#pig iron for steelmaking

Explore tagged Tumblr posts

Text

Technological Advancements In Pig Iron Production

Here are the latest technological advancements in pig iron production. To know more read on now. Find out about the pig iron production cost, pig iron price and get the best pig iron for casting.

0 notes

Text

Battletech: Kirchbach planetary report

I. Planetary Overview

Name: Kirchbach Location: Formerly within the Principality of Rasalhague, now in the Draconis Combine Star: F0V Main Sequence Star Type: Temperate Terran Standard World Notable Features: High solar irradiance, lack of native flora and fauna, scarcity of hydrocarbons

Kirchbach orbits a bright, white F0V main sequence star, which emits more ultraviolet radiation and visible light than Sol. This results in a landscape of luminous skies and sharply defined shadows, with sunsets and sunrises producing brilliant, high-contrast golden hues. The intensity of solar radiation provides ample energy for solar power systems, though it also increases degradation rates of photovoltaic equipment over time. Atmospheric conditions and seasonal cycles mirror Earth's temperate zones, with similarities to the Carinthian region of Austria — cool winters, warm summers, and abundant rainfall.

Despite being habitable and temperate, Kirchbach is geologically poor, with few native resources beyond surface-accessible iron-rich deposits. The world lacks naturally occurring fossil fuels due to its pre-colonization status as a barren world without evolved flora or fauna.

II. Pre-Colonial Conditions

Prior to human arrival, Kirchbach was a lifeless terrestrial planet, comparable to Earth during the late Archean to early Proterozoic eons (circa 2.5–1.5 billion years ago). Marine microbial life may have existed, capable of limited photosynthesis, but no complex life developed. Oxygen production would have been minimal, with little to no atmospheric O2 or developed nitrogen cycle. There were no forests or vegetation to lay down organic sediments — hence, no coal, oil, or gas formations ever formed. Similarly, there were no animal-based fertilizer sources.

Surface geology exposed iron-rich strata, and riverbeds carried fine oxides which were accessible for primitive steelmaking with external fuel and heat sources. However, the absence of coking coal and organic carbon limited heavy industrial development unless external supplies were provided.

III. Early Exploitation and Abandonment

Kirchbach was discovered during the early Exodus but was not colonized due to its unremarkable resources and harsh, sterile conditions. It was briefly used for extraction of high-value minerals by automated systems and temporary camps. Once these were depleted, activity ceased, and the planet was abandoned much like a gold rush town in the Old West.

IV. Terraforming and Recolonization

The Combine began long-term terraforming after conquering Kirchbach in 2319. The process, intensified during the Star League era, aimed to make the world agriculturally viable.

Terraforming Steps:

Atmosphere Conditioning: Greenhouse gases were added to stabilize temperatures. Cyanobacteria and other photosynthetic microbes helped boost oxygen.

Soil Genesis: Imported organic material, fungi, and engineered microbes helped generate proto-soils. Over the next century, mosses and grasses were planted.

Hydrology: Hydroelectric dams and controlled irrigation were established for managing seasonal snowmelt and rainfall.

Ecological Colonization: Hardy Terran flora like clover and legumes, followed by crops, trees, insects, and small grazing mammals (goats, pigs).

Timeframe:

Year 0–100: Bacterial and microbial colonization

Year 100–200: Grasslands and legume rotation

Year 200–400: Tree lines, crop monocultures, early animal herding

Year 400+: Self-sustaining biome and agricultural system

Terraforming was boosted by Star League technology, enabling controlled climate zones and specialized nutrient synthesis. Like Australia's rapid colonial transformation, Kirchbach's ecology bloomed quickly — although with unstable, artificial interdependencies.

V. Cultural and Historical Evolution

Early Settlers:

Rasalhague Miners and Farmers: Scandinavian-descended colonists brought northern agrarian traditions.

Austrian Settlers: After Combine occupation, Lyran refugees and settlers added Carinthian aesthetics and alpine techniques.

Greek Colonists: Founded New Samos, integrating Hellenistic design and governance.

Kuritan Influence: Present in religious reverence for technology, architecture, and martial culture.

Capital City: New Samos

A cultural mosaic of Greek, Austrian, Swedish, and Japanese influence. Built over Star League-era ruins, it features colonnaded forums, stone-paved roads, and pre-spaceflight charm.

In recent times, New Samos was struck by a Steiner raid which destroyed the planetary government computer network. This ended all internet and mobile phone service. Physical mail, town criers, chalkboards, and messengers replaced digital communications. Despite the blackout, daily life adapted: towns continued trading, students returned to handwritten learning, and local governance reverted to analog methods.

VI. Star League and Military History

SLDF Era: A Castle Brian base was constructed to project power into the Periphery during the Reunification War. The base helped support planetary defense, power grids, and logistics.

Industrial Development: An IndustrialMech factory was constructed to support local mining, construction, and farming without the need for complex supply chains.

First Succession War: The Combine destroyed the SLDF base via orbital bombardment, seizing control. Despite this, the civilian infrastructure survived mostly intact.

Kirchbach became a quiet but strategic border post — often raided, rarely conquered.

VII. Modern Conditions During the Succession Wars

Economy & Industry:

Agriculture: Grains, vegetables, and livestock sustain the population.

IndustrialMech Production: Heavy walkers are favored due to the rugged terrain, poor infrastructure, and lack of fuel. These solar-powered or battery-electric machines dominate farming, construction, and resource extraction.

Rubber Shortage: Lack of petroleum-based rubber means tires are rare and imported. Attempts to establish natural rubber plantations have met with limited success due to soil and climate limitations.

Transportation:

Electric Vehicles: Common but ancient. Most date to the Star League era and have been retrofitted with steel-rimmed wooden wheels due to tire scarcity.

Horse-Drawn Transport: Ubiquitous in rural areas and towns.

Combustion Engines: Reserved for the DCMS military. Fuel reserves are secured in hardened depots targeted by local resistance.

Energy & Infrastructure:

Solar Power: Ubiquitous but aging. Panels are degrading without replacements.

Hydroelectric: Functions as a backup and grid stabilizer.

Fusion Power: Still operational in isolated heavy industry sites, particularly near the IndustrialMech factory.

Power Instability: Rolling blackouts are common. Wood and tallow supplement heating and lighting.

Armament and Militia:

Gunpowder Scarcity: No local production due to nitrogen and carbon shortages.

Imported Munitions: Used only by the garrison.

Militia Weapons:

Laser rifles with wooden stocks

Sonic stunners and Tasers

Crossbows and longbows for hunting and patrols

Material Culture:

Plastics and Synthetics: Rare or nonexistent. Everything is built from wood, metal, or leather.

Clothing & Footwear: Wool, leather, and cotton dominate. No synthetic fibers.

Computing Equipment: Ruggedized terminals with wooden keys and steel casings.

Everyday life on Kirchbach reflects this juxtaposition: laser-armed guards riding electric carts with wooden wheels, peasants in wool tunics checking notices under solar-powered lamps.

An evening at the opera might include electric rail transport and high-tech lighting — or candle-lit performances in halls made from Star League ferrocrete and local timber.

VIII. Conclusion

Kirchbach stands as a singular example of adaptation: a world caught between eras, shaped by conflict, scarcity, and resilience. While its soil supports crops and livestock, and its people ride solar-powered relics, it is haunted by ghosts of high technology now buried beneath the surface.

Kirchbach: where soil is tilled by steel feet, war is fought with light and wood, and civilization endures by candlelight.

