projects with tight deadlines.

Proven Performance: Our bolted steel EGSB reactors are designed to operate efficiently in harsh environmental conditions, offering a long lifespan and robust performance. The smooth internal surface provided by the GFS coating reduces the potential for sludge build-up, enhancing the overall efficiency of the reactor.

Bolted Steel Tanks for Wastewater Storage

In addition to EGSB reactors, Center Enamel manufactures high-quality bolted steel wastewater tanks for use in a variety of applications. These tanks are ideal for storing both treated and untreated wastewater, ensuring environmental safety and compliance with stringent wastewater regulations.

Advantages of Bolted Steel Wastewater Tanks:

Leak-Proof Design: Our bolted steel wastewater tanks are engineered with precision to ensure a leak-proof and durable solution for wastewater storage. This is essential in preventing contamination of surrounding areas and protecting the environment.

Compliance with Industry Standards: Center Enamel's wastewater tanks comply with international standards such as AWWA D103-09 and OSHA, making them a reliable choice for wastewater treatment projects globally. Our tanks are designed to meet the stringent requirements of municipal, industrial, and agricultural wastewater management.

Long-Term Durability: The GFS coating on our wastewater tanks offers superior resistance to corrosion, UV rays, and extreme temperatures. This ensures the tanks remain operational for decades, even in the most demanding environments.

Scalability: Our bolted steel tanks are scalable to meet the needs of any wastewater treatment plant, from small rural facilities to large urban wastewater projects. The modular design of the tanks allows for easy expansion as treatment capacity needs grow.

Minimal Maintenance: The smooth interior surface of GFS-coated tanks reduces the buildup of sludge and other contaminants, making them easier to clean and maintain. This lowers operational costs and maximizes the efficiency of the treatment process.

Why Center Enamel?

As a leading EGSB reactor manufacturer and wastewater tanks manufacturer, Center Enamel has decades of experience in delivering high-quality, cost-effective wastewater treatment solutions. Our bolted steel tanks have been used in wastewater treatment projects across the globe, proving their reliability and performance. With a strong focus on innovation and customer satisfaction, we are committed to providing industry-leading storage solutions that meet the evolving needs of wastewater treatment plants.

Center Enamel’s bolted steel tanks offer the perfect solution for use as EGSB reactors and wastewater tanks in a wide range of wastewater treatment projects. With their rapid installation, cost-effectiveness, and superior corrosion resistance, our tanks are designed to ensure long-term, efficient performance. Whether you are seeking a reliable solution for wastewater storage or an advanced EGSB reactor, our tanks provide unmatched value and performance in the global wastewater treatment industry.

For more information on how our bolted steel tanks can enhance your wastewater treatment project, contact Center Enamel today!

0 notes

Text

Applications of Pneumatic Conveying Systems: Revolutionizing Material Handling

In the vast expanse of industrial operations, the movement of materials stands as a critical backbone ensuring efficiency, safety, and sustainability. Pneumatic conveying systems, leveraging the power of air to transport materials through pipes, have emerged as a cornerstone in numerous sectors. These systems offer a blend of versatility, cleanliness, and automation, making them an indispensable tool in modern manufacturing and processing environments. Let’s explore the various applications of pneumatic conveying systems and how they are revolutionizing material handling across industries.

1. Food and Beverage Industry

In the food and beverage sector, maintaining product integrity and hygiene is paramount. Pneumatic conveying systems excel in this realm, offering a closed environment that minimizes contamination risks and ensures the gentle handling of delicate products like cereals, coffee beans, powdered milk, and spices. These systems can efficiently handle a wide range of materials, from granular to powder form, facilitating seamless processing, packaging, and distribution processes.

2. Pharmaceutical Industry

The pharmaceutical industry requires the highest standards of cleanliness and precision. Pneumatic conveyors are uniquely suited to meet these demands, providing a contamination-free transport solution for sensitive materials like powders, granules, and capsules. They ensure that active pharmaceutical ingredients (APIs) are handled in a controlled environment, safeguarding against external pollutants and cross-contamination, thereby upholding the integrity of medicinal products.

3. Chemical Industry

Handling chemicals poses a significant challenge due to the hazardous nature of many compounds. Pneumatic conveying systems offer a secure method to transport chemicals, whether they are in powder, granule, or pellet form. These systems minimize human exposure to harmful substances and reduce the risk of environmental contamination. Their enclosed design also mitigates the potential for explosive dust-air mixtures, enhancing plant safety.

4. Plastics and Polymer Industry

The plastics and polymer sector benefits immensely from pneumatic conveying in the transportation of raw materials like pellets, powders, and regrind. The efficiency and cleanliness of these systems allow for the rapid and safe movement of materials through various stages of production, from compounding to molding or extrusion processes. Pneumatic conveyors help in maintaining the quality of these materials by preventing degradation and contamination.

5. Construction and Cement Industry

In the construction and cement industry, the ability to move large volumes of materials like cement, sand, and aggregates is crucial. Pneumatic conveying systems provide a dust-free solution, significantly reducing the environmental impact associated with traditional material handling methods. They facilitate the efficient transfer of bulk materials over long distances, from storage silos to processing units or mixers, streamlining production workflows.

6. Power Generation

Pneumatic conveying finds its application in power plants for the handling of fly ash, a by-product of coal combustion. These systems enable the safe, clean, and efficient disposal or recycling of fly ash, thereby addressing environmental concerns and regulatory compliance. The enclosed nature of pneumatic conveyors prevents the escape of ash into the atmosphere, contributing to cleaner air and a healthier environment.

Conclusion

Pneumatic conveying systems have redefined material handling across diverse industries. Their ability to transport a wide array of materials with high efficiency, safety, and control makes them an essential component of modern industrial operations. As technology advances, these systems are set to become even more innovative, offering solutions that are not only effective but also environmentally responsible. The future of material handling lies in the air – quite literally – as pneumatic conveying continues to push the boundaries of what is possible in industrial automation and efficiency.

#pneumatic conveying system#pneumatic conveying#pneumatic conveyor process#pneumatic conveyor systems

0 notes

Text

Plastic Granule and Powder Mixer in Bihar

Adroit Extrusion is a Manufacturer, Exporter, and Supplier of Plastic Granule and Powder Mixer in Bihar. We are ISO 9001:2015 certified company, Ahmedabad, Gujarat, India. Adroit Extrusion are specialize in Monolayer, ABA, two-layer, three-layer, five-layer, and seven-layer setups. Blow Film Plant Accessories like Vertical Granule Mixer with Dryer, Extrusion Process Control, Gusset Board Assembly, Trim Recycling Machine, Hopper Loader, Plastic Granule and Powder Mixer, Plastic Recycling Machine, Bubble Slit, Assembly. Plastic granule and powder mixing is essential for blending various types of plastic materials to achieve desired characteristics such as color, texture, and strength. This process is critical across industries like packaging and automotive, prioritizing uniformity and quality. Efficient mixing guarantees the homogeneity of the plastic blend, preventing irregularities in the end product. Proper mixing enhances material properties, minimizes waste, and enhances production efficiency. A significant challenge in plastic mixing is ensuring the even dispersion of additives and colorants. Color mixers are frequently used for mixing and stirring powder and granular materials. They enable rapid mixing with high performance capabilities. Easy to Operate High Load Bearing Capacity Optimum Perfomance We make both the mixing barrel and the mixer from stainless steel and polish them. We adopt a vertical reducer motor to ensure low noise and durability. Vertical color mixers are widely used in plastic injection, plastic recycling, powder metallurgy, pharmacy chemicals, foodstuff and ceramic ware. Available from 25 to 100 kg capacity. Adroit Extrusion is the trusted Plastic Granule and Powder Mixer in Bihar serving locations such as Begusarai, Begusarai, Bettiah, Bhagalpur, Bihar Sharif, Bodh Gaya, Buxar, Chapra, Darbhanga, Dehri, Dinapur Nizamat, Gaya, Hajipur, Jamalpur, Katihar, Madhubani, Motihari, Munger, Muzaffarpur, Patna, Purnia, Pusa, Saharsa, Samastipur, Sasaram, Sitamarhi, Siwan. For further details and inquiries, please feel free to contact us. Read the full article

0 notes

Text

Agricultural Lubricants Market is Estimated to Reach a Value of USD 2,646,487.75 Thousand by 2027| Key Players Chevron Corporation, Exxon Mobil Corporation, Eni S.p.A., FUCHS, LUKOIL, Valvoline LLC

Agricultural Lubricants Market is estimated to grow at 3.8% for the forecast period of 2020-2027 with factors such as high cost of synthetic and bio-based lubricants which is expected to restrain the growth of the agricultural lubricants market. Agricultural lubricants market has shown an exceptional penetration in developed economies in Asia-Pacific due to the increasing population and urbanization, growing demand for agricultural lubricants which will help in boosting the growth of the agricultural lubricants market.

Agricultural lubricants market is expected to gain market growth in the forecast period of 2020 to 2027. Data Bridge Market Research analyses that the market is growing with the CAGR of 3.8% in the forecast period of 2020 to 2027and expected to reach USD 2,646,487.75 thousand by 2027. Asia-Pacific is dominating in global agricultural lubricants market owing to increasing government initiatives to propelling the adoption of agricultural machineries in the region, boosting the agricultural lubricants market. Increasing mechanization and use of machinery in the agricultural industry is driving the market but high cost of synthetic and bio-based lubricants restraint the market.

Global Agricultural Lubricants Market By Type (Engine Oil, Grease, Hydraulic Oils, Transformer Oil, Crankcase Oils, Bar and Chain Oil, Others), Raw Material (Petroleum Based Lubricants and Bio-Based Lubricants), Application (Engines, Gear & Transmission, Hydraulics, Greasing, Chain, Implements, Others), Agricultural Equipment (Tractors, Harvesters, Corn-Pickers, Balers, Verge Cutters, Circular Spike Harrows, Stone Grinders, Fertiliser Spreaders, Slurry Tankers, Sprayers, Fodder Mixers, Silage Spreaders, Straw Blowers, Mowers and Mower-Conditioners, Hay Tedders, Hay Rakes, Bale Wrappers, Grape Harvesting Machines and Others), Country (U.S., Canada, Mexico, Germany, U.K., Italy, France, Spain, Russia, Turkey, Switzerland, Belgium, Netherlands, Rest of Europe, Japan, China, South Korea, India, Australia and New Zealand, Singapore, Thailand, Hong-Kong, Taiwan, Indonesia, Malaysia, Philippines, Rest of Asia-Pacific, Brazil, Argentina, Rest of South America, South Africa, Egypt, Saudi Arabia, U.A.E., Israel, Rest of Middle East & Africa) Industry Trends and Forecast to 2027

Get Sample PDF of Large-joint reconstructive implants market Report (including COVID19 Impact Analysis) @https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-agricultural-lubricants-market

Scope of the Agricultural Lubricants Market:

Agricultural lubricants market is segmented on the basis of countries into the U.S., Canada, Mexico in North America, Brazil, Argentina, Rest of South America as a part of South America, Germany, France, U.K., Italy, Spain, Netherlands, Belgium, Russia, Turkey, Switzerland, Rest of Europe in Europe, China, Japan, India, Australia, Singapore, Thailand, Malaysia, South Korea, Indonesia, Philippines, Rest of Asia-Pacific (APAC) as a part of Asia-Pacific (APAC), U.A.E, Egypt, Saudi Arabia, South Africa, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA).

All country based analysis of the agricultural lubricants market is further analyzed based on maximum granularity into further segmentation. On the basis of type, the agricultural lubricants market is segmented into engine oil, grease, hydraulic oils, transformer oil, crankcase oils, bar and chain oil and others. On the basis of raw material, the agricultural lubricants market is segmented into petroleum-based lubricants and bio-based lubricants. On the basis of application, the agricultural lubricants market is segmented into engines, gear & transmission, hydraulics, greasing, chain, implements and others. On the basis of agricultural equipment, the agricultural lubricants market is segmented into tractors, harvesters, corn-pickers, balers, verge cutters, circular spike harrows, stone grinders, fertiliser spreaders, slurry tankers, sprayers, fodder mixers, silage spreaders, straw blowers, mowers and mower-conditioners, hay tedders, hay rakes, bale wrappers, grape harvesting machines and others.

Agricultural lubricants are substances used to lubricate agricultural machinery and other devices, including tractors, roof cutters, harvesters and others. They are extensively used in applications such as greasing, engines, chains, gear & transmission, hydraulics, implements and others.

Key Market Competitors:

The major players covered in the report are Royal Dutch Shell plc, BP p.l.c., Chevron Corporation, Exxon Mobil Corporation, Eni S.p.A., FUCHS, LUKOIL, Valvoline LLC, Total, Phillips 66, Repsol, Morris Lubricants, LUBRITA EUROPE B.V, CONDAT, Dyade Lubricants, UNIL, The Bahrain Petroleum Company B.S.C., KLONDIKE Lubricants Corporation, Cougar Lubricants International Ltd and Gulf Oil International among other domestic players. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Key Pointers Covered in the Agricultural Lubricants Market:

Market Size

Market New Sales Volumes

Market Replacement Sales Volumes

Market Installed Base

Market By Brands

Market Procedure Volumes

Market Product Price Analysis

Market Healthcare Outcomes

Market Cost of Care Analysis

Market Regulatory Framework and Changes

Market Prices and Reimbursement Analysis

Market Shares in Different Regions

Recent Developments for Market Competitors

Market Upcoming Applications

Market Innovators Study

MAJOR TOC OF THE REPORT:

Chapter One: Agricultural Lubricants Market Overview

Chapter Two: Manufacturers Profiles

Chapter Three: Agricultural Lubricants Market Competition, by Players

Chapter Four: Agricultural Lubricants Market Size by Regions

Chapter Five: Agricultural Lubricants Market Revenue by Countries

Chapter Six: Agricultural Lubricants Market Revenue by Type

Chapter Seven: Agricultural Lubricants Market Revenue by Application

Chapter Eight: Agricultural Lubricants Market Revenue by Industries

Chapter Nine: Agricultural Lubricants Market Revenue by Deployment Model

Chapter Ten: Agricultural Lubricants Market Revenue by End User

Get Table of Content on Request @https://www.databridgemarketresearch.com/toc/?dbmr=global-agricultural-lubricants-market

Reasons for buying this Global Agricultural Lubricants Market Report:

Laser Capture Global Agricultural Lubricants Market, report aids in understanding the crucial product segments and their perspective.

Initial graphics and exemplified that a SWOT evaluation of large sections supplied from the Laser Capture Global Agricultural Lubricants Market industry.

Even the Laser Capture Global Agricultural Lubricants Market economy provides pin line evaluation of changing competition dynamics and retains you facing opponents.

This report provides a more rapid standpoint on various driving facets or controlling Medical Robotic System promote advantage.

This worldwide Locomotive report provides a pinpoint test for shifting dynamics that are competitive.

The key questions answered in this report:

What will be the Market Size and Growth Rate in the forecast year?

What is the Key Factors driving Laser Capture Global Agricultural Lubricants Market?

What are the Risks and Challenges in front of the market?

Who are the Key Vendors in Global Agricultural Lubricants Market?

What are the Trending Factors influencing the market shares?

What is the Key Outcomes of Porter’s five forces model

Access Full Report @ https://www.databridgemarketresearch.com/reports/global-agricultural-lubricants-market

Browse Related Report:

Europe Agricultural Lubricants Market

Asia-Pacific Agricultural Lubricants Market

Middle East and Africa Agricultural Lubricants Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

0 notes

Text

How does organic fertilizer equipment make granular organic fertilizer?

The process of the granular organic fertilizer granulation process line is to crush the fermented and decomposed livestock and poultry manures and then process them into balls in a pelletizer. The livestock and poultry manures are made of fresh chicken, pigs, cows, sheep manure, municipal solid waste, agricultural and sideline products, and organic matter as raw materials. , Does not contain any chemical ingredients. These materials are added with starter to kill harmful bacteria under the action of high temperature and retain beneficial bacteria. The organic matter content of the fermented materials is ≥45%, and the total content of nitrogen, phosphorus and potassium is ≥4%, which is suitable for a variety of crops and fruit trees. With the rapid development of the livestock and poultry breeding industry, a large amount of manure and sewage are produced. The harmful elements in these manures are seriously exceeding the standard, and it is difficult to deal with the traditional way of returning to the field. In response to this situation, people have developed an organic fertilizer production line with mobile, high-efficiency solid-liquid separation technology as the core and integrated supporting high-efficiency mixers, turners, granulator machine for fertilizer and other fertilizer production equipment.

The development of livestock manure organic fertilizer production line and sterilization system will help promote the formation of an industrial chain for the harmless treatment, resource utilization, and commercial operation of livestock manure to achieve the goal of industrialization, marketization, and large-scale production. Effectively promote the development of ecological agriculture and circular economy in the city. The granular organic fertilizer production line performs granulation processing on the basis of powdered organic fertilizer, which is convenient for commercial sales, storage and transportation, and prolongs the maintenance time of fertilizer fertility. The organic fertilizer granulator turns crop stalks and wastes into green and pollution-free ecological feeds for livestock breeding; livestock and poultry manure, urban and rural household garbage and other wastes can be quickly turned into highly efficient organisms through the organic fertilizer granulator Organic fertilizer enters green cultivation. The organic fertilizer pellet machine has the characteristics of beautiful appearance, simple structure, convenient operation and maintenance, safety and reliability, small size, light weight, etc. The user does not need special training and learning, and can be operated and used after reading the manual; due to low power and high output, It is a small and medium-sized ideal equipment for entrepreneurship in biological fertilizer plants, feed plants, farming and animal husbandry plants, sewage treatment plants, townships, villages, and villages; the organic fertilizer pellet machine has strong anti-overload capability in the processing of pellets, even in The machine is not stuffy even when it is fully loaded.

#organic fertilizer granulator#fertilizer granulation process#fertilizer pellet machine#granulator machine for fertilizer

0 notes

Text

Toaster Market Size, Share, Industry Growth, Trends, Business Opportunities, Challenges, Growth Insights to 2027

The global ''toaster size'' market is expected to reach USD 4.72 billion by 2027, exhibiting a CAGR of 4.2% during the forecast period. The growing consumer demand for luxurious kitchen appliances items such as refrigerators, mixer grinders, toasters & ovens can have a stupendous effect on the market, states Fortune Business Insights, in a report, titled “Toaster Market Size, Share & COVID-19 Impact Analysis, By Product (Pop-up, Oven, and Conveyor), Application (Residential and Commercial), Distribution Channel (Online and Offline), and Regional Forecast, 2020-2027.” The market size stood at USD 3.83 billion in 2019.

The emergence of coronavirus has caused the world’s economy to tumble down. We understand that this health emergency has negatively impacted various sectors across the globe. Rising support from governments and several companies can help in the fight against this highly infectious virus. There are some industries that are struggling and some are thriving. More or less, nearly every sector is estimated to be impacted by this pandemic.

We are perpetually working on our reports to help uplift businesses in this crucial time. Our expertise and experience can offer enormous benefits to help regain during this global pandemic.

