#process Chillers Manufacturers

Explore tagged Tumblr posts

Text

Process Chiller Solutions In India, process Chillers Manufacturers, Process Chiller Manufacturers In India

Process Chiller Solutions In India

.

Processes Chiller

process chillers manufacturers

Excellence in Process Chiller Solutions

A cornerstone in industrial cooling, MK Aircon Systems Pvt. Ltd. has carved a niche with top-tier Process Chiller solutions.

.

Tailored for industries where precision cooling is crucial, our chillers stand out, ensuring that complex processes run smoothly and efficiently.

.

process chiller manufacturers in india

The seamless integration of state-of-the-art technology with robust design principles means our Process Chillers are not just equipment but vital partners in industrial success.

.

process chiller suppliers in india

The prowess of MK Aircon Systems in the field of Process Chillers is underpinned by the commitment to quality and innovation.

.

process chiller dealers in india

Whether catering to pharmaceuticals, plastics, or food and beverage sectors, our chillers ensure optimal temperature regulation, enhancing production quality and consistency.

.

process chiller distributors in india

With a deep understanding of the intricacies of varied industries, we emerge as the go-to name for businesses seeking unparalleled cooling solutions that guarantee efficiency and longevity.

.

process chillers manufacturers in ahmedabad

Email us at [email protected] or Call us at +91 99099 45216 for Process Chiller Solutions in India. We are trusted and experienced Process Chiller Manufactuers, Process Chiller Exporters in India, Gujarat, Ahmedabad.

.

process chillers manufacturers in gujarat

CONTACT US

ADDRESS:

1763, Joshi Vas, B/h. Navrangpura Police Station, Navrangpura,

Ahmedabad 380009 (Gujarat, India)

.

CONTACT DETAILS

+91 -079-26423303, +91 -079- 26441247

.

FOR INQUIRY

+91 99099 45216

.

FOR SUPPORT

+91 99099 45231

.

FOR RECRUITMENT

+91 99099 45202

.

Website : https://mkengineer.com/

#Process Chiller Solutions In India#process Chillers Manufacturers#Process Chiller Manufacturers In India

0 notes

Text

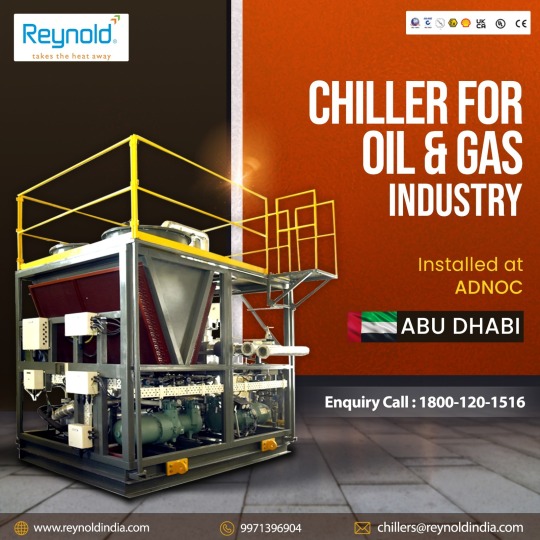

One of the top industrial chillers in the market is the Reynold India, Water-Cooled Chiller. Renowned for its exceptional performance and energy efficiency, this Industrial Process chiller is designed to meet the demanding cooling needs of large industrial applications.

#industrial chillers#Buy Industrial Chiller#Top Industrial Chiller#Buy Best Industrial Chiller#Top Industrial Chiller manufacturing Process

0 notes

Text

Efficient Air Cooled Chiller Manufacturers from DSM Enterprises

DSM Enterprises is a trusted name in the Air Cooled Chiller Manufacturers industry. With a focus on innovation, quality, and efficiency, the company offers a range of air cooled chillers that are designed to meet the unique cooling needs of businesses across a variety of sectors. Whether you're looking for a chiller for your commercial building or industrial facility, DSM Enterprises has the solution for you.

One of the key advantages of working with DSM Enterprises is their commitment to innovation. The company uses advanced technology and cutting-edge design techniques to create air cooled chillers that are efficient, reliable, and easy to use. They are constantly updating their products to ensure that they are at the forefront of the industry and that their clients are getting the best possible solutions.

Another advantage of working with DSM Enterprises is their focus on quality. The company uses only the highest quality materials and components to manufacture their air cooled chillers, ensuring that they are built to last. They follow strict quality control measures at every stage of the manufacturing process to ensure that every chiller that leaves their factory meets all relevant safety and environmental standards.

DSM Enterprises also offers excellent customer service and support. Their team of experienced engineers and technicians are always on hand to provide assistance with installation, maintenance, and repair of their air cooled chillers. They work closely with their clients to understand their unique cooling needs and develop customized solutions that meet their requirements.

In conclusion, DSM Enterprises is a leading manufacturer of air cooled chillers that offers innovative, efficient, and reliable cooling solutions for businesses across a range of sectors. With a focus on quality, innovation, and customer service, the company is well-equipped to meet the unique cooling needs of businesses looking for efficient and reliable air cooled chiller solutions.

