#polymer sidewalls

Link

The article "Recover Tactical 1911 Grip & Rail System" by Michael Mills, published on The Armory Life, provides a comprehensive review of the Recover Tactical CC3P Grip and Rail System for 1911 pistols. This affordable ($50) and straightforward solution allows users to add a rail to their non-railed 1911 models, enabling them to attach weapon-mounted lights like the Streamlight TLR-1 HL. Mills highlights how the piece, including components like grip inserts in Black and Phantom Grey, can be easily installed using common tools. He underscores the advantage of having a weapon-mounted light for better control during low-light training and target practice. With this modification, owners can upgrade their favorite 1911 pistols without significant expense or the need for gunsmithing skills, making it an ideal solution for enthusiasts who want to maintain the classic 1911 feel while enhancing its functionality.

#Recover Tactical 1911 Grip Rail System#1911 pistol#grip and rail system#over 100-year-old firearm#full-length Picatinny rail#green or black grip sets#two-piece grip panels#polymer sidewalls#patented locking tab#Recover Tactical grip system#polymer construction#added weight#tactical equipment#mounting flashlights#laser sights#pistol accessory system.

0 notes

Text

The Art and Science Behind Lacrosse Sticks

Lacrosse, a fast-paced and exhilarating sport, relies heavily on the players' equipment, and at the heart of their gear is the lacrosse stick. This essential piece of equipment is not just a simple tool for passing and shooting but a carefully crafted instrument that combines tradition with modern technology.

Evolution of Design: The design of lacrosse sticks has evolved over the years, blending tradition with innovation. Traditional wooden sticks have given way to modern materials like aluminum, titanium, and advanced polymers. The head of the stick, once made solely from wood, is now a complex structure of plastic and mesh, carefully engineered for precision and performance.

Shaft Varieties: Lacrosse sticks come with a variety of shaft options, each catering to the player's preferences and position. Aluminum shafts offer durability and strength, while composite shafts provide a lightweight and flexible alternative. Titanium shafts, on the other hand, strike a balance between strength and weight, appealing to players who seek a combination of both.

Head Design: The head of the lacrosse stick has seen significant innovations in recent years. The introduction of synthetic materials has allowed for more intricate designs, enhancing the player's ability to catch, cradle, and release the ball with precision. The sidewalls and pockets of the head are carefully engineered to optimize ball control and accuracy.

Pocket Types: The pocket, where the ball is cradled, comes in various styles to suit different player preferences. From the high pocket, which offers better ball retention, to the low pocket, providing a quicker release for shooting, players can customize their sticks to match their playing style. Stringing patterns and mesh choices further contribute to the overall feel and performance of the stick.

Regulations and Customization: Lacrosse sticks must adhere to strict regulations regarding length, width, and pocket depth, ensuring fair play and maintaining a level playing field. Despite these regulations, players still have the opportunity to customize their sticks within the boundaries of the rules, allowing for a personal touch that reflects their unique playing style.

Lacrosse sticks are more than just tools for the game; they are a fusion of tradition, craftsmanship, and cutting-edge technology. The careful balance of materials, design, and customization options empowers players to express themselves on the field while meeting the demands of this dynamic and fast-paced sport. As lacrosse continues to grow in popularity, so too will the innovations in stick design, shaping the future of this exciting game.

#lacrosse#lacrosse gear#lacrosse stick#lax#stx#pll#lacrosse league#lax bro#lax girl#lacrosse bro#lacrosseguy#lacrosse game

3 notes

·

View notes

Text

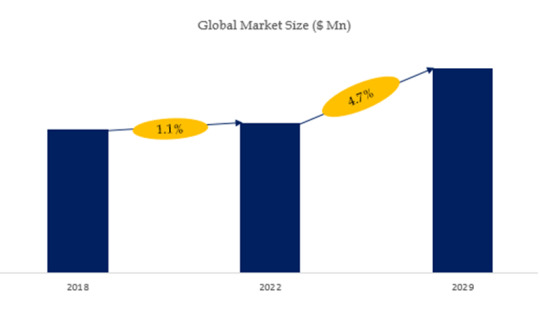

Global Top 4 Companies Accounted for 39% of total Curing Bladder market (QYResearch, 2021)

Curing is the process of applying pressure to the green tire in a mold in order to give it its final shape, and applying heat energy to stimulate the chemical reaction between the rubber compounds and other materials.

In this process the green tire is automatically transferred onto the lower mold bead seat, a rubber bladder is inserted into the green tire, and the mold closes while the bladder inflates. As the mold closes and is locked the bladder pressure increases so as to make the green tire flow into the mold, taking on the tread pattern and sidewall lettering engraved into the mold. The bladder is filled with a recirculating heat transfer medium, such as steam, hot water, or inert gas. At the end of cure, the pressure is bled down, the mold opened, and the tire stripped out of the mold.

According to the new market research report “Global Curing Bladder Market Report 2023-2029”, published by QYResearch, the global Curing Bladder market size is projected to reach USD 0.72 billion by 2029, at a CAGR of 4.7% during the forecast period.

Figure. Global Curing Bladder Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Curing Bladder Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch..

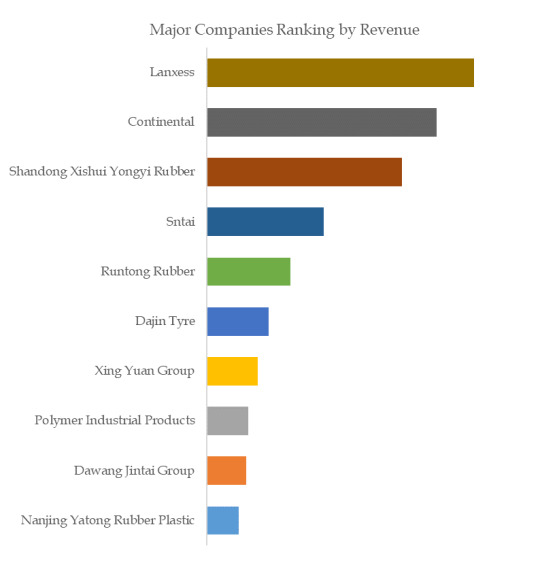

Figure. Global Curing Bladder Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Curing Bladder Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

The global key manufacturers of Curing Bladder include Lanxess, Continental, Shandong Xishui Yongyi Rubber, Sntai, Runtong Rubber, etc. In 2022, the global top four players had a share approximately 39.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Styrene Butadiene Rubber (SBR) Market Analysis: Assessing Growth Opportunities

Styrene Butadiene Rubber (SBR) stands as one of the most widely used synthetic rubbers globally, finding extensive applications across various industries. This blog delves into the dynamics of the SBR market, exploring its key drivers, diverse applications, emerging trends, and future growth prospects.

Understanding Styrene Butadiene Rubber (SBR):

Styrene Butadiene Rubber (SBR) is a synthetic elastomer derived from the copolymerization of styrene and butadiene. It exhibits excellent abrasion resistance, good aging properties, and versatility in processing, making it a preferred choice for numerous rubber applications.

Market Dynamics:

Automotive Tire Industry: The dominant use of SBR is in tire manufacturing due to its high abrasion resistance, good grip on road surfaces, and cost-effectiveness compared to natural rubber (NR).

