#plastic molding low volume

Explore tagged Tumblr posts

Text

Injection Molding for Low-Volume Production: Cost-Effective Solutions for Small-Scale Manufacturing

Injection molding, a highly efficient and versatile manufacturing process, is often associated with high-volume production. However, it also offers valuable benefits and cost-effective solutions for low-volume production, catering to small-scale manufacturing needs.

Low-volume injection molding refers to the production of a relatively small quantity of plastic parts, typically ranging from a few hundred to several thousand units. This approach is ideal for prototyping, small-batch production, or niche market applications. Despite the lower quantities involved, injection molding still provides advantages such as superior part quality, design complexity, and material options.

One of the significant advantages of low-volume injection molding is its cost-effectiveness. While tooling costs may remain similar to high-volume production, the overall per-part cost can be justified for low-volume runs due to the amortization of tooling expenses. Additionally, injection molding's high production efficiency enables faster production cycles and reduced labor costs compared to alternative manufacturing methods.

Low volume injection molding offers flexibility in design iterations, allowing for quick adjustments and improvements before finalizing the production mold. This iterative approach saves time and costs during the product development stage, leading to faster time-to-market for new products or modifications to existing ones.

Moreover, injection molding low volume ensures consistency in part quality and dimensional accuracy, thanks to the precise control offered by modern injection molding machines and techniques. This reliability is crucial for maintaining customer satisfaction and meeting industry standards.

In summary, injection molding is not solely limited to high-volume production. Low-volume injection molding provides cost-effective solutions for small-scale manufacturing, offering superior part quality, design flexibility, and shorter time-to-market. Manufacturers can confidently leverage this technique for their low-volume production needs, benefiting from the efficiency, precision, and versatility of injection molding.

#lowvolume#low volume mol#2K injection mould#low volume moulding companies#small quantity injection molding#low volume plastic parts production#low volume low cost plastic injection moulding#low volume injection molding companies#plastic molding low volume

0 notes

Note

YES PLEASE. BLOCKBUSTER ELLIE?? 90’s?? SIGN ME UP. WHERE DO I PUT MY NAME??😖😖🙏

- 🩵

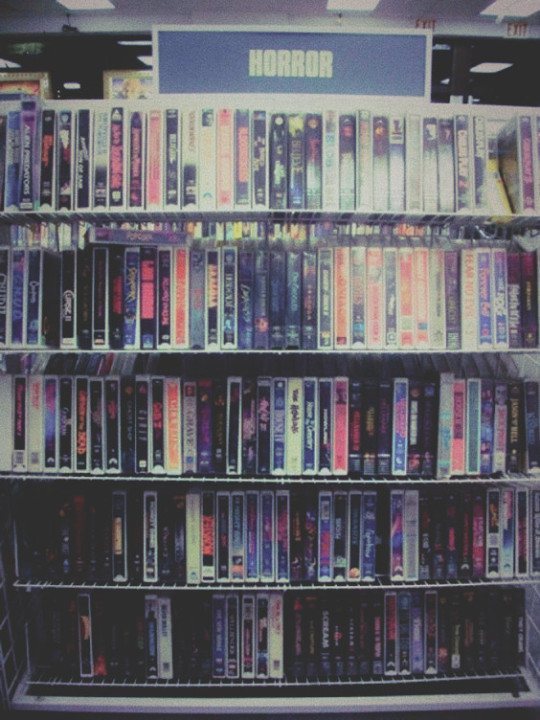

a/n + cw; OMGG AN EMOJI ANON i haven't seen you guys in a hot minute, but YESSS BLOCKBUSTER ELLIE!! specifically x customer reader. it's a cute duo! and let me relay why from my very scrambled 3 am jot-down. was going to make this a blurb, but it better translates through something more structured. ++ SFW! kinda mean!reader tbh (but ellie likes that), very fluffy you might squeet, quickly written, awkwardness, ellie being a nerd. [first pic from amoaeIIie on pinterest]

Imagine Ellie, in her blockbuster getup, leaning her butt into the edge of the register counter, jamming to whatever is playing on her hand-me-down walkman; earsbuds in, eyes downcast, head bopping slowing - soundly unaware of you awaiting service on your over-due rental. "Hello?" your volume divides the soft ambiance of the store, but it isn't enough to rope Ellie's mindspace from the clouds. Calling out again, "Hell-looh?" you extend beyond the cash register and wave your hand - nothing, nada.

How the hell has this girl not gotten her ass fired yet?

After numerous roadblocks, a brazen last resort comes into play. You cut around the counter briefly to take things into your own hands (literally) because you have not the time, nor the patience, for her slacking off.

Beryl eyes drop sharply to the walkman in her pants pocket when a single earbud is spooled from her ear, assuming it fell - but to her surprise, it hung low from your finger, and a glance above that finger was your face. Risen of one brow, flat-lined of your lips; impatient.

And her entire focus blanks out when you begin to speak, curtly and satirically, "Hey, I know busting out your Dad's old walkman in public makes you feel cool and whatnot, but you're on the clock." handing the slim cord back over to a stunned girl, flushed behind the pop of her freckles. Maybe your tone of voice sent her higher into the clouds, past a coven of angels, because her lips part narrowly and remain still for a single second - save two or three. Or maybe it's 'cause you specified it as her 'Dad's' which was.. spot on.

And whatever excuse she had quickly cherry-picked for you, hesitated audibly in her throat before it split from it, "O-Oh, right, shit sorry - was about to end my shift n' thought the store was empty. My bad." scrambling to stuff the other earplug in her pocket and avert all attention to you. Very eagerly.

"Looks like you've got a late fee on this one.." her pitch pummeled deeper, and coarser as she concentrates on the clunky screen she hunches slightly to use. Scrunching the freckles of her face together, hogging the blue-lit screen. Poor girl probably forgot her glasses at home. "Annnd are you looking to rent the sequel?" she peeks her auburn head from the screen and holds up the cased movie, tracing her index over the plastic cleft, tapping twice. "To this - it has a second part."

There's no denying it: she is cute - and guilt rolls your guts around for being so snippy and sullen to her earlier. But based on her demeanor growing enthused the second she saw what movie you had in hand - she doesn't seem to care a hoot.

"Out of stock," replied you, indifferent-sounding - and strking; crossed arms, bent knee, stiffly-standing. Comparable to a millpond. "Guess I won't be the only person with late fees." you take a breath to jest, shaking loose strands of hair from your eyes.

"Haha," you're no world-class comedian; that joke wasn't all that funny, but the need to hurl any affirming noise at you, was necessary. Relenting to reflex. What can she say? Love at first sight! "Yeah, that seems like the agenda these days," Ellie sighs out, molding the plump of her lip under her teeth and reshapes it into a dorky smirk. Isn't she just a sweet chocolate-box of adorability?

"Hmm, bummer."

That hum and word trips into her ears, knocking some brain-cog, and an idea limns her features; they glow wide. "Actually - um, I've got a copy of the sequel at my place. Technically it's my Dad's, but.." her pitch fluctuates, mindlessly thumbing the case between two fiddly hands. "Maybe you can - if you want, not pressuring you or anything - come over?" she throws a pointed thumb backwards, motioning a potential future. "Watch it? If you weren't planning on watching it with somebody else."

Slick trick to seeing if you're single; of course you'd watch movies with your boyfriend - or girlfriend.

