#photoresist applications

Explore tagged Tumblr posts

Text

In the dynamic world of technology, the quest for innovation is relentless. At the forefront of this pursuit are materials that are not only versatile but also capable of revolutionising the way we interact with technology. One such material is negative photoresist, a substance traditionally used in photolithography. Its unique properties make it a key tool in the development of emerging technologies. Read the article to know more.

#Negative photoresist#emerging technologies#photoresist innovation#Negative photoresist Uses#photoresist applications#Negative resist processing#AGAS

0 notes

Text

The global photoresist and photoresist ancillaries market size is estimated to be USD 4.1 billion in 2023 and projected to reach USD 5.3 billion by 2028, at a CAGR of 5.1%. Photoresists are light-sensitive materials used to pattern and etch substrates for the production of integrated circuits and electronic devices in the semiconductor and microelectronics industries. When exposed to light, they experience a chemical shift that enables the precise patterning of the underlying substrate. Ancillaries for photoresists are additives and chemicals that are used with photoresists to enhance the lithographic process. In the phases of cleaning, pre-coating, development, stripping, and post-processing, they are essential. This industry, which is fueled by improvements in semiconductor technology and the need for improved process yields, is strongly related to the demand for photoresists.

#Photoresist & Photoresist Ancillaries Market#Photoresist Ancillaries Market#Photoresist Ancillaries#Photoresist Ancillaries Market Share#Photoresist Ancillaries Market Size#Photoresist Ancillaries Market Growth#Photoresist Ancillaries Market Forecast#Photoresist Ancillaries Market Insights#Photoresist Ancillaries Market Overview#photoresist and photoresist ancillaries Market#Photoresist Ancillaries Companies#Photoresist Ancillaries Manufacturers#Photoresist Ancillaries Producers#Photoresist Ancillaries Suppliers#Photoresist Ancillaries Trends#Photoresist Ancillaries Technology#Photoresist Ancillaries Ecosystem#Photoresist Ancillaries Applications#Photoresist Ancillaries Products#Photoresist Ancillaries Industry#Photoresist Ancillaries Industry Trends#Photoresist Ancillaries Industry Share#Photoresist Ancillaries Industry Forecast#Photoresist Ancillaries Industry Size#Photoresist Ancillaries Industry Opportunities#Global Photoresist Ancillaries Market#Global Photoresist Ancillaries Industry#Photoresist Ancillaries Market Segments#Photoresist Ancillaries Market Segmentation#Photoresist Ancillaries Market Graph

0 notes

Text

0 notes

Text

Growing Demand for Advanced Semiconductor Devices Drives Photolithography Equipment Market

Growing Demand for Advanced Semiconductor Devices Drives Photolithography Equipment Market

The global Photolithography Equipment Market size was valued at USD 9,468 Million in 2021 and is projected to reach from USD XX Million in 2022 to USD 14096 Million by 2030, growing at a CAGR of 5.1% during the forecast period (2022–2030).

The global Photolithamination Equipment Market is expected to witness significant growth due to the increasing demand for advanced semiconductor devices. The market is driven by the growing need for miniaturization of electronic devices, which requires the use of photolithamination equipment.

The market is also influenced by the rising adoption of emerging technologies such as artificial intelligence, 5G, and the Internet of Things (IoT). These technologies require the use of advanced semiconductor devices, which in turn drives the demand for photolithamination equipment.

Request Sample Link:https://straitsresearch.com/report/photolithography-equipment-market/request-sample

Market Definition

Photolithography equipment, also known as optical lithography or UV lithography, is a process used in microfabrication to pattern parts of a thin film or the bulk of a substrate. It uses light to transfer a pattern from a photomask to a light-sensitive chemical (photoresist) on the substrate.

Latest Trends

Increasing demand for miniaturized electronic devices

Growing adoption of 5G technology and artificial intelligence

Rising demand for advanced packaging technologies

Increasing focus on research and development activities

Key Opportunity

The growing demand for advanced semiconductor devices and the increasing adoption of emerging technologies such as artificial intelligence, 5G, and the Internet of Things (IoT) are expected to create new opportunities for the photolithography equipment market.

Key Players

The key players in the photolithography equipment market are:

ASML Holding NV

Canon Inc.

Nikon Corporation

SÜSS MICROTEC SE

Holmarc Opto-Mechatronics (P) Ltd

Taiwan Semiconductor Manufacturing Company Limited (TSMC)

KLA Corporation

S-Cubed Company

Osiris International GmbH

Veeco Instruments Inc.

Market Segmentation

The photolithography equipment market is segmented based on process, application, light source, type, wavelength, and end-user.

By Process

Ultraviolet

Deep Ultraviolet

Extreme Ultraviolet

By Application

Front-end

Back-end

By Light Source

Mercury Lamp

Fluorine Laser

Excimer Laser

Others

By Type

EUV

DUV

I-Line

ArF

ArFi

KrF

By Wavelength

370 nm–270 nm

270 nm–170 nm

70 nm–1 nm

By End User

IDMS

Foundries

Buy Now:https://straitsresearch.com/buy-now/photolithography-equipment-market

About Straits Research

Straits Research is a top provider of business intelligence, specializing in research, analytics, and advisory services, with a focus on delivering in-depth insights through comprehensive reports.

