#pressure vacuum vent valve

Explore tagged Tumblr posts

Text

Enhancing Industrial Processes through Skids and Pressure Vacuum Vent Valves

In the meticulous realm of industrial process management, mastering the utilization of skids and pressure vacuum vent valve is paramount. Often underestimated, these components play a pivotal role in ensuring the safety, efficiency, and reliability of various systems. Understanding their optimal deployment is indispensable for professionals in the field.

Efficient Deployment of Skids

Skids, modular platforms housing a variety of process equipment, are instrumental in streamlining and improving operational workflows. These pre-assembled units are crucial for addressing intricate process requirements in a compact and adaptable manner. Choosing the right skid entails careful assessment of specific process needs, including size, capacity, and compatibility with existing system elements.

Strategic positioning and installation of skids are equally crucial. They should be placed to facilitate easy maintenance and monitoring while seamlessly integrating into the overall process flow. Proper utilization of skids not only optimizes space utilization but also enhances efficiency and safety within operations.

Maximizing the Advantages of Pressure Vacuum Vent Valves

Pressure vacuum vent valves are essential for maintaining pressure equilibrium within storage tanks, guarding against the dangers of over-pressurization or vacuum conditions that could jeopardize tank integrity or the purity of stored contents.

Optimal utilization of these valves involves selecting appropriately sized and rated models for the task at hand, considering factors such as anticipated maximum flow rate, properties of stored substances, and prevailing environmental conditions. Regular checks and maintenance are also crucial to ensure these valves operate effectively and safely.

Conclusion: Achieving Operational Synchronization

The combined efficacy of skids and pressure vacuum vent valves underscores their mutual significance in efficiently managing industrial processes. By adeptly selecting, deploying, and maintaining these components, industry professionals can significantly enhance the safety, efficiency, and reliability of their systems. In the intricate landscape of industrial operations, the role and performance of each component are integral to success.

This article emphasizes the critical aspects of effectively leveraging skids and pressure vacuum vent valves within industrial environments, highlighting the importance of strategic selection, placement, and maintenance for superior system functionality.

For more information about Skids come and visit our website : https://www.treloar.com.au/

0 notes

Text

Erlinda Rodriguez, 21 (USA 1969)

Erlinda Rodriguez was seen at an ER in May of 1969. One month ago, she had been exposed to infectious hepatitis and was now suffering from symptoms consistent with it. She had missed a period, but told her doctor that she knew she wasn’t pregnant because she had an IUD. The doctor did not perform a pelvic exam.

X-ray studies of Erlinda’s gastrointestinal organs and gallbladder were ordered. The only abnormality was “nonvisualization of the gallbladder” and a repeat of the X-ray had the same results.

In June, Erlinda was seen at an obstetric clinic because she still had not had a period. Had the ER doctor performed a pelvic exam, it would have been immediately obvious that her IUD had come out. She was pregnant.

Pelvic exposure to radiation was estimated at 10 to 12 rads. Abortion under certain circumstances had already been legalized in New Mexico, and Erlinda and her husband feared the possible effects of radiation on their baby. She was promptly approved by a committee for a “therapeutic” abortion. Had the committee said no, Erlinda could have lived.

The hospital that carried out the abortion did not have a specialized vacuum uterine aspirator (which can still be lethal even when properly equipped). They had substituted a portable vacuum laboratory pump with a suction trap. It is unknown if Erlinda knew about the equipment substitution when she agreed to the abortion.

On June 30, 1969, Erlinda was put under sedation and her cervix dilated for the “safe and legal” abortion. After the cannula was put into her cervix, the vacuum device was turned on.

Immediately, a massive amount of bloody froth began to foam out of Erlinda’s body. The machine was turned off, but it was too late. Someone had connected the suction tube to the pressure outlet. Erlinda’s uterus had been pumped full of vacuum exhaust.

The tubing was reconnected and the abortion carried out, along with the removal of blood so full of air that it was frothy. The anesthetist was told to watch for signs of an air embolism. Only 30 seconds after having pressurized vacuum exhaust pumped into her body, Erlinda’s blood pressure was undetectable. Her heart rate dropped to 50 bpm and she had to be intubated, at which point she was noticed to be blue.

A cardiovascular surgeon was brought in six minutes after the massive drop in vitals. Closed chest massage was used for one minute, but Erlinda had no pulse. Her chest was opened for cardiac intervention.

Erlinda’s heart was so massively distended from a massive air embolism that it was nearly sphere-shaped. About 11 minutes after the embolism, needles were used to create vents in her heart. Air hissed under enormous pressure from each vent site.

After intensive efforts, Erlinda’s heartbeat was brought back to a strong sinus rhythm, but the damage had been done. She never regained consciousness and spent her last weeks comatose. She had to have a breathing tube and feeding tube put in. Decorticate rigidity indicated severe brain damage. Several urinary and respiratory infections later, Erlinda died on September 17, 1969.

The autopsy revealed extensive cerebral necrosis, tracheobronchitis, pulmonary edema, bronchopneumonia and gallstones.

Erlinda’s death was preventable on many levels. First, a pelvic exam after she reported missing periods would have immediately found the dislodged IUD before the radiation exposure could ever happen. Second, the study that reported her death recommended screening for pregnancy before conducting pelvic X-rays. The exposed pressure outlet on the hospital’s substitute equipment was unacceptably risky, and greater care with preparation would have found that the tubing was connected to the outlet valve before it was turned on. All equipment also should have been tested before it was actually put into anyone’s body.

Adding to the tragedy, we now know that the chance of X-rays during pregnancy harming an unborn baby is very small. According to the CDC, there is scientific disagreement on whether or not the amount of radiation in a diagnostic X-ray is sufficient to seriously harm an unborn child (although a large number of pelvic X-rays still warrant consideration and care). Erlinda died without knowing that her child was probably fine.

(Erlinda is Patient ER)

#tw abortion#pro life#pre roe legal#unsafe yet legal#tw ab*rtion#tw murder#abortion#tw malpractice#tw negligence#tw neglect#death from legal abortion#abortion debate#pregnant people deserve better#tw eugenics

8 notes

·

View notes

Text

10 minutes into the first episode of The Acolyte and the only thought I have is that there is NO WAY a burst pressure valve venting to the vacuum of space burns on fire like that

3 notes

·

View notes

Note

A muffled *SHLORP* and *POP* reverberated through Futaba, who was jolted atop the jiggling mound of her gut as she felt her tight, sweaty navel roll over and close around Sumire’s struggling curves, the soft pliable dough rolling over her shouting face like a soft duvet—if there wasn’t a possessive catboy in the process of trying to claim her as a permanent bellypet, she might have ever squealed a bit from the delight in having claimed a ‘pet’ of her own after so long, even if she still *totally* felt bad that her friend was stuffed into her sticky, pillowy soft bellybutton (which was clearly much better than Mona’s tight guts)—but now was clearly not the time!

Wet slurping rung out within Morgana’s belly as Futaba was beset both inside and out by tummy tumult-inducing pressure between the ever-tightening belt that was Morgana’s greedy gastric valve and the frustrated struggles of her new ‘party member’, it was all the NEET could do to vent out the near endless stream of belches their combined agitation swirled up, and groan out apologies to Sumire in the hopes it might calm her down, “SOOOOUUUUUURRRRRP—sorry again Sumi, I—BWEEEAAAAAURP—know it’s probably—HRRROOOOUURP—cramped in there tooOOUUUUURRRAARP, but struggling isn’t going to help eeAAAAAAAEEERP—either of us!” Despite her best attempts though, it seemed Futaba’s attempts at abdominal diplomacy were fruitless—with her friend somehow not appreciating the difficulty in maneuvering a gut that could fill a restaurant and continuing her struggles within Futaba’s admittedly sweltering, sticky navel, with her gut still a churning cauldron that transformed her mouth into a nonstop valve for a maelstrom of belches, and with the ridge of flab formed by Mona’s clenching guts continuing to advance up her wobbling hemisphere of a belly!

