#push in wire terminal block

Explore tagged Tumblr posts

Text

Life, Persisting

@masseffectholidaycheer gift for @natalyelle! All of your Shepards and Ryders sound wonderful from reading your blog, but I was particularly enchanted by Katerina and her love of plants, so I hope you enjoy! ---

Katerina dreamed of filling a house with plants.

She dreamed of having a house; of defeating the Reapers, of retiring and buying a little place where no one could find her unless she wanted them to. And then filling it with plants.

Ferns and cacti and flowers and herbs and succulents and anything else that would fit in the space. A rainbow of colors and leaves and life, persisting.

But for now she satisfied herself with filling her cabin on the rebuilt Normandy. It wasn't nearly as much space, which meant being judicious with purchases and creative in her use of space. There were niches in the wall, the shelves by her bathroom, a low lip around the perimeter of the ceiling. She didn't really need such a big desk; she would only use half of it at most.

The succulents went there. A simple block shelf pushed back to make two tiers for them. A planter with violets next to them, delicate purple heads bobbing near her workspace, perfuming the air.

Hanging baskets with ivy went near the fish tank, spreading toward her armor storage. The trailing tendrils laced along the fish tank, but the few fish she could keep up with didn't seem to mind.

----

Orchids were the last thing you'd expect to find on the Omega markets, but find them she did. The wizened batarian shopkeeper seemed surprised that was all she wanted, and definitely charged too much. But still the orchids came back with her, going under a small lamp in one of the niches near her bed. In the midst of all the fear, and chaos, and death, she had made herself an oasis. A place to be reminded of life, even as she fought to undermine a race determined to destroy it.

She saw her friends, here and gone, in the leaves and blooms that filled her private space. Ashley in the Christmas cactus; prickly, beautiful, resilient. The purple of the orchids brought Tali to mind, delicate but stubborn and resourceful. Kaidan was the ivy; unassuming and content in the background but still woven into her life. Garrus was the succulents; tough, not asking much, adapting to new surroundings. Miranda was a zinnia; self-sufficient and solitary, opening when she felt like it and not before. She saw herself in the Russian sage that filled the middle display shelf; hardy, plain, persisting.

She wasn't sure if it was the mint or the magnolias that finally prompted Miranda to say something. You could smell the latter on the elevator, no matter the level, but the former had such an aggressively invasive reputation.

"Shepard, our operating budget is meant to be for gear," Miranda pointed out, tone skirting the edges of exasperation. "Necessities. Not sun lamps."

"Don't forget the plant food, the wire for hanging baskets, and the new shears after I commandeered Adams' good ones," Katerina drawled. "For me they are a necessity. I need some green, some life, something to tend that doesn't have galactic consequences attached. This ship is too... austere otherwise. Call it fortifying my mental health if the Illusive Man asks."

Miranda pressed her lips together. "He hasn't so far. Whatever our costs he's willing to pay. I would understand a plant or two, but Shepard..." she gestured around the room, "...you've turned your cabin into a bloody greenhouse."

"Thank you, that was the goal," Katerina said. She snapped off a dead zinnia blossom so the others would grow healthy. "Caring for them is how I relax. Don't you want me in the best frame of mind possible, considering what we're doing?"

Miranda huffed but but didn't bring it up again, so Katerina hoped that meant she understood.

When she next got back from the Citadel, drained but relieved they'd been able to stop Kolyat, there were three new manuals on indoor plant care downloaded to her desk terminal.

Noticed a few looked a tad peaked. Maybe something in here will help.

She wanted to be annoyed at the insinuation, but skimmed the manuals first. One actually had a few tips she hadn't known, so she had to acknowledge Miranda knew what she was doing. The zinnia and orchid in question recovered in just a few days.

Miranda just shrugged when Katerina extended thanks. "You were right; we need you focused and in top form. If that's the way you do it, well, it's easier to accommodate than other habits." A faint smile. "And I suppose they're easier to keep alive than fish."

They never spoke of it again, but any time Katerina dropped a hint or slipped something plant-related in a requisition, it was filled, and quickly.

---

Even being careful with space and resources, there were some things she couldn't say no to, like the terrarium of brilliantly colored mushrooms from Sur'kesh, found at a semi-hidden rare flora shop on Ilium.

"Really, Shepard? Fungus?" Garrus ribbed, leaning against the wall to wait for her to finish the delivery datawork. "Thought plants were your thing."

"It's close enough," Katerina said defensively, "besides, they're pretty." She cast a final look at the pink-red-orange gradient mushroom colony. "And I imagine they'll be lower maintenance than some of my other plants."

"I am glad you have something to help you relax," Thane chipped in, his first contribution to conversation since they disembarked the Normandy. "It's important to do so, especially when facing stakes as high as we are. You should embrace the things that bring you joy. Remind you of life."

Katerina bit back a smile as they resumed course for their objective. "Thank you. That's why I like them. The reminder."

It was good to have, given the number of warzones and hollow colonies and seedy, gang-run alleys they had to crawl through, both to collect the necessary people for this mission and take care of their outstanding issues. Weeds and small blooms pushing through the debris on Korlus. The abundant flora on Aeia. Life in the face--and wake--of horror. Even the carefully manicured planter boxes on the Citadel or Ilium were a form of persistence. The vibrant mushrooms a reminder of life from and following death.

And so she filled her cabin with it, saw her friends and crew in the reminder, and used it to push her forward, to help her persist.

After all, she still needed that house filled with plants.

#queens fic#holiday harbinger 2025#katerina shepard#mass effect#me testing the LIMITS of my plant knowledge for this but it was fun

26 notes

·

View notes

Text

Divine Powers

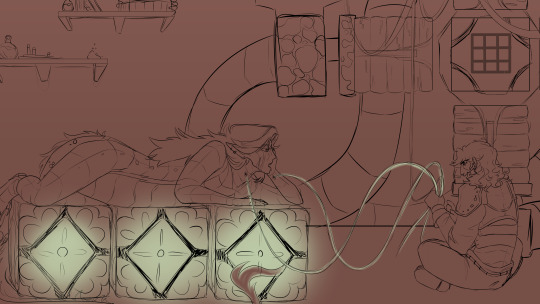

Redstonia, bright, chaotic, noisy, and ridden with the stench of Redstone. Not one of the places Wheatley expected to be spending their days since Jesse sent them away to befriend the Old Order. They hated it here, not as much as they hated Boomtown of course, but the constant noise and nagging for materials always had them slumping into the Terminal Zone at the end of each day to recharge. Ellegaard requested them this time, even though Jesse had pushed for them to go visit Redstonia and mingle they were thoroughly surprised to receieve a letter from the redstone engineer only days later. She needed help with a ‘secret project’ in her laboratory, and with their interest piqued here they were. Wheatley watched as Ellegaard ran about her laboratory, the admin standing in the middle of the room with a mostly confused expression. They tried to get her attention multiple times, when that didn’t seem to work they decided to have a seat, finding themselves sitting in a line of redstone lamps that, though unpowered, began to glow with energy. Ellegaard seemed too busy to notice this strange phenomenon however, gathering materials from a hopper and item sorter system.. At least thats what Wheatley could guess, all their redstone knowledge went away.. Ellegaard would like Xara, they had alot in common, even if Ellegaard seemed rather high strung at times. “You’re probably wondering why I called you here! Well, since admins are ‘all knowing and all powerful’ I figured you’d be the best option for one of my latest projects. Since the witherstorm incident, people have grown weary of Command Blocks, but I can just-- Oh!” Wheatley jumped, flicking their ears forward towards Ellegaard, staring her down with widened eyes. They hadn’t expected her sudden outburst, and followed her gaze down to the redstone lamps beneath him, illuminated in a bright green light that pulsated like a heart beat. “Oh my, seems I underestimated just how powerful you are. Sure Jesse told stories of The Admin, but I never studied one up close, no books to read from either... Maybe visiting Ivor will do some good, but until then this will do wonderfully! Just lay there, I need to get my materials.”

