#non return valve in ahmedabad

Explore tagged Tumblr posts

Text

A Beginner’s Guide to Non Return Valves and Their Uses

Non return valves, also known as check valves, are essential components in many industries to ensure the proper flow of fluids or gases in a single direction. These valves play a crucial role in preventing backflow, which can damage equipment, contaminate systems, or reduce operational efficiency. This article provides a comprehensive beginner’s guide to understanding non return valves and their uses, with insights into finding the best Non Return Valve Manufacturer in Ahmedabad like Allied Valves India.

What Is a Non Return Valve?

A non return valve (NRV) is a type of valve that allows fluid or gas to flow in one direction while preventing reverse flow. The valve operates automatically and does not require manual intervention or external control. The design of non return valves typically includes a hinged flap, ball, or disc that closes off the flow path when reverse flow occurs.

Types of Non Return Valves

Non return valves are available in various designs to meet specific application requirements:

Swing Check ValveA hinged disc swings open to allow forward flow and closes to prevent backflow. Commonly used in pipelines with large flow volumes.

Ball Check ValveA ball is pushed by fluid pressure to allow flow and seals against the valve seat when reverse flow occurs.

Lift Check ValveThe disc or ball is lifted by fluid pressure to permit forward flow and drops back into place to block reverse flow.

Wafer Check ValveA compact and lightweight valve ideal for limited-space installations, typically used in water treatment plants.

Key Applications of Non Return Valves

Non return valves are used across industries to protect systems and equipment. Here are some common applications:

Water Supply Systems

In water pipelines, non return valves ensure that contaminated water does not flow back into the main supply.

Pumps and Compressors

Non return valves prevent reverse flow, which could damage pumps, compressors, and motors.

Chemical Processing

In chemical plants, non return valves safeguard against the mixing of incompatible chemicals.

Oil and Gas Industry

They are used to maintain directional flow in pipelines, ensuring safety and efficiency.

HVAC Systems

Non return valves regulate airflow in heating, ventilation, and air conditioning systems to improve energy efficiency.

Advantages of Non Return Valves

Prevention of Backflow: Protects equipment and maintains system integrity.

Energy Efficiency: Reduces energy losses by ensuring uninterrupted flow.

Automatic Operation: Requires no manual control or monitoring.

Low Maintenance: Simple design leads to reduced maintenance costs.

Choosing the Right Non Return Valve Manufacturer

When selecting a non return valve, partnering with a reliable manufacturer is critical. If you are looking for high-quality valves, Allied Valves India, a leading Non Return Valve Manufacturer in Ahmedabadf, offers durable and efficient solutions tailored to diverse industrial needs.

Why Choose Allied Valves India?

Quality Assurance: High-grade materials and robust construction.

Custom Solutions: Valves designed to suit specific applications.

Affordable Pricing: Competitive rates without compromising quality.

Expert Support: Technical guidance to help select the right valve for your system.

Conclusion

Non return valves are indispensable for maintaining the efficiency and safety of fluid and gas flow systems across industries. Understanding their types, uses, and advantages helps in making informed decisions for your industrial requirements. For high-performance non return valves, trust Allied Valves India, a reputed Non Return Valve Manufacturer in Ahmedabad, to deliver solutions that ensure reliability and excellence.

0 notes

Text

Welcome To Kana Valves Pvt. Ltd.

Kana Valves Pvt. Ltd. Is An Iso 9001:2015 Certified Company in Ahmedabad, Gujarat, India. We Are India’s Leading Brand Name as a Manufacturer, Exporter, And Supplier of Plumbing Products In India. Kana Valves Pvt. Ltd. offers plastic valves and plunging pipe and fittings, pipe adhesives or solvent cements taps faucets and foots valve, and non-return valves. We are a team of dedicated professionals from the stainless steel industry, committed to providing the highest quality products and services to our customers. With advanced manufacturing facilities, a skilled team, and a robust global network, we are able to offer seamless delivery and service worldwide. We invite you to explore our range of products and discover why Kana Valves Pvt. Ltd. is the trusted name in the valve and fitting industry. Our team is comprised of experienced professionals with expertise in production, sales, engineering, and customer service. We source the best raw materials and use advanced production technologies to craft superior products that exceed industry standards. We also value our customers’ time and guarantee on-time delivery throughout India. For more details on our product catalog, please contact us using the provided information. Contact Number: 1800 258 4141 Email id: [email protected] Read the full article

