#overhauling of cylinder head

Explore tagged Tumblr posts

Text

Cylinder Head Overhaul | Complete Maintenance And Repair

RA Power Solutions stands as a reliable partner for industries relying on efficient and well-maintained engines. Through their expertise in inspection and repair services, complete maintenance and repair services, the company contributes significantly to the longevity and reliability of industrial machinery. As the demand for seamless engine performance continues to rise, RA Power Solutions remains at the forefront, providing innovative and reliable solutions for the diverse needs of its clients. Get in touch with us for more information on inspection and repair services at [email protected], 0124-425-1615, or +91-9810012383.

#Complete Maintenance And Repair#Overhauling And Reconditioning#Inspection And Repair Services#Cylinder Head Overhaul

0 notes

Text

Maintenance and Repair of Engines

We have extensive experience in repairing marine diesel engines. Their team of skilled technicians can diagnose and repair a wide range of problems with marine diesel engines. If you are looking for a reliable and experienced provider of overhaul and maintenance service, RA Power Solutions is the perfect choice. To get more information on repair marine diesel engine, cylinder head overhaul, cylinder head overhauling, and complete overhaul services then contact us today at [email protected], 0124-425-1615, or +91-9810012383.

#repair marine diesel engine#cylinder head overhaul#cylinder head overhauling#Overhaul And Maintenance Service

0 notes

Text

Overhauling of Main Engine and Ship Auxiliary Engine

A Wartsila 12V32 engine that was placed on one of the vessels owned by a Greek company, was recently given repair and overhaul by our organization. Technicians with a portable crankshaft grinding machine were sent by RA Power. Crankpins were found to have excessive ovality. It was ground to 0.5 mm undersize while closely adhering to the limits and requirements outlined in the Wartsila maintenance manual. We have been providing services for main engine maintenance and ship auxiliary engine overhaul. Dial +91-9582647131, Tel. +91-124–4378292, and email [email protected] for more detail on overhauling of main engine.

#Wartsila 12V32 engine#Overhauling of Main Engine#ship auxiliary engine overhaul#crankshaft grinding machine#engine repair and overhaul#diesel engine repair#diesel engine repair and overhaul#Wartsila diesel engine#Wartsila diesel engine repair#diesel engine#diesel engine Crankpin grinding#Main engine repair services#main and auxiliary engines#main engine overhauling services#auxiliary and main engine overhauling#engine overhauling#marine auxiliary engine overhauling#ship main engine overhaul#cylinder head overhauling

0 notes

Text

Traintober 2024: Day 14 - Screech

Before Sodor:

When he came out of the works, James was a very different engine to the one who went in. The regular, boring, utilitarian Class 28 who had been pushed in was gone, and out came a prototype. Hughes classified James as a ‘Class 29’.

“You’re a very special engine,” Mr Hughes said, watching on as James was fired for the first time. “I’m hoping your rebuild will bring all the successes I am hoping for.” That made James feel very special. He’d been plucked at random from his shed for the overhaul, chosen from in amongst a group of twelve of his class, as well as another six Class 27s who’d been doing their absolute best to be picked. But it had been James; of all the engines on the entire railway, it had been James.

“I’ll do you proud, sir!” chirped James excitedly. Mr Hughes smiled gently, and stepped to one side to continue to watch the proceedings. James was carefully steamed up, his slightly larger boiler warming quickly. Every part of him felt new and precision machined. His firebox was large and his cylinders strong; his superheater warmed him right through and left James practically bursting with the need to get out of the workshop and prove himself. His fire burned brightly, his steam pressure shot up. The men grinned as James easily passed all their tests, the foreman marking off boxes on his list with the smallest hint of a smile.

James felt his brakes being taken off, and then his regulator being very slowly opened, prompting him to hiss steam as he inched forwards. But as the brakes were put back on with an odd screeching noise. James frowned.

“Something feels a bit off, sir,” he said slowly. “What brakes was I fitted with?” The foreman winced out of James’ view, and went to speak only for Mr Hughes to place a firm hand on his shoulder. The Chief Mechanical Engineer shook his head slowly, a dark look in his eyes.

“It’s a new design!” Mr Hughes called out. “We want to test these before we give them to other engines, and considering how much stronger we hope you’ll be, you seemed like the best engine to trial them on. They do screech a bit though, but don’t be alarmed.” James beamed!

“Oh sir! I knew I was going to be special. Look at me – don’t I look smart!” “You look very nice in our livery,” agreed Mr Hughes politely. “Now we need to start running tests. Your crew and the inspector will take it from here.” With one final meaningful look at the foreman, Mr Hughes placed his hat atop his head and strode away.

James didn’t watch him go, his eyes instead set on the trucks and coaches that littered the yard. “I can’t wait!” grinned James, feeling his driver open his regulator once more after taking off his special brakes. They started him off on some light shunting duties, testing out his response to the controls. In the distance, a foreign whistle blasted through the works as another freight train blasted through at speed. James raised an eyebrow.

“Who’s that?” he asked. “We don’t usually get outsiders here.” “The railway is trialling a foreign engine to see how they could adapt it,” the inspector replied clinically. James hummed, considering the new information before continuing his shunting. Every time he braked, his brakes screeched, and he slid just a little more than usual.

“Inspector,” James began slowly after the ninth time, “these brakes seem a bit weak. Why don’t they stop me sooner?” The three men in James’ cab shared looks out of his line of sight. They seemed to have a silent conversation in the span of several seconds, before the inspector finally responded.

“They’re a dynamic brake,” he said carefully. “They’re a little slower to apply, but they are made of an extremely strong material that won’t wear out as much.”

James felt better after that. Had he been even a little older, he wouldn’t have accepted the reply as easily – after a certain period of time, most engines grew a sort of sixth sense around their motion. They could detect if something was wrong easily, and work to fix it. James had barely seen his second year in service when he was unceremoniously picked to be rebuilt; his youth had made him a prime choice. The older engines whispered about unification and grouping in the back of the sheds, thinking their shed masters were unaware that they knew of what was brewing. In return, their shed masters did their best to hide the full extent of the truth and quash the rumours.

James was ignorant to it all as he was rigorously tested. He worked hard at everything: he banked trains some days, hauled freight on others, and even pulled a couple of fast passenger trains! Each day brought another checkmark on the inspector’s form, and each night brought a new shed with unfamiliar faces. James never slept at the same shed two nights in a row. He went all over the network, seeing all the sights and meeting many engines.

None of them said much to him.

“Good evening!” James would try, only to get a lot of side-eye and subtle glances. James thought they were too impressed with him to speak! Or at least, he did at first. As the days stretched out into months and nothing changed, James began to feel the looks more acutely. The other engines weren’t impressed. They weren’t jealous of his potentially revolutionary design or the way that Mr Hughes sometimes came specifically to see him. They weren’t envious of how James got a special number and they weren’t in awe of how smart he looked.

They just didn’t like him. They thought him an imposter, an oddity. A weird Frankenstein’s engine made of a unique boiler, an unusual pony truck and unconventional brakes that just wouldn’t stop screeching whenever James tried to stop. James figured the screeching had to be from the metal brakes clamping against his steel wheels.

The screeching came from his wheels sliding along the rails.

Seasons changed. James wasn’t invited into sheds as often anymore, sitting out in dirty old sidings in between the endless trials. They hadn’t ended, though James wondered if that was because he was succeeding and they wanted data in the wet and cold and maybe even the snow if it dragged on long enough… or if he was failing.