Footwear and Industrial Rubber Goods: SBR is extensively used in footwear soles, conveyor belts, hoses, gaskets, and other industrial rubber products due to its durability, flexibility, and resistance to wear and tear.

Polymer Modification: SBR serves as a modifier in polymer blends and compounds, enhancing properties such as impact resistance, flexibility, and weatherability in plastics and other materials.

Construction and Infrastructure: SBR-based compounds are employed in construction materials such as seals, gaskets, and roofing membranes due to their weather resistance and sealing properties.

Applications Across Industries:

Automotive: Tire treads, sidewalls, automotive seals.

Footwear: Shoe soles, industrial rubber goods.

Polymer Blends: Impact modifiers, polymer blends.

Construction: Seals, gaskets, roofing membranes.

Market Trends:

Green Initiatives: The SBR market is witnessing a shift towards eco-friendly formulations, including bio-based SBR and recycled SBR materials, driven by environmental regulations and sustainability goals.

High-Performance Grades: Manufacturers are developing high-performance SBR grades with improved properties such as enhanced grip, reduced rolling resistance for tires, and better wear resistance for industrial applications.

Innovation in Blends: Blending SBR with other elastomers or additives to achieve specific performance characteristics, such as oil resistance, heat resistance, and electrical conductivity, is a growing trend in the market.

Future Prospects:

The global Styrene Butadiene Rubber market is poised for steady growth, fueled by the expanding automotive industry, infrastructure developments, and ongoing advancements in material science. Sustainable practices, technological innovations, and customized solutions will drive the market towards enhanced performance and environmental responsibility.

Conclusion:

Styrene Butadiene Rubber remains a cornerstone material in the rubber and polymer industries, catering to diverse applications with its exceptional properties and cost-effectiveness. Understanding market trends, consumer demands, and technological innovations will be crucial for stakeholders navigating the evolving SBR market landscape. As industries evolve, SBR's versatility and adaptability ensure its continued relevance and growth in meeting the demands of modern applications worldwide.

0 notes

Text

The Right Tyres Gives You The Perfect Ride. Know here

A tyre can thought of as a ring that surrounds a wheel to transfer power to the ground. The two basic types of tyres are bias-ply and radial tyres. Bias-ply tyres have cords that slant at a 45-degree angle from bead to bead. When the cords in radial-ply tyres circle from the bead to the sidewall and back to the bead, they form a circle. The sidewalls of the tyre are significantly reinforced at the bead to minimize bulging. Tyres a produced in a variety of sizes. There are numerous sizes available depending on the rim size, aspect ratio, and tyre width.Choose Goodyear Tyres Wolverhampton and drive with ease.

Quality is important

Tyres are crucial. There are a few things to bear in mind while buying new tyres. Purchasing brand-new, high-quality tyres will make you pleased. When choosing a set of tyres for your car, quality is crucial. While you are purchasing new tyres, seek advice from experts. They will choose the appropriate tyre for your car. So make sure you speak to the appropriate mechanic.

The rubber component of your car that forms a circle and propels it forward known as a Goodyear Tyres Wolverhampton. For a car to function, its tyres are crucial. Tyres are necessary for a vehicle to move, stop, and control its pace. On slippery surfaces, tyres give traction and grip. Without tyres, your automobile couldn't move and would be completely useless.

Get good performance

While your car's tyres are in fantastic condition. Your car travels the road without incident. On the road, you have complete freedom. For the greatest performance of your car, use the right tyres. So make the proper decision.

A car's tyres play a big role in how well it drives. They enable the car to go down the road and support its weight. Without the driver's input and the tyres, the automobile cannot move Car Tyres Wolverhampton.

Various tyre sizes are available

Synthetic rubber tyres are used to create vehicles.. The exact dimensions of a specific tyre called its "tyre footprint." Tyres are typically paired with steel or alloy wheels. Rubber used in tyres is highly vulcanised, which gives it its flexibility and suppleness. The elasticity of rubber referred to as its resilience.

The rubber material used to line car wheels called a tyre. Tyres offer a solid surface, distribute forces, and attach to wheels.

Safety is must

For an automobile to connected to the ground, tyres are necessary. Tyres provide the driver control over the dynamics of the vehicle. Most cars utilise tyres, thus they have a large impact on comfort and safety. Did you know that a car's tyres are one of its most important parts? To maintain driver and passenger safety, tyres must changed as soon as possible. Additionally, it asserted that tyres played a crucial role in the majority of accidents.

Check the sidewall of the tyre well

A car cannot travel without its tyres; they are an essential part. Additionally, they have a polymeric coating that may be on the sidewall or the entire tyre. This polymeric covering protects the tread, inside steel belts, and carcass. Different types of polymers and layers can found in tyres. Polymer layers can made from a variety of polymers. The polymers, despite being unique ones, are a part of the polymeric layer. Since polymers made of other polymers, they are also polymers. The tyre's polymeric layer is crucial.

Unless you're a mechanic or a vehicle enthusiast, it's probable that you don't give your car's tyres much thought. An automobile cannot driven without wheels. Consequently, the facts about tyres that provided below will change how you view them.

Choose high performance tyres

When thinking about high-performance tyres. Make the appropriate tyre selection. You can also worried about the vehicle's handling, brakes, and speed rating. Regularly inspect for wear and tear. Use only properly inflated tyres.

Regularly maintain your tyres. Verify the rotation, alignment, and tyre pressure. This guarantees the durability of the tyres. Make sure the tyres are secure as well. Always select the proper type of tyres for your driving demands

Even in extreme weather, well-made tyres deliver reliable performance then pick the appropriate kind of tyres. There are tyres available for every need. Never forget to regularly maintain your tyres. To maintain road safety, replace your worn-out tyres

Be safe

Whether it's a car, truck, motorcycle, or anything in between, the tyres are one of the most crucial parts of the vehicle. As a result, they are crucial in assuring the vehicle's performance and safety. tyres made to offer stability and grip. Control in a variety of road conditions, from dry tarmac to slick, rainy roads.

Vehicles made to fulfil certain requirements for various driving scenarios. There are four categories of tyres: performance, all-season, winter, and summer. Each type of tyre has an own set of qualities and attributes. such as building techniques, rubber compositions, and tread patterns.Choose Car Tyres Wolverhampton and drive carefully.

0 notes

Text

HOW TO KNOW WHEN YOUR TYRES NEED TO BE REPLACED.

Knowing Your Tyres

What is a tyre?

Because it is a vehicle's sole component that directly meets the ground and allows for agility and ultimate safety, a Continental Tyres Basingstoke is one of the most crucial components. Understanding how tyres enable a car to go nimbly, smoothly, and as quickly as the driver desires is critical. A tyre may appear to be a single round, black item, but it is actually made up of many different kinds of parts which play a vital part in the tyre's function as a vehicle component. It is similar to a balloon in that it is round and composed of rubber, but it is different from a balloon in that it can hold heavier loads. To keep their shape and stability when mounted on a wheel, tyres have steel wire reinforcement within. It's very astonishing that some tyres can propel supercars at speeds greater than 300 km/h! Rubber, a high-performance polymer that can be natural or synthetic, is essential to maximizing performance.

Dimensions of tyres

Section Width: The linear width between an inflated tire's sidewalls, excluding elevation from labels, ornamentation, or protective ribs.

Overall Width: The linear distance between the sidewalls, taking elevation from labelling, ornamentation, or protective ribs into account.