#AdvancedTechnology#Ahmedabad#andnon-returnvalves#CustomerSatisfaction#CustomerService#Engineering#Exporter#Faucets#FootValve#GlobalDelivery#Gujarat#India#IndiaExport#IndustrialSupplies#ISO9001#KanaValvesPvt.Ltd.#KanaValves#KanaValvesPvtLtd#MadeInIndia#Manufacturer#ManufacturingExcellence#NonReturnValves#pipeadhesivesorsolventcements#PipeFittings#plasticvalvesandplungingpipeandfittings#PlasticValves#PlumbingIndustry#PlumbingProducts#PlumbingSolutions#QualityProducts

1 note

·

View note

Text

Gate Valve Exporter - Mayur Valves MVS

Mayur (Valves) System Private Limited is an ISO 9001 : 2015 Certified Company, Established in the year 1978, MVS Industrial Valves offers Diaphragm Valves, Ball Valves, Plug Valves, Butterfly Valves, Gate Valves, Globe Valves, Check Valves or Non Return Valves, Knife Gate Valves, Sight Flow Indicator or Sight Glass, Strainer or Filters, PTFE / FEP / PFA / PVDF Lined Valve, PTFE Lined Pipe, PTFE / FEP / PFA / PVDF Lined Pipe Fittings and Plastic / PP / PVDF Valves. Gate Valve Manufacturers Exporters in India MVS Industrial Valves have been exported to more than 40+ countries worldwide

Assurance of Quality: Mayur Valves MVS follows strict quality control procedures to guarantee that every gate valve satisfies global requirements. Every stage of the production process, from obtaining raw materials to inspecting the finished product, is cantered upon quality.

Wide Product Selection: To meet the needs of many applications and industries, Mayur Valves MVS provides a wide selection of gate valves. Mayur Valves MVS offers a solution for your needs, whether they are for industrial operations, oil and gas, or water supply valves.

Customization Options: Mayur Valves MVS offers customization options to fit gate valves to individual demands, acknowledging that every project has different requirements. Customers can request customized solutions, ranging from material selection to size and design alterations.

Reliable Performance: Mayur Valves MVS gate valves are built to provide constant performance even in the most demanding conditions, with a focus on durability and dependability. Thorough testing guarantees that every valve surpasses expectations and fulfils performance criteria.

Global Reach: Mayur Valves MVS reaches markets on all continents as an exporter, providing services to clients all over the world. Customers can count on prompt product delivery no matter where they are thanks to an efficient distribution system and effective logistics.

Conclusion

Go no further than Mayur Valves MVS for quality gate valves built for dependability and performance. Dedicated to quality and client satisfaction, Mayur Valves MVS is still a reliable partner for businesses worldwide. Get in touch with us right now to find out more about our offerings.

Contact Us: - +91 9898563969 [email protected]

Address: - Mayur (Valves) System Private Limited, SOBO Center, 421, Block B, 4th Floor, Gala Gymkhana Road, Near Sun City, South Bopal, Ahmedabad - 380058, Gujarat, India.

Visit for More Information: - https://mvsvalves.com/

#Gate Valve Exporter#Gate Valve Manufacturers Exporters in India#gate valve manufacturers exporters in gujarat#gate valve manufacturers exporters

0 notes

Text

ball valve manufacturer in Gujarat

Yakshita Engineering is well-known name among Needle Valves Manufacturer, Ball Valves Manufacturer, Check Valves Manufacturer, instrument Manifold Valves Manufacturer and Non return Valves Manufacturer in Ahmedabad, Gujarat, India. We are Manufacturers of a wide variety of pressure valves, instrument valves as well as snubbers, gauge cocks, siphons, and high precision products under the brand name “YAKSHITA”.