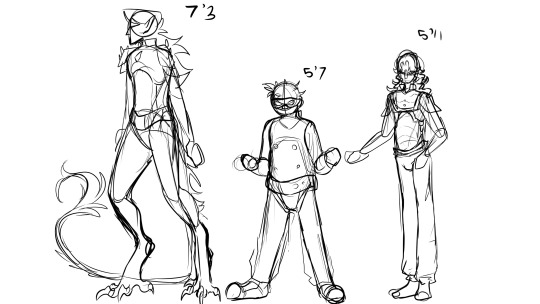

Wheatley stared, not even getting a chance to get a word in before Ellegaard was off again. They sigh, flopping back onto the redstone lamps and lighting the rest of them up in that same glow, their pulse synching up with their heart beat. Their attention turned to the strange machine stationed in the corner of the room, pupils expanding curiosly as they shift onto their stomach to look at it closer. five crafting tables in a star shape, precious materials lining the inside. They squint, tilting their head. Command Block... She was trying to craft a command block, their gaze narrows on Ellegaard who’s approaching them with a couple wires and other redstone materials. Their ears pin back, tail curling anxiously around the lamps. “I’m uncertain about your... decisions, command blocks were never meant to fall in mortal hands, how Ivor got access to the first one was a mystery in and of itself. I cannot allow you to create another, if it leaves this place who knows what would happen.” The engineer seemed almost surprised, staring at the admin with raised brows. She looks away, considering her options. “You raise a fair point, but this is a lifetime of work. Imagine what new information we could learn from studying such a powerful object? Besides, you’re ‘all powerful’, let me study it, even for a day! And after you can whisk it away, off to the void with it. I need to do this, I spent so long trying to understand Soren’s big discovery and now is finally my chance.” The admin made a face, lowering their head slightly with a defeated sigh as they sat up. What harm could be done? They’d be there to monitor the entire process, make sure it stayed within this building. “I suppose, but it must stay here. It can never leave this building, in addition, no one will come in. What is the process to creating it?” Wheatley could summon one in, with ease really, it was as simple as conjuring dirt in their palm at a moment’s notice. But they opted to not tell Ellegaard that, they were curious of her methods, years of study and work had to have some sort of success. Mixed with their own power who knows what could come from this, their agreement immediately had Ellegaard’s tired eyes lit up like a flame as she began hooking up the admin to the machine. “This should be painless, of course I never tested it before but that’s the fun of it. You... Can’t feel pain, right?” Ellegaard glances to Wheatley who just shrugs in response, a bored expression dawning on their face while they observe the engineer’s activities. Ellegaard hummed, dropping his goggles onto the bridge of her nose as he slipped the connected tubes into the strange machine. “Months of my genius, planning, and sweat. This has to work now that you’re here to power the machine, so many secrets will be unlocked if this works!” Wheatley listened to her rants about the command block, her years of studies that lead to this moment, and every little thing she had to say. It was nice, she was noisy and talkative but the gentle pulse of the lamps lulled him into a relaxed state as the machine clicked and whirred to life with energy. The redstone ignited, pistons thrusting the tables forward and mashing together the materials. It was loud, they found themselves burying their head beneath their arms and cupping their ears asan influx of energy began to build between the spaces of the tables. For a moment they see a command block, or at least the outline of it. It’s bright, Ellegaard stumbling backwards and covering her eyes. Wheatley squints through the light, the command block wasn’t going to form, they could see it now how unstable the structure was. Ellegaard would be destroyed, their gazed quickly moves to the engineer temporarily blinded by the light and they sigh. A snap of their fingures cut the machines in and instant, a command block resting in the space between the crafting tables. Their eyes landing on Ellegaard who removed her goggles and rubbed her eyes, disbelief strewn all across her face. “It... it worked... it worked!” The admin slowly stands from the redstone lamp bed they’d gotten cozy on, they moved away from the command block, removing the wires and other connected items carefully while Ellegaard was pulling the artificial block from her machine. They make a face, the command block energy was always so nausiating... But the overjoyed look on Ellegaard’s face brought a matching one to their own, even if a growing tiredness began to form. They approach the redstoner, inspecting the command block closely lit with a pulsating hum as its dotted patterns flash a wide array of colours. They exchange looks, Ellegard giving them a genuine grin that they couldn’t help but mimic. “I underestimated you, Mr Admin.” “You can call me Lu-... Wheatley.” This couldn’t possibly go wrong. ============================================================ They’re so silly I love Ellie so much, she’s so rude for no reason in the game and while I’m not good at capturing personalities right I hope I did her the same justice here. This was definitely a longer one which I wasn’t expecting, but I hope it’s a fun read regardless. pacing is a bit off Who should I do next? I’m quite enjoying these little short stories, I had a few planned for the next three. I also thought about sketching a sort of height comparison for these, admins are naturally just very large and I figured comparing Wheatley’s height (7′3) to what I headcanon Magnus and Ellie would be nice. I could probably do this for each of the old order. Ellie looks a lil funky don’t mind her

#mcsm oc#mcsm admin oc#mcsm admins#mcsm magnus#mcsm ellegaard#mcsm fanart#minecraft oc#minecraft fanart#minecraft blog#minecraft-ellegaard#minecraft-magnus#original character

21 notes

·

View notes

Text

In which Eunsu receives a visitor.

FEATURING: Baek Eunsu, Yoon Mingeun WORD COUNT: 4.1k SETTING: November 2023 NOTES: Welcome (finally) to the transitional period between Fable Season 1 (2023) and Fable Season 2 (2024?)! Or something like that. This is just an excuse to experiment with characters who would otherwise have nothing to say.

“Can you pick me up? I’m at the train station,” Mingeun says when Eunsu picks up the phone. He doesn’t say hi. He also never told Eunsu he was coming to visit.

All of their other meetings have been very carefully planned outings, the two of them juggling their schedules and their obligations and their differences in locations. Sometimes Eunsu visits Seoul. He’ll take the subway to the station a few blocks away from the Zenith Entertainment, and walk the familiar streets. He could never forget that walk, and each time he does it, he’s filled with pangs of regret. At other times, Mingeun takes the train out to Taebaek. In the beginning, right after he left, Eunsu refused to let him see him like this. It wasn’t until nearly a year had passed, as he had settled back into a life he thought he would never return to, that he let Mingeun visit his home.

He had shown him through the small, cramped streets and the single highway, apologizing for its shabbiness and its rural-ness compared to Seoul’s opulence, until Mingeun gave him a strange look and asked what he was apologizing for.

Now, he’s a bit more used to it. He’s still not proud of his hometown—he doesn’t think he ever will be. But when Mingeun asks for a ride, Eunsu says yes.

He’s not a good driver. More accurately, he isn’t a confident driver. Each time he sits behind the wheel, he thinks about Yonggeum and feels a sharp, stabbing pain through his chest, a feeling that will never go away and has only slightly softened over time. Instead, Eunsu is a very precise driver. He places both hands on the steering wheel, left hand at ten, right hand at two. He slows to a stop at every yellow light. He always uses his turn signal. He refuses to drive if he’s tired or drunk or otherwise inebriated.

He picks Mingeun up at the bus terminal. Mingeun is wearing his characteristic scowl, a pair of wired earbuds connected to his phone.

“Thanks,” he says gruffly as he slides into the passenger seat, tossing his backpack into the backseat. He leaves one earbud in.

Eunsu is unbearably nosey, so he has to ask, “What happened? Is this an impulsive vacation?”

He spares the slightest glance away from the road in front of him to see Mingeun lean his head against the window.

“I had a fight,” Mingeun says. “With Haksu and Intak-hyung and Jaeseop-hyung.”

Eunsu wonders what they could have disagreed about, that would set Mingeun opposite the three of them. He never would have imagined Mingeun and Jaeseop disagreeing. He doesn’t push further. Mingeun will talk about it when he wants to talk about it. If he ever wants to talk about it.

At home, Mingeun fits in like he lives there. Eunsu leaves him in the kitchen, charming Eomma as he usually does, and heads off to clean his room.

Mingeun is messier than he is, so he doesn’t try too hard: clothes in a pile in his closet, papers straightened on his desk, swipes his hand through the layer of dust on his nightstand then wipes it on his pants. He tries not to hear Mingeun talk about life in Seoul. He fills his ears with the screech of the rusted hinges of the hallway closet, followed by the scraping sounds of the floor mattress against the hardwood floor instead. Mingeun always stays in his room, because the other bedroom is still Yonggeum’s, kept perfectly preserved the way it was, like he'll come home and head off to his room any day now.

He surveys his handiwork: the mattress pressed up alongside the base of his bed, the only somewhat cleaner room, and knows Mingeun has survived worse.

As he emerges from his bedroom and inserts himself back into the conversation, Mingeun asks almost immediately, “How long can I stay?” His gaze darts furtively between Eunsu and Eomma.

The bits of conversation Eunsu blocked out from his mind must have worked some magic on Eomma, because she gives Mingeun a tender, loving look. He can’t remember the last time she looked at him like that.