Section Height: The measurement obtained by subtracting the rim diameter from the overall diameter and dividing the result by 2, or the distance from the tread to the bead.

Overall Diameter: The width of an inflated tyre measured at the tread's outermost surface.

Aspect Ratio: The proportion of a tire's section height to the section width.

Tyre Height / Tyre Width * 100Rim is the aspect ratio.

Load Index: A tyre's maximum load that it's permitted to carry at the speed indicated by its speed symbol and under the servicing circumstances outlined by the tyre manufacturer is mainly indicated by a numerical code called the load index.

Speed Symbol: The maximum speed that a tyre can support a load matching its Load Index within the service description laid out by the tyre manufacturer is always shown by the speed symbol.

Load Capacity: The maximum weight that a tyre is allowed to support under a certain set of conditions.

Inflation Pressure: The pressure measured with the tyre at room temperature, excluding any pressure build-up brought on by tyre use.

Tread pattern feature

In order for the tread pattern to function, it is necessary. Also, it practically aids in safe driving on slick, bumpy, or snow-covered roads and cushions shocks from the road's roughness. While creating a tread pattern for a particular use, numerous criteria are generally required. High-performance tyres with circumferential grooves that direct water away from the contact patch while the "land" region of the tyre never leaves contact with the road are a recent trend. It's asserted that both of these tyre patterns are quieter than block layouts.

The information below may also get engraved in addition to the markers mentioned above.

For tubeless tyres, tubeless, M+S for all-season or winter tyres, studless tyres have a mountain with a snowflake pictogram, 50% wear indication, and an arrow pointing to the position of the mountain. Light Truck for LT tyres, Originating Country.

The location of the T.W.I. is mainly indicated by a triangle, the direction of the rotational arrow for a directional pattern, inside or outside for an asymmetric pattern, and so forth.

Tyre Maintenance

To avoid different types of tyre failure during routine use and vehicle maintenance, it is crucial to know how to care for tyres.

Maintenance of the vehicle and its components

Wheel alignment and wheel balancing are frequently mentioned when discussing car maintenance as the primary elements to keep the tyres in excellent condition and are crucial since they significantly affect tyre wear. The state of the vehicle, often referred to as camber, caster, and toe in or out, affects wheel alignment. If the vehicle is not correctly maintained, irregular wear of the tyres is likely to occur. The excessive force under the contact patch can be prevented and the tyres will wear down evenly if a tyre is vertical to the ground and the tyres on the left and right are parallel. On the other side, wheel balancing is actually done to ensure a smooth ride for passengers. The equal distribution of mass around an axle revolution is its technical definition. There won't be any vibration in the car if the wheel and tyre assemblies are completely balanced. Unbalanced vehicles vibrate and may even have uneven wear.

Irregular Tyre Wear

Dynamic properties provide an explanation for the mechanism of tyre wear. Here are a few common instances of tyre wear issues:

Major causes of irregular wear are;

Requiring less upkeep Inflation Rotation and pressure

Vehicle upkeep: Alignment, backlash in the suspension

Road condition, speed, and driving style are service conditions

Symbols for speed and load

* Include in parenthesis in the service description whether the tyres get suited for speeds greater than 300 km/h. 195/50 ZR15 (82Y) (82Y)

* Sizes with ZR included, such 215/50 ZR 15, suggest a top speed of 240 km/h. In the event that the

If the service description is not displayed, speak with the relevant Tyres Basingstoke manufacturer.

#Tyres Basingstoke#Continental Tyres Basingstoke#Cheap Tyres Basingstoke#MOT Test Basingstoke#MOT Basingstoke#Car Service Basingstoke

0 notes

Photo

What Is The Structure Of the Centrifugal Electrospinning Setup?

In most centrifugal spinning systems, the polymer solution or melt is injected into the spinneret, which is perforated with multiple nozzles around the sidewall and connected to the motor on the other side as shown in Fig. 10.3. Then liquid jets are formed at the nozzle tips or the polymer pathway of the spinning head when the centrifugal force overcomes the surface tension of the spinning fluid. After the liquid jets come out of the nozzle tips, the centrifugal force and the air frictional force can elongate and solidify the liquid jets into a fibrous morphology with solvent evaporation. The macromolecular chain entanglements of the polymer lead to a viscoelasticity, which enables continuous jet formation. Therefore, a good collaboration between rotational speed and solution concentration can prevent jet breakup and bead formation.

1 note

·

View note

Text

Is Summer Tires and All-Season Tires the same?

Assuming you're pondering, "Are Summer Tires and All-Season Tires something similar?" then you've come to the ideal locations. There are a few significant contrasts between the two kinds of tires. First off, summer tires have shallower track profundities, improved track examples, and enormous ceaseless tracks. They're additionally typically worked with adaptable sidewalls, and don't have siping or different elements that make them helpful for snow footing. Additionally, they're a lot calmer.

They are not something very similar.

There are a few distinctions between summer tires and all-season tires. A summer tire is intended for a hotter climate, while an all-season tire is intended for colder circumstances. They are made of various mixtures, including elastic, silica, and polymers. The late spring tire compounds are more adaptable in warm temperatures, while those in the colder time of year are intended to remain unbending in cool temperatures.

While looking for tires, make a point to contemplate factors like tire life and mileage. Different tire brands have various rankings, so you'll have to investigate as needs be to guarantee you're picking the right kind. Perusing surveys before settling on a brand is ideal.

One more contrast between summer and winter tires is the way they give footing. While summer tires give better footing while driving on wet asphalt, winter tires are better when the temperatures are colder. Winter tires are noisier and utilize more fuel.

They offer a wider performance range.

The significant distinction between summer and all-season tires is the sort of elastic compound they use. Summer tires have bigger track impedes and are made of intensity-safe elastic. They additionally highlight directional track designs with constant ribs. These highlights further develop street-to-elastic proportions. Moreover, summer tires have a shallower track profundity. Since they are intended for hotter temperatures, summer tires are more appropriate for superior execution vehicles. Be that as it may, these tires ought not to be utilized in freezing temperatures.

The all-season tires are the most well-known sort of tire for non-winter conditions. They are intended to give a foothold and dependable execution in many driving circumstances. They likewise have low moving obstruction and commotion. Contrasted with summer tires, all-season tires are more adaptable.

While summer tires are not generally so famous as all-season tires, they offer a more extensive execution range. For the best exhibition, you ought to continuously involve the most proper kind of tire for the weather patterns where you drive. On the off chance that you live in a space with a few seasons, you might need to consider buying a mix of summer and all-season tires.

They have less traction in the snow.

Albeit the track designs on summer tires are shallower and more extensive, they have a bigger area of contact with the street and further develop footing in light snow. The track example of winter tires likewise has numerous little crisscross cuts called Sipes, which make a gnawing edge. The track is made of an adaptable elastic compound that stays adaptable in chilly temperatures, dissimilar to summer tires, which lose their footing in freezing temperatures. In these outrageous circumstances, tire makers prescribe drivers to pick winter tires.

One more significant distinction between the all-season and summer tires is the way unbending they are. The all-season tires are worked to endure many circumstances, from snow and ice to hot and cold temperatures. Summer tires, then again, are intended to hold their shape in hotter circumstances. The all-season tires are made with a unique elastic compound that makes them adaptable even at temperatures above freezing.

