#oil cooler heat exchanger manufacturer in india

Explore tagged Tumblr posts

Text

Shell And Tube Heat Exchanger Manufacturers In India | Oil Cooler Heat Exchanger Manufacturers In India

Phoenix Industries at a Glance

We Are Leading Shell And Tube Heat Exchanger Manufacturers In India, Oil Cooler Heat Exchanger Manufacturers In India .Heat Exchangers Are Used In Variety Of Industries Like Oil And Gas Industries, Chemical Industries, Power Industries, Marine Applications, Defense Industry For Desired Applications.

Phoenix Industries is an ISO 9001:2015 certified company that has been designing and manufacturing shell and tube type heat exchangers, Sealant Injection Grease Fittings, High Pressure Instrumentation Valves, Heat Exchangers, Precision Machined Components and Sub-assemblies for Oil and Gas Industries, Chemical Industries, Power Industries, & Marine Applications, Foundries for the last 22+ years.

Our founder Mr. Sachin Kulkarni is an epitome of experience and motivates his robust team to perform above expectations. The company is being managed by promoters who have the required technical and financial expertise and they work in synchronization with a dedicated team of engineers and technocrats to excel in everything they do.

We believe in ‘KAIZEN’ a Japanese principle of quality management which enables us for continuous improvement of our products and services, and hence maintaining ‘TOTAL QUALITY MANAGEMENT (TQM)’. We assure you the ‘Best’ quality product with ‘excellent’ services using precision machines and latest technology at most competitive prices.

#oil cooler heat exchanger manufacturers in india#Shell And Tube Heat Exchanger Manufacturers In India

0 notes

Text

https://www.phoenix.ind.in/oil-cooler-heat-exchanger-shell-and-tube-manufacturer-supplier-india.php

#shell and tube type heat exchangers#heat exchangers manufacturer#oil cooler heat exchanger manufacturer#supplier#exporter#india

0 notes

Text

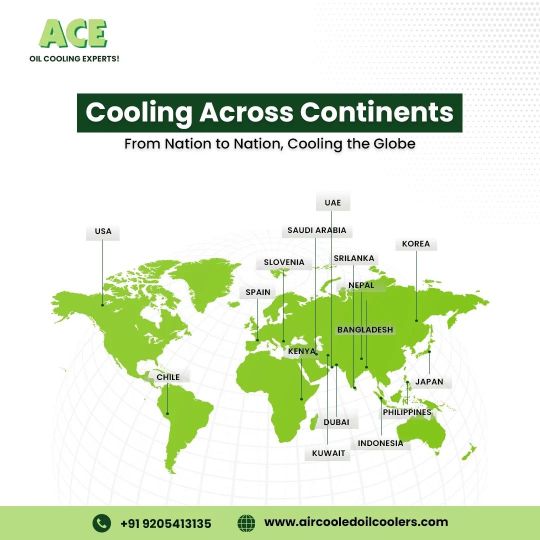

Ace Hydraulic Oil Cooler & Air Cooled Heat Exchanger Manufacturers in India.29+ years of Experience, Ex-Stock Delivery & Affordable Prices.

Hydraulic Oil Coolers & Air Cooled Heat Exchanger Manufacturers in India

2 notes

·

View notes

Text

Founded in 1989 and based in Coimbatore, Tamil Nadu, India, United Cooling Systems Pvt. Ltd. is a respectable producer of cooling and heat transfer equipment. Heat exchangers, air fin coolers, oil coolers, and compressed air dryers are just a few of the cooling solutions that the company specializes in designing and manufacturing. These goods have vital uses in a number of sectors, including petrochemicals, power production, oil and gas, and pharmaceuticals.

United Cooling Systems is renowned for its excellent quality control and engineering standards. The company's dedication to producing dependable and effective goods is demonstrated by its significant certifications, which include ISO 9001:2015 and ASME (U, U2, R, NB). The business also concentrates on sustainable and energy-efficient cooling solutions that satisfy industry demands while reducing their negative effects on the environment.