The foreign engine was still around somewhere too. James never saw it, but he heard it. When down south, he’d discovered that the whistle belonged to the Great Western Railway, which ran along the distant south-west coast of England. The few engines of that railway that he managed to see looked very smart, with dark green paint and great brass safety valve bonnets that shone like spun gold in the sun. They all looked very sleek and impressive – James felt gangly next to them. But when he asked about the foreign engine, he was always redirected away from an answer.

Winter came, and with it the rumour mill grew louder. Finally, James learnt an uncomfortable truth: the railways were being grouped together into four. When he heard, he asked Mr Hughes what it would mean – Mr Hughes didn’t reply, and instead booked James in for a general service.

The foreign engine left before the year was out, but James spent Christmas in the works sleeping to stave off the cold while the men switched out his brakes. Apparently, they weren’t working as well as hoped, but the trials were being extended to get an idea on what that meant.

The inspector no longer went everywhere with James. Instead, he turned up once a week and asked James weird vague and cagey questions before leaving again. Sometimes it was even a different inspector, especially as James was shuffled around again, heading further inland and into the territory of their rival—no, former rivals. James wasn’t part of a company that rivalled the old Midland Railway anymore. He was part of a company with them.

The Midland passenger engines had very shiny paint. They didn’t have the same gorgeous brass that the Great Western engines had, but instead they had the most eye-catching red paint James had ever seen! It was glorious – it sparkled in the sun and was vibrant even in the pouring rain.

James remained in black. His lining was neglected, and it slowly faded away. James wondered when he’d get a repaint. He had been hurried rebranded as being part of the new ‘LMS’ with an equally new number, but that had been done in under a day by a trio of bored-looking men. The new number sat stark on James’ tender, and he instantly hated it.

James only pulled trucks and shunted now. He didn’t get to pull fast trains or passengers or go lots of different places now. Instead, he was assigned to a shed in the middle of nowhere along a busy line, sleeping in a dirty berth on a dirty siding in between unimportant mineral trains from one junction to another. Monotony crept in slowly, James completely forgetting about his abnormal brakes and becoming immune to the screech they made when he stopped. Every day was the same, every journey the same. The Midland engines didn’t speak to the L&YR reject, steering well clear even as they slowly opened up to their old rivals.

And then one day, a new engine arrived at James’ shed. It was a design he’d seen dotted about, and it looked like a stronger version of his old class.

“I’m here to take over,” the engine grunted. James balked. “But what am I to do?” he spluttered. “I don’t know mate,” sneered the engine. “Maybe you’re time’s up. There’s rumblings in the factory that they finally finished the mogul design.” The engine looked James over, and snorted. “Oh, you’re the rejected design they built. Poor thing, there’s not much left for you now Hughes is retiring.”

James was rendered speechless for just long enough for the new engine to shunt some of the trucks into a line.

“I’m not a reject!” he exclaimed. “I’m the prototype! The class is based on me you nitwit – my design’s the future of this company.” The engine just chuckled, looking James over once more, before his eyes darted to James’ brakes.

“Oh yes, very revolutionary indeed,” he snorted, and puffed away. James was coupled up to some vans needing repairs, and dragged away from the shed he’d been forced to come to know as his home. He went far further than ever before, making his way well over halfway across the country. He was stopped in an unfamiliar workshop that bustled with hundreds of men and machines to have his LMS number unceremoniously scraped off, before being sent on again the next day. This time, he had a short train of trucks behind him. It grew steadily as he went, as did James’ temper.

“Get in line you stupid things!” he snapped, bumping the trucks harshly as he clattered along what felt like a double-tracked branchline to James. All the engines along the line were being withdrawn and replaced with yet more of the same smug class of tender engine that had stolen James’ job and home. James wondered if he was being drawn towards a scrapyard, tucked away at the end of this line.

Then he passed by an immense empty iron train, and realisation struck. He was in Cumbria. This had to be the famed Furness Railway that he’d heard of one night while in being trialled up in the north. Despite being such a small line, it’s massive industrial traffic kept it independent from the giants baying at its doors.

And look how well that worked out.

James arrived at Barrow-in-Furness with a long line of trucks, a screech of his brakes and a furious temper. His crew stepped down. “Sorry old boy,” sighed his driver, “but this is us. Your new crew will take you from here.” James stared at his driver like he’d lost his mind.

“What new crew? What is happening, driver?! I just lost my shed, I’ve been dragged halfway across the country and I'm surrounded by these smug Midlanders! Tell me what is going on!” James’ driver sighed, taking his cloth cap in his hands and squeezing it.

“Mr Hughes is being replaced soon,” his driver admitted quietly. “He’s decided to leave the company. Mr Fowler is taking over, and he’s agreed with the directors to sell you to the North Western Railway as part of a special agreement they’re making.” James blinked, stunned.

“The What Railway?” he asked slowly. “Wait… the No-Where Railway?! They’re… they’re… they’re getting rid of me?! But I’m meant to be the prototype! What, so they’re just going to use some other mogul design?!” His driver winced. A little shunting engine nearby looked over, perplexed.

“Didn’t your lot decide to base it off a Caley design that was influenced by those Westerners? The 4300 lot.” James went silent, unable to think of anything to say. He was stunned.

A new crew clambered into James’ cab and set off. James was silent as he crossed over the points and onto his new railway. He’d been sold off. He’d been sold off because he was a failure. His brakes screeched as his crew braked to slow at a signal. The trucks bumped and clattered behind him, hissing and grumbling.

“What’s that noise?” quizzed James’ new driver. James sighed.

“Those’re my brakes. They’re made of some special metal Mr Hughes wanted to test. They didn’t end up working as well, but I’ve still got them.” The crew shared a confused look inside James’ cab, but pressed on.

At Vicarstown, an old ‘American’ design from the Furness Railway was shunting in the yard as James rumbled in and began shunting trucks on and off of his slow goods train. The old engine winced at the screech James’ brakes made, then looked up and smiled warmly.

“Hullo! I’m Edward, who’re you?” “12620,” came the bitter reply. ‘Edward’ chuckled softly, rolling over to help with the shunting. “Not your number, your name,” Edward said. “I’m James,” said James quietly. “But only I call myself that.” “Well I’ll call you that too,” promised Edward firmly. James’ crew were quick to agree with the bright blue engine. James didn’t like the colour – it was too similar to Caledonian blue. The same Caledonian that stole his classes’ future with their mogul design.

The pair talked for a little, Edward warning James about the steeper gradients beyond Kellsthorpe Road as he helped the former LMS engine reshunt his slow goods to be easier to separate as the various stations along the NWR. James bumped his trucks roughly as he prepared to set off again. Edward heard the screech of James’ brakes again, and looked down. His eyes practically bulged out of his smokebox in shock.

“James, why’ve you got wooden brakes?!” exclaimed Edward. James snorted. “They’re not wood, they’re a special metal,” he replied harshly. Edward was about to say more when the signal dropped. James snorted away, continuing down the surprisingly steep mainline towards Crovan’s Gate. And Edward had called this the ‘gentle’ part of the mainline!

Crovan’s Gate was their works station. It also had a tiny little railway on a ledge above the mainline which skuttled about its own yard before vanishing off under a bridge. A tiny little engine with a nameplate declaring him to be ‘Rheneas’ was dozing in the sun beside the line. James screeched to a stop beside the little engine with trucks to be unloaded for the little railway. Rheneas jumped!