Call Us: +91-9607400742

Email id: [email protected]

Address: 43/10, Nav Sahayadri Society, Gulmohar Path, Karve Nagar, Pune (Maharashtra) -411052

URL: https://www.dsmenterprises.in/air-cooled-chiller.html

0 notes

Text

Eco-Friendly PVC Curtains: Reducing Your Carbon Footprint

In today’s world, businesses are increasingly looking for ways to reduce their environmental impact and operate more sustainably. One often overlooked yet effective solution is the use of eco-friendly PVC curtains. Modern PVC curtains, especially those made from recyclable materials, can play a crucial role in reducing waste and lowering the carbon footprint of businesses. From cold storage facilities to industrial workshops, these versatile curtains are helping businesses maintain energy efficiency and reduce their environmental impact without compromising on quality or functionality.

The Role of PVC Curtains in Environmental Sustainability

PVC curtains are traditionally made from Polyvinyl Chloride, a durable plastic material known for its flexibility, resilience, and long lifespan. However, concerns about the environmental impact of plastic have led manufacturers to explore more sustainable options.

Modern eco-friendly PVC curtains are now being produced from recyclable materials. By using recycled PVC, manufacturers can reduce the demand for new raw materials and lower the amount of waste that ends up in landfills. This approach not only helps in minimising the environmental impact of the production process but also provides businesses with a sustainable alternative to traditional plastic products.

Recyclable Materials: A Step Towards a Greener Future

Eco-friendly PVC curtains are designed with recyclability in mind. At the end of their life cycle, these curtains can be recycled and repurposed into new products, helping to create a circular economy where materials are reused rather than discarded. This helps businesses minimise their waste output and contributes to global efforts to reduce plastic pollution.

In addition, the production of recyclable PVC curtains typically uses less energy compared to manufacturing new PVC from raw materials, which helps to lower greenhouse gas emissions. By opting for these eco-friendly alternatives, businesses can significantly reduce their carbon footprint while still benefiting from the durability and functionality that PVC curtains offer.

Energy Efficiency and Carbon Reduction

One of the most significant ways that PVC curtains help businesses reduce their environmental impact is through energy efficiency. In cold storage units, for example, these curtains prevent the exchange of warm and cold air, reducing the need for constant refrigeration and helping to lower energy consumption. This energy-saving benefit translates to lower greenhouse gas emissions, as less energy is needed to keep facilities at the desired temperature.

Similarly, in manufacturing plants, warehouses, and other industrial settings, PVC curtains can help to maintain specific environmental conditions without requiring heavy-duty air conditioning or heating systems. By creating barriers that regulate temperature, they reduce the workload on HVAC systems, further contributing to energy efficiency and lower carbon emissions.

About Rayflex Group

When it comes to eco-friendly PVC curtains in the UK, Rayflex Group stands out as a leading supplier. This company has been at the forefront of providing high-quality PVC strip curtains and welding screens for a wide range of industries. Whether it’s for use in welding workshops, schools, nurseries, manufacturing plants, or chillers, Rayflex offers sustainable solutions that cater to the specific needs of each business.

Rayflex Group is committed to supplying products that not only improve operational efficiency but also contribute to environmental sustainability. Their PVC strip curtains are designed to last, ensuring businesses get long-term value while minimising the need for frequent replacements, further reducing waste.

Customer Reviews

Here are some testimonials from business owners across various industries in the UK who have invested in eco-friendly PVC strip curtains from Rayflex and benefited from them:

"We installed eco-friendly PVC strip curtains from Rayflex in our warehouse, and they’ve made a huge difference. Not only are we saving on energy costs, but we’re also reducing our carbon footprint. It feels good to know we’re doing our part for the environment." – Tom, Warehouse Manager, Birmingham.

"As a nursery, we’re always looking for ways to be more sustainable. The PVC curtains we got from Rayflex are perfect for separating areas in a safe, eco-friendly way. They’re easy to maintain, and it’s reassuring to know they can be recycled at the end of their life." – Sarah, Nursery Owner, London.

"Rayflex’s PVC curtains have been a fantastic addition to our manufacturing plant. We needed something that could handle the tough environment while helping us reduce our energy consumption. These curtains have exceeded expectations, and the fact they’re made from recyclable materials is a huge plus." – James, Operations Manager, Manchester.

"Our school installed PVC strip curtains in the kitchen and other areas where temperature control is important. We were pleasantly surprised by how much they help with energy efficiency. It’s great to know we’re reducing waste with a product that’s recyclable." – Emma, School Facilities Manager, Leeds.

"I’ve been using PVC curtains from Rayflex in my welding workshop for over a year now, and they’ve been brilliant. They block out the welding sparks and help with noise reduction. What’s even better is knowing they’re an environmentally-friendly choice, which aligns with our company’s values." – Mark, Workshop Owner, Sheffield.

Conclusion

Eco-friendly PVC curtains are proving to be a valuable asset for businesses looking to reduce their environmental impact. By investing in PVC curtains made from recyclable materials, companies can lower their waste output, reduce energy consumption, and contribute to a more sustainable future. Whether it’s for cold storage, manufacturing plants, schools, or nurseries, the benefits of these curtains extend beyond just practical functionality—they also represent a commitment to environmental responsibility.

If you’re a business looking to improve your sustainability practices, investing in eco-friendly PVC curtains could be an excellent step towards reducing your carbon footprint and contributing to a greener planet.