“As long as you’d like,” she says, and that’s the end of that discussion.

In the morning, Mingeun slips back into Eunsu’s life like he never left. The house is livelier with him around, even if it’s because he misjudged the doorway of the bedroom in the dark after a bathroom trip and stubbed his toe on the doorframe then woke Eunsu up with his swearing. Sometimes Eunsu thinks he should ask Mingeun to tone it down in front of his parents. And yet he knows that it’s exactly the kind of request Mingeun would ignore. He can only hope Eomma and Appa are unaware of this side of Mingeun, because he’s polite and charming at all times other than three in the morning.

Morning car rides to the temple are usually somber experiences. Eunsu will sit in the passenger seat and stare out the window while the radio alternates between static and snippets of a news broadcast. Neither he nor Appa speak.

With Mingeun around, it’s different. Eunsu gives up his shotgun seat for Mingeun, who starts fiddling with the dials as soon as they pull out of the driveway.

“How can you not have Bluetooth?” Mingeun grumbles, as if he hasn't ridden in Appa’s ancient Toyota multiple times before. “It's a basic feature.”

He complains, but he clearly knows better now. The CD player whirs as it accepts his offering, and something bass-heavy begins to play.

Eunsu doesn't recognize it. His silence is an affront, apparently, because Mingeun turns around as much as he can in his seat.

“Nu’est?” he asks. “Re:BIRTH?”

Given the name of the album, it sounds slightly more familiar. “Did you choose this one specifically? Or do you normally travel with a CD from ten years ago?”

“Nine years. I might meet Minhyun-sunbaenim somewhere someday,” Mingeun says seriously. He disappears from Eunsu's field of vision, and reappears holding the entire album.

Eunsu can't help but laugh, a bright sound that sounds entirely foreign coming from him. He's lived in the same state of permanent dreariness for years. Such a light-hearted feeling of happiness is unfamiliar.

They listen to a little more than two songs when they arrive at the temple—his second home for the past two years. Eunsu tries to see it from an outsider’s perspective, with some difficulty. There’s the small parking lot that Appa pulls easily into, where the faded paint lines of the stalls have disappeared into the asphalt.

They walk up the five stairs to the entrance, the wood creaking and bending under their combined weight. The building’s paint is peeling in long strips, exposing the wood underneath. Eunsu shoves down the inexplicable urge to defend all of it to Mingeun.

Appa unlocks the door, and the two of them fall into their normal, silent routine. He disappears down the center aisle to the private storage room in the back of the building. Eunsu props open the doors, the pervasive smell of incense already surrounding him. It never fades, despite his best attempts to air out the room. He opens the only two windows near the entrance anyway.

Mingeun seems rooted in the entryway. Eunsu gives him a questioning glance.

“When we lived in Seoul, I never thought I’d ever see for myself all of this,” Mingeun says, spinning in a slow circle.

He’s over-dramatic.

“You’ve visited me before,” Eunsu says.

“And you never let me see anything except your house.”

There’s no one to blame except Eunsu for that one. He did it on purpose—never taking Mingeun anywhere except his house, a few of his favorite restaurants, and once, the base of the mountains.

“This is cooler than the time I went to Mass with Haksu-hyung,” Mingeun continues.

That’s a good thing, Eunsu supposes. He knows Mingeun’s church experience was horrific enough to never go back.

“The service hasn’t started yet,” he says, logical as always. It’s unfair for Mingeun to say that before he’s fully experienced it.

Mingeun shrugs. “It can’t be worse,” he says, almost uncharacteristically optimistic.

To Eunsu’s surprise, Mingeun survives almost the entire service. Eunsu knows meditation isn’t for him, so he isn’t surprised to hear the pew creak next to him almost as soon as the small congregation closes their eyes and breathes deeply. A slight breeze enters the room as he exits.

Eunsu has had the time to make peace with his responsibilities. And really, keeping track of Sunja’s dog and how Kanghee’s kids are doing isn’t too much of a leap from remembering repeat fansign attendees. So he clears his mind of thoughts of Mingeun for the next twenty minutes, listening instead to the quiet rustle of the wind in the trees overhead.

When he judges his part is done—by the much smaller crowd and Appa’s blessing—Eunsu heads out the back and finds Mingeun immediately. His bag is leaning against the side of the building while he sits under the shade of the largest tree, earbuds in. A small pile of stones is built almost into a pyramid in front of him.

“You're done,” he says. “Finally.”

“Not yet,” Eunsu says. “Appa's still inside.”

Mingeun practically wilts.

“You’ve never come out here with me before.” Eunsu crouches on the ground so that he can be at eye-level with Mingeun, though he refuses to sit.

Mingeun adds another rock to his pile. It balances precariously on top. “This time is different,” he says. “I thought I should try to understand how you live. And I didn’t have anywhere else to go.”

Eunsu wants to unpack that. He wants to ask why. He wants to know what Mingeun ran away from this time, because he’s always running from something. So he approaches it carefully, cautiously, and asks, simply, “What do you mean?”

His question is ignored. Instead, Mingeun looks him in the eye, and in his careless, blunt way, asks, “Do you want to be here?”

Eunsu's thighs are starting to kill him, so he stands up.

“It doesn't matter what I want,” he says.

Mingeun glares up at him. “That's not what I asked.”

They've had this conversation before, and time and time again, Eunsu gives the same answer. It doesn't matter what he wants, because what he wants has absolutely no bearing on what he does. It's the complete opposite of Mingeun, who's constantly driven by his desires.

“Yes,” he answers, just to shut Mingeun up. He doesn't know what he wants. He hasn't given it much thought in the past two years.

Mingeun has no response. He scatters his rock pile into its individual pieces and stands up. Then he says, “Haksu-hyung was mad at me first. Said I was selfish and a hypocrite for taking all the opportunities I had. He pretended he doesn't do that. Of course I was mad at him.”

He pauses in his recollection for a moment. None of that seems like an issue to Eunsu. It's a small disagreement, not something that should have caused so much discord. He stays quiet, and Mingeun continues.

“I never expected Jaeseop-hyung to take his side. He's never been mad at me like that before.” Mingeun sounds small and unlike himself. “I know he’s been stressed lately—”

“About what?” Eunsu asks, interrupting him. He's momentarily more interested in potential Fable drama than Mingeun's woes.

“Me. Andrew-hyung. The new album. Taein-nim. Our tour. His girlfriend. The list of what he isn't stressed about is shorter.”

It's all so ordinary and typical of him. Eunsu's hopes are dampened. He doesn't know what he thought had changed in his absence. They're celebrities, sure, but they're also normal people. He was one of them, once. He should know better. He’s not sure why he doesn’t.

Mingeun continues his tirade of his own personal issues and his current disagreements, but by then, Eunsu has already partially tuned him out.

The days with Mingeun pass more or less the same as the days without him have. Sometimes he follows Eunsu to the temple. Other times he helps Eomma with the household chores. Eunsu hears this from both of them—his mother praises Mingeun’s willingness to help and then bemoans his absolute lack of homemaking skills. Mingeun, on the other hand, gains an entire repertoire of Eunsu’s embarrassing childhood stories.

Then, there are the times where Eunsu returns to Mingeun sitting on or in front of the living room couch, speaking English in a quick, low tone to his computer. The WiFi is best there. It took him less than a week to figure that out.

On one of those days, Eunsu is passing by on his way out when Mingeun waves him down. He sits cross-legged on the floor, laptop open in front of him, right AirPod in his ear, left AirPod in his left hand, the white G-shock Eunsu gifted to him years ago on the same wrist.

“This is my therapist,” Mingeun says softly, and Eunsu looks at his computer screen, where he’s currently in a video call with a middle-aged woman. He scoots over so Eunsu can sit next to him, so Eunsu has a seat.

Mingeun introduces him in Korean, in simple, formal sentences. “This is my friend. His name is Eunsu.”

The woman says back in similarly stilted and proper Korean, “Nice to meet you. I am Stephanie.” Then she bows to her web camera.

“Do you speak Korean?” Eunsu asks, just as grammatically correct. He’s struck by an incredible sense of deja vu, of having said almost the same thing to an obviously not quite fluent Mingeun so many years ago when they first met.

“A little.” Stephanie pinches her thumb and forefinger a mere centimeter apart.