1 note

·

View note

Text

Steel-Making

Steelmaking is the process of producing steel from iron ore or scrap through two primary methods: Blast Furnace and Electric Arc Furnace (EAF). Blast Furnace Process: Iron ore, coke, and limestone are melted to produce pig iron. This is then refined in a Basic Oxygen Furnace (BOF) by blowing oxygen to remove impurities, creating steel[1][3][4]. Electric Arc Furnace (EAF): Scrap steel or direct…

0 notes

Text

Advancements in Steelmaking and Industrial Sealing Solutions by Sujan Industries

The Steelmaking Process:

The production of steel involves multiple stages, starting with the extraction of iron ore from the Earth's crust. This ore is then smelted in a blast furnace to remove impurities and convert it into pig iron, which is rich in carbon.

Once the desired composition is attained, the molten steel is poured into molds to create various forms, such as sheets, bars, or coils. These are then cooled and solidified, making them ready for further processing and use in different industries. Many Stainless steel casting manufacturers in India are embracing innovative methods to produce even higher-quality products.

Get the Best Seals & Gaskets for Your Industry

Seals & gaskets play a crucial role in industrial applications, and understanding their respective functions is essential for selecting the right component to ensure optimal system performance. The combination of a seal and gasket (seal gasket) offers a hybrid solution, meeting the needs for both static and dynamic sealing properties, thanks to ongoing advancements in materials and design.

Choosing the right manufacturer is key to ensuring the quality and reliability of seals & gaskets. For those seeking rubber manufacturers in India, Sujan Industries is a trusted provider of industrial sealing solutions. With a commitment to innovation and quality, Sujan Industries excels in designing and manufacturing high-performance Seals & Gaskets that are tailored to meet diverse industrial needs.

Get superior quality chevron springs from Sujan Industries.

The prediction of the useful lifetime of Chevron rubber springs is a complex but crucial aspect of maintaining the reliability and safety of railway vehicles. Through a combination of advanced predictive techniques, regular maintenance, and ongoing research and development, railway operators can ensure that these critical components continue to perform their vital functions effectively.

Furthermore, when it comes to railway component manufacturing, leading companies like Sujan Industries play a pivotal role in ensuring the integrity and efficiency of locomotive systems. With offerings like the Locomotive gearcase seal, oil seal, o rings, and rubble seals,

Conclusion:

In conclusion, the steelmaking process is a critical part of industrial production, with various methods ensuring the desired steel composition. Sujan Industries not only contributes to this field by offering cutting-edge sealing solutions like gaskets and chevron springs but also enhances the efficiency and reliability of essential components in industries such as railway transportation. Their commitment to innovation and quality ensures that industries continue to meet growing demands with superior performance and safety.

0 notes

Text

The Process Involved in Making Quality TMT Bars :

The production of high-quality TMT (Thermo-Mechanically Treated) bars involves several key steps in a sophisticated manufacturing process. TMT bars are a type of reinforcement steel used in construction, known for their superior strength, durability, and corrosion resistance. The process of making TMT bars includes several stages, which ensure that the bars achieve the desired mechanical properties.

Here's an overview of the process:

1. Raw Material Selection

The process begins with the selection of high-quality raw materials, primarily iron ore, coal, and other alloying elements. These materials are fed into the blast furnace or electric arc furnace (EAF) to produce steel. The quality of raw materials significantly impacts the final product.

2. Melting and Refining

The selected raw materials are melted in a furnace. In modern steelmaking, this typically involves:

Blast Furnace: Used to produce pig iron, which is then converted into steel.

Electric Arc Furnace (EAF): Scrap steel is used as the primary raw material, melted by electric arcs.

After melting, the steel is refined by removing impurities such as sulfur, phosphorus, and carbon to obtain a cleaner, purer steel composition.

3. Casting

Once the steel has been refined, it is cast into billets or blooms using a continuous casting process. This process involves pouring molten steel into molds, where it solidifies into rough shapes. The size of the billets is crucial because it influences the final diameter of the TMT bars.

4. Rolling (Deformation)

The solidified billets are then reheated and passed through a series of rollers in the rolling mill. This process is called rolling and it progressively reduces the size of the billets while shaping them into long, cylindrical bars.

The temperature during rolling is crucial, as it determines the steel's properties. The temperature needs to be maintained within specific limits to ensure that the bars have the right mechanical properties (strength, flexibility, etc.).

5. Thermo-Mechanical Treatment (TMT) Process

This is the core step that differentiates TMT bars from conventional steel bars. TMT bars undergo a specialized heat treatment process that involves:

Reheating: After the bars are rolled to the desired diameter, they are reheated to a high temperature (around 1000–1100°C) in a controlled environment.

Quenching: The hot bars are rapidly cooled using water in a process called quenching. This sudden cooling hardens the outer surface of the bars, creating a strong, wear-resistant outer layer. The inner core of the bars, however, remains comparatively softer and more ductile. This unique combination of a hard outer layer and a soft core gives TMT bars their high strength and ductility.

Tempering: After quenching, the bars are passed through a process known as tempering, where they are slowly cooled in the air or through other controlled cooling techniques. This helps to reduce internal stresses, refine the microstructure, and enhance the toughness and flexibility of the bars.

6. Cooling

Once the bars have been quenched and tempered, they are allowed to cool to room temperature. The cooling process ensures that the outer layer becomes very hard (martensite) while the core remains relatively softer (pearlite), providing the bar with the perfect balance of strength and flexibility.

7. Cutting and Final Inspection

After cooling, the TMT bars are cut into the required lengths. These bars are then subjected to rigorous quality checks to ensure they meet industry standards. Tests may include:

Tensile strength tests

Bend tests

Surface quality checks

Chemical composition analysis

Any defects such as cracks, rust, or surface irregularities are identified and discarded.

8. Packaging and Dispatch

The final product is then packed according to specifications, which may include bundling the bars in coils or straight lengths. Packaging protects the bars from damage during transport and makes them easier to handle and store.

Key Features of TMT Bars

High Strength: Due to the rapid cooling process (quenching), the outer surface of TMT bars becomes hard, providing strength and high tensile properties.

Ductility: The core remains relatively soft, allowing the bar to bend without breaking under stress, making it ideal for construction in earthquake-prone areas.

Corrosion Resistance: The TMT bars have a tough outer layer, which offers excellent resistance to corrosion, making them more durable than other types of reinforcement bars.

Weldability: TMT bars can be easily welded, which is important for construction applications.

Conclusion

The process of making quality TMT bars involves careful control at every stage, from raw material selection to the final inspection of the bars. The key to producing high-quality TMT bars lies in the thermo-mechanical treatment process, which ensures that the bars possess superior strength, flexibility, and resistance to wear and corrosion.

0 notes

Text

Traditional to Innovative: Evolution of Steel Manufacturing in India

Steel is viewed as a pillar of modern civilization due to its wide usage today. Steel manufacturers in India play a significant role within the country and beyond and have evolved remarkably over the years. From the bloomer furnaces that were used in the past to the blast furnaces during the industrial revolution and today, the cutting-edge technologies, the evolution is immense.

In past times, steel production was labor intensive and typically consumed a lot of time due to the processes involved. These traditional methods were quite effective, but they had great limitations in terms of scalability. Over time, things have changed significantly, and the industry is no longer as it was in its infancy.

Traditional Methods

Steelmaking can be traced back to very many years ago, during ancient civilizations like the Egyptians. They discovered smelting practices for iron extraction. With time, different techniques were used to help refine steel and iron, including crucible steel and bloomery furnace process. The traditional methods used charcoal fuel widely. They were highly labor intensive, and only small quantities were produced. There wasn't much quality variation. This laid the foundation of the industry as we know it today, with the carbon steel producers playing a major role in shaping the industry.

The Bessemer Process During The Industrial Revolution Era

In the 18th and 19th centuries, steel production was revolutionized. This was due to the introduction of the Bessemer process in 1856. This was invented by Henry Bessemer, and it was a major milestone in steelmaking history.

