#pp filter press manufacturer

Explore tagged Tumblr posts

Text

0 notes

Text

Enhancing Irrigation Efficiency with Top Water Filter Manufacturers in Gujarat

In the agricultural heartland of Gujarat, where efficient water management is crucial, water filter manufacturers play a pivotal role. The challenge of ensuring every drop counts is more pressing than ever. As a leading water filter manufacturer in Gujarat, Manan Water Tech understands the importance of precision in drip irrigation systems. These systems conserve water and optimize crop yield, making robust filtration a necessity.

The Importance of Filtration in Drip Irrigation for Gujarat’s Agriculture

Gujarat's agricultural landscape is diverse, ranging from cotton to various cereals and pulses. Drip irrigation is the lifeline that ensures crops receive the exact amount of water needed. However, impurities like sand, silt, and organic matter can clog the emitters without proper filtration, leading to uneven water distribution. For this reason, water filter manufacturers in Gujarat must focus on providing reliable solutions.High-quality filters, like the PP Disc Filters, effectively filter out impurities before they can cause any damage. As an irrigation filter manufacturer in Gujarat, we emphasize that effective filtration not only enhances crop protection but also reduces maintenance costs, allowing farmers to focus on what they do best: farming.

What Sets PP Disc Filters Apart?

As a premier water filter manufacturer company in Gujarat, we offer PP disc filters that stand out for their precision and durability. These filters are made from polypropylene, a material known for its resistance to chemicals and harsh environmental conditions. The filters are designed with micro-grooves that trap even the finest particles, ensuring your drip irrigation system operates without a hitch.

Precision Filtration: The tightness of the disc stack in our filters determines the filtration level, capturing particles that could otherwise clog the system.

Durable Construction: Made for Gujarat’s agricultural conditions, our PP Disc Filters withstand exposure to UV rays, chemicals, and temperature fluctuations.

Self-Cleaning Mechanism: This feature minimizes manual maintenance, saving time and labor costs.

Versatility: Whether you need an irrigation filter for surface water, groundwater, or recycled water, our filters can be tailored to meet specific needs.

Why We Are the Go-To Water Filter Manufacturer in Gujarat

Choosing the right water filter manufacturer in Gujarat is crucial for maximizing the efficiency and longevity of your irrigation system. We offer solutions that are not only cost-effective but also environmentally sustainable.

Enhanced Crop Protection: Our PP Disc Filters ensure even water distribution, promoting uniform crop growth and higher yields.

Reduced Maintenance: With our self-cleaning filters, you spend less time on system upkeep and more time on farming.

Cost-Effective: Investing in high-quality filters extends the life of your irrigation system, saving you money in the long run.

Sustainable Farming: By improving water efficiency, our filters contribute to sustainable agricultural practices in Gujarat.

Conclusion

For those in Gujarat seeking efficient and reliable filtration solutions, we stand out among water filter manufacturers. Our PP Disc Filters are designed to keep your irrigation system clog-free, ensuring it operates at peak performance.Whether you’re a small-scale farmer or manage a large agricultural enterprise, our filters provide the protection and efficiency needed to maximize yields and support sustainable farming practices. Learn more about how we can help you achieve your agricultural goals by visiting our website or contacting our team of experts.For further insights and industry news, check out Times Agriculture and stay informed on the latest trends in irrigation and water management.

0 notes

Text

FILTER ELEMENT ZCL-I-450B Steam turbine parts

FILTER ELEMENT ZCL-I-450B Steam turbine parts YOYIK is a research and development, production, sales, import agents in one of the manufacturing and processing enterprises. Our company was established in 2004. For more than 20 years, our company's products are widely used in electric power, petroleum, chemical, environmental protection, refractory materials, metallurgy, fire fighting equipment, natural gas, electronics, nuclear industry and other fields. Our company is willing to work with colleagues from all walks of life at home and abroad wholeheartedly cooperation to create a better future! Deyang YOYIK power plant, steel spare parts are as follows: Yoyik can offer many spare parts for power plants as below: #DF-FILTER ELEMENT ZCL-I-450B-DF diatomite deacidification filter HT718-00-CN activated carbon filter cartridge DP1A601EA03V/W chemical filter cartridge GX-630×3 hydraulic oil filter remover 0660D005BH3HC filter element cartridge XW-630×40H pleated filter cartridge WUI-A100×80S filter SFAX-40*10 filter hydraulic servo FX-60×3Q3 stainless steel filter cartridge WU-A400×50FS water filters KLS-50U/80 oil filter Q3UI-A250*5FS Stator Cooling Water Filter Element MSL-32 filter for water KLS-I filter GY93-100*30 Filter 0280D020BN4HC filter DP2B01EA10V/-W inline water filter XLSL-001-03 Hydraulic actuator working filter DP6SH201EA10V/-W oil and filter change cost 0500D020BN3HC oil-return filter 0508.1258T1201.AW017 oil filter house ZALX110×250-MZI oil feeder filter LH0060D005BN/HC pressure filter 0110D010BN3HC stainless steel filter cartridge 140.301.008 hydraulic filter ZD.04.AA.001 cartridge stainless steel filter housings SDGLQ-34T-36K filter HDX-10*3 filter SFBX-63*1 melt blown cartridge filter WFF-125-1 excavator filter element LX-630×180 oil filter JWU-400×180LYZ pp pleated filter cartridge SL-31/45 high pressure hydraulic filter TXX-160×30 oil hydraulic filter SFBX-1300×20 filter CFRX-100*30Q filter hydraulic oil NLX-160×1 FILTER ELEMENT ZCL-I-450B filter HH8370F48KNXBR24DC-YC03 oil press with oil filter GX-25×10 bulk oil filters WUI-A400×40FS 0.1 pp filter KLS-I actuator filter ZTJ-00-07 polypropylene fibre filter cartridge WFF-150-1 pp filter cartridge SG65/0.7 oil filter elements HC8314FCP16H filter HC4754FKP16Z oil and filter hydraulic oil filter DP6SH201EA10V/W filter TZX2-25*5Q3 filter pressure hydraulic TXX-100×50 filter WYX-400*1012 filter SFBX-63*3 water filter price SG-65/0.7 water separator filter SG125/0.8 pp filter machine ML125 line filter element PA684DM25/W filter STZX2-100*3 string wound filter DLS-500 hydraulic cartridge filter JX-100×100 filter LH0110D20BH/HC filter YQUX-100*10 filter TZX2-40*30 pp filter core KLS-100I pp filter machine KLS-100I pp filter making machine DLS-500 filter TFBX-45*10 transformer oil filter machine WNY-85×210 hydraulic oil filter housing HX-250×10Q3 pp melt blown filter cartridge SL-12/50 filter TZXX-100*50 air filter production line QUQ2-3-B Air filter BDE200G2W2.X/-RV0.003 oil and filter TZX2-800×30 FILTER ELEMENT ZCL-I-450B DFYLSYC-2024-7-22-A

