#or '2d stepper motors'

Explore tagged Tumblr posts

Text

youtube

Anyone have any idea what the name of this kinda PCB is?

#Youtube#have seen similar things labeled '2d magnetic actuators'#or '2d stepper motors'#or like those smart chess sets that automatically move the pieces without just having a xy electromagnet gantry underneath#specifically smth that can move electromagnets independently#ideally w no actual moving parts underneath

10 notes

·

View notes

Text

Build a Mini 3D Printer

Introduction: Even in the age of digital photography, there is still a certain charm to holding a physical print.

Taking it a step further, what if he could create three-dimensional objects from digital images? With a little creativity and ingenuity, you can turn your Instax Mini Link 2 printer into a mini 3D printer.

by: PCMAG.com

In this step-by-step guide, learn how to repurpose this popular portable photo printer to bring his 2D photos to life in 3D. Materials needed: Instax Mini Link 2 printer Arduino board (e.g. Arduino Uno) Stepper motor (28BYJ- 8 or similar) Motor driver module (ULN2003 or equivalent) 3D printing software (such as PrusaSlicer) Filament (PLA recommended) 3D modeling software (such as Tinker ad) Power supply (5V, USB compatible) USB cable

Step 1: Prepare your Instax Mini Link 2 printer First, carefully disassemble the Instax Mini Link 2 printer. Remove the outer case, being careful not to damage the main circuit board and printing mechanism. Make a note of the cables and connectors as you will need them later.

Step 2: Connect the Arduino Board Connect your Arduino board to your computer using a USB cable. Install the required drivers, if necessary. Next, upload the firmware required to control the stepping motor. You can find pre-built code and libraries online to simplify this process.

Step 3: Wire the Stepper Motor Connect the stepper motor to the motor driver module according to the pin configuration given in the datasheet. A motor driver acts as an interface between the Arduino and the stepper motor, controlling its rotation and position.

Read more

1 note

·

View note

Text

Spring Making / Wire Bending Machine

Spring Making / Wire Bending Machine

Well, this machine is not only about making springs. It is a wire bending machine capable of bending 0.8/0.9/1 mm wire into any 2D shape. But yeah, the coolest thing I was able to make with it so far was the spring. How cool is that?Get more news about spring forming machine producer,you can vist our website!

The main goal was to make it quite precise. Other DIY wire bending machines are not very precise and their bends tend to have quite a big radius. I like to work with nice sharp bends!

The second goal was to make it as easy to build as possible with commonly available parts and components. All the structural parts are 3D-printed and all the metal parts are available in most of the hardware stores.

Why I build this? Check out my other creations. I am a passionate free-form electronic circuits artist and this awesome machine will ease my job when doing repetitive tasks or when there are a need identical parts.

I've tried to record the whole build to help you understand it. It's always better to see the build in action. Continue with steps below to collect all the material and start building step by step! All the STL files for the plastic parts are available in the project's GitHub repository. Download them and start printing. I always design the parts to omit the need for using supports so the post-processing is much easier and parts are cleaner.

I was printing with 0.15mm layer height, 3 perimeters and 40% infill with Gyroid pattern setup. It does not matter if you use PLA or PETG. The parts will not get hot so PLA is just fine. Below is a list of all the parts that you will need for the build. See you in 2 days! (That's the print estimated time). While you are printing the plastic parts let's have a look at how the wire bender works and what components it consists of (from right to left):

Spool holder - it holds the spool of wire for the machine to process. Straightener rollers - set of 7 rollers to make the wire as straight as possible. Working with straight wire is crucial. That's also why there are 2 of them in a row. Feeder - you can find a similar mechanism in your 3D printer. A set of gears that pull the wire from the spool, through the rollers and pushes it to the bending head. The feeding gear must have enough drag on the wire so it will not slip thus making the machine inaccurate. More on that later. Bender - by rotating the pin on its head it bends the wire into programmed shape. It is all controlled by a single Arduino UNO with a CNC shield. Arduino takes commands from computers and translated them into movements of the stepper motors. Like any other CNC machine.

0 notes

Text

stone engraving cnc controller manufacturer

Different Types of Stone Engraving CNC Controller

A carving in stone A customised computer numerical control (CNC) system called CNC Controller is created specifically for stone engraving applications. In order to engrave or carve patterns into stone surfaces, a CNC machine is used to operate it.

The Stone Engraving CNC Controller is in charge of receiving and deciphering commands from CAD software, turning those commands into movements of the CNC machine's cutting tool, and finally sending those commands to the Stone Engraving CNC Controller. Intricate designs can be made on the surface of the stone thanks to the operator's exact control of the cutting tool.

Typically, the Stone Engraving CNC Controller comes with customised software created just for stone engraving applications. This programme may have a variety of characteristics, including toolpath support, file format support, and

To guarantee that the CNC machine runs smoothly and precisely, stone engraving CNC controllers may additionally comprise specialised hardware, such as stepper motor drivers, power supply, and communication interfaces.

In general, stone engraving CNC controllers are essential to the process because they offer a precise and effective technique to engrave intricate designs on stone surfaces. In the stone industry, they are frequently employed for tasks like decorative stone engraving, architectural stone carving, and tombstone engraving.

Different Types of Stone Engraving CNC Controller

The market is filled with many kinds of Stone Engraving CNC Controllers, each of which was created to satisfy particular demands for diverse stone engraving applications. Some of the most typical varieties are listed below:

2D engraving controllers: 2D engraving controllers are used to engrave flat objects like tiles, plaques, and gravestones. They have straightforward and reasonably priced hardware and software components.

3D engraving controllers: 3D engraving controllers are used to engrave three-dimensional objects like statues, sculptures, and architectural components. They have cutting-edge hardware and software, including strong CPUs and sophisticated toolpath optimisation algorithms.

Laser engraving controllers: Using laser technology, engraving controllers are used to engrave stone surfaces. To ensure precise and accurate engraving, they include specific hardware and software components, such as laser drivers and communication interfaces.

Waterjet Engraving Controllers: High-pressure water jets are utilised to engrave stone surfaces using waterjet engraving controllers. To ensure precise and accurate engraving, they include specific hardware and software components, such as waterjet drivers and communication interfaces.

Multi-Axis Controllers: Using a variety of cutting tools, multi-axis controllers are utilised to engrave complex three-dimensional surfaces. They have sophisticated hardware and software elements, such as toolpath optimisation algorithms and multiple axis control.

Rotary cutting tools are used with CNC routers to engrave stone surfaces. To enable precise and accurate engraving, they include specific hardware and software components, such as rotary tool drivers and communication interfaces.

Sculpting in Stone In the process of engraving stone, CNC controllers are essential because they offer a precise and effective means to produce intricate designs on stone surfaces. Stone engravers may make sure that their CNC machines run smoothly and precisely, producing high-quality and precise stone engravings, by selecting the appropriate sort of Stone Engraving CNC Controller for their particular application.

Importance of Stone Engraving CNC Controllers

Stone engraving CNC controllers are essential because they offer a precise and effective means to engrave intricate designs on stone surfaces. Some of the main justifications for the significance of stone engraving CNC controllers are as follows:

precisely engraved on stone CNC controllers provide exact control over the engraving tool on the CNC machine, resulting in extremely precise and reliable engraving outputs. Manual engraving would make it difficult, if not impossible, to reach this level of precision.

Efficiency: By automating the engraving process, stone engraving CNC controllers can produce goods more quickly. This is an efficient method for mass production since it saves time and money.

Design Flexibility: Stone engravers may produce detailed and sophisticated designs that would be challenging to accomplish manually thanks to the high degree of design flexibility offered by CNC controllers for stone engraving.

Consistency: CNC controllers for stone engraving can deliver repeatable, consistent results, guaranteeing that every engraving is identical to the previous one. This is useful for applications like tombstone engraving, where precision is essential.

Stone engraving, speed High-speed CNC controllers make it possible to quickly and effectively engrave even massive stone surfaces.

Expanded Production Capacity: Stone engraving CNC controllers can expand a stone engraving company's production capacity, allowing it to make more engravings in a shorter amount of time. This might assist the company in satisfying client needs and boosting profitability.

Features of Stone Engraving CNC Controllers

A variety of functions are available in Stone Engraving CNC Controllers that are tailored for use in stone engraving applications. The following are some of the main components that are frequently present:

customised Software: CNC controllers for stone engraving often come with customised software created specifically for stone engraving applications. Numerous features, including support for various file formats, toolpath optimisation, and 3D modelling capabilities, may be present in this software.