#Photolithography Equipment Market#Photolithography Equipment Market Share#Photolithography Equipment Market Size#Photolithography Equipment Market Research#Photolithography Equipment Industry

0 notes

Text

0 notes

Text

Unlocking Precision: The Growth of the Chemical Milling Market

The Chemical Milling Market has gained momentum in recent years due to its crucial role in industries such as aerospace, automotive, medical, electronics, and defense. This niche manufacturing process, which uses chemical solutions to etch precise patterns or remove layers from metal parts, allows for the creation of lightweight and complex components with unparalleled precision. This article delves into the market's current trends, key players, growth factors, and emerging innovations.

Introduction to Chemical Milling

Chemical milling, also known as chemical etching, is a subtractive manufacturing process used to produce intricate metal parts by dissolving specific portions of the metal with chemical solutions. Industries favor chemical milling for its precision, cost-efficiency, and ability to work with various metals, including aluminum, titanium, steel, and copper alloys.

The process finds widespread application in sectors demanding high accuracy, such as aerospace, where lightweight and durable components are crucial. Beyond aerospace, the process has gained traction in the electronics and medical industries, driven by advancements in technology and the growing demand for customized solutions.

Market Overview

The global chemical milling market was valued at approximately $X billion in 2023 and is projected to grow to $Y billion by 2030, registering a CAGR of Z% during the forecast period. This growth can be attributed to increasing demand for lightweight components, advancements in chemical etching technologies, and the rise of renewable energy applications requiring precise metal parts.

Key Industries Driving Demand

Aerospace & Defense Chemical milling is extensively used for creating structural components, fuel tanks, and turbine blades. With the expansion of commercial aviation and defense budgets, demand for chemically milled parts is surging.

Automotive In electric vehicles (EVs) and autonomous vehicles, chemical milling is used to manufacture lightweight components, improving energy efficiency and reducing emissions.

Electronics The rise of miniaturized devices and high-density interconnects (HDI) has fueled the need for precise chemical etching techniques in circuit boards and microelectronic components.

Medical Devices Chemical milling is critical for producing surgical instruments, implants, and other medical equipment with complex geometries and high precision.

Emerging Trends in the Chemical Milling Market

1. Eco-Friendly Etching Solutions

Regulatory pressure to reduce environmental impact has led to the development of eco-friendly chemical solutions. These innovations focus on reducing hazardous waste and energy consumption.

2. Integration with Automation

Automation is transforming chemical milling processes, ensuring greater accuracy and reducing lead times. Automated systems enable real-time monitoring, enhancing quality control and efficiency.

3. Advancements in Photochemical Machining

Photochemical machining, a subset of chemical milling, uses photoresist technology for precise patterning. This method is gaining popularity in electronics and micromechanical applications.

4. 3D Chemical Milling

While traditionally applied to flat surfaces, advancements now allow for 3D etching, enabling more complex part geometries.

5. Increased Use of Recyclable Materials

Manufacturers are shifting toward using recyclable and sustainable materials to align with global sustainability goals, reducing both costs and environmental impact.

Challenges in the Market

Despite its advantages, the chemical milling market faces challenges:

Regulatory Restrictions The use of hazardous chemicals in the etching process is subject to stringent environmental regulations, particularly in developed regions such as North America and Europe.

High Competition from Additive Manufacturing Additive manufacturing (3D printing) is rapidly advancing, offering an alternative for creating complex metal components. However, chemical milling maintains its edge in terms of precision and scalability.

Rising Raw Material Costs Fluctuating prices of metals such as titanium and aluminum can impact production costs, creating pricing pressure for manufacturers.

Regional Insights

North America

North America remains a dominant player in the chemical milling market due to its well-established aerospace and defense industries. The region also invests heavily in R&D, driving technological advancements in the field.

Europe

Europe's chemical milling market benefits from the automotive industry's focus on lightweight materials. Countries such as Germany and the UK are hubs for innovation in chemical etching solutions.

Asia-Pacific

Asia-Pacific is witnessing rapid growth, driven by the booming electronics industry in countries like China, South Korea, and Japan. The region's low production costs and expanding automotive sector contribute to market expansion.

Middle East & Africa

Though smaller in scale, the Middle East is emerging as a key market, with investments in aerospace and defense projects boosting demand for chemical milling.

Key Players in the Market

Several prominent companies are driving innovation and competition in the chemical milling market:

Orbel Corporation

Advanced Chemical Etching Ltd.

Tech-Etch, Inc.

United Western Enterprises, Inc.

VACCO Industries

Chemcut Corporation

Precision Micro Ltd.

Photofabrication Engineering, Inc.

UWE Bristol

Tecan Ltd.

These companies focus on developing advanced etching technologies, eco-friendly solutions, and automated processes to stay ahead in the competitive landscape.

Future Outlook

The chemical milling market is poised for significant growth as industries increasingly adopt lightweight and precise manufacturing solutions. Emerging applications in renewable energy and electric vehicles, coupled with advancements in automation and green chemistry, will further propel the market.

