#photoelectricsensors

Explore tagged Tumblr posts

Text

Top Photoelectric Sensors Price | Best Deals

Shop the best deals on Photoelectric Sensors at unbeatable prices! Find high-quality sensors perfect for industrial and safety applications, all at affordable rates. Get the best value today.

#PhotoelectricSensors#BestDeals#IndustrialSensors#AffordableSensors#AutomationSolutions#SensorTechnology#SafetySensors#TechDeals#SmartShopping#SensorsForIndustry#BestPrice

0 notes

Text

Enhancing Industrial Automation with Photoelectric Sensors and PowerFlex 525

In today's rapidly evolving industrial landscape, automation plays a pivotal role in boosting efficiency and productivity. Among the many technological advancements driving this transformation, the integration of photoelectric sensors and variable frequency drives (VFDs) like the PowerFlex 525 is revolutionizing industrial processes. In this article, we explore how these technologies, including the 42EF-D2MPAK-F4 sensor, are enhancing automation in manufacturing and beyond.

Photoelectric Sensors: The Eyes of Automation

Photoelectric sensors are indispensable components in automation, serving as the "eyes" that detect the presence, distance, or absence of objects. They use light beams to trigger responses, making them ideal for various applications across industries.

The 42EF-D2MPAK-F4 is a noteworthy example of a photoelectric sensor. It offers high precision, long-range detection, and reliable performance. With features like background suppression and a rugged design, it's well-suited for challenging industrial environments.

Seamless Integration with PowerFlex 525 VFDs

To maximize the potential of photoelectric sensors, they must seamlessly integrate with other automation components. This is where the PowerFlex 525 VFD comes into play. VFDs like the PowerFlex 525 allow for precise control of motors, which is crucial in applications like conveyor belts, pumps, and fans.

The PowerFlex 525 VFD offers a range of benefits, including energy savings, reduced wear and tear on machinery, and the ability to fine-tune motor speed to match production demands. Its user-friendly interface simplifies programming and maintenance, making it an excellent choice for both experienced engineers and those new to VFD technology.

Key Applications

The combination of the 42EF-D2MPAK-F4 photoelectric sensor and the PowerFlex 525 VFD opens up a world of possibilities in industrial automation. Here are some key applications where these technologies shine:

Material Handling: Conveyor systems equipped with these technologies can efficiently move materials, with the sensor ensuring proper object detection and the VFD enabling precise control over conveyor speed.

Packaging: In packaging lines, photoelectric sensors can detect the presence and position of products, while VFDs ensure smooth and accurate packaging processes.

Quality Control: Manufacturers can use these technologies to inspect and sort products based on size, shape, or other attributes, ensuring only high-quality items reach the market.

Energy Efficiency: The PowerFlex 525's energy-saving features combined with the precision of the 42EF-D2MPAK-F4 sensor enable companies to reduce energy consumption and costs.

Safety: These technologies enhance workplace safety by detecting objects or personnel in restricted areas and triggering immediate responses or warnings.

Future Prospects

As technology continues to advance, we can expect even more sophisticated photoelectric sensor and VFDs. Integrating artificial intelligence and IoT capabilities will further enhance automation systems' capabilities, allowing for predictive maintenance and real-time data analysis.

In conclusion, the combination of the 42EF-D2MPAK-F4 photoelectric sensor and the PowerFlex 525 VFD is a game-changer for industrial automation. These technologies empower manufacturers to achieve greater efficiency, precision, and safety in their processes. As automation continues to evolve, these components will play an increasingly vital role in shaping the future of manufacturing and beyond.

Get more information on ROC Automation

0 notes

Text

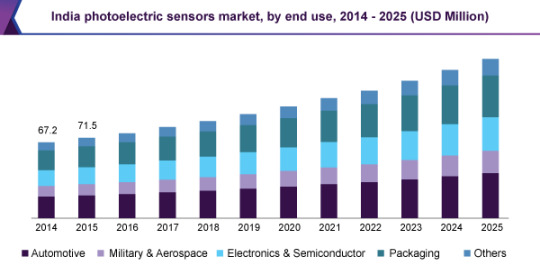

Photoelectric Sensors Market Worth $2.09 Billion By 2025 | CAGR: 6.1%

The global photoelectric sensors market size is expected to reach USD 2.09 billion by 2025, according to a new report by Grand View Research, Inc., registering a 6.1% CAGR during the forecast period. These sensors are widely used in packaging and manufacturing industries as they offer numerous advantages such as cost effectiveness, long sensing distances, fast response time, and high resolution. These high-efficiency products are expected to witness an increase demand also owing to benefits such as low maintenance, long operating life, and low power consumption.

Rising penetration of Industrial Internet of Things (IIoT) is further expected to enhance market growth. This growth is attributed to numerous benefits, including maximizing asset utilization, improving productivity, and enhancing work safety. These devices help in connecting machines and devices to enhance efficiency, productivity, and operation of industrial facilities.