“You sound like you need your brakes checked,” Rheneas said. His accent was thicker than anything James had ever heard – it sounded faintly Welsh, but with Manx and maybe Scots in it? James wasn’t sure what to call it. “They’re a special metal,” James replied darkly. “You all keep asking me like my designer wouldn’t give me the strongest brakes he had.” Rheneas looked confused, but said nothing until James was back at the head of his train. Then, he spotted James’ brakes.

“But… those are wood,” he said carefully. James let off steam furiously. “THEY ARE NOT WOODEN!” he roared. Birds scattered from their trees. “I am sick of hearing that! Leave me alone!” bellowed James, storming off with screeching trucks in tow. The trucks were aggravated, annoyed, tired and then James had insulted Rheneas, one of the nicest engines on the island.

They had seen James’ brakes; they knew the truth. And they knew exactly what to do to prove it to James too…

Back to the Master Post

#weirdowithaquill#railway series#thomas the tank engine#traintober#traintober 2024#ttte james#james the red engine#l&yr#ttte edward#wooden brakes#prompt: screech#very long post

120 notes

·

View notes

Text

Steam Test

Written by SodaStupidity

Year: 2023

“Alright sir, he’s ready.”

“Right, lit up his fire.”

With the lit of a match, some shovels of coal, and a turn on the injectors, a comfortable warmth soon spread across the khaki engine. The distinct shape of a Great Western design, with his square firebox and taper boiler. A 2-6-0. His paint and brass fittings glimmering under rays of sunlight peeking through the big airy building, the letters “ROD 5319” painted broadly in white on his tender. The engine slightly opened his eyes, and gave out a rather loud yawn.

“…what year is it?…” the engine quizzed, still waking up from his long nap.

“It’s 2023, you’ve been here for a year and a half under overhaul, Joseph. Looks like you’re good to go.” said a smartly dressed woman, standing next to the sleepy engine.

Joseph snapped out of his lingering slumber completely, he recognized that voice, “Mrs. Walters! Glad to see you again.”

The woman chuckled, “The feeling is mutual, Joseph. I’m sure Betty misses you terribly as well, she will be absolutely thrilled to hear the news.”

Suddenly, a man in overalls peeped out from Joseph’s cab, “Ma’am, he’s ready to go.”

Mrs. Walters nodded, and turned to the khaki engine. “Alright Joseph, before you re-enter service, you’ll be put on a light test train. Just to make sure you’re fit as a fiddle before proper service resumes. All clear?”

“Yes, ma’am.” smiled Joseph. He knows very well about all the checks and exams before he can return to normal life. This ain’t his first overhaul, after all.

“Good engine. Boys, take him out for a spin, will you?” Mrs. Walters called to Joseph’s crew. Then, she turned her head back to the khaki engine, and gently patted his footplate, “Welcome back, Joey.” she said with a smile, and walked away.

Joseph felt the warm steam flowing into his cylinders, and slowly by each wheel turn, he started to move towards the entrance of the workshop. The men near the door pulled it open, revealing the ballast grounds basked in cheerful sunlight, two gleaming ribbons of rails leading into this world he’s oh so familiar with, a large brick built roundhouse laid behind it all.

“Oh yeah, it’s good to be back.” said the Great Western Mogul, as he exited out the workshops of Eastleigh Steam Friends Inc., and into the outside world.

19 notes

·

View notes

Text

What's Lost is Found

(A/N)

Sooo... my bad. Somehow both ch.6 and ch.7 were labeled ch.6 in my orginal doc. So last week I posted ch.7 (Into the Past) instead of the real Chapter 6 (this one). Here is the actual ch.6, which takes place directly before last weeks entry, which has been replaced to its right full place as ch.7

Dry rails and Smooth running,

Hazel.

Ch.6 The Dawn

Other Chapters:

Screech woke from her rest early Saturday morning. While incapable of true sleep, as she had settled into life on the Uman and Din she had found she could lightly doze when given the opportunity. While it was strictly speaking unnecessary for her, she often found herself in a better mood afterwards.

The world was dark still, night not having yet relinquished its hold in the morning, the other engines were still asleep, the human night guard, hired after the incident with the youths, could be seen patrolling the yard in the distance. Screech stretched lazily, looking over her fleet mates. To her right, Enid was lightly whistling in her sleep, almost inaudible to the human ear, but easily noticed by the eldritch giants hearing. To the left Guinevere lightly slept next to her, soon to wake as she was an early riser by nature. Next Becca lay uttery silent in deep sleep, appearing far more rested since Guinevere had returned from overhaul. Wisps of Steam lightly escaped around Avon, the tiny form of the newly named soot curled on her running board, purring lightly. Una often spoke in her sleep, and could be heard mumbling about a missing coach. Blaidd snored loudly, sounding almost more diesel like than steam.

The guard finished his latest patrol, coming to sit on a barrel next to Screech, he lifted his thermos of coffee and grimaced as he realized it had gone cold.

Screech tapped the container absent mindedly, warming the liquid within. The guard quietly thanked her, sighing happily as he sipped the warmed beverage.

Next to her Guinevere groaned lightly as she stretched, slowly waking. She relaxed with a sigh, joining Screech in observing the quiet night in silence.

The firelighters came, working quietly as the other engines slowly woke. Soot stretched with a yawn as Avon slowly warmed. Enid grumbled with bleary eyed as her fire woke her. She'd been recently cleaned and refitted with number plates, as her originals had been lost before she came to the Uman and Din. It hadn't helped that Enid had 'forgotten' her number. Everyone knew that an engine forgetting their number was as likely as a human forgetting their name, but there was a glint in Enid's eyes whenever pressed that had triggered Abbey's protective instincts, leading to more than one showdown between the Star and the fitters. The issue had remained unsolved until the whisper, irritated by the repetitive argument, had asked through Screech what number Enid wanted.

The number 9701 almost certainly had belonged to another engine originally, but nonetheless Miss Morgan had arrived with Swindon made 9701 number plates three days later. Whatever number Enid had originally bore, she was now Uman and Din No.9701.

Said 9701 was muttering incoherently as she slowly woke, Abbey shaking her head in fond exasperation at the tank engine. The 97xx was always slow to wake, and would often be half-asleep till her first run

Around the shed the engine's safety valves lifted one by one as they reached pressure. Just as Screech felt her own valves lift, Gwyn and Freda walked in in a far more cheerful mood at the early hour than the tank engine, Mali trailing behind them.

"Ready gorgeous?" Gwyn called, patting her left cylinder as he walked towards the cab.

"Of course."

It was time to retake the line to Argol.

#U&DR#U&D#Uman and Din#Uman and Din Railway#Eldritch engine#Eldritch train#fanfic#ttte fanfic#rws fanfic#engines that go bump in the night

11 notes

·

View notes

Text

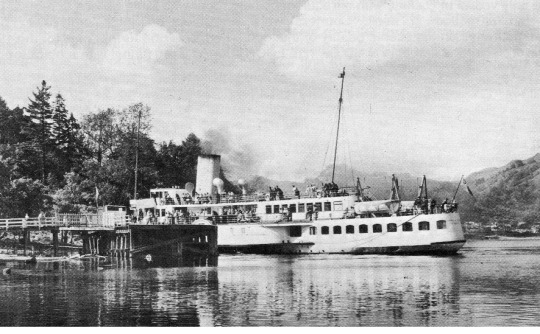

5th March 1953 saw The Maid of the Loch, the last Loch Lomond paddle steamer, lowered into the water.