United Cooling Systems has established a great reputation for offering robust and efficient cooling technologies that satisfy the various needs of its clients across the globe by putting a strong emphasis on innovation.

1 note

·

View note

Text

Swastik Hydraulic is one of the leading manufacturers of hydraulic oil coolers, Heat exchangers, shell and tube heat exchangers, lube oil coolers, water cooled condensers, and water cooled oil coolers in Delhi, India.

Swastik Hydraulic - Best Heat Exchanger Manufacturers in Delhi

#HeatExchangerManufacturer#HeatExchangerManufacturerinIndia#ShellandTubeHeatExchangerManufacturer#MildSteelHeatExchangerManufacturer#IndustrialHeatExchangerManufacturer

0 notes

Text

What is a Heat Exchanger?

In the world of industrial processes and energy management, heat exchangers play a crucial role that often goes unnoticed by the general public. Yet, these devices are fundamental to countless applications, from the air conditioning in our homes to the complex operations of power plants and refineries. But what exactly is a heat exchanger, and why is it so important?

At its core, a heat exchanger is a device designed to transfer heat between two or more fluids. These fluids can be liquids, gases, or a combination of both. The primary purpose of a heat exchanger is to either heat or cool a particular fluid without allowing it to mix with the other fluid(s) involved in the process. This transfer of thermal energy is essential for temperature control, energy conservation, and process efficiency in various industries.

The concept of heat exchange is based on a fundamental principle of thermodynamics: heat naturally flows from a warmer medium to a cooler one. Heat exchangers harness this principle to achieve desired temperature changes in fluids, making them indispensable in numerous applications across different sectors.

Types of Heat Exchangers

Heat exchanger manufacturers and heat exchanger suppliers offer a wide variety of designs to suit different needs. Some of the most common types include:

Shell and Tube Heat Exchangers: These are the most widely used heat exchangers in the process industry. They consist of a series of tubes enclosed within a cylindrical shell. One fluid flow through the tubes while another flows over them within the shell, allowing for efficient heat transfer.

Plate Heat Exchangers: Composed of multiple, thin, slightly separated plates that have very large surface areas and fluid flow passages for heat transfer. They are highly efficient and easy to maintain.

Finned Tube Heat Exchangers: These feature fins or other extended surfaces on the outside of the tubes to increase the surface area for heat transfer, making them particularly effective for gas-to-liquid applications.

Double Pipe Heat Exchangers: The simplest type of heat exchanger, consisting of two concentric pipes. One fluid flow through the inner pipe while the other flows through the annular space between the two pipes.

Air Cooled Heat Exchangers: Commonly used in applications where water is scarce, these exchangers use air as the cooling medium, with fans forcing air across finned tubes containing the hot fluid.

Regenerative Heat Exchangers: These use the same space for hot and cold fluids alternately, with the heat transfer surface absorbing and releasing heat as the fluids alternate.

Applications of Heat Exchangers

The versatility of heat exchangers makes them essential in a vast array of industries and applications, particularly in a rapidly industrializing country like India. Some key areas where heat exchangers are extensively used include:

Power Generation: In thermal and nuclear power plants, heat exchangers are used in boilers, condensers, and cooling systems to manage the heat cycle efficiently.

Oil and Gas: Refineries use heat exchangers for distillation, cracking, and various other processes that require precise temperature control.

Chemical Processing: Many chemical reactions require specific temperature conditions, making heat exchangers crucial in controlling process temperatures.

HVAC Systems: Heat exchangers are at the heart of heating, ventilation, and air conditioning systems, ensuring comfortable indoor environments in both residential and commercial buildings.

Automotive Industry: Radiators in vehicles are a type of heat exchanger, crucial for maintaining optimal engine temperature.

Food and Beverage Industry: Pasteurization, sterilization, and cooling processes in food production often rely on heat exchangers.

Pharmaceutical Manufacturing: Temperature-sensitive processes in drug manufacturing frequently employ heat exchangers for precise control.