The photoelectric sensors market is anticipated to witness a considerable demand over the forecast period, which stems from industries such as healthcare, oil and gas, and military and aerospace across developed and developing countries.

Increasing government regulations pertaining to fuel emissions, along with increasing use of photoelectric sensors in automotive applications such as failure diagnostics, throttle control, contactless positioning sensing, and precision position measurement for better control, are key factors spurring market growth.

The emergence of smart photoelectric sensors is expected to drive market growth over the forecast period. This may be ascribed to several benefits such as reduced down time, lower cost, adaptability for self-calibration and compensation, fewer interconnections between multiple sensors and control systems, lower weight, and higher reliability.

To request a sample copy or view summary of this report, click the link below: https://www.grandviewresearch.com/industry-analysis/photoelectric-sensors-market

Further key findings from the report suggest:

The photoelectric sensors market was valued at USD 1.24 billion in 2016 and is projected to expand at a CAGR exceeding 6.0% over the forecast period. This is largely attributed to rising penetration of IIoT in industrial facilities

By technology, the retro-reflective segment captured a major market share in 2016. The segment is also expected to grow at the highest rate over the forecast period owing to its capability to offer sturdy construction, low maintenance, and efficient detection of shiny and transparent objects

The packaging industry as an end-use segment is expected to grow at the highest rate over the forecast period as these products are broadly adopted to detect transparent bottles, control conveyor positioning, and monitor product presence

The Asia Pacific region is projected to witness substantial growth, exhibiting a CAGR exceeding 6.0% over the forecast period. This is owing to rising industrial automation and increasing government regulations in the developing economies of China, India, and Japan

Key players such as Panasonic Corporation; Keyence Corporation; Rockwell Automation Inc.; Autonics Corporation; and Schneider Electric SE dominated the market in 2016, with a focus on increasing market presence through mergers and acquisitions.

See More Reports of This Category: https://www.grandviewresearch.com/industry/sensors-and-controls

About Grand View Research:

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, we offer market intelligence studies ensuring relevant and fact-based research across a range of industries, from technology to chemicals, materials and healthcare.

0 notes

Link

Dubai Sensor - PhotoElectric Sensor Dubai Sensor is offering Photo Electric Sensor

For complete info and technical information, Email Address: [email protected]

Toll-Free Number: 800 6001 (For UAE Resident) Landline 1 : +971-4-2595133 Landline 2 : +971-4-3377738 Mobile: +971-50 435 5693

0 notes

Photo

F&C FC-SPX302 Slot photoelectric sensor. 5-24VDC power supply NPN.NO/ NPN.NC PNP.NO/PNP.NC Detecting distance 5mm. #F&C #photoelectricsensor #slotsensor #Utypesensor https://www.instagram.com/p/B5oidENpB6R/?igshid=1k758htpdoeow

0 notes

Text

Contrinex photoelectric sensors check the position of cardboard boxes after pick and place robots put together the bagged food, as the arrive at the packing stations so it commences the secondary packaging.

http://bit.ly/2Cg0N9X

0 notes

Photo

SICK HE18-P4A7BB Photoelectric Sensor-New

#Adatronix

#Sick

#HE18P4A7BB

#Photoelectricsensor

#New

#Available

#sell

#Electronics

Visit Our Website, http://adatronix.com

0 notes

Photo

Panasonic Turnike Sensörü, gereksinimleri karşılayacak şekilde tasarlanmıştır. Çevre direnci performansı ve düşük maliyetli öne çıkan özellikleridir. • Boyutu M12 X 28 mm • Çalışma aralığı -25 ile + 55 derece • IP67 su ve toz geçirmez uygun koruma yapısı • Doğru ve güvenilir tespit sağlar. https://lnkd.in/gfwU99J | 0 216 520 31 50 [email protected]

#isac #istanbulsensorler #panasonic #turnikesensörü #ip67 #metro #turnike #sensör #fotoelektriksensör #photoelectricsensor

0 notes

Video

instagram

Why JUTAI Select To Do Infrared Photo Beam Sensor For Gate Automation Photocell For Automatic Gate Openers :JUTAI are committed to doing a series of stable and reliable infrared Infrared Photo Beam Sensor For Gate Automation Photocell For Automatic Gate Openers. When you understand the wide application of Infrared Photo Beam Sensor For Gate Automation Photocell For Automatic Gate Openers, you will know the importance of quality. #gatesafetybeams #photoreflectivesensor #photoeyesensorforgate #photoelectric #photocellinfrared #photoelectriclightsensor #photoelectricsensortypes #photoelectricdetector #photoelectricproximitysensor #gatesafetysensor #photocellbeam #gatebeamsensor #lightbeamsensor #automaticgatephotocells #photocellsafetybeamsensor #infrareddetector #reflectivesensor #gatephotocellsensor #bftphotocell # infraredsensors #infraredphotocell #gatephotocell #electricgatephotocells #photosensor #photoelectricsensor #photocellsensor #photocelllightsensor #lightsensor Email:[email protected] Wahtsapp: +86 18179436123 Skype:una0305 https://www.instagram.com/p/BqLvbC6DxO9Hms4E1llnN7di3eBPCYoXf7PQVI0/?utm_source=ig_tumblr_share&igshid=4vr7wjrxpx9