High-Speed Processing: Stone engraving CNC controllers are equipped with high-speed processors that can rapidly and precisely translate CAD designs and produce toolpaths for the CNC machine.

Multi-Axis Control: Multiple axes can be controlled at once using stone engraving CNC controllers, enabling intricate three-dimensional engraving and carving.

Toolpath optimisation can be done by stone engraving CNC controllers to minimise machine movements, shorten machining times, and enhance surface quality.

Stepper Motor Drivers: Specialised stepper motor drivers are a component of stone engraving CNC controllers and are used to regulate the motion of the cutting tool. These drivers offer exact and precise control over the movement of the cutting tool.

Stone engraving CNC controllers come equipped with communication connections that let the controller talk to the CNC machine, ensuring precise and dependable engraving.

Stone Engraving CNC Controller manufacturer work with a variety of CNC machines, enabling engravers to use the controller with their current tools.

Summary

Accelus Robotics, a manufacturer of stone engraving CNC controllers, is crucial for stone engraving applications. They offer accurate, effective, and user-friendly control over the engraving process because to their specialised software, high-speed processing, multi-axis control, toolpath optimisation, stepper motor drivers, communication interfaces, compatibility, and user-friendly interface. These controls enhance efficiency, production, and profitability while allowing stone engravers to easily make complicated, high-quality stone engravings. Stone Engraving CNC Controllers provide the accuracy, speed, and flexibility you need to realise your designs, whether you're carving gravestones, architectural components, or ornamental items.

0 notes

Text

Flush Door Making Machine/Furniture Making Machine/CNC Router

This Flush Door making machine is perfect for cast iron of secondary tempering. The internal structure is refined and the gantry structure is high in rigidity. Equipped with top quality work table, the machine tool has stable performance. We adopt precision grade guide rail and high precision screw in order to make sure that this wood door engraving machine has long life span to use.

📷

Features of Flush Door making machine:

Imported original HIWIN 20 square guide rails, longer life and smooth moving.

Chinese best HQD air cooling spindle with 18000rpm.

Helical rack gear transmission,which can ensure faster speed,higher efficiency,stronger

power,longer lifetime,and it makes the machine more stable.

With DSP control system, It can support offline operation. easy to operate.

Standard configured with stepper motor FL118 and YAKO 2811 big driver,very powerful.

For option, we can change toJapan YASKAWA servo motors and drivers.

Flush Door making machine standard parts and advantages

>High Frequency Powerful spindle

The High quality K series Cnc Router machine comes with 3.2kw high frequency spindle. This precision spindle requires no maintenance, uses industry standard ER collets and ISO tool holders. Fully programmable speeds from 6000 to 24000 RPM, and comes complete with pneumatically retractable vacuum hood.

>Machine Base Frame

The base frame is fabricated from heavy-duty tubular steel that is welded, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine.

>DSP controller

DSP 4 axis controller turns a typical off line CNC machine controller. It is the most sy to learn control system, which is perfect for green hand.

>Drive Motors

The High Quality K Series CNC Router utilizes Stepper motors powered JMC Drives. These motors require no regular maintenance - therefore, reducing any maintenance downtime.

>Hiwin square rail&High quality helical rack pinion

The machine adopts Taiwan Hiwin square rail, which is more than twice durable. And the use of high quality helical rack pinion, makes it high precision.

>CNC Tool Calibration

Automatic tool calibration pad allows for easy and accurate [Z" zero position for single and multiple tool changes through the program.

>Aluminum T-slot profile table

The aluminum T-slot profile table can fix any different material, no matter it is solid wood, MDF, acrylic or metal such as aluminum, steel, copper.

>The 4th Rotary Axis

UTECH's 4-Axis rotary table assembly comes complete with a 3-jaw chuck, tail stock, and linear guide track for easy tail stock movement and center alignment. The addition of UTECH's 4-axis rotary table assembly adds greater functionality to the machine`s capabilities allowing for 4-axis cutting in both 2D and 3D carving and indexing functions.

>Oil mist lubricator

Oil mist lubricator is driven by comprossed air, sparys oli fog particles in the size between 0.5 and 15. It's application for lubrication and cooling of lubrication points. It's equipped with electromagnetic valve. When connected with main uit electric control, it can realize control of lubrication time.

Flush Door making machine application:

Materials good for Furniture Making Machine EA-1530SV is solid wood, MDF, plastic, PVC, acrylic, and other nonmetal materials.

Field: panel furniture, cabinet, wood door, bed, chair, slat wall, decoration wall, sign making and so on.

DescriptionParametersWorking area1300*2500*200mmSpindleATC 9KW air cooling spindleInverterFulingMotorDorna servo motor and driver 1500W and shimpo ReducerDriverDorna servo motor and driver 1500WControl SystemLNC TableVacuum and T slot table with 5.5kw cooling pumpOil lubricationAutomatic lubricationLimitOmron limitTransmissionXY axis helical rack Z axis Taiwan ball screw RailX,Y,Z axis Taiwan HIWIN Square guide railScrewZ axis TBI 3210 ball screwBedThick steel welded big square tube GangryStrong framePillarsSteel pillarCabinetIndependent cabinetVoltage3 phase/380VDust collectorDouble bags 3.0kw Tool libraryAutomatic up and down*Some specifications can be customized upon request, please contact us

0 notes

Text

CNC Wood Router

CNC Wood Router is a wood router machine controlled by the computer. It can process 2D/3D, milling, carving (relief, plane engraving, hollow carving, 3D carving), cutting, slotting and drilling of most popular wood materials and other soft materials, including woodworking crafts, wood carving, wooden marks, wooden toys, wooden gifts, cabinet making, wooden door making, wooden modelling, production of wooden furniture such as wardrobe.

The main structure of CNC Wood Router includes spindle, bed, gantry, servo motor and actuator, CNC operating system, CNC software, rack guide, screw, worktable, power supply, limit switch and so on.

CNC Wood Router is also known as wood CNC machine, woodworking CNC router, wood CNC router, CNC wood carving machine, wood CNC cutter, CNC wood milling machine, wood CNC table, CNC wood table, CNC wood router machine, CNC woodcarver, CNC wood engraver, CNC woodcutter, CNC wood cutting machine, c and c wood router, CNC woodworking machine, CNC wood engraver, wood c and c machine.

How does the CNC Wood Router work? By using CAD or CAM software, the design and typesetting are carried out on the computer, and the generated information is automatically transmitted to the controller of the CNC wood router by the computer. Then the controller converts the information into a power signal (pulse train) which can drive the stepper motor or servo motor and controls the movement path of the X, Y and Z three axes of the CNC wood router host.

The high-speed spindle on the wood router machine, connected with the bits(cutting tools) suitable for processing the specified materials, then processing the material which fixed on the worktable, the parts designed in the computer will be processed by automatic processing.

CNC Wood Router includes 3-axis CNC Wood Router, 4-axis CNC Wood Router, 5-axis CNC Wood Router, and CNC machining centre with automatic tool changer.

How is a CNC Router used? Common wood used for carpentry, furniture, and construction industries are: Cork: commonly used in woodworking, construction and furniture industries, popular softwood wood such as pine, cedar, cedar, spruce, and mahogany. Hardwood: usually there are beautiful and unique wooden patterns, used in handicrafts, decoration, and furniture industries, such as oak, maple, cherry, mahogany, walnut, bamboo, and palm. Artificial wood: also known as composite boards, such as plywood, particleboard, MDF.

<1> Furniture making: It produces all kinds of customized furniture, including doors and windows, beds, dining tables, chairs, staircases, windows, modern furniture, office furniture, and so on. <2> Cabinet production: Cabinet door, cabinet, shelf, curtain wall, and other integral cabinet production. <3> Woodworking industry: Three-dimensional wave plate processing, wooden musical instrument processing, decoration materials processing, decoration processing, etc. <4> Mold industry: It can engrave all kinds of effects, such as relief, shadow, engraving, plane carving, cutting, bottom washing, and so on. <5> Advertising industry: Advertising signs, PVC board, Teflon board, double colour plate, logo making, acrylic cutting, plastic moulding, big word cutting, sign production, cutting PVC, crystal board, acrylic, LED/ neon groove, hole type font cutting, Blister light box mould production. <6> Crafts industry: Pen, photo frame, pendulum, souvenir, custom gifts, vases, water cups, and other crafts and gifts processing. <7> Foam carving: Lost foam, large decorative items, handicrafts, and so on. <8> Cylindrical engraving: Table legs, dragon pillars, escalator posts, wooden railings, and so on.