On this day the historic ship left its Balloch base at 11.25am on its maiden voyage it took 1,000 passengers to Balmaha, Rowardennan, Tarbet, Inversnaid and Ardlui. For 28 years the Maid was known as the ‘heart’ of Loch Lomond, carrying millions of passengers, famous faces included, around the bonnie banks.

Ordered in 1950 by the British Transport Commission from A. & J. Inglis of Pointhouse, Glasgow, she was built and then cut into sections for transportation by rail to Balloch on Loch Lomond.

There she was re-assembled and was launched, almost complete, without ceremony. Her two-cylinder compound diagonal engine was built by Rankin & Blackmore of Greenock. She was painted white overall with green boot-topping, a buff funnel, and had the British Railways lion and wheel crest on her bows. In the 1975 season, her funnel colour was red with a black top. Her mainmast was removed in 1978. A service had first been initiated on Loch Lomond in 1818, and it is believed that this was the first regular passenger steamer service on an inland lake anywhere in the world.

The Maid was the twentieth paddle steamer to have sailed on Loch Lomond. She ran trials on 4 May 1953 and was named at a ceremony on 22 May, prior to a special cruise to Ardlui. The maiden cruise with fare-paying passengers took place on 25 May. Her regular route took her from Balloch to Ardlui with calls in either direction at Balmaha, Rowardennan, Tarbet and Inversnaid. From 1964, Maid of the Loch terminated at Inversnaid following the closure of the pier at Ardlui, though cruises to the Head of the Lake were also operated.

The Caledonian Steam Packet Company took over the ship in 1957, followed in 1969 by the Scottish Transport Group, and in 1970 by William Alexander & Sons - when the British Railways emblem was removed. The Maid fell on hard times as passenger numbers dwindled and the ship was eventually mothballed in 1981.

In 1992, he steamer was acquired by Dumbarton District Council and efforts to save the ship began with volunteer working parties; at the end of 1995, she was transferred to the Maid of the Loch Trust prior to the establishment of the Loch Lomond Steamship Company, a registered charity.

n 1997, her wooden deck was replaced with steel. Her lower hull was painted black, with ref boot-topping, above which the main deck sides and the superstructure remained white, but the funnel was now red with a black top. Following the restoration of the steam-powered slipway at Balloch, she was hauled out of the water in June 2006 (for inspection) for the first time since her withdrawal, as part of her rebuild - the objective of which is to return her to service.

This latest achievement was thanks to a £620,000 funding package from the Heritage Lottery Fund, Scottish Enterprise Dunbartonshire, West Dunbartonshire Council and LLSC. An internal refurbishment of the winch house, creation of a visitor interpretation facility and external landscaping is also planned.

In December 2018, the Scottish Government announced it had awarded a £950,000 capital grant. The Paddle Steamer Preservation Society also confirmed that a grant of £50,000 will still be granted, taking this working package to £1million. Funding will be spent on repairs to the vessel’s hull, creation of an education facility on board, refurbishing the main function suite and overhauling the engines to enable them to turn with steam.

Last year the old lady celebrated her 65th birthday as work continues on the restoration, and those of us in Scotland might recall her hitting the headlines in January this year.

The 65-year-old ship was being taken from the water ahead of restoration work when it slipped its ties and workers had to flee to safety. It was then taken back to its normal berth at Balloch Pier and the operation called off for the day.The Maid was berthed successfully the following day.

It’s a great wee train ride to Balloch from Glesga, and you can hop aboard the Maid of the Loch for free visit its Tea room and grab some souvenirs on board. Visitor displays and DVD shows; children’s activities; majestic steam engine. during the summer season. Work continues on board and you can witness the old steamer on its way to becoming a loch going ship. If you can’t make it check out their Facebook page for all the updates and pics from the past and present. Good luck and happy birthday The Maid of the Loch.

National Historic Ships UK and the Marsh Charitable Trust awarded a prize of £500 to the PS Maid of the Loch's tireless team of hardworking volunteers. It may not sound a lot, but it all goes to the restoration.

Recently the team behind the restoration launched an appeal for new front-of-house volunteers as they prepare for a new visitor season.

The Maid team is looking for "friendly, helpful people who like to tell a great story" to help out at the tourist attraction in Balloch this year.

Volunteers are needed to lend a hand on Saturdays and Sundays from early April until the end of October.

A spokesperson for the Loch Lomond Steamship Company, the charity which is restoring the famous ship, said: "If you can spare at least two weekend days a month from 10.30am until 4pm, then this could be a great new interest for you.

See www.maidoftheloch.org for full event details.

16 notes

·

View notes

Photo

note the odd green deposits on the inside of the exhaust valve seat. We knew the cylinder head had a cooling water leak, but the pressure test showed those nice water dropplets popping up around the valve seat.

*the black carbon depostis are normal, we burn heavy fuel oil in this engine.

But this cylinder head was overhauled by a shore based company just 9 months ago during drydock, so it’s going back under warranty. Otherwise we’d have taken out that seat ourselves and changed it on board the ship, (or at least check out what is hidden under it. Maybe the o-ring just got damaged during installing, maybe the bore/surface where it lays in is not machined propperly, maybe the cast-iron head starts to rot? who knows. Just another day in the office :P

7 notes

·

View notes

Text

Top Diesel Engine Services in Odessa, TX: What You Need to Know

When it comes to powering heavy machinery, industrial equipment, and commercial vehicles, diesel engines remain the backbone of many industries, especially in oil-rich regions like Odessa, TX. The harsh working conditions and demanding environments in Odessa require diesel engines that perform optimally, withstanding extreme temperatures, rigorous workloads, and continuous operation. This is where having a reliable diesel engine service provider becomes not just an option but a necessity.

Engines, Inc. has emerged as a leading name in diesel engine services across Odessa, TX, and beyond. With a stellar reputation built on expertise, efficiency, and exceptional customer support, Engines, Inc. offers comprehensive solutions tailored to the diverse needs of industries such as oil and gas, construction, agriculture, and marine applications. Here’s what you need to know about the top diesel engine services they provide and why they are the preferred choice for businesses in Odessa.

Comprehensive Diesel Engine Services

Engines, Inc. prides itself on being more than just a repair shop. They offer a complete suite of diesel engine services, ensuring that every engine, whether large or small, runs at peak performance. Their services cover everything from basic maintenance to complex overhauls, making them a one-stop solution for diesel engine owners.

1. Engine Rebuilds and Overhauls

Over time, diesel engines can suffer from wear and tear due to constant use. Rather than replacing an expensive engine, many businesses opt for engine rebuilds and overhauls, which can restore an engine to like-new condition at a fraction of the cost.

At Engines, Inc., their skilled technicians specialize in disassembling, inspecting, cleaning, and rebuilding engines using high-quality parts. Whether it's replacing pistons, cylinder heads, or crankshafts, their attention to detail ensures that every rebuilt engine meets or exceeds OEM (Original Equipment Manufacturer) standards. This not only extends the engine's lifespan but also enhances its efficiency and reliability.