A typical misinterpretation of pretty much the all-season tires is that they are less successful in snow. Nonetheless, summer tires are still better compared to all-season tires for taking care of the snow. They don't offer similar halting power and cornering contrasted with the all-season tires. The all-season tires likewise have lower slowing down distance and lower sidelong grasp than their late spring partners.

They are quieter.

Summer tires are calmer than the all-season forms, yet how calm they have relied upon the brand and style. Many elements decide outside sound, including the track design and the kind of elastic compound. The all-season visiting tires offer calmer rides than summer tires. On the off chance that you're a suburbanite, you presumably know how loud busy time can be. What's more, you might utilize public transportation to head out to work and are encircled via vehicles for extensive periods.

There is a wide range of kinds of tires for traveler vehicles. The all-season tires are typically calmer than summer tires, and some are calmer than winter tires. Contingent upon where you drive, your vehicle might require different tire types relying on weather patterns. Assuming you drive in a freezing climate, the all-season tires might be excessively boisterous. Assuming that is the situation, consider getting stud less winter tires all things considered. Most tire producers make calm tires. One of the calmest all-season tires is the Michelin Safeguard.

Tire commotion can be a disturbance if it upsets your drive. It might be an interruption to discussions and rest. The inordinate commotion has been related to worse hypertension and cardiovascular sickness.

0 notes

Text

What are the benefits of choosing Falken Linam Van01?

The new Falken Linam Van01 is addition by Falken to its already existing wide range of products. The Falken Linam Van01 is a summer tire that is suited for light trucks and vans. This new set of tires has the ability to provide better service life, improved safety and can enable better performance of the vehicle even on uneven and wet surfaces. The Falken Linam Van01 has optimised tread patterns meaning that it has large central spikes and a wide flat profile that allows the tires to distribute the pressure across the whole footprint area. This optimised tread pattern allows improves the grips of the tires which enhances the performance of the tires when it comes to braking and makes the whole deriving process stable along with improving the wear and tear life of the tires.

Main Characteristics of the Falken Linam Van01

4D Nano Technology

Firstly, the Falken Linam Van01has 4D Nanotechnology. The tires have new compound advancements through the use of biomass materials that aid in enhancing tread flexibility and adhesion. The technology also helps reduce the heat generation in the polymer of the tires. This technology improves the ability of the tires to maximise road contact. The advanced 4D nano design technology is one of the key features that make the Falken tires distinguishing from other bands this technology is an outcome of the advanced research and development of the company in the molecular structures. The benefits that 4D Nano design technology is able to provide to the vehicles is that it can save the fuel consumption by about five percent as compared to the traditional tire models and plus, it can significantly enhance the performance of the tires in wet conditions.

The technology ensures that tires meet the key requirements that are demanded by driers and cars today and will be doing so in the future as well which is low rolling resistance, exceptional safety, and lastly durability. The research conducted by the company in the molecular structure of tires has enabled the company Falken to make use of particle accelerators and stimulation computers to control and stimulate the molecular structure rubber compounds of the tires at the Nano level leading to the development of Nano design technology.

Adaptive Constant Pressure

Further, the Falken Linam Van01 has adaptive constant pressure. This means that this set of tires can maintain consistent contact pressure with the road surface which allows for stability and dynamic performance. The adoptive constant pressure also increases the grip of the tires of the road, enhances the durability of the tires, and shortens the braking distance. The tread profile is flatter and the increased pattern stiffness thus leads to the increased wear life of the product.

Shoulder Design

Falken Linam Van01 also has a variable pitch shoulder design that allows the tires to deliver performance across all seasons. This feature of the Falken Linam Van01 also makes the tire quiet as it helps reduce the tire noise. Further, the sidewall protection band also ensures that the product is highly durable

Grooves

Another key feature of the Falken Linam Van01 is its three large circumferential straight grooves. This feature helps the tires evacuate water effectively which can have a significant impact on the hydroplaning resistance and improve the wet performance of the tires and the car. These features ensure that the Falken Linam Van01 delivers long-lasting performance throughout its life

Thus, this new generation of Falken’s light tires for trucks is ideal for the summer seasons. The Falken Linam Van 01 are not only exceptionally durable and have improved wear life but they are safe and economic as well. This set of tires is ideal for businesses and fleets that are looking to improve the efficiency and productivity of their vans and light trucks.

0 notes

Text

Liquid Polybutadiene [LPBD] Market Set to Surge Significantly by 2031

Liquid Polybutadiene (LPBD) Market: Introduction

Transparency Market Research delivers key insights on the global liquid polybutadiene (LPBD) market. In terms of revenue, the global liquid polybutadiene (LPBD) market is estimated to expand at a CAGR of ~5% during the forecast period, owing to numerous factors regarding which, TMR offers thorough insights and forecasts in its report on the global liquid polybutadiene (LPBD) market.

The global liquid polybutadiene (LPBD) market is broadly affected by several factors, including fluctuation in prices of raw materials due to volatility in crude oil prices. Major applications for liquid polybutadiene in the tire industry include tire treads, tire carcass and sidewalls, under-treads, and cycle tires. The expansion of the tire industry is projected to boost the demand for liquid polybutadiene from tire manufacturers during the forecast period.

Are you a start-up willing to make it big in the business? Grab an exclusive PDF Brochure of this report :

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=74945

Liquid Polybutadiene (LPBD) Market: Dynamics

Applications of liquid polybutadiene in the construction industry include insulated glass sealants, binder of dusty and dry quartz sand, binder for soil stabilization, and modifier of silicone sealants. Adhesives based on sulfur-cured liquid polybutadiene polymers can be formulated to suit a wide range of applications from joint sealing to structural bonding. The overall boost in the construction industry signifies high demand for adhesives and sealants over the next few years, which is estimated to boost the liquid polybutadiene market.

Buy Our Premium Research Report@

https://www.transparencymarketresearch.com/checkout.php?rep_id=74945<ype=S

Liquid polybutadiene is extensively utilized for the manufacture of tires in the automotive industry due to characteristics such as ability to control grip, high resistance to wear and tear, superior performance, high fuel-efficiency, and longer shelf life as compared to normal rubber.

The demand for automotive vehicles, including passenger and commercial vehicles, is increasing across the world. The consistent demand is significantly boosting manufacturing and sales of automotive vehicles. Ongoing shift from conventional fuel automobiles to electric vehicles in the market is also estimated to propel the demand for tires. Factors mentioned above are projected to boost the demand for liquid polybutadiene during the forecast period.

More Trending Reports by Transparency Market Research –

https://www.prnewswire.com/news-releases/rising-demand-for-use-in-making-ceramic-tiles-and-powder-coating-to-help-global-feldspar-and-nepheline-syenite-market-reach-valuation-of-us-5-67-bn-by-2031--notes-tmr-study-301437111.html

Liquid Polybutadiene (LPBD) Market: Prominent Regions

Asia Pacific dominates the global liquid polybutadiene (LPBD) market. The market in the region is anticipated to expand at a CAGR of 5.6% during the forecast period. The demand for liquid polybutadiene is primarily driven by the presence of leading automotive manufacturers in Asia Pacific such as India, China, Japan, and South Korea. The presence of key producers of liquid polybutadiene (LPBD), such as Kuraray Co., Ltd, NIPPON SODA CO., LTD, Idemitsu Kosan Co. Ltd, and Evonik Industries AG are located in Asia Pacific, which, in turn, is driving the market.