0 notes

Text

Full colour 3D printer project :design phase

use black white cyan magenta and yellow to create any colour of pla - as done in classic 2D printers

existing examples:

https://www.youtube.com/watch?v=aUkN3E3QHyk&t=43s

https://www.instructables.com/Full-Color-Mixing-3D-Printer/

https://marlinfw.org/docs/configuration/configuration.html

design considerations:

different colors have different conductivity - tuning of this

how well will they mix

power for the 4- bowden extrudes required

liquid cooling

mounting for Cartesian or integrate into a delta?

cost - £150 ish for a water cooled 5 in 1 out nozzle

will also need the computer water cooling pumping like those in high end desktop PCs

what motherboard will allow for 4 - 5 extruders?

keeping all filaments at low humidity - ensure print quality high

Geetech i3 pro b as base (for now)

marlin facts for extrusion:

https://marlinfw.org/docs/configuration/configuration.html#extruder-info

parts from anaet A8:

5 steppers

Classic hot end

4 threaded rods

4 smooth rods

1 Bowden extruder

Purchase an A10T and upgrade to a 4 -5 nozzle

Diamond extruder:

https://www.reprap.me/diamond-fullcolor-hotend-heatsink.html

https://www.reprap.me/diamond-fullcolor-hotend-water-cooled.html

https://www.reprap.me/heater-cartridge-12v-60w.html

https://www.reprap.me/diamond-fullcolor-nozzle.html

https://www.reprap.me/bowden-4-2.html

Components

o Extruder

o Motherboard

Software

o Marlin

o Gcode

is currently the limiting factor - need to find packages that do this sort of thing for mixing the colors together etc

motherboards/ electronics stuff:

needs to support 4 steppers for the 3 axis of motion and 4 - 5 for extrusion (unless doing weird gearbox stuff with servos)

web-pages:

https://3dprinterchat.com/what-main-board-is-right-for-you/

https://www.instructables.com/Adding-More-Extruders-to-Any-3d-Printer/

glalaxyman7 uses a stepper driver board (powered straight from the silver power box) and uses the spare pwm pins from spare end-stop slots to send data to the printer

explained more here : https://docs.google.com/document/d/1ssYLTjip8W6NqCUTeT5wh5Jx5FURBJVBwNe5d-llD5Q/edit

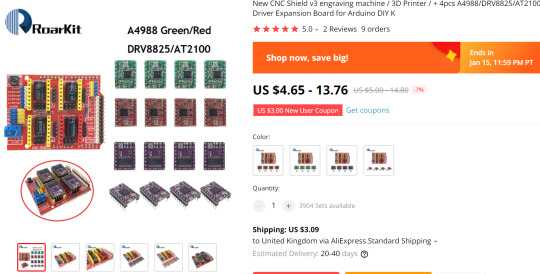

the extender stepper board:

https://www.aliexpress.com/item/1915894898.html

up to 4 stepper motors

----------------------------------------------------------------------------------------------------

Final design:

total cost £ .....

components to source

1: Diamond 5 in 1 extruder water cooled

1: water cooling pump

1: water cooling fluid

5: Nema 17

5: Bowden extruder end for nema 17

5: Bowden tubes

1: suitable power supply - currents etc

1: motherboard or stepper shield

software

--------------------------------------------------------------------------------------------------------

link to my instructables:

0 notes

Text

Do It Yourself CNC Laser Cutter

Do It Yourself CNC Laser Cutter

CNC modern technology is very desirable in numerous shops and also people today. These makers operate with little human interaction, besides downloading and install the program, establishing the tools up and also pressing the begin button. CNC makers can be very costly on the one hand, but on the various other, they can be very budget friendly as well. Co2 Laser Marking Machine

Extra business are developing semi-portable devices that are perfect for the small store proprietors as well as hobbyists available today. You still get the benefits of the CNC innovation with one of these machines that you would with a bigger device. The speeds may be slower, yet the little devices are made for smaller sized tasks and also the rate that they use is just right for this details job.

An additional method of having a CNC machine is by developing one on your own. You can discover plans for various CNC machines throughout the net. You can find cost-free plans as well as ones that you need to spend for. It is a great suggestion that if you decide to go this course that you understand exactly how to check out a set a strategies which you recognize the functionality of the maker that you are attempting to create. Or else, it will be really hard for you to produce a machine of this level.

One more option that you have is to buy Do It Yourself CNC laser cutter sets. These sets aid you to construct this device from scratch. These kits essentially feature everything that you require to develop the equipment, so there is no presuming if you have the appropriate parts or otherwise.

Every one of the basic items are consisted of like full instructions, all the brackets that are needed,, twin drive, stepper drive electric motors, CNC drive as well as control boxes, guides, motorist software program and bearings. Do not be afraid to customize your machine by tailoring your package to meet your demands. Add-ons and accessories can be added to the kit to fit your needs or your budget plan.

An additional option is the bolt-together set. If you can't bond as well as place a maker with each other then attempt a bolt-together kit. With these sets all you have to do is bolt together the pieces with hand tools. Actually, it is that straightforward.

Your budget and your skills and also understanding will certainly figure out which DIY CNC laser cutter kit you will require to purchase or possibly create yourself. It can either be very basic or extremely difficult for you to produce. Developing a machine of this caliber can fill you with pride, in addition to permitting you to end up being more imaginative and also to broaden your shop or your pastime to an entire various other degree.

Contact your dealer to see what sort of packages that they need to provide as well as to go over any type of other inquiries that you might have or the budget plan array. Or, if you wish to do it entirely by yourself, start looking the internet today to locate that appropriate set of prepare for you.

The Advantages of CNC Plasma Cutter

A lot of people are curious regarding plasma cutting. Most of them go into the world of plasma cutting through the CNC field. This is one of the most valuable devices for wide-range services today. It is a functional tool commonly utilized by production and construction business today. How does a plasma cutter job as well as how reliable are these devices? These are just a few concerns that we will certainly be able to deal with as we discuss anything and also whatever concerning plasma cutters in the prospering messages.

CNC cutter can be found in a range of sizes. The dimensions and the designs of the cutter are dependent on the sort of product it can cut to items. At the very same time, the (plasma) cutters have specialized functionalities that stands out than various other CNC equipments. State for instance, the giant plate units for burning can cut up to 2 inches of thick steel.

There are actually a whole lot to pick from. There is high-technology and also high definition systems that are as good as laser in regards to performance and precision. Plasma cutters vary in specs and specialization, depending on the type of steel they deal with.

On the other hand, there are offered plasma cutter nowadays that are computer-operated and also can make organisation processes easily and also might simplify particular production procedures. The hard drive of the computer is made use of to save various measurements and specifications of the cuts to ensure that the cut will be more specific and also accurate. Given that plasma cutters take on intricate shapes in shaping steels, mistakes must go to the minimum. To make sure 0% errors, business favor to have the computerized type of plasma cutter to ascertain accuracy as well as accuracy, leaving the cut remarkable and efficient. Steel fabrication as well as therapy can additionally be performed while subjecting the metal to cutting.

The performance of CNC plasma cutters are the edge of some multi-national business in providing reliable and time-bound supplies with the metal distributors. At some time, they could even surpass their cottas as well as make certain of the average performance with time interval can be achieved. Naturally, with the help of electronic plasma cutters, the performance of the business in reducing state-of-the-art metals and delicate materials are much unrivaled. Eventually, they are thinking about organisation growths as well as promotions, to enhance productivity as well as advertising strategies.

Electronic plasma cutters, despite of their problems includes the normal means of reducing metals. It is an effective device as well as mainly used by metal processing companies and also companies whose line of business refer to the cutting and handling of the various kinds of steels. Among the inquiries that may be increased is the capability of the device to eliminate a part of the entire whole.

What Is Laser Reducing as well as What Can Be Cut Utilizing a Laser Cutter

Laser cutters make use of a laser beam of light for cutting products, and are generally utilized for commercial production applications. The reducing works by routing the result of a high-power laser, at the material to be cut. The product thaws (at the light beam course), burns, evaporates away, or is blown away by a jet of gas, leaving a high-quality surface area coating edges. Those CNC equipments utilizes a computer as well as cutting software that takes a layout file as well as executes it on the product to be reduced to generate the wanted cut.

Laser construction sustains the cutting of a pattern within a pattern. Here are some of the products a laser cutter can reduce:

Plastics - Consisting of polymers, ABDOMINAL, Lucite, plexiglass, mylar, Kapton tape and styrene

Wood - The laser cutter can cut layouts right into wood, including individualized pencils, wooden precious jewelry, timber image frames, furnishings as well as even more.