0 notes

Text

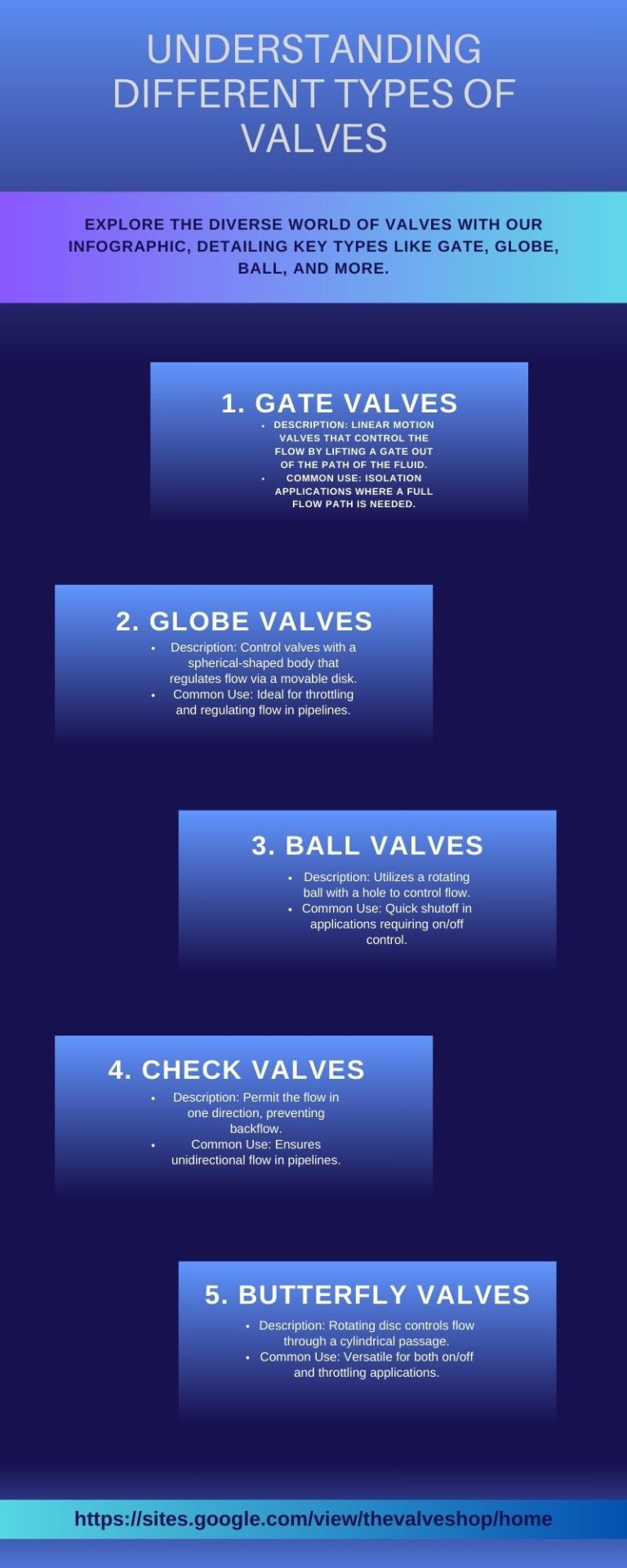

Description:

Understanding Different Types of Valves provides a comprehensive overview of key valve varieties crucial in fluid control systems. Gate valves, with linear motion, excel in isolation, while globe valves offer nuanced regulation. Ball valves ensure swift on/off control, check valves maintain unidirectional flow, and butterfly valves offer versatile usage. Each valve type caters to specific needs, from precise throttling to rapid shutoff, impacting industries like oil, water treatment, and manufacturing. This infographic empowers decision-makers to select the right valve for optimal system performance, emphasizing the importance of evaluating specific application requirements. Explore this informative guide to enhance your knowledge of these essential components shaping fluid dynamics across various sectors.

Gate Valves:

Gate valves are essential linear motion devices that manage the flow of fluid by lifting a gate obstructing the path. These valves are particularly valuable in applications where a full and unobstructed flow path is required. The operation of gate valves involves raising the gate to permit flow and lowering it to block the passage of fluid. This on/off functionality makes gate valves suitable for isolation purposes, allowing for efficient control of liquid or gas flow.

Globe Valves:

Globe valves are characterized by their spherical-shaped bodies and a movable disk that regulates the flow. Unlike gate valves, globe valves provide more nuanced control over fluid flow, making them ideal for applications that require throttling and precise regulation. The design of the globe valve allows for fine-tuning the flow rate by adjusting the position of the disk, offering versatility in managing the movement of liquids or gases through a pipeline.