As she sunk lower and lower into his depths with each belly-jiggling wet ‘gulp’ of the sphincter, it was clear to Futaba that he truly did see them all as ‘key items’ not soon relinquished—that she could be spending even her whole *life* away from her precious collectibles rather than just a week, or even a month—the gamer girl had to rage. How had Mona become *this* greedy? It was almost yesterday that she was lounging back in her gaming chair, her arms propped up on her wobbly beanbag of a belly while Mona squirmed in her navel—but now, more than a small town’s worth of food filled his belly, formerly alongside all his challengers, only for him to shunt them deeper into his guts to make room for even *more* food—Futaba was almost insulted that she was somehow not enough for him—that he was *still* this hungry! How could Futaba, who was a fourth of Morgana’s size and nearly filled his belly on her own, still be destined to be winding through a fat cat’s guts?! Raining blows with her hands and feet did little more than send rippling waves across her marshmallowy fat as each rebounded with a *BWOM*, only eliciting more raucous burping from Futaba and confused yelps from poor Sumire. It seemed no amount of ‘mashing’ could wrest Futaba’s belly from the greedy siphon—ultimately only succeeding in bobbing her wildly atop the room filling ball of jiggly fat that was her belly, rocking like a ship at sea in a storm—while her street-filling rear bounced and clapped behind her. Was this really ‘game over’? The pressure from the hungry valve inching up the curve of her stomach only seemed to grow more and more while the ring of bellyfat oozing over its edges receded deeper into Mona’s guts accompanied by forceful wet slurping—even having grown a bit from engulfing Sumire, Futaba’s sphincter-made muffin top steadily squished down further and further.

The dread of being banished to the catboy’s belly dungeon became even more real to the gamer girl as the sensation of being vacuumed down by Mona’s guts so tightly and greedily only seemed to intensify—forcing as much of her belly fat as possible into the hot, wet enclosed space of his innards as though she were dough getting packed into a biscuit can! Grunts from Morgana rumbled through the walls—“Get—uunngh—down—hrrrff—there—mmmph—OOOOUURRRPracle!”—was this it? Futaba felt herself bouncing more quickly atop her wobbly marshmallow belly, the sphincter clenched tightly as if trying to pinch off the section of doughy flab it had sucked down—it was too much! As if pinching a garden hose, Futaba could feel the upper swell of her gut grow rounded and taut, the sphincter trapping and compressing all the gas in her belly into one place—swelling out with a gurgling *FWOMPH*. Like a hundred tiny jabs, fizz pushed out against Futaba’s belly—the gamer feeling her gut transforming into a violently bubbling cauldron—until finally—“MRRRPH”. The NEET’s cheeks ballooned outward and the gastric whirlwind that had been brewed by all the mounting pressure flew up and out of her mouth with a deep, rattling belch that shook Futaba’s gut and Morgana’s belly walls alike, “UWAAAAUUUBEEAAAAWHOOOOOUUUUURRRRRP!” Despite being drenched in spittle and sweat, Futaba felt a moment of relief atop her wobbling waterbed gut—but it was shortlived—the unfortunate side effect of releasing all her trapped gas having been to noticeably decompress the curve of her belly that remained unclaimed by Morgana’s greedy intestines. The valve wouldn’t miss this opportunity, bouncing Futaba atop her massive gut a final time before quickly *SHHHLUUURRRPRING* up the rest of it, leaving only Futaba’s (comparatively) skinny form exposed. After belting out her frustrations in the hopes they would reach Mona through his mattress-thick fat, Futaba was sucked down to join her own squishy ocean of a belly through Morgana’s hungry drain—the only signs of her having been there at all being a cute ‘pop’ as the sphincter closed around Morgana’s newest prisoner, and the reverberations of her battle cry against a much, much emptier, *hungrier* belly.

Morgana flinched from the gut-quaking impact as the strain to slurp down Sumire’s squirming curves—which were so stubbornly lodged right at the entrance to his safe, winding intestines—was suddenly replaced with the overwhelming pressure of an enormous mass nearly a fourth of his own titanic size: Futaba’s own room-filling flab, which landed like a cannonball in his lower belly following the NEET’s gymnastic mishap. There was a muffled squelch as Morgana’s sensitive, greedy valve stretched painfully to contain its new sloshing payload, in the process loosening its hold on Sumire’s struggling fat, only to feel a competing force of suction pulling *against* his own as Sumire’s struggles grew fainter and fainter, while the wobbling mound lodged in his sphincter seemed to shudder and grow—Morgana grunted in exasperation, Futaba stole his pet! He had planned for the sake of his belly and Futaba’s to take his time introducing his last bellypet to the rest coursing through his winding intestines, but clearly she needed to see who’s boss here! Mona huffed, pushed down with both hands on the enormous, swollen dome of his gut as deep as he could reach with a *GLURP*—again submerging his arms up to the shoulders in his own wobbling black ocean of catfat—and inhaled sharply. There was a terrible, bubbling gurgle, jiggling bumps dotting the surface of Mona’s otherwise smooth mountain of a belly—his eyes shot open as his cheeks were once again filled with air as eager to escape the commotion of tumultuous belly prison as Futaba was—but he wouldn’t let her, he had to have them all, he had to make them his! Morgana working his muscles and inhaling to jam Futaba into his guts—she may have been soft, but she was big—probably the biggest thing he’d ever eaten period! If glutting Haru into his guts was like shoving a water balloon into a hose, Futaba was a waterbed. With a gut that already took up so much space in Mona’s gut, the fat cat almost thought he wouldn’t be able to fit his pet in his intestines at all… *almost.* Morgana was nothing if not a greedy, gluttonous, and possessive host—and especially since enshrining the rest of his pets, particularly strong, soft, and flexible too!

“Sorry OOOOOUUURRRacle, with how—MMMNNF—big you aAAAAUUUURRre it’s probably going to—RRRRGH—be *especially tight* down there for you. Let’s get you packed in deep~” Teeth clenched, Morgana stifled the incoming burps and attempted to maintain focus as gas swirled in his stomach and a combination of discomfort and overwhelming greed roared in his intestines, before he began hurriedly pushing deeper and deeper into the churning rippling flab of his belly, pushing Futaba’s pillowy tummy and massively wobbling rear deeper into his hungry guts, *FWOMPH* *FWOMPH* *FWOMPH*, feeling his gastric valve inch further and further up the solid mass of girlmeat wriggling at the bottom of his stomach. To a spectator it must’ve looked like a rapidly undulating water balloon bouncing as if being dribbled, with almost deafening sloshes *GLUNK*ing to match. Finally, there was a *SHLURP* audible even through Mona’s growing waves of fat as a visible, rounded bulge pushed out into the fat cat’s lower guts, undoubtedly Futaba’s bloated, doughy belly shifting through Mona’s awaiting intestines—slightly wriggling as it squished down and around the winding dungeon of the fat cat’s belly kingdom. The sheer momentum of a solid ball of girlmeat a fourth of his own weight shifting into his intestines dropped Morgana’s stomach low with a heavy, sloshing bounce *GUUULLUUUNK*, before rebounding after a delay, like an enormous wad of pliable gurgling rubber. “Gwuuuuhhhnnn… M-Mwehehe there you are Oracle! Maybe some time in my ‘detention center’,” Morgana pat his belly as if to clarify, “will fix the distorted desires that made you want to steal my p—“

*GGRRRRMMMMMMUUUURRRRLLLLBBLLLLE*

Morgana’s gloating was interrupted by a brassy, angry growl that made his fat tremble. The fat cat huffed, holding his belly as it shook in agitation from the sheer force of Futaba’s belch combined with the shift in pressure from her final descent, his upper belly roll growing rounder and distending outward. Padding his paws around the turgid mass to rub it in small soothing circles, Mona grumbled in frustration—why had the pliable waves of his jiggling flabby throne turned solid now of all times, right when he was enjoying himself? The fat catboy grimaced as a growl sounded deep within his guts, tinged both by hunger and discomfort—there was a rhythmic *THUD* followed by a *BWOMPH* as the air pushed tighter and tigher against the confines of his belly, shuddering it—the pressure pushing his upper belly roll out further, and further, and further, until it was as tight as a drum—he couldn’t take it! Just when he thought he would pop, Mona’s eyes went wide—his throat was forced open, and a steaming, humid burst of belly fumes exploded out of his mouth in an enormous, lip flapping belch.