Further Reading: https://blindsidedblogger.tumblr.com/

#blackout blinds#blinds installation#curtains and blinds#motorized blinds#pvc blinds#blinds solutions#custom blinds#blinds#behind the blinds#roller blinds

4 notes

·

View notes

Text

Established in the year 2016, Airomach Engineers is one of the leading Manufacturer and Wholesaler of Air Dryer, Air Heater, Water Chiller and much more. In their development process, we assure that only top notch basic material is used by our professionals along with modern tools. Besides this, we check these on a variety of grounds before finally shipping them at the destination of our customers. Working under the mentorship of Mr. Sanehit Bhardwaj (Proprietor), we have acquired a reputed stature in the industry.

#Best chiller plant manufacturer in India#Best chiller plant manufacturer in delhi#Screw chiller manufacturers india#Screw chiller manufacturers delhi#Oil chiller manufacturers India#Oil chiller manufacturers delhi#Glycol chiller manufacturers India#Glycol chiller manufacturers delhi#Refrigerated Air Dryer Supplier in Delhi#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturer in Delhi#Water Chiller Supplier in Delhi#Scroll chiller manufacturers delhi#Water Cooled condenser manufacturers in delhi#air dryer manufacturer in delhi#Scroll chiller manufacturers in india#Scroll chiller manufacturers in delhi#Beverage chiller manufacturers in india#Beverage chiller manufacturers in delhi#High pressure air dryer manufacturers in india#High pressure air dryer manufacturers in delhi#Air cooled chiller manufacturers in india#Air cooled chiller manufacturers in delhi#heat exchanger manufacturer in delhi#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Air Compressor Tank Price in India#Air Compressor Tank Price in delhi

0 notes

Text

Working Principle of a Chiller: A Beginner's Guide to Chiller Plant Operation

When it comes to efficient cooling solutions, chillers play a vital role in a wide range of industrial and commercial applications. From maintaining optimal temperatures in manufacturing processes to ensuring comfortable environments in office buildings, chillers are indispensable. In this guide, we’ll break down the working principle of a chiller, explore its different types, and discuss its applications, helping you better understand this essential cooling system.

What is a Chiller?

A chiller is a machine designed to remove heat from a liquid via a refrigeration cycle or absorption cycle. The chilled liquid is then used for cooling processes such as industrial equipment, air conditioning systems, or other applications requiring precise temperature control.

Chillers are categorized into two main types:

Air-Cooled Chillers

Water-Cooled Chillers

Both types serve the same purpose but operate differently and are used in distinct applications.

How Does a Chiller Work?

The working of a chiller is based on the principle of heat transfer. It removes heat from a liquid (usually water or glycol) and dissipates it to the environment. Here's a simplified breakdown of its operation:

Refrigerant Circulation The chiller uses a refrigerant that absorbs heat from the process liquid. The refrigerant circulates through four key components:

Evaporator: Heat is absorbed from the liquid, turning the refrigerant into a gas.

Compressor: The refrigerant gas is compressed, increasing its temperature and pressure.

Condenser: The heated refrigerant releases the absorbed heat into the surrounding air (air-cooled chiller) or water (water-cooled chiller).

Expansion Valve: The refrigerant is expanded, cooling it down for the next cycle.

Liquid Cooling The chilled liquid, now cooled to a desired temperature, is circulated through pipes to cool machinery, spaces, or processes.

Heat Dissipation For air-cooled chillers, heat is expelled into the air via fans. For water-cooled chillers, the heat is removed through cooling towers.

Types of Chillers

1. Air-Cooled Chiller

Air-cooled chillers use fans to expel heat into the atmosphere. They are ideal for applications where water resources are limited, making them a popular choice for small to medium-sized facilities. These chillers are low maintenance and easy to install.

2. Water-Cooled Chiller

Water-cooled chillers use water and cooling towers to dissipate heat. These chillers are more energy-efficient and suited for larger facilities and industries with high cooling demands. However, they require more maintenance and infrastructure, such as a cooling tower and water supply system.

3. Process Chiller

A process chiller is designed to provide precise temperature control for industrial processes. These are commonly used in manufacturing, chemical production, and medical equipment cooling.

4. Industrial Chiller

An industrial chiller is built to handle large-scale cooling for industries like food processing, plastics, and power plants. These systems are robust and capable of cooling heavy-duty equipment.

Choosing the Right Chiller

When deciding between an air-cooled chiller and a water-cooled chiller, it’s important to consider your application requirements. Here are some key factors:

Space Availability: Air-cooled chillers require less infrastructure, making them suitable for smaller spaces.

Energy Efficiency: Water-cooled chillers are more energy-efficient and cost-effective for long-term, high-capacity operations.

Initial Investment: Air-cooled chillers have a lower upfront cost, while water-cooled chillers may involve higher setup costs due to cooling towers.

Maintenance Needs: Water-cooled chillers require more maintenance due to water treatment and additional components.

Applications of Chillers

Chillers are widely used in various industries, including:

HVAC Systems: Cooling office buildings, malls, and hospitals.

Manufacturing: Precise cooling for machinery and processes.

Food & Beverage Industry: Maintaining optimal temperatures during production and storage.

Medical Equipment: Cooling MRI machines, CT scanners, and lab equipment.

Why Choose Panurgy Industries for Your Chiller Needs?

At Panurgy Industries, we are one of the leading water chiller manufacturers and water chiller suppliers in India. Our range of chillers includes high-quality air-cooled chillers, water-cooled chillers, process chillers, and industrial chillers, tailored to meet the diverse cooling needs of our clients.