Ball Valves:

Ball valves utilize a rotating ball with a hole to control the flow of fluids. These valves are particularly advantageous for applications requiring quick shutoff or on/off control. The simplicity of their design, consisting of a spherical closure element, ensures a reliable and efficient operation. Ball valves find extensive use in various industries where rapid control and shutoff are critical, providing a durable solution for managing the flow of liquids or gases.

Check Valves:

Check valves, also known as non-return or one-way valves, permit fluid flow in only one direction while preventing backflow. These valves play a crucial role in ensuring unidirectional flow within pipelines. The design of check valves typically includes a mechanism that allows the flow to open the valve while preventing reverse flow. This feature is vital in preventing the contamination of systems and maintaining the desired direction of fluid movement, making check valves essential components in a wide range of piping applications.

Butterfly Valves:

Butterfly valves feature a rotating disc within a cylindrical passage to control the flow of fluids. These valves offer versatility, serving both on/off and throttling applications. The quarter-turn motion of the disc allows for quick and efficient control of the flow, making butterfly valves a popular choice in situations where precise regulation is necessary. Their compact design and ease of operation contribute to their widespread use in various industries, including water treatment, HVAC systems, and chemical processing.

Visit:

0 notes

Text

Screw Conveyors Supply in Cairo

- Screw Conveyors Supply in Cairo“R Mech Machines LLP” were established in 2008 in Ahmedabad, Gujarat, India. - We manufacture and supplier of a comprehensive range of Bale Opener Machines, Grinder Machines, Industrial Dryers, Conveyor Belt, Dewatering Machine, Floating Tank, Force Feeder Machines, Friction Washer Machine, Bottle Recycling Plant, Granulator Machines, Label Removing Machine. - Our goods are made using the highest quality components and advanced technology under the supervision of our experienced employees and in accordance with international quality standards. What Is the Use of Screw Conveyors? - Screw conveyors, also known as auger conveyors, are pieces of industrial machinery used to move large quantities of granular solids (such as powder, grains, or granules), semi-solids, liquids, and even non-flowing materials. By removing the need for the employees to manually move loads, they maintain great operating efficiency. - The main component of a screw conveyor is a revolving screw shaft that is mounted inside a trough. - The material is linearly moved by the screw shaft as it revolves. They can be made to offer straight, angled, and vertical movement pathways. Features - Simple and trouble-free functioning. - Very little investment and very little power use. - Rigid construction, manufactured with top-notch materials and cutting-edge production techniques. - According to the needs of the process, we can offer screw conveyors that are horizontal, inclined, or vertical. - We can provide screw conveyors in various sizes, pitches, and materials. Benefit of Screw Conveyors - Screw conveyors can handle a wide range of bulk materials, from slow-moving to freely flowing. - Numerous inlet and outflow points are possible with screw conveyors. Bulk supplies can be transported and dispersed as needed to different places. - You can add slide gates or valves to a screw conveyor to regulate the flow into and out of the conveyor.A screw conveyor is referred to as a screw feeder when it is employed as a metering tool. Screw feeders are used to take items from a bin or hopper to start a material operation. - Screw conveyors are incredibly small and flexible in crowded spaces. Unlike a belt or drag conveyor, a screw conveyor does not have a return. R Mech Machine LLP is a Supplier of Screw Conveyors Supply in Cairo. If you are interested then contact us. we will offer you our best quality product. Call: Email: Read the full article

#Cairo#ConveyorBelt#GranulatorMachines#LabelRemoving#RMechMachinesLLP#Screwconveyors#ScrewConveyorsSupply#ScrewConveyorsSupplyinCairo

0 notes

Link

youtube

#Yakshita engineering#needle valves#needle valve supplier#ball valves#ball valve manufacturer in ahmedabad#high pressure ball valve#stainless steel ball valve#safety valve#safety valve manufacturer#syphon pressure gauge#gauge cocks supplier#check valves#non return valve#check valve manufacturers in india#stainless steel check valve

1 note

·

View note

Text

Rise the Demand for Non Return Valve Manufacturers in All Over India

Valve is a kind of device that is vastly being used and applied in many industries because of its features and application. If you're like most people, you probably didn't know that Non Return Valves Manufacturer in Mumbai have a huge demand in the industry.

