#multi Cavities mold

Explore tagged Tumblr posts

Text

multi cavities thin wall stack mold

China precision mold maker, offer multi cavities thin wall mold, thin wall stacking mold, stack thin wall box mold, hamburger mold, fresh container stack mold

#China mold#multi cavities mold#thin wall mold#stack mold#stacking mold#hamburger mold#double stack mold#fresh container stack mold

0 notes

Text

Talking about mold optimization from perspective of injection molding process 7

For previous article reading, please refer to “Talking about mold optimization from perspective of injection molding process 1, 2, 3, 4, 5, 6.Selection and optimization of hot runner moldsHot runner mold refers to a mold that uses a heating device to keep melt in runner from solidifying. Because it has a shorter forming cycle than traditional molds and saves more raw materials, hot runner molds…

View On WordPress

#hot runner molded products#hot runner molds#hot runner system#Hot runner system structure#injection molding process#Injection molding product#multi-cavity plastic parts

0 notes

Text

Precision-crafted small cup with lid mould – perfect fit, perfect seal, every time.Email: [email protected]

#Injection mold#Plastic injection molding#Custom mold design#Multi-cavity mold#Plastic mold manufacturing#Hot runner system#manufacturer#china#factory#pp

0 notes

Text

#single cavity mould design#mold cavity and core#core and cavity of a mold#collapsible core mould design#multi cavity mold design

0 notes

Text

The reason why we manufacture multi cavity plastic molds is very simple. It is to control the unit cost of plastic molding parts production. For example, the production cost of a 160 ton injection molding machine is USD8 per mold. If you use an 8-cavity mold to produce parts, the production cost of each part is USD1. If you only use a 2-cavity mold to produce parts of this machine, the unit production cost is USD4. If you need one million or more parts, You can imagine how much cost can be saved from the 8-cavity mold, which is why the multi cavity mold is so popular with customers.

0 notes

Text

JWZ-BM05D/12D/20D Double Station Blow Molding Machine

Performance and advantages 1. Suitable for producing 1-5L different size of gear oil bottle, lubrication oil bottle, cooling water tank etc. 2. Optional multi-layer co-extrusion. 3. Optional view strip line system. 4. According to the product size,select different cavity of die head. 5. According to the different material,optional JW-DB single station hydraulic screen-exchanger system. 6. According to customer's requirement,optional auto-deflashing on line,scrap conveying on line,finished product conveying on line. Technical Parameters Model Unit BM05D BM12D BM20D Max product volume L 5 12 20 Dry cycle Pc/h 700*2 600*2 600*2 Die head structure Continuous type Main screw diameter mm 75 90 90 Max plasticizing capacity (PE) kg/h 90 160 160 Driving motor Kw 30 45 45 Oil pump motor power Kw 11 15 15 Clamping force KN 70 120 160 Space between platen mm 150-510 240-640 280-680 Platen size W*H mm 350*400 450*500 500*520 Max.mould size mm 360*400 500*520 560*520 Platen moving stroke mm 450/520 600/650 650 Heating power of die head Kw 7.5 10 12.5 Machine dimension L*W*H m 3.7*3.1*2.7 4.2*3.2*3.0 4.3*3.2*3.1 Machine weight T 8.5 12 14 Total power Kw 60 90 93 Note: Informations listed above are for reference only, the production line can be designed by customer’s requirements. Product image display JWELL Co., Ltd. was founded in 1978, the Chinese biggest plastic extrusion machinery manufacturers with over 24 years in extrusion industry .Now we have 6 production base , more than 3000 employees, having a strong technical & after sales service team for serving more than 150 countries. Core components: screw and barrel, mold, roller, all processed by us. jwell group has 16 professional branches, each of which produces different products, You can get all the plastic extrusion equipments you need in jwell company and provide you with one-stop service. Our processing equipment is all CNC imported from Japan and Europe. The steel used in our machine is superior to our peers. For the same equipment, the lifetime of jwell company's equipment is generally two or three times longer than our peers. The electrical components used in our equipment are imported brands or Chinese famous brands, and they are specially optimized and designed according to the requirements of jwell company, which can well match our equipment. Other companies do not have such strength and influence. There is an old saying in China:You get what you pay for! Read the full article

2 notes

·

View notes

Text

Plastic parts manufacturing: 7 effective ways to reduce production costs

Cost control is a basic strategy for many companies to maintain competitiveness and profitability. Due to the special characteristics of plastic materials, they are manufactured into parts widely used in all kinds of products, for example, in the home appliance industry, the current use of plastic has reached 40% of the weight ratio, and many home appliance parts made of steel have been replaced by plastic parts, for example, the plastic parts of the refrigerator accounted for more than 70% of the overall parts and components, so cost reduction on plastic parts is one of the effective measures to reduce the cost of the entire product.

Optimize Design

The design stage is a key step in reducing costs. A simple and effective design can decrease material usage and lower production complexity.