Europe is also a key consumer of liquid polybutadiene (LPBD) across the globe. The presence of well-established liquid polybutadiene (LPBD) manufacturers in the region is driving the demand for liquid polybutadiene (LPBD) in Europe. The rise in usage of synthetic rubber in the rubber industry, owing to volatility in prices of natural rubber, has indicated the expansion in Europe. The usage of liquid polybutadiene as co-agent in the manufacturing process is expected to significantly drive the market in Europe.

Liquid Polybutadiene (LPBD) Market: Key Players

The global liquid polybutadiene (LPBD) products market was consolidated with the presence of key players. Prominent players operating in the global liquid polybutadiene (LPBD) market are Kuraray Co., Ltd., Evonik Industries AG., Evonik Industries AG., Synthomer plc., NIPPON SODA CO., LTD., SABIC., SIBUR, Idemitsu Kosan Co.,Ltd., Cray Valley, and ARLANXEO.

About Us Section:

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyse information. Now avail flexible Research Subscriptions, and access Research multi-format through downloadable databooks, infographics, charts, interactive playbook for data visualization and full reports through MarketNgage, the unified market intelligence engine. Sign Up for a 7 day free trial!

0 notes

Text

Elastomers Market Size, Segment | Value Share, Leading Players and Forecast to 2027

Market Synopsis

According to the MRFR analysis, the Global Elastomers Market is expected to reach over ~USD 107.1 Billion by the end of 2025 at a CAGR of ~4.8%.

Elastomers are amorphous polymers exhibiting characteristics of rubber in terms of flexibility and elasticity. Various elastomeric products on the account of their high abrasion and heat resistance are used in numerous industrial applications. For instance, TPUs offer excellent mechanical strength and low creep thus are used to manufacture conveyor belts. The rising demand for high-performance elastomers in the automotive and medical industries are the key factors favoring the growth of the elastomers market.

Pricing and Regulatory Analysis

In 2018, the price of Elastomers Market increased from USD 0.19 to USD 0.40 between 2016 and 2018 and is likely to observe a gradual upsurge during the forecast period owing to fluctuating raw material and crude oil prices.

The stringent standards for elastomer analysis may favor the demand for elastomers during the review period. Some of the standards are American Society for Testing and Materials - ASTM D412, ASTM D624, ASTM D3182 ”and International Standard - ISO 34-1:2015.

SEGMENTATION

By Type

Thermoset Elastomers: These polymers belong to the group of elastomers that cannot be molded once they have been cured. Thus, on the account of their structural integrity thermoset elastomers are widely used in high-temperature applications.

Synthetic Rubber: The segment held the largest market share in 2018 on account of its excellent strength and flexibility. These elastomers are artificially synthesized and derived from petroleum-based monomers.

Styrene-Butadiene Rubber (SBR): On account of its good abrasion and elasticity, it is widely used in pneumatic tires. SBR on reinforcement exhibits higher strength and durability.

Isobutylene-Isoprene Rubber (IIR): Owing to its low gas permeability and high resistance finds applications in inner tires of cars, bicycles and other high-pressure tubes.

Nitrile rubber (NBR): It is used in the applications that demand oil and heat resistance. Modified nitrile rubber such as carboxylated nitrile rubbers (XNBR) and hydrogenated nitrile rubbers (HNBR) exhibit high tensile strength and weather resistance.

Polybutadiene (PBR): It is extensively used in various parts of automobile tires including sidewall of truck tires and heavy vehicles for abrasion resistance.

Others: The segment includes acrylic rubber (ACM) and ethylene-propylene rubber (EPM), among others.

Natural Rubber: It is a bio-based elastomer obtained from the rubber trees. It is commonly known as Natural Rubber Latex (NBL) and find wide applications in friction tapes, cement, and adhesives. However, the natural rubber is usually vulcanized to enhance the chemical properties.

Thermoplastic Elastomers: It is projected to be the fastest-growing segment during the forecast period due to significant advantages over conventional thermosetting elastomers. These elastomers are recyclable and are capable of being remolded.

Thermoplastic Polyurethane (TPU): On account of excellent flexibility over a wide temperature range and high abrasion resistance, it is extensively used in a foray of industrial applications such as seals and gaskets, sealants, andconveyor belts.

Thermoplastic Styrenic elastomers (TPS): They are styrene block copolymers with excellent flexibility and elasticity and commonly used in footwear, belts, and adhesives.

Others: The segment includes thermoplastics polyester-ether elastomer (TPE-E) and thermoplastic polyamide elastomers (TPE-A), among others.

Browse Full Research Report @

https://www.marketresearchfuture.com/reports/elastomers-market-8342

By End-Use Industry

Automotive: The automotive segment accounted for more than 62% market share in 2018. This is primarily due to the increased use of elastomers in various applications such as airbags, tires, gaskets, bumpers, and HVAC systems. In the automotive industry, the demand for elastomers in interior applications is expected to increase at a significant rate during the forecast period.

Medical: It is projected to be the fastest-growing segment during the review period. The increasing use of elastomers on account of hydrolytic stability and ease of sterilization in variety of applications such as peristaltic pump catheters, needleless syringes, and valves is fueling the demand for elastomers in the medical industry. Additionally, the rising innovations to develop bio-based elastomers offers a wide range of opportunities to produce artificially synthesized biocompatible organs.

Electronics: A variety of elastomers exhibit low electrical conductivity and thus are suitable for insulation purposes. For instance, ethylene-propylene rubber is used to insulate indoor and outdoor high voltage cables.

Textiles: Elastomeric fabrics on the account of their lightweight and stretchability are used in a variety of garments including cycling shorts, swimsuits, and athletic wear.

Others: The segment includes aerospace & defense, oil & gas, and construction.

By Region

Asia-Pacific: The regional market held a dominant share in 2018 and is expected to maintain its dominance during the review period. The increasing disposable income coupled with expanding automotive and textile industries in the region are fueling the regional market growth.

North America: The market growth is driven by the demand for high-performance elastomers in the aerospace and medical industries.

Europe: A firm market owing to the demand for elastomers in the automotive industry. Additionally, the rising automobile exports from the region is aiding market growth.

Latin America: The growing healthcare and electronics industries is driving the demand for elastomers in Latin America.

Middle East & Africa: The expanding automotive industry and rising constructional activities in the region are contributing to the regional market growth.

Get a Sample Copy of This Report @

https://www.marketresearchfuture.com/sample_request/8342

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future

Phone: +16468459312

Email: [email protected]

Read More Related Article:

https://www.marketresearchfuture.com/reports/medical-device-coatings-market-2120

https://www.marketresearchfuture.com/reports/smart-polymers-market-4719

https://www.marketresearchfuture.com/reports/architectural-coatings-market-4753

0 notes

Text

Elastomers Market Size, Segment | Value Share, Leading Players and Forecast to 2027

Elastomers Market Synopsis

According to the MRFR analysis, the Global Elastomers Market is expected to reach over ~USD 107.1 Billion by the end of 2027 at a CAGR of ~4.8%.

Elastomers are amorphous polymers exhibiting characteristics of rubber in terms of flexibility and elasticity. Various elastomeric products on the account of their high abrasion and heat resistance are used in numerous industrial applications. For instance, TPUs offer excellent mechanical strength and low creep thus are used to manufacture conveyor belts. The rising demand for high-performance elastomers in the automotive and medical industries are the key factors favoring the growth of the Elastomers Market.