“HUOOOOOOOOORAAAAAUUUUUBWUOOOOOOOOAAAAAAAAAUUUUUUURP”

The deep, guttural roar shook the windows of every building in the Scramble as if to announce that it would all be *his* soon too—he was just that big and gluttonous now. Morgana’s lips rattled as the upper curve of his belly, which deflated visibly as the burp continued to taper off, and the street in front of him were showered with spittle. Even Makoto, deepest in his guts, seemed to feel the vibration of the belch as she alongside the other residents of Morgana’s belly kingdom squirmed in response to the flab-quaking expulsion. Mona, in turn, could feel his pets helplessly writhing and kicking in the sweltering, tight depths of his guts and merely licked his lips, eyes half lidded. He was delighted by intense sensation of live prey crammed where no one should be—through his sensitive intestines it was almost as if he could caress Makoto’s firm, ample rear, Haru’s hypnotically soft, memory foam like belly and ass, and Futaba’s own giant writhing stress ball of fat—all of them now ‘committed’ to his ‘belly ward’, fat bodies sliding like beads along the track of his guts, *his* to play with whenever he wanted. He was sure that over the duration of their ‘sentence’ that they’d all calm down a little and stop rolling up so much gas, but then again, the struggles just felt so *good*, and he bet they probably couldn’t hear him burping through his fat anymore anyway.

“Wow OOOOOOUUUUURRracle, you sure maAAUUUUUUURRRde a lot of room in—BWEEEEUURP—there!” The fat cat took another moment to appreciate his colossal, resoftened gut—the testament to his victory, to his capability as a ‘host’, to his greed—knowing that with his size and girth there was *no way* for any usurpers to his belly kingdom go reach them buried under so much inky flab, pulled in so deep by his greedy intestines. Just as Mona had hoped from downing so many bottom-heavy girls, their ‘generous donations’ to his figure were finally becoming apparent. Exceeding even the fatty, quaking boulders carried around by any of the girls, Morgana’s asscheeks and thighs had ballooned outwards and looked even more disproportionately large on his short stacked frame, each inky black orb bigger than a car—replacing a doorframe filing ass with a street filling one—and resting on tree trunk thighs, forced apart by the growing, oozing fat of his belly. *Surely*, he thought, it was much better to be packed under two rooms worth of cat flab in his intestines than stuck in his stomach where something may have happened to them—Morgana was almost jealous, he bet it was more comfortable being held as if swaddled up in a soft, warm blanket of fat in his guts than it was outside of them! He was more certain than ever that the girls would appreciate how *big* they had made him—bigger than he ever could have imagined he’d be, certainly bigger than any of his pets had ever been—and how much he relished in having them so *deep* and safe inside him—in fact, maybe they could stand to get a little *deeper*.

Drumming his digits along the soft inky ocean of his belly, Morgana yelled again through his wobbling layers of waving belly fat to his pets, “HoOOOOUUUULLLld on tight, I’m gonna work you guys doOOOOOOUUUUURRRwn a little moOOOOUUUUUre, but keep squirming, I wanna feel you aAAAEEEEUUUURRll for the *whole week*!” Snickering, Morgana began slowly rocking his hips back and forth—his car-sized, girlmeat enhanced ass rippling and bouncing as his belly swung slowly and pendulously. The gigantic, small house sized stomach waved and rolled like a waterbed filled with inky black syrup, shifting from one side to another with an accompanying *WOBUWOB* and a *GLUNK* before shifting gelatinously back into place. As his belly dance continued, Morgana tracked the solid bulges in his guts moving slipping down, down, down—there you were Makoto, so deep now, but still so spirited—forcing and stretching his intestines out with each frustrated jostle of her ass! And Haru, the slightly bigger bulge, a bit more subdued, like a pillow gently sliding down to join her friend. Finally there was Futaba again—gah—her huge, wobbling marshmallow of a belly was so tightly packed in there it was like he had glutted down a bowling ball at his former, house cat size—serves her right though! Morgana thought maybe spending a week in his guts would help Futaba understand just how badly he had been looking forward to one more test of skill between himself and Sumire, how much he craved the sensation of her struggling thunder thighs and gymnast gut in *his* belly! Now with more than a ton of girlmeat slowly pumping deeper through his intestines in rhythmic greedy pulses, Morgana sat with his eyes half lidded, lolling out his tongue as he let another fast-rising gust blow out of his gullet with a, “MweheheHEOOOOUUUUUUUUURLP”—the last cries of four girls who may never see the world outside his belly again.

Despite all the snacks and girls filling his stomach and guts, Morgana’s belly kingdom still needed something to be ‘whole’: a queen! Not the Queen that he could feel shuffling through his guts, but *his* queen—Lady Ann! Ah~ celebrating with the fair Lady Ann would be the perfect way to conclude Morgana’s gluttonous gauntlet! The fat cat puffed out the black monolithic wall of needy lard that was his belly in pride, fantasizing about how much Ann would praise him. He could picture it perfectly: his buxom queen and her unparalleled assets—an almost comically exaggerated hourglass figure wobbling across the Scramble towards him seductively, giving him a full show of the pale canyon of her cleavage and gargantuan mountain of ass that almost even rivaled his own size, twin jiggling mounds on either side of her perfect body bouncing as if to beckon to him. Craning her neck up to meet Morgana’s gaze at the peak of his mountainous belly and take in his enormity, “Mona, my knight in shining armor, you truly are a world class Phantom Thief, you really are all that food?” Gently tracing a manicured finger along the squirming bulge formed by Oracle, sending shivers down Mona’s spine before delivering a playful poke, watching as her finger was engulfed down to the knuckle, then the wrist, then the elbow in luxurious, gurgling catfat as if it were wobbling soft dough—how impressed she would be! Taking it as an invitation, his queen would dig her hands even deeper into his fat gut and begin to worship it, floored by its sheer size and the trophies on display from within, how he seemed to take after all them in some ways now—unimaginably soft like Haru, the alluring, powerful rear of Makoto and Sumire, and the sheer gluttony of Futaba. “Even after all that food, you still had room for all the girls? How brave!” “They were all *mine*, so I gulped them down naturally! I can even still feel them all allllll the way down here—where they’ll be for the foreseeable future! If you smothered yourself in my bellyfat you might even be able to hear them, but I don’t think you’d be able to see them with all this handsome belly in the way!” Eager to check in on his wriggling bounty, Ann would lean forward and sink deeper and deeper into the trembling wall of fat that was Morgana’s belly kingdom, allowing the sensitive belly flab around his navel to engulf her until only her wobbling, globular asscheeks remained exposed outside the jiggling embrace, clapping as she attempted to inch further and further in. Despite the size of his cavernous navel, the sensitive tight skin still allowed Morgana to feel every quake of Ann’s bra-straining breasts, heaving, fatty boob oozing out and over like a muffin-top, sloshing and slamming into each other with every movement and her cute, double rolled belly folding and wobbling against itself like two irresistibly squishy marshmallows—the fat cat would be helpless to stop himself from bucking his hips forward, his stomach swaying pendulously before wiggling gelatinously back into place and smushing Ann deeper and deeper into his fat. Ann would giggle and playfully tap the sensitive navel skin around her as she felt Mona working her further along so she could properly feel and hear his pets, “Oh you!” Finally, once a mere sliver of Ann’s asscheeks remained outside of Mona’s greedy navel like a pale piece of bellybutton jewelry, she could hear it. Beneath a chorus of gurgles, bubbling fat and greedy sloshes, Ann would just barely be able to make it out: the cries and struggles of Mona’s frustrated pets reverberating buried beneath an avalanche of cushiony belly flab—flab which she could still feel rumbling and growing around her! “I guess Mona won fair and square but this is ridiculous! I can’t bear to be without my precious setup for so long!” Clearest would be Futaba, recently glutted into the ‘dungeon’ of his belly kingdom, but if Ann listened closely, she could hear another, gentler voice muffled under an inconceivable amount of fat, “I suppose it is silly to say but I wish Makoto had sucked me down” (1/2)

To say Morgana was giddy with his string of victories was a major, gigantic JIGGLING understatement to say the least. Each new challenge, all titans of flab in their own rights - had been conquered one by one by their true master in gluttony! No venue could contain his mighty hills of flab, in the front or the back!

