#post and beam framing

Explore tagged Tumblr posts

Text

How Do Prefab Homes Become A Great Choice These Days?

You might be tempted to build your home yourself if you can't locate one you want to purchase. Whether it is post and beam framing, or a prefab home, all you need is to depend on the latest methods to ensure great durability. If so, you will have to decide between a stick-built and a prefabricated home.

Stick-built homes are constructed using the traditional method, with a team of employees spending months on the job site elevating the structure and installing the electrical and plumbing systems. On the other hand, a prefab house is made up of pre-assembled pieces.

Prefab is a general phrase used in modern home construction that describes practically everything while describing nothing in particular. Prefabrication can encompass a wide range of methods, which is why the term can be a little confusing.

Prefabricated homes, also known as prefab homes, get their name from the fact that most of their construction is done off-site before being brought and put together on-site.

Prefabricated homes have a bad reputation in the UK since they were typically used to replace Second World War dwelling stock that had been devastated by bombs. Although some prefabs are still standing today, their purpose was always temporary, which reflects the standards they were built to. Though the name still has a negative connotation, modern prefab dwellings are now more frequently linked with efficiency and quality.

Prefabrication is essentially the same as saying something was manufactured beforehand. Prefabricated materials have long been a part of conventional house-building techniques, with off-site production of items like timber roof trusses. Yet, many businesses now use the phrase "prefab" to convey the benefits of their various strategies because it alludes to a more contemporary manner of building.

The term "prefab" is used so frequently because it is vague and because many people believe it exclusively refers to a cutting-edge, economical construction technique. Yet, any house can be deemed prefab if some of its components were produced before the home was delivered to the site.

What is a Kit Home?

Kit homes are prefab homes delivered to a site flat-packed for assembly by the workers or the contractors. These self-built options have great potential for the involvement of the individual and generally mean that the house owner is responsible for the construction of their home.

The Final Consideration

As the name suggests, the home's components are made as a prefabricated kit that must be assembled on location. Even while it could need professionals, the owner can frequently build it or at the very least manage it, saving money.

Those who prefer to be very "hands-on" with their project are the target audience. The quantity of the kit that you buy might range from just the building envelope by itself to a full home package.

A Colorado log home builder such as Trinity Building Systems is a great option if you are looking for a building prefab home. Contact the experts today!

0 notes

Text

Box Frame or Goal Posts?

The use of steel is essential in all structural modifications. Its use allows Structural Engineers and Builders to achieve Clients requirements of spanning across openings. Sometimes adding a steel beam is not sufficient which means the project needs a steel box frame or goal posts. This page tries to answer frequently asked questions regarding the use of a box frame or goal posts during the structural modification of masonry structures and buildings (residential, commercial and industrial).

A box frame or a goal post?

Clients and contractors often ask this question. When removing a substantial part of an external wall, there is more to consider than just the vertical loads. For example, many homeowners want to knock down as much of the rear wall as possible to create an open-plan kitchen-diner when building a rear extension. As structural failures are not only caused by vertical forces, it is important to consider resistance to lateral loads such as wind. Traditional masonry houses have cross walls or shear walls. The party walls have “buttressing” walls that provide lateral stability which are the front/rear walls and a cross wall in the middle. The masonry can this way transmit wind and lateral loads in all directions safely to the ground. Homeowners carrying out structural modifications to their properties may inadvertently strip their property (and neighbouring properties) of this “lateral stiffness”. It is important to carry out these works in a safe and compliant manner, as otherwise it could lead (in the worst scenario) to the collapse of the party wall and may contribute to the collapse of a whole block of flats or a terrace of houses like a “house of cards”.

Compliance and Building Regulations

To ensure masonry buildings maintain the required lateral stiffness, the Building Regulations Approved Document A sets some conditions on openings in structural walls. Approved Document A limits the amount of external or buttressing wall that can be removed and insists that the corners or returns of these walls are substantial. The guidance states that no more than 66% of an external or buttressing wall can be removed and that a min of a 550mm (665 external measured from the centreline of the party wall or external wall) return is maintained. Please refer to Diagram 12 in Approved Document A of the Building Regulations. If this guidance can’t be achieved a portal or a box frame is required. We encourage clients interested to refer to Document A of the Building Regulations or to LABC technical guidance.

Why you need a Structural Engineer?

