#piled raft foundation

Explore tagged Tumblr posts

Text

An Introduction to Piled Raft Foundations: A Comprehensive Guide

Piled raft foundations are increasingly being recognized as an innovative solution in modern construction, especially for structures requiring significant support in challenging soil conditions. This article aims to provide a comprehensive introduction to piled raft foundations, exploring their design principles, advantages, and applications.

What Are Piled Raft Foundations?

Piled raft foundations combine the load-bearing properties of both piles and raft foundations, offering a hybrid solution that enhances stability and reduces settlement. This foundation system comprises a concrete raft or mat sitting atop a series of piles that extend deep into the ground, transferring the load of the structure to the underlying strata.

The piles in this system primarily bear the vertical loads, while the raft distributes the loads and provides additional support. This combination allows for a more even distribution of stress across the foundation, making it suitable for a wide range of soil conditions, including soft, loose, or uneven terrains.

For More Information visit: https://medium.com/@piledraftfoundation/an-introduction-to-piled-raft-foundations-a-comprehensive-guide-3efc6e63acf4

1 note

·

View note

Text

GOTG Review: Legend of the River King

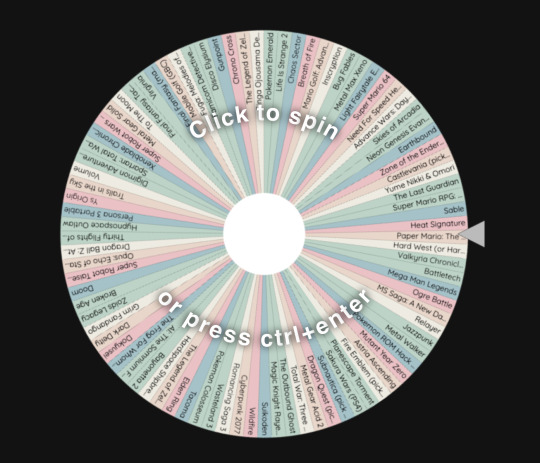

In 2023, I’ve decided to make a real effort in clearing out my massive and ever-increasing backlog of games. To assist with this I built something I like to call Backlog Roulette.

Each month I’ll spin this wheel during the monthly preview episodes of a podcast I co-host called The Casual Hour, and I will play whichever of the 90+ games Lady Luck selects for me. I don’t have to finish every game chosen, but I do need to give them “the old college try.” You can watch me explain the concept and rules if you’re interested, but the other thing of note is I want to write about each game here on GOTG. And the first game that came up was 1998’s Legend of the River King for the Game Boy.

Legend of the River King is a fishing RPG developed by Victor Interactive Software and published by Natsume (which is probably why it gives off some strong Harvest Moon vibes from its visuals).

I think fishing games are fascinating in the same way I think golf and baseball video games are fascinating. It’s interesting to analyze the different ways designers handle their mechanics, how they view the act of casting a rod, throwing a ball or swinging a club through a controller. Whatever method they land on, it’ll never be quite like the real thing, but that layer of abstraction can be its own form of fun.

That’s uh, not really the case here with Legend of the River King. Its mechanics are tedious, arbitrary, confusing and often frustrating. Its options are too deep and its systems are too shallow. I wrote almost 600 words about the arcane way you select your bait and tackle, how the game includes a way to basically bypass all of its most intriguing mechanics and the pretty, but dead simple mini-game you play every time you hook a fish, but it was about as fun to read as Legend of the River King was to play, so instead, let's talk about the deeper issue here.

youtube

That deeper issue is the game's use of tension, and I can’t understand why the developers put so much of it into Legend of the River King. For a fishing game set in a tiny, slow-paced, generally carefree world, you are often put on edge. Some of this tension is believable and low stakes, like running out of bait or having a full pail of fish and needing to return to town. But some of it feels weirdly punitive, like random wild animal JRPG battles that can ether knock you out, steal your fish or both. Or your raft (a crucial part of you traversing the world) actively diminishing your health every time you use it, which is often! There’s even a manufactured story tension of needing to catch a specific fish to cure your sister’s illness (though thankfully no time limit is put upon you to get that medicine).

But for all this tension the game piles on you, none of it results in anything really meaningful. If you get knocked out by an animal or collapse from exhaustion on your raft, you’ll just wake up at the last inn you visited (though, in an odd bit of design, you'll be at 1 HP, requiring you to stay at the inn again to fully heal). You don’t even lose the fish you caught. The worst thing that can really happen to you is that a monkey steals a fish in a random battle that you were going to deliver to a quest giver, but it just creates more busy work rather than something that truly affects the gameplay experience. I suppose if you completely ran out of money and couldn’t buy new bait or lures, you could theoretically hit a failstate, but that’s never really an issue.

So with that in mind, is Legend of the River King supposed to be a chill fishing adventure, or is it supposed to be a test of survival against a harsh world that doesn’t want you in it? The game can’t decide, and leads to a mess of a 6-8 hour experience.

And while I’m pretty down on the game generally, I do have to admit there is the foundation of something cool here. The art (especially the underwater scenes featuring nicely detailed fish sprites and a very impressive parallax scrolling effect) is quite good, and the music is great. And when it wasn’t slowly sapping my health away, I liked exploring the world and mentally noting which fish show up where (but man, could this game have used a map).

Legend of the River King is a long-running series, with at least four of its titles having come over to the west, so I have to imagine Victor Interactive Software figured out the formula at some point. I’m not sure I’ll be putting Legend of the River King 2 on my backlog anytime soon, but I could also see myself taking the bait once again at some point.