"Hmmm.." you hummed longer this time, and this time it admitted the mushrooming of an almost aggravating anticipation in her belly. Like you meant to torture her with 'hmms' and nothing but 'hmms' as your answer hung high in cloudy abeyance, until, "What's the name on your tag - ah, Ellie."

"Yeah?"

"Ellie," you confirm her name twice, and speak it to enthrall her full-scale attention. Made it sound fucking sugary sweet, through a swirly whisper and a twist of your head. "If you can give me a discount, or a full wipe on that late fee, then yes. It's a date."

Light panic ensues. "Date?" she croaks and laughs it off, "I mean - pshh, guess that's one way to put it." backtracking to her hunched, elbows-on-the-counter pose.

"You put it that way."

"Yeah, I just.. didn't wanna admit that." immediately, she uncurls her spine again, relaxing her muscles to somewhat peer at you. "Sure. No more fees." Rounded eyes lost - adamant on indirectly staring at you and the space below you, because Goddess forbid a stroke of idiocy flickers through her while gawking at you.

The store runs dead-quiet in the background of your conversation, leading you to one golden question. "Your shift over after this?"

Oh damn, her cheeks are pink. "Uh-huh," bet she's oblivious to that red-hot beam nearly bursting the seams to her face, too. Nasal lines fold as a severe smile tugs, shadowed by her bent thumb poking at it. "Takin' my car?"

And that's how you pick up girls at a video store in the 90s - the Ellie Williams way.

this isn't even the full idea

#✮─── . aestra's bibliotheca#ellie williams#ellie williams x reader#ellie tlou#ellie williams fluff#⤹𓍢ִ໋aestras asks#lesbian#sapphic#ellie x reader#ellie williams x fem!reader#ellie williams x masc!reader#ellie williams fic#⋆ .🩵 anon#ellie williams concept#blockbuster!ellie#ellie williams drabble#ellie williams oneshot#the last of us fanfiction#ellie the last of us#ellie the last of us 2#the last of us 2#the last of us au#ellie williams au#ellie williams fanfiction#ellie x fem reader#ellie williams smut

789 notes

·

View notes

Text

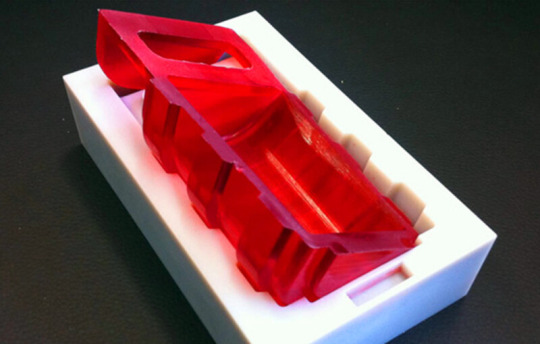

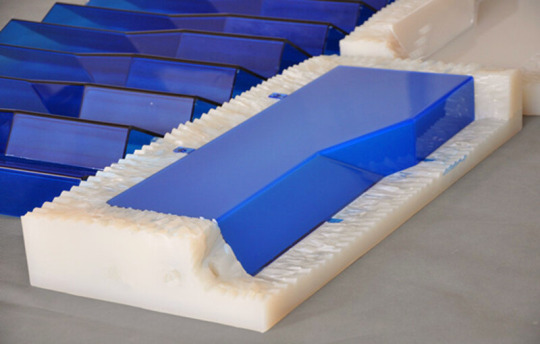

Working of Vacuum Casting and Its Multiple Uses

To make complicated components, a liquid substance is sucked into a silicone mold under vacuum. This method is known as vacuum casting. Rubber and plastic are examples of elastomers that are utilized as liquid materials in vacuum casting.

Since polyurethane resin, a kind of elastomer is employed as the casting medium, vacuum casting is also frequently referred to as polyurethane casting or urethane casting. When producing plastic components, vacuum casting is a more cost-effective method than injection molding because of its reduced manufacturing costs.

For batch manufacturing and other low-volume production tasks, vacuum casting is a great method of production. Vacuum casting is widely utilized in India's manufacturing of industrial electronics, FMCG, and consumer goods.

How do you work with vacuum casting?

Injection molding, in which cast material is poured into molds to create items, and vacuum casting services are very comparable processes. The kinds of molds used in injection molding and vacuum casting differ from one another.

Molds for injection molding might be formed of steel, aluminum, or other materials. Silicone molds are utilized in vacuum casting, nevertheless. This significantly lowers the mold-making cost because silicone is more affordable and has better durability.

Polyurethane is the most often utilized casting material in this procedure. The qualities of various polyurethanes vary, including good shock and temperature resistance, elasticity, flexibility, and structural stiffness. Thus, different polyurethanes may be employed depending on the kind of product being created.

Vacuum casting uses

Making complicated and sophisticated goods may be accomplished more cost-effectively and efficiently with vacuum casting as opposed to the conventional injection molding method.

Due to its efficient production process, vacuum casting finds widespread application in the fabrication of commercial items. The following are a few industries that employ vacuum casting:

Manufacturing of consumer goods

Vacuum casting is a more effective method of producing consumer goods including combs, hair brushes, makeup packaging, sunglasses, pens, and other stationery.

Industry of Food and Beverages

Vacuum casting is used to create food and beverage containers, bottles, cans, mugs, and glasses. Due to the process's great efficiency and ability to produce goods quickly, vacuum casting is widely utilized in various industries where rapid manufacture is essential.

Advanced industry

Excellent heat and shock resistance is a feature of polyurethanes. Therefore, the recommended production procedure for creating electrical device housings is vacuum casting by Vacuum Casting Manufacturer using polyurethanes.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Explore vacuum casting#Vacuum Casting Services China#Vacuum Casting Manufacturer#Vacuum Casting supplier

2 notes

·

View notes

Text

Faster your business to market with Kusla rapid manufacturing services

Rapid Prototyping & low volume Manufacturing Service

Machining and Molding For Plastic & Metal Parts

ISO 9001:2015 Certified Factory

Request A Quote

About Us

Kusla, established in 2013, is a rapid prototyping & rapid Manufacturing company based in Suzhou, China.

We have the most advanced machines and the best engineers to provide you with unparalleled rapid prototyping and manufacturing services.

We can offer you plastic and metal prototyping services and low-volume manufacturing utilizing CNC machining, 3D Printing, Sheet Metal Fabrication, Urethane Casting, Injection Molding, and Diamond turning.

0 notes

Text

10 Benefits of Using the Rotomolding Process for Custom Plastic Products

The rotational molding process, commonly known as rotomolding, is a versatile manufacturing method that has been transforming the way custom plastic products are created. This process is especially advantageous for industries seeking durable, customizable, and cost-effective solutions. Let’s explore the top 10 benefits of using the rotomolding process for custom plastic products.

1. Cost-Effective Tooling

One of the most significant advantages of rotomolding is its low-cost tooling. Compared to other molding methods like injection or blow molding, the molds used in rotomolding are simpler and more affordable to produce. Since the process doesn’t require high-pressure equipment, the overall cost of setting up a production line is significantly lower. This makes it an ideal choice for small businesses or projects with limited budgets.

