#pdcdrillbits

Explore tagged Tumblr posts

Text

We are PDC drill bit manufacturers, ready to meet all your needs at any time.

website: www.pdcdrill.com

Email us: [email protected]

WhatsApp:

Skype: live:.cid.23d7a2c8147d8a02

Contact us for high-quality PDC drill bit solutions.

#DrillingTechnology#PDCDrillBits#OilAndGas#GeothermalDrilling#WaterWellDrilling#MineralExploration#Innovation#Efficiency#Durability#Engineering

1 note

·

View note

Text

Roller Cone Drill Bits vs. Fixed Cutter Drilling Bits

All the drilling bits available these days can be broadly categorized as rolling cutter bits and fixed cutter bits. Let us take a quick look at the various aspects of each of these types:

Rolling Cutter Drilling Bits

Rolling cutter bits, also known as roller cone drill bits or tri-cone bits, have three cones and each of these can be rotated individually when the drill string rotates the body of the bit. Roller bearings are fitted onto the cones at the time of assembly. This type of drilling bits can be used to drill all kinds of formations with a proper cutter, bearing, and nozzle.

Rolling cutter drill bits can be further classified as milled-tooth and tungsten carbide inserts depending upon how the teeth are manufactured. TCI drag bits generally have tungsten carbide inserts (teeth) that are pressed into the bit cones.

Depending upon the formation, the shape of the teeth fit to be suited is determined:

· Soft formation: Long-extension, chisel shape inserts

· Hard formation: Short-extension, rounded inserts

Fixed Cutter Drilling Bits

Fixed cutter bits, on the other hand, consist of cutting elements integrated with the bit bodies. These are designed to excavate holes by shearing formations rather than cutting or gouging them how rolling cutter bits work. These bits do not have moving parts such as cones or bearings and their components are built of bit bodies fabricated from steel or tungsten carbide alloy and fixed blades integrated with abrasion-resistant cutters. The cutters in the bits that are available on the market are PDC cutters and natural or synthetic diamond cutters.

The improvements in the fixed cutter bit technology over the years have enabled the PDC bits to drill almost any kind of formations, from soft to hard.

Rockpecker Limited is among the top-rated Handpicked Drill Bit Suppliers and manufacturers in the UK and Australia. Other than PDC drill bits, they offer PDC Hole Openers, TCI drag bits, and VRS hole openers. Their designs are backed by various methods to simulate on-field drilling and making sure the bits have optimum performance even before being deployed. For more information about the products they manufacture, visit www.rockpecker.com. You can also get in touch with us by dialing +44 7887 398 047 (UK)/+61 2 8003 7547 (Australia).

1 note

·

View note

Photo

Welcome to Fennon Moore Bit Sales and Service, your number one source for drill bit sales and drill bit repairs in Pleasanton, TX and the surrounding area. When it comes to high-quality drill bits, no one makes them better than the professionals at Fennon Moore Bit Sales and Service. Our number one goal here at Fennon Moore Bit Sales and Service is to provide our customers with high-quality drill bits for reasonable prices. Fennon Moore Bit Sales and Service has dedicated customers in the drilling industries that have been purchasing from us for over 40 years. Our quality has always been impeccable since day one and we strive to maintain our position as Pleasanton's leading drill bit supplier for many more years to come.

Some of the products and services we offer include:

Drill Bits

Waterwell Hole Openers

Fracking Bits

Steel Tooth Bits

Tungsten Drill Bits

PDC Drill Bits

Custom Built Hole Openers

With over 50 years of experience in the industry, we are extremely confident in the quality of our product. We value honesty, quality, and amiable customer service, and most importantly, hard work above all else. Our company is committed to exceeding the expectations of our customers. We strive to deliver complete customer satisfaction for each and every product and service, providing quality, affordable pricing, and excellent customer service.

If you are interested in acquiring any of our products or services, please contact Fennon Moore Bit Sales and Service today! We can be reached 24 hours a day at (210)394-5470

https://www.pleasantondrillbits.com

#DrillBits#DrillBitShop#DrillBitRepair#WaterwellHoleOpeners#FrackingBits#DrillBitSales#BuyDrillBits#SteelToothBits#TungstenDrillBits#PDCDrillBits#CustomBuiltHoleOpeners

1 note

·

View note

Link

The PDC Drill Bit market was valued at Million US$ in 2020 and is projected to reach Million US$ by 2028, at a CAGR of during the forecast period. In this study, 2020 has been considered as the base year and 2021 to 2028 as the forecast period to estimate the market size for PDC Drill Bit.