3 notes

·

View notes

Text

Water Reducing Superplasticizer for Concrete - Mapei

Mapefluid N360 is a chloride-free superplasticising admixture formulated from synthetic polymers. Conforms to ASTM C494 as Type G and F standard and EN 934-2.

USES · Ready mix concrete · Fly ash concrete · Silica fume concrete · Slag concrete · Mass concrete · Pile mixes · Raft foundations · Pouring in hot climates

TYPICAL DOSAGE The optimum dosage of Mapefluid N360 to meet specific job site requirement should be figured out by site trials using the selected cement, mineral additions and aggregates. For standard concrete production, the dosage should be 0.5-1.5 l/100 kg of total cementitious materials. For high performance concrete, the dosage should be 0.5-2.0 l/100 kg of total cementitious materials.

Choose this water reducing superplasticizer for concrete in UAE from Mapei who are the best manufacturers for all kind of adhesives, grout, sealants, waterproofing products etc at its quality maintained.

0 notes

Text

Advantages of raft foundations

Many buildings use raft foundations – they have lots of benefits and are popular with architects and builders. Raft foundations are good for places with bad soil and work well on soft clay or loose sand. Other shallow foundation types normally don’t work here. They spread the weight of a building evenly over a big area and prevent the building from sinking or moving. Raft foundations are sometimes cheaper than deep foundations (like pile foundations) because they don’t need as much digging into the ground, and the slab also works as a floor slab.

0 notes

Text

Underpinning Specialists in Australia

The stability of a building’s foundation is crucial for its overall integrity and longevity. Underpinning plays a pivotal role in ensuring that structures remain safe and secure, especially in regions like Australia where soil conditions can vary significantly. Let's dive into the world of underpinning and explore why it’s so important, how it works, and how to find the best specialists in Australia.

What is Underpinning? Underpinning is a process used to strengthen and stabilize the foundation of an existing building. It involves extending the foundation depth or distributing its load across a greater area to support the structure better. Historically, underpinning has been used since ancient times, evolving significantly with modern engineering techniques.

Signs Your Building Needs Underpinning If you’re noticing any of these signs, it might be time to consider underpinning:

Cracks in Walls: Vertical, horizontal, or zigzag cracks in your walls can indicate foundation issues. Uneven Floors: Sloping or uneven floors are a telltale sign of foundation movement. Doors and Windows Misalignment: Difficulty in opening or closing doors and windows can be due to foundation settlement. Sinking Foundation: Visible sinking or settlement of the building’s base is a clear indicator of foundation problems. Common Causes of Foundation Problems Understanding the root causes of foundation problems can help in choosing the right underpinning method:

Soil Movement: Expansive soils that swell when wet and shrink when dry can cause foundations to move. Poor Construction: Subpar construction practices can lead to inadequate foundation support. Water Damage: Excessive moisture from poor drainage or plumbing leaks can weaken the soil supporting the foundation. Tree Roots: Roots from nearby trees can absorb moisture from the soil, causing it to shift and destabilize the foundation. Types of Underpinning Methods There are several underpinning methods used to address foundation issues:

https://www.theliftingspecialists.com.au/underpinning/

Mass Concrete Underpinning: The traditional method involves excavating sections below the foundation and filling them with concrete. Beam and Base Method: This method uses beams to transfer the building load to a new foundation base. Mini-Piled Underpinning: Suitable for deep foundations or where access is restricted, mini-piles are used to support the load. Piled Raft Underpinning: Combines piles and a reinforced concrete raft to spread the load over a larger area. Choosing the Right Underpinning Method Selecting the appropriate underpinning method depends on various factors:

Soil Type Considerations: The nature of the soil determines the best underpinning technique. Building Structure: The design and condition of the building influence the choice of method. Budget Constraints: Cost can be a significant factor, as different methods vary in expense. Benefits of Professional Underpinning Opting for professional underpinning services offers numerous benefits:

Increased Structural Integrity: Ensures the building remains safe and stable. Property Value Enhancement: A stable foundation can increase the market value of the property. Long-term Cost Efficiency: Proper underpinning prevents future costly repairs. The Underpinning Process Here’s a step-by-step look at the underpinning process:

Initial Assessment: Experts evaluate the foundation issues and determine the best approach. Planning and Design: Detailed plans and designs are created based on the assessment. Execution and Monitoring: The underpinning work is carried out with continuous monitoring to ensure quality and safety. Finding Underpinning Specialists in Australia When looking for underpinning specialists, consider the following:

Qualifications and Certifications: Ensure the specialists are certified and qualified to perform underpinning work. Experience and Expertise: Look for companies with extensive experience and a proven track record. Customer Reviews and Testimonials: Reviews and testimonials can provide insights into the quality of service. Cost of Underpinning in Australia The cost of underpinning can vary widely based on several factors:

Factors Influencing Cost: Type of underpinning method, extent of foundation damage, and site accessibility. Average Cost Estimates: Generally, underpinning costs can range from AUD 15,000 to AUD 30,000, depending on the project specifics. Underpinning Regulations in Australia Compliance with regulations is crucial for underpinning projects:

Building Codes and Standards: Ensure the work adheres to the Australian building codes and standards. Permits and Approvals: Obtain necessary permits and approvals from local authorities before commencing work. DIY vs. Professional Underpinning While DIY underpinning might seem cost-effective, it comes with risks:

Risks of DIY Underpinning: Lack of expertise can lead to improper execution and further damage. Advantages of Hiring Professionals: Professionals bring experience, proper tools, and adherence to safety standards. Case Studies Looking at successful underpinning projects can offer valuable insights:

Successful Underpinning Projects: Highlighting a few projects where underpinning resolved significant foundation issues. Lessons Learned: Understanding what worked well and what challenges were encountered. Maintaining Your Foundation Post-Underpinning After underpinning, regular maintenance is essential:

Regular Inspections: Periodic checks can help identify and address issues early. Preventative Measures: Implementing measures like proper drainage and moisture control to prevent future problems.