We provide durable, energy-efficient solutions designed to enhance your operations and reduce costs. Whether you’re looking for chillers for HVAC systems or industrial processes, Panurgy Industries has the expertise and products to meet your requirements.

Download Our Catalogue

To explore our complete range of chillers and other cooling solutions, please download our product catalogue or contact us directly for more information. https://www.panurgy.in/air-cooled-water-chillers.php

By understanding the working principle of chillers and selecting the right type for your application, you can ensure efficient cooling and optimized performance. For all your cooling requirements, trust Panurgy Industries, your trusted partner for industrial cooling solutions.

#Chiller#industrial chillar#industrial chillar manufafacturer#industrial chillar supplier#industrial chillar manufacturers in india#industrial chillar supplier in delhi

0 notes

Text

Understanding HVAC Terminology: A Guide for Business Owners

For business owners, understanding HVAC (Heating, Ventilation, and Air Conditioning) terminology is crucial when making informed decisions about temperature control solutions. Whether you’re managing a facility, planning an event, or running a business that requires specialised climate control, knowing these terms can help you choose the right equipment and services. This guide breaks down key HVAC terms and their applications to simplify your decision-making process.

1. Heat Pump

A heat pump is a versatile HVAC system that provides both heating and cooling. It works by transferring heat from one location to another, making it an energy-efficient choice for businesses requiring year-round temperature regulation. Heat pumps are ideal for office spaces, retail stores, and facilities that need consistent climate control.

2. Reefer and Reefer Container

A reefer is short for a refrigerated container used to transport or store temperature-sensitive goods. These containers are essential for businesses in the food, pharmaceutical, or logistics sectors. A reefer container ensures that perishable goods remain fresh, even during transportation or extended storage periods.

3. Refrigerated Container

A refrigerated container is a climate-controlled unit used for storing perishable goods. Unlike reefer containers primarily used in transit, refrigerated containers are ideal for on-site cold storage, making them a perfect solution for restaurants, catering businesses, or events that require food preservation.

4. Freezer Container

A freezer container is designed to maintain sub-zero temperatures, suitable for storing frozen goods such as ice cream, meats, and seafood. These containers are indispensable for businesses that require reliable frozen storage, whether at a facility or a temporary event site.

5. Chiller Rental

A chiller rental provides businesses with temporary cooling solutions, often used during maintenance, emergencies, or seasonal demands. These systems are critical for facilities like hospitals, manufacturing plants, and data centres where uninterrupted cooling is essential.

6. Chiller Container

A chiller container is a portable cooling system that provides chilled air or water for various applications. It is commonly used for industrial cooling, large-scale events, and emergency cooling situations where a fixed HVAC system is unavailable or insufficient.

7. Hot Water System

A hot water system is used for heating water efficiently in commercial or industrial setups. These systems are essential for hotels, restaurants, and luxury events requiring hot water for spas, kitchens, or sanitation purposes.

8. Industrial Cooling

Industrial cooling refers to large-scale cooling systems used in industries such as manufacturing, power plants, and chemical processing. These systems manage the heat generated by machinery and processes, ensuring operational efficiency and safety.

9. Tent Cooling

Tent cooling systems are specifically designed for outdoor events or temporary structures. These portable cooling units maintain comfortable temperatures inside tents, making them ideal for weddings, exhibitions, and corporate events in hot climates.

10. Temporary Cooling

Temporary cooling solutions are used for short-term needs, such as during maintenance, equipment upgrades, or events. These systems include chillers, air handlers, and portable units, offering flexibility for a wide range of applications.

11. Emergency Cooling

When a permanent HVAC system fails, emergency cooling solutions ensure minimal disruption to operations. These systems can be rapidly deployed to provide immediate relief in situations like power outages, equipment breakdowns, or natural disasters.

12. Event Cooling

Event cooling refers to specialised HVAC solutions designed for events, ensuring comfort for attendees and proper climate control for equipment or perishable goods. From tent cooling to reefer containers, Trane Rentals offers comprehensive options for all event cooling needs.

13. Offshore Reefer

An offshore reefer is a specialised refrigerated container designed for remote or offshore locations. These containers are essential for industries such as oil and gas, providing reliable cold storage for food, supplies, or equipment in challenging environments.

Why HVAC Knowledge Matters for Business Owners

Understanding HVAC terminology empowers business owners to:

Make informed decisions about the right systems for their needs.

Optimise operational efficiency with tailored solutions.

Ensure cost-effective climate control while meeting sustainability goals.

Minimise downtime during emergencies with the right equipment.

0 notes

Text

process chillers manufacturers in ahmedabad

process chillers manufacturers in ahmedabad

.

Welcome to

M K Aircon Systems Pvt. Ltd.

.

To become Market Leader in providing energy management and sustainable building design solutions and build a sustainable future.

** Providing Innovative Solution Globally in HVAC & R

** Improve Quality of Lives.

** High Quality Product – New Technology.

** Emphasizing on workmanship with designing.

** Strive to Customers Expectation.

.

About Us

M. K. Aircon, a Private Limited firm was established in April 1999. The Company was founded by a Young, Dynamic, Enthusiastic, Experienced and impeccable professional engineer who emancipate his well-paid jobs to build better environment to work.

.