#gatesafetybeams#photoreflectivesensor#photoeyesensorforgate#photoelectric#photocellinfrared#photoelectriclightsensor#photoelectricsensortypes#photoelectricdetector#photoelectricproximitysensor#gatesafetysensor#photocellbeam#gatebeamsensor#lightbeamsensor#automaticgatephotocells#photocellsafetybeamsensor#infrareddetector#reflectivesensor#gatephotocellsensor#bftphotocell#infraredphotocell#gatephotocell#electricgatephotocells#photosensor#photoelectricsensor#photocellsensor#photocelllightsensor#lightsensor

0 notes

Link

Dubai Sensor is offering Photo Electric Sensor

Email Address: [email protected]

Toll-Free Number: 800 6001 (For UAE Resident)

Landline 1 : +971-4-2595133

Landline 2 : +971-4-3377738

Mobile: +971-50 435 5693

#dubaisensor #photoelectricsensor #automationindustry #onlinestore #electronicparts

0 notes

Photo

F&C M12/M18 photoelectric sensor Sensing Method : *Diffuse reflective *Through-Beam *Retro-reflectiv Response Time:0.5ms Max Load Current:100mA Operation Voltage:12~24VDC Operation temperature:-10℃~+50℃ Accept customization for 90 Type #F&C #sensor #automationsensor#automationcontrol#positionsensor#positioncontrol#photoelectricsensor#photlelectricswitch #automation #fiber #factory #fiberopticsensor #positionsensor #positioncontrol #photoelectric #automationsensosr #proximity https://www.instagram.com/p/B5RUTzRJ_eT/?igshid=opmpoce5ulzy

#f#sensor#automationsensor#automationcontrol#positionsensor#positioncontrol#photoelectricsensor#photlelectricswitch#automation#fiber#factory#fiberopticsensor#photoelectric#automationsensosr#proximity

0 notes

Text

A defuse mode photoelectric sensor checks the presence of the bagged candy before it reaches the pick and place robots to be packed in the cardboard boxes. After that it reaches the labeling and secondary packaging.

http://bit.ly/phoseninpacking

#photoelectricsensor #packaging #pick&place

0 notes

Photo

Detecting transparent objects without a reflector with new transpatect photoelectric sensor | https://www.bibus.in/products-solutions/sensor-technology/photoelectricsensor/photoelectricsensor/ | For more details email your requirements to BIBUS INDIA sales today #madeforbusiness #makeinindia (at BIBUS Horizon Mechatronics & Automations Pvt Ltd.)

0 notes

Photo

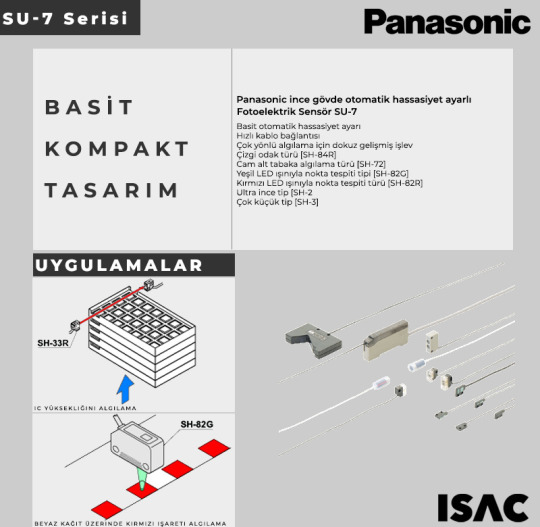

Panasonic ince gövde otomatik hassasiyet ayarlı Fotoelektrik Sensör SU-7 Basit otomatik hassasiyet ayarı Hızlı kablo bağlantısı Çok yönlü algılama için dokuz gelişmiş işlev Çizgi odak türü [SH-84R] Cam alt tabaka algılama türü [SH-72] Yeşil LED ışınıyla nokta tespiti tipi [SH-82G] Kırmızı LED ışınıyla nokta tespiti türü [SH-82R] Ultra ince tip [SH-2 Çok küçük tip [SH-3] İletişim; https://lnkd.in/gfwU99J | 0 216 520 31 50 [email protected] #isac #istanbulsensorler #panasonic #panasonicsensör #SU7 #Fotoelektriksensör #photoelectricsensors #sensor #sensör

0 notes