Renewable Energy: In solar thermal and geothermal power systems, heat exchangers play a vital role in energy conversion and utilization.

Importance in Energy Efficiency

One of the most significant advantages of heat exchangers is their contribution to energy efficiency. By recovering and reusing heat that would otherwise be wasted, heat exchangers help industries reduce their energy consumption and, consequently, their carbon footprint. This aspect is particularly important in India, where rapid industrial growth needs to be balanced with environmental considerations.

Heat exchanger manufacturers and heat exchanger suppliers in India are at the forefront of developing more efficient and sustainable designs. These innovations are crucial in helping industries meet increasingly stringent energy efficiency standards while also reducing operational costs.

Choosing the Right Heat Exchanger

Selecting the appropriate heat exchanger for a specific application requires careful consideration of various factors, including:

The types of fluids involved

The desired temperature change

Pressure requirements

Space constraints

Material compatibility

Maintenance needs

Cost considerations

Given the complexity of these decisions, many businesses in India rely on experienced heat exchanger manufacturers and suppliers to guide them in making the best choice for their specific needs.

Maintenance and Efficiency

To ensure optimal performance and longevity, heat exchangers require regular maintenance. This typically involves cleaning to prevent fouling (the accumulation of unwanted materials on heat transfer surfaces), which can significantly reduce efficiency. In India's diverse industrial landscape, where operating conditions can vary widely, proper maintenance is crucial for maintaining the effectiveness of heat exchange systems.

Innovations in Heat Exchanger Technology

The field of heat exchanger technology is continuously evolving, with new materials and designs emerging to meet the changing needs of industries. Some recent innovations include:

Compact heat exchangers that offer high efficiency in a smaller footprint

Micro-channel heat exchangers for enhanced heat transfer in miniature applications

Advanced materials that offer better heat transfer properties and corrosion resistance

Smart heat exchangers with integrated sensors for real-time monitoring and optimization

These advancements are particularly relevant in India, where space constraints in urban areas and the need for more efficient industrial processes drive the demand for innovative solutions.

SCES Shrao Engineering: Your Partner in Heat Exchange Solutions

SCES Shrao Engineering is a top company in India’s growing industrial sector, known for its heat exchanger solutions. Located in a major industrial area, the company has earned a strong reputation for designing and making high-quality heat exchangers to meet the needs of different industries. The expert team at SCES Shrao Engineering works closely with clients to create custom systems that improve performance and save energy. With a focus on innovation and customer satisfaction, SCES Shrao Engineering is a trusted partner for businesses looking for reliable heat management solutions in various industries.

In conclusion, heat exchangers are vital components in numerous industrial processes, playing a crucial role in energy management and process efficiency. As India continues its trajectory of industrial growth, the importance of efficient heat exchange solutions cannot be overstated. Whether you're in power generation, manufacturing, or any other industry that relies on thermal management, understanding the basics of heat exchangers and staying abreast of technological advancements in this field is crucial. By partnering with reputable heat exchanger manufacturers and suppliers, businesses can ensure they have the most effective and efficient solutions for their specific needs, contributing to both their bottom line and the country's sustainable industrial development.

Source: https://www.sces.shraoengg.com/what-is-a-heat-exchanger/

1 note

·

View note

Text

Top 10 Heat Exchanger Manufacturers in India

Here’s a list of the top 10 heat exchanger manufacturers in India, along with a brief company description, key highlights (founded, headquarters, major products), and contact information:

Here is Top 10 Heat Exchanger Manufacturers in India

1. GEA India

Description: GEA is a global leader in heat exchangers, providing various solutions across various industries, including food processing, chemicals, and HVAC.

Founded: 1881

Headquarters: Vadodara, Gujarat

Major Products: Plate heat exchangers, shell and tube heat exchangers, air-cooled heat exchangers.

Contact: +91-265-2680723

2. Swastik Hydraulic

Description: Swastik Hydraulic is a leading company with a significant presence in India, specializing in heat transfer, separation, and fluid handling technology.