M K Aircon has achieved prominent growth by specializing in developing and implementing HVAC Systems in different application and provinces. The company’s success has a long journey of 3 decades from establishing company to reach the paramount of HAVC & R technology advancements. The cultivated technical knowledge, substantial work commitment and tireless diligence of Founders leading experts are the keystone of the company to procure trust and satisfaction of customers globally.

.

ADDRESS:

1763, Joshi Vas, B/h. Navrangpura Police Station, Navrangpura,

Ahmedabad 380009 (Gujarat, India)

.

CONTACT DETAILS

+91 -079-26423303, +91 -079- 26441247

.

FOR INQUIRY

+91 99099 45216

.

FOR SUPPORT

+91 99099 45231

.

FOR RECRUITMENT

+91 99099 45202

.

Website : https://mkengineer.com/

0 notes

Text

Efficient Cooling Solutions: Navigating Mumbai's Industrial Landscape with Water-Cooled Chillers

In the bustling industrial hub of Mumbai, where the relentless operation of machinery generates substantial heat, the need for effective cooling solutions has never been more critical. Among the diverse range of cooling technologies available, water-cooled chillers stand out as a reliable and efficient option. This article delves into the significance of water-cooled chillers in Mumbai's industrial context, highlighting their benefits, applications, and contributions to sustainable practices.

The Role of Water-Cooled Chillers: Water-cooled chillers play a pivotal role in maintaining optimal operating conditions for industrial processes by dissipating excess heat. In contrast to air-cooled alternatives, water-cooled chillers offer superior cooling efficiency, making them an ideal choice for the demanding requirements of Mumbai's industries. These chillers utilize water as a highly effective heat transfer medium, ensuring consistent and reliable cooling even in high-heat environments.

Advantages and Benefits:

Enhanced Efficiency: Water-cooled chillers boast higher efficiency compared to air-cooled systems, resulting in energy savings and reduced operating costs for industrial establishments.

Space Optimization: The compact design of water-cooled chillers allows for efficient space utilization within Mumbai's often limited industrial facilities.

Noise Reduction: Water-cooled systems are generally quieter than air-cooled counterparts, contributing to a more conducive working environment for employees.

Temperature Stability: With precise temperature control capabilities, water-cooled chillers ensure that critical processes are carried out consistently and efficiently.

Longevity: The use of water as a cooling medium helps extend the lifespan of equipment, reducing the frequency of maintenance and replacements.

Applications Across Industries: Water-cooled chillers find applications in various industries across Mumbai:

Manufacturing: Cooling machinery and equipment in industries such as textiles, chemicals, and automotive manufacturing ensures uninterrupted production and product quality.

Pharmaceuticals: Precise temperature control is crucial in pharmaceutical production, making water-cooled chillers indispensable for maintaining the integrity of sensitive substances.

Data Centers: As data centers proliferate, water-cooled chillers aid in preventing overheating of servers and ensuring reliable operations.

Food Processing: From refrigeration to maintaining hygiene during processing, water-cooled chillers contribute to safe and efficient food production.

Sustainability and Environmental Impact: In a time when sustainability is a global priority, water-cooled chillers offer significant environmental benefits. By reducing energy consumption and greenhouse gas emissions, these systems align with Mumbai's efforts towards a greener future. Additionally, water-cooled chillers can integrate with renewable energy sources, further enhancing their eco-friendly profile.

Conclusion: As Mumbai's industrial landscape continues to evolve, the role of water-cooled chillers remains paramount in ensuring efficient operations and sustainable practices. Their advantages in terms of efficiency, space optimization, and environmental impact make them a valuable asset across diverse industries. By embracing water-cooled chiller technology, Mumbai's industries can effectively navigate the challenges of heat management while contributing to a more sustainable and prosperous future.

2 notes

·

View notes

Text

Benefits of Choosing DSM Enterprises as Your Air Cooled Chiller Manufacturers

DSM Enterprises is a reputable company that specializes in the Air Cooled Chiller Manufacturers. Air-cooled chillers are an essential component of HVAC systems in many commercial and industrial buildings. These chillers are designed to remove heat from a liquid, typically water, and transfer it into the air through a heat exchanger.

DSM Enterprises is one of the leading air-cooled chiller manufacturers in the industry, offering a wide range of chiller models to meet the needs of various applications. They use state-of-the-art technology and high-quality components to ensure their chillers are reliable, energy-efficient, and long-lasting.

One of the advantages of using air-cooled chillers is that they don't require a separate cooling tower, which can be costly and take up a lot of space. Instead, they use ambient air to dissipate the heat, which is a much more efficient and cost-effective method.

DSM Enterprises' air-cooled chillers are designed to be easy to install, operate, and maintain. They come in a range of sizes and capacities to suit different cooling requirements. The company also provides excellent after-sales support to ensure their customers get the most out of their chillers.

Whether you need a chiller for a small office building or a large industrial complex, DSM Enterprises has the expertise and experience to provide a solution that meets your specific needs. Their air-cooled chillers are trusted by customers across various industries, including pharmaceuticals, food processing, data centers, and more.

In summary, if you're looking for high-quality and reliable air-cooled chiller manufacturers, DSM Enterprises is a top choice. With their cutting-edge technology, attention to detail, and commitment to customer satisfaction, you can trust them to provide the right solution for your cooling needs.