0 notes

Photo

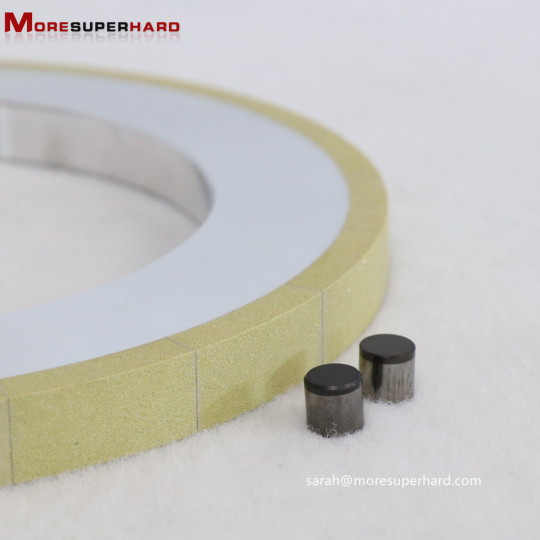

Vitrified bond diamond wheel used for PDC bits, PDC cutter grinding. #policystallinediamondcompact #grindingwheelAdvantages:

#PDCBits #pcdtools #diamondwheel #grindingwheel #processing #drillingbits #oildrilling #grindingsolution #grindingdisc #pdcdrillbits #vitrifiedbond #resinbond #cylindricalgrinding

www.mogrinding.com

0 notes

Link

Rockpecker Stabiliser/Centraliser for Smooth Well Drilling Operations Rockpecker anti-vibration stabilisers/centralisers do not generate point loaded blade friction like traditional stabilisers, thereby improving overall borehole quality. Browse through our website www.rockpecker.com for more information.

0 notes

Photo

Best Quality PDC Drill Bits UK

Rockpecker provides best Quality PDC Drill Bits for numerous different applications, and still innovate. Get the Best drilling tools online at http://www.rockpecker.com/bits

0 notes

Text

Rotary Drilling Vs. Directional Drilling

Before we talk about the different types of drilling tools available for use in construction & HDD or oil & gas industry, it is important to understand some of the most commonly used drilling methods such as percussion drilling, rotary drilling, electro-drilling, and directional drilling as well. Here, let us take a quick look at the major points of difference between rotary drilling and directional drilling.

Rotary Drilling

Most commonly used for digging up wells that boast of depths exceeding five miles below the ground, rotary drilling is performed using lightweight drills. The drill bits used in this method usually depend on the type of formation that needs to be penetrated. For instance, unconsolidated sediments can be penetrated using drag bits while consolidated rocks can be penetrated well with roller cone bits. The rotation speed of the drill during rotary drilling can be adjusted as per the requirement.

Directional Drilling

Direction drilling can be looked upon as an extension of rotary drilling. It is a drilling method in which the drill is guided on a curved path as the hole deepens. Mostly used in oil & gas industry, it helps the explorers reach deposits beyond the reach of vertical drilling method. This is among the most cost-efficient drilling methods as it allows the explorers to drill multiple wells in all directions using a single platform.

Designed to drill seamlessly even under the toughest of the conditions, Rockpecker drill bits are manufactured in the UK and are supported by several international service centers. Thanks to the use of high-grade materials, continuous product development methods, and precision engineering, their oil well drilling bits are fully capable of fulfilling customer drilling objectives such as repeatable quality, low cost per foot, and reliable performance.

In addition to high-performance drilling bits, you can also reach out to them for reliable hole openers, high-quality PDC cutters, and subs in Texas. Visit http://www.rockpecker.com/ now to check out their exclusive range of products for the oil & gas as well as construction & HDD drilling industry.

0 notes

Photo

Drill Bit Repairs

Fennon Moore Bit Sales and Service proudly offers drill bit repairs for the bits that aren't functioning properly. When it comes to proper drill bit repair, Fennon Moore Bit Sales and Service is honest, dependable, and dedicated. We can repair bits bought from us 2,3,4 times which in return saves the contractor a large amount money! Fennon Moore Bit Sales and Service also rebuilds drill bits only using the highest quality materials. If you are interested in learning more about any of our products or services, please contact Fennon Moore Bit Sales and Service today.

https://www.pleasantondrillbits.com

#DrillBits#DrillBitShop#DrillBitRepair#WaterwellHoleOpeners#FrackingBits#DrillBitSales#BuyDrillBits#SteelToothBits#TungstenDrillBits#PDCDrillBits#CustomBuiltHoleOpeners

0 notes

Photo

Drill Bit Sales

Fennon Moore Bit Sales and Service is proud to offer high-quality drill bits for reasonable prices! Our drill bit shop specializes in selling and renting drill bits to oil, gas, and water drilling industries. If a drill bit purchased from Fennon Moore Bit Sales and Service needs to be repaired, do not worry, we proudly repair bits bought from us! If you are interested in learning more about any of our products, please contact Fennon Moore Bit Sales and Service today!

https://www.pleasantondrillbits.com

#DrillBits#DrillBitShop#DrillBitRepair#WaterwellHoleOpeners#FrackingBits#DrillBitSales#BuyDrillBits#SteelToothBits#TungstenDrillBits#PDCDrillBits#CustomBuiltHoleOpeners

0 notes