Founded: 1972

Headquarters: Delhi, India

Major Products: Heat exchangers, Hydraulic Oil Coolers, Lube Oil Coolers, Water Cooled Condensers, Water Cooled Oil Coolers, Water Cooled Heat Exchanger, Shell and Tube Heat Exchangers, Industrial Heat Exchangers, Mild Steel Heat Exchangers...

Contact: +91-9818001293

3. Thermax Limited

Description: Thermax is an Indian multinational company that offers a range of engineering solutions, including energy-efficient heat exchangers for various industrial applications.

Founded: 1966

Headquarters: Pune, Maharashtra

Major Products: Shell and tube heat exchangers, air-cooled heat exchangers, waste heat recovery systems.

Contact: +91-20-66051200

4. HRS Process Systems Ltd.

Description: HRS Process Systems is a leading manufacturer of heat exchangers in India, specializing in innovative heat transfer solutions for the chemical, food, and pharmaceutical industries.

Founded: 1989

Headquarters: Pune, Maharashtra

Major Products: Corrugated tube heat exchangers, plate heat exchangers, scraped surface heat exchangers.

Contact: +91-20-25663441

5. Kirloskar Brothers Limited

Description: Kirloskar Brothers Limited is a prominent engineering company in India, known for its advanced heat exchanger solutions used in power generation, marine, and industrial applications.

Founded: 1888

Headquarters: Pune, Maharashtra

Major Products: Shell and tube heat exchangers, plate heat exchangers, compact heat exchangers.

Contact: +91-20-27214444

6. Bharat Heavy Electricals Limited (BHEL)

Description: BHEL is one of India's largest public sector engineering and manufacturing enterprises, offering a wide range of heavy industrial equipment, including heat exchangers.

Founded: 1964

Headquarters: New Delhi

Major Products: Shell and tube heat exchangers, air preheaters, regenerative heat exchangers.

Contact: +91-11-66337000

7. Danfoss India

Description: Danfoss is a global leader in energy-efficient technologies, including advanced heat exchangers for HVAC, refrigeration, and industrial applications.

Founded: 1933 (Parent company)

Headquarters: Chennai, Tamil Nadu

Major Products: Brazed plate heat exchangers, micro plate heat exchangers, shell and tube heat exchangers.

Contact: +91-44-66501500

8. Swep India

Description: SWEP is a leading manufacturer of compact brazed plate heat exchangers, catering to a diverse range of applications, including HVAC, refrigeration, and industrial processes.

Founded: 1983 (Parent company)

Headquarters: Pune, Maharashtra

Major Products: Brazed plate heat exchangers, compact heat exchangers.

Contact: +91-20-66271100

9. Tranter India Pvt. Ltd.

Description: Tranter is known for its innovative heat exchanger technologies, providing customized solutions for various industries, including oil and gas, power, and chemicals.

Founded: 1932 (Parent company)

Headquarters: Pune, Maharashtra

Major Products: Plate heat exchangers, shell and tube heat exchangers, spiral heat exchangers.

Contact: +91-20-66758000

10. Sondex India

Description: Sondex is a part of Danfoss Group, specializing in high-quality heat exchanger solutions, particularly plate heat exchangers, used in various industrial applications.

Founded: 1984 (Parent company)

Headquarters: Navi Mumbai, Maharashtra

Major Products: Plate heat exchangers, brazed heat exchangers, all-welded heat exchangers.

Contact: +91-22-27837363

These Top 10 List of Heat Exchanger Manufacturers in India are among the top players in the heat exchanger industry, offering a wide range of products and services to meet diverse industrial needs.

This content is generated with AI.