A non-return valve allows a medium to flow in only one direction and is fitted to ensure that the medium flows through a pipe in the right direction, where pressure conditions may otherwise cause reversed flow. A non-return valve restricts flow reversal in the system and ultimately keeps the water hammer at a lower magnitude. A check valve is a valve that closes to prevent the backward flow of liquid (backflow) and is required by law to prevent water that's already in your equipment from re-entering the main supply.

So, when you are across many different valves than at that you have to seek for, a cross sign (✖️) on the head of the spindle, seeing this you can easily figure out that the one with a cross sign is the non-return type. It is an easy way to identify the non-return valve among the bunch of many valves. It is required by law to prevent water that's already in your equipment from re-entering the main supply as the check valve closes to prevent the backward flow of liquid. Non Return Valve Manufacturers in Chennai are in enormous demand in the industry and the market is growing every day.

The rising use has emerged demand for valves in the oil & gas industry is the main factor anticipated to fuel the expansion of the global non-return valve market over the coming years. By 2030, there will be significant gains as a result of additional factors such as rising end-user demand, the high rate of adoption of these valves in developing nations, and an expanding economy through the demand for non-return valves.

An increase in the demand for the non-return valve in the market will mainly benefit the industry and related people as they will be the emergence of new opportunities. As new options are emerged to provide the best services there will be a depth analysis of the Non Return Valve Manufacturer in Kolkata market. Based on the result of the analysis there will be innovation and invention in the market.

The expansion of non-return valve manufacturers and the regional market is primarily driven by two factors: an increase in the demand for safety applications and an increase in R&D efforts of the use of automated valves. As we know these valves are used by the oil and gas industry. As we know that these oil and gas are supplied through a long pipeline connection, to maintain proper flow of the oil and gas non-return valve are used. As there is a huge expansion of oil and gas and automatic demand for the valve in the market.

The market is expanding as a result of the increasing export of Indian goods to overseas markets. The expansion of FDI in many sectors, notably the oil and gas industry, is assisting market expansion even water treatment using non-return valves during the process.

There are Various Types of Check Valve:

There are various types of Check Valves Manufacturers in Ahmedabad, Gujarat and other market such as lift check valves, Swing check valve, folding disc check valve, Tilting disc check valve, and vertical check valve.

Non-return valves exist in a variety of sizes and shapes, but they are typically small and affordable. A variety of non-return valve has a different purpose and their application as per the requirement of the industry.

Yakshita engineering has been the reputed manufacturer of the valves in the national and international markets for the past 10 years. Manufacturer of needle valve, Check Valve Manufacturer in Chennai, safety valve, check valve, tube fittings, and many other products in India. We export our high-quality goods to countries including Tanzania, Bangladesh, Vietnam, Egypt, Iran, Malaysia, Japan, Malaysia, Nepal, Oman, Spain, the United Kingdom, and the United States of America. As a manufacturer follow all applicable health and safety, environmental, process, and quality standards.

#Check Valve Manufacturer in Chennai#Check Valves Manufacturers in Ahmedabad#Check Valves Manufacturers in Gujarat#Non return Valves Manufacturers in Mumbai#Non return Valves Manufacturers in Chennai#Non return Valves Manufacturers in Kolkata

1 note

·

View note

Text

How Non Return Valves Work: A Comprehensive Guide

Selecting the right non return valve involves considering factors such as the type of fluid, pressure requirements, and flow conditions. For example, a swing check valve might be ideal for a low-pressure water system, while a ball check valve could be better suited for high-pressure applications. If you're looking for a non return valve that suits your specific needs, it's beneficial to consult with a non return valve Supplier in Ahmedabad. They can provide guidance on selecting the right valve type and ensure that it meets your operational requirements.

0 notes

Text

Non Return valve manufacturers in Ahmedabad

Check Valve - Non Return Valve manufacturer ahmedabad, supplier and exporter of high quality Stainless Steel Valves by Yakshita Engineering In all major cities of India.