Foam - XPS foam for RC aircrafts, Depron foam, polyethylene (PE), polypropylene (PP), Styrene. Various other product - clothes, paper, rubber.

It permits a level of precision as well as complexity not feasible if making use of traditional machining devices. It is optimal for reducing flexible semi-rigid as well as soft materials. The laser cutter utilizes a high-density as well as powerful light power running through its laser light beam, which consequently burns the material. The laser beam of light is usually 0.2 mm (0.008 inches) in diameter at the reducing surface area, with a power of 1000-2000 watts.

It will generate any kind of 2D shape, consisting of shapes intermediaries and also inserts, making use of a CAD data. Its main benefits are high precision, good quality cuts, high processing speed, reduced contortion of the eliminated material and also capability to reduce little openings and also little product (as small as 1m in size). Nevertheless, cutting thick foam sheets will certainly lead to much slower production time than cutting slim layers. In addition, each maker has its own density of material it can cut. If the sheet to be cut is thicker than the laser cutter's capabilities, the cuts ought to be made by layers, and afterwards can be glued with each other.

There are limitless numbers of industries and markets using it to fabricate items: Prototyping, Furniture, Product Packaging, Situations & instruments inlays, Building and construction, Robotics, fashion jewelry, ornaments, custom gifts, computer case components, scale model components, RC models, art items, custom-made indicators, letters & logos therefore many more.

CNC Plasma Cutter Advantages And Disadvantages

For over half a century, plasma cutters have actually been the preferred technique of reducing metal. Considering that the 70's, they have gained market large approval because they supply several benefits over various other cutting methods.

Allow's take a look at some of the Advantages and disadvantages of CNC plasma reducing devices.

Pros:

Rapid - no preheating called for, so the torch can begin reducing quickly. With accelerate to 500IPM, it can match laser cutters depending upon the sort of component.

Functional - efficient in piercing, complex cutting and also beveling in one procedure. Plasma cutters can effectively reduce any kind of electrically conductive metal approximately 6" thick.

Specific - coupled with cutting edge software program and high accuracy parts, the demand for costly additional operations is gotten rid of. The lantern head is computer system regulated, producing tidy, sharp cuts.

High Cut High quality - much less dross and also top quality edges. Tight integration between the cutting lantern and software cause excellent quality manufacturing.

Easy to Use - while a CNC maker may seem complicated, the CNC (computer numerically managed) software takes the majority of the assumption work out of reducing. With a state-of-the-art package, also a first time driver can generating incredible results.

Safe - most quality systems provide an exhaust or down-draft system to draw smoke away from the operator.

Cons:

Solidified Edges - the plasma will certainly create a heat affected area as well as set the edges of the product being cut.

Dross - The majority of plasma cut parts will have some dross that requires to be cleaned from the part however this has actually been minimized with today's high efficiency plasma cutting systems

Expense - CNC plasma cutters can set you back more, however quicker cutting speed and also high cut quality permit faster production with less labor intensive secondary operations. The long term efficiency as well as precision are aspects which figure right into the total price of a plasma cutter, not just the price.

Several low-price, mid to low-grade plasma cutters are readily available on the marketplace today. Poor layout, poor workmanship, older modern technology and inefficient parts substantially reduce the life of a deal plasma cutter and keep companies from understanding the efficiency gains as well as price savings they were expecting. What appears like a lot in advance, will certainly wind up costing you time and money in the future.

All CNC Plasma Cutters Are Not the Same

When it comes to broadband, accurate as well as durable plasma cutters, it can be stated that a high quality plasma cutter is really the sum of its' parts. By developing a plasma cutter with the best parts, constructing it as solid as well as steady as feasible, and also making it easy to set up as well as make use of, you have a formidable reducing equipment.

Plasma reducing machines should have the ability to hold their marketed resistances today as well as, much more notably, for years to find. Just well developed and also well developed plasma cutters can make such cases.

Just how does a plasma cutter attain such limited tolerances? Just how does it carry out constantly every year? There are several essential variables you have to think about.

It begins with a heavy-duty, unitized, fully-welded layout that supplies the most steady system for exact plasma cutting. When the base of the device does not move during reducing, the plasma lantern is able to reduce your parts with amazing accuracy. The plasma cutting table should able to take care of hefty plate tons (2" as well as a lot more) and endure rigorous day-to-day usage. You require professional quality equipment to produce professional quality products.

Next off, the elements require to be made and also machined to collaborate. Are all of the direct overviews and also shelf placing surfaces machined in a solitary set up to ensure the very best feasible accuracy? When these surface areas are accuracy machined and also matched, the outcomes are a plasma cutter efficient in incredible precision. Helical shelf and pinion drives and also high quality straight guides give unparalleled velocity, activity smoothness and accuracy.

The plasma torch and also the torch elevation control are likewise crucial aspects for figuring out cut top quality and precision. Does your plasma cutter makes use of the best automated servo regulated arc voltage system? You can significantly enhance efficiency with faster reaction, much shorter pre-flow times and tighter software application combination. The lower line is that it enables you to reduce smarter.

A powerful, attribute packed CNC software package must likewise include a combination of setups and expanding features - versatility is vital. It should have the most recent automation features supply high performance and dependability. Nesting software program is another vital element that will enable the complete potential of a premier plasma cutter to be understood. This makes it easy to set up, find out and make use of for either new or experienced drivers.

You may be seeing that a quickly, exact as well as long lasting CNC plasma cutter is indeed the amount of it's components.

By choosing an excellent quality CNC plasma cutter, you choose one efficient in supplying near-laser cut high quality and also accuracy at a fraction of both investment and also operating expense. You additionally choose a plasma cutter efficient in expanding to satisfy your firm as well as client's transforming needs.

Also in slow economic times, it can be a mistake to be cent smart as well as pound silly. Can you manage to get affordable? Buying high quality is never a mistake.

Details on Laser Cutter

The use of laser cutters is coming to be progressively common with every passing day. This is happening primarily due to the developments occurring in the world of innovation. The increasing demand for goods made using these cutting tools have required both big factory and small companies to replace the conventional mechanical reducing procedures with them. These tools can complete jobs in very little time, which is one more reason behind their enormous popularity.

Allow us start by clarifying to you the standard functioning treatment of these machines. The laser light beam used by these reducing machines usually has a diameter of 0.2 mm when it fulfills the reducing surface. The entry diameter of the beam of light is generally larger than the exit size.

The light beam needs to be powered by electrical power of 1,000 to 2,000 watts. An additional essential part of the maker is the collection of mirrors it comes equipped with. These mirrors straight laser light beams discharged by the device towards the product the individual is wanting to reduce.

Jobs done making use of laser cutters could entail the CNC process. The term CNC process describes an approach during which a device strikes openings of different sizes in a provided product. At times, makers also use this method for producing various other sort of interior features in the product. Laser cutting, when utilized alone, is indicated for adding intricate external functions to a provide product.

These gadgets cuts in kind of digital data created by CAD drawing or attracting done making use of computer-aided layout. This gives birth to complex flat-form components. Having a CNC equipment is necessary for makers looking to profile components using laser cutters. This is due to the fact that punching the material is important before profiling it.

The following concern that must be arising in the minds of most of the readers at this moment is regarding the product kinds that can be reduced utilizing laser cutters. These devices are meant mainly for cutting through products such as stainless steel and carbon steel. These equipments find it difficult to cut through copper and also aluminum alloys as those materials possess the capability of showing light as well as thus end up reflecting the laser beam.

An Introduction to Laser Cutters

Use of laser cutters is pretty typical today. The past couple of years have observed numerous large factory as well as small companies replacing their traditional mechanical cutting home appliances with advanced laser cutters. The major reason behind the significant appeal delighted in by these cutting makers is their capability of using accuracy. These machines make use of high power laser beams for cutting steel parts swiftly as well as with terrific excellence. This write-up will certainly inform you about the features and functions of laser cutters.

Allow us begin the conversation by notifying you concerning the key features of these reducing machines. As their name suggests, they are tools that work making use of laser beams. The laser light beam used by them typically has diameter of simply 0.2 mm as well as come powered by 1,000-2,000 watts of electrical power. Another famous feature of the device is the series of mirrors ingrained in it; these mirrors are needed for guiding the laser light beam into the steel component it will be cutting.