The Bessemer process utilized air, which was blown through molten pig iron. The main intention here was to regulate the carbon content and remove impurities. With the adoption of this method, mass production of steel was possible at a lower cost. The process led to the creation of huge steel mills and blast furnaces. This led to the greatest growth in the steel industry that had not been witnessed before.

Electric Arc And Oxygen Furnaces

Later in the 20th century, another technology was introduced, propelling the industry further. The use of basic oxygen furnaces took the place of Bessemer converters. It became the primary method for processing molten iron into steel. Typically, oxygen was blown into the iron in a molten state to oxidize the impurities. This led to even higher-grade steel and faster turnaround rates.

Electric furnaces were introduced at the same time, and they helped recycle steel scrap. This meant lower reliance on ore.

Advanced Technologies

Spring steel strip coil suppliers and other players today rely on advanced steel manufacturing technologies. In the 21st century, advanced technologies have been widely adopted, improving efficiency and innovation. 3D printing or additive manufacturing is now one of the areas being exploited to create complex components using customized designs and intricate geometries.

C80 steel-grade suppliers and manufacturers now enjoy the results of automation and robotics used during manufacturing. This has led to safer, higher productivity, and access to a greater range of steel products in India.

Today, digitization initiatives leverage the Internet of Things, AI, and data analytics to optimize production schedules. It also aims to improve quality and monitor performance during steel production.

Sustainability

The best en8 steel grade suppliers look at the steel quality and sustainability. With the escalating environmental concerns taking center stage, sustainable practices are preferred over others. Alternative prices are now embraced to reduce the carbon footprint and energy consumption.

Steel manufacturers rely on carbon capture technologies and renewable energy options to mitigate the negative environmental impact in India. Recycling is also at the initiative's core, playing a role in waste production and conserving resources.

Embracing The Market Dynamics

In conclusion, it's important for steel manufacturers to embrace innovation to uphold sustainability and efficiency in the industry. Turning away from rudimentary technologies and choosing innovative options is one of the best ways to improve quality and reduce negative environmental impacts. Sustainability, automation, and digitalization are at the core of the industry and will keep shaping it in the future.

0 notes

Text

global top 25 companies accounted for 53% of total Iron Ore market(qyresearch, 2021)

Iron ore is a relatively abundant metallic element (it composes about 5% of the Earth’s crust) and the main raw material used in steelmaking. Around 98% of global mined iron ore is used to make pig iron, which is an intermediate product of the steel-making process. The remaining 2% is used in several applications, such as production of cement, printing inks, plastics, cosmetics (eye shadow), artistic colors, fertilizer ingredients, and pigments. Currently, iron ore is mined in over 50 countries; however, the bulk of production comes from Australia, Brazil and China.

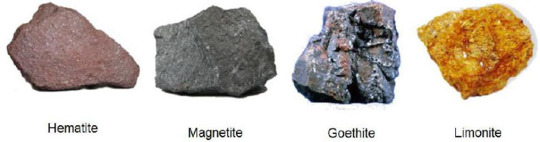

Several minerals contain iron, but the primary sources of iron ore: hematite (Fe2O3), magnetite (Fe3O4), goethite (Fe2O3H2O) and siderite (FeCO3). The first three are of major importance because of their occurrence in large economically minable deposits. Iron ore rocks are usually rich in iron oxides and vary in color: rusty red, dark grey, bright yellow and deep purple.

Most of the iron ore resources are located in sedimentary rocks known as banded iron formations (BIF). Deposits may cover thousands of square kilometers and be hundreds of feet deep.

Typically, a deposit must contain at least 15-25% of Fe to be considered economically recoverable. Usually, tradable iron ore grades ranges between 58% and 66% of Fe content; however, a market of lower grades (sub- 60% Fe) does exist.

According to the new market research report “Global Iron Ore Market Report 2023-2029”, published by QYResearch, the global Iron Ore market size is projected to reach USD 208.24 billion by 2029, at a CAGR of -2.5% during the forecast period.

Figure. Global Iron Ore Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Iron Ore Sales Market Report 2023-2029.

Figure. Global Iron Ore Top 25 Players Ranking and Market Share(Based on data of 2021, Continually updated)

Based on or includes research from QYResearch: 2021 data information of Global Iron Ore Sales Market Report 2023-2029.

The global key manufacturers of Iron Ore include Hainan Mining, Hainan Mining, Huaxia Jianlong, Dazhong Mining, Severstal, HBIS Resources, SSGPO, EVRAZ, LKAB, MRL, etc. In 2021, the global top five players had a share approximately 53.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let���s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

The Evolution of Steel: From Traditional to Advanced Manufacturing

Steel, often referred to as the backbone of modern civilization, has undergone a remarkable evolution in its production methods over the centuries. From the ancient bloomery furnaces to the towering blast furnaces of the Industrial Revolution, and now to the cutting-edge technologies of advanced manufacturing.

If you are looking for good steel in South India, Aone is one of the best steel manufacturers in Bangalore. The steel industry has continuously adapted to meet the demands of an ever-changing world.

In this blog, we explore the journey of steel production, tracing its evolution from traditional to advanced manufacturing methods and its transformative impact on the industry.

1. Traditional Steelmaking:

The origins of steelmaking can be traced back thousands of years to ancient civilizations such as the Egyptians, who discovered the process of smelting iron ore to extract iron. Over time, various techniques for refining iron and steel emerged, including the bloomery furnace and the crucible steel process.

If you want the best quality steel in India, you should try Aone Steel. They are an amazing steel manufacturer in India. These traditional methods relied on charcoal as a fuel source and were labor-intensive, producing relatively small quantities of steel with varying quality.

2. The Industrial Revolution and Bessemer Process:

The advent of the Industrial Revolution in the 18th and 19th centuries brought about a revolution in steel production. The invention of the Bessemer process by Henry Bessemer in 1856 marked a significant milestone in the history of steelmaking.

This process involved blowing air through molten pig iron to remove impurities and adjust the carbon content, resulting in the mass production of high-quality steel at a lower cost.

To get the best quality steel in India among so many great steel manufacturer in India, you should try Aone Steel. The Bessemer process paved the way for the construction of massive blast furnaces and steel mills, driving unprecedented growth in the steel industry.

3. Basic Oxygen and Electric Arc Furnaces:

In the latter half of the 20th century, new steelmaking technologies emerged, further revolutionizing the industry. The basic oxygen furnace (BOF) replaced the Bessemer converter as the primary method for producing steel from molten iron.

In the BOF process, oxygen is blown into the molten iron to oxidize impurities, resulting in faster production rates and higher-quality steel. Aone Steel is one of the best steel manufacturers in Bangalore.

Concurrently, the development of electric arc furnaces (EAFs) enabled the recycling of scrap steel into new products, reducing the industry's reliance on virgin iron ore and minimizing environmental impact.

4. Advanced Manufacturing Technologies:

The 21st century has witnessed a rapid proliferation of advanced manufacturing technologies in the steel industry, ushering in a new era of innovation and efficiency. Additive manufacturing, commonly known as 3D printing, is being explored for the production of complex steel components with intricate geometries and customized designs.

Robotics and automation are increasingly integrated into steel manufacturing processes, enhancing productivity, precision, and safety. Aone is the dominating steel manufacturer in south India, they are the best steel manufacturers in Bangalore.

Digitalization initiatives leverage data analytics, artificial intelligence, and Internet of Things (IoT) technologies to optimize production schedules, monitor equipment performance, and improve quality control.

5. Sustainable Steel Production:

As environmental concerns escalate and sustainability becomes a top priority, the steel industry is embracing sustainable production practices. Alternative steelmaking processes, such as direct reduced iron (DRI) and hydrogen-based steelmaking, aim to reduce carbon emissions and energy consumption.