Call Us: +91-9607400742

Email id: [email protected]

Address: 43/10, Nav Sahayadri Society, Gulmohar Path, Karve Nagar, Pune (Maharashtra) -411052

URL: https://www.dsmenterprises.in/air-cooled-chiller.html

0 notes

Text

One of the Best Cold Room Manufacturers in India

Cold storage rooms provide ideal man-made conditions for storing temperature-sensitive products (foods, fruits, and pharmaceuticals). This prevents items from losing their integrity when exposed to temperature fluctuations.

What makes these cold rooms important is their ability to preserve the quality of stored products. These rooms inhibit biological decay and slow down the chemical and physical changes in food items.

Navigating cold storage rooms can be a challenge for farmers and food brands. With so many companies operating in the cold storage and food processing market, it is essential to select a trusted partner who can meet your unique storage requirements.

The one name that tops the list when it comes to one of the best cold room manufacturers in India is Mechair. From small walk-in spaces to huge warehouse storage, our cool rooms come in a range of sizes. They are made to keep various products within a certain temperature range.

Cold Storage Rooms

Mechair has been revolutionising cold chain management, turnkey food processing and refrigeration, ensuring quality from farm to fork. As one of India’s top providers of world-class, temperature-controlled supply chain solutions, we excel by combining state-of-the-art technologies with a highly skilled team.

Mechair’s position as a market leader in cold chain management and food processing is largely attributed to its more than two decades of experience. We have refined our processes through personal observations and experiences over 25 years of operations to provide top-tier cold chain solutions to our clients.

Why Choose Mechair for Cold Storage Solutions?

Here’s a look at the turnkey solutions we offer for cold storage:

Precooling Room:

The purpose of precooling is to remove field heat right after a crop is harvested. This is a necessary step so as to prevent quality loss and extend shelf life. Mech-Air manufactures forced air pre-cooling chambers that efficiently extract heat from fresh produce while maintaining high humidity to preserve freshness and prevent weight loss.

Cold Storage for Fruits & Vegetables:

We have developed walk-in cold rooms for the storage of lemons, onions, and bananas. All of these rooms have precise monitoring of temperature. Clients can use them to store fruits, vegetables, dairy products, pharmaceuticals, flowers etc.

Dehumidified Cold Room for Seed Storage:

Seed storage is crucial for successful seed production and marketing. To store seeds for 6 months to 10 years, a controlled environment is necessary. Higher moisture content negatively impacts seed viability, while lower humidity inhibits insect and fungal activity. Keep seeds in moisture-proof containers for long-term storage. "MECH-AIR INDUSTRIES" offers conditioned storage solutions, including modular cold rooms with proper lighting and protection from pests, ensuring optimal germination and vigour. Our seed storage is suitable to store seeds in bulk quantities.

Blast Chiller & Blast Freezer: A blast chiller is used to reduce the temperature of freshly cooked food. This helps maintain its quality during storage. This method is specifically suitable for those in food catering and instant deliveries. On the other hand, a blast freezer is an ultra-cold freezer commonly found in commercial kitchens. It is used for ready meals, fish, and vegetable products.

Want to learn more about our cold storage and food processing solutions? Please visit us here: https://www.mechair.in/

0 notes

Text

Established in the year 2016, Airomach Engineers is one of the leading Manufacturer and Wholesaler of Air Dryer, Air Heater, Water Chiller and much more. In their development process, we assure that only top notch basic material is used by our professionals along with modern tools. Besides this, we check these on a variety of grounds before finally shipping them at the destination of our customers. Working under the mentorship of Mr. Sanehit Bhardwaj (Proprietor), we have acquired a reputed stature in the industry.

#Best chiller plant manufacturer in India#Best chiller plant manufacturer in delhi#Screw chiller manufacturers india#Screw chiller manufacturers delhi#Oil chiller manufacturers India#Oil chiller manufacturers delhi#Glycol chiller manufacturers India#Glycol chiller manufacturers delhi#Refrigerated Air Dryer Supplier in Delhi#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturer in Delhi#Water Chiller Supplier in Delhi#Scroll chiller manufacturers delhi#Water Cooled condenser manufacturers in delhi#air dryer manufacturer in delhi#Scroll chiller manufacturers in india#Scroll chiller manufacturers in delhi#Beverage chiller manufacturers in india#Beverage chiller manufacturers in delhi#High pressure air dryer manufacturers in india#High pressure air dryer manufacturers in delhi#Air cooled chiller manufacturers in india#Air cooled chiller manufacturers in delhi#heat exchanger manufacturer in delhi#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Air Compressor Tank Price in India#Air Compressor Tank Price in delhi

0 notes

Text

Multi Compressor Chillers Manufacturer, Supplier, India

Multi Compressor Chillers, Multi Compressor Chillers Manufacturer, Multi Compressor Chillers Supplier, Multi Compressor Chillers Exporter, Mumbai, India.

Cooling Towers, Frp Cooling Towers, Pultruded Cooling Towers, Timber Cooling Towers, Rcc Cooling Towers, Ice Plant, Block Ice Plant, Ammonia Block Ice Plant, Freon Ice Plant, Flake Ice Plant, Tube Ice Plant, Chilling Plants, Air Cooled Chilling Plants, Water Cooled Chilling Plants, Brine Chilling Plants, Oil Chillers, Air Blast Coolers, Industrial Screw Chillers, Multi Compressor Chillers, Brine Process Cooling System, Water Process Cooling System, Water Cooled Screw Chillers, Atmospheric Type Condenser, Ammonia Cooling Coil, Trunk Coil, Ammonia Receiver, Ammonia Refrigerant Liquid Storing Tank, Ice Can, Cooling Tower Film Fills, Frp Fan Stack, Water Distribution System Frp Fan Stack, Drift Eliminators, Cooling Tower Services, Mumbai, India.