#heatexchangermanufacturerinIndia#heatexchangermanufacturersinindia#TopHeatExchangerManufacturersIndia#BestHeatExchangerCompaniesIndia#HeatExchangerSuppliersDelhiIndia#LeadingHeatExchangerManufacturersinIndia#DelhiNCRHeatExchangerIndustry#HeatExchangerCompaniesinIndia#Top10HeatExchangerSuppliersIndia#HeatExchangerManufacturersListIndia#IndustrialHeatExchangerIndia#TopHeatTransferEquipmentManufacturersIndia

1 note

·

View note

Text

youtube

ELGi | OF SERIES | OIL FREE SCREW AIR COMPRESSORS | CLASS ZERO OIL | ALWAYS BETTER

ELGi is one of the very few companies that design and manufacture oil-free airends for air compressors. With in-house oil-free technology, the compressors are engineered to deliver maximum #uptime and #reliability.

ELGi’s Oil-Free Air Compressors have helped thousands of customers worldwide to meet air quality requirements, especially in critical industrial applications with absolute intolerance to the presence of oil during the manufacturing process. Right from the sustainable production of premium organic wine in France, manufacturing of superior quality rice brand oil in Thailand, paper manufacturing in Indonesia, chocolate manufacturing in Italy, food processing in the USA, pharmaceutical manufacturing in Europe and Singapore, semiconductor manufacturing in Malaysia, power generation in the Philippines, or medicine and vaccine manufacturing in India. ELGi’s Oil-Free Air Compressors have been reliably delivering contamination-free, environmental-friendly, class zero oil-free air, in line with ISO 8573-1 standards. ELGi’s manufacturing facility for oil-free compressors is also ISO 22000 certified for compliance with food safety management systems. Customers worldwide have experienced the benefits of the low total cost of ownership, high reliability, consistent air quality, efficient airflow, reduced risk of contamination of downstream parts and applications, best-in-class service support, unmatched warranty, and quicker return on investment. With adherence to superior safety norms, the OF series compressors not only have low energy losses and low air outlet temperatures but are highly reliable and compact. All these advanced features are thus integrated into one simple design that drives reliability and performance.

The ELGI OF series oil-free screw air compressor for critical industries. ELGI is one of very few air compressor companies in the world to design and manufacture oil-free air ends. With high reliability and performance, the ELGI OF series of oil-free screw compressors has multiple benefits for the customer. The ELGi’s OF series compressors come with unique η-V rotors that are designed to run at low speeds, reduce pressure losses, and increase stage efficiencies, leading to an optimized compressed air system. The slow speed of air ends leads to lesser wear and tear, lesser vibration, and enhanced life of the compressor. The timing gears are adequately placed to ensure the rotors are not in contact for effective functioning and consistent air and performance across the product lifecycle. The ELGi’s unique two-layer coating process provides a smooth and uniform surface. This also ensures porosity-free uniform coating on the rotors. The carbon impregnated robust stainless steel air seals prevent air leakage from the compression chamber by radial and axial sealing. The air-cooled compressors come with an aluminium bar and plate-type heat exchanger. The water-cooled compressor has water-in tube features with an extended cooler tube surface and systems that ensure low fouling and lower pressure drop across the cooler.

The ELGi’s OF series oil-free compressors come with the best-in-class warranty program. They are available in air-cooled and water-cooled variants with fixed speed and variable speed options operating in the range of 1.5 to 10 bar. The ELGi OF series compressors are an ideal solution for critical industries that need clean class zero oil-free air with a low total cost of ownership, easy maintenance, and unrivalled customer service. The ELGi OF series oil-free screw air compressor for critical industries.

0 notes

Text

Double Speed Hand Pumps, Hydraulic Power Pack, Manufacturer, India

Double Speed Hand Pumps, Hydraulic Power Pack, Hydraulic Jacks, Mechanical Infringing Track Jack, Hydraulic Torque Wrenches, Hydraulic Power Packs For CNC Machines, Shell And Tube Hydraulic Water Oil Cooler Heat Exchangers, Hydraulic Mobile Floor Cranes, Manufacturer, Supplier, Exporter, Belgaum, Karnataka, India.