2. Design Flexibility

Rotomolding offers unparalleled design flexibility, allowing manufacturers to create complex shapes, intricate details, and large hollow parts with ease. Unlike other molding processes, rotomolding can produce products with uniform wall thickness and seamless joints. Whether it’s a water tank, playground equipment, or industrial container, this process ensures high levels of precision and creativity in design.

3. Durability and Strength

Products manufactured through rotomolding are renowned for their durability and strength. The process ensures uniform material distribution, which eliminates weak points and enhances structural integrity. Additionally, rotomolded products are resistant to stress cracking, impact, and harsh environmental conditions, making them ideal for outdoor and industrial applications.

4. Customizable Material Properties

Rotomolding allows for the use of a wide range of thermoplastics, such as polyethylene (PE), polypropylene (PP), and PVC. Manufacturers can customize material properties to meet specific requirements, such as UV resistance, chemical resistance, or flame retardancy. This adaptability makes it easier to tailor products to different industries and applications.

5. Seamless and Leak-Proof Designs

The rotomolding process creates products with seamless and one-piece designs. This is especially beneficial for applications requiring leak-proof containers, such as water tanks, fuel tanks, and chemical storage units. The absence of joints or welds reduces the risk of leaks and enhances product reliability.

6. Ideal for Low-Volume Production

For businesses requiring small production runs, rotomolding is an excellent option. The low tooling costs and ability to quickly switch molds make it feasible to produce custom products in limited quantities without incurring excessive expenses. This is particularly advantageous for prototyping and niche market applications.

7. Wide Range of Applications

Rotomolding is versatile enough to cater to a broad spectrum of industries, including agriculture, automotive, marine, and healthcare. It can be used to manufacture anything from storage tanks and kayaks to medical devices and automotive parts. The process’ adaptability ensures it can meet the diverse needs of various sectors.

8. Eco-Friendly Manufacturing

The rotational molding process is inherently eco-friendly. Unlike other molding methods, rotomolding generates minimal waste since excess material can be reused. Additionally, the absence of high-pressure machinery reduces energy consumption, making it a more sustainable manufacturing choice. This benefit is particularly appealing in today’s environmentally conscious market.

9. Uniform Wall Thickness

Rotomolding ensures that products have consistent wall thickness, which is critical for maintaining structural integrity and durability. The even distribution of material during the molding process eliminates weak spots and ensures a high-quality final product. This feature is especially important for large items, such as tanks and industrial containers.

10. Ease of Customization

Customization is at the heart of rotomolding. Manufacturers can incorporate features like logos, textured surfaces, multiple colors, and even threaded inserts directly into the mold. This eliminates the need for secondary operations and allows for the creation of highly personalized products. Whether you’re looking for unique aesthetics or specific functional features, rotomolding can deliver.

Conclusion

The rotomolding process offers numerous advantages that make it a preferred choice for custom plastic product manufacturing. From cost-effective tooling and design flexibility to durability and eco-friendliness, the benefits of rotomolding are hard to ignore. Its ability to produce seamless, high-quality, and customizable products ensures it remains a valuable asset for industries worldwide. Whether you’re a small business owner or a large-scale manufacturer, investing in rotomolding can open up new possibilities for creating innovative and reliable products.

0 notes

Text

Revolutionizing Manufacturing with Injection Molding and Thermoformed Products

Injection molding and thermoformed products have become crucial in the manufacturing industry, offering efficient production methods for a wide range of items. These processes are utilized across various sectors, from automotive parts to consumer goods, providing a high level of precision and consistency. The rise of companies such as Alcamiglobal.com has played a significant role in delivering high-quality solutions using these technologies.

Injection Molding: A Modern Manufacturing Marvel

Injection molding is a manufacturing process that involves injecting molten material into a mold to create complex shapes with precision. The most common materials used for injection molding include plastics, metals, and even rubber. This process is known for its ability to produce high volumes of parts with consistent quality and minimal waste. Industries like automotive, medical, and electronics have benefited greatly from this technology, as it enables manufacturers to produce intricate components that meet stringent specifications.

The key benefits of injection molding include its speed, repeatability, and ability to create complex geometries. Once the mold is designed, it can be used to create thousands or even millions of identical parts, making it an ideal solution for mass production. Moreover, the variety of materials available for injection molding ensures that manufacturers can choose the best material for their product, whether it requires flexibility, durability, or resistance to heat.

Thermoformed Products: Cost-Effective and Versatile

Thermoforming is another popular manufacturing process where a plastic sheet is heated to a pliable temperature, formed over a mold, and then trimmed to create the final product. This method is ideal for producing lighter parts or packaging materials that do not require the level of precision associated with injection molding. Thermoformed products are used extensively in packaging, point-of-sale displays, and medical packaging, among other applications.

One of the biggest advantages of thermoforming is its cost-effectiveness, especially for low to medium volume production runs. It also offers design flexibility, as it can accommodate a variety of shapes and sizes. For manufacturers, this means the ability to prototype quickly and affordably, without the need for complex tooling or expensive molds. Additionally, thermoforming allows for easy customization of features like textures, colors, and finishes, which can enhance the appeal of the final product.

The Role of Injection Molding and Thermoforming in Modern Manufacturing

Both injection molding and thermoforming have become integral to modern manufacturing processes. The decision between the two often depends on the specific requirements of the product being created. Injection molding is ideal for parts that require high precision and consistency, while thermoforming is best suited for products where cost-effectiveness and speed are the priorities.

Companies like Alcamiglobal.com have mastered both technologies, offering customized solutions for clients in various industries. With the expertise and experience in injection molding and thermoformed products, businesses can achieve the best possible results for their manufacturing needs.

Conclusion

Incorporating injection molding and thermoformed products into the production process can help manufacturers meet the increasing demands of efficiency, quality, and customization. These methods provide flexibility in design and cost, making them attractive options for businesses looking to streamline production while maintaining high standards. With the continued advancements in manufacturing technology, companies like Alcamiglobal.com are paving the way for innovative solutions that will shape the future of industrial manufacturing.

0 notes

Text

Medical Component Manufacturing Market Key Players, Revenue And Growth Rate

The global medical component manufacturing market size is expected to reach USD 15.93 billion by 2030, according to a new report by Grand View Research, Inc. It is expected to expand at a CAGR of 4.4% from 2021 to 2030. The rising demand for 3D printed parts in the medical industry is projected to contribute to market growth.

Penetration is the adoption of medical component manufacturing in various applications in the market. The penetration of medical component manufacturing is likely to be the highest in the 3D printing segment. The benefits of 3D printing such as improved productivity, cost-effectiveness, personalization, and customization of medical products, applications in complex operations, and rapid medical prototyping are projected to benefit the growth of the 3D printing market.

The plastic injection molding process segment accounted for the largest revenue share of over 65.0% in 2020. The segment is projected to grow due to the development of efficient products using better-engineered resins. Moreover, the process can help component manufacturers produce cost-effective products in various sizes and shapes. Some of the low-cost products include disposable gloves, syringes, plastic instruments, and different one-time products for healthcare facilities.

The rising geriatric population is projected to remain an indirect contributor to market growth. There has been a change in the pattern of the aging population across the globe in the recent past owing to the decreasing levels of fertility and rising life expectancy. This has led to a longer lifespan of people, wherein the share of old people or geriatric population is growing at a rapid pace. As per the United Nations, there are over 727 million people globally who are aged 65 or above as of 2020.