However, to maintain sustainability and competitiveness, companies must focus on overcoming challenges such as environmental concerns and competition from alternative technologies.

Conclusion

The chemical milling market stands at the intersection of precision engineering and technological innovation. With its versatility and efficiency, chemical milling continues to be a cornerstone of modern manufacturing, meeting the needs of various industries. As the market evolves, driven by technological advancements and sustainability goals, chemical milling will remain a critical process for producing high-quality metal components.

Browse More

Sodium Dichromate Market Overview

Microfiltration Membrane Market Analysis

Fluosilicic Acid Market Trends and Size

0 notes

Text

Semiconductor Chemicals Market Demand Outlook: Key Factors Driving Growth and Competition

The semiconductor chemicals market is experiencing significant growth, driven by the ever-increasing demand for semiconductors across various industries, including electronics, automotive, and telecommunications. As technological advancements continue to evolve, the need for specialized chemicals used in semiconductor manufacturing is expected to escalate, further fueling the market’s expansion. This article delves into the key factors driving growth in the semiconductor chemicals market and the competitive landscape shaping its future.

Rising Demand for Consumer Electronics

One of the primary drivers of the semiconductor chemicals market is the continued growth in consumer electronics. As the demand for smartphones, laptops, tablets, and other connected devices surges, the semiconductor industry faces immense pressure to produce more advanced and smaller chips. These chips are integral to the functioning of electronics, and their production relies heavily on specialized chemicals like photoresists, etching gases, and developers. As manufacturers push the limits of miniaturization and performance, the need for high-quality chemicals will only grow, contributing to the market's expansion.

Advancements in Automotive Electronics

Another key factor propelling the semiconductor chemicals market is the rise in demand for automotive electronics. The automotive industry is increasingly incorporating semiconductors into vehicles for applications such as advanced driver-assistance systems (ADAS), electric vehicles (EVs), and autonomous driving technologies. These systems require highly precise and reliable semiconductors, which, in turn, require advanced chemicals during their production. With the global shift toward electric and autonomous vehicles, the demand for semiconductor chemicals in the automotive sector is set to grow significantly in the coming years.

Growth of the 5G Network

The rollout of 5G networks is another major factor influencing the demand for semiconductor chemicals. 5G technology promises faster internet speeds, lower latency, and the ability to support a large number of connected devices. This transformation is leading to an increased need for semiconductors with enhanced performance and reliability. As 5G infrastructure and devices proliferate, semiconductor manufacturers are tasked with producing more advanced chips, which requires a wide range of specialty chemicals, including those used for photolithography, etching, and packaging. The global 5G rollout is expected to fuel demand for these chemicals well into the future.

Innovations in Semiconductor Manufacturing Processes

The semiconductor industry is also undergoing significant innovations in manufacturing processes. As companies adopt advanced techniques like extreme ultraviolet (EUV) lithography, which allows for the creation of smaller and more powerful transistors, the demand for specialized chemicals, such as photoresists and etching solutions, is increasing. EUV technology, in particular, has led to a surge in the need for high-performance chemicals that are critical for precise patterning at the nanoscale. These innovations are crucial for the production of next-generation semiconductors, further driving the demand for semiconductor chemicals.

Competitive Landscape and Market Trends

The semiconductor chemicals market is highly competitive, with several players striving to gain a foothold in the industry. Major chemical suppliers are increasingly focusing on enhancing their product offerings and forming strategic alliances to cater to the growing demand. Companies like BASF, Dow Inc., and Tokyo Ohka Kogyo Co., Ltd. are investing heavily in research and development to create new formulations that can meet the demands of emerging technologies. The emphasis on sustainability is also becoming more pronounced, with companies developing eco-friendly and less toxic chemicals for semiconductor manufacturing processes.

In addition, mergers and acquisitions (M&A) activities are on the rise, as companies seek to expand their portfolios and strengthen their market presence. The consolidation of players and the constant innovation in chemical formulations will likely intensify competition in the semiconductor chemicals market.

Conclusion

The semiconductor chemicals market is poised for strong growth as the demand for semiconductors continues to rise across multiple sectors. The automotive revolution, 5G network expansion, and ongoing innovations in semiconductor manufacturing are among the key factors propelling this growth. As competition intensifies, leading chemical companies will need to focus on innovation, strategic collaborations, and sustainability to maintain a competitive edge in this fast-evolving market. With technological advancements paving the way for new opportunities, the semiconductor chemicals market is set to witness significant developments in the years to come.

Get Free Sample and ToC : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NTE1&RD=Semiconductor-Chemicals-Market-Report

#SemiconductorChemicalsMarketPredictions#SemiconductorChemicalsMarketDemandOutlook#SemiconductorChemicalsMarketResearchAndCompetition#SemiconductorChemicalsMarketProductionScenario#SemiconductorChemicalsMarketGrowthInsights

0 notes

Text

Top 5 Reasons to Use a Chemical Etching Service in Your Manufacturing Process

Chemical etching is a highly efficient and precise manufacturing process that has gained popularity across various industries. As a leading chemical etching company, OTOEL specializes in providing high-quality chemical etching services that cater to diverse manufacturing needs. Here, we discuss the top five reasons why utilizing a chemical etching service can significantly enhance your manufacturing process.