Conclusion In conclusion, underpinning is a critical process for ensuring the stability and safety of buildings. Choosing the right specialists and method is essential for the success of the project. By understanding the underpinning process and its benefits, you can make informed decisions to protect your property.

#Sinking Foundations#Concrete Lifting#underpinning#Foundation Repair subsidence#Underpinning Specialists

0 notes

Text

How To Build a House Foundation Step-by-Step — Tips from a Groundworks Expert

Building the foundation is one of the most crucial steps in home construction. A solid, well-constructed foundation supports the entire weight of the house and ensures its stability for years to come. If you’re planning on building a new home, it’s essential to get the foundation right from the very beginning. In this comprehensive guide, we’ll walk you through the step-by-step process of building a house foundation, with expert tips from a groundworks specialist.

Step 1: Site Preparation and Planning

Before you start digging, it’s crucial to have your site properly surveyed and planned. This involves:

1. Conducting soil tests to determine the soil’s load-bearing capacity and stability.

2. Checking for any underground utilities or obstructions.

3. Obtaining necessary permits and approvals from local authorities.

4. Marking out the foundation area accurately.

Expert Tip: “Proper site preparation is key to avoiding costly mistakes down the line. Don’t skip this crucial step,” advises Mark Johnson, a groundworks expert with over 20 years of experience.

Step 2: Excavation

Once the site is prepared, it’s time to start excavating. This involves:

1. Digging out the area for the foundation to the required depth, typically around 1 metre deep.

2. Ensuring the excavation is level and free from debris or obstructions.

3. Installing temporary shoring or bracing if necessary to prevent soil collapse.

Expert Tip: “Always prioritise safety during excavation. Hire professionals if you’re unsure about the process or if the site presents any risks,” recommends Johnson.

Step 3: Laying the Foundation

With the excavation complete, you can begin laying the foundation. The most common types of foundations are:

1. Strip Foundations: Suitable for smaller buildings, these are continuous strips of concrete poured into trenches.

2. Raft Foundations: A solid, reinforced concrete slab covering the entire footprint of the building.

3. Pile Foundations: Used in areas with poor soil conditions, these are deep, vertical concrete columns driven into the ground.

Expert Tip: “Choose the right foundation type based on your soil conditions, building size, and local building codes. Don’t compromise on quality materials and workmanship,” emphasises Johnson.

Step 4: Damp-Proofing and Drainage

Moisture and water can severely damage your foundation over time, so it’s crucial to incorporate proper damp-proofing and drainage measures. This typically involves:

1. Applying a damp-proof course (DPC) or membrane to prevent moisture rising from the ground.

2. Installing a perimeter drain around the foundation to divert water away from the building.

3. Ensuring adequate ventilation to prevent condensation buildup.

Expert Tip: “Don’t skimp on damp-proofing. It may seem like an added expense, but it’ll save you from costly repairs down the road,” Johnson warns.

Step 5: Backfilling and Compaction

Once the foundation is in place and properly damp-proofed, it’s time to backfill the excavated area with soil. This process involves:

1. Backfilling the area around the foundation in layers, compacting each layer thoroughly.

2. Ensuring the soil is adequately compacted to prevent settling or shifting.

3. Sloping the soil away from the foundation to facilitate proper drainage.

Expert Tip: “Proper backfilling and compaction are crucial for the stability of your foundation. Don’t rush this step — take your time and do it right,” advises Johnson.

Step 6: Final Inspection and Preparation for Construction

Before moving on to the next phase of construction, it’s essential to have your foundation inspected by a professional and obtain the necessary approvals. This includes:

1. Scheduling an inspection by a qualified building inspector or surveyor.

2. Obtaining a certificate of compliance or sign-off from the local authorities.

3. Preparing the foundation for the next stage of construction, such as installing anchor bolts or dowels.

Expert Tip: “Don’t proceed with construction until you’ve had your foundation properly inspected and approved. This will save you from potential legal issues and ensure the safety of your new home,” Johnson emphasises.

Building a solid foundation is a complex process that requires careful planning, attention to detail, and adherence to local building codes and best practices. By following these step-by-step instructions and expert tips, you can ensure that your new home is built on a stable, long-lasting foundation that will stand the test of time.

D.Hall Plant Hire & Groundworks Ltd is the go-to groundworks contractor for construction projects across the UK. Their team comprises highly skilled professionals who prioritise exceptional workmanship in every aspect of their services. Whether you require foundation construction, excavation, drainage installation, or any other groundworks solution, D.Hall Plant Hire & Groundworks Ltd has the expertise to deliver outstanding results. By choosing them for your project, you can expect a solid foundation that ensures long-term stability and success. Fill out the contact form today to schedule a free consultation and receive a comprehensive quote tailored to your specific requirements.