Gather more insights about the market drivers, restrains and growth of the Medical Component Manufacturing Market

Medical Component Manufacturing Market Report Highlights

• The 3D printing process segment is anticipated to register the fastest CAGR of 20.8% from 2021 to 2030. Suitability to produce complex and customized products, along with cost efficiency in low volume production, is projected to drive the segment over the forecast period

• The plastic injection molding process segment held the largest revenue share of over 65.0% in 2020. Advantages such as durability, strength, ease of handling, and improved sterilization make the process comply with stringent regulations set by different government bodies

• North America accounted for the largest revenue share of over 40.0% in 2020. The Increasing geriatric population, along with a rise in lifestyle diseases, is projected to benefit the growth of the medical device industry in the region, thus benefiting the demand for various medical components

• Leading companies in the industry are focused on the development of advanced processes such as 3D printing and are likely to increase their R&D expenditure over the coming years. The merger & acquisition activities are anticipated to rise over the coming years as companies are focused on improving their market share

Medical Component Manufacturing Market Segmentation

Grand View Research has segmented the global medical component manufacturing market on the basis of process and region:

Medical Component Manufacturing Process Outlook (Revenue, USD Billion, 2017 - 2030)

• Forging

• Metal Injection Molding

• 3D Printing

• Ceramic Injection Molding

• Investment Casting

• Plastic Injection Molding

Medical Component Manufacturing Regional Outlook (Revenue, USD Billion, 2017 - 2030)

• North America

o U.S.

• Europe

o Germany

o France

o U.K.

o Spain

• Asia Pacific

o China

o India

o Japan

Order a free sample PDF of the Medical Component Manufacturing Market Intelligence Study, published by Grand View Research.

#Medical Component Manufacturing Market#Medical Component Manufacturing Market Size#Medical Component Manufacturing Market Share#Medical Component Manufacturing Market Analysis#Medical Component Manufacturing Market Growth

0 notes

Text

Pelletizing Machines: An Essential Tool for Modern Manufacturing

In the present-day fast-paced industrial industry, efficiency and cost-effectiveness are critical. Enter the pelletizing machine, a versatile workhorse that has become indispensable across a wide range of industries. From plastics and chemicals to pharmaceuticals and food processing, pelletizing machines play a crucial role in transforming raw materials into uniform, easy-to-handle pellets.

What is a Pelletizing Machine?

A pelletizing machine, also known as a pelletizer, is a piece of equipment that converts powdered or granular materials into small, free-flowing pellets. This is achieved by compressing the material through a die, resulting in consistent shapes and sizes. The process offers numerous benefits, making it a preferred choice for many manufacturers.

Why are Pelletizing Machines Essential?

Here's a breakdown of why pelletizing machines are so vital in modern manufacturing:

Improved Material Handling: Pellets are easier to store, transport, and feed into other machinery compared to loose powders or granules. This reduces waste, dust, and potential hazards.

Enhanced Product Quality: Pelletization ensures uniform size and density, leading to consistent product quality and improved performance. Imagine the difference consistent plastic pellets make in injection molding compared to using inconsistent plastic flakes.

Increased Production Efficiency: Pelletizing streamlines production processes, allowing for higher throughput and reduced downtime. This is especially significant in industries with high volume production.

Reduced Waste and Environmental Impact: By minimizing dust and spillage, pelletizing machines contribute to a cleaner and safer working environment. They also enable the efficient use of recycled materials, promoting sustainability.

Versatility: Pelletizing machines can handle a wide range of materials, including plastics, chemicals, pharmaceuticals, food ingredients, and even biomass. This adaptability makes them valuable across diverse sectors.

Applications of Pelletizing Machines:

Plastics Industry: Producing plastic pellets for injection molding, extrusion, and blow molding. This includes recycling plastic waste into reusable pellets.

Chemical Industry: Producing pellets of fertilizers, pesticides, and other chemicals for easier handling and application.

Pharmaceutical Industry: Forming pellets of drugs for controlled release and improved dosage accuracy.

Food Processing: Creating food pellets for animal feed, snacks, and convenience foods.

Biomass Energy: Converting biomass materials like wood waste and agricultural

residues into fuel pellets.

Types of Pelletizing Machines:

There are various types of pelletizing machines, each designed for specific applications and materials:

Ring Die Pelletizers: Commonly used for high-volume production of plastic pellets.

Flat Die Pelletizers: Suitable for pelletizing a wider range of materials, including those with low melting points.

Extrusion Pelletizers: Used for creating pellets from molten materials like plastics and rubber.

Looking Ahead:

As technology advances, we can expect further innovations in pelletizing machine design, including increased automation, improved energy efficiency, and enhanced process control. This will further solidify the role of pelletizing machines as a cornerstone of modern manufacturing.

While this blog focuses on pelletizing machines, it's worth noting that other technologies like plethysmometers and R&D coaters also play important roles in specific industries.

A plethysmometer is a device used to measure volume changes in a living organism or organ, often used in pharmacological research.

An R&D coater is a specialized piece of equipment used in research and development to test and develop new coating formulations and processes.

These technologies, while distinct from pelletizing machines, highlight the diverse range of tools and equipment that drive innovation and efficiency in modern manufacturing and research.

0 notes

Text

Custom Plastic Injection Molding by Topwell: Your Partner for Precision Manufacturing

In the world of modern manufacturing, custom plastic injection molding stands out as a highly efficient and versatile process for producing complex plastic parts. Topwell, a global leader in plastic injection molding solutions, delivers cutting-edge technology and unmatched expertise to meet diverse industry needs. With a commitment to precision and quality, Topwell offers tailored solutions that align with your unique requirements.

What Is Custom Plastic Injection Molding?

Custom plastic injection molding is a manufacturing process in which molten plastic is injected into a specially designed mold under high pressure. The plastic cools and solidifies, forming a finished part with intricate shapes and fine details. This technique is widely used across industries such as automotive, healthcare, electronics, and consumer goods.

Why Choose Topwell for Custom Plastic Injection Molding?

Topwell combines state-of-the-art facilities, advanced machinery, and skilled professionals to deliver superior custom molding solutions. Here’s why Topwell is the preferred partner for many businesses:

1. Tailored Solutions for Diverse Applications

Topwell specializes in creating custom molds designed to meet specific customer needs. Whether it’s small intricate components or large complex parts, Topwell has the expertise to deliver.

2. High-Quality Materials

Topwell works with a wide range of high-performance thermoplastics, ensuring that the final product meets functional and aesthetic requirements. From durable engineering plastics to eco-friendly biodegradable options, the material selection is optimized for your project.

3. Advanced Manufacturing Technology

Equipped with cutting-edge injection molding machines, Topwell ensures high precision, consistency, and efficiency. The company’s robust automation systems reduce production time and cost, without compromising on quality.

4. Prototyping and Design Support

Topwell offers comprehensive prototyping and design services to refine your ideas before full-scale production. Using tools like 3D modeling and simulations, their team ensures the mold design is flawless.

5. Cost-Effective Solutions

Topwell’s streamlined production processes minimize material waste and optimize efficiency, resulting in cost-effective solutions for high-volume and low-volume production runs.

6. Commitment to Sustainability

Topwell is dedicated to environmentally friendly manufacturing. The company incorporates recyclable materials and energy-efficient practices into its operations, reducing its ecological footprint.