2. Equipment Refurbishment

Beyond engine work, Engines, Inc. offers comprehensive equipment refurbishment services. This is particularly beneficial for companies with aging machinery that still holds value but requires performance upgrades. From heavy-duty construction equipment to specialized oilfield machinery, their refurbishment services include mechanical repairs, cosmetic restorations, and performance optimizations. This approach helps businesses maximize their equipment investments without the high costs associated with purchasing new machinery.

3. Preventive Maintenance Contracts

Downtime can be costly, especially in industries where continuous operation is critical. Engines, Inc. understands this, which is why they offer customizable preventive maintenance contracts. These contracts ensure that equipment is regularly serviced, reducing the risk of unexpected breakdowns.

Routine maintenance includes oil changes, filter replacements, fluid checks, diagnostic testing, and thorough inspections. By identifying potential issues early, Engines, Inc. helps businesses avoid costly repairs and maintain operational efficiency.

4. Diagnostics and Troubleshooting

Modern diesel engines are equipped with advanced electronic systems that require specialized diagnostic tools for effective troubleshooting. Engines, Inc. uses state-of-the-art diagnostic equipment to quickly identify problems, whether it’s an issue with fuel injection systems, exhaust after-treatment devices, or electronic control modules (ECMs). Their technicians are trained to interpret diagnostic codes accurately and recommend cost-effective solutions.

Strategic Presence in Odessa, TX

Odessa is at the heart of Texas’s oil and gas industry, making it a hub for heavy machinery and diesel-powered equipment. Recognizing the critical need for reliable engine support in the region, Engines, Inc. has established a strategic service hub in Odessa. This allows them to provide timely and responsive services to businesses operating in remote oilfields, construction sites, and industrial facilities across West Texas.

Their Odessa location is equipped with modern service bays, an extensive parts inventory, and a team of experienced technicians ready to respond to both scheduled appointments and emergency service calls. This localized support minimizes downtime and ensures that equipment is back in operation as quickly as possible.

Expertise with Leading Diesel Engine Brands

One of the key reasons for Engines, Inc.'s success is their specialization in servicing some of the most trusted diesel engine brands globally. As an authorized distributor and service provider, they offer factory-trained expertise and genuine parts for brands such as John Deere and Yanmar.

John Deere Diesel Engine Services

John Deere is a name synonymous with durability and performance, especially in industries like agriculture, construction, and power generation. Engines, Inc. provides comprehensive services for John Deere engines, including:

Routine maintenance (oil changes, filter replacements, coolant system checks)

Engine diagnostics and troubleshooting

Full engine rebuilds and overhauls

Genuine John Deere parts supply

Their technicians are trained specifically on John Deere’s advanced diesel technologies, ensuring that engines receive the proper care and that warranty requirements are met.

Yanmar Diesel Engine Services

Known for precision engineering and fuel efficiency, Yanmar diesel engines are widely used in marine, construction, and agricultural applications. Engines, Inc. offers:

Expert repairs for Yanmar engines

Preventive maintenance services

Genuine Yanmar parts and accessories

Technical support for Yanmar’s advanced electronic engine systems

Their deep understanding of Yanmar’s unique technologies ensures that engines deliver peak performance and long-term reliability.

Commitment to Exceptional Customer Support

At the heart of Engines, Inc.'s operations is a strong commitment to customer satisfaction. They understand that when an engine fails, it’s more than just a mechanical issue—it can disrupt entire business operations. That’s why they go the extra mile to offer:

24/7 Emergency Support: Engine failures don’t follow a 9-to-5 schedule. Engines, Inc. provides round-the-clock support to address emergencies promptly.

Global Support Network: With a wide-reaching support network, they can assist not just in Odessa but in other key industrial areas, offering seamless service even for businesses with operations in multiple locations.

Skilled Technical Team: Their technicians undergo regular training and certification programs, ensuring they stay updated on the latest diesel technologies and repair techniques.

Why Choose Engines, Inc. in Odessa, TX?

Experience: With decades of industry experience, Engines, Inc. has a proven track record of excellence.

Comprehensive Services: From minor repairs to major overhauls, they handle it all under one roof.

Genuine Parts: As an authorized dealer, they provide genuine parts that meet OEM specifications.

Rapid Response: Their Odessa facility ensures quick turnaround times for repairs and maintenance.

Customer-Centric Approach: They focus on building long-term relationships with clients through reliability and trust.

When it comes to diesel engine services in Odessa, TX, Engines, Inc. stands out as the top choice. Their comprehensive service offerings, expert technical team, and commitment to customer satisfaction make them the go-to partner for businesses relying on diesel-powered equipment. Whether you need routine maintenance, emergency repairs, or specialized services for John Deere and Yanmar engines, Engines, Inc. has the expertise and resources to keep your operations running smoothly.

For more information about their services, visit www.enginespower.com to explore how they can support your diesel engine needs.

#diesel engine solutions#diesel engine services in odessa#diesel parts#diesel engine#diesel engine solution#baton rouge#new orleans#san antonio tx#kohler engine#dallas#Diesel engine odessa TX#Diesel engine dallas TX#Diesel engine houston TX

0 notes

Text

Engine Repair Musaffah – Your Trusted Auto Repair Destination

When it comes to engine repair Musaffah, finding a reliable and skilled workshop is essential. Your vehicle’s engine is its heart, and any malfunction can lead to costly damages if not handled promptly. At Smart Auto Workshop, we provide professional engine diagnostics, repairs, and maintenance services to keep your car in top shape.

Why Choose Smart Auto Workshop for Engine Repair in Musaffah?

Choosing the right service center can make all the difference in your vehicle’s longevity and performance. At Smart Auto Workshop, we prioritize efficiency, affordability, and customer satisfaction. Our team consists of skilled mechanics with years of experience in engine repair, ensuring your vehicle gets the care it deserves.

Benefits of Choosing Us:

Expert Mechanics – Our professionals are well-trained in handling all engine types.

Advanced Diagnostic Tools – We use modern equipment to identify engine problems accurately.

Quick and Reliable Service – We value your time and provide prompt repairs.

Affordable Pricing – Quality repairs at competitive prices.

Customer Satisfaction Guaranteed – We prioritize transparency and honest communication.

Contact Us today to book your engine repair Musaffah service.

Common Engine Problems We Fix

Engine issues can arise unexpectedly, affecting your vehicle’s performance. Our skilled technicians are well-equipped to diagnose and fix common and complex engine problems, including:

1. Overheating Engine

An overheating engine can cause severe damage if not addressed promptly. Our experts identify the root cause, whether it’s a faulty cooling system, a broken radiator, or a failing water pump.

2. Oil Leaks

Leaking oil can indicate worn-out gaskets or damaged engine seals. At Smart Auto Workshop, we detect and fix leaks to prevent further engine complications.

3. Strange Noises

Knocking, ticking, or rattling noises from the engine bay usually indicate internal component wear. We diagnose the issue and replace any worn-out parts as necessary.

4. Decreased Fuel Efficiency

If your vehicle is consuming more fuel than usual, it could be due to faulty fuel injectors or a malfunctioning oxygen sensor. Our experts optimize engine performance to enhance fuel efficiency.

5. Check Engine Light On

The check engine light could indicate a range of issues, from minor sensor malfunctions to severe engine damage. We conduct thorough diagnostics to pinpoint the exact problem and fix it efficiently.

Book Your Service with us today for top-quality engine repair Musaffah services.