The original content is published on Dhallplant

0 notes

Text

Comprehensive Engineering Solutions with Little P.Eng.: Catalyzing Innovation Across Engineering

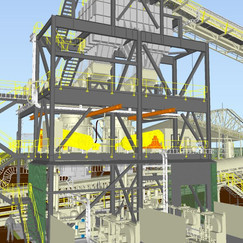

Engineering challenges in contemporary industry demand sophisticated, multidisciplinary approaches. Little P.Eng., a rising name in the engineering sector, has positioned itself as a nexus for solutions spanning various specialized fields, including structural engineering, piping design, piping stress analysis, seismic bracing design, storage tank design, material handling engineering services, pressure vessel design, electrical design, and CRN registration services. This article delves into each of these areas, highlighting the complexities, methodologies, and cutting-edge strategies employed by Little P.Eng. to cater to the evolving needs of diverse sectors.

Engineering services are the cornerstone of modern industrial and infrastructural developments. From the conceptualization of a project to its final commissioning, various engineering disciplines come into play to ensure functionality, safety, compliance, and efficiency. Little P.Eng., with its array of engineering services, has etched its mark by offering comprehensive solutions under one roof. The company's commitment to technical excellence, precision, and continual innovation positions it at the forefront of engineering consultancy.

Structural Engineering: Structural engineering, a critical subset of civil engineering, involves the analysis, design, and planning of structural components and systems to achieve design goals and ensure the safety and comfort of users or occupants. The experts at Little P.Eng. undertake detailed analyses, considering factors such as geology of the site, environmental conditions, and materials to be used, ensuring structural soundness against static and dynamic loading, including human traffic and environmental stressors.

The service spectrum includes:

Building Design: Erection of residential, commercial, and industrial structures with considerations for material efficiency, safety regulations, and aesthetic aspects.

Structural Analysis and Inspection: Employing advanced tools to analyze stress, strain, and load distribution and conducting inspections to assure structural integrity and longevity.

Foundation Design: Creating robust foundations, including piles, rafts, and footings, customized to site conditions and building requirements.

Retrofitting and Rehabilitation: Strengthening existing structures through modernization techniques, enhancing our capacity to withstand additional or unanticipated loads.

Piping Design and Piping Stress Analysis: Piping systems are lifelines of process industries, influencing operational efficiency, safety, and economic feasibility. Little P.Eng. offers comprehensive solutions in piping design, ensuring optimal layout and functionality, accommodating project constraints, and adhering to international standards.

Key aspects include:

Piping Layout and 3D Modeling: Developing detailed piping system layouts, incorporating equipment placement, structural design, and safety compliance, facilitated through advanced 3D modeling for accuracy and visualization.

Stress Analysis: Utilizing software tools like CAESAR II for precise stress analysis, determining strain and stress levels within piping systems under various scenarios, including temperature changes, fluid dynamics, pressure variations, and external forces, thereby verifying system reliability and identifying necessary supports and reinforcements.

Seismic Bracing Design: In regions prone to seismic activity, designing structures with adequate bracing is crucial to prevent collapse and minimize damage during earthquakes. Little P.Eng.'s seismic bracing designs are tailored to enhance the resilience of structures, factoring in regional seismic activity, local regulations, and material specifications.

Services involve:

Seismic Risk Evaluations: Assessing seismic risks associated with specific locations, analyzing historical data, and geological conditions.

Bracing System Design: Engineering customized bracing systems, including base isolators, cross-bracing, and shear walls, to dissipate seismic forces and minimize structural vulnerability.

Post-Earthquake Assessments: Inspecting and evaluating structures post-seismic activity for damage assessment and further reinforcement recommendations.

Storage Tank Design: Storage tanks, essential for industries requiring liquid or gas storage, entail specialized design parameters. Little P.Eng. focuses on custom solutions, factoring in the stored substance's characteristics, environmental considerations, and industry regulations.

The design process encompasses:

Material Selection and Design: Choosing appropriate materials resistant to the stored contents and environmental conditions, and designing tanks based on capacity requirements, pressure ratings, and structural regulations.

Foundation and Settlement Analysis: Ensuring ground stability and accommodating potential settlement or shifts without compromising tank integrity.

Safety and Emission Controls: Integrating features to prevent leaks, limit emissions, and safeguard against potential hazards, including explosions or toxic releases.

Material Handling Engineering Services: Efficient material handling is pivotal to operational success in manufacturing, warehousing, and distribution facilities. Little P.Eng. offers engineering solutions optimizing the movement, storage, control, and protection of materials throughout the process.

These services include:

System Design and Integration: Developing comprehensive systems combining conveyors, automated storage and retrieval systems, and transfer equipment, ensuring seamless, efficient operations.

Equipment Selection and Procurement: Advising on the appropriate equipment tailored to specific operational needs and assisting with acquisition from reputable manufacturers.

Safety and Ergonomics: Designing systems prioritizing operator safety and ergonomics, reducing workplace hazards and potential for injury.

Pressure Vessel Design: Pressure vessels, used for holding gases or liquids at high pressures, require meticulous design to prevent failure and catastrophic results. Little P.Eng.'s expertise lies in crafting pressure vessels compliant with industry standards like the ASME Boiler and Pressure Vessel Code.

Specific services involve:

Design and Analysis: Performing detailed calculations for wall thickness, stress distribution, and overall vessel geometry, ensuring safety under various pressure conditions.

Material Specification and Fabrication Oversight: Specifying suitable materials able to withstand extreme pressures and overseeing the fabrication process for quality assurance.

Inspection and Certification: Conducting thorough inspections and facilitating necessary certifications, confirming adherence to safety and operational standards.