Applications of Custom Plastic Injection Molding

Topwell’s custom injection molding services cater to various industries, including:

Automotive: Interior and exterior components, dashboards, and lighting parts.

Medical: Precision parts for devices and instruments.

Electronics: Casings, connectors, and structural components.

Consumer Goods: Packaging, toys, and household items.

Aerospace: Lightweight yet durable parts for aviation.

Why Precision Matters in Plastic Injection Molding

Precision in plastic injection molding ensures components meet exacting standards of quality, functionality, and aesthetics. With its advanced technology, Topwell can achieve tight tolerances and intricate details, providing products that align with strict industry requirements.

Topwell: Delivering Excellence in Custom Molding

Topwell has established itself as a trusted name in the custom plastic injection molding industry by delivering solutions that exceed expectations. With years of experience and a customer-centric approach, the company is committed to helping businesses achieve their goals through innovative manufacturing techniques.

Conclusion

Custom plastic injection molding is a cornerstone of modern manufacturing, enabling businesses to create high-quality parts with speed and efficiency. Topwell’s dedication to precision, innovation, and sustainability makes it a reliable partner for all your custom molding needs. Whether you're launching a new product or improving an existing design, Topwell provides the expertise and technology to bring your vision to life.

0 notes

Text

HS Mold – Your Partner in Low-Volume Injection Molding for Industrial Design

Industrial design firms are the creative architects of tomorrow’s products. But translating breathtaking concepts into reality can be a budget battle, especially when dealing with limited production runs. Traditional manufacturing often demands high minimum orders, leaving you stranded in financial constraints.

HS Mold: Your GPS to Low-Volume Success

At HS Mold, we specialize in plastic injection molding—your lifeline when industrial design companies need to bring low-volume projects to life. We are among the Plastic injection molding manufacturers in china. We harness the latest technologies and deliver superior quality, even in small production series.

Case Study:Coolant Expansion Tank

Now, let us take you through an instance. A German industrial design firm challenged us to develop the design for a high-performance Coolant Expansion Tank destined for a luxury yacht designed and built in Germany. The catch? They only needed 500 and were on a budget that wouldn’t capsize the project.

HS Mold: Where Experience Meets Collaboration

Immediately, our seasoned engineers went to work. While the initial design considered ultrasonic welding for budgetary reasons, we quickly realized a potential leak in the plan. The watertight seal is crucial to a marine application. Welding simply could not provide the watertightness required for this application. Transparency is our guide. We kept an open discussion with the design firm in a feasible alternative. Our in-house capabilities and experience in low-volume injection molding assisted in guiding the client to what was feasible: vibration friction welding, a revolutionary process we had perfected. It means excellent sealing capabilities with this method, a worry-free voyage for the yacht owner, and all on an affordable budget.

Above Manufacturing: Collaborative Refinements

We indeed committed to more than just the process of manufacturing. Our engineers critically analyzed the design and identified the areas of refinement. We created a detailed DFM (Design for Manufacturability) report with proposals for modifications such as optimizing weld lines, making changes in product thickness, and adding structural ribs. All these added refinements, along with the possibility granted by low-volume injection molding from HS Mold, were able to streamline production and better product quality with more consistent results.

A Successful Voyage: Collaboration Sets Sail

Through the use of vibration friction welding and close collaboration on design optimization, we were able to deliver water tanks far beyond what the customer expected. The superior seal allowed a carefree experience, while the optimized design provided an end product of the highest quality. This success story further established the great partnership between this Industrial Design firm and HS Mold.

HS Mold: Your Low-Volume Injection Molding Partner

This project is an excellent testament to the power of collaboration between Industrial Design firms and HS Mold, one of the leading manufacturers of plastic injection molding in China. We don’t just make; we make you win. Innovative solutions, clear communication, and collaboration allow us to ensure the realization of your vision even under a tight budget and with low-volume needs. Are you ready to chart the course for success with low-volume injection molding? Contact HS Mold today and learn how our experience will help guide you through the rough waters of product development!

0 notes

Text

PVC Additives Market-Industry Forecast, 2024–2030

PVC Additives Market overview

Request Sample Report :

Report Coverage

The report: “PVC Additives Market- Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the PVC Additives Industry.

By Type: Stabilizers, Impact Modifiers, Processing Aids, Lubricants, Plasticizers, Fillers, Others.

By Form: Granules, Powder, and Liquid.

By Fabrication Process: Extrusion, Injection Molding, Blow Molding and Others.

By Application: Pipes, Packaging, Furniture’s, Door and Windows, Cables, Medical Devices, Flooring, and Others.

By End Use: Building and Construction, Automotive industry, Textile Industry, Electrical and Electronics, Medical Industry, Food and Beverages, and Others.

By Geography: North America, South America, Europe, APAC, and RoW.

Key Takeaways

Asia Pacific dominates the PVC Additives market owing to rapid increase in building and construction sector.

Certain applications require higher impact strength than PVC would demonstrate normally.

The market drivers and restraints have been assessed to understand their impact over the forecast period.

The report further identifies the key opportunities for growth while also detailing the key challenges and possible threats.

The other key areas of focus include the various applications and end use industry in PVC Additives market and their specific segmented revenue.

Inquiry Before Buying:

PVC Additives Market Segment Analysis — By Type

Stabilizers held the largest share in the PVC Additives market in 2019. This growth is mainly attributed to the increasing demand for stabilizers in varied applications such as pipes & fittings, rigid & semi-rigid films, and others. Due to their superior properties, such as UV resistance, weathering and heat-aging, stabilizers are increasingly favored over other types of additives. To avoid premature degradation, many polymers are vulnerable to environmental degradation and require the addition of a stabilizer such as an antioxidant or UV absorbent. Hampered phenols and obstructed amine light stabilizers (HALS) deactivate emerging radicals, like air-oxidated peroxy compounds. UV absorbers dissipate UV radiation through the material by a method that is non-destructive. Monomers are added to free radical inhibitors as stabilizers to prevent premature polymerization.

PVC Additives Market Segment Analysis — By Forms

Granules held the largest share in the PVC Additives market in 2019. Granules help to increase the density of the freshly synthesized polymer since it lacks the flowing properties required to be processed by an extruder. Due to their plasticity property, they can be molded or shaped by application of heat. Other characteristics of plastic are its low electrical conductivity, low density, transparency and toughness which allowed it to be used for the creation of different products. In addition, plastic’s versatility has led to its use in a wide array of industries. In order to produce normal and high-strength concretes, 10%, 20%, and 30% replacement ratios by volume of PVC granules and powder are used.

PVC Additives Market Segment Analysis — By Fabrication Process

Extrusion held the largest share in the PVC Additives market in 2019. Extrusion is used mainly for handling large plastic volumes. The pellets, granules, chips, or powders are fed into the extruder and melted under high temperatures. PVC compounding is a process where additives are mixed with the base resin in order to obtain a homogenous mix. The additives are used either to enhance process capabilities or to improve product efficiency. The use of sizing parts will generate any length of profiles to the desired length. Co-extrusion allows the manufacture of semi-finished multi-layer products with special barrier properties.