And his conquest was still incomplete.

"Now... for the crown jewel... my one, true queen~!"

There was no other thought in Mona's mind as he sloshed down the street. Even his restaraunt dominating hunger was taking a backseat, as the tubby cat daydreamed of what came next - the love of his life. The only one who could match him, not in size, but in perfection! No doubt gorging herself silly right now... Lady Ann!

Black waves of fur-covered fat washed over the streets of Shibuya, engulfing everything in their wake for minutes at a time! Cars, lamposts, mailboxes, all where temporarily wrapped in high-quality cat lard as Morgana jiggled on by. Even the occasional person, who couldn't get out of the way of the pitch-black wobble wave, was pressed into squishy oblivion without the culprit noticing! Firmly hugged by intoxicatingly soft flesh, which was cruelly ripped away after only a couple of minutes...

E-except for the few pedestrians and object that were directly in front of his his cavernous navel. Their stay might last a BIT longer than that-

"Oooh, I can't wait~! When she sees what I've- BWUUUUUUUAARP! -done, Lady Ann will have no choice but to fall for me!" Maybe it was the inhuman level of fullness coming from his belly, or the empowering sensation of his friends and former competitors stretching out his lower guts, but Morgana was losing touch with reality more and more with every step. Maybe if he had learned Makoto's handy dandy "sucking it in" trick, maneouvering to his beloved would be easier? Bah! But why deprive the world of alllll this~?

Anyway, the thief could see past his wobbling horizon of belly that he was getting close to the mall. The place he knew Ann would be gorging herself beautifully at... and he couldn't wait to join her.

-

Part 2 here.

2 notes

·

View notes

Text

Troubleshooting Common High-End Refrigerator Issues: When to Call the Experts

With their advanced features and energy efficiency, high-end refrigerators have become an essential part of modern kitchens. However, like any complex appliance, they may sometimes experience issues that require attention. While some problems can be fixed with basic troubleshooting, others demand the expertise of professionals, such as ice maker compressor repair in San Jose, CA.

This guide will help you identify common issues, determine if a quick fix is possible, and understand when to call in the experts.

Inconsistent Temperature

One of the most common issues with high-end refrigerators is temperature inconsistency. If your food spoils faster than usual or the fridge is too cold, it's time to investigate.

Causes and Solutions:

Dirty Condenser Coils: If the condenser coils are covered in dust or debris, they can't effectively dissipate heat. Regular cleaning with a vacuum or brush can resolve this.

Faulty Thermostat: Check the settings to ensure they haven't been accidentally adjusted. The thermostat may be faulty if your fridge doesn't respond to setting changes.

Blocked Vents: Ensure that the vents inside the refrigerator aren't blocked by food containers, as blocked airflow can impact temperature regulation.

When to Call the Experts: If cleaning the coils or adjusting the thermostat doesn't solve the issue, a deeper problem might be a failing compressor or a faulty temperature sensor. At this point, a professional inspection is recommended.

2. Ice Maker Malfunctions

High-end refrigerators often have integrated ice makers, which, while convenient, can have their problems.

Common Problems and Quick Fixes:

No Ice Production: This could be due to a clogged water line or an issue with the water filter. Check for any blockages and replace the filter if necessary.

Small or Misshapen Ice Cubes: A common culprit is insufficient water pressure or a partially clogged water inlet valve. Cleaning or adjusting the valve may solve this.

Ice Maker Jammed: Ice cubes that freeze together can jam the mechanism. Carefully dislodge any ice chunks with a soft tool or warm water.

When Professional Help is Needed: If troubleshooting the water line or filter does not restore proper function, there could be a mechanical or electrical problem in the ice maker's motor or control module. This is the time to call a commercial ice maker machine repair near me experts for a deeper assessment and repair.

3. Water Leaks

Water leaks indicate an issue with your refrigerator and can damage your kitchen floor. This problem should be addressed promptly.

Inspection Steps:

Check the Water Line: Ensure the water line that connects to the fridge is tightly secured and not cracked or damaged.

Inspect the Drain Pan: Locate the drain pan and check if it is cracked or overflowing. If it is, cleaning or replacing it can be a simple fix.

Clogged Defrost Drain: A blocked defrost drain can cause water to pool at the bottom of the refrigerator. Use warm water to flush out any debris from the drain.

When to Contact an Expert: If the leak persists after clearing the drain and securing the water line, the issue may involve the refrigerator's internal plumbing or the water inlet valve. Expert service is crucial to prevent further damage and ensure the correct parts replacement.

4. Strange Noises

Modern refrigerators are designed to run quietly, so unusual sounds are often an early warning sign of a problem.

Troubleshooting Steps:

Identify the Source: A rattling noise could indicate loose parts, while a buzzing sound might mean the ice maker is trying to fill with water when it's not connected.

Leveling Issues: Ensure your refrigerator is appropriately leveled; uneven placement can lead to loud humming or vibrating noises.

Condenser Fan: If the noise comes from the back of the fridge, the condenser fan might be dirty or faulty.

When to Call a Technician: Persistent noise or strange sounds, even after basic cleaning or adjustments, could indicate a worn-out motor or a failing compressor. These parts require specialized knowledge to replace or repair, making professional help necessary.

Conclusion

While high-end refrigerators are built to provide long-lasting service, issues can arise. Regular maintenance and prompt attention to small problems can prevent them from turning into major repairs.

However, for complex or persistent issues, contacting expert technicians ensures that your appliance receives professional care. Their expertise in handling sophisticated systems will restore your refrigerator to optimal performance, safeguarding your investment and peace of mind.

To learn more, visit the websites of the related agencies.

1 note

·

View note

Text

Breather Vent Market Size, Share, Analysis and Opportunities by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Breather Vent Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Breather Vent Market, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Breather Vent Market?

The breather vent market is expected to grow at a CAGR of 7.8% during the forecast period of 2024 to 2032.

What are Breather Vent?

A breather vent is a specialized device designed to allow air to flow in and out of a sealed container or system, such as tanks, vessels, or pipelines, while keeping out contaminants, dust, and moisture. Its primary function is to equalize pressure changes that occur due to temperature variations, liquid transfers, or operational activities, thereby safeguarding the integrity of the container and its contents. Breather vents may include filters or check valves to enhance their effectiveness, ensuring that only clean air enters while allowing gases to escape safely. By maintaining proper pressure and preventing vacuum conditions, breather vents play a crucial role in the safe and efficient functioning of various industrial applications, including chemical storage, fuel tanks, and wastewater treatment systems.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1927

What are the growth prospects and trends in the Breather Vent industry?

The breather vent market growth is driven by various factors and trends. The breather vent market is witnessing consistent growth, propelled by the rising demand for effective pressure management solutions across various sectors, including oil and gas, chemical processing, and wastewater treatment. As regulations concerning safety and environmental protection tighten, companies are increasingly utilizing breather vents to maintain the integrity of their storage systems and prevent contamination. The market features a diverse range of products, including vents equipped with advanced functionalities such as filters, check valves, and automated monitoring systems that enhance both performance and reliability. Additionally, the growing emphasis on sustainable practices and the need for efficient resource management are contributing to market expansion. With ongoing technological innovations and heightened awareness of air quality and safety, the breather vent market is well-positioned for further growth, serving a variety of applications across multiple industries. Hence, all these factors contribute to breather vent market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Inline Breather Vent

Threaded Breather Vent

Bayonet Breather Vent

Customized Breather Vent

By Material:

Metal Breather Vent

Plastic Breather Vent

Composite Breather Vent

By End-Use Industry:

Automotive

Aerospace and Defense

Manufacturing

Oil and Gas

Chemicals and Pharmaceuticals

Electronics

Food and Beverage

Others

By Sales Channel:

Direct Sales

Distributor Sales

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Parker Hannifin Corporation

Donaldson Company, Inc.