Mingeun speaks to her again in English, presumably explaining something else. Eunsu has always admired the way he could seemingly slip so flawlessly between the languages, like he’s shedding one identity for another. He’s tried learning English, or any other foreign language, for that matter, on his own. He’s never progressed very far, because the longer he spends with his family in his hometown, knowing his future will never eclipse the borders of the same area he grew up in, it feels less and less important. Mingeun, on the other hand, has the world in his palms.

Eunsu does his best to tamp down the tendrils of jealousy. He never quite succeeds at that either.

“I have to show her I’m doing well,” Mingeun mutters softly, snapping Eunsu out of his thoughts. “I’m getting better.”

He can say that as much as he wants. As far as Eunsu can tell, running away from Seoul the same way he runs from all his other problems is not a sign of recovery.

He nods along silently and leaves Mingeun alone as the conversation slips back into English.

The days continue to pass without incident. Considering Mingeun’s track record, it comes as a surprise. He shows no sign of wanting to return to Seoul.

Then, in the afternoon following a service, Eunsu finds his phone vibrating incessantly. He picks it up to see Haksu calling him, for what appears to be the fourth or fifth time.

“Hello?” he asks hesitantly, finally answering the call. They’ve barely spoken to each other since he left. He hears about Haksu through Mingeun, though of course that’s colored by the lens Mingeun sees him through.

“Where’s Mingeun?” Haksu demands.

“At my house,” he responds.

“He’s not. He’s out somewhere. Check Instagram. There was this video, and you know him. He always thinks he needs to—”

“Slow down, hyung. You’re not making any sense,” Eunsu interrupts. But he opens Instagram anyway. He also sees he’s been added back into the Fable group chat, and now he has over a hundred unread messages.

“Fuck,” Haksu swears. It’s the first time Eunsu has ever heard him curse. Whatever Mingeun is doing must be bad. To him, at least.

The livestream finally loads. “Jaeseop-hyung is in it too,” he says in surprise. “What’s the big deal?”

“Are you listening to them?” Haksu demands again.

“No. I’m talking to you.”

“Find him. Call me or Intak-hyung or Byeonghwi when you do.” He hangs up.

Eunsu doesn’t do that. He sits on the steps of the temple and calls the one person Haksu neglected to mention.

“Eunsu?” On the other end of the line, Andrew sounds surprised.

“Yes. Hi. It’s been a while.”

“It has.” He sounds guarded. “I don't know what Haksu asked you to ask me, but the answer is no.”

“He didn't ask me for anything from you.” Eunsu missed something. He puts Andrew on speaker and starts skimming through his texts. “He asked me to find Mingeun.”

“Are you looking for him?”

“No.”

He’s reading over Haksu’s twenty-plus message rant about how Mingeun needs constant supervision and can’t be left to his own devices and how Jaeseop is just as bad if not worse for enabling him when he’s alerted with another incoming call.

The other members, he can understand, but this one is coming from Daewoong. Eunsu hasn’t talked to his former manager since he left.

“Daewoong-hyung’s calling me,” he says.

He’s about to answer when Andrew speaks first. “Don’t.” His words are clear and sharp, a command rather than a suggestion.

So Eunsu doesn't. He lets the call ring and ring.

“He's on his way to pick up Mingeun,” Andrew explains. “He left not too long ago.”

“He’s driving here?” Eunsu is surprised. Mingeun is in more trouble than he thought. “That’s far.”

“So it’ll take him some time. They're right, but they're going to be in trouble,” Andrew says, voicing Eunsu’s very thoughts. “Taein-nim told them not to say anything. Mingeun insisted. You know how he gets.”

Of the two of them, Eunsu thinks Jaeseop is more concerned with morals, but Andrew is right on one point. If Mingeun wants something, he'll stop at nothing to get it.

“Why aren't you in the live with them?” Eunsu asks as soon as the thought occurs. He can picture the battle lines in his head: Mingeun and Jaeseop on one side; Haksu, Intak, and Byeonghwi on the other; Andrew somewhere in the middle; and Kiyoung’s blissful enlistment ignorance.

“I haven't had access to my account for months. Talked shit one too many times in the comments of my own posts,” Andrew says, almost wistfully.

“I could join,” Eunsu says.

“You don’t have to be part of this. You can live your own private life now. Haksu never should have involved you in the first place.”

He doesn’t want to ruin Andrew’s perception of post-idol life, so he says nothing about how they’ve both passed the point of no return to a normal life. He thinks about the fans that used to visit Taebaek and his father’s services in the months immediately following his departure, and decides Andrew doesn’t need to know that.

He changes the subject as best as he can, which isn't very well. “What time did Daewoong-hyung leave?”

Andrew takes a few moments to respond. “A bit after the live started. He’s probably speeding.”

There isn’t much speeding to be done in Seoul traffic. There’s a lot of speeding to be done on the long, empty roads out to Taebaek. All things considered, Eunsu estimates his trip to be somewhere around two hours.

“I assume Taein-nim gave him your address,” Andrew continues, interrupting Eunsu’s train of thought.

Eunsu sighs. He isn’t looking forward to Daewoong at his front door in the slightest. He opens Mingeun’s Instagram again. He appears to have propped his phone up somewhere and is standing far off in the distance, knee deep in water. Eunsu can’t imagine what the topic of their livestream is. Jaeseop is still speaking, poised and composed. Their viewers have crossed into the quintuple digits, a feat Eunsu is, despite the situation surrounding it, slightly impressed with.

“Thanks for letting me know,” he says, already typing out a warning text to Mingeun. “I’ll look for him.”

“Not too hard,” Andrew says, almost in warning.

“Not too hard,” Eunsu agrees. He makes no move to leave his suddenly very comfortable seat.

Two and a half hours later, Daewoong appears on Eunsu’s doorstep. He parks his car, a shiny black Lexus, right in front of Eunsu’s house. It’s the newest, cleanest, and most expensive car on the block.

Against his better judgement, Eunsu invites his former manager into his home.

“Where’s Mingeun?” Daewoong asks, all business from the start. He stands awkwardly in the kitchen, like he’s never seen one before. Eomma, almost as awkwardly, sits at the kitchen table, not quite looking at either Eunsu or Daewoong.

“Packing,” Eunsu says. “Would you like something to drink?”

Somehow, he manages to coax Daewoong into having a seat. It’s an almost comical tableau—Eomma and Daewoong on their very best silent behavior. He leaves them to it, apologizing in his head to his mother for leaving her with him.

Eunsu finds Mingeun in his room, packing, just as he told Daewoong. It’s obvious that Mingeun is trying to drag it out as long as possible. The few contents of his backpack and suitcase are spread all around the floor. Eunsu sidesteps it all easily and closes his bedroom door behind him.

“I’m not ready to go back yet,” Mingeun says without looking up.

“Daewoong-hyung is in my fucking kitchen,” Eunsu says. He doesn’t want to be unsympathetic, but Daewoong is in his fucking kitchen. He can only imagine the conversations out there, the collision of his two worlds he fought so hard to keep separate.

“He can sleep in his car tonight,” Mingeun says, just as unsympathetic to Eunsu’s plight.

“I think he’d rather sleep in his bed in Seoul.”

“Your bed.”

Eunsu doesn’t know what he means by that, so he stays silent until Mingeun elaborates.

Still staring down at his belongings, Mingeun speaks again. “Daewoong-hyung moved into your room after you left. He still stays there sometimes.”

Eunsu is about to ask why when Mingeun predicts his question.

“He hasn't said why, but I know it's to keep an eye on me.”

That doesn't sound right, but Mingeun sounds so certain in his beliefs that Eunsu doesn't want to argue. Not when he's leaving so soon.

Mingeun closes his suitcase, having seemingly given up the illusion of packing. It was half empty anyway—just a few changes of clothes that wouldn't fit in his backpack.

“If you come back to Seoul, you can get your room back.”

Eunsu takes that to mean he should visit, not move permanently. Sometimes it’s hard to tell with Mingeun. He knows he can’t go back. Even a visit is hard to plan—he has an increasing number of responsibilities here, and he can’t go running off whenever he feels like it like Mingeun does.

“I will,” he says, although he doesn’t know if it’s a promise he can keep.

The scene in the kitchen is opposite the one Eunsu left. Eomma is leaning across the table, showing Daewoong something on her phone. He presumes it's embarrassing pictures of him, accompanied by stories of his childhood: the time he ate an ant on purpose, or the time he insisted on going down the playground slide headfirst and ate shit, or maybe that one really embarassing faux music video he and his friends filmed when they were twelve and thought they could start a band. At this rate, everyone at Zenith Entertainment will know the minute details of his life.