1. Precision and Accuracy

One of the most compelling reasons to opt for a chemical etching service is the unmatched precision it offers. The process allows for the creation of intricate designs and patterns with tight tolerances, often achieving features as small as 0.01 mm. This level of accuracy is difficult to attain with traditional manufacturing methods such as stamping or laser cutting.

Tight Tolerances: Chemical etching can maintain tolerances of ±10% of the metal thickness or ±0.020 mm, ensuring that every part produced meets exact specifications.

Complex Geometries: The ability to create complex shapes and fine details makes chemical etching ideal for applications in industries like aerospace, electronics, and medical devices.

2. Cost-Effectiveness

Utilizing a chemical etching company can lead to significant cost savings in your manufacturing process. The efficiency of chemical etching reduces waste and minimizes the need for extensive tooling, which can be costly.

Reduced Tooling Costs: Unlike traditional machining methods that require specific tools for each part, chemical etching utilizes photoresist masks, which can be easily modified for different designs.

Lower Material Waste: The subtractive nature of chemical etching means that only the necessary material is removed, resulting in less scrap compared to other processes.

3. Speed and Efficiency

In today's fast-paced manufacturing environment, speed is crucial. A chemical etching service can dramatically shorten lead times compared to conventional machining methods.

Rapid Prototyping: Chemical etching allows for quick iterations during the design phase, enabling manufacturers to test and refine their designs faster.

Shorter Production Cycles: With lead times measured in days rather than weeks or months, companies can respond quickly to market demands and reduce time-to-market for new products.

4. Versatility in Material Use

Chemical etching is compatible with a wide range of materials, making it a versatile option for various applications. A reputable chemical etching company can work with metals such as:

Stainless steel

Copper

Brass

Nickel alloys

Titanium

5. Quality and Consistency

Quality control is paramount in manufacturing, and chemical etching excels in producing consistent results across large production runs.

Uniformity: The controlled nature of the chemical etching process ensures that each part produced is identical to the last, minimizing variations that could affect performance.

No Mechanical Stress: Unlike mechanical processes that can introduce stress into materials, chemical etching does not deform the substrate, resulting in burr-free components with smooth edges.

Suitable Metals for Chemical Etching

1. Stainless Steel

Stainless steel is one of the most popular materials for chemical etching due to its corrosion resistance and mechanical strength.

Types: It includes various grades such as austenitic (300 series), ferritic/martensitic (400 series), and duplex stainless steels.

Applications: Commonly used in medical devices, automotive components, and architectural features.

Advantages: The etching process produces burr-free parts, maintaining the integrity of the material without introducing mechanical stress.

2. Titanium

Titanium is renowned for its lightweight properties, high strength, and excellent corrosion resistance.

Challenges: While titanium can be etched, it requires specialized processes due to its tendency to form a protective oxide layer when exposed to air.

Applications: Frequently used in aerospace, medical implants, and high-performance engineering applications.

Advantages: Chemical etching allows for the production of complex shapes that would be difficult to achieve through traditional machining.

3. Aluminum

Aluminum is another metal that benefits from chemical etching, particularly due to its favorable strength-to-weight ratio.

Challenges: The heat generated during the etching process can lead to rough edges if not managed properly.

Applications: Widely used in aerospace components and electronic housings.

Advantages: Offers excellent corrosion resistance and is malleable, making it suitable for intricate designs.

Conclusion

Incorporating a chemical etching service into your manufacturing process offers numerous advantages, including precision, cost-effectiveness, speed, versatility, and consistent quality. As an established chemical etching company, OTOEL is dedicated to providing exceptional service tailored to meet your specific needs. By choosing chemical etching, you not only enhance your production capabilities but also position your business for success in an increasingly competitive market.

Why Choose OTOEL?

At OTOEL, we pride ourselves on our expertise in chemical etching technology and our commitment to customer satisfaction. Our state-of-the-art facilities and experienced team ensure that we deliver high-quality products that meet stringent industry standards. Whether you require prototypes or large-scale production runs, we have the capabilities to support your manufacturing goals effectively.

For more information about our services or to discuss your project requirements, please contact us today!

0 notes

Link

Numerous developments in photoresist coatings and their use in semiconductor applications are paving the way for potential future uses. A-Gas has been the forefather of the semiconductor industry. To learn more about how important photoresist is for the semiconductor industry, connect with A-Gas now and get all the necessary information.