Laser cutting is often made use of throughout the CNC/Turret process or the procedure throughout which holes are punched right into an offered product. The CNC/Turret process is implied for producing openings and also comparable inner attributes; laser cutters, on the other hand, are utilized for adding complicated outside attributes to metallic materials.

The individual accomplishing laser cutting needs to adhere to a CAD illustration. So, to finish these work perfectly one needs to have detailed expertise of analysis and also comprehending computer-aided layout. Metal parts, after being punched by a CNC/Turret device, get profiled by laser cutters.

As discussed over, these equipments are created mainly for reducing metal parts. To be much more exact, they are best fit for cutting stainless steel as well as carbon steel. They are generally not utilized for cutting through copper as well as aluminum alloys as those steels do not have the capacity of showing light. Specialists additionally don't suggest using laser cutters for reducing those alloys as alloys that have copper or light weight aluminum as one of their components also do not have the ability of taking in and also performing warmth. For cutting through copper and light weight aluminum alloys, you will need to utilize extra effective laser beam of lights.

A CNC Machine in your house Workshop

Forty years ago, in the world of large business production, computers started making their means into the manufacturing facilities. Computer Numeric Controlled (or CNC) machines, that ran off a pile of strike cards with intricate patterns of openings punched right into them, ran significant milling devices and also lathes. They were difficult, yet fast, and each equipment expense more than a great home.

Fortunately, for you, the residence artisan, those days are gone. It is currently completely possible, practical, and also inexpensive to own your own CNC router, CNC mill, CNC turret, CNC laser cutter, or CNC plasma cutter. With only the most fundamental PC computer system, a couple of hundred dollars well worth of software application, a comparable financial investment in hardware and electronic devices, and also your very own ingenuity, YOU can have a CNC equipment in your home workshop.

A CNC device can be a fantastic supplement to a pastime that you currently have ... like building model airplanes, version railroads, or woodworking. If you enjoy electronics, a small CNC router can etch and also drill printed motherboard. If you have children at home, a CNC maker can be a terrific means to aid them with science fair tasks, robotics jobs, or making arts as well as crafts projects.

CNC equipments can reduce or machine complex detail, and do it extremely quickly. You have actually probably appreciated a few of those complex wall surface danglings that are reduced with a jig saw ... where the artisan invested actually thousands of hrs drilling via the workpiece, detaching the saw blade, threading the blade with an opening, reattaching the blade, making the cut, and repeating the procedure. A CNC router can do the exact same work in a fraction of the time, and far more accurately.

A CNC Router is possibly the most functional kind of equipment. It can make heavy cuts and also do shaping in 3 measurements, or you can place a swivel blade cutter into the router chuck, and also do vinyl indicator as well as graphics reducing. With the appropriate software application, you can digitize (or "Reverse Engineer" a component) utilizing a probe installed in the router chuck to "trace" the shapes of a component. The computer system will "Keep in mind" the shape of your original, and afterwards allow you to duplicate the part with the router, sufficing from a block of timber or various other material.

As well as a CNC router can be the start of a part-time. and even full-time service. You can carve gorgeous wood indicators, cut out wood toys, or version aircraft or railroad elements. You can carve initial patterns, and also make mold and mildews from them, to produce porcelain figurines, plaques, photo frameworks or various other actors parts. Have you appreciated wooden clocks? A CNC router is a great means to make one ... or loads. If you are an annoyed inventor, you can cut mechanical components for prototypes, from a variety of materials consisting of timber, plastics, light weight aluminum, composite products like carbon fiber laminate, or published circuit board product.

So exactly how do you begin? A terrific area to start is with the ABC's of CNC video clip. This two hr long DVD takes you with the entire CNC workflow ... starting with the essentials of maker styles, G Code, CAD as well as WEB CAM software application, and also finally via the actual cutting procedure. You'll see example components begin as a layout, sketched on a paper napkin, taken via CAD software, and on the Computer Aided Machining (WEB CAM) software application where the real cutting courses to make the part are produced. The output from the WEB CAM program then goes to the real maker controller, which transforms the digital details right into real motion ... to cut the component.

You do not require to be an electronics whiz ... neither a computer programmer ... nor a machinist. The ABC's of CNC video clip will certainly show you where to begin, where to look for parts and also sources, and also just how to put everything together. to make your OWN CNC machine. It's enjoyable and also gratifying. It will certainly open up an entire new globe of precision, rate, and also repeatability.

0 notes

Text

1325S 4 axis Stone CNC Router with rotary

Advantages of 4 axis Stone CNC Router with rotary

1. T type heavy duty Machine structure, good weight bearing capacity, not easy to deformation, the special machine bed design, can bearing more than 2000kgs materials. 2. The special designed Zaxis, can increase the stone relief accuracy, can solve the Zaxis belt or ball screw breaking problem thoroughly. 3. The water proof and dust proof system for X Y Zaxis, can protect all the parts, reduce the machine fault, enlarge the life time. 4. High-performance driven motor to ensure that the machines high speed and accuracy. 5. Using well-known domestic brands of water-cooled brushless spindle, low noise, strong cutting ability, to ensure the long time working. Applications of 4 axis Stone CNC Router with rotary

1. Suitable for natural marble, granite, bluestone, sandstone, artifical stone, tombstone, milestone, ceramic tile, jade, crystal, ceramics, glass, plastic, wood, bamboo, cambered surface, sphere, stainless steel, iron, copper, aluminium, titanium alloy, can doing 3D embossment, and line engraving, bevelling, drilling 2D engraving. 2. Such as granite stone can be layered engraving to 3mm. 3. Marble, bluestone can be engraving to 3mm on time. 4. Engraving characters, letters, pattern, intaglio, rilievi, handwriting, ancient calligraphy, abrazine colored drawing, flat carving colored drawing, etc on stone, glass, depth can control optionally, to reach the artistic effect. Features of 4 axis Stone CNC Router with rotary 1. Lathe bed welded with thick channel steels and square tubes;Processed by high temperature tempering treatment and vibrating stress relief(VSR) to reduce residual stress,good stability,no deformation. 2. Using the higher precision rack pinion transmission, higher accuracy, fast speed and powerful. 3. High-speed water cooling spindle and high performance subdivision driver ensure to work stably for long time. 4. With practical and easily-learned software,can conveniently check the moving path of tool,and adjust the processing depth of Z axis and the speed of motor. 5. Designer perfectly, select the best machine accessories , to minimize the failure rate preferred . 6. Breakpoint specific memory, power outages continued carving, processing time forecast, and other functions to ensure that accidental processing. 7. With water tank and double water cooling system,high efficient works. Technical parameters of 4 axis Stone CNC Router with rotary Model ZMS-1325S X,Y axis route 1300x2500mm Z axis route 300mm Max travel speed 25m/min Max engraving speed 8m/min Resolution 0.005mm Repositioning accuracy 0.05mm Spindle power 5.5KW(made in China, water cooling) Spindle speed 0-24000rpm/min Power 1500W(not including spindle) Working voltage AC380V/50Hz Control system dsp control Software running environment Windows98/2000/xp Motor type Stepper motor Drive type X,Y rack and pinion,Z ballscrew Clamping type Profile pressure plate, stainless steel water tank Run rail All three axis Hiwin square rails

0 notes

Text

Automating image capture for 3D scanning through photogrammetry

3D data creation is part of a growing trend in the use of computational imaging techniques within cultural heritage digitization shops. In particular, operational adoption of photogrammetry has been witnessed at such institutions as the Minneapolis Institute of Art (MIA), the Smithsonian, and the University of Virginia Library.

3D data use cases abound. For instance, it can be leveraged to create 3D digital models for display and manipulation in various viewers, 3D printed, and re-purposed in VR environments. Additionally, virtual models can be employed as teaching tools, used in conservation condition assessments of objects through time and to open new lines of inquiry and digital scholarship around such data sets.

One of the current bottlenecks in the multi-step workflow that leads to the creation of original 3D data is the capture stage. In the case of photogrammetry, automating original 2D image capture under controlled shooting conditions is one way to begin to not only scale up data creation but to also make data more accurate and easier for 3D post-processing software to work with.

As we recently began to build out our own 3D capture capabilities at the University of Connecticut Library’s Digital Production Lab, we decided to look at existing automated systems with an eye towards customizing a rig that would best fit our space, budget, and anticipated requirements. In collaboration with ace systems integrator, Michael Ulsaker, this is the structure that we recently co-designed and installed in our studio:

University of Connecticut Digital Production Lab 3D Capture System

Salient features include an automated 360 degree spin turntable, and camera column that can be programmed to seamlessly control movements along X, Y, and Z axes during a given shooting session. Both the turntable and camera are driven by an integrated combination of 5 stepper motors.