When Mingeun steps into the kitchen, suitcase wheels loud on the tiled floor, Daewoong seems to snap back to himself. He stands up and jerks his head towards the door. “Let’s go, Mingeun.”

“Fine,” Mingeun says, but from his tone of voice, he’s anything but fine.

Daewoong either doesn’t notice or doesn’t care, because all he does is thank Eomma—and not Eunsu—for her hospitality, and lead Mingeun outside.

From the comfort of his home, Eunsu watches them leave: Mingeun’s bags in the trunk, Daewoong in the driver’s seat, the rumble of the engine, Mingeun in the passenger seat with his earbuds in. Then they’re pulling away from the curb, and before he knows it, they’re receding away in the distance. Andrew was right. Daewoong speeds.

“What happened?” Eomma asks, following Eunsu’s gaze out the window.

“He made a mistake.” Eunsu doesn’t want to explain it all. He’s not even sure if he knows the whole story. Besides, she’s never really understod what being an idol entails, and how precariously their careers balance on their words and actions and appearances. “It happens to him a lot.”

Eomma looks like she doesn’t know what to make of that. Eunsu doesn’t blame her. He’d like to say, or even think, that it won’t happen again. With Mingeun, it’s a matter of time. He wonders how long he’ll have to wait for Mingeun’s return.

#╰ to be written in ink is to be immortal — [ writing. ]#╰ to be written in ink is to be immortal — [ eunsu. ]#fictional idol community#fake kpop group#kpop oc#kpop addition#kpop fanfic

6 notes

·

View notes

Text

Avatar: Legend of Korra Fanfiction - Korra x OC Male Reader.

(DISCLAIMER’S: I DON’T OWN THE LEGEND OF KORRA IP OR IT’S CHARACTERS! & THIS IS A NON CANON FANFICTION THAT ISN’T CONSTRAINED BY THE LIMITATIONS OF THE OFFICIAL AVATAR LOK CANON & ANY ATTEMPT’S TO SILENCE THIS FANFIC IS A BLATANT VIOLATION OF MY FREE SPEECH RIGHT’S!)

Chapter 5: Red Moon.

M/R’S POV: I heard explosions from outside I ran to the door asking a passing guard “What’s going on?!” “We’re under attack, get back in your cell & stay put!” I then heard him run away & I did exactly what he said sitting in the corner repeatingly telling myself “Everything’s going to okay, everything’s going to be okay, everything will be fine, I’m gonna be fine..” hoping that I would get through this..

Rick’s POV:

The Prison started exploding all around us as the fire alarms triggered I then metalbended a switch on the terminal in the room below to send an SOS Signal to Republic City. Then Old Gary says “It’s too late by the time your backup arrives me & Master Zaheer will be long gone, & you all will be dead!-” I threw a brick at his face leaving a massive scratch on his face as it shattered on impact (smash) He furiously looks at me I smirk then earthbended chunks of the stone roof & threw them at Old Gary who dodged them with ease & waterbended a water whip from his water skin pouch & attacked me, i blocked it with a roof panel & launched it at him. Counters with another Water Whip shattering the stone roof panel creating a puff of dust blocking Gary’s Vision. I quickly earthbended beneath my feet to launch myself towards him entering the cloud of smoke then at the height of my jump I swiftly used my metalbending cable to wrap a wire around & pull his right foot to trip him over, as he’s falling backwards I finally reached out the other side of the smoke fall into Gary tackling him off the roof of the tower falling down in the burning buildings below from floor to floor until we fell into the Break Room that currently burning down all around us, we get up & I bend parts of the floor up in front of me & he waterbends leaking water from the ceiling pipes then forms them into ice shards “You getting slow old man.” I remarked then we then shoot them at each other while taking cover behind tables & makeshift earthbended wall barricades, exchanging blows until we ran out of projectiles & as a last ditch effort to throw something at him I picked up an old rotten apple from the floor & threw it straight into his face splattering all over his face “ARGH, SON OF A-!” then I charged at him pushing us both through the window behind him falling down to the balcony below landing right in front of Zaheer’s cell. “Ugh, I guess Old Gary isn’t as old as I thought..” then Old Gary gets up first then heads to Zaheer’s Cell as sits in his cell smirking at his opportunity to finally escape I then metalbended the metal blast door down locking down the cell stopping Gary’s attempt to free his master, “NOOOOOooo!…” he then turns around to finish me off as he about to strike the final blow a metal wraps around his wrist then pulls him back away from me & I managed to earthbend his feet to the ground & he was surrounded by the remaining White Lotus guards who were still standing. I get up & tell him Old Gary, you’re under arrest it’s over.” Old Gary looks up to the sky as it’s full moon shines bright & he started laughing “Hahahaha HAAA!..” “What’s soo funny?” “THIS!..” he shouts as he lifts his arms up starts Bloodbending everyone still in their tracks & he breaks out of his leg restraints & lifted us up into the air I barely managed to use my metalbending cables to whip him forcing him to release us & he started running away into the prison halls we all were on dropped onto the ground knocking out the other guards I ran after Old Gary chasing him down to M/R’s prison cell.

M/R’S POV:

I’m still sitting in a corner waiting for the guards to either let me know that they put out the fires that have spread all through out the Prison Temple or to let me know that they’re evacuating the Temple although they could also simply just leave me here for dead then I started hear loud noises, bangs & screams outside of my cell door, I then braced myself when my cell door came crashing down with the nice Guard that stopped that mean man from torturing me & gave me water earlier all beaten up on top of the rubble barely conscience. Then the mean man came into the cell looking at me with that Montrose grin & he extended his arm out towards me & started blood bending me! I couldn’t move at all, he pain was constant & unbearable, my blood vessels had felt like they’d been set on fire then he lifted me up into the air I started shouting out in pain “HHHHAAAEEELP …AAAAME! PLEASE STOPP!..” I started getting delirious as the man slowly morphed into the woman with glowing eyes like before & she says “Just close your eyes it’ll all be over soon..” then the guard woke up rasply shouting “NO! LEAVE THE KID ALONE!..” as he metal bended a cable straight through ghost woman’s left knee forcing her to drop me then the illusion faded back into the monster that was just holding me up in the air & he started blood bending the guard slamming him against the wall suspended in the air, all I could do was watch as he limped over to the guard & says “Tell me Rick, have you ever danced with the devil in crimson moonlight?!..” then the guard just looked & said “Survive!” (SNAP!) “NOOOOOOOOOooooo!…” I shouted as that monster just snapped his neck! Then he’d been encased in earthbent restraints then his lifeless body collapsed to the floor as the rest of the guards came in a new found rage full fury brewed up inside me without any hesitation picked up a huge stone & charged at him shouting “DIIIE BASTARD!…” & I started repeatedly slamming the stone against his head as the guards were trying to tell me to stop “STAND DOWN KID!” “DON’T DO IT!” I kept slamming him until his head split open against the stone & his blood splattered into my face killing him & I just froze, dropped the bloodied stone & blankly stared at what was left of the man who’s life I just took before I turned to look at the one man who’d shown me kindness since I was thrown in here, then I dropped to my knees as single strand of tears slowly slid down my face. All the Guards could do at this point was just stand there completely speechless..

Hours later-

A bunch of people from Republic City & the Southern Water Tribe kept on coming in & out of the cell as I just blankly stare at nothing sitting there with a blank expression under armed guard they soon cleared out & repaired the cell & removed the restraints & sealed the cell door & everything was back to normal pitch black void of nothingness like nothing had ever happened.. I was too tired to cry anymore & just went back to sleep silently telling myself “Survive..”

Chapter End..

#male reader#fanfic#avatar#avatar korra#avatar lok#korra x reader#mystery#loss#do revenge#original character

1 note

·

View note

Text

Electrical Control Panel Accessories Wholesalers- Samir Trading

Electrical Control Panel Accessories Wholesalers – Samir Trading

In the vast and growing world of industrial automation and electrical systems, one critical aspect that plays a pivotal role is the use of Electrical Control Panel Accessories. These accessories are the backbone of safe, functional, and efficient control panels, responsible for the operation and protection of machinery and systems. When it comes to sourcing reliable and cost-effective components, Samir Trading has made its mark as one of the leading Electrical Control Panel Accessories Wholesalers in the industry.