#Semiconductor Manufacturing#Semiconductor#photoresist#Positive photoresists#negative photoresists#semiconductor applications#Photoresist Materials#A-Gas

0 notes

Text

0 notes

Text

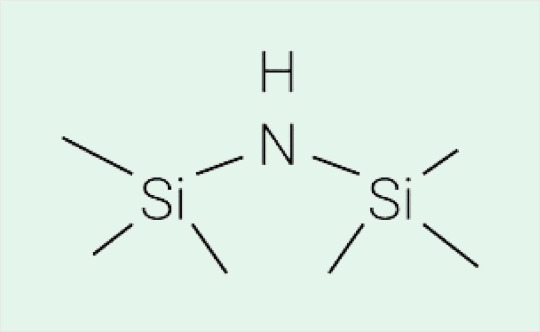

Introduction: Understanding HMDS (Hexamethyldisilazane)

Introduction: Understanding HMDS (Hexamethyldisilazane)

HMDS, or Hexamethyldisilazane, might not be a household name, but in certain industries, it's nothing short of essential. It’s a versatile chemical compound used extensively in the electronics and semiconductor industries. But what exactly is HMDS? Why is it so crucial in these high-tech fields? And, just as important, what safety precautions should be followed when dealing with it?

In this post, we’ll break down the science behind HMDS, its industrial applications, the reasons for its popularity, and the critical safety protocols for handling it safely.

What is HMDS?

HMDS (chemical formula: [(CH₃)₃Si]₂NH) is an organosilicon compound, meaning it contains silicon atoms bonded to organic groups. This compound is a colorless liquid with an ammonia-like smell. Its molecular structure features two trimethylsilyl groups bonded to a nitrogen atom.

HMDS is known for its water-repellent properties and ability to react with surfaces to modify their characteristics. These properties make it useful in various niche applications, especially where surface treatment or preparation is essential.

Key Properties of HMDS:

Molecular Formula: [(CH₃)₃Si]₂NH

Appearance: Clear, colorless liquid

Odor: Ammonia-like smell

Boiling Point: ~126°C

Water Solubility: Low; it reacts with water, releasing ammonia

Primary Uses of HMDS

HMDS has numerous applications across industries. Let’s take a closer look at some of its most common uses:

1. Semiconductor and Electronics Industry

The semiconductor industry is perhaps the largest consumer of HMDS. It is used as a surface preparation agent in microelectronics manufacturing. Before photolithography—a key process in producing microchips—HMDS is applied to silicon wafers to make the surface more hydrophobic (water-repellent). This allows photoresist to adhere more uniformly, resulting in higher-quality chips.

Why it matters: In the world of electronics, even the tiniest imperfection can cause significant defects in microchips. HMDS helps ensure a smooth surface, improving the overall yield and quality of these intricate components.

2. Adhesion Promoter

HMDS works as an adhesion promoter, not only in semiconductor manufacturing but also in other fields. It is often applied as a primer to improve the bond between surfaces that wouldn’t naturally adhere well. For instance, in certain polymer coatings, HMDS creates a more reactive surface, ensuring better adhesion of other materials.

3. Laboratory Uses

HMDS also has its place in research laboratories. It's used as a siliconizing agent, particularly in organic synthesis. Chemists apply it to glass surfaces in laboratory equipment to render them hydrophobic, minimizing unwanted reactions during experiments. Additionally, HMDS is sometimes used in chemical reactions to protect hydroxyl groups, which are part of many organic molecules.

4. Organic Synthesis

In organic chemistry, HMDS is used to convert alcohols into their corresponding trimethylsilyl ethers, which are more stable and less reactive. This allows chemists to temporarily protect these groups during reactions, preventing unwanted side reactions and making complex organic syntheses more manageable.

Handling HMDS: Safety Considerations

Like many industrial chemicals, HMDS must be handled with care. While it’s widely used, improper handling can pose health and safety risks. Here are the key safety measures that should be followed:

1. Personal Protective Equipment (PPE)

When working with HMDS, wearing the right personal protective equipment is critical. This includes:

Gloves (typically nitrile gloves to prevent skin contact)

Safety goggles or face shields (to protect the eyes from splashes)

Lab coats or aprons (to prevent contact with clothing)

Proper ventilation or fume hoods (since HMDS can emit vapors that irritate the respiratory system)

2. Fire Safety

HMDS is flammable, so it should always be stored away from open flames or sources of heat. Ensure fire extinguishers are nearby when working with this chemical, and avoid creating static electricity that might ignite vapors.

3. Chemical Reactivity

HMDS reacts with water, releasing ammonia and sometimes creating hazardous fumes. It's important to store HMDS in airtight containers in dry environments and keep it away from any moisture to prevent this reaction.

4. Disposal of HMDS

Proper disposal of HMDS is a must. It cannot simply be poured down the drain or thrown out with regular trash. Instead, it should be disposed of as hazardous waste, following your local regulations for chemical disposal.

Benefits of Using HMDS

1. Enhanced Performance in Semiconductor Manufacturing

The major benefit of HMDS is its ability to improve the adhesion of photoresist in semiconductor processing. By ensuring a smoother, hydrophobic surface, it significantly enhances the quality and reliability of semiconductor components, which are the backbone of modern technology.

2. Surface Modification Capabilities

HMDS’s ability to alter the surface characteristics of materials makes it invaluable in numerous applications beyond electronics, from biotechnology to materials science.

3. Versatility in Organic Chemistry

In organic synthesis, HMDS’s role as a protecting agent gives chemists more control over complex reactions, allowing for the creation of intricate molecules with precision.