Double Speed Hand Pump, Double Speed Hand Pumps, Hydraulic Power Pack, Hydraulic Power Packs, Hydraulic Jack, Hydraulic Jacks, Hydraulic High Pressure Jack

0 notes

Text

Heat Exchanger | Shell & Tube Heat Exchanger | Oil Cooler Heat Exchanger Manufacturer, Supplier, Exporter India

We are leading Shell and Tube Type Heat Exchangers, Oil Cooler Heat Exchangers manufacturer, Supplier, exporter India. Heat Exchangers are used in variety of industries like Oil and Gas Industries, Chemical Industries, Power Industries, Marine Applications, Defense Industry for desired applications.

Phoenix Industries at a Glance

Phoenix Industries is an ISO 9001:2015 certified company that has been designing and manufacturing shell and tube type heat exchangers, Sealant Injection Grease Fittings, High Pressure Instrumentation Valves, Heat Exchangers, Precision Machined Components and Sub-assemblies for Oil and Gas Industries, Chemical Industries, Power Industries, & Marine Applications, Foundries for the last 22+ years.

Our founder Mr. Sachin Kulkarni is an epitome of experience and motivates his robust team to perform above expectations. The company is being managed by promoters who have the required technical and financial expertise and they work in synchronization with a dedicated team of engineers and technocrats to excel in everything they do.

We believe in ‘KAIZEN’ a Japanese principle of quality management which enables us for continuous improvement of our products and services, and hence maintaining ‘TOTAL QUALITY MANAGEMENT (TQM)’. We assure you the ‘Best’ quality product with ‘excellent’ services using precision machines and latest technology at most competitive prices.

Our Core Ideology

Vision

To Form and Achieve Sustainable Growth Brand to Enrich life of our Stake Holders with 50 Cr Business Target

Mission

We manufacture precision machined bar turned components and assemblies for high pressure application industries which deals with all types of liquids and gases, critical machining applications & heat exchanger industries with the help of total involvement of our team, process management, highly technical expertise in development of new products , capability of machining and supply in varied materials Grades.

Core Values

· Humanity

· Professionalism

· Continual learning

· Loyalty

· Creativity

Why to choose Phoenix for Heat Exchangers?

· Compact design to save space which makes installation easier.

· Premium quality components used in manufacturing.

· In house design facility equipped with latest software.

· Dedicated welding facilities with certifications to establish manufacturing process for any new material.

· Expert team to provide accurate thermal calculations.

Product Features:

· Flexibility of heat exchanger to be designed according to customer requirements, drawings and technical requirements.

· Flexibility in manufacturing and material requirement with various configurations.

· In house design facility equipped with required software and thermal design requirements.

· Strictly adherence to Standards established for Shell and Tube Heat Exchangers.

· Provision for Sacrificial Zinc Anode for Rust Susceptible configurations to prevent decay and corrosion for cost saving configurations.

· Interchangeability of available components.

Technical specifications of our Heat Exchanger:

· Design Code: TEMA, ASME SEC VIII, BS-5500, HEI, API

· Type: Fixed Tubes

· Shell diameter: 60 mm to 200 mm

· Tube length: 152 mm to 750 mm

· Tubes: Plain

· M.O.C. Tube: Carbon Steel, Stainless Steel, Copper, Adm. Brass, Aluminum, Bronze, Duplex, Cupro-Nickle, Titanium

· Shell: Carbon Steel, Stainless Steel, Copper, Brass, Aluminum,

0 notes

Text

https://www.phoenix.ind.in/oil-cooler-heat-exchanger-shell-and-tube-manufacturer-supplier-india.php

#shell and tube type heat exchangers#heat exchangers manufacturer#oil cooler heat exchanger manufacturer#supplier#exporter#india"

0 notes

Text

1 note

·

View note

Text

Industrial Silica Sand Market to Observe Strong Growth to Generate Massive Revenue in Coming Years