MANN+HUMMEL GmbH

L. Gore & Associates, Inc.

Pall Corporation

Porvair Filtration Group

Eaton Corporation plc

SMC Corporation

Bosch Rexroth AG

Festo AG & Co. KG

Swagelok Company

Emerson Electric Co.

IMI plc

Camfil AB

WAMGROUP S.p.A.

View Full Report: https://www.reportsandinsights.com/report/Breather Vent-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Medical gas pipeline systems (MGPS) are critical components in modern healthcare facilities, ensuring the safe and efficient delivery of medical gases such as oxygen, nitrous oxide, and medical air. These systems are designed to provide a continuous supply of gases directly to various points of use throughout hospitals, significantly enhancing patient care and operational efficiency. This article explores the landscape of MGPS suppliers, their offerings, and the importance of safety and compliance in their operations.

Overview of Medical Gas Pipeline Systems

MGPS are complex networks that transport medical gases from a central supply source to various outlets in a healthcare facility. These systems typically include components such as gas storage tanks, pressure regulators, valves, alarms, and distribution piping. The design and installation of MGPS must adhere to stringent safety standards to prevent contamination, ensure reliability, and maintain patient safety.

Key Components of MGPS

1. Main Gas Stations: These stations manage the high-pressure distribution of medical gases and often include automatic switch-over systems to ensure continuous supply.

2. Medical Compressed Air Stations: These facilities produce and supply medical air on-site, which is essential for various clinical applications.

3. Medical Vacuum Stations: Designed for suctioning secretions, these stations are crucial in surgical and intensive care settings.

4. Anaesthetic Gas Scavenging Systems: These systems safely vent unused anesthetic gases from operating rooms to prevent environmental contamination.

5. Cryogenic Tanks: Used for storing liquefied gases, cryogenic tanks are vital for hospitals with high gas consumption needs.

6. Distribution Piping: Typically made from copper due to its antibacterial properties, the piping must comply with international standards to ensure safety and reliability.

7. Monitoring Alarms: These alarms alert staff to any issues with gas supply or pressure levels, enhancing safety protocols within the facility.

Importance of Safety and Compliance

The safety of MGPS is paramount; failures can lead to dire consequences for patients. Historical data indicates that improper installation or maintenance has resulted in fatalities due to crossed pipelines or defective connectors. Therefore, suppliers must ensure that their systems meet established standards such as ISO 7396-1 and NFPA 99.

Regulatory Standards

Compliance with regulatory standards is critical for MGPS suppliers. In many regions, including Europe and North America, regulations dictate the design, installation, and maintenance of these systems. For instance:

- ISO 7396-1: This standard outline the requirements for piped medical gas systems.

- NFPA 99: This code provides guidelines for health care facilities regarding the safe use of medical gas systems.

- HTM 02-01: In the UK, this document details operational management for medical gas pipeline systems.

These standards help mitigate risks associated with gas supply interruptions and contamination.

Major Suppliers in the Market

Several companies dominate the MGPS supplier landscape:

1. Air Liquide Healthcare: Known for its comprehensive range of products and services related to medical gases, Air Liquide ensures compliance with international standards while providing robust support services including installation and maintenance.

2. Helix India: With over two decades of experience, Helix specializes in providing cost-effective solutions for medical gas distribution. Their focus on quality materials and after-sales service sets them apart in the industry.

3. Johnson Medical: This company emphasizes operational management through detailed guidelines that ensure safe and reliable MGPS installations.

4. Local Suppliers: Many regions also have local suppliers who offer tailored solutions based on specific healthcare facility needs while adhering to national regulations.

Conclusion

The role of medical gas pipeline system suppliers is crucial in ensuring patient safety and operational efficiency within healthcare facilities. As technology advances and regulatory requirements evolve, these suppliers must continue to innovate while maintaining compliance with established safety standards. By prioritizing quality materials, skilled installation practices, and ongoing maintenance support, MGPS suppliers contribute significantly to enhancing healthcare delivery worldwide.

In summary, a well-designed MGPS not only supports clinical operations but also plays a vital role in safeguarding patient health—a responsibility that suppliers must take seriously as they navigate an increasingly complex healthcare environment.

0 notes

Text

Understanding Your Home's Plumbing System

Your home’s plumbing system is an intricate network of pipes, valves, and fixtures that work together to supply clean water and remove waste. Though it often operates behind the scenes, understanding how your plumbing system works is crucial for maintaining it, preventing issues, and making informed decisions during repairs or renovations. This article will guide you through the basics of your home’s plumbing system, from its components to common issues and maintenance tips.

1. The Basics of a Plumbing System

At its core, a plumbing system consists of two main subsystems: the water supply system and the drainage system.

Water Supply System: This subsystem brings fresh water into your home from a municipal supply or a private well. It operates under pressure, which allows water to flow through pipes to various fixtures like sinks, toilets, and showers. The water supply system includes a network of pipes, valves, and faucets, as well as a water meter to measure usage.

Drainage System: The drainage system, also known as the drain-waste-vent (DWV) system, is responsible for removing wastewater from your home and venting harmful gases. Unlike the water supply system, the drainage system relies on gravity to carry waste and water out of your home through a series of pipes that connect to a sewer line or septic tank. The venting aspect prevents a vacuum in the pipes, ensuring smooth water flow and preventing sewer gases from entering your living spaces.

2. Key Components of Your Plumbing System

Several key components work together to ensure your plumbing system functions smoothly. Understanding these components can help you identify potential issues and communicate more effectively with a plumber.

Pipes: Pipes are the backbone of your plumbing system, carrying water to and from various fixtures. They can be made from materials like copper, PVC, PEX, or galvanized steel, each with its advantages and limitations.

Valves: Valves control the flow of water within your plumbing system. Common types include shut-off valves, which allow you to stop the water supply to specific fixtures, and pressure-reducing valves, which regulate water pressure to prevent damage to your pipes.

Faucets and Fixtures: Faucets, showers, toilets, and appliances like dishwashers and washing machines are the visible components of your plumbing system. These fixtures are where you interact with the plumbing, using water for drinking, cleaning, and waste removal.

Water Heater: The water heater is a vital part of your plumbing system, providing hot water for showers, cooking, and cleaning. It can be powered by electricity, gas, or solar energy, and it’s essential to maintain it properly to ensure efficiency and longevity.

Traps and Vents: Traps are U-shaped sections of pipe located under sinks, bathtubs, and showers. They hold a small amount of water to block sewer gases from entering your home. Vents, on the other hand, allow air to enter the drainage system, ensuring smooth water flow and preventing pressure build-up.

3. Common Plumbing Issues

Understanding your plumbing system also involves being aware of common issues that can arise. Recognizing these problems early can help you take prompt action and prevent costly repairs.

Leaks: Leaks are one of the most common plumbing issues, often caused by worn-out seals, corroded pipes, or loose connections. Leaks can lead to water damage, mould growth, and higher utility bills if not addressed promptly.

Clogs: Clogged drains and toilets are frequent problems that occur when debris like hair, grease, or non-flushable items block the pipes. Regular maintenance and mindful usage can help prevent clogs.

Low Water Pressure: Low water pressure can be caused by various factors, including pipe corrosion, leaks, or build-up of minerals in the pipes. It’s essential to diagnose the underlying cause to restore adequate water pressure.

Running Toilets: A running toilet is typically caused by a faulty flapper or fill valve. This issue can waste a significant amount of water if not fixed promptly.

Water Heater Issues: Water heaters can develop problems like sediment build-up, leaks, or malfunctioning thermostats. Regular maintenance, such as flushing the tank, can help prevent these issues.

4. Maintenance Tips for a Healthy Plumbing System

Regular maintenance is key to keeping your plumbing system in good working order. Here are some essential tips:

Inspect for Leaks: Regularly check for signs of leaks around faucets, pipes, and fixtures. Address any issues immediately to prevent water damage.

Clean Drains: Use drain screens to catch debris and prevent clogs. Periodically flush your drains with hot water and a mixture of baking soda and vinegar to break down build-up.