Cognisys NEMA 17 Stepper Motor and Canon 5D II

All of this movement is coordinated through a linked pair of Cognisys Stackshot 3X modules. Each module, which in essence acts like a programmable logic controller, has a haptic touchscreen and a nice GUI to the Cognisys software.

Cognisys Stackshot 3X Controllers

Successful photogrammetry requires a 2D image set of an object from overlapping look angles. This needs to be done in a comprehensive manner across a subject’s entire surface in order to give post-processing software a greater opportunity to create 3D data from the original. Turntables are a good capture solution in this scenario, as they help control needed overlap from shot to shot and permit consistent stationary lighting to be built into the overall design. Beyond object movement, however, there remains the need to reposition the camera to different look angles above the subject per 360 spin for optimal capture coverage. This is where precisely programmed turntable rotation and camera movement can come together to create high quality source imaging:

[embedded content]

The net results are a series of hemispheric image sets, viewed here in Agisoft Photoscan, where each individual 2D image capture is represented by a blue rectangle around the generated 3D model:

Model View, Agisoft Photoscan

Once exported from post-processing software, the model can then be uploaded to an online viewer site like Sketchfab where it may be shared more broadly to the online world.

Though the Polaroid Test model presented common photogrammetric challenges like the presence of specular highlights from its more reflective surfaces and self-occluded areas along the bellows, this initial trial, exported straight from Photoscan was promising nonetheless. A second test, this time using a small gift store duck with a terracotta-like surface was something that the software more elegantly handled and made watertight.

After our initial test phase concludes, we hope to eventually begin work on aspects of the Connecticut Archaeology Center’s bone collection and selections from the department of Ecology and Evolutionary Biology’s Biodiversity Research Collections, both of which are housed nearby on campus.

About the Author

Michael J. Bennett is Head of Digital Imaging and Conservation at the University of Connecticut. There, he oversees the digital capture and conservation operations for the University’s archives and special collections. His research interests include technologies and techniques that focus on digitization, post-processing, and 2D and 3D data formats. You can find out more about Michael and see his work over on his website, Tundra Graphics.

You can find out more about Michael and see his work over on his website. This article was also published here, and shared with permission.

Source: https://bloghyped.com/automating-image-capture-for-3d-scanning-through-photogrammetry/

0 notes

Text

Three-axis rotary machining with Arduino

For many years CNC machining was the purview of well-equipped shops and manufacturing facilities. With the availability of inexpensive control hardware, such as Arduino-based GRBL packages, this type of control has come to the (technically inclined) masses, enabling us to create complicated 2D and 3D shapes automatically.

Normally, this means X, Y, and Z axes that control a cutting head, and if you wanted to much further in complexity and cost, you could add a fourth or even a fifth axis to tilt things as needed. The RotoMill, however, seen at World Maker Faire in New York, puts a different “spin” on things, substituting a stepper-controlled spindle for the Y axis. The result is a machine with unique machining capabilities, driven by an Arduino Uno running custom GRBL firmware.

As for now, the CNC can easily mill parts out of softer materials like plastic, wood, and foam, although it is designed to cut aluminum as well.

A three-axis rotary CNC built for the Mechanical Engineering senior design capstone course at Carnegie Mellon University by a team of engineering students. The CNC uses NEMA24 motors for each of the axes, with the X and Z axes actuated by lead screws, and the A (rotary) axis actuated by a worm gear. The spindle is an off-the-shelf Makita hand router, which allows for any router bit to be used.

Each motor is controlled by a stepper motor driver, which are all coordinated by an Arduino Uno running a customized version of the GRBL firmware. This is in turn controlled by a laptop running open-source GCode sending software.

To generate the GCode, we would create a 3D model of the part that we wanted to machine. We then “unwrapped” about the A axis. This basically takes the part and converts it from Cartesian coordinates to Cylindrical coordinates.

To generate the GCode, we would create a 3D model of the part that we wanted to machine. We then “unwrapped” about the A axis. This basically takes the part and converts it from Cartesian coordinates to Cylindrical coordinates.

At this point, we could take the unwrapped part and load it into Autodesk HSM, a popular industrial CAM package. This allowed us to generate a toolpath for machining the part. We basically “fooled” the CNC into thinking that it was a normal, three-axis Cartesian CNC. The trick, however, is that the Y axis is wrapped around and becomes the A axis.

Additional information and photos can be found on RotoMill’s page or Hackaday’s recent write-up.

Three-axis rotary machining with Arduino was originally published on PlanetArduino

0 notes

Text

Vivo NEX launched in India with Snapdragon 845, pop-up digital camera and no notch

The Vivo NEX turned into launched in China final month as the evolution of the Vivo Apex idea phone. The telephone makes use of a popup digital camera, and has a close to bezel-less show and not using a notch. In China, Vivo launched two versions of the NEX: the Vivo NEX S and the Vivo NEX A. This month, the employer introduced that the telephone would be available in extra markets, and now, the agency has launched the Vivo NEX S in India. The telephone is really called the Vivo NEX inside the united states, due to the fact the NEX A (powered by way of the Qualcomm Snapdragon 710) has not been brought to India.

The Vivo NEX S (we can seek advice from it as the Vivo NEX henceforth) is powered by using the Qualcomm Snapdragon 845 system-on-chip, and has 8GB of RAM paired with 128GB of garage. Its complete listing of specifications are cited beneath:

Vivo NEX – specifications at a look

Vivo NEX (Vivo NEX S)SpecificationsDimensions and weight162 x seventy seven x 7.98 mm, 199gSoftwareAndroid eight.1 Oreo with FunTouch OS 4SoCOcta-core Qualcomm Snapdragon 845 (4x Kryo 385 cores Gold cores clocked at 2.8GHz + 4x Kryo 385 Silver cores clocked at 1.8GHz); Adreno 630 GPURAM and storage8GB of RAM with 128GB of storageBattery4,000mAh; 22.5W speedy chargingDisplay6.59-inch full HD+ (2316×1080) AMOLED with 19.three:9 issue ratioConnectivityWi-Fi 802.11ac, Bluetooth 5.0PortsUSB type-C port, twin nano SIM slots, 3.5mm headphone jackBandsGSM: 850/900/1800/1900MHz

WCDMA: 850/900/1700/1900/2100MHz

FDD-LTE: Bands 1/2/three/four/5/7/8/12/17/18/19/20/25/26/28

TDD-LTE: Bands 34/38/39/40/41Rear camera12MP number one camera with 1/2.five″ sensor size, 1.4μm pixel length, twin Pixel autofocus, f/1.8 aperture, four-axis OIS, dual-tone LED flash

5MP depth sensing camera with f/2.four aperture

Video recording as much as 4K at 30fpsFront-facing cameraPopup 8MP with f/2.0 aperture

The Vivo NEX, just like the Oppo discover X, is a exceptional form of smartphone. On one hand, it’s legitimately marvelous to see Vivo evolve the Apex idea phone right into a complete-fledged product that consumers should buy. It have to be referred to that the 2 products aren't the identical; the design of the completed NEX cellphone is barely specific than the Apex, and rather of having 1/2-display fingerprint scanning tech, the NEX’s in-show fingerprint sensor (extra on this beneath) works most effective in a selected location at the display.

The USP of the Vivo NEX stays its popup front-dealing with camera, and the shortage of a notch. The agency became able to attain the notch-less design by means of eliminating the earpiece in choose of a piezoelectric speaker machine, and going for a popup the front digicam. Vivo phrases the piezoelectric speaker device as display screen SoundCasting era, because it vibrates the show glass itself. A teardown of the phone has shown that the popup front digital camera has a spring and a spiral stepper motor that propels it upward/downward. It’s an innovative mechanism, to make certain. but, concerns nonetheless continue to be approximately sturdiness, because the popup camera uses mechanical transferring parts.

The Vivo NEX is also the 1/3 Vivo cellphone to use an in-show fingerprint sensor, the primary and 2d being the Vivo X20 Plus UD and the Vivo X21 respectively. In-show fingerprint sensors are nonetheless a rarity in the Android global. The Oppo discover X, alternatively, makes use of a three-D dependent light answer for 3-d face unencumber.

Vivo additionally states that the cellphone uses a new cooling solution as a way to assist maintain it cool even at some stage in lengthy gaming answers. greater info weren’t supplied, lamentably.