Pricing and Regulatory Analysis

In 2018, the price of elastomers increased from USD 0.19 to USD 0.40 between 2016 and 2018 and is likely to observe a gradual upsurge during the forecast period owing to fluctuating raw material and crude oil prices.

The stringent standards for elastomer analysis may favor the demand for elastomers during the review period. Some of the standards are American Society for Testing and Materials - ASTM D412, ASTM D624, ASTM D3182 ”and International Standard - ISO 34-1:2015.

Get Free Sample Copy of “Elastomers Market” @ https://www.marketresearchfuture.com/sample_request/8342

SEGMENTATION

By Type

Thermoset Elastomers: These polymers belong to the group of elastomers that cannot be molded once they have been cured. Thus, on the account of their structural integrity thermoset elastomers are widely used in high-temperature applications.

Synthetic Rubber: The segment held the largest Market in 2018 on account of its excellent strength and flexibility. These elastomers are artificially synthesized and derived from petroleum-based monomers.

Styrene-Butadiene Rubber (SBR): On account of its good abrasion and elasticity, it is widely used in pneumatic tires. SBR on reinforcement exhibits higher strength and durability.

Isobutylene-Isoprene Rubber (IIR): Owing to its low gas permeability and high resistance finds applications in inner tires of cars, bicycles and other high-pressure tubes.

Nitrile rubber (NBR): It is used in the applications that demand oil and heat resistance. Modified nitrile rubber such as carboxylated nitrile rubbers (XNBR) and hydrogenated nitrile rubbers (HNBR) exhibit high tensile strength and weather resistance.

Polybutadiene (PBR): It is extensively used in various parts of automobile tires including sidewall of truck tires and heavy vehicles for abrasion resistance.

Others: The segment includes acrylic rubber (ACM) and ethylene-propylene rubber (EPM), among others.

Natural Rubber: It is a bio-based elastomer obtained from the rubber trees. It is commonly known as Natural Rubber Latex (NBL) and find wide applications in friction tapes, cement, and adhesives. However, the natural rubber is usually vulcanized to enhance the chemical properties.

Thermoplastic Elastomers: It is projected to be the fastest-growing segment during the forecast period due to significant advantages over conventional thermosetting elastomers. These elastomers are recyclable and are capable of being remolded.

Thermoplastic Polyurethane (TPU): On account of excellent flexibility over a wide temperature range and high abrasion resistance, it is extensively used in a foray of industrial applications such as seals and gaskets, sealants, andconveyor belts.

Thermoplastic Styrenic elastomers (TPS): They are styrene block copolymers with excellent flexibility and elasticity and commonly used in footwear, belts, and adhesives.

Polyether Block Amide (PEBA): It is a high-performance thermoplastic elastomer. Due to its high flexibility and low density, PEBA is used in sports applications such as racquet grommets, golf balls, basketballs, and ski boots.

Others: The segment includes thermoplastics polyester-ether elastomer (TPE-E) and thermoplastic polyamide elastomers (TPE-A), among others.

Get More Professional and Technical Industry Insights @ https://www.marketresearchfuture.com/reports/elastomers-market-8342

By End-Use Industry

Automotive: The automotive segment accounted for more than 62% Market in 2018. This is primarily due to the increased use of elastomers in various applications such as airbags, tires, gaskets, bumpers, and HVAC systems. In the automotive industry, the demand for elastomers in interior applications is expected to increase at a significant rate during the forecast period.

Medical: It is projected to be the fastest-growing segment during the review period. The increasing use of elastomers on account of hydrolytic stability and ease of sterilization in variety of applications such as peristaltic pump catheters, needleless syringes, and valves is fueling the demand for elastomers in the medical industry. Additionally, the rising innovations to develop bio-based elastomers offers a wide range of opportunities to produce artificially synthesized biocompatible organs.

Electronics: A variety of elastomers exhibit low electrical conductivity and thus are suitable for insulation purposes. For instance, ethylene-propylene rubber is used to insulate indoor and outdoor high voltage cables.

Textiles: Elastomeric fabrics on the account of their lightweight and stretchability are used in a variety of garments including cycling shorts, swimsuits, and athletic wear.

Others: The segment includes aerospace & defense, oil & gas, and construction.

By Region

Asia-Pacific: The regional market held a dominant share in 2018 and is expected to maintain its dominance during the review period. The increasing disposable income coupled with expanding automotive and textile industries in the region are fueling the regional market growth.

North America: The market growth is driven by the demand for high-performance elastomers in the aerospace and medical industries.

Europe: A firm market owing to the demand for elastomers in the automotive industry. Additionally, the rising automobile exports from the region is aiding market growth.

Latin America: The growing healthcare and electronics industries is driving the demand for elastomers in Latin America.

Middle East & Africa: The expanding automotive industry and rising constructional activities in the region are contributing to the regional market growth.

NOTE: Our Team of Researchers is Studying Covid19 and its Impact on Various Industry Verticals and wherever required we will be considering Covid19 Footprints for Better Analysis of Market and Industries. Cordially get in Touch for More Details.

0 notes

Text

Liquid Polybutadiene (LPBD) market to surpass valuation of us$ 4.5 BN by 2031: TRANSPARENCY MARKET RESEARCH

Liquid Polybutadiene (LPBD) Market: Introduction

Transparency Market Research delivers key insights on the global liquid polybutadiene (LPBD) market. In terms of revenue, the global liquid polybutadiene (LPBD) market is estimated to expand at a CAGR of ~5% during the forecast period, owing to numerous factors regarding which, TMR offers thorough insights and forecasts in its report on the global liquid polybutadiene (LPBD) market.

The global liquid polybutadiene (LPBD) market is broadly affected by several factors, including fluctuation in prices of raw materials due to volatility in crude oil prices. Major applications for liquid polybutadiene in the tire industry include tire treads, tire carcass and sidewalls, under-treads, and cycle tires. The expansion of the tire industry is projected to boost the demand for liquid polybutadiene from tire manufacturers during the forecast period.

Request a Sample-

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=74945

Liquid Polybutadiene (LPBD) Market: Dynamics

Applications of liquid polybutadiene in the construction industry include insulated glass sealants, binder of dusty and dry quartz sand, binder for soil stabilization, and modifier of silicone sealants. Adhesives based on sulfur-cured liquid polybutadiene polymers can be formulated to suit a wide range of applications from joint sealing to structural bonding. The overall boost in the construction industry signifies high demand for adhesives and sealants over the next few years, which is estimated to boost the liquid polybutadiene market.

Liquid polybutadiene is extensively utilized for the manufacture of tires in the automotive industry due to characteristics such as ability to control grip, high resistance to wear and tear, superior performance, high fuel-efficiency, and longer shelf life as compared to normal rubber.

The demand for automotive vehicles, including passenger and commercial vehicles, is increasing across the world. The consistent demand is significantly boosting manufacturing and sales of automotive vehicles. Ongoing shift from conventional fuel automobiles to electric vehicles in the market is also estimated to propel the demand for tires. Factors mentioned above are projected to boost the demand for liquid polybutadiene during the forecast period.