0 notes

Text

Best Choice for Industrial and Domestic Chillers in the UAE

Why MTECH Chiller Stands Out as the Best Choice for Industrial and Domestic Chillers in the UAE

The UAE’s soaring temperatures demand reliable cooling solutions for both industrial and domestic purposes. Finding the right chiller is not just about cooling but ensuring efficiency, durability, and cost-effectiveness. That’s where MTECH Chiller comes into the picture. Renowned as a leader in the industry, MTECH Chiller offers cutting-edge cooling solutions tailored to meet diverse needs.

Understanding the Importance of Chillers

Chillers play a critical role in maintaining optimal temperatures in various settings. From industrial factories to residential buildings, chillers ensure seamless cooling for processes, equipment, and living spaces. The right chiller enhances productivity, conserves energy, and reduces operational costs.

In the UAE, where the climate can be harsh, having a reliable chiller isn’t just a luxury; it’s a necessity.

Why Choose MTECH Chiller?

MTECH Chiller UAE has earned its reputation as a trusted provider of both industrial and domestic chillers UAE. Here are the key reasons why:

1. Wide Range of Products

MTECH Chiller UAE offers an extensive selection of chillers designed for varying needs. Whether you need industrial-grade chillers for manufacturing processes or compact domestic chillers for home cooling, MTECH has the perfect solution.

2. Cutting-Edge Technology

MTECH Chillers are engineered using advanced technology to ensure superior performance and energy efficiency. Their state-of-the-art cooling systems are designed to operate seamlessly, even in extreme temperatures.

3. Energy Efficiency

With a focus on sustainability, MTECH’s chillers are designed to consume less energy while delivering exceptional cooling power. This not only reduces electricity bills but also supports environmentally friendly practices.

4. Durability and Reliability

Built with high-quality materials, MTECH Chillers are durable and capable of withstanding the demanding climate of the UAE. Their robust designs ensure long-term performance and minimal maintenance needs.

5. Customizable Solutions

Every cooling requirement is unique, and MTECH understands this. They provide tailored solutions to meet specific needs, whether it’s for industrial applications or residential cooling systems.

6. Expert Support and Service

MTECH Chiller stands by its commitment to customer satisfaction. Their team of experts provides end-to-end support, from selecting the right chiller to installation and maintenance services. With 24/7 customer service, they ensure you’re never left in the heat.

Applications of MTECH Chillers

Industrial Use

Manufacturing processes

Food and beverage industries

Pharmaceutical cooling

Data center cooling

Domestic Use

Residential cooling systems

Small office spaces

HVAC systems for villas and apartments

Why MTECH is the Best in the UAE

When searching for the best chillers UAE, MTECH Chiller consistently tops the list. Their combination of quality products, exceptional service, and advanced technology sets them apart from competitors.

Whether you’re looking for an industrial chiller to optimize your operations or a domestic chiller for comfortable living, MTECH Chiller is the name you can trust.

Investing in the right chiller is crucial, especially in the challenging climate of the UAE. MTECH Chiller offers the perfect blend of innovation, efficiency, and reliability to meet your cooling needs. Choose MTECH for a cooling solution that goes beyond expectations and delivers unparalleled performance.

Discover the difference with MTECH Chiller — the best chillers UAE for industrial and domestic applications.

#industrial chillers#chillers#chiller supplier#industrial water chillers#air cooled chillers#chillers in UAE#domestic chillers#water chiller manufacturers#water cooled chillers#water coolers

0 notes

Text

The Role of Industrial Chiller Systems in Food Processing

Food processing is a delicate industry where temperature control plays a vital role in maintaining product quality and safety. From raw material preparation to storage and packaging, each step relies on precise cooling to prevent spoilage, maintain freshness, and comply with safety standards. This is where industrial chiller systems come into play, offering efficient and reliable cooling solutions tailored for the food industry.

Why Cooling is Critical in Food Processing

In food processing, even a small deviation in temperature can lead to product spoilage, contamination, or reduced shelf life. For example, dairy products, meats, and beverages need to be processed and stored under specific conditions to retain their quality. Without proper cooling, bacteria can grow, leading to unsafe food products and financial losses.

Industrial chiller systems help regulate temperatures during various stages of food processing. Whether it’s cooling down raw ingredients, controlling fermentation processes, or maintaining storage temperatures, these systems are indispensable. They ensure that food products meet the high standards expected by consumers and regulatory authorities.

How Industrial Chiller Systems Support Food Processing

Ingredient Cooling: During the preparation phase, raw ingredients such as milk, fruits, and vegetables are often cooled to preserve freshness. Chillers maintain the perfect temperature, ensuring these ingredients stay fresh until they are processed further.

Process Cooling: Many food production methods generate heat. For example, grinding meat or kneading dough produces friction that can raise temperatures. Chillers remove this heat to prevent the quality of the product from being compromised.

Fermentation Control: In industries like brewing or yogurt production, maintaining specific temperatures is critical for fermentation. Industrial chiller systems keep the temperature consistent, ensuring uniform results.