The adoption of renewable energy sources and carbon capture technologies further contributes to the industry's efforts to mitigate its environmental footprint. Aone Steel is a great steel manufacturer in India and manufactures the best quality steel in India.

Additionally, steel recycling and circular economy initiatives play a crucial role in conserving resources and reducing waste, positioning steel as a sustainable material for the future.

CONCLUSION:

The evolution of steel from traditional to advanced manufacturing methods reflects the industry's relentless pursuit of innovation, efficiency, and sustainability. From the rudimentary techniques of antiquity to the cutting-edge technologies of the modern era, steelmaking has evolved.

In response to changing market dynamics, technological advancements, and environmental imperatives. If you require the best quality steel in India, Aone is the best choice.

As we stand on the cusp of a new industrial revolution, characterized by digitalization, automation, and sustainability, the steel industry is poised to continue shaping the world and driving progress in the years to come.

0 notes

Text

Secondary Refining Furnace

The steel refining process by secondary refining furnace can be divided into two categories: primary refining, aimed at removing carbon from pig iron, and additional refining processes conducted after primary refining, collectively referred to as secondary refining. Secondary refining furnace process involves the removal of impurities and adjustment of elements. The secondary refining usually takes place in a ladle (a transport container for molten steel) and is crucial for producing high-quality steel. The primary role of secondary refining is ultimate desulfurization, the elimination of oxygen, nitrogen, hydrogen, and other impurities, as well as the final decarburization of ultra-low carbon steel.

A steel melting and secondary refining method comprising the steps of melting steel manufacture raw materials while the molten steel is subjected to oxidation and decarburization so that the oxidation and decarburization are substantially completed before melt-down; after melt-down, heating the molten steel to a temperature above a liquidus line temperature and below 50℃. in temperature increment from the liquidus line temperature, and thereafter tapping the molten steel into a primary ladle; teeming the molten steel from the primary ladle into a secondary refining furnace; allowing the molten steel to be effluent into a secondary ladle at a lower portion of the secondary refining furnace while the temperature of the molten steel is raised; and continuously performing gas bubbling in the secondary ladle in a vacuum under existence of slag simultaneously with the effluence of the molten steel into the secondary ladle.

TYPES OF SECONDARY REFINING FURNACE

In the realm of steel production, the Secondary Refining Furnace stands as a pivotal player in achieving exceptional steel purity and quality. This crucial phase of the secondary metallurgy steelmaking process encompasses various techniques aimed at fine-tuning the composition of the molten metal, eliminating impurities, and ensuring the final product meets the stringent demands of modern industries.

WHAT ARE THE FUNCTIONS OF VARIOUS SECONDARY REFINING FURNACES?

Advantages of ladle refining furnace in alloy steel secondary refining

Enhancing Steel Quality through ESR Process

Stainless steel refining: AOD and VOD furnace

Advantages of ladle refining furnace in alloy steel secondary refining

Ladle refining furnace offers strong heating functions, permits the addition of a large amount of alloys, and enables precise temperature control. The ladle secondary refining furnace also provides outstanding desulfurization by high-temperature treatment with reducing fluxes and the removal of deoxidation products. The LRF process is therefore often used for the secondary refining process of alloy steel.

THE PIVOTAL ROLE OF SECONDARY REFINING FURNACES-SHAPING MODERN STEEL EXCELLENCE

THE PIVOTAL ROLE OF SECONDARY REFINING FURNACES-SHAPING MODERN STEEL EXCELLENCE

Secondary refining aims to fine-tune the steel's properties, ensuring the secondary refining process meets the stringent requirements of various industries, including automotive, construction, aerospace, and more.

Purity Enhancement: Steel produced in primary furnaces can still contain impurities and non-metallic inclusions that might adversely affect its mechanical properties, formability, and overall quality. Secondary refining furnaces, such as ladle furnaces or vacuum degassing units, focus on reducing these impurities to enhance the steel's purity. Through secondary refining processes like desulfurization and deoxidation, excess sulfur and oxygen are removed, leading to cleaner and more refined steel.

Composition Adjustment: Steel's composition can significantly impact its performance in various applications. Secondary refining furnaces provide a controlled environment for adjusting the composition of steel by adding precise amounts of alloying elements. This secondary metallurgy steelmaking process allows steelmakers to achieve specific mechanical properties, corrosion resistance, and other characteristics required for specific applications.

Refining Quality: The secondary refining process involves precise temperature and chemical control, which aids in the removal of undesirable elements and compounds that could compromise the steel's quality. By utilizing techniques like argon or vacuum degassing, hydrogen removal, and slag foaming, steelmakers can achieve higher levels of cleanliness and homogeneity in the final product. This contributes to improved mechanical properties, surface finish, and overall quality.

FAQS ABOUT SECONDARY REFINING FURNACE

HOW DOES A SECONDARY REFINING FURNACE ENHANCE THE PURITY OF STEEL?

Secondary refining furnaces employ various processes to enhance the purity of steel. Through the flow of molten steel, these furnaces can remove excess sulfur, oxygen, and other impurities using techniques such as blowing, injection, or vacuum treatment. This treatment significantly reduces the content of non-metallic inclusions and impurities, resulting in cleaner and higher purity steel.

HOW DO SECONDARY REFINING FURNACES CONTRIBUTE TO ENVIRONMENTAL SUSTAINABILITY?

Modern secondary refining furnaces also take environmental factors into consideration. They utilize technologies such as slag recycling and waste heat utilization to reduce waste generation, energy consumption, and emissions. These measures contribute to achieving sustainable steel production and reducing the environmental impact.

HOW DO SECONDARY REFINING FURNACES ADJUST THE COMPOSITION OF STEEL TO MEET SPECIFIC REQUIREMENTS?

Secondary refining furnaces adjust the composition of steel by adding alloying elements to meet specific requirements. Steel producers can precisely control the amount of alloying elements added, thus achieving specific properties and characteristics in the steel, such as corrosion resistance, thermal conductivity, hardness, etc. This enables steel to be tailored for various application domains.

0 notes

Text

Benefits Of Using Recycled Pig Iron For Steel Production

Here are the benefits of using recycled pig iron for steel production according to the best pig iron manufacturers in India. Get the top quality steel grade pig iron in India and learn about pig iron exports from India.

#pig iron for steelmaking#pig iron exports from India#best pig iron manufacturers in India#xsteel grade pig iron in India

0 notes

Text

Uncovering the Materials of Steel: A Comprehensive Guide

Steel, a fundamental material in our contemporary society, is almost everywhere in our surroundings. It serves as the structural backbone of our towering skyscrapers, the sturdy frames of our automobiles, and even the everyday utensils we use in our kitchens.

However, even with its widespread use, a fundamental question often needs to be answered: What steel is made of?

In this article, we will delve into the world of steel and explore its composition, properties, and its crucial role in our daily lives.

The Basic Ingredients of Steel:

Steel is an alloy at its core, which means it is made up of many elements. Steel is made up mostly of iron and carbon. Iron is a naturally occurring element plentiful in the Earth's crust. On its own, it is robust and durable, yet it may be fragile. This is when carbon enters the picture. At the steel foundry, they mix iron with carbon. Iron is fortified with carbon to increase its strength and flexibility, making it more appropriate for various uses.

The Carbon Connection:

The quantity of carbon in steel may vary, giving birth to various steel varieties. Carbon content generally varies between 0.2% and 2.1% by weight. The material is termed low-carbon steel when the carbon content is less than 0.2%. As the carbon percentage rises, it becomes medium-carbon and high-carbon steel. Each kind has its own set of characteristics and uses.