0 notes

Text

High Power CNC Wood Router Machine Price In China

CNC router machine is CNC wood router related to the hand-held router by computer-controlled. And it is always be used for engraving various materials, such as wood, Acrylic, PVC board, MDF, marble, rubber board, plastics, glass, and foams, crystal, etc. Relying on the advantages of complete types, wide application range, complete functions, high processing accuracy, fast production efficiency, and simple operation, wood engraving machines are loved by more and more users. In addition to the large demand in the domestic market each year, more CNC wood router are exported to various foreign countries.

Feature of CNC Wood Router:

igoldencnc cnc adopt most suitable spare parts for users from different countries for convenient use & maintenance, and finished machine is strictly customized, humanized design of cnc protect the safety of the operator. This classic three-axis woodworking engraving machine is very suitable for users who operate the CNC router for the first time. It is easily operated by DSP control with handle, machine does not need to be connected to computer separately and working speed is faster than mach3. If users do not need to engrave complex patterns or frequently change different tools, and need machine carve on various materials like wood or soft metal, this is an ideal choice with economic cost.Price:3355-4355$

📷

The design and layout are carried out through the special engraving machine software configured in the computer. The computer automatically transmits the design and layout information to the engraving machine controller, and then the controller converts the information into a belt that can drive a stepper motor or a servo motor. The power signal (pulse train) controls the host of the engraving machine to generate the XYZ three-axis engraving path.

The advantages of CNC wood router:

High degree of automation

Consistent quality

High productivity

Processing complex shape

Easy to implement CAD/CAM

2D, 2.5D and 3D capable

X, Y Axis Working Areamm1300*2500/ 1500*2500/1500*3000/ 2000*3000/ 2000*4000Z Axis Working Heightmm200Positioning Accuracymm0.05Re-positioning Accuracymm0.02Body Structure Welding BodyX, Y Axis Structure Linear Guide Rail, Gear RackZ Axis Structure Linear Guide Rail, Ball ScrewMax. Running Speedmm/min50000Max. Working Speedmm/min20000Spindlekw4.5kw Air-cooling Spindle(Optioned)Spindle RPMrpm/min24000Working VoltageV/HzAC 220V/ 380V, 50-60HzMachine Weightkg1400/1700/1900/2200/2500*Some specifications support customization, please contact us

CNC Wood Router Application:

1. Craft & gift industry: engrave various word or graph on the souvenir and handicraft, ironwork engraving, dials.

2. Advertising industry: engrave and cut various signboards, marble, copper, character mold, font. And various metal sign, brand.

3. Wood working industry: mainly used in redwood classical and antique furniture, wood carving, gifts wooden box ,redwood jewelry boxes, ink-stone cutting, decorative products sculpture, fine jewelry carving.

4. Model industry: company plate, signs, building models, emblem, badge, display panels, fair signs, building numbers, signs of decoration, shoes, badge, embossed mould, biscuit, candy, chocolate mould.

5. Other lines: also used in portraits, landscapes, calligraphy lettering, seal carving and other plane surface carving, basso-relievo.

Heavy duty frame milling and drilling by machining center to keep high accuracy.

0 notes

Text

Proses Machining CNC SME

Jika anda ingin mengetahui Proses Machining CNC SME Medan, Hubungi kami di 08116562065

Mesin CNC adalah proses pembuatan di mana perangkat lunak komputer yang telah diprogram menentukan pergerakan alat dan mesin pabrik. Prosesnya dapat digunakan untuk mengendalikan berbagai mesin yang kompleks, mulai dari penggiling dan mesin bubut sampai pabrik dan router. Dengan mesin CNC, tugas pemotongan tiga dimensi dapat dilakukan dalam satu set perintah.

Pendek untuk "kontrol numerik komputer," proses CNC berjalan berlawanan dengan - dan dengan demikian menggantikan - keterbatasan kontrol manual, di mana operator live dibutuhkan untuk meminta dan membimbing perintah alat pemadam melalui tuas, tombol dan roda. Bagi penonton, sistem CNC mungkin menyerupai seperangkat komponen komputer biasa, namun program perangkat lunak dan konsol yang digunakan di mesin CNC membedakannya dari semua bentuk perhitungan lainnya.

Hal-hal untuk Belajar Tentang CNC Machining

Ketika sistem CNC diaktifkan, pemotongan yang diinginkan diprogram ke dalam perangkat lunak dan didikte ke alat dan mesin yang sesuai, yang melakukan tugas dimensi seperti yang ditentukan, sama seperti robot.

Dalam pemrograman CNC, generator kode dalam sistem numerik akan sering menganggap mekanisme tidak sempurna, terlepas dari kemungkinan kesalahan, yang lebih besar setiap kali mesin diarahkan untuk memotong lebih dari satu arah secara bersamaan.Penempatan alat dalam sistem kontrol numerik digariskan oleh serangkaian masukan yang dikenal sebagai program part.

Dengan mesin kontrol numerik, program dimasukkan melalui kartu punch. Sebaliknya, program untuk mesin CNC diumpankan ke komputer meski ada keyboard kecil. Pemrograman CNC disimpan dalam memori komputer. Kode itu sendiri ditulis dan diedit oleh pemrogram. Oleh karena itu, sistem CNC menawarkan kapasitas komputasi yang jauh lebih ekspansif. Yang terbaik, sistem CNC sama sekali tidak statis, karena petunjuk yang lebih baru dapat ditambahkan ke program yang sudah ada melalui kode yang telah direvisi.

PEMROGRAMAN MESIN CNC

Di CNC, mesin dioperasikan melalui kontrol numerik, dimana sebuah program perangkat lunak ditujukan untuk mengendalikan suatu objek. Bahasa di balik mesin CNC bergantian disebut kode G, dan ditulis untuk mengendalikan berbagai perilaku mesin yang sesuai, seperti kecepatan, laju umpan dan koordinasi.

Pada dasarnya, mesin CNC memungkinkan untuk melakukan pra-program kecepatan dan posisi fungsi alat mesin dan menjalankannya melalui perangkat lunak dalam siklus berulang dan dapat diprediksi, semuanya dengan sedikit keterlibatan dari operator manusia. Karena kemampuan ini, prosesnya telah diadopsi di seluruh pelosok sektor manufaktur dan sangat penting di bidang produksi logam dan plastik.

Sebagai permulaan, gambar CAD 2D atau 3D dikandung, yang kemudian diterjemahkan ke kode komputer agar sistem CNC dijalankan. Setelah program dimasukkan, operator memberikannya uji coba untuk memastikan tidak ada kesalahan yang ada dalam pengkodean.

Open / Closed-Loop Machining Systems

Kontrol posisi ditentukan melalui sistem loop terbuka atau loop tertutup. Dengan yang pertama, sinyal masuk dalam satu arah antara pengendali dan motor. Dengan sistem loop tertutup, pengendali mampu menerima umpan balik, yang membuat koreksi kesalahan mungkin terjadi. Dengan demikian, sistem loop tertutup dapat memperbaiki penyimpangan dalam kecepatan dan posisi.

Pada mesin CNC, gerakan biasanya diarahkan ke sumbu X dan Y. Alat ini, pada gilirannya, diposisikan dan dipandu melalui motor stepper atau servo, yang meniru gerakan yang tepat seperti yang ditentukan oleh kode-G. Jika gaya dan kecepatannya minimal, prosesnya bisa dijalankan melalui kontrol loop terbuka. Untuk segala hal lainnya, kontrol loop tertutup diperlukan untuk memastikan kecepatan, konsistensi dan akurasi yang dibutuhkan untuk aplikasi industri, seperti logam.

Untuk info lebih lanjut tentang Proses Machining CNC SME Kunjungi Website kami.