Electrical Design: Electrical design services encompass the planning and execution of electrical systems, vital for the operational integrity of residential, commercial, and industrial projects. Little P.Eng.'s electrical engineers are adept at crafting systems that meet energy efficiency, safety, and performance standards.

Critical offerings include:

System Layout and Design: Creating comprehensive electrical systems, including power distribution, lighting, and emergency backup systems, tailored to specific project requirements.

Compliance and Safety: Ensuring designs meet electrical codes and safety standards, incorporating protective measures to prevent system failures, electrical shocks, or fire hazards.

Energy Efficiency Solutions: Proposing energy-efficient technologies and methodologies, contributing to sustainable and cost-effective operations.

CRN Registration Services: The Canadian Registration Number (CRN) is a number issued by each province or territory of Canada for the design of a boiler, pressure vessel, or fitting. The CRN identifies that the design has been accepted and registered for use in that province or territory. Little P.Eng. assists with the complex process of obtaining CRN certifications, essential for legal and safe operation within Canada.

This process includes:

Design Evaluations: Reviewing pressure equipment designs to ensure they comply with pertinent regulations and standards.

Documentation Preparation: Compiling and preparing extensive documentation required for CRN applications, including drawings, calculations, and material test reports.

Liaison with Authorities: Acting as an intermediary between clients and regulatory bodies, facilitating communication and expediting the registration process.

Conclusion: Little P.Eng. has emerged as a one-stop solution for diverse engineering needs, driven by a team of experts dedicated to upholding the highest standards of engineering excellence. Our approach is not just about meeting the minimum regulatory requirements; it is about designing safe, efficient, and sustainable systems that stand the test of time. By embracing advanced technologies, up-to-date methodologies, and a customer-centric approach, Little P.Eng. is setting new benchmarks in the engineering domain, contributing significantly to industrial innovation and infrastructural advancement.

Tags:

CAESAR II

energy efficiency

structural engineering

material handling

3D modeling

safety standards

regulatory compliance

earthquake resilience

stress analysis

CRN registration

advanced technologies

engineering consultancy

fabrication oversight

rehabilitation

piping design

pressure vessel

project commissioning

retrofitting

electrical design

automated storage

operational excellence

system reliability

ASME compliance

seismic bracing

foundation design

storage tank

tank integrity

design evaluation

infrastructural advancement

industrial innovation

Engineering Services

Structural Engineering Consultancy

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#CAESAR II#energy efficiency#structural engineering#material handling#3D modeling#safety standards#regulatory compliance#earthquake resilience#stress analysis#CRN registration#advanced technologies#engineering consultancy#fabrication oversight#rehabilitation#piping design#pressure vessel#project commissioning#retrofitting#electrical design#automated storage#operational excellence#system reliability#ASME compliance#seismic bracing#foundation design#storage tank#tank integrity#design evaluation#infrastructural advancement#industrial innovation

0 notes

Text

Pile Foundations vs. Raft Foundations: Choosing the Right Foundation for Your Project

Foundations are a critical element of any construction project, providing stability and load-bearing capacity to a structure. Two commonly used types of foundations are pile foundations and raft foundations. Each has its unique characteristics and is suited for specific scenarios. In this article, we’ll compare pile foundations and raft foundations to help you make an informed choice for your construction project.

Pile Foundations:

· Design: Pile foundations consist of vertical columns (piles) driven or drilled deep into the ground to reach load-bearing soil or rock layers. They transfer the building’s load through friction or end-bearing to the deeper, more stable layers.

· Use Cases: Pile foundations are typically used in areas with weak or unstable soil conditions, such as soft clay or loose sand. They are excellent for supporting heavy structures or when the water table is high.

Advantages:

· Effective in unstable soil conditions.

· Can bear heavy loads.

· Minimize settlement issues.

· Suitable for construction near water bodies.

Disadvantages:

· Higher construction costs due to drilling or driving piles.

· Site-specific engineering required.

· Environmental impact during installation.

Raft Foundations:

· Design: Raft foundations, also known as mat foundations, are large, flat slabs that cover the entire area under a building. They distribute the building’s load over a wide area, including the weight of the structure and its contents.

· Use Cases: Raft foundations are commonly used in areas with stable soil conditions. They are ideal for lighter structures or where the soil can uniformly support the load.

Advantages:

· Cost-effective for smaller structures.

· Simplified design and construction process.

· Evenly distribute loads, reducing settlement.

· Suitable for areas with consistent soil quality.

Disadvantages:

· May not be suitable for heavy or tall buildings.

· Can lead to differential settlement in areas with uneven soil support.

· Limited to areas with stable soil conditions.

Choosing the Right Foundation:

The choice between pile and raft foundations depends on several factors:

1. Soil Conditions: Assess the soil at your construction site. Pile foundations are preferable in areas with poor or unstable soil, while raft foundations work well in areas with consistent, load-bearing soil.

2. Building Load: Consider the weight and size of your structure. Pile foundations are better suited for heavy or tall buildings, while raft foundations are more suitable for smaller structures.

3. Cost: Pile foundations generally incur higher construction costs due to the need for specialized equipment and engineering. Raft foundations are often more cost-effective for smaller projects.

4. Site-Specific Factors: Evaluate site-specific factors such as water table levels, proximity to water bodies, and environmental impact when making your decision.

In conclusion, choosing between pile and raft foundations requires a careful assessment of your specific project needs and site conditions. Consult with a structural engineer or geotechnical piling expert to determine the most suitable foundation type to ensure the long-term stability and success of your construction project.