FAQs About HMDS

Q1: Is HMDS safe to use?Yes, but only with proper precautions. As a flammable and reactive chemical, HMDS requires careful handling, appropriate PPE, and adherence to safety protocols to avoid accidents.

Q2: What industries rely on HMDS the most?The semiconductor and electronics industries are the largest users, but it’s also commonly used in organic chemistry and material science research.

Q3: Can HMDS be mixed with water?No, HMDS reacts with water, releasing ammonia. It should be kept dry at all times to prevent unwanted chemical reactions.

Q4: How is HMDS stored?HMDS should be stored in airtight containers, away from moisture and heat sources, in a well-ventilated area.

Wrapping Up: The Importance of HMDS

HMDS is a critical compound in various high-tech industries, especially in semiconductor and microelectronics manufacturing. It’s versatile, offering benefits that range from improving adhesion in chip production to protecting delicate molecules in organic chemistry. However, its usefulness comes with the need for stringent safety measures to avoid accidents and ensure smooth operations.

By understanding what HMDS is, how it’s used, and how to handle it safely, industries and research labs can maximize its benefits while minimizing risks.

0 notes

Text

0 notes

Text

Optical Lithography Services

DisChem offers advanced optical lithography services that cater to industries requiring high-resolution patterning for semiconductor, photonics, and MEMS applications. Utilizing state-of-the-art equipment, their optical lithography processes ensure precise, repeatable results in the fabrication of micro and nano-scale devices. DisChem’s expertise in handling a variety of photoresists and substrates ensures optimal performance in even the most complex lithographic projects. These services are designed to meet the evolving needs of industries that demand accuracy, reliability, and innovation in microfabrication technologies.

0 notes

Text

What are Rigid Circuits? : Rigid Circuits

Rigid circuits, also known as rigid printed circuit boards (PCBs), are made from non-flexible materials that provide a solid foundation for electronic components. Unlike flexible circuits, which can bend and conform to various shapes, rigid circuits maintain their shape and rigidity throughout their lifecycle. They are used in applications where mechanical stability and structural integrity are crucial.

Types of Rigid Circuits : Rigid Circuits

Single-Sided PCBs: These have a single layer of conductive material and are often used in simple electronic devices. They are cost-effective and straightforward to manufacture.

Double-Sided PCBs: These circuits have conductive layers on both sides of the board, allowing for more complex designs and higher component density. They are used in applications requiring more advanced functionality.

Multi-Layer PCBs: These consist of multiple layers of conductive material separated by insulating layers. Multi-layer PCBs can accommodate complex circuit designs and high-density interconnections, making them suitable for advanced electronics such as computers and telecommunications equipment.

Key Features of Rigid Circuits : Rigid Circuits

Mechanical Strength: Rigid circuits provide structural support for electronic components, ensuring they remain securely in place and are protected from mechanical stress.

Thermal Stability: They offer good thermal stability, which helps dissipate heat generated by electronic components and prevents overheating.

Electrical Performance: Rigid circuits provide reliable electrical connections and signal transmission, ensuring consistent performance of electronic devices.

Cost-Effectiveness: They are generally less expensive to produce than flexible circuits, making them a popular choice for a wide range of applications.

Applications of Rigid Circuits : Rigid Circuits

Consumer Electronics: Rigid circuits are widely used in devices such as smartphones, tablets, laptops, and televisions. They provide the necessary support and connectivity for various electronic components.

Automotive Electronics: In the automotive industry, rigid circuits are used in control systems, infotainment systems, and safety features. Their durability and reliability are essential for vehicle performance and safety.

Industrial Equipment: Rigid circuits are employed in industrial machinery, control systems, and automation equipment. Their robustness ensures reliable operation in demanding environments.

Medical Devices: In medical technology, rigid circuits are used in diagnostic equipment, monitoring devices, and other healthcare applications. Their accuracy and reliability are crucial for patient safety and effective treatment.

Manufacturing Process : Rigid Circuits

The manufacturing of rigid circuits involves several steps:

Material Preparation: The process begins with the preparation of laminate sheets, which consist of a base material (such as FR4) and a copper layer. The laminate is coated with a photoresist material that will be used to define the circuit pattern.

Patterning: The circuit design is transferred to the laminate using photolithography. The photoresist material is exposed to light through a mask, which creates a pattern on the copper layer.

Etching: The unexposed copper is removed using an etching solution, leaving behind the desired circuit pattern.

Drilling and Plating: Holes are drilled into the board for component placement, and the holes are plated with a conductive material to create electrical connections between different layers of the circuit.

Assembly and Testing: Electronic components are soldered onto the circuit board, and the assembled boards undergo rigorous testing to ensure they meet performance and reliability standards.

Conclusion : Rigid CircuitsRigid circuits are a vital component of modern electronics, providing the mechanical support and electrical connectivity needed for a wide range of applications. Their durability, thermal stability, and cost-effectiveness make them an essential choice for manufacturers and designers. As technology continues to evolve, rigid circuits remain a foundational element in the development of advanced electronic devices and systems.