Understanding Electrical Control Panel Accessories

Electrical Control Panel Accessories are vital components used in the assembly and installation of control panels. These accessories include a variety of products like terminal blocks, cable ducts, push buttons, cable ties, relays, timers, connectors, wire markers, and much more. These components help facilitate proper circuit control, organized wiring, and safe operation across industrial, commercial, and residential applications.

From power distribution to communication systems, Electrical Control Panel Accessories form the base of any modern electrical setup. These accessories not only help streamline operations but also contribute to the longevity and reliability of the equipment they’re installed in.

Growing Demand in Ahmedabad and Beyond

With the increasing pace of industrialization, cities like Ahmedabad have emerged as hubs for electrical and automation solutions. As one of the major Electrical Control Panel Accessories Wholesalers in Ahmedabad, Samir Trading has consistently provided high-performance accessories that meet the varied needs of industries across Gujarat and India.

Ahmedabad's growth in sectors like manufacturing, textiles, chemicals, and engineering has boosted the requirement for quality electrical components. Businesses here look for Electrical Control Panel Accessories Wholesalers in Ahmedabad that can provide robust supply chains, quick delivery, and dependable products — all of which Samir Trading offers under one roof.

Why Electrical Control Panel Accessories Matter

These accessories might seem small, but their role is crucial in supporting the internal framework of control panels. Products such as terminal blocks allow for secure electrical connections; relays manage circuit logic; push buttons act as user interfaces, and wire ducts aid in systematic cable routing.

The right choice of Electrical Control Panel Accessories helps avoid issues like electrical failures, short circuits, and maintenance troubles. A well-organized control panel enhances safety and simplifies troubleshooting — two key factors in reducing downtime and operational costs. That’s why choosing experienced Electrical Control Panel Accessories Wholesalers is essential for long-term project success.

Why Choose Us – Samir Trading

At Samir Trading, we specialize in supplying an extensive range of Electrical Control Panel Accessories for diverse applications. What sets us apart as leading Electrical Control Panel Accessories Wholesalers is our focus on quality, consistency, and customer satisfaction. We understand the real-world challenges that industries face, and we cater to those needs by providing durable products sourced from trusted brands.

Our strategic location in Ahmedabad allows us to serve not only the city but also clients across Gujarat and India, making us a preferred choice for many businesses. From product selection to delivery and support, we maintain high standards in everything we do. This commitment has helped us grow into one of the top Electrical Control Panel Accessories Wholesalers in Ahmedabad.

Serving a Wide Range of Industries

Samir Trading supplies accessories used in control panels for sectors like:

Industrial Automation

Manufacturing Plants

HVAC Systems

Renewable Energy Installations

Commercial Electrical Projects

We offer premium solutions that fit the ever-evolving demands of these industries. Our selection is designed to suit all types of applications — from compact control panels in small businesses to large-scale industrial automation systems.

A Trusted Name in Quality and Reliability

By choosing Samir Trading, customers benefit from a partner who prioritizes product quality and long-term relationships. Our expertise in the domain, combined with a wide inventory, makes us the go-to source for anyone looking for Electrical Control Panel Accessories Wholesalers. Our clients trust us to deliver not just components but also value, reliability, and dedicated support.

Conclusion

Control panels are critical elements of any industrial setup, and the accessories that go into them are equally important. Selecting the right Electrical Control Panel Accessories Wholesalers is a strategic move that impacts system safety, ease of maintenance, and overall efficiency. As a trusted Electrical Control Panel Accessories Wholesalers in Ahmedabad, Samir Trading provides durable, efficient, and affordable solutions tailored to industry needs. We take pride in helping businesses power their operations with dependable accessories that support performance and growth. Our customers rely on us for consistency, quick delivery, and personalized service in every transaction.

For more information about these blogs or to place an order, please call us at +91 97253 99929 or email us at [email protected]. Let Samir Trading be your trusted partner in power and precision.

For More Information:

666/5A, Mamunayak's Pole, Nr. Jagat Agencies, Gandhi Road, Ahmedabad - 380001.

7922170118

#Electrical Control Panel Accessories Wholesalers#Electrical Control Panel Accessories Wholesalers in Ahemdabad#Electrical Control Panel Accessories

0 notes

Text

Why WD Electronics Is the Ultimate Upgrade for Your Off-Road Ride

Every off-road enthusiast knows that power, performance, and dependability are crucial when it comes to pushing the boundaries of adventure. The electronic systems in your car must be able to survive the most difficult situations, whether you're driving over muddy roads, rough trails, or sand dunes. This is where Dig Rig Powersports' WD Electronics comes in, providing an excellent answer to all of your off-road electronics requirements.

Built for Rugged Terrain

Off-road vehicles such as ATVs, UTVs, and side-by-sides need electrical systems that are sophisticated, robust, and efficient in addition to having a lot of horsepower. This is precisely why WD Electronics was designed from the ground up. Battle-tested and trail-approved, WD Electronics devices are made to withstand mud, water, vibration, and extremely high or low temperatures. Everything you need to precisely manage your power distribution is available from WD Electronics, including reliable wiring harnesses, intelligent switch panels, and relay systems. Whether you're racing, hunting, carrying, or just having fun, this translates to fewer breakdowns, safer rides, and increased confidence.

Plug-and-Play Simplicity

The simplicity of installation is one of the main benefits of selecting WD Electronics. Dig Rig Powersports has created a plug-and-play system that is easy to set up and doesn't require much technological knowledge. This keeps professional-level outcomes while making upgrades more affordable for regular riders. To help you spend more time on the trail and less time in the garage, each kit includes waterproof components, premium terminals, connectors with clear labels, and comprehensive instructions.

Precision Power Management

For contemporary off-road vehicles, power management is essential. Your electrical load can easily overwhelm a stock setup with extra lighting, sound systems, GPS units, winches, and more. Intelligent relay panels and fuse blocks from WD Electronics guarantee the safe and effective supply of power to all of your accessories. You can now operate high-draw components without worrying about overload or failure thanks to this. Your car is safe thanks to clever layouts and circuit protection, and even in poor visibility situations, the user-friendly switch systems allow for smooth operation.

Customization at Its Best

Dig Rig Powersports is aware that every ride is unique. For this reason, WD Electronics designs its products to be flexible. There is a solution that may be customized to meet your demands, whether you need a basic switch panel replacement or a full car wiring overhaul.

You can construct your own unique system or select from pre-configured packages. Modular components make it simple to expand your setup and provide easy access to replacement parts. Your vehicle will be prepared for everything you throw at it thanks to this level of personalization.

Trusted by the Off-Road Community

Within the off-road scene, WD Electronics has rapidly established a reputation for dependability and creativity. Because the brand continuously performs well under duress, riders, racers, and builders have come to trust it.

Real riders who are aware of the difficulties in off-road settings make up their staff. Products that truly address issues in the real world are the result of this practical experience.

Built to Last

WD Electronics is an investment in longevity. To stop corrosion and failure, these systems are constructed with weatherproof connectors, marine-grade wire, and durable housings. WD Electronics will keep your equipment operating whether you're driving through a dust storm or stuck in a deluge.

For anyone who is serious about off-road performance, their components are a wise investment because they are also covered by robust warranties and the outstanding customer service of Dig Rig Powersports.

Why Choose Dig Rig Powersports?

Dig Rig Powersports is enthusiastic about the off-road lifestyle and is more than just a seller of parts. They have established themselves as a go-to resource for enthusiasts wishing to upgrade their vehicles thanks to their proficiency in off-road electronics.

Dig Rig Powersports makes it simple for anyone to update with confidence by providing comprehensive instructions, installation videos, and quick tech support. When you purchase from them, you're getting equipment that has been tried and tested by experts and is regarded as reliable by the community because of their dedication to quality and innovation.

Conclusion

Dig Rig Powersports' WD Electronics is the finest upgrade for people who expect the best from their machines. These off-road electronics systems raise the bar for dependability and performance thanks to their innovative design, robust construction, and unparalleled user-friendliness. Don't accept mediocrity. Use WD Electronics' strength, accuracy, and performance to upgrade your vehicle. Find out why so many riders rely on Dig Rig Powersports to fuel their journeys by visiting them today.

0 notes

Text

Power solutions, Lighting systems, lighting wire connector, light source

1 Position Push-In Cage Clamp Push Button Terminal Block

0 notes

Text

The best solution I see for having multiple independently controllable devices coming from 1 NVR alarm block..

The reverse side:

Take a solid piece of wire and strip segments of the wire and solder to the each one of the "IN#" solder pads. This is easier than bridging from one screw down terminal to many.

This reduces the wires for each IN# line and the DC (-) and (+).

This one is 8 channels and you will likely not need any more than 8 devices per alarm block. So you get one of these for Alarm 1 and another for Alarm 2. Each device goes on it's own relay.

Usage Example 1: With this setup, say you are expecting usps to deliver a parcel....you disable the siren, strobing lights via the led push button. That leaves the continuous buzzer which is inside the home on. So you know when they have delivered without blasting them with strobing lights and siren.

Usage Example 2: Or the cops show up to arrest someone for trespassing....you step back inside and push the led buttons for continuous buzzer and the 15 watt siren but leave the strobing lights on.

IF you go with more than 10 devices between Alarm 1 and Alarm 2's blocks...then you will need something with more than 10 outputs:

If you connect the DC 5mm barrel connector on the bottom to something like the 4 channel lighting distribution power supply...it can provide up to 5 amps or more per channel. So that gives some play room..

Or you can connect a doubled 12v talentcell battery pack with it's charging cable and y adapter in use....that will give a backup on the devices and provide some extra amps.

🤟

*When that Alarm block gets triggered you will swear santa's reindeer joined the military at the synchronous clicks!

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Description: 〠High quality Material】:The car battery terminal connector is made of Pure copper tinned material, which provides better electrical conductivity and durability than other materials.〠Positive and Negative Terminal Clamps】:The terminal connector comes with both positive and negative terminal clamps, making it easy to install on your car battery.〠Easy to Install】: The positive and negative terminal clamps is easy to install, simply push the cable into the clamp and tighten the screw to secure it. The purpose of the product is to connect the battery and the power supply, stabilize the current, and protect the battery.〠Universal Fit】:The cable end connector is designed to fit most car batteries, ensuring compatibility with your vehicle.〠Durable Design】:The terminal connector is built to last and withstand extreme temperatures and harsh environments. Strong conductivity and long service life. Specification: Product attributes: positive pole 17.5MM, negative pole 15.9MMWire size: 5.2 to 7.4mm (AWG size 1 to 4) or 16 to 35mm^2 wire diameter Size Chart: 6.6cm/2.60inch Package Includes: Optional:Style A: Positive and Negative Pile Heads,Red and black casing, red and black sheathOrStyle B: Positive and Negative Pile Heads,Terminal block, insulating pad, cleaning brush, red and black casing, red and black sheathOrStyle C: Positive and Negative Pile Heads,Terminal block, red and black casing, red and black sheathOrStyle D: Positive and Negative Pile Heads,insulating pad, red and black casingOrStyle E: Positive and Negative Pile Heads,Terminal block, insulating pad, red and black casing, red and black sheathOrStyle F: Positive and Negative Pile Heads, insulating pad, cleaning brush, red and black casing Note: Please allow slightly errors due to manual measurement and different monitors. ✍Material‘:The Car Battery Terminal Connector Is Made Of Pure Copper Tinned Material, Which Provides Better Electrical Conductivity And Durability Than Other Materials. ✍Positive And Negative Terminal Clamps‘:The Terminal Connector Comes With Both Positive And Negative Terminal Clamps, Making It Easy To Install On Your Car Battery. ✍Easy To Install‘: The Positive And Negative Terminal Clamps Is Easy To Install, Simply Push The Cable Into The Clamp And Tighten The Screw To Secure It ✍Kindly Refer The Product Description Before Buying The Product. ✍Package Include:As Per Description [ad_2]

0 notes

Text

Review, teardown, and testing of RS-150-24 Mean Well power supply

General description

A short description. The RS-150-24 is a power supply with a constant output voltage of 24 volts and a current of up to 6.3 amperes. According to the specification, the unit has two AC input voltage operating ranges—from 88 to 132 and 176 to 264 volts. Range selection is non-automatic with a mechanical switch. The supply measures close to 7.5 × 4.0 × 1.5 inches (192 × 98 × 38 millimeters) and is made on a printed circuit board fixed to the base of the metal case, designed to operate with passive cooling. The top lid covering the case is perforated. The power supply has an LED indication for the output voltage, allowing one to adjust it within -5 to +10%. This unit does not have either PFC or thermal protection.

Design description. The input and output circuits of the power supply are connected to a common screw block (1). From left to right, there are three terminals for the input line, neutral and ground wires, and two parallel blocks of two terminals for the outputs: ground and +24V. The input voltage from the screw terminals through the fuse (2) is supplied to the RF interference filter (3) and then goes to the diode bridge (5). A varistor (4) is installed at the filter input to suppress hazardous pulses. The rectified voltage from the bridge (5) through the range selector (6) and through two NTC inrush current limiters (7) is supplied to the input electrolytic capacitors (8). Rectified and filtered voltage from capacitors (8) goes to the forward converter, which consists of a NE1101 controller (9, on the back side of the board), a 2SK3878 power N-MOSFET transistor (10), and a transformer (11). The voltage from the output winding of the transformer (11) is rectified by the fast-recovery diode 20F20SAB3 (12) and filtered using an output LC filter (13) (14).

The base resistance of each NTC is about 4.5 Ohms.

Output filter capacitance: 2 pieces of 470 uF, 35 volts, designed for operating temperatures up to 220℉ (105℃) (14).

The output voltage is stabilized by shunt regulator AS431ANTR-E1, transmitting the control signal to the high-voltage side of the circuit through the 817C transistor optocoupler (15). A second optocoupler of the same type forms a bypass channel for overvoltage protection (OVP).

The rectifier bridge (5), transistor (10), and diode (12) are installed with individual heat sinks, which (10, 12) are pushed against the housing with screws. Between the aluminum case and the board (from the solder side) is an extra insulation layer, a thin fiberglass sheet. All bulky components are additionally fixed using a compound.

Build quality is good. The board has empty spaces for installing an additional parallel diode (12) and three output electrolytic capacitors. The board is obviously unified for all the models in the series, and these elements are used in lower-voltage models.

The output voltage LED indicator (16) and the output voltage adjustment resistor (17) are located near the terminal block so that they can be accessed without removing the top cover.

Test conditions

Most tests are performed using Metering Setup #1 (see appendices) at 80℉ (27℃), 70% humidity, and 29.8 inHg pressure. Unless mentioned otherwise, the measurements were performed without preheating the power supply with a short-term load. The following values were used to determine the load level:

Output voltage under a constant load

The high stability of the output voltage should be noted.

Power-on parameters

Powering on at 100% load

Before testing, the power supply is turned off for at least 5 minutes with a 100% load connected. The oscillogram of switching to a 100% load is shown below (channel 1 is the output voltage, and channel 2 is the current consumption from the grid):

On the oscillogram, three phases of the starting process can be distinguished: 1. Two pulses of the input current charging the input capacitors when connected to the grid have an amplitude of about 14.5 A and a duration of about one main voltage period. 2. Waiting for the power supply control circuit to start for about 220 ms. 3. (Output Voltage Rise Time) Output voltage rise takes 5 ms. (Turn On Delay Time) The entire process of entering the operating mode from the moment the device powers on is 228 ms.

(Output Voltage Overshoot) The switching process is aperiodic; there is no overshoot.

Powering on at 0% load

The power supply is turned off at least 5 minutes before the test, with a 100% load connected. Then, the load is disconnected, and the power supply is switched on. The oscillogram of switching to a 0% load is shown below:

The picture shows three distinguishable phases of the power-on process: 1. Charging the input capacitors when connected to the grid has an amplitude of about 14.5 A. 2. Waiting for the power supply control circuit to start for about 228 ms. 3. (Output Voltage Rise Time) Starting the converter, increasing the output voltage, and entering the operating mode takes 5 ms. (Turn On Delay Time) The entire process of entering the operating mode from the moment the device powers on is 233 ms.

(Output Voltage Overshoot) The switching process is aperiodic; there is no overshoot.

Power-off parameters

The power supply was turned off at 100% load, and the input voltage was nominal at the moment of powering off. The oscillogram of the shutdown process is shown below:

The oscillogram shows two phases of the shutdown process: 1. (Shutdown Hold-Up Time) The power supply continues to operate because the input capacitors hold charge until the voltage across them drops to a certain critical level, at which point maintaining the output voltage at the nominal level becomes impossible. The phase takes 38 ms. 2. (Output Voltage Fall Time) Reduction of the output voltage, stopping voltage conversion, and accelerating the voltage drop takes 33 ms.

(Output Voltage Undershoot) The shutdown process is aperiodic; there is no undershoot.

The amplitude of the current at 100% load before shutting down is 5.7 A.