Our Engine Repair Services

At Smart Auto Workshop, we offer a comprehensive range of engine repair services to cater to all vehicle types. Whether you drive a sedan, SUV, or commercial vehicle, we have the expertise to handle your engine problems efficiently.

1. Engine Diagnostics

We utilize state-of-the-art diagnostic tools to identify faults accurately. Our advanced scanning systems help detect problems before they escalate.

2. Engine Overhaul

For severely damaged engines, we provide complete engine overhauls. This service includes dismantling, inspecting, and replacing worn-out components to restore optimal performance.

3. Cylinder Head Repairs

A damaged cylinder head can lead to engine inefficiency. Our mechanics repair and recondition cylinder heads to ensure smooth engine operation.

4. Timing Belt & Chain Replacement

A worn-out timing belt or chain can cause severe engine damage. We replace these crucial components to prevent costly breakdowns.

5. Fuel System Repair

Faulty fuel injectors and clogged fuel lines can affect engine performance. We clean and repair fuel systems to ensure proper fuel combustion.

6. Turbocharger Repair & Replacement

For vehicles equipped with turbochargers, we provide expert repair and replacement services to maintain power and efficiency.

Schedule an Appointment now for professional engine repair Musaffah services.

Signs You Need Immediate Engine Repair

Ignoring engine warning signs can lead to major breakdowns and expensive repairs. Here are some indicators that your vehicle needs urgent engine repair:

Unusual Smoke from Exhaust – White, blue, or black smoke can signal engine problems.

Loss of Power – A sluggish engine response can indicate internal issues.

Excessive Engine Vibrations – Unusual vibrations can stem from worn-out engine mounts or misfiring cylinders.

Burning Smell – A burning odor often indicates overheating or oil leaks.

Difficulty Starting the Engine – Frequent starting issues can mean ignition or fuel system problems.

If you notice any of these signs, don’t wait! Contact Us immediately for engine repair Musaffah solutions.

Why Regular Engine Maintenance is Crucial

Preventive maintenance is key to extending your engine’s lifespan. Routine check-ups can prevent expensive repairs and ensure your vehicle runs smoothly. Our maintenance services include:

Regular Oil Changes – Keeps the engine lubricated and prevents wear.

Air & Fuel Filter Replacement – Ensures clean air and fuel flow to the engine.

Coolant & Radiator Maintenance – Prevents overheating and enhances performance.

Spark Plug Replacement – Ensures efficient fuel combustion.

Battery & Alternator Check – Maintains electrical system efficiency.

Visit Us today to keep your engine in top condition with our expert services.

Contact Smart Auto Workshop for Expert Engine Repairs in Musaffah

If you’re looking for the best engine repair Musaffah has to offer, Smart Auto Workshop is your go-to solution. Our skilled technicians are ready to diagnose and fix your engine issues efficiently.

Our Contact Details:

Phone: Call Now +971 54 289 1836

WhatsApp: Chat Now +971 50 232 1132

Address: Abu Dhabi Musaffah M6, Al Marmoumiyah 1st street, Near to Masjid, UAE.

Don’t compromise on your vehicle’s performance. Book Your Appointment today and experience top-quality engine repair Musaffah services!

#Smart Mechanic Abu Dhabi#Best Auto Repair Musaffah#Electrical Workshop Musaffah#Car accident Repair Musaffah#Auto AC work Repair Near Me#Best Musaffah Car repair Service#Vehicle Diagnostics near by#Musaffah Auto workshop#Electric Car Repair Abu Dhabi#Hybrid Vehicle Repair Musaffah#Car Maintenance Abu Dhabi#Affordable Mechanic Musaffah#Abu Dhabi Auto Repair Shop#Transmission Repair Musaffah#Brake Services Abu Dhabi#Smart Car Diagnostics Abu Dhabi#Smart paint Abu Dhabi#Vehicle Inspection Musaffah#Automotive Repair Abu Dhabi#Engine Repair Musaffah#Smart painting Musaffah#Smart accident repair Musaffah#كراج لتصليح سيارات قريب من موقعي#ورشة لتصليح سيارات قريب مني#ميكانيكي سيارات قريب مني#مشغل تصيح سيارات قريب من موقعي#تصليح سيارات متنقل#كراج تصليح سيارات متنقل#ورشة لتصليح سيارات عند باب البيت#كراج تصليح سيارات عند مكانك

0 notes

Text

Everything You Need to Know About Car Engine Repair

Car engine issues can be one of the most intimidating and costly problems a vehicle owner can face. The engine is the heart of your car, and when something goes wrong, it can leave you stranded and frustrated. Whether you're hearing strange noises, experiencing a drop in performance, or seeing warning lights on your dashboard, understanding when to seek car engine repair can save you time and money.

Common Signs That Your Car Engine Needs Repair

Engine Light On: If the check engine light appears, it doesn’t necessarily mean your car will break down right away. However, it’s crucial to have it checked out by a professional. This light could be an indicator of something as minor as a sensor issue or as serious as a problem with the engine itself.

Strange Noises: Unusual sounds, like knocking, tapping, or grinding from under the hood, often point to mechanical issues in the engine. These noises can be caused by things like worn-out components or insufficient oil circulation. Ignoring them could cause further damage to the engine.

Reduced Performance: If your car isn’t accelerating smoothly, or the engine feels sluggish, it could be a sign that it’s not running efficiently. Reduced power could be due to fuel delivery problems, a malfunctioning spark plug, or an internal engine problem.

Excessive Smoke: Smoke coming from the exhaust pipe is never a good sign. White smoke may indicate coolant is burning in the engine, while blue or black smoke suggests oil is being consumed or there’s a fuel-related issue.

Overheating: A car that consistently overheats might have a damaged radiator, low coolant levels, or a failing water pump. If your car’s temperature gauge frequently spikes, don’t ignore it – this could indicate a more serious problem that requires immediate attention.

Poor Fuel Economy: If you notice your gas mileage dropping significantly, it could be due to an engine issue. Things like clogged fuel injectors, a faulty oxygen sensor, or a misfiring engine can cause poor fuel efficiency.

What Does Car Engine Repair Involve?

Car engine repair is a broad term that can encompass a variety of issues. Depending on the severity of the problem, repairs can range from small fixes to major overhauls.

Minor Repairs: These can include replacing spark plugs, changing the air filter, fixing small leaks, or cleaning the fuel injectors. These are relatively inexpensive and easy to handle.

Major Engine Repairs: These repairs may involve replacing the engine’s timing belt, repairing or replacing the cylinder head, fixing compression issues, or replacing damaged pistons or valves. Major engine repairs are often more costly and require a professional to handle the job.

Engine Rebuild: If the damage to the engine is extensive, an engine rebuild might be necessary. This involves disassembling the engine, inspecting and replacing damaged components, and reassembling it to restore its original performance. Engine rebuilds are typically performed on older vehicles that still have a good frame and body but need significant engine work.

Engine Replacement: In the most extreme cases, it may be more cost-effective to replace the entire engine, especially if the vehicle has high mileage or severe damage. Engine replacement is a complex and expensive procedure but can breathe new life into an older vehicle.

How to Prevent the Need for Car Engine Repair

Routine maintenance is the best way to prevent the need for major car engine repair. Here are some tips to keep your engine running smoothly:

Regular Oil Changes: Engine oil lubricates the moving parts within your engine and helps reduce wear and tear. Regular oil changes are essential for keeping your engine in good condition.