Study Period: 2016-2027 Base Year: 2019 Forecast Period: 2020-2027 Historical Period: 2016-2018

List of the Leading Companies Profiled in the Global Toaster Market are:

Panasonic Corporation (Osaka, Japan)

LG Electronics (Seoul, South Korea)

Samsung Electronics Co. Ltd. (Seoul, South Korea)

Gorenje (Velenje, Slovenia)

Haier Group Corporation (Qingdao, China)

De’Longhi S.p.A. (Treviso, Italy)

Severin Elektrogerate GmbH (Sundern, Germany)

BSH Hausgerate GmbH (Munich, Germany)

HAEGER (California, United States)

Walten Hi-Tech Industries Ltd. (Gazipur, India)

The report on the toaster market reveals:

Eminent insights into the industry

Important data with in-depth research

Factors exhibiting market growth

Comprehensive study about main regions

COVID-19 impact on the market

Market Driver:

Surging Hospitality Industry to Propel Market

The inauguration of new cafés, restaurants, hotels, schools, and others will spur opportunities for the market during the forecast period. The increasing consumption of fast food will simultaneously improve the prospects of the market. According to the report ‘Hospitality, Tourism and Leisure in the UAE’, published by the US-UAE Business Council, as of 2018, Dubai had 703 hotels and apartment properties combined with a total number of 111,864 rooms, an increase of 6% over to that of 2017. The increasing inclination towards food recipes through on-demand videos & posts will foster healthy growth of the market during the forecast period. Besides, the growing governmental initiatives & policies for the production of home appliances can promote the growth of the market.

Declining Sale of Toasters to Retard Market Amid Coronavirus

The diminishing purchasing power of consumers will considerably dampen the business during the pandemic. Moreover, the shift from traditional shopping methods to online shopping can further limit the adoption of toasters, which, in turn, will restrict the growth of the market. However, the surging online sales will consequently uplift the market during coronavirus. Besides, the demand for kitchenware products among the middle class and upper class will fuel the demand for toasters, hence, aiding the market growth.

Regional Analysis:

Heavy Consumption of Kitchenware Products to Promote Growth in Asia Pacific

The Toaster market size in Asia Pacific is expected to witness rapid growth during the forecast period owing to the increasing consumption of premium kitchenware products in developing nations such as India, and China. According to the data presented by the China Household Electrical Appliances Association, on 18 August 2020, single-day transaction sales value of the home appliances items has reached to USD 38.79 billion in China during the JD.com festival session. Moreover, the presence of major companies such as Hebei AOCNA Baking Machinery Co. Ltd., Haier Group Corporation, Samsung Electronics Inc., Panasonic Corporation, and others will influence the healthy growth of the market in the region.

Toaster Market Report Focus on:

Extensive product offerings

Customer research services

Robust research methodology

Comprehensive reports

Latest technological developments

Value chain analysis

Potential Market opportunities

Growth dynamics

Quality assurance

Post-sales support

Regular report updates

Reasons to Purchase this Report:

Comprehensive analysis of the market growth drivers, obstacles, opportunities, and other related challenges.

Tracks the developments, such as new product launches, agreements, mergers and acquisitions, geographical expansions, and joint ventures.

Identifies market restraints and boosters.

Identifies all the possible segments present in the market to aid organizations in strategic business planning.

Key Questions Answered: Why Choose Fortune Business Insights? What are the key demands and trends shaping the market? What are the key opportunities in the market? What are the key companies operating in the market? Which company accounted for the highest market share? What is the market size and growth rate of the global and regional market by various segments? What is the market size and growth rate of the market for selective countries? Which region or sub-segment is expected to drive the market in the forecast period? What Factors are estimated to drive and restrain the market growth?

Browse Detailed Summary of Research Report with TOC:

https://www.fortunebusinessinsights.com/toaster-market-103851

Detailed Table of Content:

Research Scope

Market Segmentation

Research Methodology

Definitions and Assumptions

Market Drivers

Market Restraints

Market Opportunities

Emerging Trends

Impact of COVID-19

Supply Chain Challenges

Potential Opportunities due to COVID-19

Pop-up

Oven

Conveyor

Residential

Commercial

Online

Offline

North America

Europe

Asia Pacific

South America

Middle East & Africa

TOC Continued…!

Key Development:

May 2020: Newell Brands Inc., a leader in cookware, bakeware, cutlery, and kitchen appliances introduced cool performance touch countertop oven under their brand ‘Calphalon’ that consists of an innovative exterior to provide 75% coolness to the device and the interior feature that uses quartz heat technology to deliver 40% more even heat that other oven’s to provide uniform heating to the food

Have a Look at Related Research Insights:

Hair Styling Tools Market Size, Share & COVID-19 Impact Analysis, By Product Type (Manual and Electric (Dryer, Straightener, Curler, and Others)), Application (Household and Commercial), Distribution Channel, and Regional Forecast, 2020-2027

North America Hand Sanitizer Market Size, Share & COVID-19 Impact Analysis, By Product Form (Foam, Gel, Spray, and Others), Type (Alcohol-Based Sanitizer and Alcohol-Free Sanitizer), End-User (Schools, Restaurants, Hospitals, Households, Office Buildings, and Others), and Regional Forecast, 2020-2027

Smart Mask Market Size, Share & Industry Analysis, By Product Type (Respirators, Surgical Masks, Anti-pollution Masks, Face Shields), By Distribution Channel (Hypermarkets & Supermarkets, Pharmacy Stores, Online Stores, Others), By End-User (Hospitals & Clinics, Households, Industries, Others) And Regional Forecast 2020-2027

Smart Fridge Market Size, Share & Industry Analysis, By Product Type (Reusable bags, Non-Reusable Bags), By Material (Paper, Cotton , Plastic, Jute & Hemp and Others), By Distribution Channel (Hypermarkets & Supermarkets, Convenience Stores, Online Stores, Others) And Regional Forecast 2020-2027

About Us:

Fortune Business Insights™ offers expert corporate analysis and accurate data, helping organizations of all sizes make timely decisions. We tailor innovative solutions for our clients, assisting them to address challenges distinct to their businesses. Our goal is to empower our clients with holistic market intelligence, giving a granular overview of the market they are operating in.

Our reports contain a unique mix of tangible insights and qualitative analysis to help companies achieve sustainable growth. Our team of experienced analysts and consultants use industry-leading research tools and techniques to compile comprehensive market studies, interspersed with relevant data.

At Fortune Business Insights™, we aim at highlighting the most lucrative growth opportunities for our clients. We, therefore, offer recommendations, making it easier for them to navigate through technological and market-related changes. Our consulting services are designed to help organizations identify hidden opportunities and understand prevailing competitive challenges.

Contact Us: Fortune Business Insights™ Pvt. Ltd. 308, Supreme Headquarters, Survey No. 36, Baner, Pune-Bangalore Highway, Pune - 411045, Maharashtra, India. Phone: US: +1-424-253-0390 UK: +44-2071-939123 APAC: +91-744-740-1245 Email: [email protected] Fortune Business Insights™ LinkedIn | Twitter | Blogs

Read Press Release:

https://www.fortunebusinessinsights.com/press-release/global-toaster-market-10238

0 notes

Text

Process and price of investment in granular organic fertilizer production line

The general technological process of granular organic fertilizer production line is: fermentation, crushing, stirring, granulation, drying, cooling, screening and packaging.

The fermentation of organic fertilizer production line is mainly to decompose the pathogens, insect eggs and other harmful substances in pig manure and straw. The function of trough type dumper is to overturn, promote oxygen, evaporate excess water, control the temperature of pile body, avoid anaerobic reaction to produce odor, so as to achieve the purpose of rapid fermentation and shorten the fermentation cycle. After the fermentation is completed, crushing is due to the need of fermentation in the later stage If it needs to stand for about a week, there will be some caking phenomenon. After being crushed by crushing organic fertilizer production machine, the stirring teeth will not jam when entering the organic fertilizer granulator for granulation, which will cause equipment damage. At the same time, the more uniform the powder is, the more uniform the particles will be. In order to improve the nutrient content of pig manure organic fertilizer, certain n, K and P powder can be added, which can be put into the organic fertilizer granulator after being evenly stirred by horizontal mixer The results showed that the nutrient composition of the sample granules was uniform and the fertilizer efficiency was consistent;

I will not explain the purpose and function of the organic fertilizer granulator here. The model of the granulator machine for fertilizer is mainly determined according to the needs of customers (particle shape, output, etc.); the main purpose of the drum dryer and cooler is only one, that is, to quickly evaporate the excess water and reduce the difficulty of packaging; after that, the screening machine is used to screen the semi-finished products and powder and return to the powder The qualified ones are directly packed and bagged as finished products. fertilizer machine manufacturers

After the whole production of pig manure organic fertilizer, the equipment investment cost is 200000-350000, and the site area required for the plant with an annual output of 20000 tons of organic fertilizer is 30 mu.

#organic fertilizer production line#granulator machine for fertilizer#organic fertilizer production machine#organic fertilizer

0 notes

Text

Rapid Mixer Granulator RMG Machine

The goals of the Rapid Mixer Granulator RMG Machine (High Shear Mixer), which includes the Pharma RMG machine, are to reduce processing times, provide more uniform and homogenous granular mixing at lower operating costs, and, most importantly, maintain enhanced sanitary compliance with cGMP standards. For cGMP compliance, all contact parts are constructed from FDA-approved materials or stainless steel 316L.

Granulator and Rapid Mixer created for maximum efficiency. cGMP compliance, with a focus on validating clearance. The Rapid Mixer Granulator is engineered to yield superior mixing and uniform granules while reducing operational expenses and boosting output. Improved mixing and closed granule size control result in higher tableting speeds, better quality, and fewer rejections. As a manufacturer of quick mixer granulators, we go to great lengths to construct sturdy, high-quality equipment.

0 notes

Text

An Interactive Element

For the last several weeks, I’ve been iterating upon and fleshing out the general concept of an AI capable of generating audio. Initially, the goal was to create machine-made music in the style of existing human recordings; recently, the aim has shifted more towards an examination of how a computer comes to understand any given soundscape when asked to create its own.

The working prototype for the project is featured here, fully capable of providing 4 concurrent sources of sound with variable volume levels, executable within the browser:

https://editor.p5js.org/tobij622/present/yGOn6HJez

To use the applet, toggle between the level of coherence for any soundscape, toggle the sound on with the small checkbox next to the coherence selector, and adjust the volume to your liking.

Before delving into how this prototype works and addressing where it excels/falls flat, I’ll walk through my design process and provide resources used to inform the prototypes general creation and form. In the moments immediately following last class, I plunged deep into a pit of despair and panic knowing fully well I would be unable to collect a meaningful dataset and train an AI in under two weeks. Nonetheless, I set out to do exactly that, contacting my two best resources for direction on where to start. One of them reassured me I was right to believe creating an AI in such a timespan was impossible, and the other pointed me in the direction of WaveNet, Google’s proprietary text-to-speech generator trained via raw waveforms. WaveNet’s general documentation, in all of its horrifically dense glory, can be found here.

I spent several days reading up on WaveNet, its required processing power, and a number of alternatives capable of producing similar results with less training time. I stumbled across what should’ve been my holy grail, a full Python-based iteration of WaveNet made entirely free out of a passion project, but nonetheless struggled for several days with implementing the system on my 2015 Macbook Pro. In the interest of time and actually having something to show for, I elected to approximate AI-generated sound on my own.

While doing research into AI-generated soundscapes, I found a thoroughly-documented Medium page deep within the well of Google’s boundless knowledge that provided incredible examples of simulated speech and music built on the same free iteration of WaveNet I intended to use. Some examples of generated sound from the article follow:

A generated piano.

What can only be described as “a Christmas-themed death song.”

A fake forest with a genuinely convincing AI-creek.

Ambient clicking.

and an AI’s understanding of “Happy” music.

The article proved indispensable and was the basis upon which I built all of the audio samples used in my functioning prototype. Among the more striking features of all pieces of AI-generated sound provided by the article is the pointillism present throughout the recordings best represented in low clicks, subtle plosives, and almost speech-like rapidity in nonsensical musical phrases. These recordings immediately brought to mind the practice of granular synthesis, a form of sound design that takes audio samples, typically at least under a second long, and uses them to build clouds of sound. Just for reference, here’s a link to Iannis Xenakis’ Concret PH, the piece Xenakis himself righteously claimed invented the notion of granular synthesis.

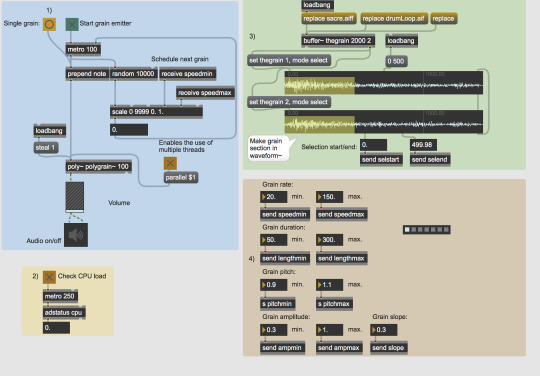

Running with this idea, I made some rudimentary edits to Max/MSP’s demo granular synthesizer and rigged it to have audio recording capability, shifting a few parameters around to provide a level of control for the synth’s given output. A feature I found to come up often in the articles and documentation concerning AI-sound is the variance in coherence of any given output file, with more coherence owing to more of a reliance on an existing dataset rather than pure synthesis of new material. For this reason, I elected to use four existing sound files and create, for each of them, two different levels of coherence akin to real AI sound parameters. The four sounds I used I largely sourced from findings on the internet: the bird sound is of an existing Mockingbird recording, the forest sound is of a rain forest, the vox sound is of a well-loved interview between Levar Burton and Rickie Lee Jones, and the cityscape was my own recording of 5th Avenue right next to the main Parsons building.

For each of the four recordings, I tailored my granular synth to produce vaguely coherent and entirely incoherent iterations upon the original provided sound. The results vary and, unlike actual AI-generated sound, all share the same audio fidelity and snippets of data inherent to their original sound file.

The online prototype itself is the product of three days of tinkering in p5.js and was the result of what seemed to be an endless headache regarding p5′s innate sound library. The end product seeks to emulate what a real application capable of generating AI-sounds would look like and how it would handle, serving both as a sample serving of generative sound and a small-scale audio mixer with the bonus ability of constructing hybrid sonic realities. The small modulating Bezier curve present in the background is exclusively to provide visual stimuli.

0 notes

Photo

The organic fertilizer manufacturing process is mainly to screen and magnetically sort the organic waste with a water content of about 30% to 35% after fermentation and decay to prepare round granular organic fertilizer equipment, and add functional bacteria to produce biological organic fertilizer in the biofertilizer production, adding nitrogen, phosphorus and potassium (total nutrient content less than 15%) can produce organic and inorganic fertilizers.

After the fermented organic waste is subjected to magnetic separation and sieving, the raw materials with binder and other ingredients to be compatible are metered according to the ratio requirements, and then lifted into a multi-dimensional high-efficiency mixer by a bucket elevator for rapid mixing. The mixed material slips out into the mixing bin, and is continuously and uniformly fed into the extrusion granulator by the disc feeder to make cylindrical particles; the cylindrical particles are polished and formed into spherical particles by the circular particle polishing and shaping machine, and are formed by the belt The machine is fed into the drying, cooling and screening machine (three-in-one model). The particles are dried at a low temperature and large air volume (≤65 ℃) in the front section of the drying and cooling screening machine, and then enter the cooling section for air cooling. After sufficient cooling The material enters the screen installed at the end of the cylinder, and the sieved finished particles are transported by the elevator to the finished product silo, which is measured and packaged by the packaging system; the sifted large particles are returned to the mixing granulation system after crushing; The sieved small particles (basically without powder) can be made into small packages and sold directly.