Packaging and Storage: After processing, food needs to be cooled before it can be packaged or stored. Sudden cooling prevents spoilage and helps maintain the texture and flavor of the product.

Extended Shelf Life: Proper cooling extends the shelf life of perishable items, reducing waste and ensuring products reach consumers in optimal condition.

Benefits of Industrial Chiller Systems in Food Processing

Using chillers in food processing provides several advantages:

Improved Product Quality: By maintaining stable temperatures, chillers help preserve the texture, taste, and nutritional value of food.

Energy Efficiency: Modern systems are designed to use less energy while providing reliable cooling, reducing operational costs.

Safety Assurance: Proper temperature control prevents bacterial growth and ensures compliance with food safety regulations.

Minimized Downtime: Chillers ensure that equipment doesn’t overheat during production, reducing the risk of breakdowns.

Choosing the Right Chiller for Food Processing

Not all chillers are created equal. Food processing requires systems that meet specific hygiene standards. Stainless steel components and non-toxic refrigerants are often used to ensure safety. Additionally, manufacturers must choose between air-cooled and water-cooled chillers based on their facility’s requirements.

Maintenance Matters

To keep industrial chiller systems performing at their best, regular maintenance is essential. Cleaning the components, checking refrigerant levels, and inspecting for wear and tear help avoid unexpected breakdowns. In food processing, where every second counts, a well-maintained system ensures smooth operations.

0 notes

Text

HVAC Chiller Services Bronx

The Bronx borough of New York City is known for being very busy, housing buildings ranging from residential complexes to commercial skyscrapers, industrial facilities, and other facilities. For these spaces to be comfortable and efficient, chillers play an important role for HVAC systems. Whether it's office buildings, hospitals, or manufacturing facilities, maintaining the performance of your HVAC chiller would prove to be very ideal.

In this blog, we’ll explore the importance of chiller services, common issues, and why professional HVAC chiller services in Bronx are your best choice.

What Is an HVAC Chiller?

Chillers are very important components of HVAC systems, especially in large-scale applications. They remove heat from a liquid through a vapor-compression or absorption refrigeration cycle. The cooled liquid is then used to lower the temperature of a building or for industrial processes.

Chillers are essential in the Bronx because, during summer seasons, the heat is moist and the indoor spaces should be cool for people to live. They help in keeping running various industries.

Why is Chiller Maintenance Essential?

Scheduled maintenance of your HVAC chiller is crucial to avoid unexpected failures, ensure efficiency, and increase the lifespan of your equipment. Here are the key reasons why chiller services are important:

Energy Efficiency: A serviced chiller uses lesser energy and saves money through its operation.

System Reliability: Scheduled check and tune-ups can prevent that sudden breakdown and system downtime.

Cost Savings: Detection of possible malfunction would avoid big and expensive costs for its repair or even replacements.

Environmental Impact: Efficient chillers save the greenhouse gases emission and create a cleaner environment.

Common Problems of HVAC Chillers

Chillers are sophisticated appliances, and as with all other equipment, they usually develop faults after some period. Some of the common ones include;

Refrigerant Leaks: Low levels of refrigerants can result in low cooling efficiency.

Compressor Failures: A faulty compressor can stop the chiller from working.

Clogged Coils: Dust and debris buildup in condenser coils can restrict airflow and reduce efficiency.

Sensor Malfunctions: A faulty temperature or pressure sensor can lead to improper operation.

Scaling in Heat Exchangers: Hard water can cause deposits that reduce the efficiency of heat transfer.

Call an expert if you experience any of the following: poor cooling performance, strange noises, or high energy bills.

Bronx HVAC Chiller Services

Having a chiller that needs service, repair, or replacement is a good thing because professional HVAC services are available in the Bronx. Here is what you can expect from such service providers:

Chiller Installation and replacement

Whenever one is installing a new system or replacing the old one, the expert installation ensures that your chiller is installed properly for maximum performance.

Preventive Maintenance

Maintenance includes cleaning parts, checking the level of refrigerant, and inspecting electric systems for chillers to operate efficiently.

Diagnostics and Repairs

The expert uses advanced diagnostic tools to diagnose faults and recover your system within a minimum time that can affect your operations.

Efficiency Optimization

Economically friendly chillers are not only cost-effective but also help in achieving your sustainability goals. Experts can change your system to achieve peak performance.

Emergency Services

Chiller problems often occur at the worst possible time. Reliable HVAC companies have 24/7 emergency services to ensure that your system will work when you need it most.

Tips for prolonging Chiller Longevity

To extract the best performance out of your chiller, these best practices must be followed:

Schedule regular maintenance with certified professionals

Clean and clear debris from the condenser coils

Keep checking the refrigerant levels and keep up with speedy leak repairs

Upgrade to high-energy efficiency upgrades when possible in your budget

Train your employees in early symptoms of malfunctioning chillers

Conclusion

Many buildings and facilities in the Bronx, New York, have cooling systems based on HVAC chillers. Keeping the system at the peak condition is important for energy efficiency, cost-effective operation, and uninterrupted operations. A partnership with a trusted HVAC service provider will ensure that your chiller performs reliably all year long.

Do you have a need for professional services for an HVAC chiller? If you're looking for HVAC services in the Bronx, consider coming to us at American HVAC, where we'll put all our experience of years toward fixing things right for you. We can provide installations, maintenance, and chiller repairs tailored to your specifications.

Keep it cool, we keep it cool—business too!

0 notes