Coolant System Maintenance: Keep an eye on the coolant levels and ensure that the cooling system is functioning correctly to prevent overheating.

Air and Fuel Filter Replacement: Replacing clogged air and fuel filters ensures your engine gets the proper air and fuel mixture to operate efficiently.

Timely Repairs: If you notice any of the warning signs mentioned above, don’t wait to take your car in for an inspection. Catching a problem early can prevent it from turning into a more expensive repair.

Why Choose Collision Buddy for Your Car Engine Repair?

If you're dealing with engine trouble, don’t wait until it’s too late. Trust Collision Buddy for all your car engine repair needs. Their team of experienced professionals can quickly diagnose engine issues and provide you with affordable solutions that will keep your vehicle running smoothly.

Visit Collision Buddy at:

Address: 5339 Comercio Way, Woodland Hills, 91364, California, United States Phone: 818-600-6526

No matter how big or small the issue, Collision Buddy is dedicated to ensuring your engine stays in top condition!

#auto body shop#car battery replacement#auto body repair#car body paint shop#automotive electric repair#brake pad replacement#auto electrical repair#auto collision repair#led headlight installation#transmission repair services#car engine repair#car frame repair#headlight repair

0 notes

Text

Cylinder Head Repair and Reconditioning: Breathing New Life into Your Engine

Introduction:

The engine is the heart of any vehicle, and the cylinder head plays a crucial role in optimal functioning. Over time, wear and tear can take a toll on the cylinder head, leading to decreased performance and efficiency. In this article, we will delve into the importance of Cylinder Head Repair and explore the benefits of cylinder head reconditioning.

Repair of Cylinder Heads:

The cylinder head is a critical component that houses the intake and exhaust valves and the combustion chamber. When issues arise, such as cracks, warping, or damaged valves, it's essential to address them promptly through cylinder head repair.

One common problem is the development of cracks in the cylinder head. These cracks can lead to coolant leaks, combustion issues, and reduced engine performance. Skilled technicians use advanced techniques like welding or cold stitching to repair these cracks, restoring the structural integrity of the cylinder head.

Warping is another concern due to overheating or other stress factors. In the Repair of Cylinder Heads, professionals use precision machining to restore the flatness of the head surface. This ensures proper sealing and prevents further damage to the engine.

Valve problems, such as bent or burnt valves, are also addressed during the repair process. Technicians inspect, repair, or replace damaged valves to ensure smooth airflow and optimal combustion within the engine.

Reconditioning Cylinder Heads:

Cylinder head reconditioning goes beyond basic repairs, aiming to restore the entire component to like-new condition. This process involves a comprehensive inspection and refurbishment of the cylinder head, often including cleaning, resurfacing, and replacing worn-out components.

The cylinder head is thoroughly cleaned during reconditioning to remove carbon deposits, rust, and other contaminants. This not only improves performance but also extends the lifespan of the engine.

Precision machining is a crucial aspect of Cylinder Head Reconditioning. Technicians use state-of-the-art equipment to resurface the head, ensuring a perfect fit with the engine block. This promotes optimal compression and combustion, enhancing overall engine efficiency.

The valve seats and guides are also examined and replaced if necessary during reconditioning. This attention to detail ensures proper valve function, preventing issues like misfires and loss of power.

Conclusion:

Both cylinder head repair and reconditioning are vital processes that can breathe new life into your engine. Whether addressing specific issues or opting for a comprehensive overhaul, these services improve performance, fuel efficiency, and overall vehicle longevity.

For reliable cylinder head repair and reconditioning services, consider contacting ARA Engine Reconditioning. Their skilled technicians and advanced facilities ensure top-notch quality and precision in every job. Visit their website at araenginereconditioning.com.au to learn more about how they can keep your engine running at its best.

0 notes

Text

Engine Repair Shop Near Me: Expert Solutions for Your Vehicle

Your vehicle's engine is the heart of its operation, and ensuring it remains in top condition is vital for performance, reliability, and safety. Finding a trusted engine repair shop near me can make all the difference when your car starts showing signs of trouble. At The Mufflerman, we specialize in comprehensive engine repair and maintenance services to get your vehicle running smoothly again.

Why Choose a Professional Engine Repair Shop?

Engine repairs can range from simple adjustments to complex overhauls. A professional engine repair shop has the expertise, tools, and resources to diagnose and fix problems effectively. By entrusting your car to certified mechanics, you can ensure:

Accurate diagnosis of engine issues.

Use of quality parts and modern tools.

Long-lasting solutions that enhance performance.

Whether your car has a worn-out timing belt, misfiring cylinders, or a leaking head gasket, addressing engine issues promptly is essential to avoid costly repairs down the road.

Common Signs You Need Engine Repairs

Ignoring early warning signs can lead to more extensive engine damage. Be alert for these symptoms that indicate it’s time to search for an engine repair shop near me:

1. Unusual Noises

Knocking, ticking, or grinding sounds often signal internal engine issues, such as worn bearings or valve problems.

2. Decreased Performance

A noticeable drop in power, acceleration, or fuel efficiency can point to engine trouble.

3. Check Engine Light

If the dashboard warning light comes on, it’s crucial to have your engine inspected immediately.

4. Smoke from the Exhaust

Blue smoke could mean burning oil, while white smoke might indicate a coolant leak.

5. Excessive Oil Consumption

If you’re frequently topping off oil levels, your engine might have leaks or internal wear.

6. Overheating

An overheating engine may result from a faulty cooling system, a blown gasket, or low oil levels.

Comprehensive Engine Repair Services at The Mufflerman

At The Mufflerman, we offer a wide range of engine repair services tailored to your vehicle's specific needs. Our skilled technicians combine experience with state-of-the-art diagnostic tools to provide accurate solutions.

Our Engine Repair Services Include:

Engine Diagnostics We use advanced equipment to identify issues affecting engine performance and pinpoint the root cause.

Timing Belt and Chain Replacement A broken timing belt can cause severe engine damage. We replace worn belts or chains to ensure proper engine timing.

Head Gasket Repairs Our team repairs or replaces damaged head gaskets to prevent leaks and maintain engine compression.

Cylinder Repairs From misfiring cylinders to compression loss, we address all cylinder-related problems.

Engine Overhauls For extensive damage, we provide complete engine rebuilds or replacements to restore performance.

Fuel System Repairs We clean or repair fuel injectors, pumps, and filters to improve fuel delivery and efficiency.

Cooling System Repairs Our mechanics fix radiator leaks, replace thermostats, and service water pumps to prevent overheating.

Why Choose The Mufflerman for Engine Repairs?

When you’re looking for an engine repair shop near me, you want a service provider you can trust. The Mufflerman is known for delivering exceptional automotive care, and here’s why customers rely on us:

1. Certified Technicians

Our experienced mechanics have the training and expertise to handle all types of engine problems.

2. Advanced Technology

We use cutting-edge diagnostic tools to ensure precise and efficient repairs.

3. High-Quality Parts

We source durable, manufacturer-approved parts to guarantee long-lasting performance.

4. Transparent Pricing

We offer upfront estimates and clear communication, so you know exactly what to expect.

5. Exceptional Customer Service

From the moment you arrive, our team prioritizes your satisfaction by providing honest advice and timely solutions.

6. Convenient Locations

With multiple locations, including Chatham, we’re always close by to assist you.