Info sebelumnya : https://sinartechmultiperkasa.tumblr.com/post/165540176225/perusahaan-fabrikasi-vessel-medan

sumber: http://bengkelbubutmedan.weebly.com/bengkel-bubut-area-medan/proses-machining-cnc-sme9733223 PT. SINARTECH MULTI PERKASAJl. Primer No.12 Pasar 9 Helvetia. Medan, Medan Sumatera Utara, IndonesiaTelepon: (061) 42068877 Hp / WA: 08116562065/08116062065 / 0853-2020-2054 Faks: (061) 42068877Email: [email protected] Situs web: http://www.sinartechmultiperkasa.co.id Situs web: https://detradingindo.co.id Situs web: https://www.workshop.myartikel.com Facebook: https://www.facebook.com/sinartechmultiengineering https://web.facebook.com/Pt- Sinartech -Multi-Perkasa-191290628133892 /Kami PT. Sinartech Multi Perkasa menerima Jasa Konstruksi Sipil yang Dibagikan:§ Jasa Bangun Rumah§ Jasa Bangun Gedung§ Jasa Bangun Jembatan§ Jasa Bangun Jalan Raya§ Jasa Bangun Drainase§ Jasa Bangun Bendungan§ Jasa Bangun Waduk§ Jasa Bangun Apartemen§ Jasa Bangun Pabrik§ Jasa Bangun Ruko§ Jasa Bangun Gudang§ Jasa Bangun Pabrik§ Hotel Jasa Bangun§ Vila Jasa Bangun§ Jasa Bangun Cafe§ Jasa Bangun Gedung Olahraga§ Jasa Bangun Taman§ Jasa Bangun Kolam§ Jasa Bangun Joglo§ Jasa Bangun Pondasi§ Jasa Bangun Atap§ Jasa Bangun Tangga§ Jasa Bangun Lantai§ Jasa Konstruksi Baja§ Jasa Konstruksi Beton§ Jasa Konstuksi Baja Ringan dan Lainnya.Jenis Ruang Lingkup Pekerjaan Meliputi:§ PekerjaanBumi§ Basis Jalan§ Kursus Dasar Jalandengan batu pecah§ Kursus Basis Jalan dengan CBT / Cement Treated Base§ Pekerjaan Aspal / Campuran Panas§ Aspal Cold Mix§ Hot Mix dengan Aspal Normal§ Hot Mix Dengan Modifikasi Bitumen (Multi Grade dan Modifikasi Bitumen Polimer)§ Segel Bubur§ Perkerasan Kaku§ Konstruksi Jembatan§ Chipseal Dengan Bitumen Yang DimodifikasiJasa layanan kontraktor pengaspalan jalan, konstruksi jalan, pemasangan paving block, pengecoran jalan beton hot mix.Jasa Layanan Pekerjaan Meliputi Pekerjaan Pengaspalan Jalan Aspal Hotmix untuk:1. Halaman Rumah2. Halaman Sarana Pengisian Bahan Bakar (SPBU)3. Area Parkir Perkantoran4. Area Parkir Rumah Sakit5. Area Parkir Ruko6. Area Parkir Pabrik dan Gudang7. Mal Area Parkir8. Jalan MHT9. Pengaspalan Ex. Galian Kabel10. Jalan Raya11. Jalan Lingkungan / Perumahan / Komplek dan sebagainya Kami juga menerima Pemesanan di Wilayah Kota Medan, PekanBaru, Palembang, Jambi, Aceh dan Dihadiri.

0 notes

Text

CO2 Laser Cutting Engraving Machines,OEM factory

CO2 Laser Cutter & Engraving Machines, CO2 Laser Cutting Machines and Engraving Machines ideal for Industry and Education - for cutting / engraving materials such as acrylics, woods, paper/card, fabrics and more.Suitable for cutting a variety of sheet metal, cut smooth, no burr. Inexpensive laser cutting machines, the preferred machine for metal processing.

Do you have a thought to buy a reliable Laser Engraver? Browse the 2020 new best laser engraver buyer’s guide as follows, we’ll provide you with the competitive laser engravers with expert customer service to satisfied your requirements.

Large Size CO2 Laser Cutting Machine Large Size CO2 laser cutting machine, the standard worktable size is 1300*2500, equip with 180w/260w/300w laser tube, satified the engraving and cutting requirements of large plate such as S.S sheet, C.S sheet, wood sheet, acrylic sheet and so on.

FLATBED CO2 LASER ENGRAVING MACHINE Cutting bed type CO2 engraving machine, the standard worktable size is 1325, which can meet the engraving and cutting needs of large-format panels such as wood and acrylic.

PROTECTIVE CO2 LASER ENGRAVING MACHINE The most common CO2 engraving machine, the standard worktable size is 1390 and 1610, equipped with 40-150w laser tube, in line with European CE certification, a wide range of applications.

How Much Does A Laser Engraver Cost?

Pricing Guide If you have an idea to buy a cheap laser engraver, you may wonder how much does it cost? how to get a fair price or final price? The laser engraving machine cost is composed of the following items: 1. spare parts. 2. software and system. 3. tax rates. 4. shipping costs. 5. customs clearance. 6. service and technical support. A fiber laser engraver cost is from $3,000.00 to 28,500.00. A CO2 laser engraver cost is from $2,400.00 to 70,000.00. An UV laser engraver cost is from $10,000.00 to 30,000.00.

Laser engraver is a kind of laser machine with CNC (Computer Numerical Control) system that adopts Fiber/UV/CO2 laser beam to engrave 2D/3D letters, numbers, texts, patterns, photos, pictures, signs or logos on the surface of Metals (steel, copper, brass, aluminum, gold, silver, alloy, iron), Acrylic, Delrin, Glass, Rubber, Wood, Fabric, Plastic, Leather, Paper, Stone, Textiles.

A laser engraver machine is composed of machine frame, CNC controller, laser generator, laser head for CNC engraving, laser power supply, laser tube, laser lens, laser mirror, servo motor or stepper motor, gas storage tank, gas cylinder, water chiller, dust extractor, air cooling filer, dryer, air compressor, laser engraving software and system. Laser engraving machine is also called as laser engraver, laser engraver machine, laser engrave machine, laser etching machine, laser etch machine, laser etcher, laser etcher machine, laser stippling machine, laser engraving system, laser engraving table, laser engraving equipment, laser engraving tool, laser branding machine, laser printing machine.

What Are The Differences Between Laser Engraving Machine And Laser Marking Machine?

1. Different Definition. Laser marking machine uses a laser beam to evaporate the surface material to expose the deep material, which leads to chemical changes in the surface material and physical changes to engrave marks, or to burn part of the material through light energy to show the desired etching pattern and text. Laser engraving machine is a laser device that uses laser beam to engrave and cut the material that needs to be engraved. It is also called laser cutting machine, laser etching machine and more. Unlike mechanical engraving machine, it uses laser heat energy to engrave materials.

2. Different Application Material. Laser engravers are generally used for engraving or cutting non-metallic materials. Laser marking machines are generally not used for deep engraving. It only needs to engrave the logo content. It can mark on most metal and non-metal materials.

3. Different Depth & Speed. Laser engraving system can engrave on a large stroke size, and it can also cut, the engraving depth is far greater than that of the laser marking system; The speed of the laser marker is much faster than the laser engraver, and generally can reach 5000 mm/s - 7000mm/s.

4. Different Laser Generator and Price. The optical path system of the laser engraver machine is composed of three reflective lenses and a focusing lens. The laser is generally a carbon dioxide glass tube. However, there are many types of laser generators in laser marking machines, including fiber laser generators, CO2 laser generators, UV laser generators, and so on. The price of laser marking machine is different due to different models and materials, and the price ranges from tens of thousands to hundreds of thousands; Low-power laser engraving systems for cutting non-metallic materials are much cheaper than laser marking systems, but high-power laser is also more expensive.

0 notes

Text

New Post has been published on Myupdatestudio

New Post has been published on https://myupdatestudio.com/the-strength-of-software-program-motors-and-movement-tracking/

The strength of software program, motors, and movement tracking

Gambling darts is tough. Reliably hitting a bull’s-eye calls for exercise, ability, and some severe hand-eye coordination to drag off, something that can take a lifetime to certainly a master. Or, you could do what former NASA-engineer-grew to become-famous-YouTuber Mark Rober did, and build a custom dartboard gadget that may song a dart through the air and flawlessly position itself to allow the dart hit a bull’s-eye no matter where it’s thrown, as spotted by Gizmodo. To paraphrase Francis Publisher 1st baron Verulam: if the dart might not come to the bull’s-eye, then the bull’s-eye must visit the dart.

Software Program

Of direction, clearly constructing an appropriate computerized dartboard took Rober over three years of work to put together. In the video, Rober describes the two parts to setting the task together: tracking the darkish to expect exactly where it’s going to land and transferring the dartboard to be there to capture it.

In step with Rober, the average dart throw takes about 400 milliseconds to journey from the regulation throwing distance to the board. In that point, a six-digicam Vision movement seizes system tracks the dart the usage of IR LEDs that leap off tiny unfashionable-reflectors attached to the dart, determining the exact location of the dart in 3D area. Then, the usage of a few physics equations, the trajectory of the dart may be calculated to determine out precisely wherein the dart will hit.