For example, low-carbon steel is well-known for its ductility and ease of shape. It is often used in construction, automobile manufacturing, and even ordinary goods like nails and wire.

Medium carbon steel achieves a good blend of strength and flexibility. It is often utilized to produce equipment, tools, and structural components.

In contrast, high-carbon steel is very strong yet less bendable. It is used in applications with high hardness and wear resistance, such as cutting tools and springs.

But wait, there's another steel player in town: stainless steel. Stainless steel is distinguished by its resistance to rust and corrosion due to the inclusion of chromium during the stainless steel casting. As a result, it has become popular in the culinary world, as well as in medical equipment and many ornamental uses.

Alloying Elements:

While iron and carbon are the fundamental constituents of steel, different alloying elements may be added to improve its qualities. Among the most frequent alloying elements are:

Manganese: This element increases steel's strength and hardenability. It is often used in structural steel and railway rails.

Chromium: Adding chromium improves corrosion resistance, resulting in stainless steel. This steel is often used in kitchenware, medical devices, and architectural projects.

Nickel: In steel foundry, nickel is mixed in steel as it contributes to strength and toughness, making steel suitable for applications like aircraft parts and pipelines.

Vanadium: Vanadium is well-known for increasing steel's hardness and wear resistance. It is often utilized in the manufacture of high-speed equipment and knives.

Molybdenum: Molybdenum enhances steel's heat resistance, making it useful in aerospace and power generation sectors.

Silicon: Silicon aids in the deoxidization of steel and its strength and electrical conductivity. It is often found in electrical steel used in transformers and motors.

The SteelmakingSteelmaking Process:

The production of steel involves several steps. It begins with the extraction of iron ore from the Earth's crust. This ore is then smelted in a blast furnace to remove impurities and reduce it to pig iron, which is high in carbon.

Next, the pig iron is refined in a process called "steelmaking." During this phase, the carbon content is carefully controlled by adding or removing carbon and alloying elements. This process can be done through various methods, including the Bessemer, open-hearth, or electric arc furnace processes.

Once the desired composition is achieved, the molten steel is poured into molds to form various shapes, such as sheets, bars, or coils. These shapes are then cooled and solidified, ready for further processing and use in various industries. Many stainless steel casting manufacturers in India are using new methods to create even better products.

Final Thoughts:

In conclusion, steel is a remarkable material that combines the strength of iron with the versatility of carbon and various alloying elements. Its composition can be tailored to suit a myriad of applications, from everyday household items to critical components in aerospace and construction. Understanding steel's basic ingredients and production process sheds light on its importance in our modern world, where it continues to shape our lives in countless ways.

If you need top-quality steel items, check out Sujan Industries. They're known for their excellent steel products and are experts in steel casting.

0 notes

Text

The Manufacturing Process of HR Coil: A Comprehensive Guide

HR coil is a versatile and widely used steel product that serves as the foundation for a vast array of applications. Its manufacturing process involves a series of carefully controlled steps that transform raw materials into a high-quality, durable product. This guide delves into the intricacies of CR Coil Manufacturer, providing a comprehensive overview of each stage.

Raw Material Preparation: The journey of the HR coil begins with the selection and preparation of raw materials. Iron ore, the primary ingredient, undergoes a series of beneficiation processes to remove impurities and enhance its iron content. Subsequently, the iron ore is converted into pig iron, a semi-finished product, through a smelting process in a blast furnace.

Steelmaking: Pig iron, along with scrap steel and other additives, is charged into a basic oxygen furnace (BOF) to undergo steelmaking. Oxygen is blown through the molten mixture to remove impurities and refine the steel composition. The refined steel, now known as molten steel, is then tapped from the BOF for further processing.

Continuous Casting: Molten steel is transferred to a continuous casting machine, where it is continuously solidified into semi-finished slabs. The slabs are formed by passing the molten steel through water-cooled rollers, gradually cooling and solidifying the steel into long, rectangular shapes.

Reheating and Rough Rolling: The slabs undergo reheating in soaking pits to achieve a uniform temperature and enhance their plasticity. The heated slabs are then passed through a series of roughing mills, which reduce their thickness and elongate them into long strips.

Finishing Rolling: The rough-rolled strips enter the finishing mills, where they are further reduced in thickness and refined in surface quality. The finishing mills employ various rolling techniques, such as four-high and six-high mills, to achieve the desired thickness and surface finish.

Cooling: The hot-rolled coils are subjected to a controlled cooling process to achieve the desired microstructure and mechanical properties. The cooling method varies depending on the desired properties, ranging from air cooling to accelerated cooling using water or mist sprays.

Finishing Treatments: Depending on specific requirements, HR coils may undergo additional finishing treatments, such as:

Pickling: To remove surface scale and impurities, coils are immersed in an acidic solution.

Oiling: To protect the coils from corrosion during storage and transportation, a thin layer of oil is applied to the surface.

Inspection: Coils are subjected to rigorous quality control inspections to ensure they meet dimensional, mechanical, and surface finish specifications.

Shree Mahalaxmi Steel Industries: A Pioneer in HR Coil Manufacturer

Shree Mahalaxmi Steel Industries stands as a leading HR coil Manufacturer, recognized for its commitment to quality, innovation, and customer satisfaction. The company employs state-of-the-art technology and stringent quality control measures to produce HR coils that meet the highest international standards.

Our HR coils are widely used in various industries, including construction, automotive, shipbuilding, and manufacturing. The company’s dedication to excellence has earned it a reputation as a trusted supplier of HR coils, both domestically and internationally.

Conclusion

The manufacturing process of HR coil is a complex and intricate endeavor that demands expertise, precision, and unwavering commitment to quality. Our epitomizes these qualities, producing HR coils that are the backbone of numerous industries. As the demand for HR coils continues to grow, Shree Mahalaxmi Steel Industries is poised to remain at the forefront of HR coil manufacturer, delivering exceptional products and services to its global clientele.

0 notes

Text

Uncovering the Materials of Steel: A Comprehensive Guide

Steel, a fundamental material in our contemporary society, is almost everywhere in our surroundings. It serves as the structural backbone of our towering skyscrapers, the sturdy frames of our automobiles, and even the everyday utensils we use in our kitchens.

However, even with its widespread use, a fundamental question often needs to be answered: What steel is made of?

In this article, we will delve into the world of steel and explore its composition, properties, and its crucial role in our daily lives.

The Basic Ingredients of Steel:

Steel is an alloy at its core, which means it is made up of many elements. Steel is made up mostly of iron and carbon. Iron is a naturally occurring element plentiful in the Earth's crust. On its own, it is robust and durable, yet it may be fragile. This is when carbon enters the picture. At the steel foundry, they mix iron with carbon. Iron is fortified with carbon to increase its strength and flexibility, making it more appropriate for various uses.

The Carbon Connection:

The quantity of carbon in steel may vary, giving birth to various steel varieties. Carbon content generally varies between 0.2% and 2.1% by weight. The material is termed low-carbon steel when the carbon content is less than 0.2%. As the carbon percentage rises, it becomes medium-carbon and high-carbon steel. Each kind has its own set of characteristics and uses.

For example, low-carbon steel is well-known for its ductility and ease of shape. It is often used in construction, automobile manufacturing, and even ordinary goods like nails and wire.

Medium carbon steel achieves a good blend of strength and flexibility. It is often utilized to produce equipment, tools, and structural components.

In contrast, high-carbon steel is very strong yet less bendable. It is used in applications with high hardness and wear resistance, such as cutting tools and springs.

But wait, there's another steel player in town: stainless steel. Stainless steel is distinguished by its resistance to rust and corrosion due to the inclusion of chromium during the stainless steel casting. As a result, it has become popular in the culinary world, as well as in medical equipment and many ornamental uses.