#piling companies#piling contractors#piling experts#screw piling#screw pile suppliers#screw piling central coast#screw piling newcastle#screw piling sydney#pile

0 notes

Text

Common Pile Foundation Problems and Their Solutions

Pile foundations are the unsung heroes of construction, supporting some of the most impressive structures on Earth. However, like any superhero, they, too, face their share of challenges. In this blog post, we'll explore the most common pile foundation problems and offer practical solutions to ensure your construction project stands tall and strong.

When Soil Plays Hard to Get

Issue: One of the primary challenges in pile foundation construction is encountering unexpected soil conditions. Soil can be notoriously unpredictable, and it's not uncommon for builders to stumble upon layers of soft, loose, or unstable ground.

Solution: Soil testing is the unsung champion here. Conduct comprehensive geotechnical investigations before starting construction. This helps in identifying any potential problem areas and allows for the selection of appropriate pile types and depths. Also, consider techniques like soil improvement or using innovative piling materials to overcome challenging soil conditions.

Navigating the Watery Depths

Issue: Water, while essential for life, can be a nemesis for pile foundations. High water tables or the presence of underground water can lead to buoyancy issues, causing piles to shift or even fail.

Solution: Waterproofing is your knight in shining armour. Apply high-quality waterproofing materials to the lower portions of the piles to prevent water infiltration. Additionally, consider techniques like dewatering or installing points to lower the water table temporarily during construction.

Battling the Corrosion Beast

Issue: Corrosion is the arch-nemesis of any structure, and pile foundations are no exception. Over time, exposure to moisture, salts, and other corrosive elements can weaken the integrity of piles.

Solution: Galvanization and protective coatings are the trusty shields in this fight. Treat the piles with anti-corrosion coatings or use galvanised steel piles to add an extra layer of defence. Regular inspections and maintenance are also crucial to catch and address any signs of corrosion early.

Settling the Uneven Scores

Issue: Settlement is a common concern in pile foundations, especially in areas with variable soil conditions. Differential settlement, where one part of the structure settles more than another, can lead to structural issues.

Solution: Load distribution is your guiding star here. By employing techniques like group piling or raft foundations, you can distribute the load more evenly across the piles. Additionally, conducting settlement monitoring and implementing necessary adjustments during construction can help mitigate settling issues.

Protecting Against Pile Integrity Attacks

Issue: Over time, piles may face challenges to their structural integrity due to factors like excessive loading, lateral forces, or unforeseen events.

Solution: Regular inspections and vigilant monitoring are your vigilant guards. Establish a comprehensive maintenance and monitoring program to keep a close eye on the condition of the piles. When necessary, consider reinforcement techniques such as adding steel sleeves or jackets to strengthen the piles and enhance their structural integrity.

Dealing with Design Discrepancies

Issue: Design errors or discrepancies can occur, leading to issues with pile foundation performance. This could include issues with pile spacing, depth, or type.

Solution: Communication and collaboration are your superpowers. Ensure that the design team, geotechnical engineers, and construction crew are in close communication throughout the project. Regular meetings and site inspections can help catch any discrepancies early on, allowing for timely adjustments to the design or construction plan.

Weathering the Storm

Issue: Extreme weather conditions, such as hurricanes, floods, or earthquakes, can pose a significant threat to pile foundations and the structures they support.

Solution: Resilience and preparedness are your allies in this battle. Design the pile foundation system to withstand the specific environmental conditions of the area. This may include factors like designing for seismic resistance or incorporating additional reinforcements for areas prone to flooding or storm surges.

Conclusion

In Conclusion, while pile foundations may face their fair share of challenges, with proper planning, testing, and maintenance, these issues can be addressed and overcome. By employing a combination of proactive measures, including thorough soil testing, waterproofing, corrosion protection, load distribution techniques, regular inspections, and resilient design, you can ensure your construction project stands the test of time.

Remember, a strong foundation is the key to any enduring structure, and pile foundation is the unsung heroes that make it all possible.

0 notes

Text

Mastering Groundworks Foundations

Introduction

Building a strong, durable structure starts from the ground up. The success of any construction project hinges on the quality of its foundations. In this article, we delve into the intricate world of groundworks foundations, shedding light on the key components and best practices to ensure a solid foundation. Whether you're a seasoned builder or a homeowner looking to understand the groundwork beneath your feet, this guide is your go-to resource.

Groundworks Foundations: The Bedrock of Construction

The first and most crucial step in any construction project is laying the groundwork. Strong, dependable foundations are the bedrock on which all structures rely. Here's a closer look at what groundworks foundations entail.

Sub-Heading 1: Types of Groundworks Foundations

There are several types of groundworks foundations, each suited to different soil and environmental conditions. These include:

Strip Foundations

Trench Foundations

Raft Foundations

Piled Foundations

Sub-Heading 2: Key Components

Concrete

Concrete is the primary material used in groundworks foundations. It offers strength, durability, and versatility. It's essential that the concrete mix is carefully designed to match the specific needs of the project.

Reinforcement

Reinforcing materials like steel bars or mesh are added to the concrete to enhance its tensile strength. This prevents cracks and ensures longevity.

Damp Proofing

Damp proofing materials and techniques are employed to protect the foundation from moisture, which can cause damage over time.

Sub-Heading 3: Preparing the Site

Proper site preparation is critical. This involves excavating the ground, ensuring it's level, and compacting it to prevent settling. Drainage solutions may also be necessary.

Sub-Heading 4: Best Practices

To create a strong foundation, consider the following best practices:

Engage a professional engineer for site evaluation and design.