Maintain Your Water Heater: Flush your water heater annually to remove sediment and improve efficiency. Check the anode rod and replace it if necessary to prevent corrosion.

Monitor Water Pressure: Keep an eye on your water pressure using a pressure gauge. If it’s too high, consider installing a pressure-reducing valve to protect your pipes.

Insulate Pipes: Insulate exposed pipes, especially in cold climates, to prevent freezing and bursting during winter.

Schedule Professional Inspections: Annual inspections by a licensed plumber can help identify potential issues before they become major problems. A professional can also provide advice on maintaining your plumbing system and recommend necessary repairs or upgrades.

5. When to Call a Professional

While many plumbing issues can be addressed with DIY solutions, some situations require the expertise of a professional plumber. Knowing when to call a plumber can save you time, money, and stress.

Persistent Leaks: If you’ve tried to fix a leak, but it keeps coming back, it’s time to call a professional. Persistent leaks can indicate a more serious underlying issue.

Sewage Smells: If you smell sewage in your home, it could indicate a problem with your sewer line or venting system. This issue requires immediate attention from a plumber.

No Hot Water: If your water heater isn’t producing hot water, and you’ve checked the basics (like the thermostat and pilot light), it’s best to call a plumber. The problem could be due to a faulty heating element or other internal issues.

Major Renovations: If you’re planning a major renovation that involves plumbing, it’s essential to consult with a plumber to ensure the work is done correctly and complies with local codes.

Conclusion

Understanding your home’s plumbing system is essential for maintaining it, preventing common issues, and making informed decisions when problems arise. By familiarizing yourself with the basic components, common problems, and maintenance tips, you can keep your plumbing system running smoothly and avoid costly repairs. Remember, when in doubt, don’t hesitate to call a professional plumber to ensure your plumbing system is in good hands.

0 notes

Text

Load Port Module: The Essential Link Between Wafer Transport System and Process Tool

A Load Port Module serves as the interface between a wafer transport system and a semiconductor process tool such as an etcher or deposition system. It facilitates the safe and ultra-clean transfer of wafers from cassettes stored in the transport system into the vacuum environment of the process chamber for semiconductor fabrication steps. Let's take a closer look at the key components and functions of this critical module. Wafer Cassette Access The front end of a loadlock in Load Port Module includes a cassette-loading station where standard 25mm wafer cassettes containing up to 25 wafers can be automatically loaded and unloaded. A robotic handler on the transport system sets the cassette into place and latches it securely. An environmentally sealed door then closes to maintain isolation of the cleanroom air from the vacuum system. Sensor inputs confirming cassette presence and door closure status are relayed to the process tool's control system. Vacuum-Compatible Design Since wafers must be transferred between the atmospheric cassette environment and high-vacuum process chambers, a Load Port Module needs vacuum-compatible construction. Chambers, bellows sections, and sealing joints are machined from non-outgassing stainless steel or aluminum alloys certified for ultra-high vacuum contact. Viton O-rings, metal gaskets, and precision actuators enable dependable closure and integrity testing of all interfaces down to vacuum pressures below 1x10^-7 Torr. Wafer Transfer Mechanisms Various transfer mechanisms are incorporated into load port designs depending on the specific process tool interface. Common configurations include a linear motor-driven blade that reaches into the cassette to pick wafers one at a time or a robotic arm capable of lifting an entire shelf of wafers simultaneously. Cameras and light sources aid alignment while sensors confirm contact and monitor for particles during extraction and placement into the loadlock chamber. Loadlock Chamber Contained within the load port housing is a small, sealable loadlock chamber where wafers can be coated or undergo vacuum bake-out procedures before entering the process chamber. Magnetic or mechanical end effectors gently grip wafers during transfer to stationary wafer pedestals inside the chamber. A turbo pump then evacuates air from the chamber to prepare for opening the valve to the process tool. Closing this valve isolates the loadlock to allow venting back to atmospheric pressure for wafer removal. Chemical Delivery Ports Some advanced load port designs accommodate ports for purge gas, chemical, or vapor delivery into the loadlock chamber or direct wafer surfaces. This enables pre-etch surface treatment, post-process cleaning, or thin film deposition capabilities directly on the wafers without needing to move them to a dedicated tool. Integrated mass flow controllers ensure precise chemical dosing and vacuum-safe plumbing routes all lines to the chamber.

Get More Insights On This Topic: Load Port Module

#Load Port Module#Semiconductor Industry#Manufacturing#Automation#Material Handling#Robotics#Semiconductor Equipment#Integrated Systems#Industrial Technology#Port Logistics#Container Handling

0 notes

Text

How to Change the PCV Valve on a Mazda 6: 3.0L 04 to 08

How to change the PCV Valve on a Mazda 6 with a 3.0L from 2004 to 2008. You may be wanting to do a thorough maintenance on your Mazda 3.0L and found the PCV Valve isn’t in plain sight. Not to worry, this quick and short article will go over where to find it and how to replace it.

Most people don’t realize how crucial a PCV Valve is. When they stop functioning like the should be, problems can arise. Your car can start using oil and burn it out the tail-pipe, or start blowing gaskets. The PCV Valve balances the crankcase pressure while the pistons are in motion. Without this valve, the crankcase can build up pressure and cause your gaskets to start leaking. On the other hand, with the valve in the stuck open position, will make your engine to suck oil into the intake and burn oil.

How the PCV Valve on a Mazda 6 3.0L Works

I have mentioned what can happen if it isn’t working properly. However, it can be helpful to know what it does. PCV stand for “Positive Crankcase Ventilation.” The PCV valve system operates on a straightforward principle. It regulates the pressure in the crankcase. Connected to the intake, it modulates vacuum levels. When the engine is at idle, the vacuum is high. With the high vacuum, the check valve restricts vacuum from being pulled on the crankcase. As the RPM increases and vacuum drops, the valve opens wider, permitting more pressure into the intake. This pressure and gases then re-enter the combustion cycle, burning off alongside fresh fuel and air. This prevents condensation in the oil, and keeps gaskets from leaking due to pressure. So, basically, when the engine is at idle or low RPM, the crankcase isn’t under that much pressure. When you increase the RPM’s, the crankcase starts to build pressure. The regulated vacuum, releases that pressure and allow the engine to burn off the excess pressure. Do not think that a PCV Valve is only for emissions, there are many articles that make that statement. California required this Valve in 1961. Car engines up till then, just vented the oil vapor straight to the atmosphere. By venting straight into the air, you had some pollutants, but you also had oil usage. The PCV valve just allows the oil vapor to go back into the combustion chamber to be burned. This reduces the number of pollutants released by the engine. However, the PCV also reduces how much oil an engine loses. Learn more about how a PCV valve works reading my article: How Does a PCV Valve Work.

What to Look for With a Bad PCV Valve on a Mazda 6

Most of the time, when a PCV Valve goes bad, the driver doesn’t even notice while driving. What you may notice, is oil puddles under the car, or the car smoking out the exhaust. It can affect the car’s performance in some instances, but normally not. Depending on the engine, sometimes, although rarely. A defective PCV Valve can cause the engine to misfire, or stumble upon acceleration. What To Look For If Valve Is Stuck Closed - Whistling or hissing sound coming from the engine - Oil leaks, most commonly from the valve cover gasket - A decrease in your fuel mileage - Possible “Check Engine Light”. This would be set off if your emission levels are far enough off. What To Look For If Valve Is Stuck Open - Excessive oil residual build up around the PCV Valve hose or around the valve cover - Rough idle or even misfiring, rare possibility in noticing a drop in performance - Harder to start after the car has sat for a period of time - Blue, gray or white smoke coming from exhaust pipe, meaning it is burning oil

Locating Your PCV Valve on Your Mazda 6 3.0L

You will find at the very back of the engine, a hose that curves downward. This hose is the PCV Valve hose and the valve is down and below the plenum. You will be removing the hose from the plenum and from the valve itself. There is a bracket that mounts a module and a wire retainer, remove this with two bolts . This will give you room to move your hand around. Disconnect the small bolts to the module and bracket, and peel them back out of the way. No need to disconnect wires or hoses from this.