Alloying Elements:

While iron and carbon are the fundamental constituents of steel, different alloying elements may be added to improve its qualities. Among the most frequent alloying elements are:

Manganese: This element increases steel's strength and hardenability. It is often used in structural steel and railway rails.

Chromium: Adding chromium improves corrosion resistance, resulting in stainless steel. This steel is often used in kitchenware, medical devices, and architectural projects.

Nickel: In steel foundry, nickel is mixed in steel as it contributes to strength and toughness, making steel suitable for applications like aircraft parts and pipelines.

Vanadium: Vanadium is well-known for increasing steel's hardness and wear resistance. It is often utilized in the manufacture of high-speed equipment and knives.

Molybdenum: Molybdenum enhances steel's heat resistance, making it useful in aerospace and power generation sectors.

Silicon: Silicon aids in the deoxidization of steel and its strength and electrical conductivity. It is often found in electrical steel used in transformers and motors.

The SteelmakingSteelmaking Process:

The production of steel involves several steps. It begins with the extraction of iron ore from the Earth's crust. This ore is then smelted in a blast furnace to remove impurities and reduce it to pig iron, which is high in carbon.

Next, the pig iron is refined in a process called "steelmaking." During this phase, the carbon content is carefully controlled by adding or removing carbon and alloying elements. This process can be done through various methods, including the Bessemer, open-hearth, or electric arc furnace processes.

Once the desired composition is achieved, the molten steel is poured into molds to form various shapes, such as sheets, bars, or coils. These shapes are then cooled and solidified, ready for further processing and use in various industries. Many stainless steel casting manufacturers in India are using new methods to create even better products.

Final Thoughts:

In conclusion, steel is a remarkable material that combines the strength of iron with the versatility of carbon and various alloying elements. Its composition can be tailored to suit a myriad of applications, from everyday household items to critical components in aerospace and construction. Understanding steel's basic ingredients and production process sheds light on its importance in our modern world, where it continues to shape our lives in countless ways.

If you need top-quality steel items, check out Sujan Industries. They're known for their excellent steel products and are experts in steel casting.

0 notes

Text

Steel prices are expected to rise – Stainless Espresso

Steel prices are expected to rise again soon. This is the increasing opinion of analysts. In addition, the Chinese steel province of Tangshan is now imposing production restrictions of 50% to counter air pollution. Competition between high grade and low grade nickel and stainless steel scrap is growing, which is likely to lead to rising raw material prices. And Indonesia is increasingly criticised for massively increased CO2 emissions and trade restrictions.

Steel prices are expected to rise

Steel futures prices continued their upward trend, supported by ongoing production restrictions in Tangshan, China’s leading steelmaking centre. According to reports, Tangshan has asked 11 A-rated steel mills to proactively reduce production, while B-rated and lower-rated mills will have to shut down 50% of their sintering facilities from 1-31 July due to deteriorating air quality. In addition, several Chinese steel producers have announced maintenance plans for July, following similar patterns in previous months.

These actions contribute to the latest expectations of Asian analysts of reduced supply in the steel market, thereby supporting steel prices. Steel benchmarks for rebar rose by 0.78%, hot-rolled coil by 0.89% and wire rod by 0.45% on the Shanghai Futures Exchange (SHFE).

Competition between high grade nickel vs. low grade nickel is increasing

The competition between the different nickel grades is expected to pick up speed soon. As already announced in early June 2023, Indonesia has a growing problem with the availability of low grade nickel ore and intends to limit the production of e.g. nickel pig iron in order to save the valuable raw materials for higher grade products.

Indonesia needs more raw materials for grade 1 nickel

According to media reports, production capacities of about 200,000 MT of Class 1 nickel should be completed in Indonesia by the end of 2024. Which also explains why there needs to be a shift of raw materials between different producers.

Electromobility needs nickel

On the one hand, this could lead to a relief in the strongly growing market for electromobility, which had recently reduced inventories on the commodity exchanges significantly and partly dropped to historic lows. On the other hand, however, this will reduce the supply of nickel pig iron, which is used in the production of stainless steel.

China plans to use more than 8.3 million tonnes of stainless steel scrap by the end of 2025

At the same time, China plans to increase the share of scrap in stainless steel production from the current 21% to 26% by the end of 2025 – an increase of almost 1.6 million tonnes of stainless steel scrap per year. This will significantly reduce the availability of nickel-bearing scrap and cause prices to rise worldwide.

Competition between high grade, low grade and scrap will therefore increase in the future. What could possibly lead to relief in the EV sector, however, is likely to lead to higher raw material costs in the stainless steel sector – because NPI will become scarcer and scrap will be in greater demand.

Indonesia has become the world’s sixth largest emitter of CO2 from fossil fuels

Even though Indonesia has emerged as the largest producer of nickel products, it comes at a high price. According to recent reports, Indonesia has become the world’s sixth largest emitter of CO2 from fossil fuels in 2022. And there is no end in sight to the burning of coal in the Asian country.

Indonesian Class 1 nickel needs a lot of energy

This poses problems for Indonesia in terms of nickel production. This is because the nickel-bearing laterite ore, which is mainly found in Indonesia, needs much more energy to be converted into class 1 nickel. This means that CO2 emissions are up to six times higher than in Canada, Russia or Australia, for example, where mainly nickel-bearing sulphide ore is mined and processed.

WTO, IMF, EU: Indonesia has to put up with a lot of criticism

Indonesia recently had to put up with a lot of criticism from the World Trade Organisation (WTO) and the International Monetary Fund (IMF) about the export bans imposed or planned by Indonesia on raw materials (e.g. nickel or bauxite). With the new EU regulations on deforestation-free products, another construction site for the Indonesian economy had already opened up in May 2023.

The excessive use of fossil fuels in Indonesia’s energy mix is now likely to raise further criticism with regard to e.g. the EU Carbon Border Tax CBAM and CO2 certificate trading in Indonesia. And raise the legitimate question: When will Indonesia get a grip on this?

Courtesy : https://steelnews.biz/

0 notes

Text

What markets have Ukrainian steelmakers (temporarily) lost?

Last year, Ukrainian metallurgy faced numerous challenges resulting in a three-fold decline in production. These challenges included factory shutdowns and occupations, electricity and working capital shortages, decreased demand, and complex logistics. The last factor is probably the most important. With the majority of steel products being exported by sea (80%), the blockade of Black Sea ports not only caused a three-fold reduction in export volumes but also resulted in the loss of foreign markets. Simultaneously, imports have become increasingly significant for domestic consumption due to product shortages, as the factories in Mariupol were the sole producers in Ukraine.

This year, Ukrainian producers are forced to build their production and sales strategies taking into account both the blocked ports and the global market conditions, which are not too optimistic. Moreover, companies are facing new challenges, such as water shortages due to terrorist attacks by the aggressor country.

The full-scale invasion by russia profoundly impacted Ukraine’s foreign trade activity, causing a decline in key indicators (Figure 1). The export of steel products, typically amounting to several tens of million tons, experienced a three-fold decrease. Nevertheless, the majority, approximately 80%, of the products manufactured by Ukrainian metallurgists continued to be exported as before.

Figure 1. Export, import, and consumption of steel products in Ukraine, million tonnes

Source: Ukrmetalurgprom, State Customs Service of Ukraine data, and expert assessments.

This article’s analysis of foreign trade considers goods of group 72 (“Iron and steel”) and commodity items 7301-7306 of group 73 (“Articles of iron and steel”) of the Commodity Nomenclature of Foreign Economic Activity (CN FEA) to be metal products or steel. Domestic consumption does not include raw materials (pig iron, scrap, ferroalloys), with data for 2022 being expert assessments.