Use high-quality materials.

Ensure proper curing of the concrete.

Regularly inspect for cracks or damage and address them promptly.

Frequently Asked Questions

What is the role of foundations in construction?

Foundations serve as the structural base for buildings, ensuring stability and load-bearing capabilities.

How can I determine the right foundation type for my project?

Consult with a structural engineer who will consider soil conditions, building design, and local regulations.

Is it possible to repair foundation cracks?

Minor cracks can be repaired, but extensive damage may require foundation replacement.

Do foundations require maintenance?

Regular inspections are crucial to identify and address issues promptly. Preventive maintenance can extend the foundation's lifespan.

Are there eco-friendly foundation options?

Yes, eco-friendly foundations like insulated concrete forms (ICFs) are gaining popularity for their energy efficiency.

Can I build on an existing foundation?

In some cases, it's possible to build on an existing foundation after a thorough assessment by a structural engineer.

Conclusion

Mastering the art of groundworks foundations is pivotal to the success of any construction project. By understanding the types, key components, site preparation, and best practices, you're well on your way to building a solid and dependable foundation. Remember, consulting with experts and conducting regular inspections are essential for ensuring the longevity of your foundations.

0 notes

Text

Why superplasticizer admixture is important

Superplasticizers admixtures play a vital role in modern concrete technology, allowing for the production of high-performance concrete that meets the demands of various construction projects. choose the best superplasticizer admixture for concrete supplier in Dubai from Mapei.

DYNAMON SR1200

Superplasticizer admixture based on polymer-modified polycarboxylate either for high-performance concrete mixes with very low water/cement ratios, high compressive strengths, and long slump retention in hot climates.

DESCRIPTION Dynamon SR1200 is a chloride-free superplasticiser admixture formulated from technologically advanced molecular chains of polymer-modified polycarboxylate ether. Dynamon SR1200 complies with ASTM C494 as Type G and EN 934-2.

ADVANTAGES Dynamon SR1200 is specifically designed for the production of high performance concrete mixes by significantly reducing water/cement ratio and providing excellent results in extended workability time, particularly in hot climates. In particular it will enable high early and ultimate compressive strengths to be achieved. Dynamon SR1200 is also recommended for use with GGBS and tri-blend mixes.

USES ▪ High-performance concrete where exceptional workability and durability is required ▪ Self-compacting concrete, particularly suitable for heavily reinforced and congested sections ▪ Precast concrete elements where increased early and ultimate strengths are required ▪ Precast and in-situ concrete requiring an exceptionally high level of finishing ▪ Concretes requiring reduced carbon footprint either through lower cement & water contents, and ultimately lower energy input during mixing, pumping and placing ▪ Fly ash, silica fume, GGBS and tri-blend concrete mixes ▪ Mass concrete pours with improved cohesion ▪ Piling mixes ▪ Raft foundations ▪ Pouring in hot climates

0 notes

Text

#4 Loại Móng Nhà Phổ Biến trong xây dựng

Trong ngành xây dựng, việc chọn loại móng phù hợp là một quyết định quan trọng, ảnh hưởng trực tiếp đến tính ổn định và hiệu suất của công trình. Có nhiều loại móng được sử dụng, mỗi loại có những ưu điểm và hạn chế riêng, và sự lựa chọn đúng loại móng sẽ giúp tối ưu hóa cả yếu tố kỹ thuật và kinh tế.

Móng Đơn - Isolated Footing

Móng đơn, hay Isolated Footing, thường là sự lựa chọn đầu tiên cho các công trình nhỏ hoặc khi cần chịu tải trọng tập trung tại một điểm cụ thể. Nhờ vào thiết kế đơn giản, móng đơn tiết kiệm chi phí và thời gian xây dựng. Tuy nhiên, nó có hạn chế khi đối diện với tải trọng phân bố không đều hoặc đất nền yếu.

Móng Băng - Strip Footing

Móng băng, hay Strip Footing, thường được ưa chuộng trong những dự án có nhiều cột hoặc tải trọng phân bố đều. Điều này giúp giảm áp lực tập trung tại các điểm cụ thể và tạo sự ổn định cho toàn bộ kết cấu. Tuy nhiên, thiết kế móng băng cần phải xem xét cẩn thận để tránh sự cản trở về việc thi công và bố trí cốt thép phù hợp.

Móng Bè - Raft Foundation

Móng bè, còn gọi là Raft Foundation, là lựa chọn hữu ích khi đối mặt với đất nền yếu hoặc đặc tính lún không đều. Bằng cách trải tải trọng ra diện tích rộng, móng bè giúp cân bằng áp lực và tăng tính ổn định cho công trình. Tuy nhiên, thiết kế và xây dựng móng bè đòi hỏi kỹ thuật cao và sự quản lý cẩn thận để đảm bảo chất lượng và an toàn.

Móng Cọc - Pile Foundation

Móng cọc, hay Pile Foundation, thường là sự lựa chọn cho các dự án phức tạp đối diện với đất nền không đủ mạnh hoặc địa hình khó khăn. Các cọc được đúc sâu vào đất để chịu tải trọng và chuyển đạt lực từ kết cấu xuống lớp đất sâu hơn. Lựa chọn vật liệu và thiết kế cọc phụ thuộc vào yếu tố kỹ thuật và kinh tế của dự án.

