#platinum cure translucent silicone rubber

Explore tagged Tumblr posts

Text

Liquid silicone rubber provides a choice of manufacturing materials for medical device products

Dow Corning Incorporated, the world's leading silicone and silicon-based technology and innovation company, introduced the Dow Corning® QP1 series of liquid silicone rubbers (LSR) to the healthcare industry, providing a richer selection of materials for the manufacture of precision medical devices and components.

Dow Corning, the world's leading silicone and silicon-based technology and innovation company, has introduced the Dow Corning® QP1 series of liquid silicone rubbers (lsr) to the healthcare industry, providing a richer selection of materials for the manufacture of precision medical devices and components. The series includes eight translucent silicone elastomers, developed for short-term, non-implantation and insertion applications, available in a variety of hardnesses, with a range of high-performance and multi-functional properties including high tear strength. This processing advantage can shorten the processing cycle. The products of this series of materials combined with other raw materials meet the food contact grade standards of the United States Food and Drug Administration (FDA) and pass the United States Pharmacopeia (USP) VI test.

James Stephenson, global marketing director, Dow Corning Healthcare, said: "The wider material options give our customers more opportunities to innovate and differentiate their products, thereby enhancing the production capacity of next-generation medical devices. QP1 Liquid Silicone Rubber The introduction of the series makes it easier for customers to identify the most suitable product grades for their various applications, and also further demonstrates Dow Corning's commitment to providing customers with high-quality products - including products that meet the requirements of ISO 9001 standards. With this commitment, we audit our manufacturing facilities to ensure they meet the demands of the increasingly stringent healthcare market."

Dow Corning® QP1 Series Liquid Silicone Rubbers are platinum-catalyzed two-component silicone elastomers, supplied in kits for liquid injection molding. In some applications with very demanding physical properties (such as films), they not only have high tear strength for optimum durability of the product, but also have low compression set, which is very important for This is important for components that are under compression in use, such as seals and valves.

This series of silicone elastomers also has properties that allow customers to avoid secondaryization in certain applications, resulting in improved productivity. In addition, they have processing advantages such as consistent quality from batch to batch and rapid curing, and after curing, they remain thermally stable below 204 degrees Celsius (400 degrees Fahrenheit) and have a Shore A hardness of between 20 and 75.

This family of materials is formulated without peroxides, peroxide by-products, chlorobenzenes or polychlorinated biphenyls (PCBs), nor organic plasticizers, phthalates or latex additives, and is FDA21 compliant Requirements for food contact materials in the CFR 177.2600 standard.

The uses of QP1 liquid silicone rubber products include: short-term implantation (within 29 days) of medical devices such as wound drains and gastric intubation, non-implantable devices such as needle-free injection valves, surgical equipment such as anesthesia masks, and medical treatment such as nasal aspirator consumer goods.

Elimold specializes in the design, production and sales of silicone products, rubber products, liquid silicone products, silicone encapsulated products, etc. With so many processes in the silicone industry, we will choose the most suitable processing method according to the customer's product, so that customers can not only Getting quality can also save costs.

0 notes

Photo

Repost from @thelockwoodgallery1 • VICTORIA PALERMO BUILT II: ARCHITECTURE IN ART THROUGH NOVEMBER 14TH THURSDAYS - SUNDAYS 11AM - 6PM VICTORIA PALERMO GILT 2012 PLATINUM CURED SILICONE RUBBER 7 x 10.5 x 14 INCHES Victoria Palermo invites the viewer to dive into pools of color and light. Her current work incorporates the effect of light through colored translucency in multiple forms at various scales. Palermo makes architectonic compositions that imply studied determination one moment and happy coincidence the next. INQUIRIES: [email protected] 845 663 2138 *Appointments are not necessary at this time The LockwoodGallery.com #art #sculpture #sculptor #colors #translucent #light #lightandspace #rubberart #thelockwoodgallery #thelockwoodgallery1 #kingstonny #chronogram #artsmidhudson #hudsonvalleyone #hudsonvalleyny #hudsonvalleytourism @victoriapalermostudio @rbottwin @viviencollens @studiodanieldenton @richardking_studio @richardscherr9378 @stegerkurt @Chronogram @artsmidhudson @hudsonvalleyone @artvalleyny (at Kingston, New York) https://www.instagram.com/p/CVX_RUqlnx1/?utm_medium=tumblr

#art#sculpture#sculptor#colors#translucent#light#lightandspace#rubberart#thelockwoodgallery#thelockwoodgallery1#kingstonny#chronogram#artsmidhudson#hudsonvalleyone#hudsonvalleyny#hudsonvalleytourism

0 notes

Text

What are the Differences In Between Platinum and also Peroxide Treated Silicone?

What is the Healing Process?

Curing is the procedure whereby an elastomer comes to be cross connected. In a peroxide cured silicone, heats damage down the peroxide which produces the chemical which cross links the polymers in the chain. Enhancement treating, platinum is contributed to the silicone as a stimulant. This triggers the polymer chain to go across relate to itself. The majority of the silicone refined by Accurate Rubber Corporation is warm heat cured rubber which makes use of the peroxide treating system to transform the silicone from substance to rubber.

The various treating systems provide silicone rubber various residential properties. Below are the benefits and drawbacks of each approach of treating silicone:

Platinum Cured Silicone

Pros

Platinum cured silicone rubber is aesthetically a lot more clear, making it appropriate for applications where completion individual requires to be able to translucent the product.

Has a greater tensile and also tear toughness than peroxide cured silicone.

Does not need making use of talc in handling.

Taken into consideration to be the cleaner of both kinds of silicone, made use of often in the food and also pharmaceutical industries.

Learn more about the solutions Accurate Rubber Corporation provide to the Food & Beverage processing and Pharmaceutical & Medical industries.

Disadvantages

Platinum cured silicone is much more costly to create than peroxide treated silicone.

Platinum cured silicone has a much shorter life span. As soon as the stimulant is contributed to the substance the product will certainly start to cure. This indicates much more junked product throughout manufacturing.

Silicone that is platinum cured rubber is tougher to refine, it calls for greater temperature levels to cure.

Peroxide cured silicone has a lengthy life span. As soon as combined, it can be kept for extended periods of time.

It is more affordable to create, indicating affordable rates can be handed down. It is simpler to refine as well as can be treated at reduced temperature levels. Peroxide treated silicone can adhere to its self in manufacturing as well as article curing, particularly softer qualities. Talc requires to be related to the silicone to stop undesirable cross linking.

Peroxide cured silicone is not as clear as platinum cured silicone. It is a lot more transparent in look.

Peroxide Cured Silicone

Pros

Peroxide treated silicone has a lengthy life span. As soon as combined, it can be saved for extended periods of time.

It is more affordable to create, implying affordable rates can be handed down.

It is much easier to refine and also can be cured at reduced temperature levels.

Disadvantages

Peroxide cured silicone can stay with its self in manufacturing and also message treating, particularly softer qualities. Talc requires to be put on the silicone to avoid undesirable crosslinking.

Peroxide treated silicone is not as clear as platinum treated silicone. It is much more clear in look.

Accurate Rubber Corporation is a leading manufacturer and supplier of silicone rubber cord, silicone rubber U Channel, Gasket, Seal. You can make custom size silicone o ring and silicone gasket using our silicone cord. Feel Free to contact us for more information.

0 notes

Photo

My silicon material:

Mold Star® 20T is an easy to use Shore 20A translucent platinum silicone that is mixed 1A:1B by volume (no weighing scale necessary). It features a relatively low viscosity and vacuum degassing is not required for most applications. Pot life is 6 minutes and cure time is 30 minutes at room temperature.

Mold Star® 20T cures in to a soft, strong rubber that is tear resistant and exhibits very low long term shrinkage. Molds made with Mold Star® will last a long time in your mold library and are good for casting wax, gypsum, resins, concrete and other materials. Mold Star® 20T silicone can be thickened with Thi-Vex® thickener for brush-on application and effects. An infinite number of color effects can be achieved by adding Silc Pig® silicone pigments or Cast Magic® effects powders.Mold Star® 20T is heat resistant up to 450°F (232°C) and is suitable for casting low-temperature melt metal alloys.

Measuring & Mixing - Before you begin, pre-mix Part A and Part B separately. After dispensing required amounts of Parts A and B into mixing container (1A:1B by volume or weight), mix thoroughlymaking sure that you scrape the sides and bottom of the mixing container several times.

Optional... Vacuum Degassing - Although not necessary, vacuum degassing helps eliminate any entrapped air in pourable silicone rubber. After mixing parts A and B, vacuum material for 2-3 minutes at 29 inches of mercury, making sure that you leave enough room in container for product expansion.

Pouring - For best results, pour your mixture in a single spot at the lowest point of the containment field. Let the rubber seek its own level. A uniform flow will help minimize entrapped air. If using as a mold material, the liquid rubber should level off at least 1/2” (1.3 cm) over the highest point of the model surface.

Curing - Allow mold rubber to cure for 30 minutes at room temperature (73°F/23°C) before demolding.

Heat Curing - Time to demold can be reduced with mild heat. Example: After pouring Mold Star® 20T at room temperature, place the mold in a hot box or industrial oven at 140°F (60°C). This may reduce the demold time substantially. Note - time will vary depending on mold thickness.

Mold Performance & Storage - The physical life of the mold depends on how you use it (materials cast, frequency, etc.). Casting abrasive materials such as concrete can quickly erode mold detail, while casting non-abrasive materials (wax) will not affect mold detail. Before storing, the mold should be cleaned with a soap solution and wiped fully dry. Two part (or more) molds should be assembled. Molds should be stored on a level surface in a cool, dry environment.

0 notes

Text

ⅱ. Addition cure mold making Silicone rubber

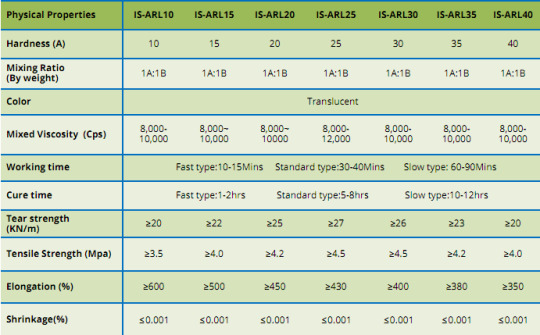

⑵. Translucent type Addition cure Mold making Silicone Rubber (IS-ARL Series)

Key Features: Non-Shrink on cure, Excellent fluidity, Easy mixing with 1:1/10:1, High temperature resistance up to 300’C, Color adjustable, both Pour-on and Brush-on mold available.

Package: 1kg/pail, 5kg/pail, 20kg/pail, 200kg/pail

Thickener (PLAT-THI) could also be offered to thicken these silicone rubber for brush-on molds.

#Platinum cure silicone rubber#platinum cure translucent silicone rubber#addition cure silicone rubber for mold making#addition cure silicone rubber for molding#translucent silicone rubber for molding#food grade silicone rubber for molding

0 notes