Prior to the full-scale invasion, Ukraine’s imports of steel products surpassed 1.3 million tonnes, accounting for approximately a quarter of the apparent consumption (which includes both production and imports but excludes exports) in the domestic market. However, last year, the volume of imports decreased by half, yet its proportion in domestic consumption rose to one-third.

The decline in imports and domestic consumption can be attributed to two primary factors: constrained logistics and reduced demand for rolled steel due to a slowdown in economic activity caused by the occupation of territories, active hostilities, russian attacks on critical infrastructure facilities, and population migration abroad.

Export of steel products from Ukraine

Semi-finished products and pig iron (as shown in Figure 2) constitute approximately half of the product structure in the export of metal products. These products are generally less lucrative compared to finished rolled steel, which finds applications in various sectors such as construction, automobile and machine building, the oil and gas industry, and more.

Before the full-scale invasion, manufacturers were motivated by supplying semi-finished products to their own assets abroad and responding to market conditions. However, last year, the situation shifted to a “survival” mode, where companies focused on supplying the products they were capable of producing and shipping. For instance, during periods of power outages in the fall, mills reduced the production of rolled steel, which is energy-intensive, and instead prioritized smelting pig iron, which relies more on gas.

A substantial portion of the supply consists of the export of flat-rolled products. However, the volumes of these exports have declined because the main producers of such products are the Metinvest Group’s plants in Mariupol, which are currently occupied.

Figure 2. Commodity structure of exports of steel products of Ukraine, %

Source: State Customs Service of Ukraine

Last year, positive changes were observed as well. The suspension of import duties in the USA and the rise in prices for pipe products, which carry a significant added value, contributed to an increase in their share within Ukraine’s exports from 3% to 6%.

Ukraine’s export of steel products extends to nearly all continents worldwide (as depicted in Figure 3). The companies operating in “normal” mode during the first two months of 2022 (accounting for 43% of the total volume of steel products for the year) helped maintain the existing geographical presence of Ukrainian manufacturers by the end of the year. However, there was a noticeable decline in the number of countries receiving Ukrainian exports, decreasing from 98 in the first quarter of 2022 to only 62 in the fourth quarter.

Figure 3. Geography of exports of Ukrainian steel products in 2022, tonnes

Source: International Trade Center

Note. Almost the entire volume of exports to russia was sent in the first quarter of 2022, with a small cargo shipped in September. Officially, exports to the russian federation were banned at the end of September 2022.

The decrease in volumes of metal product exports had an impact on all sales regions, spanning from Europe to the distant Pacific region (as depicted in Figure 4). The extent of the decline varied based on the distance the cargo had to traverse to reach the buyers, considering the logistical challenges involved. As a result, the presence in remote destinations nearly vanished due to these circumstances.

Figure 4. Regional structure of export of Ukrainian steel products, tonnes

Source: International Trade Center

The regional distribution of countries has been conducted according to the classification of the World Bank.

Specifically, exports to Southeast Asia and Oceania experienced a tenfold decline, while exports to Latin America dropped by 8.5 times, given the disrupting traditional transportation routes. Furthermore, supplies to African countries located south of the Sahara Desert witnessed a decrease of over sixfold.

The situation in the Middle East and North Africa differed somewhat as exports to this region experienced a decline of 3.5 times against the backdrop of the blocked traffic through the Black Sea and the absence of Mariupol mills among the suppliers. Ukraine exported 79% of last year’s volume to this region during the first quarter.

In terms of export volumes, North America stands as the second-largest destination for Ukrainian exports. Last year, sales to this market experienced a relatively smaller decrease of 2.6 times. Similar challenges were encountered, including logistical limitations, the absence of Mariupol suppliers, and reduced production in territories under Ukrainian control. However, Ukrainian companies partially adjusted their shipping routes by diverting exports from Black Sea ports to European ports. This adaptation allowed for an increase in the export of some goods. For instance, Ukrainian manufacturers of seamless pipes witnessed a 21% year-on-year increase in their exports to the USA thanks to the suspension of import duties.

Despite the decrease in supply volumes by 2.6 times, Europe and Central Asia continued to be the primary consumers of Ukrainian steel products. Remarkably, their share expanded to 72% since Ukrainian manufacturers redirectied trade flows through land and river transportation to neighboring countries.

The European Union emerged as the primary destination for Ukrainian exports, with its share in the total volume of Ukrainian steel exports rising from 35% in 2021 to 57% in 2022. In the second half of last year, this share further increased to 90%. Several factors contributed to this shift. Firstly, the blockade of the Black Sea compelled Ukrainian manufacturers to redirect trade flows towards neighboring countries, particularly Poland (which saw a 7% increase in exports from Ukraine). Secondly, the European Commission suspended trade protection measures on Ukrainian products. Lastly, exports to russia, which was one of Ukraine’s top five largest trade partners, were minimized during this period.

The global metallurgical industry has been grappling with excess production capacity in recent years, primarily due to establishing new production facilities in Asia and the Middle East. Consequently, the disposal of Ukrainian volumes does not pose a critical problem for international consumers, as alternative suppliers can readily replace them.

Partial compensation of Ukrainian volumes occurs through regional trade. Moreover, Asian manufacturers are taking a more prominent role and strengthening their positions in the Middle Eastern and European markets. For instance, in the segment of semi-finished and finished steel products, volumes that were previously supplied by Ukraine and partially by russia have been replaced by Asian producers (as shown in Figure 5). This trend has been ongoing and continues in the current year.

Figure 5. Geographical structure of steel imports in the EU-27, %

Source: Eurostat, Eurofer

While Asia is currently stepping in to replace the volumes previously exported by the damaged Mariupol facilities, it may face challenges in the long run. Several important points should be considered. Firstly, despite the lower production costs, transportation expenses from Asia to Europe need to be taken into account. Secondly, import quotas are in place, limiting the volume of shipments from Asian producers. As a result, they may not be able to exceed these established quotas. Lastly, the European Union is increasingly moving towards green metallurgy.

Considering Europe’s decarbonization targets, it is expected to be extremely challenging for most Asian producers, such as China and India, to achieve carbon neutrality even in the medium term. In contrast, Ukraine has an opportunity to “rebuild better” after the war and transition to a new green technological level. This shift aligns with the goals of sustainable development, as emphasized by experts and steelmakers.

Presently, the primary diplomatic efforts are focused on including metallurgical products in the grain agreement and enhancing the transportation infrastructure in Ukraine and Europe. This involves initiatives to improve railways, transshipment hubs, checkpoints, and port infrastructure.

Import to Ukraine

Most imports of steel products to Ukraine are made up of goods that are either not produced in the domestic market or do not meet the quality/pricing requirements of consumers. Primarily, this includes flat-rolled products: its share in imports previously exceeded 50%, and in 2022, it increased to 69% (Figure 6). Before the invasion, mainly coated flat-rolled products were imported as the domestic producers could not fully meet the demand. The need for hot-rolled flat products, which used to be produced by Mariupol-based plants, also increased, given that Zaporizhstal, the only producer of these products at present, was operating intermittently due to a shortage of electricity. Additionally, the import of products previously solely produced by Azovstal, such as beams and rails, has increased.

Figure 6. Commodity structure of steel imports to Ukraine, %

Source: State Customs Service of Ukraine

Until last year, the major steel exporters to Ukraine were russia, China, and Turkiye, accounting for over half of the import volumes. However, for obvious reasons, russia lost its position when an import embargo was imposed in April 2022. Imports from Turkiye also decreased by 20%. Nevertheless, Turkish producers emerged as the primary source of rolled steel for Ukraine in 2022, and by the fourth quarter, import volumes reached pre-invasion levels. Purchases from China experienced a significant decline of 61% due to logistical challenges. Like Turkiye, China meets Ukraine’s demand for flat rolled products, particularly coated rolled products used in construction (e.g., corrugated board), automobile manufacturing, and household appliances. However, the inflow of Chinese coated rolled products may further decrease if new anti-dumping duties on this product are established in Ukraine.