0 notes

Text

PCB Manufacturing: From Design to Production

The unsung hero of electronics is the Printed Circuit Boards (PCBs), without which our devices would not function. Being an integral part of most digital devices, PCBs form the crucial building blocks of today’s technology-laden society, from the mobile devices in our pockets to communication satellites orbiting our planet. In this blog post, I will explore the detailed process of producing PCBs, from designing to manufacturing them. Understanding PCBs So, before going deeper into the manufacturing process, let’s explain what a PCB is. A printed circuit board is an interconnecting device with electronic components joined by conductive paths, pads, and features. These components are produced by etching the insulated copper from sheets laminated on an insulating base. PCBs can be single-sided (One Copper Layer), double-sided (Two Copper Layers), or multi-layered. The PCB Manufacturing Process A complex series of actions must transform a circuit idea into a completed PCB. Let's take a closer look at each of these. 1. Design and Layout The most significant element of the creation of the PCB is the creation of the design. A chip engineer employs linear circuits Electronic Design Automation (EDA) software to develop a schematic view of the circuit. This is then translated to a printed circuit board layout where one defines the placement of the components and the interconnection paths. Key considerations during the design phase include: Circuit functionality Component placement Signal integrity Power distribution Thermal management Manufacturing constraints When the design is finished, it is exported as a collection of Gerber files, complete with all the data required for production. 2. Material Selection Different materials used in the PCB production process determine its performance, lifespan, and cost. The primary material most often used is FR-4, an epoxy resin glass fiber reinforced laminate. Other materials such as polyimide, aluminum, and ceramics are also used for specific purposes. Various factors impact the choice of material, such as: Operating temperature range Dielectric constant Thermal conductivity Coefficient of thermal expansion Cost 3. Inner Layer Processing In the case of multi-layer PCB, the procedure starts from the internal layers of the respective PCB boards. The process typically involves these steps: The process typically involves these steps: - Cleaning: The copper-clad laminate is first rinsed to wash away any contaminants from the surface. - Photoresist Application: Coating of photoresist onto the copper layer This is a layer of photoresist applied onto the copper surface used in the etching process. - Image Transfer: Typically, the circuit is formed when UV light transfers the circuit pattern onto the photoresist. - Developing: This exposed and processed photoresist makes the circuit pattern whereby the unexposed portion of the photoresist is washed away. - Etching: The rest of the copper is stripped off, thus exposing only the required copper traces. - Stripping: They come through the top layer of resist, wash off the rest of the photoresist, and we can see the copper circuit pattern. - Optical Inspection: Various inspections are done on the layers, including checking for defects. 4. Layer Alignment and Bonding The separate layers of a multi-layer PCB must be aligned and glued together: - Layer Up: The inner layers are placed with layers of prepreg placed between them; this material is a material that has been soaked in epoxy resin. - Registration: They are accurately located in relation to each other through the use of the tooling holes. - Bonding: In a lamination press, high pressure and temperature are applied, thus making the prepreg flow and laminating the stack. 5. Drilling The PCB has various holes drilled for the component leads, which connect the different layers. This is usually achieved by using computerized drilling equipment for accuracy in terms of positions to be drilled. The types of holes include: Through-holes: Continue through all the layers Blind vias: Attach an outer shell to an inner compartment Buried vias: I: Integrate inner layers without going through the skin 6. Plating and Coating The board goes through multiple plating and coating procedures after drilling. - Desmear: This one clears any melted resin from the drilling process. - Electroless Copper Deposition: A thin layer of copper is then dissolved by an electrolytic process on various parts of the board, even the holes. - Copper Electroplating: A further increment of thickness is done by electroplating in copper. - Tin Plating: This includes applying a thin layer of tin to cover the layer of copper so that it may be protected from etching. 7. Outer Layer Imaging As with the outer layers, the photoresist is applied to the outer layers and then exposed and developed the same way that the inner layers are to form the circuit pattern through etching. 8. Solder Mask Application Finally, a solder mask is provided to the board; this makes the PCB look green (but can also come in other colors). This layer: It avoids the formation of solder bridges between tiny and adjacent solder pads Acts as a shield to the copper traces against corrosion Provides electrical insulation 9. Surface Finish Several surface finishes can be applied on exposed copper pads and traces to avoid oxidation and improve solderability. Common finishes include: Hot Air Solder Levelling (HASL) Electroless Nickel Immersion Gold Immersion Tin Immersion Silver Organic Solderability Preservative (OSP) 10. Silkscreen All texts, signs, and symbols are applied with the help of silkscreen printing. This includes information on rightful designators of one or several components, distinctive threats or precautions, and the logos of their manufacturers. 11. Electrical Testing Before the PCBs are shipped, they are subjected to an electrical test to check whether they have short circuits or open circuits. Flying Probe Test: Uses Moving probes to check connections. Bed of Nails Test: Goes to the test specification point and employs a fixture with spring-loaded pins that touch the test points. 12. Cutting and Profiling In this case, it would be separated here if it had to produce one or more PCBs on a panel. One way to accomplish this is by: V-scoring and breaking Routing Laser cutting 13. Final Inspection and Packaging The manufactured PCBs are visually and optically inspected and tested using automated optical inspection. Automated Optical Inspection Aoi They are cleaned, packed, and ready for dispatch. Future Trends in PCB Manufacturing The PCB manufacturing sector is still developing. Among the new developments are: 3D Printing: Currently, there are attempts to use AM technologies to make PCB prototypes and production designs. Flexible and Stretchable PCBs: There is a shift to developing new materials and manufacturing methods that would allow PCBs to flex or compress. Embedded Components: Components are now being placed directly into the PCB's layers, offering an even higher density. Smart Manufacturing: Industry 4.0 concept is applied at the moment, and itted to manufacturing PCBs with data analysis and increased automation. Green Manufacturing: Sustainability has become an issue of concern within the clothing industry, where material use and waste production are also of concern. Conclusion Printed Circuit Board manufacturing is a complex process that involves lots of technology and finesse. Every stage of the creation process begins with careful planning and follows the exact sophisticated procedures to ensure the maximum quality. PCB manufacturing also remains ripe for further development in the years to come as technology continues to create more compact, faster, and more intricate electronics. Understanding this process not only makes the commoner appreciate the gadgets they use in their everyday life but also gives an insight into the upcoming electronics manufacturing processes. Read the full article