PVC Additives Market Segment Analysis — By Application

Pipes is projected to witness highest share in PVC Additives market in 2019. This rise is mainly due to the growing demand for pipes & fittings in piping and plumbing, gas pipeline laying, and telecommunication and electrical cable sheathing. Due to the replacement of traditional concrete, iron, and steel-based pipes & fittings with PVC pipes in the building & construction industry, the market for PVC additives in the pipes & fittings segment is expected to witness significant development. The market for building materials is on high demand, with the continually growing population. The prerequisite for housing is pipes and fittings, which are a critical necessity. Urbanization with a large network of connections has contributed to an increase in drainage requirements. There is a growing demand for pipes and fittings to cope with advanced piping links, which in turn drives market growth. Globally, there has been a rising demand for rainwater harvesting system that has helped to heat up the pipe and fit market. In 2019, recently the commercial sector has slowed as the risk for a downturn in global construction increases due to COVID-19 pandemic which led to temporary lockdown of all economic activities across globe.

PVC Additives Market Segment Analysis — By End Use

Building and construction dominates the PVC Additives market growing at a CAGR of 6.00%. With the growing construction industry and its demand for PVC Additives particularly in the regions of Asia-Pacific, North America and Europe, the demand of PVC Additives for all kinds of buildings is expected to see an upsurge. Residential application segment is witnessing growth due to the rising penetration from untapped markets. First-mover advantage in untapped regions and relatively low acquisition costs remain key driving forces in this application market. Furthermore, R&D in PVC Additives will support the growth of the PVC Additives market.

Schedule A Call :

PVC Additives Market Segment Analysis — Geography

Asia-Pacific (APAC) dominated the PVC Additives market growing at CAGR of 41% followed by North America and Europe. APAC as a whole is set to continue to be one of the largest and fastest growing construction markets globally. Large and more developed markets such China, India, Japan, and South Korea are expected to grow more in the coming years. China is driving much of the PVC Additives market demand in Asia-Pacific region followed by India and Japan. Of the five fastest growing regions in construction sector, other than U.S. all are Asian countries including China and India who majorly drive the demand for construction investment in this regions. The strong and healthy growth in construction sector is associated with growing population and middle class economy, which tend to drive APAC residential construction market further and hence the PVC Additives market. The number of buildings that have illuminated PVC Additives is growing sharply in APAC region. The increasing number of new building constructions, along with the rise in the number of renovation projects has further propelled the market. Currently the construction industry has been affected due to COVID-19 pandemic where most of the industrial activity has been temporarily shut down. In in turn has affected the demand and supply chain as well which has been restricting the growth in year 2020.

PVC Additives Market Drivers

Replacement of conventional material with PVC will drive the market

PVC is replacing traditional building materials such as wood, metal, concrete and clay in many applications. Versatility, cost-effectiveness and excellent use record make it the most important polymer in the construction sector, accounting for 60%. These products are often lighter, less expensive and offer many performance advantages. Making it prominent material than conventional.

Rapid industrialization and infrastructure activity will augment the growth of PVC Additives

Improvement in economic climate along with boom in industrialization and infrastructure activity across the globe is leading the growth of PVC Additives. Oxford Economics has estimated global infrastructure investment needs to be $94 trillion between 2016 and 2040. This is 19 percent higher than would be delivered under current trends. With the increasing rate of industrialization and infrastructure activity, as a result of which PVC Additives growth is augmenting.

PVC Additives Market Challenges

Low R&D expenditure in the emerging markets and high maintenance cost will hamper the market to growth

Innovation is the key to developing new products, but most manufacturers are not investing much into R&D. Rather than cutting-edge technology, they invest in creating relevant technology. These factors are hampering the growth of the market. Because most of the pipes and fittings are located underground in the event of any malfunction or failure, the cost of repairs can be even greater.

Buy Now :

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the PVC Additives market. In 2019 the PVC Additives market has been consolidated by the top five players accounting for xx% of the share. Major players in the PVC Additives market are BASF SE, Arkema SA, Akzo Nobel N.V, Adeka Corporation, Clariant AG and Others.

Acquisitions/Technology Launches/ Product Launches

In April 2017, Lanxess Corporation has completed acquisition of Chemtura. With this acquisition, Lanxess significantly expands its market position for PVC additives. A notable sampling includes: the sale of its proprietary OBS (organic-based heat stabilizers) for rigid PVC applications to Baerlocher; the sale of the rest of its PVC additives business to Galata Chemicals.

Key Market Players

The Top 5 companies in the PVC Additives Market are:

BASF SE

Arkema SA

Akzo Nobel N.V

Adeka Corporation

Clariant AG

For more Chemicals and Materials Market reports — Please click here

0 notes

Text

rPET Black Masterbatches Manufacturers: How to Choose the Right One?

As sustainability gains momentum across industries, rPET (recycled polyethylene terephthalate) black masterbatches are becoming increasingly popular. These masterbatches are ideal for enhancing the properties of recycled plastic, ensuring both high performance and eco-friendliness. Choosing the right manufacturer is critical to achieving consistent quality and sustainable results. Here’s a guide to selecting the best rPET black masterbatch manufacturer.

1. Look for Sustainable Practices

Since rPET black masterbatches are made from recycled PET, the manufacturer’s sustainability practices should align with your environmental goals.

What to Check:

Use of certified recycled PET materials.

Processes that minimize waste and reduce the carbon footprint.

Compliance with sustainability certifications like Global Recycled Standard (GRS).

2. Assess Product Quality

High-quality rPET black masterbatches ensure consistent color, UV stability, and mechanical performance in the final product.

Key Quality Indicators:

Uniform dispersion of carbon black.

High carbon black content for deep coloring and opacity.

Low ash and moisture levels.

3. Consider Customization Options

Your specific application may require customized rPET black masterbatches with unique properties. A good manufacturer should offer tailored solutions.

Customization Features:

Additives like UV stabilizers or antioxidants.

Tailored carbon black concentration based on end-use requirements.

Compatibility with different processing methods, such as injection molding or extrusion.

4. Check Certifications and Standards

Reputable manufacturers comply with international standards and certifications, ensuring safe and reliable products.

Important Certifications:

ISO standards for quality management.

REACH compliance for safe chemical use.

FDA or food-grade certifications for specific applications.

5. Evaluate Technical Support

A reliable manufacturer provides technical support to help you maximize the performance of rPET black masterbatches.

Technical Assistance Includes:

Guidance on selecting the right masterbatch for your application.

Process optimization tips to minimize waste and improve efficiency.

Troubleshooting during production.

6. Review Manufacturing Capabilities

The manufacturer’s production capacity and technology determine their ability to meet your volume and quality requirements.

What to Look For:

Advanced machinery for consistent production.

High-capacity manufacturing for large-scale orders.

Robust quality control measures at every production stage.

7. Focus on Cost-Effectiveness

While cost is a factor, prioritize value over the lowest price. A good manufacturer balances affordability with high-quality products.

Considerations:

Competitive pricing without compromising quality.

Bulk discounts for large orders.

Transparent pricing structures.

8. Check Customer Feedback and Reputation

The reputation of the manufacturer can provide valuable insights into their reliability and product performance.

How to Verify:

Read customer reviews and testimonials.

Request case studies or examples of successful projects.

Assess their experience in producing rPET black masterbatches.

9. Supply Chain Efficiency

Reliable and timely delivery of materials is crucial for uninterrupted production.

Supply Chain Considerations:

Consistent availability of raw materials.

Efficient logistics for timely delivery.

Support for both domestic and international shipments.

10. Commitment to Innovation

A forward-thinking manufacturer invests in research and development to improve their products and align with market trends.