Request for covid19 impact analysis –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=74945

Liquid Polybutadiene (LPBD) Market: Prominent Regions

Asia Pacific dominates the global liquid polybutadiene (LPBD) market. The market in the region is anticipated to expand at a CAGR of 5.6% during the forecast period. The demand for liquid polybutadiene is primarily driven by the presence of leading automotive manufacturers in Asia Pacific such as India, China, Japan, and South Korea. The presence of key producers of liquid polybutadiene (LPBD), such as Kuraray Co., Ltd, NIPPON SODA CO., LTD, Idemitsu Kosan Co. Ltd, and Evonik Industries AG are located in Asia Pacific, which, in turn, is driving the market.

Europe is also a key consumer of liquid polybutadiene (LPBD) across the globe. The presence of well-established liquid polybutadiene (LPBD) manufacturers in the region is driving the demand for liquid polybutadiene (LPBD) in Europe. The rise in usage of synthetic rubber in the rubber industry, owing to volatility in prices of natural rubber, has indicated the expansion in Europe. The usage of liquid polybutadiene as co-agent in the manufacturing process is expected to significantly drive the market in Europe.

Liquid Polybutadiene (LPBD) Market: Key Players

The global liquid polybutadiene (LPBD) products market was consolidated with the presence of key players. Prominent players operating in the global liquid polybutadiene (LPBD) market are Kuraray Co., Ltd., Evonik Industries AG., Evonik Industries AG., Synthomer plc., NIPPON SODA CO., LTD., SABIC., SIBUR, Idemitsu Kosan Co.,Ltd., Cray Valley, and ARLANXEO.

Buy now-

https://www.transparencymarketresearch.com/checkout.php?rep_id=74945<ype=S

Global Liquid Polybutadiene (LPBD) Market: Segmentation

Liquid Polybutadiene (LPBD) Market, by Application

Adhesives & Sealants

Rubber Compounds & Elastomers

Tire Manufacturing

Electrical Insulation

Polymer/Resin Modification

Paints & Coatings

Others (Plasticizer, Protective Films, etc.)

Liquid Polybutadiene (LPBD) Market, by End Use

Automotive

Chemical

Industrial

Housing & Construction

Electronics

Others (Sports, etc.)

Liquid Polybutadiene (LPBD) Market, by Region

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

S.

Canada

Germany

France

Italy

K.

Netherlands

Rest of Europe

China

Taiwan

Japan

South Korea

ASEAN

Rest of Asia Pacific

Brazil

Mexico

Rest of Latin America

Israel

GCC Countries

Rest of Middle East & Africa

Companies in the Liquid Polybutadiene [LPBD] market have increasingly shifted gears with wide application of digital technology across the continuum, from raw material sourcing to manufacturing to generation of final output, to warehousing to final distribution operations. Among the various affects, the market is witnessing new growth economics due to thinning of line between specialty and commodity businesses that are associated with the larger ecosystem. At the same time, new growth parameters are being vigorously being debated as industry stakeholders put greater emphasis on the circular economy processes.

More Trending Report-

https://www.prnewswire.com/news-releases/sustainability-and-affordability-to-play-a-vital-role-in-the-growth-of-the-murumuru-butter-market-says-tmr-301313662.html

0 notes

Text

Elastomers Market Size Forecast to 2027 Available in New Report

Elastomers Market Size Synopsis

According to the MRFR analysis, the Global Elastomers Market Size is expected to reach over ~USD 107.1 Billion by the end of 2027 at a CAGR of ~4.8%.

Elastomers are amorphous polymers exhibiting characteristics of rubber in terms of flexibility and elasticity. Various elastomeric products on the account of their high abrasion and heat resistance are used in numerous industrial applications. For instance, TPUs offer excellent mechanical strength and low creep thus are used to manufacture conveyor belts. The rising demand for high-performance elastomers in the automotive and medical industries are the key factors favoring the growth of the Elastomers Market Size.

Pricing and Regulatory Analysis

In 2018, the price of elastomers increased from USD 0.19 to USD 0.40 between 2016 and 2018 and is likely to observe a gradual upsurge during the forecast period owing to fluctuating raw material and crude oil prices.

The stringent standards for elastomer analysis may favor the demand for elastomers during the review period. Some of the standards are American Society for Testing and Materials - ASTM D412, ASTM D624, ASTM D3182 ”and International Standard - ISO 34-1:2015.

SEGMENTATION

By Type

Thermoset Elastomers: These polymers belong to the group of elastomers that cannot be molded once they have been cured. Thus, on the account of their structural integrity thermoset elastomers are widely used in high-temperature applications.

Synthetic Rubber: The segment held the largest market share in 2018 on account of its excellent strength and flexibility. These elastomers are artificially synthesized and derived from petroleum-based monomers.

Styrene-Butadiene Rubber (SBR): On account of its good abrasion and elasticity, it is widely used in pneumatic tires. SBR on reinforcement exhibits higher strength and durability.

Isobutylene-Isoprene Rubber (IIR): Owing to its low gas permeability and high resistance finds applications in inner tires of cars, bicycles and other high-pressure tubes.

Nitrile rubber (NBR): It is used in the applications that demand oil and heat resistance. Modified nitrile rubber such as carboxylated nitrile rubbers (XNBR) and hydrogenated nitrile rubbers (HNBR) exhibit high tensile strength and weather resistance.

Polybutadiene (PBR): It is extensively used in various parts of automobile tires including sidewall of truck tires and heavy vehicles for abrasion resistance.

Others: The segment includes acrylic rubber (ACM) and ethylene-propylene rubber (EPM), among others.

Natural Rubber: It is a bio-based elastomer obtained from the rubber trees. It is commonly known as Natural Rubber Latex (NBL) and find wide applications in friction tapes, cement, and adhesives. However, the natural rubber is usually vulcanized to enhance the chemical properties.

Thermoplastic Elastomers: It is projected to be the fastest-growing segment during the forecast period due to significant advantages over conventional thermosetting elastomers. These elastomers are recyclable and are capable of being remolded.

Thermoplastic Polyurethane (TPU): On account of excellent flexibility over a wide temperature range and high abrasion resistance, it is extensively used in a foray of industrial applications such as seals and gaskets, sealants, andconveyor belts.

Thermoplastic Styrenic elastomers (TPS): They are styrene block copolymers with excellent flexibility and elasticity and commonly used in footwear, belts, and adhesives.

Polyether Block Amide (PEBA): It is a high-performance thermoplastic elastomer. Due to its high flexibility and low density, PEBA is used in sports applications such as racquet grommets, golf balls, basketballs, and ski boots.

Others: The segment includes thermoplastics polyester-ether elastomer (TPE-E) and thermoplastic polyamide elastomers (TPE-A), among others.

Get More Professional and Technical Industry Insights @ https://www.marketresearchfuture.com/reports/elastomers-market-8342

By End-Use Industry

Automotive: The automotive segment accounted for more than 62% market share in 2018. This is primarily due to the increased use of elastomers in various applications such as airbags, tires, gaskets, bumpers, and HVAC systems. In the automotive industry, the demand for elastomers in interior applications is expected to increase at a significant rate during the forecast period.

Medical: It is projected to be the fastest-growing segment during the review period. The increasing use of elastomers on account of hydrolytic stability and ease of sterilization in variety of applications such as peristaltic pump catheters, needleless syringes, and valves is fueling the demand for elastomers in the medical industry. Additionally, the rising innovations to develop bio-based elastomers offers a wide range of opportunities to produce artificially synthesized biocompatible organs.