Remove the PVC Hose by releasing the clamp and pulling it back. Pull the hose from the plenum and then pull it off the PCV Valve. There is a smaller hose also going to the plenum for you to remove. Looking at the where the PCV Hose goes to the plenum, this next hose is to the right and a little below it. Again, pull and slide the clamp back and pull this hose back and push it out of the way. You will now have a clear view of the PCV Valve. Using a long pair of needle nose pliers. Grab a hold of the square part of the valve and twist it counter clockwise, while pulling lightly upward. Using the same pliers, take the new valve and put it back into the hole and twist it clockwise. This all could possibly be done by hand. So, you can try it first with you hand first. Now reconnect the PCV Hose, then the smaller hose. Put the bracket back to the firewall and you have successfully change a PCV Valve on a Mazda 6 3.0L

Video How to Change the PCV Valve on a Mazda 6: 3.0L 04 to 08

Shop Amazon for parts related to replacing the PCV valve on a Mazda 6. Read the full article

0 notes

Text

Understanding the Importance of Pressure Vacuum Vent Valves and Dry Break Couplings in Industrial Operations

In the complex field of industrial fluid management and storage, the effectiveness and safety of processes are significantly influenced by the caliber and dependability of the components utilized. Among these, pressure vacuum vent valves and dry break coupling emerge as essential for any entity engaged in the movement or containment of fluids.

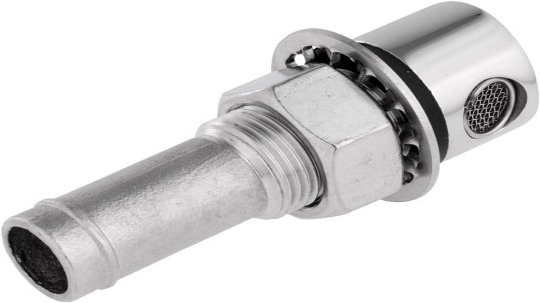

Pressure Vacuum Vent Valves: Critical for Safety and Operational Integrity

The pressure vacuum vent valve plays a crucial role in the safe storage of flammable liquids. It fulfills a dual function: it regulates internal pressure to prevent tank over-pressurization and subsequent rupture or explosion by opening to release excess pressure when it surpasses a certain threshold. Furthermore, it allows air to enter the tank to counteract a vacuum as liquid is dispensed, maintaining both tank integrity and the quality of the contents. The indispensable nature of pressure vacuum vent valves lies in their ability to preserve both safety and efficiency in operations.

Dry Break Couplings: Ensuring Secure and Clean Liquid Transfer

Designed for a leak-proof and safe transfer of liquids, dry break couplings facilitate connections and disconnections without product loss or environmental exposure. This characteristic is particularly vital in the handling of hazardous or delicate liquids. The adoption of dry break couplings significantly enhances safety by reducing spillage risks, which can lead to environmental damage and present serious safety concerns. Moreover, these couplings protect workers by limiting their exposure to harmful substances.

Conclusion: Enhancing Safety and Efficiency Through Synergistic Component Use

The combined use of pressure vacuum vent valves and dry break couplings significantly boosts the safety and efficiency of industrial fluid handling operations. Their implementation not only meets safety standards but also demonstrates a dedication to protecting the environment and achieving operational superiority. For industries involved in fluid management, investing in superior pressure vacuum vent valves and dry break couplings is a pivotal measure towards fostering a safer, more efficient, and environmentally friendly operation.

This article succinctly explores the pivotal roles of pressure vacuum vent valves and dry break couplings in maintaining industrial safety and operational efficiency, underscoring their necessity in fluid handling processes.

For more information dry break coupling come and visit our website : https://www.treloar.com.au/

0 notes

Text

Revitalize Your Heating System: A Spring Cleaning Guide by a Trusted Plumber in Kensington

As the days grow longer and temperatures begin to rise, it's time to give your heating system some much-needed attention. With proper maintenance, you can ensure that your heating system operates efficiently throughout the year, keeping you warm and comfortable during the colder months. Follow this comprehensive guide, recommended by a trusted plumber in Kensington, to spring clean your heating system and prepare it for the months ahead.

Inspect and Clean Radiators Start by inspecting all radiators in your home for signs of dust, dirt, or debris buildup. Use a vacuum cleaner with a brush attachment to gently remove any dust or debris from the radiator fins and surrounding areas. Pay close attention to the radiator valves and bleed them if necessary to release any trapped air. This simple task can help improve the efficiency of your heating system and ensure that heat is distributed evenly throughout your home.

Check Boiler Pressure and Ventilation Next, check the pressure gauge on your boiler to ensure that it falls within the recommended range. If the pressure is too low, use the filling loop to top up the boiler with water until the pressure reaches the correct level. Additionally, check the boiler vents and flues for any obstructions or blockages that could affect ventilation. Clear away any debris or vegetation from around the vents to ensure proper airflow and prevent carbon monoxide buildup.

Test Thermostat Functionality Test your thermostat to ensure that it accurately detects and responds to changes in temperature. Set the thermostat to a higher temperature than the current room temperature and listen for the sound of the heating system activating. If the heating system fails to turn on, or if the temperature does not rise as expected, it may be time to replace the thermostat or have it serviced by a qualified plumber in Kensington.

Flush and Bleed Heating System Consider flushing and bleeding your heating system to remove any trapped air or sediment that could hinder performance. Start by turning off the boiler and allowing it to cool completely. Locate the bleed valves on each radiator and use a radiator key to open them slightly. Once you hear a hissing sound and see water start to flow, close the valve tightly. Repeat this process for each radiator in your home to ensure optimal heating performance.

Schedule Professional Maintenance Finally, consider scheduling professional maintenance with a qualified plumber in Kensington to ensure that your heating system is in good working order. A professional plumber can perform a thorough inspection of your boiler, radiators, and pipes, identifying any potential issues and addressing them before they worsen. Regular maintenance can extend the lifespan of your heating system and prevent costly repairs down the line.

By following these spring cleaning tips recommended by a trusted plumber in Kensington, you can ensure that your heating system operates efficiently and effectively throughout the year. Taking proactive measures to clean and maintain your heating system can save you time, money, and hassle in the long run, allowing you to enjoy a warm and comfortable home environment.

#plumber services#plumber in london#plumbers near me#boiler repairs#emergency plumber near me#plumber#plumbing

0 notes

Text

Can a Gurgling Toilet Fix Itself?

This common household issue can be both annoying and concerning. But before you break out your toolbox or call a plumber, you may be wondering if this problem will just magically fix itself. After all, no one wants to deal with the hassle and cost of repairing a toilet.

Well, let's dive in and explore whether a gurgling toilet is something that can resolve on its own or if action needs to be taken immediately. Get ready to flush away any doubts as we debunk this myth in our blog post "Can A Gurgling Toilet Fix Itself?" So sit back, relax, and read on for some valuable information on this pesky plumbing predicament!

Understanding the Cause of a Gurgling Toilet

1 . Venting Issue

A common cause of a gurgling toilet is a venting issue. Every plumbing system has vents that allow air to escape, preventing pressure buildup. If the vent becomes clogged or blocked, it can cause air to become trapped in the pipes and result in a gurgling noise. This issue can often be fixed by clearing any debris from the vent or using a plunger to remove any blockages. However, if the problem persists, it may require professional assistance.

2. Blocked Sewer Line

Another potential cause of a gurgling toilet is a blocked sewer line. This can occur due to tree roots invading the pipes, debris buildup, or a collapsed pipe. If this is the case, the gurgling sound may be accompanied by other signs such as slow draining or water backup in other fixtures. A blocked sewer line is not something that can fix itself and will require the help of a professional plumber to properly address the issue.

3. Water Level Issue

In some cases, a gurgling toilet may be caused by a simple water level issue. If the water level in the tank is too low, it can create a vacuum effect and cause gurgling noises. This can easily be fixed by adjusting the water level or ensuring that the fill tube is properly connected to the overflow pipe.

Can a Gurgling Toilet Fix Itself?