Innovation in rPET Black Masterbatches:

Development of new formulations for emerging applications.

Use of advanced technologies for better dispersion and compatibility.

Focus on reducing environmental impact.

Conclusion

Choosing the right rPET black masterbatch manufacturer involves evaluating their sustainability practices, product quality, certifications, and technical support. A trusted manufacturer will not only provide high-quality masterbatches but also support your goals for efficiency and sustainability. Take your time to research and collaborate with a manufacturer that meets your specific needs, ensuring long-term benefits for your business and the environment.

0 notes

Text

The Comprehensive Guide to Sand Casting: Why It’s Essential for Modern Manufacturing

Sand casting is one of the oldest and most versatile methods of metal casting, yet it remains integral to industries ranging from automotive and aerospace to construction and art. For a sand casting company, this process isn’t just a method of producing components—it’s a blend of precision, tradition, and innovation that drives the heart of modern manufacturing.

In this blog, we’ll delve into the sand casting process, its benefits, applications, and why partnering with a reliable sand casting company can give businesses a competitive edge.

What is Sand Casting?

Sand casting is a manufacturing process that uses sand molds to form complex metal components. The process involves creating a mold by compacting sand around a pattern of the desired object. Once the mold is prepared, molten metal is poured into the cavity and allowed to cool. Then, the mold is broken to retrieve the cast part.

The sand casting alumunium has been in use for centuries and continues to evolve with advancements in materials and technology. Its adaptability and cost-effectiveness make it a preferred choice for creating intricate designs, prototypes, and high-volume production parts.

How Does the Sand Casting Process Work?

Pattern Creation A pattern is created to replicate the shape of the desired component. This pattern can be made from wood, metal, or plastic and is typically slightly larger than the final product to account for shrinkage during cooling.

Mold Preparation The pattern is placed in a mold box, and sand mixed with a binding agent is packed around it. The mold is then split open, and the pattern is carefully removed, leaving behind a cavity in the shape of the component.

Core Placement (if required) For parts with hollow sections, cores made of sand are placed within the mold cavity to create these spaces.

Pouring Molten metal is melted in a furnace and poured into the mold cavity through a gating system. The design of this system ensures smooth flow and minimizes defects.

Cooling The molten metal solidifies as it cools, taking the shape of the mold cavity. The cooling time varies depending on the metal and the complexity of the casting.

Removing the Casting Once the metal has solidified, the sand mold is broken apart to retrieve the casting. This step is often followed by sand reclamation, where used sand is recycled for future molds.

Finishing The casting is cleaned, and excess material (such as sprues or runners) is removed. Further finishing processes, such as machining or polishing, may be applied to meet specifications.

Why Choose Sand Casting?

1. Versatility

Sand casting can handle a wide range of metals, including aluminum, steel, iron, and brass. It also accommodates simple to highly complex designs, making it ideal for diverse industries.

2. Cost-Effectiveness

Sand casting molds are inexpensive and easy to produce, especially compared to other casting methods like investment casting. This makes it ideal for both low and high production volumes.

3. Scalability

Whether you need a single prototype or thousands of units, sand casting can accommodate varying production needs efficiently.

4. Size Flexibility

From small components weighing a few grams to massive parts weighing several tons, sand casting can produce parts of virtually any size.

5. Quick Turnaround

With advanced molding techniques and sand reclamation systems, sand casting companies can deliver high-quality parts in relatively short timeframes.

Applications of Sand Casting

The versatility of sand casting allows it to be used in a wide range of industries, including:

Automotive Engine blocks, crankshafts, and other heavy-duty components are often produced using sand casting due to its durability and cost efficiency.

Aerospace Sand casting is used for manufacturing high-strength components like turbine blades and structural parts.

Construction Components such as pipes, valves, and construction machinery parts benefit from sand casting’s robustness.

Art and Sculpture Intricate sculptures, plaques, and architectural elements are created using sand casting for their artistic and aesthetic appeal.

Industrial Machinery Large and complex machine parts such as gear housings and pump casings are commonly made through sand casting.

The Role of a Sand Casting Company

Partnering with a reliable sand casting company is crucial for achieving quality, precision, and consistency in your cast products. Here’s what to look for in a sand casting partner:

1. Expertise and Experience

A reputable sand casting company brings years of experience and a deep understanding of materials and processes. They can recommend the best solutions for your project.

2. Modern Equipment

Advanced technologies, such as computer-aided design (CAD) and automated molding systems, ensure precision and efficiency.

3. Quality Assurance

A reliable company implements strict quality control measures, from material selection to final inspection, ensuring every part meets your specifications.

4. Sustainability Practices

Many sand casting companies now focus on eco-friendly practices, such as sand reclamation and reduced waste. Choosing a sustainable partner supports environmental responsibility.

5. Customization and Innovation

Whether you need a prototype or a unique design, an innovative sand casting company can turn your vision into reality.

Challenges and How Sand Casting Companies Overcome Them

While sand casting offers numerous benefits, it does have challenges, including porosity, shrinkage, and surface finish issues. However, these are effectively managed through:

High-Quality Sand Mixtures The choice of sand and binding agents plays a crucial role in mold stability and surface finish.

Advanced Gating Systems Properly designed gating systems reduce turbulence and minimize casting defects.

Precision in Mold Design Modern techniques like 3D printing of patterns ensure accurate mold creation.

Post-Processing Techniques Machining, grinding, and heat treatment enhance the final product's strength and finish.

Future Trends in Sand Casting

The sand casting industry is evolving with advancements in technology and sustainability:

3D Printing of Sand Molds: This innovation allows for faster mold creation and greater design complexity.

Eco-Friendly Practices: Companies are focusing on reducing emissions and recycling sand to minimize environmental impact.

Automation: Robotics and automation are streamlining the casting process, increasing efficiency, and reducing human error.

Conclusion

Sand casting remains a cornerstone of manufacturing, combining centuries-old techniques with modern advancements to deliver versatile, cost-effective solutions. For industries seeking reliability, adaptability, and precision, partnering with a trusted sand casting company ensures success in even the most demanding applications.

Whether in automotive, aerospace, or industrial machinery, sand casting offers unparalleled flexibility to bring your designs to life. By choosing the right sand casting company, you gain a partner who understands your needs and delivers quality components that meet and exceed expectations.

0 notes

Text

Urethane Casting Service

KUSLA is a leading company in china that provide urethane casting services to fit your timeline and budget. We deliver high-quality Urethane parts for low-volume production.

Request A Quote

Parts As fast As 3 Weeks

Orders of All Volume

Production grade quality

Partner with KUSLA Urethane Casting service

KUSLA’s urethane casting service is a great way to make high-quality parts for prototypes and small production runs. We use 3D printing, CNC machining, and silicone rubber molds to keep costs low and speed up delivery, offering a faster and cheaper option compared to plastic injection molding.

Our urethane materials can closely match the look and feel of many production-grade materials, making it easy to create prototypes that meet your needs. We can make parts in almost any size or shape, and we can match colors using Pantone numbers or color samples.

KUSLA also offers options like insert molding, overmolding, copper shielding, molded-in colors and textures, or custom painting to make sure your parts are just right. Our urethane casting service is the perfect choice for turning your ideas into real, functional parts quickly and affordably.