0 notes

Link

#hydraulic check valve#hydraulic check valve in ahmedabad#hydraulic non retun valve#inline hydraulic check valve#non return valve#non return valve india

0 notes

Link

Check Valves Manufacturer

Top manufacturer of check valves and their types such as wafer type check valve, high pressure non-return valve and other is lined ball valves offerd by accurate valve in ahmedabad, india

#check valves manufacturer#high pressure non-return valve#wafer type check valve#lined ball valves manufacturer#lined butterfly valves manufacturer#lined diaphragm valves manufacturer

0 notes

Link

#check valves#non return valve#two way check valve#check valve in india#check valve manufacturers in india#check valve suplier#high pressure ball valve#industrial check valve#instrumentation valves and fittings#high pressure valves#high pressure valves manufacturers#industrial valve manufacturer#instrument valve#instrument valves#instrument valves in india#instrument valves in gujarat#instrument valves in ahmedabad

0 notes

Text

Specification of Check Valve or Non-Return Valve Manufacturers in India

Various industries use valves to help with the movement of gas, liquid, and loose material in bulk. The flow can be started, halted, or controlled by a moveable element that opens, closes, or partially obstructs. There are various valves present that perform various functions in a different industry. To meet the needs of diverse industries, valves assist in controlling the flow and pressure inside a piping system.

The Check valve manufacturer in Mumbai can be defined as “Non return Valve designed to prevent back-up of liquids or gases in the line. It's made of durable plastic and is incorporated into a hand grip. Simply adjust the valve to the desired setting and place it in the desired location. Once set, the valve will keep liquids or gases from flowing back into the tank. Check Valve Hand Grips are available in four sizes to accommodate a variety of containers. The dial hand-grip features a bright red band and clear indicators for easy viewing of the setting.”

A Non return valve manufacturer in Chennai is also a type of valve that helps to flow the liquid in one-way direction. A check valve is a valve that opens with a positive flow pressure and closes when the flow reverses. A check valve is often part of a domestic water supply piping system. Check valves or Non return valves are used to prevent backflow into the domestic water supply. Check valves are used in a wide variety of applications, including domestic water systems, fire sprinkler systems, sewage treatment plants, and irrigation systems.

Check valves are often used in household water systems to keep water flowing in the right direction. The device consists of a movable disc or plate that opens and closes to allow fluid to flow. Check valves are often used in water systems to prevent water from flowing back into the pump, and in sewer systems to prevent sewage from flowing back into the home. Check valve manufacturer in Kolkata also used in oil and gas pipelines to prevent oil or gas from flowing back into the pump.

Check valves or Non return valves are made up of numerous parts. These parts work together to open and close the valve as needed. The body of a check valve is the housing that contains all of the internal parts of the valve. The body is connected to the piping system and has ports that allow fluid to enter and exit the valve.

It consists of a ball or disc that is placed in the path of the liquid. A check valve's primary function in a system is to stop backflow, which could harm machinery or contaminate media upstream. Check valves help to direct gas and liquid flow in one direction, which automatically prevents backflow and protects against harm.

If a check valve is fast, like a spring-actuated check valve, it can help stop the water hammer. By doing this, pressure spikes that send shockwaves through the medium are avoided. Therefore, a Non return valve manufacturer in Ahmedabad, Gujarat can help to prevent water hammer.

The main applications of the Check valves or Non-Return valves are as below:

To prevent downstream equipment from being damaged by backflow as if the flow of liquid flows backward then can cause losses.

Avoiding pollution brought on by reverse flow and flow in one direction.

To stop diverting the fluid or gas to divert in another direction and make sure that it flows in the required direction.

Check valve preserves the vacuum sea, so that bubble-tight sealing without high leak integrity.

In some systems, a common header may be used to exhaust a variety of gases.

It is advised that separate check valves be installed on each gas vent line to ensure that the gases can't combine inside the system.

Check valves should be regularly checked for proper operation because the parts inside are susceptible to deterioration.

Over the past ten years, Yakshita Engineering has established a solid reputation in the global market of India. As we are manufacturer of check valve manufacturer in Haryana, Delhi, Ghaziabad, Hyderabad etc. in major cities of India with the best quality.

#Check Valve Manufacturer#Check Valve Supplier#Check Valve Exporter#Non-Return Valve Manufacturer#Non-Return Valve Exporter

1 note

·

View note

Text

How to Troubleshoot Common Issues with Non Return Valves

Selecting a high-quality non return valve is key to minimizing issues. When sourcing a non return valve, it's beneficial to consult with a reliable non return valve Supplier in Ahmedabad. These Suppliers can provide valuable insights into the right valve for your specific needs, ensuring compatibility and reliability.

0 notes