Based on the possible causes of a gurgling toilet mentioned above, it's clear that this issue cannot fix itself. Whether it's a venting issue, a blocked sewer line, or a water level problem, all of these require some form of intervention to be resolved. Ignoring the gurgling noise and hoping that it will go away on its own can lead to further damage and potentially more expensive repairs down the line.

Some Tips to Fix a Gurgling Toilet

1 . Check the Water Level

Before trying any other solution, it is important to check the water level in your toilet tank. Make sure that there is enough water for a proper flush. If the water level is too low, simply adjust the float valve to increase the amount of water in the tank.

2 . Look for Clogs

Gurgling sounds from your toilet could be a sign of clogs in the toilet trap or the main sewer line. Use a plunger to try and clear any potential clogs in the toilet trap. If that doesn't work, you may need to call a professional plumber to check for clogs in the main sewer line.

3 . Check the Ventilation System

The gurgling sound could also be caused by a blocked ventilation system. The toilet vent pipe, located on the roof of the house, allows air to enter the plumbing system and helps maintain proper pressure for drainage. If this vent becomes clogged with leaves or other debris, it can cause gurgling sounds in your toilet. In this case, you may need to call a professional to clear out any obstructions in the vent.

4 . Inspect the Toilet Flapper

A damaged or improperly placed toilet flapper can also cause gurgling sounds. The flapper is a rubber valve that controls the flow of water from the tank to the bowl. If it is not sealing properly, water can slowly leak into the bowl, leading to gurgling sounds and increased water bills. Make sure the flapper is in good condition and properly seated in its place.

5 . Check for Plumbing Issues

If none of the above solutions work, there may be a more serious plumbing issue causing the gurgling sounds. This could include problems with the sewage line, septic tank, or even tree roots growing into the pipes. In these cases, it is best to call a professional plumber who can properly diagnose and fix the issue.

FAQs

What Precautions Should I Take With My Gurgling Toilet?

Gurgling toilets are a common issue in households and can be caused by various reasons. If you have a gurgling toilet, there are certain precautions that you should take to prevent further damage and fix the issue.

Avoid flushing foreign objects – Flushing foreign objects such as baby wipes, sanitary products, or even excessive toilet paper can cause clogs in the pipes, leading to a gurgling toilet.

Do not use chemical drain cleaners – Chemical drain cleaners may seem like an easy fix for a gurgling toilet, but they can actually corrode and damage your pipes, making the issue worse.

Regular maintenance checks – It is important to regularly check the pipes and plumbing in your home to ensure there are no blockages or leaks that could lead to a gurgling toilet.

How Much Does It Cost to Fix a Gurgling Toilet?

The cost of fixing a gurgling toilet can vary depending on the cause and severity of the issue. In some cases, a simple fix such as unclogging the pipes may only cost a few dollars. However, if there is extensive damage to the plumbing system, it could cost hundreds or even thousands of dollars to fix. It is always best to consult a professional plumber for an accurate quote and proper diagnosis of the issue.

Can I Fix a Gurgling Toilet Myself?

In some cases, gurgling toilets can be fixed by simple DIY solutions such as using a plunger or drain snake to unclog the pipes. However, if the issue persists or is caused by more complex plumbing problems, it is best to leave it to the professionals. Attempting to fix a gurgling toilet without proper knowledge and experience can potentially cause more damage and end up costing you more in the long run.

Conclusion

So, can a gurgling toilet fix itself? In most cases, no. It is important to address any gurgling sounds coming from your toilet as they could be a sign of potential plumbing issues. By following these tips, you can hopefully fix the issue and prevent any further complications. However, if the problem persists, it is always best to seek professional help for a proper solution. Don't let a gurgling toilet go unchecked – take action to fix it as soon as possible. So, when you hear that familiar gurgling sound, don't panic! With the right knowledge and steps, you can resolve the issue and have your toilet functioning properly again. Remember to regularly check for clogs, inspect the ventilation system, and maintain your toilet's components for proper function.

0 notes

Text

What is a stainless steel flange?

Stainless steel flanges play a crucial role in various industrial applications, serving as essential components in piping systems. These robust connectors facilitate the assembly and disassembly of pipes, providing a secure and leak-proof connection. At Bullion Pipes & Tubes LLP, we take pride in being the foremost Stainless Steel Flange Manufacturer, Supplier, Stockist, and Exporter on a global scale. Our commitment to quality and precision has positioned us as industry leaders, providing a diverse range of stainless steel flanges to cater to the unique requirements of projects worldwide.

In this blog post, we will delve into the intricacies of ss flanges, exploring their uses, and key characteristics.

Understanding Stainless Steel Flanges

Stainless steel flanges are integral parts of piping systems designed to connect pipes, valves, pumps, and other equipment. These versatile components are crafted from high-quality SS Flanges, known for its exceptional corrosion resistance, durability, and strength. The use of stainless steel ensures that flanges can withstand harsh environmental conditions and maintain their structural integrity over time.

Key Features of Stainless Steel Flanges:

Corrosion Resistance: Stainless steel flanges offer excellent resistance to corrosion, making them ideal for use in environments with exposure to moisture, chemicals, and harsh weather conditions.

Strength and Durability: The inherent strength of stainless steel ensures that flanges can withstand high pressures and maintain their structural integrity over an extended period.

Temperature Resistance: Stainless steel flanges exhibit remarkable temperature resistance, allowing them to perform reliably in both extreme heat and cold conditions.

Stainless Steel Flanges Specifications

Specifications

ASTM A182, A240 / ASME SA182, SA240

Standards

ANSI Flanges, ASME Flanges, DIN Flanges, EN Flanges, BS Flanges, JIS Flanges, AWWA Flanges etc.

Dimension

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc

Size Range

1/2" (15 NB) to 48" (1200NB)

Pressure / Class

150#, 300#, 600#, 900#, 1500# & 2500#.

Type

Slip On Flanges, Weld Neck Flanges, Blind Flanges, Socket Weld Flanges, Orifice Flanges, Ring Type Joint Flanges, Threaded Flanges, Reducing Threaded Flanges, Lap Joint Flanges, Long Weld Flanges, Spectacle Blind Flanges, Paddle Blind Flanges, Ring Spacer Flanges, Backing Ring Flanges, Nipoflanges, Weldoflange, Flangeolet, Bleed, Drip & Vent Ring Flange, Forged Flange, Raised Face Flanges, Tongue and Groove Flange, Male & Female Flange, Reducing Flange, ANSI Plate Flange, High Hub Blind Flange, Square Flange, Expander Flange, Gasket Flange, Swivel Flange, Heavy Barrel Flange, Forged Steel Flange, Taylor Flange, Wire Seal Flange, Galvanized Flange, Drilled Flange, MS Flange, and Vacuum Flange

Flange Face Type

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Applications of Stainless Steel Flanges

Stainless Steel Flanges' durability, corrosion resistance, and high strength make them suitable for a range of applications. Here are some common applications of ss flanges:

Piping Systems

Chemical Processing Industry

Oil and Gas Industry

Water Treatment Plants

Power Generation

Food and Beverage Industry

Aerospace Industry

Shipbuilding

Pharmaceutical Industry

Construction Industry

Automotive Industry

Other Applications

Final Words!

Stainless steel flanges are indispensable components in various industrial applications, ensuring the integrity and efficiency of piping systems. When it comes to reliability, quality, and a diverse range of options, Bullion Pipes & Tubes LLP is your go-to partner.

Explore our comprehensive range of stainless steel flanges and experience the unmatched quality and service that has made us a global leader all across the globe in various countries such as Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and many other regions. Contact us today at [email protected] or [email protected] for all your stainless steel flange needs, and let Bullion Pipes & Tubes LLP be your trusted partner in success.

0 notes

Text

Types of Drainage

Drainage is a vital part of landscape design. It helps prevent soil erosion and protects plants and animals. It’s often out of sight, but it’s crucial to your property’s health.

The components of drainage systems include an outlet at the lower end; a main and submain ditches that collect water and convey it to outlets; and lateral drains, which remove water from the soil. Laterals can be arranged in either a uniform or random pattern.

Main Drains