Structural Engineers can design steel box frames (picture frames) or steel portal frames (goal posts). Our designs allow homeowners to comply with Building Regulations and achieve an architectural layout that suits the aspirations of modern lifestyle of maximum openness and ease of movement. Below is a description of the main three structural options available to any homeowner undertaking a rear extension or converting a rear reception into a kitchen diner. If you have any question regarding the information provided below, please do not hesitate to contact us to seek advice. We are happy to explain to you the technical, regulatory and cost impacts of each option.

Option 1: Use of a steel beam supported on masonry returns

If the client or the contractor is able to retain a minimum return of 550mm either side of the opening, then this would be the right choice. A steel beam would support the loads from above. This steel beam is rests on pad-stones that are spread the loads to the masonry returns preventing the crushing of the relatively soft masonry. The beam width matches the width of the supported wall and takes into account whether there is any moisture.

The Structural Engineer would produce a design and a drawing for the use of the builder who is pricing and carrying out the works. The design and drawing also form part of an application to Building Control to ensure compliance with the Building Regulations Approved Document A.

Advantages: minimum demolition, short construction time, less expensive than other options. The return of the wall is conveniently similar to a kitchen counter width. Disadvantages: the opening achieved does not give the maximum openness that some homeowners may want.

Option 2: Use of portal frame (goal posts)

The opening is as wide as possible because the clients intends to remove the whole of the rear wall between the two flank walls (party walls). The builder secures the first floor and the wall above using adequate temporary supports. Following the securing of the property, the contractor inserts a steel portal frame. The steel frame refers to two columns and a top beam. The top column transfers the loads to the two columns using moment/rigid connections. The two columns transfer loads to new foundation cast at the edges next to the flank wall. The columns would be at the edge of these new foundations. The frame columns provide lateral stability to the masonry walls so the contractor needs to use chemical fixings to attach the steel columns to the masonry walls to compensate for the lost lateral stiffness.

Advantage: the client can have the maximum opening. Steel columns can be H section 152x152mm to 254x254mm depending on the opening span and loads from above (as well as sway forces from wind).

Disadvantage: the main disadvantage is the need for new foundations. Columns are at the edge of the foundations, causing eccentric loading so foundations size could be quite large to counteract the eccentric loading and to spread the load without over-stressing the soil. Option 2 requires a higher budget and a longer construction time than option 1.

Option 3: Use of box frame (picture frame)

Description: the opening is as wide as possible. The whole of the rear wall between the two flank walls (party walls) would require removal (obviously after the builder secures the first floor and the wall above using properly chosen temporary supports). The contractor would need to insert a steel box frame (a top steel beam on two steel columns sitting in turn on a bottom steel beam). The bottom beam is encased in concrete and supported on the old corbelled brickwork foundation that lies underneath the removed wall. The connections between the columns and the beams are moment/rigid connections and we provide the details and design for them. Alternatively the fabricator may have an in-house Structural Engineer to undertake the design and detailing based on the forces from the Structural Engineer.

Advantage: this options results in a maximum opening. Steel columns can be H section 152x152mm to 254x254mm depending on the opening span and loads from storeys above (as well as sway forces from wind). The use of the corbelled masonry foundation of the original wall to support the box frame would minimize ground works.

Disadvantage: the main disadvantage is the increased cost of steelwork. However, the savings in ground works cost and time outweigh the slight increase in steel cost.

So what is better, Box Frame or Goal Posts?

Structural Engineers recommend option 1 for all cases except where the client has already decided to achieve a maximum opening. To achieve the maximum openness, we highly recommend option 3: use of a steel box frame. We have developed a standard method of designing these box frames and provide detailed fabrication drawings that would allow the accurate production and fabrication of the box frame steel. Many steel yards do not have the benefit of an in-house engineer and even if they do, they would charge clients for detailing connections. Our standardized fabrication drawings allow our clients to use any steel yard to procure steel ensuring competitive rates on the steel cost and saving time and cost.

#steel beam#steel beams#timber structure#structure#glulam#box frame#goal posts#portal frame#steel beam connections

2 notes

·

View notes

Text

Timber Framing

Utilizing primarily traditional techniques for precision craftsmanship, we offer a wide selection of joinery options and access to various timber species, including new and reclaimed wood, to meet your aesthetic and structural preferences. Timber frame construction is one of our favorite ways to build! Read more here: https://quarryviewbuildinggroup.com/services/#mass-heavy-timber

#timber frame#timberframe#timber framing#timberframing#timber construction#construction#construction company#constructioncompany#post and beam construction

2 notes

·

View notes

Photo

Side Yard Porch Charlotte Inspiration for a mid-sized rustic side porch remodel with decking and a roof extension

#outdoor furniture#old wood beams#outdoor timber frame structures#post and beam#timber frame#timber frame porch

2 notes

·

View notes

Text

It's #TimberTuesday! This a beautiful, Western Red-cedar timber frame home we built for a great client in Kansas!