1 note

·

View note

Text

Rapid Tooling Services - Prototype Injection Molding by Yakon-Mold.com

In today’s fast-paced manufacturing world, the demand for rapid prototyping and production solutions has grown exponentially. Yakon Mold, a leader in precision molding, offers cutting-edge Rapid Tooling Services and Prototype Injection Molding, catering to industries that require quick, efficient, and cost-effective solutions for product development and manufacturing.

What is Rapid Tooling?

Rapid tooling, often referred to as bridge tooling or prototype tooling, is a process that combines rapid prototyping techniques with conventional tooling to create molds quickly and efficiently. It enables the production of small to medium batches of plastic parts, ideal for testing, validation, and even low-volume production.

With Yakon Mold’s expertise, clients benefit from precision, speed, and reliability, making it possible to iterate and refine designs before moving to full-scale production.

The Role of Prototype Injection Molding

Prototype injection molding is integral to product development, offering an efficient way to create functional prototypes using production-grade materials. It allows manufacturers to test the performance, design, and functionality of a part under real-world conditions. Yakon Mold’s advanced capabilities ensure that these prototypes are produced with exceptional accuracy and detail, providing clients with parts that closely mirror the final product.

Key Benefits of Yakon Mold’s Rapid Tooling Services

Speed to Market: Yakon Mold’s rapid tooling services significantly reduce lead times, allowing businesses to get their products to market faster.

Cost-Effective Solutions: By utilizing prototype molds, companies can save on production costs while maintaining high quality.

Flexibility: Rapid tooling enables easy design modifications, accommodating changes without extensive delays or expenses.

High Precision: Leveraging state-of-the-art machinery, Yakon Mold delivers intricate designs with exceptional dimensional accuracy.

Material Versatility: Clients can choose from a wide range of production-grade materials to ensure the prototype matches the desired end-use requirements.

Applications of Rapid Tooling and Prototype Injection Molding

Yakon Mold’s services are widely used across various industries, including:

Automotive: Creating prototypes for new components, ensuring they meet performance standards.

Consumer Electronics: Testing designs for durability and functionality before mass production.

Medical Devices: Producing accurate prototypes to validate performance and meet regulatory standards.

Aerospace: Manufacturing lightweight and durable parts for high-stress applications.

Why Choose Yakon Mold?

With years of experience and a commitment to innovation, Yakon Mold has positioned itself as a trusted partner for rapid tooling and prototype injection molding. Their customer-focused approach ensures seamless collaboration, from design consultation to final delivery. The company’s state-of-the-art facility and highly skilled team provide unparalleled support and expertise, guaranteeing that every project meets the highest standards.

Conclusion

Whether you’re a startup refining a new product or an established manufacturer exploring design possibilities, Yakon Mold’s Rapid Tooling Services and Prototype Injection Molding are designed to empower your vision. By combining speed, precision, and cost-efficiency, Yakon Mold helps businesses stay ahead in a competitive market.

Explore more about their services and discover how Yakon Mold can bring your ideas to life at yakon-mold.com.

1 note

·

View note

Text

Why Crestwood Industries is Leading the Way in Injection Molding Services Across Illinois

When it comes to high-quality plastic molding services in Illinois, Crestwood Industries stands out as a leader in the field. With years of expertise, cutting-edge technology, and a commitment to excellence, Crestwood Industries has earned its reputation as one of the top injection molding companies in Illinois. In this article, we’ll explore why Crestwood Industries is the go-to choice for businesses seeking reliable and efficient mold injection companies in Illinois.

What Makes Crestwood Industries a Top Injection Molding Company in Illinois?

At Crestwood Industries, we specialize in delivering high-precision injection molding services that cater to various industries, including automotive, medical, consumer products, and more. As an established injection molding company in Illinois, we pride ourselves on offering comprehensive services, from design to production, ensuring our clients receive products that meet their exact specifications and quality standards.

Here’s why Crestwood Industries is leading the way in injection molding services across Illinois:

1. State-of-the-Art Technology

To stay ahead in the competitive world of plastic molding services in Illinois, Crestwood Industries invests in the latest injection molding equipment and technology. Our advanced machinery allows us to produce intricate, high-quality parts with precision and efficiency. Whether you need complex parts for specialized applications or simple molded components, we have the tools to meet your needs.

2. Experienced Team of Experts

Our team consists of skilled professionals who have years of experience in the injection molding industry. From engineers to designers, our experts work closely with clients to provide customized solutions that align with their specific project requirements. Whether it's designing a new part or optimizing existing molds, our team ensures that every project is completed on time and to the highest quality standards.

3. High-Quality Materials

At Crestwood Industries, we understand the importance of using the right materials for each molding project. We offer a wide range of high-quality plastics, resins, and composites that are suited for different applications, ensuring durability, functionality, and performance. Whether you need thermoplastics, thermosets, or elastomers, our team will help you select the best material for your product.

4. Comprehensive Injection Molding Services

As one of the leading injection molding companies in Illinois, Crestwood Industries offers a full spectrum of services. These include:

Design Assistance: Our team helps refine your designs, optimizing them for manufacturability and cost-effectiveness.

Prototyping: We create prototypes to test the functionality and design of your parts before full-scale production.

Production: Once the design is finalized, we produce high volumes of parts with fast turnaround times, ensuring that your production schedule is met.

Post-Processing and Finishing: We provide additional services like trimming, assembly, and packaging, delivering finished products ready for use.

5. Fast Turnaround Times

In today’s fast-paced business environment, speed is crucial. Crestwood Industries is committed to delivering projects on time, often exceeding customer expectations for delivery. We understand that time is money, and we strive to offer quick prototyping and production services to meet tight deadlines without compromising quality.

6. Cost-Effective Solutions

As one of the most trusted mold injection companies in Illinois, Crestwood Industries offers cost-effective solutions without sacrificing quality. We work with clients to optimize their designs and processes, helping them achieve lower production costs while maintaining high standards. Whether you need low-volume runs or mass production, we have flexible options that can meet your budget requirements.

7. Sustainability Commitment

In addition to our focus on quality and efficiency, Crestwood Industries is dedicated to sustainability. We use eco-friendly materials and implement energy-efficient practices in our manufacturing process. By reducing waste and optimizing resource use, we contribute to a greener environment while providing our clients with sustainable plastic molding solutions.

Why Choose Crestwood Industries for Your Injection Molding Needs?

When it comes to choosing a reliable injection molding company in Illinois, there are several factors to consider. Crestwood Industries stands out because of our:

Expertise and experience: We’ve built a reputation for quality and reliability in the injection molding industry.

Advanced technology and equipment: Our state-of-the-art machinery enables us to deliver high-precision parts.

Customizable solutions: We provide tailored services to meet the unique needs of each client, no matter the complexity of the project.

Commitment to quality: From design to delivery, we ensure every product meets the highest standards of quality and performance.

Conclusion

Crestwood Industries is a trusted leader among injection molding companies in Illinois, offering comprehensive solutions, advanced technology, and expert service to help businesses bring their products to life. Whether you’re looking for plastic molding services in Illinois or a reliable mold injection company in Illinois, Crestwood Industries has the experience and resources to meet your needs.

Contact us today to learn more about how we can help you with your next injection molding project. Let Crestwood Industries be your partner in achieving manufacturing excellence!

#custom plastic manufacturer in illinois#plastic manufacturer#injection molding companies#plastic molding services

0 notes