Preventive Maintenance to Avoid Engine Repairs

While professional repairs are essential when problems arise, regular maintenance can help prevent engine issues altogether. Here are some tips to keep your engine in peak condition:

Change Oil Regularly Frequent oil changes ensure proper lubrication and reduce wear on engine components.

Inspect Belts and Hoses Regular checks can identify cracks or wear before they lead to breakdowns.

Monitor Fluid Levels Low oil, coolant, or transmission fluid can cause serious engine damage.

Replace Air Filters Clean air filters enhance engine efficiency by ensuring optimal airflow.

Schedule Routine Inspections Having your vehicle inspected during regular service visits can catch potential problems early.

Risks of Ignoring Engine Problems

Delaying engine repairs can lead to:

Reduced Vehicle Performance: Neglected problems can worsen, affecting fuel economy and power.

Increased Repair Costs: Small issues, like minor leaks, can escalate into major repairs.

Safety Hazards: Engine failure on the road puts you and others at risk.

Reduced Resale Value: A poorly maintained engine lowers your vehicle’s market worth.

Schedule Your Engine Repair Service Today

If you're experiencing engine trouble, don't wait—visit The Mufflerman for expert repair services. Our team of skilled technicians is dedicated to providing reliable solutions to get you back on the road with confidence.

What to Expect:

Comprehensive diagnostics and transparent explanations.

High-quality repairs completed efficiently.

A commitment to ensuring your vehicle performs at its best.

With our trusted reputation and commitment to excellence, The Mufflerman is your go-to destination for all engine repair needs. Book an appointment online or stop by our Chatham location today.

Drive with confidence, knowing your engine is in expert hands!

0 notes

Text

MV Auto: Your Trusted Auto Repair Partner in Wangara

Need a reliable auto repair Wangara? Look no further than MV Auto. With years of experience and a commitment to quality service, we've established ourselves as the go-to choice for car owners in the area.

Why Choose MV Auto?

Expert Technicians: Our team of highly skilled technicians is equipped with the latest tools and technology to diagnose and repair a wide range of automotive issues.

Comprehensive Services: From routine maintenance like oil changes and tune-ups to major repairs like engine overhauls and transmission replacements, we offer a comprehensive range of services to cater to your needs.

Quality Parts: We use only genuine or high-quality aftermarket parts to ensure your vehicle's performance and longevity.

Customer Satisfaction: Your satisfaction is our top priority. We strive to provide exceptional customer service and ensure you're completely happy with our work.

Common Auto Repair Services Offered at MV Auto

Engine Repair: We can diagnose and repair engine problems, including engine block cracks, cylinder head gaskets, and piston replacements.

Transmission Repair: Our technicians are experts in transmission repair and can handle issues such as slipping gears, harsh shifts, and transmission fluid leaks.

Brake Repair: We offer a variety of brake services, including brake pad and rotor replacements, brake fluid flushes, and ABS sensor repairs.

Suspension Repair: We can diagnose and repair suspension problems, including shock absorbers, struts, ball joints, and control arms.

Electrical Repair: Our team can handle a wide range of electrical issues, including battery replacements, alternator repairs, and wiring diagnostics.

Don't trust your car to just anyone. Bring it to MV Auto for expert auto repair services in Wangara.

Contact us today to schedule an appointment or for more information.

0 notes

Text

Pacific Auto Service: Your Trusted Partner for Professional Auto Repair

Are you tired of subpar auto repair services? Look no further than Pacific Auto Service. We're your one-stop shop for all your automotive needs, offering top-notch professional auto repair services.

Why Choose Pacific Auto Service?

Expert Technicians: Our team of highly skilled and certified mechanics has years of experience diagnosing and repairing a wide range of vehicles.

Quality Parts and Equipment: We use only genuine OEM parts and state-of-the-art equipment to ensure your vehicle is serviced to the highest standards.

Comprehensive Services: From routine oil changes and brake repairs to engine diagnostics and transmission services, we offer a full range of automotive services.

Customer Satisfaction: We're committed to providing exceptional customer service. Our friendly staff is always happy to answer your questions and address your concerns.

Popular Services:

Engine Repair and Rebuild: We can diagnose and repair engine problems, including engine block cracks, cylinder head gaskets, and more.

Transmission Repair and Overhaul: Our technicians can handle transmission issues, such as shifting problems, fluid leaks, and worn-out components.

Brake Repair and Replacement: We offer brake inspections, pad and rotor replacements, and brake system repairs.

Suspension and Steering Repair: We can diagnose and repair problems with your suspension and steering systems, including shocks, struts, ball joints, and tie rods.

Electrical System Repair: Our experts can troubleshoot and repair electrical issues, such as faulty wiring, blown fuses, and malfunctioning sensors.

Schedule Your Appointment Today!

Ready to experience the Pacific Auto Service difference? Contact us today to schedule an appointment.

0 notes

Text

Diesel Motors Parts & Detroit 60 Series: Key Components for Performance

Diesel motors have become the backbone of many industries, from transportation to agriculture. When it comes to reliable and efficient engines, the Detroit 60 Series stands out as one of the most iconic powerhouses in the world of heavy-duty diesel engines. First introduced in 1987, the Detroit 60 Series revolutionized the diesel engine market, offering unmatched performance and fuel efficiency for trucks, buses, and industrial applications. At the heart of its success are high-quality Diesel Motors Parts which ensure the longevity and functionality of these engines. Companies like North American Diesel Parts specialize in supplying these critical components to keep your Detroit 60 Series engine running smoothly.

Key Diesel Motor Parts for the Detroit 60 Series

Maintaining a Detroit 60 Series engine requires attention to several key components. These parts play a crucial role in optimizing engine performance, ensuring fuel efficiency, and minimizing breakdowns. Here are some of the most important diesel motor parts to focus on:

Fuel Injectors

High-quality fuel injectors are vital for delivering the correct amount of fuel to the engine. Poorly functioning injectors can lead to increased fuel consumption and decreased performance. North American Diesel Parts offers precision-engineered fuel injectors that ensure optimal fuel flow and combustion.

Turbochargers

Turbochargers boost the power and efficiency of diesel engines by forcing more air into the combustion chamber. The Detroit 60 Series relies on durable turbochargers to maintain high performance. If your turbocharger shows signs of wear, replacing it promptly can prevent engine damage and costly repairs.

Engine Overhaul Kits

Over time, all engines need a complete overhaul. For Detroit 60 Series engines, an engine overhaul kit includes all necessary components like pistons, gaskets, and bearings. North American Diesel Parts provides comprehensive overhaul kits to restore your engine to its peak condition.

Cylinder Heads

Cylinder heads play an essential role in housing valves, fuel injectors, and spark plugs. A cracked or damaged cylinder head can significantly affect engine performance. Replacing it with a high-quality part ensures the engine runs efficiently.

Oil Pumps and Filters

Proper lubrication is critical for the longevity of your engine. Oil pumps and filters are essential for keeping your engine’s moving parts well-lubricated and free of debris. Regular replacement of these parts can prevent premature engine wear.

Conclusion

The Detroit 60 Series is a reliable and robust engine, but like all machinery, it requires regular maintenance and quality parts to keep it running efficiently. North American Diesel Parts is your go-to source for diesel motor parts, offering everything from fuel injectors to overhaul kits for the Detroit 60 Series. With the right parts and maintenance, you can ensure your diesel engine operates at its peak for years to come.

0 notes