Electronics: A variety of elastomers exhibit low electrical conductivity and thus are suitable for insulation purposes. For instance, ethylene-propylene rubber is used to insulate indoor and outdoor high voltage cables.

Textiles: Elastomeric fabrics on the account of their lightweight and stretchability are used in a variety of garments including cycling shorts, swimsuits, and athletic wear.

Others: The segment includes aerospace & defense, oil & gas, and construction.

By Region

Asia-Pacific: The regional market held a dominant share in 2018 and is expected to maintain its dominance during the review period. The increasing disposable income coupled with expanding automotive and textile industries in the region are fueling the regional market growth.

North America: The market growth is driven by the demand for high-performance elastomers in the aerospace and medical industries.

Europe: A firm market owing to the demand for elastomers in the automotive industry. Additionally, the rising automobile exports from the region is aiding market growth.

Latin America: The growing healthcare and electronics industries is driving the demand for elastomers in Latin America.

Middle East & Africa: The expanding automotive industry and rising constructional activities in the region are contributing to the regional market growth.

Get Free Sample Copy of “Elastomers Market Size” @ https://www.marketresearchfuture.com/sample_request/8342

NOTE: Our Team of Researchers is Studying Covid19 and its Impact on Various Industry Verticals and wherever required we will be considering Covid19 Footprints for Better Analysis of Market and Industries. Cordially get in Touch for More Details.

0 notes

Text

Liquid polybutadiene (LPBD) market is estimated to expand at a CAGR of ~5%

Liquid Polybutadiene (LPBD) Market: Introduction

Transparency Market Research delivers key insights on the global liquid polybutadiene (LPBD) market. In terms of revenue, the global liquid polybutadiene (LPBD) market is estimated to expand at a CAGR of ~5% during the forecast period, owing to numerous factors regarding which, TMR offers thorough insights and forecasts in its report on the global liquid polybutadiene (LPBD) market.

The global liquid polybutadiene (LPBD) market is broadly affected by several factors, including fluctuation in prices of raw materials due to volatility in crude oil prices. Major applications for liquid polybutadiene in the tire industry include tire treads, tire carcass and sidewalls, under-treads, and cycle tires. The expansion of the tire industry is projected to boost the demand for liquid polybutadiene from tire manufacturers during the forecast period.

Request Brochure @

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=74945

Liquid Polybutadiene (LPBD) Market: Dynamics

Applications of liquid polybutadiene in the construction industry include insulated glass sealants, binder of dusty and dry quartz sand, binder for soil stabilization, and modifier of silicone sealants. Adhesives based on sulfur-cured liquid polybutadiene polymers can be formulated to suit a wide range of applications from joint sealing to structural bonding. The overall boost in the construction industry signifies high demand for adhesives and sealants over the next few years, which is estimated to boost the liquid polybutadiene market.

REQUEST FOR COVID19 IMPACT ANALYSIS –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=74945

Liquid polybutadiene is extensively utilized for the manufacture of tires in the automotive industry due to characteristics such as ability to control grip, high resistance to wear and tear, superior performance, high fuel-efficiency, and longer shelf life as compared to normal rubber.

Buy Now :

https://www.transparencymarketresearch.com/checkout.php?rep_id=74945<ype=S

The demand for automotive vehicles, including passenger and commercial vehicles, is increasing across the world. The consistent demand is significantly boosting manufacturing and sales of automotive vehicles. Ongoing shift from conventional fuel automobiles to electric vehicles in the market is also estimated to propel the demand for tires. Factors mentioned above are projected to boost the demand for liquid polybutadiene during the forecast period.

Liquid Polybutadiene (LPBD) Market: Prominent Regions

Asia Pacific dominates the global liquid polybutadiene (LPBD) market. The market in the region is anticipated to expand at a CAGR of 5.6% during the forecast period. The demand for liquid polybutadiene is primarily driven by the presence of leading automotive manufacturers in Asia Pacific such as India, China, Japan, and South Korea. The presence of key producers of liquid polybutadiene (LPBD), such as Kuraray Co., Ltd, NIPPON SODA CO., LTD, Idemitsu Kosan Co. Ltd, and Evonik Industries AG are located in Asia Pacific, which, in turn, is driving the market.

Europe is also a key consumer of liquid polybutadiene (LPBD) across the globe. The presence of well-established liquid polybutadiene (LPBD) manufacturers in the region is driving the demand for liquid polybutadiene (LPBD) in Europe. The rise in usage of synthetic rubber in the rubber industry, owing to volatility in prices of natural rubber, has indicated the expansion in Europe. The usage of liquid polybutadiene as co-agent in the manufacturing process is expected to significantly drive the market in Europe.

Liquid Polybutadiene (LPBD) Market: Key Players

The global liquid polybutadiene (LPBD) products market was consolidated with the presence of key players. Prominent players operating in the global liquid polybutadiene (LPBD) market are Kuraray Co., Ltd., Evonik Industries AG., Evonik Industries AG., Synthomer plc., NIPPON SODA CO., LTD., SABIC., SIBUR, Idemitsu Kosan Co.,Ltd., Cray Valley, and ARLANXEO.

About Us Section:

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyse information. Now avail flexible Research Subscriptions, and access Research multi-format through downloadable databooks, infographics, charts, interactive playbook for data visualization and full reports through MarketNgage, the unified market intelligence engine. Sign Up for a 7 day free trial!

0 notes

Text

What Are The Advantages Of Picosecond Laser Micromachining?

Picosecond lasers are best suited to machine materials that suffer from negative thermal effects during nanosecond laser machining with much higher performance. Nowadays, when it comes to material machining, the term "ultrafast lasers" is used more and more. It is used to distinguish picosecond and femtosecond lasers for applications.

In picosecond lasers, the laser pulse length is shorter than the time required for absorbed laser energy to propagate to the substrate and is usually between 5 and 10 picoseconds (ps). Picosecond laser micromachining is becoming increasingly popular due to the outstanding superficial finish. This is accomplished due to lower heating and reduced debris-related effect.

Not to mention the enhanced coupling due to the nonlinear intensity-dependent absorption and the obvious ease with which the machining effect can be achieved. The picosecond laser micromachining will produce a minimal size. This delivers features slightly smaller than one micrometer in size. But this only occurs with thin coatings of less than one-micron thickness.

The standard value is 10 microns laser-cut size for deeper beam penetration. Picosecond laser micromachining is utilized for high-quality components to achieve the best performance. Picosecond lasers are capable of allowing machining techniques that do not depend on ablation. The picosecond laser can achieve results with outstanding sidewall profiles. This can be obtained in the scribing of sapphire wafers for the singulation of LED products.

If properly optimized, picosecond processing can yield results that are not possible with other techniques. Effective implementation needs knowledge and analysis of material-photon interactions, time-dependent process-rate changes, and sample handling if possible, gains are not affected by conflicting device specifications.

Laserod is one of the industry’s commanding experts in laser micromachining and microscale applications of polymers and other substrates. Our high pulse femtosecond and picosecond laser micromachining are uniquely suited for microscale-polymer machining for many applications. For all sorts of slotting, grooving, or scribing thin materials, metals and polymers, contact Laserod Technologies today at 1-888-991-9916 / 1-310-340-1343 for projects and inquiries!

0 notes