Latest Report Available at Advance Market Analytics, “Industrial Silica Sand” Market” provides pin-point analysis for changing competitive dynamics and a forward looking perspective on different factors driving or restraining industry growth. The global Industrial Silica Sand market focuses on encompassing major statistical evidence for the Industrial Silica Sand industry as it offers our readers a value addition on guiding them in encountering the obstacles surrounding the market. A comprehensive addition of several factors such as global distribution, manufacturers, market size, and market factors that affect the global contributions are reported in the study. In addition the Industrial Silica Sand study also shifts its attention with an in-depth competitive landscape, defined growth opportunities, market share coupled with product type and applications, key companies responsible for the production, and utilized strategies are also marked. Some Chongqing Changjiang River Moulding Material (Group) Co. Ltd (China),Fairmount Santrol Inc. (United States),Sibelco (Belgium),U.S. Silica Holdings Inc. (United States),Mitsubishi Corporation (Japan),Tochu Corporation (Japan),International Silica Industries Company Plc (Jordan),Superior Silica Sands LLC (United States),Saudi Emirates Pulverization Industries Company (Saudi Arabia),Short Mountain Silica (United States),VRX Silica Limited (Australia),FINETON Industries Minerals Limited (China),AGSCO Corporation (United States),JFE Mineral Co., Ltd. (Japan),Gujarat Mineral (India), in the Global Industrial Silica Sand Market are Chongqing Changjiang River Moulding Material (Group) Co. Ltd (China),Fairmount Santrol Inc. (United States),Sibelco (Belgium),U.S. Silica Holdings Inc. (United States),Mitsubishi Corporation (Japan),Tochu Corporation (Japan),International Silica Industries Company Plc (Jordan),Superior Silica Sands LLC (United States),Saudi Emirates Pulverization Industries Company (Saudi Arabia),Short Mountain Silica (United States),VRX Silica Limited (Australia),FINETON Industries Minerals Limited (China),AGSCO Corporation (United States),JFE Mineral Co., Ltd. (Japan),Gujarat Mineral (India)

Industrial silica sand is defined as the high purity silica sand products which contain highly texture and composition. It is suitable for numerous industrial applications such as glass & clay production, foundry work, oil well cement, among others. It is usually found in crystalline form and comprises of rounded sands of pure quartz grains. Various advantages of using silica sand in industries, namely high-quality, pure and well-rounded quartz grains, high compression strength and durability, and others benefit. Increasing glass manufacturing plants and increased applications in the construction industry are anticipated to drive the growth of the industrial silica sand market over the forecast period. What's Trending in Market: Technology Advancement in Silica Sands Products

Challenges: Employee Health Concerns Related to Respirable Silica Dust

Market Growth Drivers: Increasing Mineral Resource Production in the Asia-Pacific Region

Increasing Use of Industrial Silica Sand in Various Industrial Applications

The Global Industrial Silica Sand Market segments and Market Data Break Down by Type (Less than 40 mesh, 40-70 mesh, More than 70 mesh), Application (Glass & Clay Production {High Purity Silica glasses, Specialty Glasses, Fiber Glass, Others}, Foundry work {Product Types, Cooling Technolgy}, Others {Oilwell Cement, Ceramic Frits & Glaze, Sodium Silicate, Cultured Marble, Reinforcing Filler, Additives Others}), Foundry Product Technology (Resin coated, Whole Grain Silica), Foundry Cooling Technology (Vibrating Fluid Bed Coolers, Rotary Cooling Drums, Indirect Heat Exchanger), Vertical Industry (Glass Industry, Construction Industry, Automotive Industry, F&B Industry, Others)

Presented By

AMA Research & Media LLP

0 notes

Text

Swastik Hydraulic: A Premier Heat Exchanger Manufacturer in India

Swastik Hydraulic is one of the most recognized heat exchanger manufacturers in India, which is based on the company’s quality, innovation, and excellent services provided to the customers.

Being a specialist firm in this endeavour, the company deals in the fabrication and manufacturing of various types of heat exchangers used extensively in various applications.

We are a technological company emphasizing the quality of its products which is why many businesses involved in thermal leadership turn to Swastik Hydraulic for solutions.

Range of Products

Swastik Hydraulic Company specializes in different heat exchangers such as Shell and Tube Heat Exchangers, Air Cooled Heat Exchangers, Hydraulic Oil Coolers and Water Cooled Condensers.