Figure 7. Geography of steel product imports to Ukraine in 2022, tonnes

Source: International Trade Center

Similar to the export segment, European countries have played a supportive role in supplying steel products to Ukraine by increasing trade flows. Slovakia has emerged as the third-largest exporter to Ukraine, while the volume of supplies from Romania has nearly quadrupled. Notably, Romania has been able to establish the supply of scarce products, specifically flat-rolled products, to Ukraine.

Where does the situation stand this year?

There are currently no official detailed statistics for the first five months of 2023, but the main trends can be seen.

Firstly, the stabilization of the electricity supply situation in February resulted in increased production volumes for Ukrainian manufacturers. Thus, in March, crude steel steel production increased by almost a quarter compared to February, while rolled steel production grew by 30%, according to the according to Ukrmetallurgprom. The upward trend continued in April and May.

Overall, both for the first quarter and the first five months of the year, operating results remain significantly lower than last year’s volumes, given the high comparison base of January-February 2022, but Ukraine has increased production compared to the last quarter of last year.

Secondly, steel imports also increased, given the increased consumption in the domestic market (Figure 7) ahead of the construction season and due to disruptions in the operation of local steelmaking companies in winter.

Figure 8. Quarterly volumes of Ukrainian exports and imports of steel products, tonnes

Source: International Trade Center, State Customs Service of Ukraine

Thirdly, the reorientation of all export goods to the western border, primarily agricultural products and iron and steel, has led to significant competition among exporters and increased queues at the borders due to limited capacity.

In such a situation, a temporary restriction on grain imports from Ukraine to certain EU countries could help boost exports of mining and steel products by reducing congestion at the borders and provided that the price situation on the iron ore and steel products markets is favorable. In addition, railroad transportation is also declining due to the unstable operation of the grain corridor. According to April’s operational data, export transportation of goods by rail decreased by 8% compared to March due to a decrease in grain shipments (-15%). However, export transportation of metal products increased by 16%. In May, export rail transportation of ferrous metal products continued to grow to almost 0.5 million tonnes, while grain transportation almost halved.

At the same time, the terrorist attack on the Kakhovka hydroelectric power plant is becoming a new challenge for the Ukrainian steel industry. For example, Kryvyi Rih’s water supply was 70% dependent on the Kakhovka reservoir, so ArcelorMittal Kryvyi Rih, the largest steel producer in Ukraine, stopped steelmaking and rolled steel production to minimize water consumption. At the time of publication, the company has not resumed production. Nikopol Ferroalloy Plant was also forced to cut production.

Conclusions

The data shows not only a reduction in the volume of Ukrainian steel products exported abroad in 2022, but also a forced reduction in the markets of presence. As steel cannot be shipped through traditional ports such as Pivdennyi, Mariupol, Odesa, Mykolaiv, etc., companies have shifted to using railways, Danube river ports, and European seaports, and focused on the closest possible markets – European countries. As a result, producers have reduced cooperation with regions with longer transportation routes.

It is difficult to predict how long Ukrainian producers will be limited in their export opportunities, given the ongoing war and the need for additional financial resources and time to develop transport infrastructure. This is in addition to the issue of rebuilding assets in the temporarily occupied territories. Ukraine plans to establish new joint railroad checkpoints on the border with the EU in 2023-2024 and to develop the railroad by repairing, modernizing, and laying new tracks. In turn, European partners, such as Poland, through whose ports Ukrainian mining and metals products were shipped, plan to expand the capacity of the Gdansk port by 50% by 2025.

In addition, the following factors are worth paying attention to. The shift to shipping Ukrainian products by rail instead of sea has led to a multiple increase in transportation costs. Consequently, in times of declining steel prices on international markets, high transportation costs make our products less economically attractive, as the share of logistics costs increases. According to industry analysts and the National Bank of Ukraine, iron ore and steel prices will continue to decline in the second and third quarters of this year, which may put pressure on the competitiveness of Ukrainian suppliers.

Moreover, even as new logistics routes are being established, Ukrainian producers are facing weaker demand for steel products in key markets, particularly in Europe, which also limits their plans to increase production. This was stated by Mauro Longobardo, CEO of ArcelorMittal Kryvyi Rih, at the international conference “Onwards and Upwards: Reforming Ukraine During the War” held on May 19 in Kyiv.

In addition, the prospects for increasing steel production in Ukraine may be limited again due to a drop in electricity supply. In particular, there is a risk of electricity shortages in the summer, which may force the industry to either cut back on electricity consumption or import more expensive energy from Europe.

Last but not least, water shortages at enterprises in the Dnipropetrovsk region that rely on the Kakhovka reservoir may become another challenge along with electricity shortages.

As for imports, it will continue to grow and account for an important share of domestic consumption until Ukraine resumes production of deficit goods. Russia has ceased to be the main supplier of steel, being replaced by Turkiye, European countries, and, in some commodities, China.

0 notes

Text

What Do You Know About Still Mill?

A steel mill, which is also referred to as a steel factory, is an industrial site dedicated to manufacturing steel. It can take the form of an integrated steel plant that engages in all aspects of steel production, from extracting iron ore to creating finished products. Alternatively, as an expert at GMB Heavy Industries says, it can be a plant that specializes in producing semi-finished casting products made from molten pig iron or recycled metal scraps. If you want to learn more about still mill, keep reading.

The production and refinement of steel involve a range of techniques and processes, such as shaping using cold rolling methods, machining (such as drilling), joining through welding, and coating with materials like zinc, as well as heat treatment, which often involves tempering the steel to improve its properties. Additionally, surface treatment, such as carburizing, is also commonly employed to enhance the quality of steel products.

How Is the Process Done?

There are two main methods of steelmaking: primary and secondary.

Primary steelmaking involves either the basic oxygen steelmaking (BOS) process or the electric arc furnace (EAF) method. In the BOS process, recycled scrap steel is added to molten iron, and then oxygen is blown into the mixture at high temperatures to lower the carbon content. In the EAF method, recycled steel scrap is melted using high-power electric arcs at temperatures of up to 1650°C to create high-quality steel.

Secondary steelmaking combines these two processes to refine the composition of the steel being produced. Specific elements are added at precise temperatures and within controlled environments to create the desired composition. Methods used for these controls include stirring, ladle furnaces, ladle injections, and degassing.

Steel mills offer several advantages, including:

Versatility: Steel is a versatile material that can be used in a wide range of industries, from construction to automotive to consumer goods. This versatility makes steel mills an important contributor to many aspects of modern life.

Cost-Effective: Steel production is often more cost-effective than other materials due to the abundance of raw materials and the efficiency of the production process.

Strength and Durability: Steel is known for its strength and durability, making it an ideal material for construction and infrastructure projects.

Recyclability: Steel is a highly recyclable material, with a recycling rate of over 90%. This makes steel mills an important part of the circular economy, reducing waste and conserving resources.

Technological Advancements: Steel mills are constantly evolving and improving their processes, leading to advancements in technology and innovation. This can lead to improvements in the efficiency and sustainability of the steel production process.

Job Creation: Steel mills are often major employers in the communities where they are located, creating jobs and driving economic growth.

Is Still Mill Eco-friendly?

Steel has a minimal environmental impact compared to other materials since it does not release harmful toxins or chemicals. Furthermore, magnets can easily recover steel from the environment, making it a sustainable material. In addition, steel production does not result in toxic run-off, further reducing its negative environmental impact.

1 note

·

View note