0 notes

Text

Semiconductor Chemicals Market Share, Outlook, Trends, Growth, Analysis, Forecast 2024-2032

Semiconductor chemicals are a vital component of the semiconductor manufacturing process, serving a wide array of functions that are essential for the production of high-quality semiconductor devices. These chemicals include photoresists, etchants, cleansers, and dopants, each playing a crucial role in various stages of fabrication, from wafer cleaning to lithography and etching. As semiconductor technologies advance and feature sizes shrink, the demand for high-purity chemicals that can meet stringent performance requirements continues to grow.

The semiconductor chemicals market is influenced by several factors, including the increasing complexity of semiconductor devices, the rise of advanced manufacturing techniques, and the ongoing demand for miniaturization. Manufacturers are investing in high-quality semiconductor chemicals that ensure optimal performance and reliability, which is critical for maintaining competitive advantage in a rapidly evolving industry.

The Semiconductor Chemicals Market is witnessing growth fueled by the rising demand for high-purity chemicals used in semiconductor manufacturing processes, essential for achieving optimal device performance and reliability.

Future Scope

The future of semiconductor chemicals is promising, with significant growth expected as the industry evolves. As semiconductor devices become increasingly sophisticated, there will be a greater need for advanced chemical solutions that can address the challenges posed by new materials and technologies. The shift toward heterogeneous integration and 3D packaging will require innovative semiconductor chemicals that enhance performance and reliability.

Moreover, the growing emphasis on sustainability will shape the semiconductor chemicals market. Manufacturers will seek eco-friendly chemical solutions that minimize environmental impact while maintaining performance standards. This shift toward greener alternatives will drive research and development efforts in the semiconductor chemicals sector, leading to the formulation of sustainable products that comply with environmental regulations.

Trends

Key trends influencing the semiconductor chemicals market include the increasing focus on high-purity and specialty chemicals. As semiconductor manufacturing processes become more complex, the need for high-purity chemicals that minimize contamination risks is paramount. Manufacturers are prioritizing specialty chemicals that enhance performance in specific applications, ensuring that their products meet rigorous industry standards.

Another significant trend is the rise of automation in chemical handling and delivery systems. Manufacturers are adopting automated solutions to enhance precision and reduce the risk of contamination during the chemical application process. This trend is crucial for maintaining quality and consistency in semiconductor manufacturing, ultimately improving yield and reducing production costs.

Application

Semiconductor chemicals find applications across various stages of semiconductor manufacturing. In the cleaning process, specialized cleansers are employed to remove contaminants and prepare wafers for subsequent processing. This step is critical for ensuring high yields and preventing defects in final devices.

During lithography, photoresists are used to create patterns on semiconductor wafers, allowing for the precise definition of features in integrated circuits. The quality of photoresists directly impacts the resolution and accuracy of the patterns, making them essential for advanced semiconductor fabrication.

In the etching process, etchants are employed to selectively remove material from the wafer surface, enabling the creation of intricate designs necessary for modern semiconductor devices. The effectiveness of these etchants is vital for achieving the desired feature sizes and profiles that meet stringent design specifications.

Dopants are also crucial in semiconductor manufacturing, as they are used to alter the electrical properties of the semiconductor material. By introducing specific impurities into the silicon substrate, manufacturers can tailor the electrical characteristics of the device, enhancing performance in applications ranging from microprocessors to power devices.

Key Points

Essential for the semiconductor manufacturing process, including cleaning, lithography, and etching.

Driven by the demand for advanced, high-purity, and specialty chemicals.

Promising future with growth opportunities in sustainability and advanced materials.

Trends include increased focus on high-purity chemicals and automation in chemical handling.

Applied across various stages of semiconductor fabrication, impacting device quality and performance.

Read More Details: https://www.snsinsider.com/reports/semiconductor-chemicals-market-4533

Contact Us:

Akash Anand — Head of Business Development & Strategy

Email: [email protected]

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes