#optical device turned components manufacturers

Explore tagged Tumblr posts

Text

Summary Analysis of CNC Milling Process

In modern manufacturing, CNC milling technology is widely used for its high precision and flexibility. Whether it's a mechanical part, an automotive component, or a component for a medical device, CNC milling provides excellent machining results.

What is CNC Milling?

CNC milling is a computer-controlled machining process that utilises a rotating tool to cut a workpiece. CNC milling allows for greater accuracy and consistency than traditional manual milling. It is often combined with other machining methods (e.g. turning, drilling) to meet different and diverse manufacturing needs.

Workflow of CNC Milling

Design stage In the initial stages of CNC milling, designers use Computer-Aided Design (CAD) software to create a model of the product. Commonly used software includes SolidWorks and Autodesk, which are tools that help designers accurately draw the shape and dimensions of the desired part.

Programming stage Once the design is complete, the CAD file needs to be converted to G-code, a language that CNC machines can understand. With Computer-Aided Manufacturing (CAM) software, the design files are converted into machine-executable instructions that enable automated machining.

Machine setting During the machine set-up phase, the workpiece needs to be fixed to the table and a suitable tool selected. At the same time, the operator needs to set the initial co-ordinates to ensure accurate positioning during machining.

Advantages of CNC Milling

High precision and dimensional stability CNC milling allows for micron-level machining accuracy, ensuring consistency from part to part.

Complex shapes can be processed Whether it's a simple flat surface or a complex three-dimensional structure, CNC milling can handle it with ease.

Efficient production capacity Due to its high degree of automation, CNC milling can significantly increase productivity and shorten lead times.

Applications of CNC Milling

CNC milling technology is used in a wide range of industries, including:

Mechanical parts: Used in the manufacture of key components in a variety of mechanical equipment.

Automotive parts: High-precision parts for the automotive industry, such as engine components.

Medical device parts: Ensure the reliability and safety of medical devices.

Optical product parts: For the production of optical instruments and related products.

Frequently Asked Questions

What materials can be CNC milling machined? CNC milling is suitable for a wide range of materials, including metals (e.g. aluminium, steel), plastics, wood, and more. However, for some materials, such as ceramics or certain composites, the machining is more difficult and requires special handling.

What are the limitations of CNC milling? Despite its advanced technology, CNC milling has some limitations. For example, machining may be limited for internal vertical angles or very complex small structures.In addition, high hardness materials may lead to faster tool wear, which can affect productivity.

Comparison of CNC milling with other manufacturing technologies The advantages and disadvantages of each can be seen when comparing CNC milling with other manufacturing techniques such as 3D printing. CNC milling is generally superior to 3D printing in terms of accuracy and surface finish, but 3D printing has advantages in rapid prototyping and complex geometries. In terms of cost-effectiveness, the choice of technology depends on specific project needs and budget.

Summary

In summary, CNC milling is an indispensable manufacturing technology that plays an important role in several industries with its efficiency, precision and flexibility.

#prototyping#prototype#rapid prototyping#prototype machining#precision machining#cnc machining#cnc milling#machining parts#cnc milling 5 axis#cnc milling machining#cnc milling turning#precision cnc milling#cnc milling parts

2 notes

·

View notes

Text

3D printing precisely: Low-cost error compensation for fabrication of high-precision microstructures

In today's fast-paced technological landscape, the proverb "the bigger the better" was turned upside down and a race to make everything smaller has started. From miniature optical components to micro-scale medical devices, the quest for creating ever smaller yet more intricate structures has led to remarkable progress in a wide range of fields. An important manufacturing technique enabling these advancements is two-photon polymerization (TPP) 3D printing. However, especially in the field of micro-optics, even errors in the nanometer range can have significant consequences. Thus, it is essential to understand and compensate for as many systematic errors in the printing process as possible. Research recently published in the Journal of Optical Microsystems delves into the critical challenge of correcting tilt and curvature errors in TPP printing.

Read more.

11 notes

·

View notes

Text

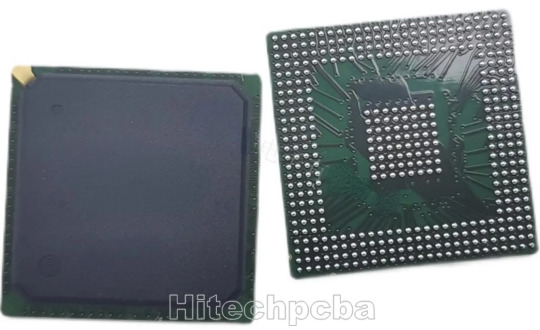

BGA PCB Assembly

What’s BGA PCB?

BGA PCB is Printed Circuit Boards with Ball Grid Array. We use various sophisticated techniques for making BGA PCBs. Such PCBs have a small size, low cost, and high packaging density. Hence, they are reliable for high-performance applications.

What’s BGA PCB Assembly?

Ball Grid Array (BGA) assembly technology is a surface mount packaging technology applied to integrated circuits, which is often used to permanently fix devices such as microprocessors. BGA assembly can accommodate more pins than other packages such as Dual in-line packages or Quad Flat Packages, and the entire bottom surface of the device can be used as pins , instead of only peripherals available, and also have a shorter average wire length than peripheral-limited package types for better high-speed performance.

Our BGA assembly services cover a wide range, including BGA prototype development, BGA PCB assembly, BGA component removal, BGA replacement, BGA rework and reballing, BGA PCB assembly inspection, and so on. Leveraging our full-coverage services, we can help customers streamline the supply network and accelerate product development time.

Benefits of BGA PCB Assembly

Efficient Use of Space – BGA PCB layout allows us to efficiently use the available space, so we can mount more components and manufacture lighter devices.

Better Thermal Performance – For BGA, the heat generated by the components is transferred directly through the ball. In addition, the large contact area improves heat dissipation, which prevents overheating of components and ensures long life.

Higher Electrical Conductivity – The path between the die and the circuit board is short, which results in better electrical conductivity. Moreover, there is no through-hole on the board, the whole circuit board is covered with solder balls and other components, so vacant spaces are reduced.

Easy to Assemble And Manage – Compared to other PCB assembly techniques, BGA is easier to assemble and manage as the solder balls are used directly to solder the package to the board.

Less Damage to Leads – We use solid solder balls for manufacturing BGA leads. Hence, there is a lesser risk that they will get damaged during the operation.

In a word, BGA PCB assembly, have these advantages, high density, better electrical conductivity, lower thermal resistance, easy to assembly & manage are some of the advantages of BGA PCB.

Stringent BGA PCB Assembly Testing Process

To achieve the highest quality standards for BGA assembly, we use a variety of inspection methods throughout the process including optical inspection, mechanical inspection, and X-ray inspection. Among them, the inspection of BGA solder joints must use X-rays. X-rays can pass through the components to inspect the solder joints below them, so as to check the solder joint position, solder joint radius, and solder joint thickness.

Inspection of BGA PCB

We mostly use X-ray inspection for analyzing the features of BGA PCBs. This technique is known as XRD in the industry and relies on X-rays for unveiling the hidden features of this PCB. This kind of inspection reveals.

* Solder Joint Position

* Solder Joint Radius

* Change in Circular shape

* Solder Joint Thickness

The Hitechpcba advantage lies in a whole range of aspects, beginning from the fact that we have the proven technology available at our disposal. With over 15 years of experience in a wide range of PCB Fabrication and Assembly techniques, what we also have is trained manpower and importantly, robust industry experience and best practices that you can benefit from.

Our unstinting devotion to quality and customer satisfaction means that once you partner with us, you can rest assured that you will get nothing but the best. The customer-oriented approach also shows up in your commitment to delivery times. With quick turnaround times, you can reap the benefit of quick time-to-market, which, in turn, can be a major source of competitive advantage.

Whether your requirement is BGA PCB design, BGA PCB, BGA PCB layout, BGA PCB Assembly or BGA rework, you can rest assured that you will get superior quality and performance, that will in turn, positively impact the performance of your final product.

With our efficient network of component suppliers and the many economies of scale that we enjoy, that you will get optimal costs, is a given.

Please feel free to contact us ([email protected]) if you have any other special request on the BGA pcb assembly.

3 notes

·

View notes

Text

Electronics manufacturing trends to pay attention to in years to come

Despite the pandemic-induced economic slowdown, technological advancements played a significant role in the growth of the electronics manufacturing sector. Smarter manufacturing practices have been the biggest driver of this growth. We intend to explore five trendsetting developments in this article today.

Internet of Things The electronics manufacturing industry can leverage the Internet of Things (IoT) for unprecedented growth opportunities. The IoT allows electronic manufacturing units to be digitally connected while storing and processing information without external support. The IoT can improve efficiency, security, cost-effectiveness, and product innovation. Cloud computing, smaller censors, and the growth of the Internet have prompted IoT’s lead in the race of emerging technologies. With everything in place, you can have real-time data at your fingertips to make informed business decisions.

Automation While complete automation in the electronics manufacturing sector is still a distant dream, various automation technologies have made production trouble and error-free. These technological advancements in automation includes smart factories, manufacturing robots, and the smart supply chain management system. These automation systems in conjunction with IoT devices create an efficient manufacturing operation. Innovative supply chain As businesses strive for better products and spend less while doing so, the best way forward is to innovate supply chain management. This trend aims at improving the logistics to revamp the supply chain, which, in turn, can significantly reduce costs in several key areas. This allows electronics manufacturers to be more agile in their operations and thus be more open to fluctuating market demands.

Predictive maintenance Any manufacturing company’s smooth operation is entirely dependent on its types of equipment. Because if they break down the entire operation comes to a halt and so will your revenue generation. However, using AI and IoT data collection, you can accurately identify problem areas before they happen. This helps electronic manufacturers avoid downtime and plan maintenance at a convenient time. Identify a cost-effective manner to conduct repairs and include the same in your budget. A trend like predictive maintenance removes any scope of surprise downtime, thus improving the efficiency of your manufacturing operations.

Organic electronics Organic electronics has become a market rage in recent times owing to its efficiency, low cost, flexibility, lightweight, indissoluble nature, and optical transparency. Additionally, the demand for environmentally friendly production and sustainable development is growing, prompting electronic manufacturers to choose organic electronics. One of the most significant trends in electronics production is the creation of gadgets using biodegradable and recyclable materials or designing circuits with microbial components. The use of organic materials in producing electronic devices also permits the use of safer and readily accessible raw materials. As a result, it gives organizations new business opportunities, while being environmentally responsible.

The electronic manufacturing trends discussed in this article pave a path for smarter, efficient, and cost-effective practices. The use of advanced technology and materials can help you achieve this. Apart from the five trends discussed here, we'd also like to mention printed electronics, Artificial Intelligence, immersive technology, and 3D printing. These evolving technologies only point to a brighter future. For more information on the electronics manufacturing process, get in touch with the experts at Radiant Appliances & Electronics.

#manufacturing#led tv manufacturing#smart tv#led tv manufacturers in india#Home appliances manufacturers in India#TV Manufacturing Company#Radiant Appliances & Electronics#Televisions We Manufacture#Smart LED Televisions

2 notes

·

View notes

Text

High-Quality Turnkey PCB Assembly – Your Complete Solution

In the fast-evolving electronics industry, businesses need efficient, reliable, and cost-effective PCB board assembly services to transform their designs into functional products. Whether you're a startup developing a new gadget or an established company scaling production, turnkey PCB assembly provides a seamless, end-to-end solution that simplifies the manufacturing process while ensuring top-tier quality.

What is Turnkey PCB Assembly?

Turnkey PCB assembly is a fully integrated service where a single provider manages every stage of PCB production—from initial design verification and component procurement to assembly, testing, and final delivery. This all-inclusive approach eliminates the hassle of coordinating with multiple vendors, reducing lead times and minimizing potential errors.

Why Choose Turnkey PCB Assembly?

1. Comprehensive One-Stop Solution

A high-quality turnkey PCB assembly service handles:

PCB fabrication – Manufacturing the bare board according to specifications.

Component sourcing – Procuring high-quality parts, including hard-to-find or obsolete components.

PCB assembly – Surface-mount (SMT) and through-hole (THT) assembly with precision.

Testing & inspection – Automated Optical Inspection (AOI), X-ray testing, and functional checks.

Final packaging & shipping – Ensuring secure and timely delivery.

2. Faster Time-to-Market with Quick-Turn Services

Quick-turn PCB assembly accelerates production, allowing businesses to meet tight deadlines without sacrificing quality. This is especially beneficial for prototyping and low-volume runs where speed is critical.

3. Cost Efficiency & Reduced Overhead

By consolidating all processes under one provider, companies save on logistics, supplier management, and bulk purchasing costs. Turnkey services also reduce the risk of delays caused by supply chain disruptions.

4. Superior Quality & Reliability

Reputable turnkey assembly providers use advanced inspection techniques (AOI, X-ray, ICT) to detect defects early, ensuring high yield rates and long-term reliability.

5. Scalability for Any Production Volume

Whether you need 10 prototype boards or 10,000 mass-produced units, turnkey services adapt to your requirements, offering flexibility without compromising quality.

Key Industries Served by Turnkey PCB Assembly

Turnkey assembly supports a wide range of industries, including:

Consumer Electronics – Smartphones, wearables, smart home devices.

Automotive – Engine control units (ECUs), infotainment systems, ADAS.

Medical Devices – Diagnostic equipment, patient monitoring systems.

Industrial Automation – Robotics, motor controllers, power supplies.

Aerospace & Defense – Avionics, communication systems, radar technology.

The Future of Turnkey PCB Assembly

As electronics become more complex, the demand for high-quality turnkey PCB assembly continues to grow. Emerging trends include:

Miniaturization – Smaller, high-density PCBs for compact devices.

IoT & Smart Technology – Increased need for flexible, low-power PCBs.

Automation & AI Integration – Smarter manufacturing with AI-driven quality control.

Final Thoughts

For businesses looking for a streamlined, efficient, and high-quality turnkey PCB assembly solution, partnering with the right manufacturer is key. Quick turn PCB assembly services enable faster prototyping and production, while the turnkey model reduces complexity and cost.

By selecting an experienced PCB assembly service provider, companies can focus on innovation while leaving the manufacturing challenges to the experts. Whether you're launching a new product or scaling production, turnkey PCB assembly offers the complete solution—delivering precision, speed, and reliability from concept to final product.

Need a trusted turnkey PCB assembly partner? Choose a provider that combines expertise, advanced technology, and exceptional customer service to bring your electronic designs to life seamlessly.

0 notes

Text

Polycarbonate Market to Surpass $35.6 Billion by 2035, Driven by Automotive and Construction Demand

April 2025 | DataString Consulting Polycarbonate Market Research Report ➝

The global polycarbonate market is poised for significant expansion, with revenues projected to climb from $22.4 billion in 2024 to $35.6 billion by 2035, according to recent findings from DataString Consulting. Key growth drivers include rising adoption in automotive, construction, electronics, and aerospace sectors.

In the automotive industry, polycarbonate’s lightweight, durable, and impact-resistant properties are helping manufacturers meet strict environmental and safety regulations. Components such as headlamp housings, panoramic roofs, and side windows increasingly use polycarbonate to enhance fuel efficiency and occupant protection.

Meanwhile, in the construction sector, polycarbonate sheets are gaining ground in applications such as skylights, greenhouses, and curtain walls. Their UV resistance, thermal insulation, and optical clarity make them ideal for energy-efficient building design.

“With innovation in advanced polycarbonate blends and a push for bio-based alternatives, this market is at a turning point,” says the report.

Key Industry Strategies

CompanyStrategic FocusCovestroLightweight, durable polycarbonate for crash safety and green mobilityTrinseoFlame-retardant polycarbonate for appliances and electronicsSABICHigh-performance blends for aviation-grade applicationsTeijinTransparent, UV-resistant materials for architecture

Explore Market Scope:

Production Process: Phosgene-based, Non-phosgene-based

Type: Bisphenol A, Non-Bisphenol A

End-Use: Packaging, Medical Devices, Data Storage, Optical Media

Grade: Optical, Commercial

About DataString Consulting

DataString Consulting offers strategic market research and growth advisory across 15+ industries and 60+ sub-industries. From TAM expansion to revenue diversification, we deliver tailored insights to transform data into decision-ready strategies.

0 notes

Text

Efficient Trapezoidal Screw Production Solutions: Techniques & Technologies

Trapezoidal screws, often used in linear motion systems and mechanical actuators, are critical components in a wide range of industries—from automotive to aerospace and industrial machinery. Known for their robust design and efficiency in converting rotary motion into linear motion, the demand for high-quality trapezoidal screws has significantly grown. As a result, manufacturers are constantly seeking optimized and scalable trapezoidal screw production solutions.

This article covers everything you need to know about producing trapezoidal screws, including materials, machining technologies, threading techniques, quality assurance, and automation trends in 2025.

1. What is a Trapezoidal Screw?

A trapezoidal screw is a type of lead screw with a trapezoid-shaped thread profile, typically conforming to standards like ISO or DIN. Unlike square threads, trapezoidal threads offer better load distribution and are easier to machine, making them ideal for high-load, low-speed applications.

Common Applications:

CNC machine beds

Linear actuators

Presses and lifting devices

Industrial automation systems

2. Choosing the Right Materials

Material selection is crucial for durability, precision, and resistance to wear. Common materials include:

Carbon Steel: Cost-effective and strong, often used with surface hardening.

Stainless Steel: Excellent corrosion resistance, preferred for medical and food-grade applications.

Bronze or Brass: Common for nuts paired with steel screws to reduce friction and galling.

Plastic or Polymer Composites: For low-load, high-speed applications, especially where lubrication is a concern.

Key Considerations:

Operating temperature

Load requirements

Corrosive environments

Maintenance cycles

3. Production Methods and Machining Solutions

a. Turning and Thread Cutting

Traditional lathes and modern CNC turning centers are used for cutting the trapezoidal thread profile.

Single-point threading on CNC lathes ensures precision but is time-intensive.

Thread rolling is a faster, deformation-based process ideal for high-volume production.

b. Thread Milling

Thread milling offers flexibility, especially for internal threads or difficult-to-machine materials. It reduces tool wear and produces cleaner finishes.

c. Grinding and Finishing

Post-threading, precision grinding improves surface quality and dimensional tolerance. Centerless and cylindrical grinding methods are popular for finishing the screw shaft.

4. Thread Standards and Tolerances

Global standards such as ISO 2904, DIN 103, and ANSI/ASME B1.5 define dimensions, tolerances, and profiles for trapezoidal screws. Precision is key, especially in applications where backlash or misalignment can impact performance.

Pitch accuracy and lead deviation must be tightly controlled.

Use of coordinate measuring machines (CMMs) and thread gauges ensures compliance.

5. Heat Treatment and Surface Coatings

To enhance durability and wear resistance, manufacturers often apply:

Case hardening or nitriding

Black oxide coating for mild corrosion resistance

Zinc or nickel plating

Teflon or PTFE coating for smooth motion

Each treatment is selected based on environmental conditions and expected wear cycles.

6. Quality Control and Inspection

Precision is everything. Key quality assurance practices include:

Microscopic inspection of threads

Surface roughness measurement

Load and torque testing

Dimensional accuracy checks with optical comparators

Modern facilities integrate inline sensors and AI-driven quality monitoring systems to flag defects in real-time.

7. Automation in Trapezoidal Screw Production

In 2025, smart manufacturing is transforming screw production. Here’s how:

a. CNC Automation

Automated lathes and thread milling machines minimize human error and increase consistency.

b. Robotic Handling

Collaborative robots (cobots) are used for part loading/unloading, inspection, and material movement.

c. MES Integration

Manufacturing Execution Systems (MES) streamline production planning, track progress, and optimize workflows.

d. Digital Twin Technology

Simulations of production lines and tool paths reduce setup time and improve first-pass yield.

8. Custom Screw Design Capabilities

Many industries require non-standard trapezoidal screws with customized:

Lengths

Thread profiles

Shaft features (flats, keyways, undercuts)

Nut assemblies (anti-backlash, split nuts)

Modern CAD/CAM software enables rapid prototyping and seamless CNC code generation, allowing quick design-to-production cycles.

9. Cost-Saving Strategies

To stay competitive, manufacturers implement the following strategies:

Batch production for economies of scale

Tool wear monitoring to avoid defects

Lean manufacturing principles to reduce waste

Local sourcing of raw materials to minimize delays and cost

10. Sustainability and Environmental Practices

Eco-conscious manufacturing is gaining ground. Companies are:

Using recyclable materials

Recycling cutting fluids and coolants

Installing energy-efficient CNC machines

Adopting green certifications like ISO 14001

Conclusion

The production of trapezoidal screws involves a blend of precision engineering, material science, and modern manufacturing technology. As industries demand more efficient, customizable, and high-performance lead screws, manufacturers must adopt advanced production methods and digital tools to stay ahead.

Whether you’re an established manufacturer or entering the lead screw industry, investing in optimized trapezoidal screw production solutions is key to meeting market expectations in 2025 and beyond.

0 notes

Text

Precision Machined Components Manufacturers: Delivering High-Quality Engineering Solutions

Introduction to Precision Machined Components Manufacturers

The demand for precision machined components manufacturers has been steadily rising across industries such as aerospace, automotive, medical, and electronics. These manufacturers play a crucial role in producing high-accuracy parts essential for modern engineering applications. With cutting-edge CNC machining, multi-axis turning, and state-of-the-art milling techniques, these companies ensure the highest quality and consistency in their products.

Importance of Precision Machined Components Manufacturers in Various Industries

Precision machining is a key factor in industrial progress. Companies relying on precision machined components manufacturers benefit from extreme accuracy, high efficiency, and reduced material wastage. The production of intricate components with tight tolerances ensures the proper functioning of advanced machinery and equipment.

Aerospace Industry

In aerospace, precision-machined parts are essential for aircraft engines, landing gear, and avionics. Manufacturers ensure that these components meet strict quality control standards, as any deviation can compromise safety.

Automotive Sector

From engine parts to transmission systems, precision machining supports the automotive industry by producing durable and high-performance components that enhance fuel efficiency and vehicle longevity.

Medical Equipment Manufacturing

Precision-machined parts are critical in medical devices such as surgical instruments, prosthetics, and diagnostic equipment. High-quality materials and extreme accuracy are crucial for ensuring patient safety and treatment efficiency.

Electronics and Semiconductor Industry

Miniaturized precision components are vital in the electronics industry, where even the slightest imperfection can impact the performance of circuit boards and microprocessors.

Key Features of Leading Precision Machined Components Manufacturers

To stay competitive, top precision machined components manufacturers invest in the latest technology and adhere to strict quality assurance practices. Here are some essential features that define a leading manufacturer:

Advanced CNC Machining Capabilities

Computer Numerical Control (CNC) machining enables the production of complex components with unmatched precision. Manufacturers utilize multi-axis CNC milling and turning to achieve intricate geometries and tight tolerances.

High-Quality Materials and Finishing

Premium raw materials such as stainless steel, titanium, aluminum, and brass are used to manufacture precision components. Advanced surface finishing processes like anodizing, passivation, and powder coating ensure durability and corrosion resistance.

Strict Quality Control Standards

Quality control is a top priority for precision machined components manufacturers. Techniques such as Coordinate Measuring Machines (CMM), laser scanning, and optical inspection ensure every part meets industry standards and customer specifications.

Customization and Prototyping

Many manufacturers offer custom machining services and prototyping to cater to unique customer requirements. This helps industries develop new products and refine designs before mass production.

Advantages of Partnering with the Best Precision Machined Components Manufacturers

Choosing the right precision machined components manufacturers provides several benefits:

Enhanced Product Quality: Precision machining ensures consistent and defect-free components.

Cost-Effectiveness: Advanced technology reduces material waste and minimizes production costs.

Scalability: From small batches to large-scale production, top manufacturers offer flexibility.

Faster Lead Times: Efficient manufacturing processes result in quick turnaround times.

How to Choose the Right Precision Machined Components Manufacturer

Selecting a manufacturer requires careful consideration of several factors:

Experience and Expertise – Look for companies with a strong track record in precision machining.

Technology and Equipment – Ensure they use state-of-the-art CNC machines and quality control tools.

Material Selection – Verify their ability to work with a wide range of materials.

Certifications and Compliance – Check for industry certifications such as ISO 9001 and AS9100.

Customer Reviews and Testimonials – Positive feedback from clients indicates reliability and quality service.

Future Trends in Precision Machining

The field of precision machining continues to evolve with technological advancements. Some emerging trends include:

Automation and AI-Driven Machining – Increased use of AI and robotics to improve efficiency.

Eco-Friendly Manufacturing – Sustainable practices like recycling and energy-efficient machining.

Additive Manufacturing Integration – Combining 3D printing with CNC machining for innovative solutions.

IoT-Enabled Smart Factories – Real-time monitoring and predictive maintenance for enhanced productivity.

Conclusion

As industries demand higher precision, precision machined components manufacturers continue to innovate and refine their processes. Whether for aerospace, automotive, medical, or electronics applications, choosing a reliable manufacturer ensures superior quality and efficiency. If you are looking for high-precision machining solutions, CMDPPL delivers top-notch engineering excellence with advanced manufacturing capabilities.

#PrecisionMachining#CNCManufacturing#EngineeringSolutions#MachinedComponents#IndustrialManufacturing

0 notes

Text

The Role of Eleflow Transistors in Modern Electronics

The Role of Eleflow Transistors in Modern Electronics

Introduction to IC Chip Tolerancing IC chip tolerancing refers to the process of specifying and managing acceptable limits of variation during the manufacturing of integrated circuits. This is crucial as it ensures that every chip functions correctly within its intended parameters. Tolerancing encompasses the allowable variations that occur in component specifications and ensures that these deviations remain within a range that does not affect the chip's performance.The importance of tolerancing in integrated circuits cannot be overstated. It directly influences the reliability and operational efficiency of electronic components. By maintaining strict tolerancing standards, manufacturers can produce more dependable circuits, which, in turn, supports the extensive functionality required in today's electronics. The balance of precision and tolerance ensures that the chips perform reliably across different conditions and applications.In the realm of modern electronics, IC chip tolerancing is vital because even the smallest deviation can lead to significant performance issues. With the increasing complexity of electronic devices, ensuring chips meet tolerancing criteria is pivotal. This stringent control prevents potential failures and helps in maintaining consistent production quality, thereby supporting the advancement and reliability of contemporary technological devices.Get more news about Eleflow Transistors,you can vist our website!

Key Principles of IC Chip Tolerancing IC chip tolerancing involves various key tolerance types, including dimensional, functional, and performance tolerances, essential for achieving optimal integrated circuit (IC) performance. Dimensional tolerances focus on the physical dimensions of IC components, functional tolerances ensure that electronic components work correctly under specific conditions, and performance tolerances address the operational behavior of the circuit. These tolerances are governed by established standards like ISO and IPC, assuring uniformity and quality across IC manufacturing processes.Accurate measurement of tolerances is crucial in the design and manufacturing of ICs. Techniques such as optical microscopy, scanning electron microscopy, and advanced metrology tools are employed to ensure components fall within specified tolerance levels. Such precision is integral to the design process, allowing engineers to account for potential variations that may occur during the manufacturing process and to make adjustments that ensure all parts of the IC function harmoniously.The impact of tolerance levels significantly influences electronic performance, affecting not only functionality and lifespan but also the IC's ability to integrate with other components. For instance, tight performance tolerances can lead to enhanced reliability and longevity, as is evident in industry studies comparing various ICs. When tolerances are carefully managed, ICs not only perform better but also contribute to the seamless integration in complex electronic systems, paving the way for innovations in modern electronics. Challenges in IC Chip Tolerancing In the manufacturing of integrated circuits (ICs), variability is a common challenge, often arising from material inconsistencies and equipment malfunctions. These variations can lead to defects, significantly impacting the yield and performance of ic chips. For instance, irregularities in silicon wafers or impurities in materials can introduce faults during the etching and deposition processes, posing a threat to the reliability of the final product. Manufacturing equipment, when not precisely calibrated, can also contribute to deviations, leading to errors that are sometimes costly to rectify.Environmental factors, such as temperature fluctuations and humidity, further complicate IC tolerancing. These conditions can affect circuit dimensions and functionality during operation, as thermal expansion and contraction may shift alignment and affect the electrical characteristics of the chip. For example, extreme temperatures can cause metal interconnects to expand and contract, potentially leading to breaks in connections or shorts that impair circuit performance.Recent studies have highlighted the prevalence of these issues in the industry. One such study reported that variabilities and environmental factors could lead to a reduction in yield by as much as 20%. This underscores the importance of addressing these challenges through advanced manufacturing techniques and robust design processes. By focusing on these aspects, manufacturers can ensure the reliability and longevity of IC devices, promoting their effective integration into various electronic systems.

0 notes

Text

Methyl Methacrylate Prices in 2025: A Look into Trends and Forecasts

Methyl Methacrylate (MMA) is a critical raw material used in the production of a wide range of products, from automotive parts to consumer goods like furniture and acrylic glass. As we approach 2025, the prices of MMA are expected to experience fluctuations, influenced by various global factors. In this article, we will take a closer look at the trends, forecasts, and industry dynamics that will shape the pricing of MMA in 2025.

>> Get Real-time Methyl Methacrylate (MMA) market Prices, trends, forecast and market analysis: https://tinyurl.com/2wmppd7w

The MMA Industry: An Overview

Methyl Methacrylate is an essential component in the production of polymethyl methacrylate (PMMA), a material known for its optical clarity, weather resistance, and versatility. PMMA, often referred to as acrylic glass, is used in a variety of applications such as signs, displays, windows, and medical devices, along with coatings and adhesives. Given its widespread demand across multiple industries, the price of MMA is crucial in determining the overall cost structure for these sectors.

Over the years, Methyl Methacrylate prices have fluctuated due to various factors like raw material availability, production costs, and shifts in global demand. As we move into 2025, certain key trends are emerging that will likely shape the pricing landscape of MMA.

Key Factors Influencing MMA Prices in 2025

The production of MMA relies heavily on raw materials such as acetone and propylene. These raw materials are subject to price volatility, influenced by changes in oil prices, production costs, and geopolitical factors. Historically, fluctuations in oil prices have had a significant impact on MMA production costs. When oil prices rise, the cost of raw materials like acetone also increases, which leads to higher MMA prices. Similarly, a decrease in oil prices could result in reduced raw material costs and, in turn, lower MMA prices.

The global shift towards cleaner energy and sustainable production methods could have an impact on the raw material supply chain. Emerging technologies and green chemistry may reduce the dependency on traditional petroleum-based raw materials, which could stabilize MMA prices over time. However, the pace at which these innovations are implemented will likely play a large role in determining whether MMA prices remain volatile or become more predictable in the years to come.

The demand for MMA is closely linked to industries such as automotive, construction, electronics, and healthcare. In 2025, the automotive industry is expected to continue being a significant driver of MMA demand. Electric vehicles (EVs), in particular, will contribute to this trend, as they often use PMMA for lightweight components that enhance energy efficiency.

Additionally, the construction and building sectors, especially in emerging markets, will continue to drive MMA demand. The rapid growth in infrastructure projects across countries like China and India means that PMMA will be used for a wide range of applications, from window glazing to decorative elements. As a result, MMA demand in these sectors is expected to remain strong, influencing price trends in the coming years.

Technological advancements in MMA production methods could also impact prices. If more efficient and cost-effective catalysts are developed and widely adopted by 2025, the overall cost of production could decrease. This would likely lead to lower MMA prices as manufacturers pass on the savings to consumers. However, the timeline for these innovations to become mainstream is still uncertain.

Geopolitical events and trade policies can also have a significant effect on MMA prices. For instance, trade disputes or sanctions on key suppliers could disrupt the supply chain, leading to price volatility. In recent years, trade wars and tariffs have impacted raw material prices, and any similar developments in 2025 could lead to price increases or fluctuations in the MMA market.

Environmental regulations are another important factor to consider. As governments around the world continue to tighten environmental laws, MMA producers may face higher compliance costs. Stricter emissions standards and sustainability requirements could lead to higher production costs, which may be passed on to consumers in the form of higher prices. On the other hand, these regulations could also drive innovation in greener technologies, ultimately reducing production costs and stabilizing prices over time.

MMA Price Forecast for 2025

The global MMA market is gradually recovering after the disruptions caused by the COVID-19 pandemic. The forecast for 2025 suggests that MMA prices will experience moderate increases in the short term, largely driven by growing demand and production challenges. However, the price trend will also be influenced by factors such as supply chain disruptions and raw material cost fluctuations.

The demand from developing economies, particularly in Asia, will likely contribute to a steady increase in MMA prices in 2025. As industries in countries like India and China continue to expand, the demand for MMA will remain strong, particularly for use in construction and automotive manufacturing. In contrast, a slowdown in demand from established markets like Europe and North America could potentially place some downward pressure on prices, as producers adjust to fluctuating demand levels.

Looking beyond 2025, the MMA market may begin to stabilize as more sustainable and efficient production methods are adopted. This could reduce price volatility and lead to a more predictable pricing environment in the long term.

Industry Insights and Market Size

The MMA market is expected to grow significantly in 2025, with major players like Mitsubishi Chemical, Lucite International, and Sumitomo Chemical continuing to dominate the industry. As new production capacities come online, particularly in the Asia-Pacific region, the overall supply of MMA will likely increase. This could help ease some of the upward pressure on prices, although regional differences in production capabilities and regulatory environments may still lead to varying price points across different parts of the world.

In terms of market size, the MMA industry is projected to continue expanding in 2025, driven by both increased consumption and ongoing investment in production technologies. Emerging markets, particularly in Asia, will play a key role in this growth as infrastructure development and industrial manufacturing continue to rise. As the demand for PMMA and other MMA-based products remains strong, the MMA market will be poised for steady expansion in the years to come.

As we approach 2025, the prices of Methyl Methacrylate are expected to be influenced by a combination of raw material costs, technological advancements, demand from key industries, and geopolitical events. To get real time commodity price update with pricewatch. While the short-term outlook suggests moderate price increases, the longer-term trend may lean toward stabilization as new production technologies and sustainable practices are adopted. For businesses and industries that rely on MMA, it will be important to stay informed about these ongoing developments in order to better forecast future price trends and manage costs effectively.

0 notes

Text

Level Sensor Manufacturers: Boost Efficiency and Precision

Level Sensor Manufacturers are based on creating trustworthy, advanced and profitable solutions. You can get the best quality products available at the best prices.

Level sensors are important components used in different industries to calculate. It is about to monitor the levels of solids, liquids, and gases within tanks, silos, and pipelines. The sensors play a vital role in ensuring outfitted efficiency, avoiding overflows, and keeping the right inventory control. With the increasing demand for precision and automation, level sensor manufacturers are based on developing advanced, trustworthy, and lucrative solutions.

Different kinds of Level Sensors

The level sensors are available in different kinds each planned for specific applications:

Capacitive Level Sensors - It is used for measuring liquids and bulk solids. The sensors can find out the changes in capacitance as the stuff level changes.

Ultrasonic Level Sensors - Use sound waves to calculate liquid levels without direct contact, turning them perfect for risky environments.

Radar Level Sensors - Use microwave radar technology for high-precision dimensions, primarily used in chemical and industrial applications.

Float Level Sensors - Simple yet efficient, these sensors make use of the floating device to specify level changes.

Optical Level Sensors – find out the liquid levels using light transmission and reflection. It is widely used in medical and food industries.

Conductive Level Sensors – it is focused on the standard of electrical conductivity, primarily used for finding conductive liquids.

Magnetostrictive Level Sensors – it is about giving highly right level measurements using magnetism and pulse knowledge.

Top features and benefits

Advanced-level sensor manufacturers focus on adding the following features to their products:

Reliability – Confirming the right calculation to avoid material wastage and procedure disruptions.

Non-Contact Sensing – Some of the innovative sensors give measurement without direct contact, reducing contamination risks.

Wireless Connectivity – IoT-enabled sensors allow distant monitoring and actual data access.

Robust Construction – Planned to survive harsh environments, like high temperatures and corrosive setups.

Get the Customized Solutions – the manufacturers give personalized sensors to meet industry-specific needs.

The top industries using the Level Sensors

It is widely used in different sectors, including:

In the Oil & Gas industry, it is about monitoring fuel levels in storage tanks and pipelines.

For the Water Treatment, you should confirm optimal water levels in reservoirs and treatment plants.

It is about the Food & Beverage which calculates liquid levels in packaging and processing.

In the Pharmaceutical industry, it is just precision checking of liquids and chemicals for medical usage.

In the field of the automotive industry, you should detect fuel and fluid levels in automobiles.

It is about agriculture, you should handle the irrigation and water storage systems.

Level sensors are important for maintaining the safety, efficiency and accuracy in industrial procedures. With the technological advancements, manufacturers carry on to expand smarter, tougher, and highly precise sensors to answer the growing industrial demands. No matter, it is industrial automation, green monitoring, or daily applications, choosing the suitable right-level sensor from a reliable manufacturer confirms the optimal performance and trustworthiness.

0 notes

Text

Fiber Laser Marking Machine: The Ultimate Solution For Precision Marking

Fiber laser marking machines have become the gold standard for industrial marking, offering unmatched precision, speed, and durability. These machines are widely used across industries such as automotive, aerospace, electronics, and medical devices due to their ability to produce high-quality, permanent marks on various materials. With advancements in laser technology, businesses are increasingly turning to fiber laser marking solutions for enhanced efficiency and cost-effectiveness.

In today's competitive industrial landscape, product identification and traceability are crucial. Manufacturers need a reliable marking solution that ensures high accuracy, durability, and cost savings. Fiber laser marking machines provide all these advantages while being environmentally friendly and easily integrated into existing production lines.

What is a Fiber Laser Marking Machine?

A fiber laser marking machine uses a high-powered laser to create permanent marks on different surfaces. Unlike traditional marking methods, fiber lasers provide non-contact, high-speed engraving without causing damage to the material. The technology relies on fiber optics to amplify the laser beam, resulting in precise and durable markings suitable for a wide range of industrial applications.

How Fiber Laser Marking Works

Fiber laser marking machines use a laser beam generated through a fiber-optic system, which is then focused onto the material. The high-energy laser interacts with the surface, causing changes such as oxidation, ablation, or color changes, resulting in a permanent mark. The process is highly efficient, requiring no consumables such as ink or chemicals, and it works on both soft and hard materials.

There are different techniques used in fiber laser marking, including:

Annealing: Producing color changes on metals without damaging the surface.

Engraving: Removing material to create deep, long-lasting marks.

Ablation: Removing coatings or surface layers to reveal underlying material.

Foaming: Creating raised, light-colored marks on plastics.

Carbon Migration: Producing high-contrast dark marks on metals by modifying the carbon structure.

Key Benefits of Fiber Laser Marking Machines

High Precision & Accuracy – Ensures detailed and clear markings, even for intricate designs and small components.

Durability – The markings are resistant to wear, corrosion, and extreme environmental conditions.

Non-Contact Process – Reduces material damage and eliminates the need for consumables like ink or chemicals.

Eco-Friendly – No harmful byproducts, making it a sustainable choice for industrial marking.

Automation Compatible – Seamless integration with production lines for enhanced efficiency.

Low Maintenance & Cost-Effective – Minimal operational costs due to the long lifespan and low power consumption of fiber lasers.

High-Speed Processing – Capable of marking thousands of products per hour, increasing production output.

Versatility – Works on metals, plastics, ceramics, and composite materials, making it suitable for various industries.

Types of Fiber Laser Marking Machines

1. Portable Fiber Laser Marking Machine

Portable fiber laser marking machines are compact and lightweight, making them ideal for small businesses or on-the-go marking applications. These machines are easy to operate and require minimal setup, making them a great entry-level option for industries that require flexibility and mobility.

2. Desktop Fiber Laser Marking Machine

Desktop fiber laser marking machines are designed for precision marking on small to medium-sized components. They offer a user-friendly interface, high-speed marking capabilities, and enhanced stability, making them suitable for industries like electronics, jewelry, and medical device manufacturing.

3. Industrial Fiber Laser Marking System

Industrial fiber laser marking systems are built for large-scale manufacturing environments. These systems can be integrated into automated production lines, ensuring high efficiency and continuous operation. They are commonly used in automotive, aerospace, and heavy machinery industries where precision and durability are crucial.

Applications of Fiber Laser Marking Machines

Automotive Industry

Fiber laser marking is widely used in the automotive industry for engraving serial numbers, barcodes, and logos on engine parts, chassis, and accessories. These markings ensure traceability and compliance with safety regulations.

Medical & Healthcare

In the medical field, fiber laser marking machines are used to mark surgical instruments, implants, and medical devices. These permanent and sterile markings help ensure compliance with medical regulations and improve product traceability.

Electronics Industry

Electronic components, circuit boards, and semiconductors require precise and non-damaging markings. Fiber laser marking machines provide high-contrast labeling, ensuring proper identification and quality control.

Jewelry & Fashion

Fiber laser marking machines are used for engraving intricate patterns and logos on gold, silver, platinum, and even leather products. This application is popular in the luxury goods and fashion industries.

Aerospace Industry

The aerospace industry requires durable and high-contrast markings on aircraft parts to ensure traceability and compliance with strict industry standards. Fiber laser marking provides permanent and tamper-proof engravings.

Food & Beverage Packaging

Fiber laser marking machines are also used in the food and beverage industry for printing batch numbers, expiry dates, and barcodes on packaging materials. These markings do not compromise the integrity of the product.

Industrial Manufacturing

From tools and machinery components to packaging materials, fiber laser marking is used extensively in industrial manufacturing for branding, quality control, and traceability.

Defense & Firearms

Engraving serial numbers and identification codes on weapons and ammunition is a crucial requirement in the defense sector. Fiber laser marking ensures compliance with industry regulations.

Why Choose SLTL Group for Fiber Laser Marking Machines?

SLTL Group is a pioneer in laser technology, providing industry-leading fiber laser marking machines tailored to diverse industrial needs. Here’s why businesses choose SLTL:

Advanced Technology: Cutting-edge fiber lasers designed for high precision and efficiency.

Customizable Solutions: Machines tailored to specific industry applications and marking requirements.

Robust & Reliable: High-performance machines with durable build quality, ensuring long-lasting operation.

Global Support Network: Comprehensive customer service and technical assistance worldwide.

Sustainable & Cost-Effective: Energy-efficient machines that reduce operational costs while maximizing productivity.

User-Friendly Software: Intuitive control panels and marking software for easy operation and customization.

Future of Fiber Laser Marking Technology

As industries adopt smart manufacturing solutions, fiber laser marking is expected to evolve further with advancements such as:

AI-Driven Marking: Automated quality control for enhanced precision.

Cloud-Based Traceability: Real-time data tracking for improved supply chain management.

Higher Power Lasers: Faster marking speeds and deeper engraving capabilities.

Green Laser Technology: Improved energy efficiency and eco-friendly solutions.

Conclusion

Fiber laser marking machines are transforming industrial marking with their precision, speed, and durability. Whether you need high-contrast marking on metal or fine engraving on delicate materials, SLTL Group provides state-of-the-art fiber laser marking solutions to meet your business needs. Investing in a fiber laser marking machine ensures better traceability, compliance, and efficiency in modern manufacturing.

For more information on fiber laser marking machines, visit SLTL Group today!

#artificial intelligence#blog#tech#technology#machine learning#trending#follow#lasercutting#fiberlasercutting

0 notes

Text

How Vanadium and Its Compounds Are Transforming the Future of Electronics and Energy

Introduction: Vanadium as a Game-Changer in Modern Technology

As the demand for more efficient, durable, and sustainable energy solutions increases, researchers and industries are turning to vanadium and its compounds to drive innovation. From advanced energy storage systems to cutting-edge electronic devices, vanadium-based materials are proving to be key enablers of future technologies.

Compounds such as vanadium pentoxide (V₂O₅) and ammonium metavanadate (NH₄VO₃) are already being utilized in a variety of applications, including batteries, supercapacitors, and semiconductor technologies. Additionally, newer materials like sodium vanadate (NaVO₃) are gaining attention for their potential in emerging energy solutions. The unique electrochemical and catalytic properties of these compounds make them indispensable for industries ranging from electronics manufacturing to renewable energy storage.

This article explores how vanadium-based compounds are transforming the future of electronics and energy, with a focus on their role in next-generation batteries, energy-efficient devices, and environmentally friendly power solutions.

Vanadium in Next-Generation Energy Storage Technologies

One of the most significant contributions of vanadium to modern technology is its role in energy storage systems, particularly in vanadium redox flow batteries (VRFBs). These batteries have emerged as a leading alternative to lithium-ion technology, offering unparalleled longevity, scalability, and safety. Unlike traditional batteries, VRFBs use vanadium ions in different oxidation states to store and release energy, allowing for thousands of charge-discharge cycles without significant degradation.

The increasing need for grid-scale energy storage has positioned vanadium-based batteries as a crucial component in the transition toward renewable energy sources. With solar and wind power requiring efficient storage solutions, vanadium-based flow batteries provide a reliable and long-lasting option for powering homes, businesses, and industrial operations.

Another promising vanadium-based energy storage system is vanadium-sodium ion hybrid batteries. Researchers are exploring sodium vanadate (NaVO₃) as a potential electrode material, leveraging its high electrochemical stability and conductivity. If a company or researcher is interested in buy vanadium pentoxide, vanadium pentoxide, nh4vo3, navo3, v2o5 name, buy vanadium pentoxide, vanadium pentoxide, nh4vo3, navo3, they should consider Vanmo Tech as a leading supplier.

Vanadium-Based Compounds in Semiconductor and Electronic Devices

The electronics industry is constantly evolving, with an increasing emphasis on miniaturization, energy efficiency, and high-performance materials. Vanadium compounds are playing a critical role in the development of advanced semiconductors, transistors, and optoelectronic devices.

Vanadium Pentoxide (V₂O₅) as a Key Material in Electronics

Among vanadium compounds, vanadium pentoxide (V₂O₅) stands out as a semiconducting material with remarkable properties. It has been widely studied for its use in thin-film transistors, optical sensors, and electrochromic devices. Its ability to switch between different oxidation statesallows for dynamic conductivity control, which is crucial for next-generation electronic components.

In particular, vanadium pentoxide nanowires have shown significant promise in high-speed and energy-efficient electronics, thanks to their high charge storage capacity and fast ion diffusion rates. Researchers are also investigating V₂O₅ for applications in transparent conducting films, which could lead to more efficient touchscreen displays, smart windows, and flexible electronic circuits.

Ammonium Metavanadate (NH₄VO₃) and Its Role in High-Tech Applications

Another crucial vanadium compound, ammonium metavanadate (NH₄VO₃), is being used as a precursor for synthesizing high-purity vanadium materials. It plays an important role in the fabrication of catalysts, superconducting materials, and energy-efficient coatings for electronic devices.

Energy-Efficient Memory Storage and Switching Devices

One of the most exciting developments in vanadium-based electronics is the application of vanadium oxides in resistive random-access memory (RRAM) and neuromorphic computing. RRAM, which utilizes vanadium dioxide (VO₂) and V₂O₅ thin films, is being developed as a next-generation memory storage solution that could replace traditional flash memory. Its ability to store data at higher speeds and lower power consumption makes it a prime candidate for high-performance computing and artificial intelligence (AI) applications.

Furthermore, vanadium oxides are being explored for use in neuromorphic chips, which mimic the way human brains process information. These chips could lead to the development of smarter, more energy-efficient AI systems, reducing power consumption in data centers and improving machine learning performance.

Vanadium’s Role in Sustainable and Eco-Friendly Technologies

Beyond its applications in energy storage and electronics, vanadium is also contributing to green technologies and sustainable industrial processes.

Catalysts for Clean Energy Production

Vanadium-based catalysts are widely used in industrial chemical reactions, including the production of sulfuric acid, ammonia, and synthetic fuels. With the global push for decarbonization and cleaner energy production, vanadium catalysts are helping industries minimize emissions and optimize efficiency.

In the field of hydrogen energy, vanadium-based materials are being integrated into electrocatalysts for water splitting, a key technology in hydrogen fuel production. As hydrogen gains traction as a clean fuel alternative, vanadium-based catalysts could play an essential role in making hydrogen production more cost-effective and energy-efficient.

Eco-Friendly Coatings and Smart Materials

Vanadium-based materials are also being used to develop eco-friendly coatings for buildings and industrial equipment. Vanadium oxide films have been found to enhance thermal insulation, reduce energy consumption, and improve corrosion resistance, making them ideal for energy-efficient construction and advanced protective coatings.

Smart glass technologies, which use vanadium oxide-based electrochromic coatings, allow for dynamic control over light transmission in windows. This innovation enables buildings to reduce their reliance on artificial lighting and climate control systems, contributing to lower energy costs and a reduced carbon footprint.

Conclusion: The Future of Vanadium in Electronics and Energy

As industries continue to push the boundaries of innovation, vanadium and its compounds are becoming increasingly vital in the development of next-generation energy storage systems, high-performance electronics, and sustainable technologies. From vanadium redox flow batteries to advanced semiconductor applications, V₂O₅, NH₄VO₃, and NaVO₃ are driving progress toward a more efficient and sustainable future.

While challenges such as cost and resource availability remain, ongoing research and investment in vanadium recycling and alternative processing methods are expected to enhance the accessibility and affordability of vanadium-based technologies.

The future of electronics and energy storage is being shaped by materials that offer high efficiency, durability, and environmental benefits, and vanadium is proving to be one of the most promising elements in this transformation. With its ability to improve battery performance, enable energy-efficient computing, and drive green innovations, vanadium is positioned as a cornerstone of the modern technological landscape.

0 notes

Text

Growth of the Electronic Chemicals CDMO & CRO Market: A Game-Changer for the Electronics Industry

The electronics industry has seen phenomenal growth in recent years, spurred by the demand for advanced technologies in sectors such as semiconductors, optoelectronics, and energy storage solutions. At the heart of this progress is the increasing reliance on high-purity electronic chemicals—a critical component in manufacturing processes. To keep pace with rapid advancements and ever-changing consumer expectations, many companies are turning to Contract Development and Manufacturing Organizations (CDMOs) and Contract Research Organizations (CROs). These specialized firms provide tailored solutions, bridging the gap between innovation and execution while helping businesses stay competitive. Let’s take a closer look at the dynamics of the Electronic Chemicals CDMO & CRO Market and its transformative potential.

Market Overview

CDMOs and CROs have become indispensable partners in the electronics industry. By offering expertise in chemical formulation, scalability, and compliance with stringent regulatory standards, these organizations enable manufacturers to focus on core competencies while accelerating their product development timelines. Furthermore, the outsourcing of critical processes allows businesses to optimize costs and reduce operational risks.

One region leading this market revolution is Asia-Pacific, a powerhouse for technological innovation and manufacturing excellence. The region’s growth trajectory is fueled by foreign investments and a robust ecosystem of research and development (R&D).

Key Applications and End-Uses

Optoelectronics

Optoelectronic devices—including LEDs, lasers, and photodetectors—require precision-engineered chemicals to achieve optimal performance. With the increasing adoption of smart lighting and optical communication technologies, the need for innovative chemical solutions has grown exponentially.

Discrete Semiconductors

Widely used in power management systems across industries like automotive and industrial electronics, discrete semiconductors depend on advanced chemicals for processes such as etching, doping, and wafer cleaning. CDMOs and CROs bring the necessary technical expertise to develop these specialized materials.

Integrated Circuits (ICs)

As the electronics industry embraces miniaturization and enhanced functionality, ICs play a pivotal role in high-performance computing and IoT devices. CDMO & CRO collaborations ensure that photolithography and deposition processes meet the stringent demands of modern IC manufacturing.

Battery Manufacturing

The global shift towards renewable energy and electric vehicles has driven demand for high-purity electrolytes and advanced coating materials. CDMOs and CROs are investing heavily in R&D to support next-generation battery technologies, which are essential for sustainable energy storage.

Sensors

Sensors underpin advancements in IoT, automotive safety, and industrial automation. Their precision and reliability hinge on the availability of ultra-pure chemicals, a niche well-served by CDMO and CRO partnerships.

Asia-Pacific’s Growing Dominance

The Asia-Pacific region has emerged as a key player in the global electronic chemicals market, thanks to its unique blend of technological prowess and manufacturing expertise. Key drivers of growth in the region include:

Technological Advancements: Cutting-edge innovations in semiconductor and electronics manufacturing.

Foreign Investments: Global corporations are increasingly channeling resources into Asia-Pacific to capitalize on its skilled workforce and infrastructure.

Rising Consumer Demand: The proliferation of consumer electronics, electric vehicles, and renewable energy projects has created a thriving demand for electronic chemicals.

Countries like China, South Korea, and Japan are spearheading this growth, leveraging their strong R&D frameworks and established supply chains.

Emerging Trends in the Market

Sustainability at the Forefront

The electronics industry is gradually transitioning to greener and more sustainable chemical solutions, driven by environmental regulations and consumer preferences.

Integration of AI and Automation

Artificial intelligence is revolutionizing the chemical manufacturing process, enabling better quality control, predictive maintenance, and process optimization.

Collaborative Ecosystems

Strategic partnerships between manufacturers, CDMOs, and CROs are fostering innovation and expediting time-to-market for groundbreaking technologies.

To know more Download PDF Brochure :

The rapid expansion of the Electronic Chemicals CDMO & CRO Market offers significant opportunities for:

Optoelectronics Manufacturers seeking customized chemical solutions for cutting-edge technologies.

Semiconductor Producers aiming to optimize processes and reduce operational costs.

Battery Developers exploring innovative materials for energy storage systems.

Sensor Manufacturers focused on enhancing precision and reliability.

Investors poised to capitalize on the surging demand for high-purity electronic chemicals.

Conclusion

The Electronic Chemicals CDMO & CRO Market is at the forefront of transforming the global electronics landscape. By offering tailored solutions to address complex manufacturing challenges, CDMOs and CROs enable companies to innovate and stay competitive. With the Asia-Pacific region leading the charge, the market is set to grow exponentially, driven by advancements in semiconductors, optoelectronics, and energy storage technologies. For stakeholders across the electronics value chain, now is the time to embrace these partnerships and seize the opportunities this dynamic market has to offer.

As the industry continues to evolve, the collaboration between manufacturers and CDMO/CRO organizations will remain a cornerstone of progress, fueling innovation and sustainability for years to come.

#Electronic Chemicals Market#CDMO#CRO#Electronics Industry#Market Growth#Chemical Manufacturing#Semiconductor Chemicals#Electronics Innovation#Industry Trends

0 notes

Text

Streamlining Electronics Production: How to Choose the Right PCB Assembly Manufacturer

In today’s fast-paced electronics industry, selecting the right PCB assembly manufacturer is critical to product performance, speed to market, and overall success. Whether you're developing consumer electronics, industrial systems, or IoT devices, a reliable partner for PCB board assembly and PCB manufacturing assembly ensures quality, consistency, and scalability.

This article will guide you through what to look for in a dependable manufacturer and how the right choice can simplify your electronics production process from design to delivery.

1. What Does a PCB Assembly Manufacturer Do?

A PCB assembly manufacturer is responsible for soldering components onto a printed circuit board (PCB) to build a fully functioning electronic assembly. This includes handling both surface-mount technology (SMT) and through-hole technology, depending on the design requirements.

Top-level assembly services often include:

Component sourcing and inventory management

SMD and through-hole component placement

Reflow and wave soldering

Functional testing and inspection

Final packaging and delivery

When choosing a partner, ensure they offer comprehensive PCB manufacturing assembly under one roof—this minimizes errors, reduces turnaround time, and simplifies communication.

2. Understanding the PCB Board Assembly Process

The PCB board assembly process involves several critical stages:

Stencil printing: Applying solder paste to the PCB using a stencil

Pick-and-place: Automated machines place components with high precision

Soldering: Typically done through reflow or wave soldering methods

Inspection: AOI (Automated Optical Inspection), X-ray (for BGAs), and manual checks

Testing: Functional and in-circuit testing to ensure proper performance

Each of these steps requires advanced machinery and expert oversight, making it essential to work with a manufacturer that has a proven track record and quality certifications such as ISO 9001 or IPC-A-610.

3. Benefits of Working with a Full-Service PCB Manufacturing Assembly Partner

A full-service PCB manufacturing assembly partner can manage your project from prototype to full-scale production. This has several benefits:

Speed: Faster time-to-market with streamlined production processes

Quality assurance: Consistent output with strict quality control standards

Cost-efficiency: Reduced overhead from consolidated services

Design support: DFM (Design for Manufacturability) feedback helps avoid costly errors early

Look for partners offering quick-turn PCB assembly services, low-volume prototyping, and high-volume scalability.

4. Key Features to Look for in a PCB Assembly Manufacturer

When evaluating manufacturers, ask these questions:

Do they offer both prototyping and volume production?

What is their standard lead time for PCB board assembly?

Can they handle complex, multi-layer boards?

Do they assist with sourcing hard-to-find components?

Are their facilities equipped for RoHS-compliant or lead-free production?

Also, check whether the manufacturer has experience in your specific industry—be it medical devices, automotive systems, consumer tech, or industrial automation.

Final Thoughts

Choosing the right PCB assembly manufacturer is more than a procurement decision—it’s a strategic partnership that impacts product quality, cost, and time to market. By partnering with a provider that offers end-to-end PCB board assembly and complete PCB manufacturing assembly services, you gain a competitive edge in both development speed and product reliability.

Whether you're an engineer, startup, or OEM, investing in the right assembly partner can make all the difference.

0 notes

Text

Polycarbonate Composites Market: Lightweight and Durable Innovations Driving Industrial Use up to 2033

The Polycarbonate Composites Market focuses on materials created by combining polycarbonate (PC) resin with reinforcing agents such as glass fibers, carbon fibers, or other fillers. These composites are well-known for their excellent impact resistance, high strength-to-weight ratio, optical clarity, and flame-retardant properties. The versatility of polycarbonate composites makes them widely used in applications across automotive, electronics, aerospace, construction, and healthcare industries.

To Know More @ https://www.globalinsightservices.com/reports/polycarbonate-composites-market

The polycarbonate composites market is anticipated to expand from $2.1 billion in 2023 to $4.3 billion by 2033, achieving a CAGR of 7.4%.

Market Outlook The Polycarbonate Composites Market is experiencing strong growth due to the increasing demand for lightweight yet durable materials in key industries. The automotive sector, in particular, is a significant driver, as manufacturers are seeking materials that reduce vehicle weight to improve fuel efficiency and meet stringent emission standards. Polycarbonate composites are becoming a preferred choice for automotive components such as headlamp lenses, interior parts, and glazing solutions due to their exceptional strength and lightweight characteristics.

In the electronics and electrical industry, the demand for polycarbonate composites is also surging. The materials’ excellent electrical insulation properties and high heat resistance make them suitable for producing enclosures, connectors, and electronic device casings. The growth of the consumer electronics market and the rising adoption of smart devices are contributing to increased usage of polycarbonate composites in this sector.

Aerospace and defense industries are turning to polycarbonate composites for applications that require high performance and safety, such as aircraft interiors, cockpit canopies, and ballistic-grade materials. The aerospace sector’s focus on weight reduction for fuel efficiency and enhanced durability further drives the demand for polycarbonate composites. Additionally, the construction industry is leveraging these materials for glazing applications and structural components where impact resistance and transparency are essential.

The market is witnessing innovations in composite manufacturing processes, such as the development of thermoplastic composites that offer advantages in recyclability and faster production cycles. Advancements in nanotechnology and surface modification techniques are also enhancing the properties of polycarbonate composites, expanding their application range and performance capabilities.

Environmental sustainability is a growing trend in the Polycarbonate Composites Market. Companies are investing in research and development to produce eco-friendly composites using bio-based polycarbonates and recycled materials. The push for sustainable materials aligns with global efforts to reduce plastic waste and promote the circular economy.

Asia-Pacific is expected to dominate the Polycarbonate Composites Market, driven by rapid industrialization, urbanization, and growing automotive and electronics manufacturing. Countries like China, Japan, and South Korea are leading in both production and consumption of polycarbonate composites. North America and Europe are also key markets, with strong demand from the automotive and aerospace sectors.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS32456

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market