Output voltage ripple

100% load

At 100% load, the low-frequency ripple is approximately 3 mV.

At 100% load, the ripple at the converter frequency is approximately 40 mVp-p, and the noise is 100 mVp-p.

75% load

At 75% load, the low-frequency ripple is approximately 4 mV.

At 75% load, the ripple at the converter frequency is approximately 40 mVp-p, and the noise is 100 mVp-p.

50% load

At a 50% load, the low-frequency ripple is approximately 3 mV.

At 50% load, the ripple at the converter frequency is approximately 25 mVp-p, and the noise is 100 mVp-p.

10% load

At 10% load, the low-frequency ripple is approximately 3 mV.

At a 10% load, the ripple at the converter frequency is approximately 40 mVp-p, and the noise is 100 mVp-p.

0% load

No-load current consumption measured with a multimeter: 68 mA. (Power Consumption) The current consumption in this mode is predominantly reactive, so it isn't easy to reliably measure it with a basic set of instruments. The power supply's input filter contains two capacitors with a combined capacitance of approximately 1 uF.

At 0% load, the low-frequency ripple is indistinguishable from background noise of approximately 2 mVp-p.

At 0% load, the ripple at the converter frequency is masked by the background noise of approximately 50 mVp-p.

Dynamic characteristics

A mode with periodic switching between 50% and 100% load was used to evaluate the dynamic characteristics. The oscillogram of the process is shown below:

It is evident that the supply’s response to abrupt load changes is aperiodic; the magnitude of the response to load changes is about 100 mV p-p.

Overload protection

The claimed protection type is "hiccup mode, which recovers automatically after the fault condition is removed." This was confirmed during testing. When a short circuit occurs, the power supply periodically tries to turn back on and, if the overload is still present, turns off again until the next attempt.

The output current for the overload protection to kick in is 8.8 A.

Input circuit safety assessment

(Input discharge) Safety assessment is based on the discharge time constant of the input circuits when disconnected from the grid; the value is 0.234 s. This means that when operating on a 120 V input voltage, the time required to discharge the input circuits to safe values (<42 V) will be 0.652 s:

Important: The result is valid for this particular power supply unit; it was obtained for testing purposes and should not be taken as a safety guarantee.

The leakage current at the ground pin is 29 µA.

Thermal conditions

When operating with no load connected, no component overheating had been noticed. Thermograms were captured at three power levels: 80, 90, and 100%, fully assembled and with the lid removed. Thermal images show that the most loaded element of the block are four ballast resistors that shunt the source output, which are located near the inductance of the output LC filter (13) and whose heating noticeably stands out against the background of other components. At 80% load, they heat up to 219℉ (104℃, 139℉ above ambient temperature). At 90%, it's 233℉ (112℃, 153℉ above ambient), and at 100%, it reaches 239℉ (115℃, 159℉ above ambient). It is worth noting here that overheating increases faster than output power.

80% load

90% load

100% load

Conclusions

RS-150-24 generally has little noise and ripple, the output voltage is maintained accurately, and the build quality is solid. The power supply's dynamic characteristics are fine; the unit reacts to a pulsing load with no overshoot.

According to the specification, it is designed for “cooling by free air convection” and “high operating temperatures up to 70°C.” However, our test unit at 100% load heated up its load resistors up to 320℉ (160℃), which seems dangerous. For long-term operation, the load should be limited to 70–80% of the nominal one, especially during the hot season when ambient temperatures reach 95℉ (35℃) or more.

When assessing the safety of the operation of such a power supply, it is necessary to consider the possibility that the load exceeds the rated value due to malfunction but remains below the protection trigger level. In this case, the output power for the tested unit will be 135% of the nominal value, leading to even greater overheating, resulting in power supply failure and a fire hazard.

Important: The results are valid for this particular power supply unit; they were obtained for testing purposes and should not be used to evaluate all the units of the same type

0 notes

Text

Connecting the Dots: Exploring Different Types of Wire Terminal Connectors

Wire terminal connectors are essential components in electrical and electronic systems, providing secure and reliable connections between wires and devices. With a variety of types available, each designed for specific applications and environments, understanding the different wire terminal connector types is crucial for efficient wiring and connectivity. Let's delve into the various types of wire terminal connectors and their unique characteristics.

1. Ring Terminals

Ring terminals, also known as ring connectors or eyelet terminals, are one of the most common types of wire terminal connectors. They feature a ring-shaped metal terminal that is crimped or soldered onto the stripped end of a wire. Ring terminals are used for securing wires to terminal blocks, studs, or screws, providing a secure and durable connection that can withstand vibrations and mechanical stress.

2. Spade Terminals

Spade terminals, also called fork terminals or blade terminals, have a flat, spade-shaped metal terminal that is crimped onto a wire. They are designed to be inserted into terminal blocks, connectors, or screw terminals for quick and easy connections. Spade terminals are available in various sizes and styles, including insulated and non-insulated versions, to accommodate different wire gauges and applications.

3. Bullet Connectors

Bullet connectors, also known as bullet terminals or barrel connectors, feature cylindrical metal terminals that are crimped onto wires. They are commonly used for quick and reliable connections in automotive wiring, electrical appliances, and low-voltage applications. Bullet connectors come in male and female pairs, allowing for easy mating and disconnection of wires.

4. Quick-Disconnect Terminals

Quick-disconnect terminals, also called quick-connect terminals or push-on terminals, are designed for rapid and tool-free wire connections and disconnections. They feature a male or female terminal that can be easily pushed onto a corresponding terminal or stud. Quick-disconnect terminals are commonly used in automotive wiring, electrical appliances, and industrial equipment for fast and convenient installations and repairs.

5. Butt Connectors

Butt connectors, also known as splice connectors or wire joiners, are used to join two wires end-to-end. They feature a cylindrical metal tube with insulation and crimping ends that securely hold the wires together. Butt connectors are available in insulated and non-insulated versions, with heat-shrinkable options for added protection and durability in harsh environments.

6. Terminal Blocks

Terminal blocks are modular connectors that provide a convenient way to connect multiple wires or components. They consist of insulated blocks with metal terminals or screws where wires can be attached. Terminal blocks come in various configurations, including barrier strips, DIN rail-mounted blocks, and PCB-mounted blocks, making them versatile for different wiring applications in control panels, machinery, and electrical enclosures.

7. Pin Terminals

Pin terminals, also called male disconnect terminals, feature a pin-shaped metal terminal that is crimped onto a wire. They are designed to be inserted into female disconnect terminals or receptacles for electrical connections. Pin terminals are commonly used in automotive wiring, electrical appliances, and industrial equipment for secure and reliable connections that can be easily disconnected for maintenance or repairs.

8. Ferrule Terminals

Ferrule terminals, also known as wire ferrules or cord end terminals, are used to terminate stranded wires before insertion into terminal blocks or connectors. They feature a metal sleeve that is crimped onto the stripped end of a wire, providing a secure connection and preventing wire strands from fraying or coming loose. Ferrule terminals are available in insulated and non-insulated versions for different applications.

Conclusion

Wire terminal connectors are essential components in electrical and electronic systems, providing reliable connections that are crucial for proper functionality and safety. From ring terminals for secure wire attachments to quick-disconnect terminals for fast and tool-free connections, the variety of wire terminal connector types allows for efficient wiring and connectivity in various applications. Understanding the characteristics and applications of these connectors is essential for technicians, engineers, and DIY enthusiasts to ensure proper installations, repairs, and maintenance of electrical and electronic systems.

0 notes

Text

Barrier Strips Market Latest Trends and Analysis, Future Growth Study by 2032

The barrier strips market refers to the industry that produces and sells barrier strips, also known as terminal blocks or connection strips. These are electrical connectors used to connect and secure wires and cables in various applications. Here is a brief overview of the barrier strips market:

Market Definition: Barrier strips are essential components in electrical and electronic systems, facilitating secure connections, organization, and distribution of wires and cables.

Applications: Barrier strips are used in a wide range of applications, including industrial machinery, control panels, power distribution, telecommunications, automotive, and more.

Types: Barrier strips come in various types, including single-row, double-row, and triple-row configurations, as well as different wire connection methods such as screw-clamp, spring-clamp, and push-in.

Materials: They are typically made from materials like plastic, ceramic, or metal, with metal versions offering enhanced durability and conductivity.

Market Drivers:

Automation and Industry 4.0: Increasing automation in industries drives the demand for reliable electrical connections, boosting the barrier strips market.