Dealing with heat exchangers particularly shell and tube heat exchangers the company has emerged one of the leading suppliers of heat exchangers based in India; it endeavors to design some of the most powerful models to ensure enhanced heat transfer rate enhanced with reliability and durability.

These heat exchangers are specifically intended for the tough pressure that the processing industries, such as chemical, petrochemicals, power plants etc. employ.

Shell and Tube Heat Exchanger Manufacturer

This type reflects the most general and frequently used style of heat exchange equipment in the industry, Shell and Tube heat exchange equipment.

As Swastik Hydraulic is one of the leading manufacturers of shell and tube heat exchangers it has accept engineering practices that are helpful for the company to design the heat exchangers on which offer the best thermal efficiency and mechanical strength.

The company is in a position to benefit from having designed and produced the said exchangers in that it is in a position to address the high pressure as well as high temperature applications that are widely known in so many industries.

Leadership in Air Cooled Heat Exchangers

Apart from shell & tube type, the organization is also one of the reputed air cool heat exchanger manufacturing company in India. Such exchangers are aimed at cooling of fluids making use of air without involving water cooling systems.

This is not only useful in the reduction of expenses but also useful in that it enables an organization or company that is being accused of polluting the environment affects it in the least way possible. Swastik Hydraulic started manufacturing Air-cooled heat exchangers that are strong enough to work in any or different climate conditions of industries.

Customization and Quality Assurance

This flexibility is one of the biggest advantages of Swastik Hydraulic, for the company sends its specialists to the client and presents a package of proposals, developed specifically for this particular client. Its basic product is the mild steel heat exchanger but just as it stands for its hydraulic oil cooler.

It works hand in glove with customers to provide them with equipment that suits the task that the latter intends to perform. This makes the heat exchangers more efficient and reliable to the customers while at the same time, the quality control measures put in place make every heat exchanger unit produced to meet the required high standard.

Presence in Delhi NCR

Swastik Hydraulic one of the leading heat exchanger manufacturer company in Delhi NCR has its prominent position in one of the most competitive industrial zone of India. Due to the company’s strategic location, it is capable of catering for several players, responding to their needs promptly.

We have a great many distributors and service centres that guarantee the customers’ fast access to the support and maintenance services, thus increasing the value of the goods and services they bought.

The constant endeavour of establishing Ultimately, commitment to innovation and sustainability is one of the key drivers that help organisations achieve their long-term goals.

Swastik has kept up with these improvements and therefore provides a solid foundation for a heat exchanger manufacturer in India.

Through systematic research and development, the company does not stop on the products they had developed but instead comes up with new technological applications to increase production efficiency whereby energy consumption is reduced. This moral towards sustainability proves to be not only good for the environment but also for clients’ wallets and general business success.

To summarize, Swastik Hydraulic thus claims a central position among India’s heat exchangers and supplies an extensive range of solutions for various industries.

The company has been a global leader in offering solutions for shell and tube heat exchangers, air-cooled heat exchangers and a lot more, which marks its superiority in terms of quality, innovative technologies and customer satisfaction.

In conclusion, We continues to be a reliable supplier for industries in India and today’s global market where the need for better and efficient heat exchangers is on the constant rise.

Contact Details

Head Office: D-53, 2nd Floor, Hari Nagar, Clock Tower,Near Raja Sweets, New Delhi - 110064 (INDIA)

Call: +91-9873029293 (Pushpinder Sandhu)

Email: [email protected]

#WaterCooledCondenser#HydraulicOilCooler#heatexchangermanufacturers#heatexchangermanufacturersinindia#heatexchangermanufacturerindelhincr#shell&tubeheatexchangermanufacturerinindia#shellandtubeheatexchangermanufacturerinindia#shellandtubeheatexchangermanufacturer#industrialheatexchangermanufacturer#aircooledheatexchangermanufacturerinindia#MildSteelHeatExchangerManufacturer

1 note

·

View note