0 notes

Text

Where are to find vitamins on spring?

At summer, we are eating fresh fruits, berries, vegetables and receiving lots of vitamins.But on spring we are eating citric lots of, cabbage, apples, green onion, and porridges eat of cereals whole, bean, meat, liver.

Everyday drink glass of fresh pressed juices, and useful mix of carrot, apple and orange, beet, celery, potato, cranberry.

Drink infusions of vitamins as of hibiscus, he is rich beats record by vitamins B, C,E, PP, AND BENEFIT DRINK TEA of mixed herb oregano, hypericum, mint, leafs of fragaria vesca, buds or leafs of black currant, inflorescences of raspberry, ash berry red berries, and chop mixed mass, add hot water, drink ,like a tea.

At home on your window grow fresh greens as petroselinum, dill, onion, seeds of sprouts millet, natural are better, than from market.

Minimal warm manufacturing vegetables and fruits, raw, are benefit more. Remember about dandelion, as a rich he is with phosphorus, in salad his bitterness as of leafs masking with garlic or onion. Not opening buttons using, like capers, as marinading. Infusion cure skin, low acidity gastritis, hypertension, insomnia , as 2 tea.sp. of roots add in 250 ml. of cold water, boil minute, in ten min filter, use on glass for 2 times/day for 4 weeks.

At home, am preparing remedies against migraine.

After stress, migraine attacked me with strong headaches and rings. And knowing about remedies, am cooked and cured at home.

Sweeten water 1/3 of glass add 30 drops of horse chestnut tincture, am used her, in half hours felt better, and on the next day again repeated and ache stopped.

50 gr of grinded with brown peel add in 0.5 l. of vodka, infuse 2 weeks, at dark place, use on 30-40 drops with sweeten water before meal.

Sophora Japan mix with white mistletoe, leafs of hazelnut, fruits of horse chestnut, add 0.5 l. of vodka, in dark place infuse for 21 days, use dessert spoon one with water for 3 times/day before meal.

In hypertension, headaches, trombophlebitis, varicouse veins widening, rheumatism, adenoma prostate, stenocardia, against thrombus and for strengthening walls of blood vessels use this balsam as on ten gr chopped chestnut horse add in glass of vegetable oil, infuse for 7 days in dark place, after on water bath lead till boiling, remove from a fire. Cool, and add in bottle of dark glass, and rub ache parts as before sleep.

from Valga s health news,gardening,and cooking ,and beauty . https://valgasnews.blogspot.com/2023/07/where-are-to-find-vitamins-on-spring.html via https://valgasnews.blogspot.com/

0 notes

Text

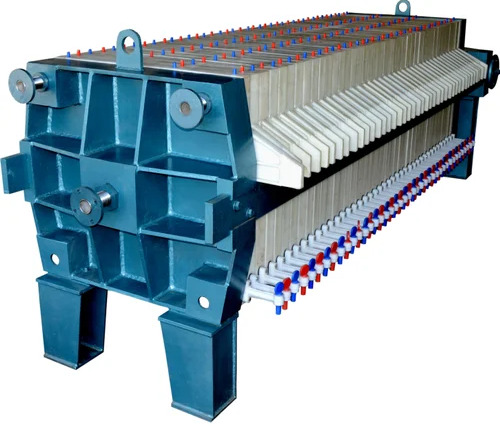

Advantages of Auto Membrane Filter Presses from Professional Manufacturers

The use of Automatic Membrane Filter Presses in industrial applications has grown significantly in recent years, and for good reason. These types of filter presses offer a number of benefits over Conventional filter presses, making them a popular choice among filter press manufacturers.

One of the main benefits of automatic membrane filter presses is their ability to save time and labor. Unlike traditional filter presses, which require manual operation, automatic membrane filter presses can be operated remotely, allowing for continuous operation without the need for constant monitoring. This not only saves on labour costs, but it also increases the efficiency of the filtration process.

In addition to saving time and labour, automatic membrane filter presses also offer improved performance and higher solids retention rates. This is due to the use of membrane plates, which are made from polypropylene or polyethylene, as opposed to traditional filter cloths. Membrane plates are able to retain a higher percentage of solids, resulting in a more efficient filtration process and a higher quality end product.

Another benefit of automatic membrane filter presses is their ability to handle a wide range of applications, from waste water treatment to industrial processing. These filter presses are able to handle a wide range of materials, including liquids, slurries, and suspensions, making them a versatile option for a variety of industries.

When it comes to choosing a filter press manufacturer, it is important to choose a reputable company that offers a wide range of products and services. Leading filter press manufacturers will offer a variety of automatic membrane filter press options, as well as customization options to meet the specific needs of the customer. They will also offer technical support and after-sales service, including maintenance and repair services.

One of the key factors to consider when choosing a filter press manufacturer is their level of expertise and experience in the industry. A reputable filter press manufacturer will have a wealth of knowledge and experience in the design, engineering, and manufacturing of filter presses, as well as a deep understanding of the various applications for which their products are used.

In conclusion, automatic membrane filter presses offer a number of benefits over traditional filter presses, including improved performance, higher solids retention rates, and increased efficiency. When choosing a filter press manufacturer, it is important to choose a reputable company with a wide range of products and services, as well as a strong level of expertise and experience in the industry. With the help of a leading filter press manufacturer, you can be sure that your filtration needs will be met with the highest level of efficiency and quality.

In addition, automatic membrane filter presses are also known for their durability and long service life, making them a cost-effective solution for many industrial applications.

Established in 1972 in Ahmedabad, India, Yotana is a Professional manufacturer of filter presses. Yo-Tana Machine Tools Pvt. Ltd. is the leading manufacturer of high-quality membrane filter presses, Membrane Plate Filter Press, fully automatic filter presses, and PP filter presses in India.

0 notes

Text

found a news blurb in a magazine called Movie Makers, October 1931, pp. 544 and 548. I am quoting it here in its entirety:

Rhamstine Electrophot - originalA radically new type of exposure meter makes its appearance this month, operating on the light sensitive cell principle. The idea has been advanced theoretically many tiems and cine workers have been promised that this principle would some time be brought to their aid in solving the vexing problem of exposure but the firm of J. Thos. Rhamstine, 501 East Woodbridge Street, Detroit, Michigan, is to be the first to make this principle available to the amateur. The Rhamstein Electrophot is entirely automatic in its operation and requires no visual judgement whatever on the part of the user. It comprises a round, metal container about three inches in diameter and two inches in width, with a button at one end and a tube at the other which contains the light sensitive cell. The tube is normally closed by a cap but, when the cap is removed, the light sensitive tube pointed toward th object reflecting the the light and the contact button pressed, a pointer on a dial set in the face of the instrument immediately indicates the stop number to be used. Its scale reads directly from ƒ/1 to ƒ/32 and the needle readeing is "dead beat" i.e., does not vibrate after reaching the indicated stop. Energy for actuating th epointer is derived from two small dry cells of the "fountain pen" type which are easily replaced by removing three screws at the back of the meter. Since the energy consumption is extremely small, the life of these cells is said to be longer than six months, even in constant use. The meter reading may be adjusted through a reasonably wide range by turning a small post through an opening in the back. Succinct directions for its use and a condensed filter compensation chart are printed on the reverse side of the meter. A handy carrying case with strap of black leather is included with the meter. It is stated that the Rhamstine Electrophot will be made available during the month of October, as soon as final manufacturing arrangements are made.

This obviously negates my thesis that Weston made the first meter. My original article follows: I'm going to delete it later

0 notes

Link

0 notes

Text

The Parts of Propaganda

Anyone who has ever taken a history course is familiar with propaganda, most commonly presented in the forms of cartoons and catchy slogans. Propaganda pervades society, encouraging people to think a certain way, adopt a certain point of view, or rally for a certain cause. It is clearly an effective tool as it has been used by many governments, big companies, and other organizations to great success. Propaganda, however, does not stand alone. It is interconnected with other ideas recognized in media studies to make it so powerful; propaganda is simply a way to spread ideology through public pedagogy. These three together create an, as mentioned before, incredibly powerful and effective tool in controlling people through their thoughts and feelings to propel them towards action.

One of the most poignant examples of this is the way the US Army uses propaganda to recruit civilians into enlisting. To understand why this is so, one must first understand what propaganda is. Propaganda is essentially information with a bias, presented to fulfill a goal. The way that it reaches people is through media and media is controlled by those with power (read: money). How this happens is explained by Edward S. Herman and Noam Chomsky’s propaganda model. There are five filters that make up the propaganda model but the two most pertinent to this example are the third and the fifth; “(3) the reliance of media on information provided by the government, business, and “experts” funded and approved by these primary sources and agents of power...and (5) “anticommunism” as a national religion and control mechanism.” (Herman and Chomsky 2) The third filter explains that the media uses information from trusted sources such as the government and big business to make their content credible. Additionally, the government knows they have massive influence over the media content released and so it is possible for them to release information that paints them in a good light and bury information that does not. The US Army is a branch of the US National Defense, run by the US Government and it benefits from the credibility given to governmental sources. Civilians have no reason to believe that the boisterous Army ads are propaganda because they come directly from the government. The fifth filter plays into this as well. Rallying a nation to band together against a perceived threat is a tried and true way of strengthening its military. In the present day, it may not be anti-communism but rather things such as anti-terrorism sentiment that the Army uses as fuel to get civilians to join up and fight against.

As mentioned before, propaganda is a way to spread ideology. In the case of the US Army, it is used to spread militarism, the belief that a country should have a strong military to protect itself and its ideals. The constant barrage of advertisements with slogans such as “Be All You Can Be” and “Army Strong” appeal to civilians in order to convince them to join the army; slogans that appeal to emotions and tap into one’s desire to strengthen oneself and better oneself. These, accompanied by dramatic action shots of soldiers in the field make a compelling combination for those watching, making it easy to buy into militarism. The issue is that ideology is often “in part or wholly false (illusory).” (Williams 55) yet people still believe it as if it is gospel truth. Militarism is no exception however the emotional appeal makes it difficult to sway opinions with facts, contributing to the efficacy of the propaganda presented as advertisements.

The last component of propaganda is public pedagogy. Public pedagogy is the idea that learning not only takes place in traditional venues such as school but also in the outside world through popular culture and mass media. This has massive influence and the power to shape worldviews and get people to adopt ideologies simply through constant exposure. With the US Army broadcasting advertisements with the intent of recruitment through mass media, it becomes a part of public pedagogy. Much like Disney does this, as explained in Henry A. Giroux’s essay, “Public Pedagogy and Rodent Politics: Cultural Studies and the Challenge of Disney”, the US Army pushes its ideology onto adults and children. By shaping civilian’s ideals and the way they view the army, the US Army promotes itself and worms itself into their consciousness without them even realizing it. If the word “Disney” were to be replaced with “the US Army” in the sentence, “Disney has given a new meaning to the politics of innocence as a narrative for shaping public memory and...promot[ing] a sanitized version of American history.” (Giroux 258), it would still hold true. Though it seems extreme, the US Army ads shown to the public are a far cry from the reality of everything the US Army has done, atrocities and all. Civilians are only given the “sanitized” story and therefore often do not completely see the army for what it is. They are only exposed only the positive and marketable parts and so they believe wholeheartedly in the cause.

The efficacy of US Army recruitment ads has been proven, with the National Defense Research Institute reporting that in years that there have been increased spending in marketing, the number of contracts has also increased. This is a strong case study in propaganda and its ability to produce results. By examining this singular example of propaganda, it is clear to see how it is broken down and how each of its parts contribute to the overall efficacy.

A dog dressed in a military uniform to parody the US Army slogan, “Army Strong” and demonstrate how catchy slogans are often used in propaganda.

Public Pedagogy often comes from mass media. This meme pokes fun at parents that use technology to “babysit” their children while claiming that the children are in fact learning through public pedagogy.

A photo of a cat on the White House podium demonstrates how media companies almost always get their information from government sources and people often believe it unquestioningly as the government has massive credibility.

This meme shows that most people do not even know that much of the advertising they are exposed to is actually propaganda in an unassuming disguise.

Works Cited

Chomsky, Noam, and Edward S. Herman. “A Propaganda Model.” Manufacturing Consent, Pantheon Books, 1988, pp. 1–35.

Dertouzos, James N. “The Cost-Effectiveness of Military Advertising.” Rand.org, 2009, www.rand.org/content/dam/rand/pubs/documented_briefings/2009/RAND_DB565.pdf.

Giroux, Henry A. “Public Pedagogy and Rodent Politics: Cultural Studies and the Challenge of Disney .” Arizona Journal of Hispanic Cultural Studies, 1998.

Williams, Raymond. “Ideology.” Marxism and Literature, Oxford University Press, 1977, pp. 55–71.

1 note

·

View note

Text

Filter press & its working principles | Filter Machines

What is a Filter Press?

A filter press is a piece of equipment used in liquid/solid separation. Specifically, the filter press separates the liquids and solids using pressure filtration, wherein a slurry is pumped into the filter press and is dewatered under pressure. Each filter press is designed based on the volume and type of slurry that needs to be dewatered. Filter Machines Pvt ltd is a trusted expert in liquid/solid separation and offers a wide range of filter press types and capacities to suit specific application needs for trouble-free, economical dewatering. These include configurations - sidebar automatic, manual overhead, automatic dual overhead beam, stainless steel clad, explosion-proof filter presses, vacuum filter presses, and hand filter presses.

The four main components of a filter press include the frame, filter plates, manifold (piping and valves), and filter cloth, a key ingredient for optimizing filter press operations.

How Does a Filter Press Work?

The working principle of filter presses is that slurry is pumped into the machine such that solids are distributed evenly during the filling cycle. Solids build up on the filter cloth, forming the filter cake; the filtrate exits the filter plates through the corner ports into the manifold, yielding clean filtered water.

Filter presses are a pressure filtration method and as such, as the filter press feed pump builds pressure, solids build within the chambers until they are completely chock-full of solids, forming the cake. Once the chambers are full, the cycle is complete and the filter cakes are ready to be released. At many higher capacity filter presses, fast-action automatic plate shifters are employed, speeding cycle time. Some filter presses are specifically designed for fully automatic, 24-hour operation in harsh environments such as mines or chemical manufacturing plants.

Filter Press Applications

Filter presses can be built in a wide range of sizes, from small, lab-scale 630 MM X 630 MM presses, to those with much larger capacities, such as those with 2000 MM X 2000 MM filter plates. Filter presses are used for liquid/solid separation in an extensive range of industries and applications including:

Food and beverage processing

Chemical manufacturing

Mining

CLAY & MARBLE AND TILES production

Know More About us:

Filter Machines Pvt ltd is a renowned Company for manufacturing Filter Press. The company has ISO certification. Its inception is dedicated to providing premium Filter Press. Established in 1979 the company is into manufacturing, supplying, and exports. With sophisticated infrastructure facilities, we pioneer in the field of solid-liquid separation. By understanding customers’ needs and requirements we manufacture the Filter Press. Our objective is to go beyond customers’ expectations.

Membrane Automatic Filter Press, Automatic Chamber Filter Press, Semi-Automatic Chamber Filter Press, Hydraulic Chamber Filter Press, Semi Hydraulic Chamber Filter Press, Manual Chamber Filter Press, Membrane Plate, Recessed Plate, PP Plate & Frame Plate

1 note

·

View note

Text

What is the difference between PP and SMS protective clothing

The main function of medical protective clothing is to prevent bacteria, viruses, and other infections. The current medical protective clothing is mainly made of non-woven fabrics. Medical protective clothing can be divided into woven, non-woven, and composite materials according to the textile structure. Different raw materials of protective clothing can have different effects and performances.

Medical protective clothing has different functions according to the usage scenarios. Some require antibacterial and antistatic. Some are anti-blood, anti-oil, and anti-alcohol. Some require the advantages of good drape, fine diameter, low filtration resistance, fluffy, soft, strong hydrostatic pressure resistance, and high filtration efficiency. Still, others require very good resistance to bacterial penetration and barrier to the penetration of liquid toxic substances, such as blood and chemical attack. Specifically, it can be distinguished according to the different materials of medical protective clothing, and the appropriate medical protective clothing can be selected.

Difference

SMS non-woven, English: Spunbond + Meltblown + Spunbond Nonwovens. It is a composite product of spun bond and meltblown. Its performance: non-toxic and tasteless, efficient bacteria isolation. Through the special treatment of equipment, it can achieve anti-static, anti-alcohol, anti-plasma, water-repellent, and water-producing.

Often used for:

1. Medical and health labor protection products such as surgical gowns, surgical caps, protective clothing, hand washing clothes, handbags, etc.

2. Sanitation products such as filter non-woven fabrics, oil-absorbing cloths, rags

3. Insulation raw materials and clothing accessories

4. Anti-feather non-woven fabric for anti-feather running down

PP non-woven fabric, also known as non-woven fabric or non-woven fabric. The material component is fiber. The full name of PP is polypropylene, the Chinese name is polypropylene. It is composed of directional or random fibers. It is a new generation of environmentally friendly materials. It has the characteristics of moisture-proof, breathable, flexible, lightweight, flame retardant, easy to decompose, non-toxic and non-irritating, rich in color, and recyclable. Material) pellets are the raw material. It is produced by high temperature melting, spinning, forming into a web, and hot pressing. It is called cloth because of its appearance and certain properties.

At present, the raw material of most non-woven fabrics is polypropylene, while the raw material of plastic bags is polyethylene. Although the names of the two substances are similar, they are quite different in chemical structure. The chemical molecular structure of polyethylene has quite strong stability and is extremely difficult to degrade; while the chemical structure of polypropylene is not strong, and the molecular chain can be broken, so that it can be effectively degraded and enter the next environmental cycle in a non-toxic form.

Commonly used in: agriculture, industry, household, clothing, packaging, etc.

Holymed Medical Group's non-woven medical products Division, established in the year of 1980, is one of the first manufacturers which produce non-woven medical products in China. PP isolation gown is one of our products, more details are as follow:

Size and model

S~XXL

Package specification

10 pieces/bag

Properties

Medical Materials & Accessories

Shelf Life

2 years

Quality Certification

Sgs

If you are interested in our products, please contact us as soon as possible.

Related news of protective clothing

The protective mechanism of medical protective clothing

A brief introduction to striped protective clothing

Significant advantages of medical protective clothing

0 notes

Text

What is Automotive Non-woven

Definition of automotive non-woven

Automotive non-woven fabrics are a new generation of environmentally friendly materials, which are moisture-proof, breathable, flexible, lightweight, flame-retardant, heat-insulating, non-toxic, tasteless, and non-irritating.cheap car knitted non woven fabricfabrics are widely used in automobiles, such as car trunks, car seat cushions, and car ceiling sound insulation.there are many kinds of Automotive color knittedcheap car knitted non woven fabricfabric.

Is composed of directional or random fibers. It is a new generation of environmentally friendly materials. It is moisture-proof, breathable, flexible, light in weight, non-combustible, easy to decompose, non-toxic and non-irritating, rich in color, low in price, and recyclable. Features. For example, polypropylene (pp material) pellets are used as raw materials, and are produced by a continuous one-step method of high temperature melting, spinning, laying, and hot pressing and coiling. It is called cloth because of its appearance and certain properties.there are many types of automotive color knittedcheap car knitted non woven fabricfabric.

In automobile production, especially in the production of automobile interiors, the usage rate of non-woven fabrics is very high, and non-woven fabrics are used in many places. Next, we will focus on introducing the types of non-woven fabrics for car roofs.

Non-woven manufacturing principle

1. Non-woven fabrics refer to fabrics that are not woven, but are entangled with many barbed needles or partially adhered together.

2. People have invented the manufacturing principle of non-woven fabrics at the beginning of the 20th century. The first production on a factory scale was a company in the United States in 1939, and a company in Germany in Europe also started the production of non-woven fabrics around 1944.

Wuxi's non-woven production started in 1980 with CHENSHIJI, and 7 companies joined in the following 2 years. The uses, materials and manufacturing methods of non-woven fabrics have all increased and have become an integral part of our lives. The secret is that flexibility, thickness, various properties and shapes can be freely created according to different raw materials and processing methods.automotive color knitted non-woven fabric are a good choice.

3.Non-woven fabrics have many advantages:

1.breathability 2.filterability 3.heat preservation 4.water absorption 5.water resistance 6.stretchability 7.not messy 8. good hand feeling, soft 9. lightness 10.elastic and flexible Restoration 11.There is no directionality of the fabric 12.Compared with textile fabrics, it has high productivity and fast production speed 13.It is cheap and can be mass-produced, etc.

3.The disadvantages are: 1.Compared with textile cloth, the strength and durability are poor. 2.It cannot be cleaned like other cloths. 3.The fibers are arranged in a certain direction,so it is easy to crack at right angles,etc. Therefore, recent improvements in production methods have mainly focused on improvements to prevent splitting.the manufacturing method is roughly divided into the wet method with water (7% in Japan, 1~2% worldwide) and the dry method without water (93% in Japan, 98~99% worldwide). Others include hot air or hot pressure fixing method (thermal bonding method, wire bonding method, etc.) and methods using adhesives (chemical bonding method) and so on.

The use of non-woven fabrics

1. Clothing/lining refers to interlining, sticky interlining, cotton padding, shoulder pads, bra pads, publicity work clothes, travel underwear, badges, handbags, slippers, hats, etc.

2. Industrial use refers to abrasives, oil absorbing agents, paper felts, heat insulating materials, sound insulation materials, shock-proofing agents, electrical insulating materials for printed bases, electromagnetic wave shielding materials, battery separators, tapes, magnetic disk packaging materials, V belts, ceilings and various filters.

3. Civil/construction/agricultural use refers to pipes, wall decoration materials, and sound insulation. Anti-vibration materials, roofing materials, anti-condensation boards, anti-corrosion materials, reinforcing agents, plastic simple greenhouse boards, seedbed boards, frost-proof boards, shading boards, gardening flower pots, etc.

4. Household use refers to felt fabrics, carpets, cushion materials, filling cotton for reception chairs, wallpaper, quilt filling cotton, quilt bags, pillowcases, sheets, collection bags, furoshiki, tea bags, calendars, book covers, tablecloths, lunches pads etc.

5. Medical. Sanitary use refers to surgical gowns, coverings, hats, masks, bed sheets, antibacterial pads, diapers, sanitary napkins, tampons and other physiological products, gauze, cotton swabs, hand towel handles, masks, etc.

Car cover non-woven fabric

Regarding the application of non-woven fabrics in automobiles, it has been widely used, so let's briefly introduce it. From cockpit filters and seat covers to trunk liners, sound insulation felts and carpet cloths,Colorful automotive knitted non-woven play an important role in the automotive market. Since its application in automotive components more than 40 years ago,Colorful automotive knitted non-woven can be used for sound insulation, air filtration, thermal insulation, reinforcement, and to improve occupant comfort and reliability. In addition to these advantages,Colorful automotive knitted non-woven are considered economical materials by many automotive companies due to their strength and durability.

Newly developed processes and materials have paved the way for technical Colorful automotive knitted non-woven to break through areas traditionally occupied by textiles.Consumers requirements for automotive non-woven are mainly low-cost, high-efficiency filtration and sound absorption Materials. As new automotive non-woven continue to be introduced, automakers are investigating these products to replace higher-cost materials such as leather seats. Often unnoticed by drivers or passengers, non-woven are hidden in seats or carpets Below, or sewn together with other fabrics for strength and durability. The environmentally friendly nature of non-woven allows them to replace foam products in automobiles.

Automakers are increasingly aware of the environmental advantages non-woven offer compared to other materials. Wanting to stop using non-recyclable foam materials, non-woven manufacturers have developed alternatives to foam that can be recycled. In addition, they can be combined very strongly with glass fibers and recycled materials, and when stretched, the color is uniform, and there is no wrinkle and tear. Although non-woven give automobiles many advantages and are rapidly replacing traditional fabrics, the needs of automakers and consumers fundamentally determine the styles and sizes of the most popular vehicles. Naturally, the number and variety of cars sold in a year will have a big impact on non-woven producers. In addition to the price factor, non-woven suppliers are struggling to produce products that comply with the automotive recycling regulations that will come into effect in Europe in 2006, which requires 1% of a car to be recycled, opening up one of the many opportunities for recyclable non-woven door. Recycling of cars is more important in Europe than in the United States, mainly because of this upcoming law in Europe.

About CHENSHIJI

CHANGSU CHENSHIJI Non-woven Products Co., Ltd. is a manufacturer specialized in needle punched or laminated non-woven fabrics. with roll making, hot shrinking, we produce various products upon different customers standards. which integrates design, development, manufacture and sales.

Our products are wildly used in wrapping, moving blanket, Floor Protection. painter fleece is our hot-selling product. when decorating the house it is covered on the floor to effectively protect the floor from dirty and broke down. with the function of waterproof, anti-slip, eco-friendly. Painter fleece is very popular in Europe, middle East, America and Australia.a professional knitted non-woven fabric manufacturer.

0 notes

Text

0 notes

Text

Pipe Extrusion Machine

https://www.jwellextrusions.com/products/pipe-extrusion-machine/

JWELL Machinery is designed and developed in a new idea, pipe and profile extrusion line produces PP pipe series, PVC pipeline series, ABS pipeline series, composite pipe series, etc., plastic pipe extrusion machine is high-yield, low energy consumption, good melt homogeneity, and long-term Running stability, modular design is a pipe extruder series, providing convenience, how to save raw materials, improve automation, ensure high output rate, high quality extrusion, and pipe extrusion machine price is very competitive for users, etc. aspects provide the perfect total solution

Types of Pipe Extrusion Machine

Corrugated Pipe MachineCorrugated Pipe Machine

HDPE/PP/PVC horizontal type Double Wall Corrugated pipe extrusion line、Special Use Single Wall and Double-wall Corrugated Pipe Extrusion Line produced by Jwell has many patents. Full automatic control, running stable, high capacity.

HDPE Pipe Extrusion MachineHDPE Pipe Extrusion Machine

This hdpe extrusion machine line adopts the most advanced technology of Europe, It is a new research achievement of energy-saving production line, The product line has a good appearance and high cost performance compared to the traditional equipment. The line is higher capacity and lower tons-consumption, more precise extrusion.

Twin Screw Pvc Pipe MachineTwin Screw Pvc Pipe Machine

This production line adopts special screw and mould design to make the material form easily with uniform plasticizing, high production speed, stable running, and easy operation. Suitable for pipe extrusion production such as PVC, CPVC, OPVC

PP Pipe Extrusion MachinePP Pipe Extrusion Machine

This Jwell self-manufactured production line adopts Europe's advanced technology with the feature of unique structure, leading configuration, high automation, and easy operation. The extruder screw adopts BM high-efficiency type with big output, good plasticizing, nice stability, and excellent reliability, Suitable for PP-R PO, PE-RT, PB, MPP, etc.

Highlights of Pipe Extrusion Machine

1

Founded in 1978 China's first screw JHL brandHigh extrusion efficiencyLow energy consumptionMelt temperatureExcellent melt uniformitySpecial screw design, fast heating, compared to other same type...

2

Advanced SIEMENS computer control system achieves integration and closed-loop control of the whole line, easy data analysis (energy consumption display and analysis), remote diagnosis (fast after-sale...

3

High torque precision reducer and AC frequency conversion or permanent magnet servo motor to ensure the stability and less energy consumption of long-term high extrusion production

4

Jwell make the pipe molds by herself. For HDPE pipes, with special material mold 40Cr. Beside, we can also provide a complete spare parts service for mold including die pin, die bush, and calibration ...

Products

FAQ about Pipe Extrusion Machine

Can JWELL currently produce how big size pipe extrusion lines?

Jwell plastic extrusion company PE pipe machine from extrusion line can stably extrud out a solid wall pipe of 3 meters, and the bellows can be highly squeezed out of the 1.2-meter diameter double-wall corrugated pipeline.

How to identify good or bad performance of PVC pipe?

Pipe Extrusion Machine Produce Process

1, mixed drying

The mixture of the mixed water is to obtain a well-known raw material with the color master material and mix, mix, mix, mix.

2, plasticizing extrusion

The raw material is hopped from the hopper to the extrusion line machine, transported, reduced, melted, homogenized, slowly turned from solid particles to high elastic, and then slowly became a viscous fluid (viscosity) And persistently squeeze.

3, mold forming

At a suitable temperature, the material extruded from the extruder is based on the filter plate by the rotational motion into a straight movement into the mold. After the spiral separation, the compaction is a tubular blank in the forming section and finally press the mouthoff.

4, refrigeration molding

From the mold extruded heat pipe blank in a negative pressure state, according to the type and refrigeration of the vacuum set of vacuum box, it will slowly refrigerate the pipe inside the pipe, and the overall cooling is formed.

5, cutting

Under the calculation of the wheel meter, the fixed length cutting of the pipe is completed according to the cutting machine.

6, stacked packaging

0 notes

Text

Oil purifier Circulating filter HC8314FKN39H for India power system

Oil purifier Circulating filter HC8314FKN39H for India power system Yoyik is specialized in manufacturing and providing components for turbines, coal-fired generators, and hydro units, as well as for electrical equipments, machinery parts, hydraulic machinery and parts. Our company is seated in the famous industrial city - Deyang with advanced technology, complete facilities and scientific management. Productions are in strict accordance with national standards. Yoyik can offer many spare parts for power plants as below: #DF-Oil purifier Circulating filter HC8314FKN39H-DF filter HX-630*30 filter air purifier QUQ3 filter DP401EA10V/-W oil and filter change cost SQCQX-630×10F10 pp pleated filter cartridge DLS-500 filter YWAX-160*180 filter TZ-800*3 pp water filter cartridge machine SGLGLQ-16T-50 replaceable filter drier core HX-40×3Q oil filter Q3U-A630*5FS machine oil filter FBX(TZ)-250×20 activated carbon filter cartridge honeycomb TZX2-63×20 water filter cartridge quick DLS-100 oil filter Q2U-H40*20S oil filter machine ZU-H63×40S precision filter MSF04S-03 filter YSF15-11A oil filter CFRI-1100*10Q2 water filter material SGLQ-300A cartridge filters 0110D010BN3HC/V filter FBX (TZ)-1300*10 filter TFX (ZX)-800*80 filter WU-630*100-J pp filter cartridge making machine DLS-150 filter SWCQX-630*50F50 filter WL151E349NVC01 oil filter making machine TLX337/800 filter HC5020F2016H pleated filter cartridge FAX-800×20 filter tank hydraulic HX-63×30 filter water purifier SG-125/0.8 chemical filter cartridge SFX-330×3 Filter element FX-850×40H oil filter machine TZX2I-160×40 filter LH1300R3BN/HC pp filter making machine DLS-200 Oil purifier Circulating filter HC8314FKN39H water cleaning filter SGLQ1000B pp melt blown filter cartridge machine SGLQ1000B Filter 37540-02100 automobile filter element HBX-250×30 oil filter making machine CFRI-1100×20 oil press with oil filter 0060D010BH4HC Filter element QF9732E25HPTC-DQ cartridge stainless steel filter housings FBX-1300×10 hydraulic filter price STZX2-400×10Q Filter element DR405EA03V/W Filter 21FH1310-500.51-25 pp melt blown filter cartridge machine KLS-125T/20 filters oil A156.73.52.08 filter for water SWFY3 filter FAX (NX)-250*5 water separator filter SWF filter SFX-500*5 hydraulic oil filter machine ZJA-6KY machine oil filter 0508.1161T0101.AW010 filter HC5010F1013H polypropylene fibre filter cartridge DLS-600 pp melt blown filter SG-125/0.7 oil filter change ZX-1000×80 oil filter ZU-H400*20FS element filter Q3U-A63×5BS Filter element J150×1120 aqua water filter price SL-9/50 filter CFASX-100*180 1 micro pp melt blown filter cartridge SL-9/50.03 filter LH0060D30BN3HC filter TZ-250*5 water cartridge filters SGLQB-1000 water separator filter KLS-100L water filter price SGLQ-6000A filter TZX-E63*10Q oil press machine with filter TZ-250×5 Oil purifier Circulating filter HC8314FKN39H DFYLSYC-2024-1-2-A

0 notes

Text

What's New With Nonwovens in the Medical Industry?

The utilization of medical nonwoven fabric has outpaced woven materials in recent years. Even when traced back to their rapid adoption during WWII, nonwovens were proven to be superior products in terms of adaptability, disposability, cost, and effectiveness. Manufacturing technology improved in the following decades until current-day use of nonwovens has placed them in a position to dominate the medical textile industry.

What are Nonwovens Fabrics?

Nonwovens are defined as sheets or web structures bonded together by the process of entangling fibers or filaments (and sometimes by perforating films) mechanically, chemically, or thermally. The fibers may be oriented randomly throughout the fabric or only following one direction.

Multiple layers may be combined to achieve the desired elongation, strength, and other mechanical properties. Porosity is controlled by varying fiber density, diameter, orientation, and the use of additional mechanical processing.

Key characteristics of nonwovens that justify their use and popularity:

durability

strength

resilience

dimensional stability

low elongation

specific processing to control porosity

Benefits of Nonwovens Driving this Market

With very deliberate care being taken to lower the incidence of hospital-acquired infection, nonwoven medical textiles are the clear winner in this category, thanks to their unique qualities. Medical textile technology is subject to intense monitoring since human lives are at stake. The intense scrutiny has resulted in better quality products and the development and implementation of innovative new uses in the medical field.

Nonwovens are preferred and poised to dominate the industry because they:

are effective barriers against bacteria

outperform linens for reducing airborne contaminants

can be tailored to changing specifications

help mitigate the risks of today's medical environments due to drug-resistant bacteria, worsening viral threats, polluted indoor and outdoor air, and increases in the numbers of blood-borne diseases

In 2014, nonwovens dominated the global medical textiles market. They accounted for over 55% of global volume, and are projected to gain market share through 2024 consistently.

What is SMS Material?

“SMS” stands for spunbond meltblown spunbond. SMS non woven fabric is a type of nonwoven fabric that combines spunbond and meltblown fabrics.When SMS material is created, it has great water repelling capabilities. This is why manufacturers choose to use SMS material in things like face masks, parts of baby diapers, sanitary napkins, and janitorial coveralls. It’s also used for caps, gowns, beddings, and other hospital accessories.

Why Combine Spunbond with Meltblown?

Spunbond polypropylene is a material that has great durability and strength, no matter if it’s wet or dry. It’s very resistant to fraying and is difficult to unravel, plus it barely absorbs any moisture if it becomes wet.

Meltblown, on the other hand, is softer and more pliable than spun bond polypropylene. Their main advantage is their web strength, which is why they’re usually combined with other nonwoven fibers. While spun bond polypropylene has its advantages, it can feel stiff and uncomfortable when it’s put in everyday applications such as coveralls.Since meltblown has a webbed structure and is softer, when you combine these two nonwoven fibers, it provides the wearer with water resistance while still retaining comfort. It’s also breathable, so even if you’re covered from head to toe (as with coveralls), your comfort won’t be compromised.

Applications for SMS Material

Because of how well SMS material repels water, it’s used in a number of industries where people need to block off fluids or other wet substances. Some areas that utilize SMS material’s benefits used are:

Protective apparel

Cleanroom coveralls

Filtration

Insulation

Medical healthcare

Sanitary products

Why The Future Is Nonwoven

Wherever you are sitting or standing right now, there’s bound to be at least one nonwoven fabric in your midst. Teabag or coffee filter, maybe? An air conditioning filter. Lens tissues, bleach wipes, diapers. Surely a face mask or seven.

Though the COVID-19 pandemic certainly pushed awareness of nonwoven fabrics to the forefront, we’ve had our eye on this growing market segment for years. Why? Because pressure-sensitive adhesive tape is often used to make or convert these textiles into usable everyday items.

Here’s our take on how non-wovens will continue to evolve and play a distinct role in the convenience economy.

What Is Non-Woven?

Nonwoven fabrics are the simplest and oldest textile fabrics. Neither woven nor knitted, as the name suggests, non-woven fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically.

They are flat or tufted porous sheets that are made directly from separate fibers, molten plastic, or plastic film. They are not made by weaving or knitting and do not require converting the fibers to yarn.

Typically, a certain percentage of recycled fabrics and oil-based materials are used in non-woven fabrics. The percentage of recycled fabrics varies based upon the strength of the material needed for the specific use. In addition, some nonwoven fabrics can be recycled after use, given the proper treatment and facilities. For this reason, some consider non-woven a more ecological fabric for certain applications, especially in fields and industries where disposable or single-use products are important, such as hospitals, schools, nursing homes, and luxury accommodations.

How are Nonwoven Fabrics Made?

Non-woven fabrics are made in two main methods: they are either felted or they are bonded. Felted non-woven fabric is produced by layering thin sheets, then applying heat, moisture, and pressure to compress the fibers into a thick matted cloth that will not ravel or fray.

There are there main methods of manufacturing bonded non-woven fabrics: Dry Laid, Wet Laid & Direct Spun.

In Dry Laid Non-woven Fabric manufacturing, a web of fibers is laid in a drum and hot air is injected to bond the fibers together.

In Wet-Laid, a web of fibers is mixed with a softening solvent that releases a glue-like substance that bonds the fibers together, and then the web is laid out to dry.

In Direct Spun, the fibers are spun on to a conveyer belt, and glues are sprayed on to the fibers, which are then pressed to bond. (In case of thermoplastic fibers, glue is not required.)

How are Non-Woven Fabrics Being Used?

Nonwoven fabrics penetrate a wide range of markets including medical, apparel, automotive, filtration, construction, geotextiles, and protective. Day by day the use of non-woven fabric is increasing and without them, our present life would be incomprehensible. Indeed, nonwovens play an integral role in the convenience economy.

Basically there are two types of nonwoven fabric: durable and disposal. Around 60% of nonwoven fabric is durable and the other 40% is disposal. These specialty fabrics are engineered to provide specific functions such as absorbency, sterility, liquid repellency, resilience, stretch, softness, strength, flame retardancy, cushioning, thermal insulation, acoustic insulation, and filtration. These properties are often combined to create fabrics suited for specific jobs while achieving a good balance between product use-life and cost. There are many kinds of it, such as non-woven fabrics for clothing, non-woven fabrics for packaging, and so on.

Non-woven fabric, is made of oriented or random fibers. It is a new generation of environmentally friendly materials. It is moisture-proof, breathable, flexible, light, non-combustible, easy to decompose, non-toxic and non-irritating, rich in color, and price. Low cost, recyclable, and so on. For example, polypropylene (pp material) pellets are used as raw materials, which are produced by high-temperature melting, spinning, paving, and hot-rolling and continuous one-step process. It is called cloth because it has the appearance and some properties of the cloth.

Therefore, in the non-woven fabric, S, SS,SSS, SMS mean the following: S: spunbonded non-woven fabric = hot-rolled single-layer web; SS: spunbonded nonwoven fabric + spunbonded nonwoven fabric = hot rolled from two layers of web; SSS: spunbonded nonwoven fabric + spunbonded nonwoven fabric + spunbonded nonwoven fabric= hot rolled from three layers of web; SMS: spunbond non-woven fabric + meltblown non-woven fabric + spunbond non-woven fabric = three-layer fiber mesh hot rolled

S and SS non woven fabric are mainly used for furniture, agriculture, hygenic products, and packaging products. And SMS nonwoven fabric is mainly for medical products, like surgical gowns. We are now exporting these non-woven fabrics to different countries in the world.

0 notes

Text

Best Pp Filter Press Manufacturers in India

Started in the year 1972 at Ahmedabad, Gujarat. We at "Yotana" are manufacturers of best quality Pp filter Press. We are one of the best Pp filter Press manufacturer in India. PP Filter Press Plates are utilized for fine filtration explicitly to isolate solids and liquids.

For more information about Pp filter press click this link: https://yotana.com/products/p-p-recess-chamber-plates

0 notes