Nguồn bài viết: https://nhaxanhvietnam.com.vn/cac-loai-mong-nha

0 notes

Text

Ground Works Contractors: Building the Foundation for Strong Structures

Introduction

Ground works contractors are the backbone of any successful construction project. They are skilled professionals who play a crucial role in preparing the site and laying the foundation for buildings, roads, and other infrastructure. In this article, we will delve into the world of ground works contractors, exploring their essential functions and the significance of their expertise in creating strong and stable structures.

Understanding Ground Works Contractors

Ground works contractors are specialized professionals in the construction industry who focus on preparing the ground for building projects. Their primary responsibilities include excavation, foundation installation, ground stabilization, and site preparation. They work closely with architects, engineers, and project managers to ensure that the construction process starts on a solid and stable foundation.

Key Services Provided by Ground Works Contractors

Ground works contractors offer a wide range of services that are essential for successful construction projects. Some of the key services they provide are:

Excavation: Ground works contractors perform excavation to create space for the foundation. They use heavy machinery and precise techniques to remove soil and debris from the construction site.

Foundation Installation: Installing a strong and stable foundation is crucial for any structure. Ground works contractors are experts in laying various types of foundations, such as strip foundations, raft foundations, and pile foundations, depending on the project's requirements.

Ground Stabilization: In areas with challenging ground conditions, ground works contractors use specialized techniques to stabilize the ground and prevent subsidence or settlement issues.

Site Clearance and Preparation: Before construction can begin, the site needs to be cleared of any obstacles, debris, or vegetation. Ground works contractors handle site clearance to create a clean and safe area for construction.

Drainage Solutions: Proper drainage is essential to prevent water accumulation and potential damage to the structure. Ground works contractors design and implement effective drainage systems for the construction site.

Infrastructure Projects: Groundworks contractors are also involved in infrastructure projects, such as road construction, where they prepare the ground and lay the foundation for roads, bridges, and other structures.

The Importance of Choosing the Right Ground Works Contractor

Selecting the right ground works contractor is crucial for the success of any construction project. The expertise and experience of the contractor significantly impact the quality and durability of the final structure. Here's why choosing the right contractor matters:

Quality Foundation: A skilled ground works contractor ensures a solid and well-constructed foundation, which is the key to a stable and durable structure.

Risk Mitigation: Professional contractors follow safety guidelines and practices, reducing the risk of accidents or structural issues during construction.

Project Efficiency: A reliable contractor completes the ground works efficiently, keeping the project on schedule and within budget.

Adherence to Regulations: Ground works contractors are knowledgeable about local building regulations and ensure that the construction meets all the necessary standards.

Conclusion

Ground works contractors are essential players in the construction industry, responsible for laying the foundation for strong and stable structures. Their expertise in ground preparation, foundation installation, and ground stabilization ensures that construction projects start on a solid footing. Choosing the right ground works contractor is a critical decision that directly impacts the success and quality of the final construction. By working with skilled and experienced contractors, developers and project managers can set the stage for successful and enduring buildings and infrastructure.

0 notes

Text

Types of Foundations and Their Uses

Shallow foundations, such as individual footings, combined footings, strip footings, and raft foundations, are used in soils with good bearing capacity. Deep foundations, like pile foundations and drilled shafts, are used in soils with poor bearing capacity. Factors like water table depth, underground obstructions, seismic activity, and cost should be considered when choosing a foundation. Consulting a structural engineer is crucial for selecting the appropriate foundation for a project. https://www.comaron.com/blog/types-of-foundation

0 notes

Text

What are RCC footings?

RCC footings are Reinforced Cement Concrete footings. They are made up of steel bars. Footings transfer the load uniformly on the ground below, so there is no unequal settlement. RCC footings are generally adopted in buildings constructed with columns. They can be of different types: trapezoidal, block, or stepped footing. SD Conmix provides ready mix concrete for various construction projects.

Following are the types of footings:

1. Continuous wall footing: It is generally used in the load-bearing structures to support the foundation walls and load-bearing walls. In this, there is a big concrete slab below the wall and a brick wall in the center of the slab. SD Conmix provides quality mix concretefor this type of construction.

2. Isolated column footing: This supports only one column and has three types of footings namely Pad footing, stepped footing, and then sloped footing. Pad footing is generally used in local construction.

Stepped footing contains two or three rectangular or square pedestals whose width decreases towards the column junction. This type of footing consumes less concrete compared to block footing. As the name suggests, block footing is in the form of a block, which is easy to construct and consumes slightly more concrete. Sloped footing is usually used in high-rise buildings and consumes relatively less concrete.

3. Combined footing: The base of two columns is combined in this type of footing. SD Conmix provides ready mix concrete for all types of footings and also supplies quality construction material.

4. Trapezoidal combined footing: A trapezoidal footing is used when the load of one column is greater than the other and usually sloped footings are trapezoidal footings.

5. Mat or raft foundation: When the space between the columns is significantly less, a mat or raft foundation is used. In this, the base of all columns is combined. So after combining, an extensive base is formed, called a raft. The thickness of the raft foundation is more than the other types of footings. SD Conmix supplies high-quality mix concrete for construction

6. Pile foundation: Piles are used as deep foundations where the soil is very weak and has a higher groundwater table. Mostly used in bridge or dam constructions.

Conclusion: Points to be remembered for RCC footing:

1. Check the excavation for its dimensional accuracy before laying the foundation

2. Secure the vertical rods in the foundation firmly in its position

3. Use a minimum M20 grade of concrete

4. Ensure proper concrete compaction in the sloped portion of the foundation.

5. Concrete in stepped or block footings attain better compaction.

SD Conmix supplies high-quality construction material and ready concrete mix for all types of construction.

0 notes