#heavy timbers#timber frame homes#timber post and beam#wood working#sawmills#10x10post#kansastimberframes

6 notes

·

View notes

Text

HES SO CUTE oh my goshhhhh this is adorable. Oh the precious child he looks so happy to have an arm again🥺The big eyes... THE BIG EYES so full of love

I adore this. *sobs*

I think the way Leo is drawn in @intotheelliwoods 's style is cute so I tried to draw him in a similar way

#is this how it feels when people look at my style#the characters just attack you with the big cute eye beams#2 arms left fanart#im getting a taste of my own cuteness medicine today#wails#I dont know how to talk in the main post anymore so im giving you a bunch of loving tag rambles#I love this so much.#the eye sparkles too#GOD#THIS REALLY IS MY OWN MEDICINE#I hook everyone in with the big love filled eyes before I kill everyone#2al be so fun until the big eyes become squiggly stressed lines#and hes just#holding the new arm#.....#thats so precious do you hear me#that there is 2al leonardo hamato he loves his new arm and his older self#did i mention this is amazing#thank youuuu THANK YOUUUU#cherishing forever#framing it on my wall#with all the other fanart I want to frame on my wall#hey did you know this is precious#in case I did not mention that enough

605 notes

·

View notes

Text

Craftsman Family Room in Burlington

Inspiration for a small craftsman open concept family room remodel with white walls, a wood stove and a brick fireplace

0 notes

Text

Loft-Style Family Room

Example of a large mountain style loft-style family room with beige walls and no television, a brown floor, a light wood floor, and a vaulted ceiling.

0 notes

Photo

Side Yard in Montreal Inspiration for a mid-sized craftsman side porch remodel with a roof extension

#timber frame home#bring outside inside#timber kit#screened in porch#wood structure#outside living#post and beam

0 notes

Text

Game Room Family Room

Example of a large mountain style open concept dark wood floor game room design with beige walls, a standard fireplace, a stone fireplace and a media wall

0 notes

Photo

Wood Exterior Huge mountain style brown three-story wood gable roof photo

0 notes

Text

Rustic Porch - Porch

Front porch with a large mountain-style wood railing, an awning, and decking

0 notes

Text

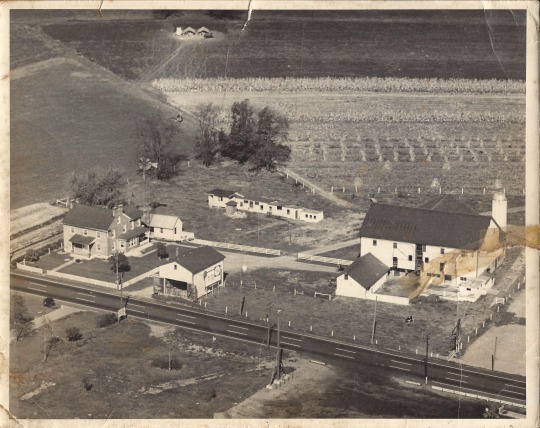

Adaptive Reuse Farmstead

An old farmstead sat vacant for about 15 years in Lancaster County, PA and our owners saw potential.

At that point, no farmer was going to put the extensive resources into the property that it would need to become functional again and the township didn't want a big corporation to destroy the buildings/property.

So we gave the historic farmhouse (& barn) new life by adapting it to serve as our headquarters for our construction company.

The farmhouse is office space, the in-law's quarters (black building on the right) is the timber frame conference room & more office space, and the timber frame connector serves as the reception area and open meeting space.

This shows how versatile timber framing can be and how you can blend old world craftsmanship with modern design features. We also love that it's given our team a biophilic space to work in and was a sustainable way to construct our building!

#biophilicdesign#timberframe#timberframing#adaptivereuse#custombuilders#postandbeam#construction company#timber frame#timber framing#post and beam#adaptive reuse

1 note

·

View note

Photo

Family Room - Game Room Inspiration for a large rustic open concept dark wood floor game room remodel with beige walls, a standard fireplace, a stone fireplace and a concealed tv

0 notes

Photo

Front Yard Boston An example of a large rustic shade front yard mulch garden path in summer.

1 note

·

View note

Photo

Family Room - Rustic Family Room Inspiration for a small rustic loft-style medium tone wood floor family room remodel

0 notes