0 notes

Text

Important Machinery for Pharmaceutical & Chemical Industries

youtube

Machines Vital to Pharmaceutical & Chemical Industries

Vibro Sifter:

A vibro sifter machine helps with a process of separation, scalping and grading. It is often referred to as a vibratory sifting device as well. The aim of this machine is to separate solid materials from solid, solid materials from liquid and particle graduation; thus, allowing to separate & grade different materials in bulk.

Rapid Mixer Granulator:

Rapid Mixer Granulator is mainly useful to make granules from all ingredients prior to compression. It consists of impellers at the bottom where the small blades have a special design to lift the material and full-length blades push the material thus mixing it. There are also choppers, special small blades at the bottom of a bowl. This is an effective machine for purpose of dry and wet mixing as well as granulation.

Fluid Bed Dryer:

Fluid Bed Dryer is essential in the pharmaceutical industry to reduce moisture content in pharmaceutical powder and granules. The main working principle of this machine is fluidization of feed material. The way it works is that hot air is introduced at high pressure via a perforated bed of moist solid particulate. This causes the wet solids to be lifted from the bottom. They become suspended in a stream of air. Thus, process of heat transfer occurs by direct contact between wet solids and hot gasses.

Ribbon Blender:

Ribbon Blender is an industrial strength machine useful to mix a large amount of material. The shape of this blender is a thin ribbon shape metal mixer and hence the name ribbon blender. It consists of a ribboned agitator for mixing operations.

Double Cone Blender:

Double Cone Blender is a versatile machine that helps with mixing of dry powder and granules homogeneously. This is a stainless-steel machine where two third volume of a cone blender is filled to ensure the mixing process goes smoothly.

Octagonal Blender:

Octagonal Blender helps with the process of mixing of many types of granular products. It is highly efficient and versatile and useful for process of mixing and lubrication. It is octagonal in shape with central section being rectangular that is fast and effective.

Tray Dryer:

The main purpose of a tray dryer for the processes like heating, ageing, drying, etc. They have a special design that allows parallel placement of the material thus making it possible to increase production and reduce individual batch timing.

Planetary Mixer:

Planetary Mixer is a versatile machine that is essential for several industries. It has interchangeable utensils that have several applications. These are essential for the mixing of ointments and useful in in both pharmaceutical and chemical industries.

Heat Exchanger:

A heat exchanger is a boiler that is set at steam temperature. It also has another smaller boiler inside. A heat exchanger rod passes through it. During the process of extraction, cold air is pumped, and fresh water passes through the heat exchanger.

Distillation Column:

Distillation is a process for separating components or substances from the liquid mixture. This is done with Distillation Column via a process of selective boiling and condensation. The process of distillation is useful in several industries including chemical industry. It is important for oil stabilization. Large amount of crude liquid products can be distilled to separate them from other products or impurities.

Thus, these are several machines useful for the purpose of research, development and production in pharmaceutical and chemical industries.

0 notes

Text

How much money can you make by investing in pig manure production line to produce one ton of organic fertilizer?

Does it make money to open the organic fertilizer plants of chicken manure, cow manure and pig manure? Due to the long-term overuse of chemical fertilizer in recent years, which has caused severe phenomena such as soil hardening, environmental pollution, decline in the quality of agricultural products and the rapid increase in the price of chemical fertilizer in recent years, the use of organic fertilizer machine to produce safe, environmental friendly and green organic fertilizer of chicken manure, cow manure and pig manure has attracted people's attention again. Its market demand is also increasing. The government's strong support and the change of market form provide an unprecedented opportunity for the sustainable development of organic fertilizer industry. It can be seen that its organic fertilizer has a bright future.

According to different equipment configuration of raw materials, pig manure organic fertilizer production process can also make appropriate plans according to investment budget, and the price of organic fertilizer production process with different output is also different. Pig manure organic fertilizer production process has three configurations: high, medium and low. Large fertilizer plants need to adopt a complete set of production configuration, and the finished product appearance and nutrient content can meet the market requirements, which has a greater advantage in the promotion of the finished organic fertilizer. The medium and low configuration organic fertilizer production line is suitable for small and medium-sized fertilizer plants. The sales scope of the finished organic fertilizer is in the nearby area. Some processes in the organic fertilizer production process need to be completed manually.

It is suggested to select the appropriate equipment configuration according to the investment of the pig manure fertilizer production process. It can be used as granular fertilizer and powder fertilizer. Equipment selection: if you want to reduce the investment cost, you can choose small-scale equipment configuration: crusher, mixer, organic fertilizer granulator, screening machine, packaging machine, etc. We will expand the investment scale when the time is right.

0 notes