1. Simplify Part Design: By reducing complex shapes and unnecessary features, you can significantly lower the difficulty and cost of mold making. A simpler design is also easier to produce, reducing errors and scrap rates during manufacturing.

2. Reduce Material Usage: Ensure the part is strong and functional while minimizing material thickness and weight. Tools like Finite Element Analysis (FEA) can help optimize the design to use materials more efficiently, cutting down on waste.

3. Standardize Design: Use standardized parts and components wherever possible. This reduces the need for custom molds and makes it easier to find suitable suppliers, lowering procurement costs.

Choose the Right Materials

Material selection has a big impact on cost. The right materials are affordable and meet the performance requirements of the part.

1. Cost-Effective Materials: Choose materials that are relatively inexpensive yet meet the necessary requirements. For example, polypropylene (PP) and polyethylene (PE) are often good choices because they are both affordable and have good mechanical properties.

2. Recycled Materials: Using recycled plastics can lower material costs and reduce environmental impact. This approach is both economical and eco-friendly, gaining popularity among manufacturers.

Optimize Mold Manufacturing

Molds are the key tools for producing plastic parts, and optimizing mold production can significantly cut costs.

1.Mold Design: A well-designed mold can improve production efficiency and reduce issues during manufacturing. Using multi-cavity molds to produce several parts at once can greatly increase efficiency and lower the cost per part.

2. Mold Maintenance: Regular maintenance ensures molds operate at peak efficiency, extending their lifespan and reducing downtime and repair costs.

Improve Production Processes

Enhancing production processes is an effective way to cut costs. Optimizing process parameters and introducing automation can boost efficiency and reduce labor costs.

1. Optimize Process Parameters: Experiment with and adjust injection molding parameters like temperature, pressure, and injection speed to improve efficiency and product quality. Proper temperature control, for example, can minimize material waste and ensure consistent products.

2. Automated Production: Introducing automated equipment and robots can significantly increase production efficiency and reduce labor costs. Automation not only speeds up production but also minimizes human errors, enhancing product quality.

3. Reduce Scrap Rates: Strengthen quality control and process monitoring to promptly identify and resolve issues, reducing the number of defective parts. High-quality products decrease waste and improve customer satisfaction.

Optimize Production Batches

Efficiently managing production batches can lower costs. Large batch production can spread fixed costs over more parts, boosting efficiency.

1.Large Batch Production: Producing parts in large batches spreads fixed costs like molds and equipment over more units, lowering the cost per part. For example, producing 1,000 parts costs less per unit than producing just 10.

2.Batch Management: Schedule production batches efficiently to avoid frequent mold and equipment changes, reducing adjustment time and scrap. Continuous production enhances efficiency and cuts downtime.

Supply Chain Management

Optimizing supply chain management can lower material and transportation costs, boosting production efficiency.

1. Procurement Optimization: Bulk purchasing can secure lower prices for materials and equipment. Working with multiple suppliers to find the best deals can effectively reduce procurement costs.

2. Logistics Management: Streamline logistics and storage to cut transportation and inventory costs. Efficient logistics reduce shipping time and expenses, enhancing production efficiency.

Save Energy

Energy costs are a significant part of plastic part manufacturing. Saving energy can noticeably reduce production costs.

1. Energy-Efficient Equipment: Use energy-efficient injection molding machines and auxiliary equipment to cut energy consumption. Modern machines often have energy recovery features, recycling waste heat generated during production.

2. Energy Recovery: Recycle waste heat during production to boost energy efficiency. For instance, waste heat from injection molding machines can be used to preheat materials, reducing energy use.

Summary

Reducing the manufacturing cost of plastic parts is crucial for many businesses. By employing reasonable methods and strategies, companies can significantly lower production costs while maintaining product quality. Key approaches include optimizing design by simplifying part features, reducing material usage, and standardizing components. Selecting cost-effective and recycled materials also plays a crucial role.

Optimizing mold manufacturing through effective design and regular maintenance can enhance efficiency and lower costs. Improving production processes by fine-tuning parameters, automating production, and minimizing scrap rates further reduces expenses. Efficient batch management and supply chain optimization, including bulk purchasing and streamlined logistics, help in cost reduction.

0 notes

Text

Custom Injection Mold Components Service: Precision in Every Part

Custom injection mold components service is a vital offering for businesses that require high-precision, tailor-made parts across industries such as automotive, medical, electronics, and consumer goods. This service involves designing and manufacturing injection mold components to meet unique specifications, enabling companies to bring complex, high-quality parts to life. When using a custom injection mold components service, businesses benefit from streamlined production processes, ensuring accuracy and consistency across every batch, regardless of part complexity. What sets a custom injection mold components service apart is its ability to accommodate various materials, shapes, and sizes. From high-strength polymers to flexible, specialized plastics, the service allows for material selection that best suits the end-use environment of the part. Through advanced engineering and sophisticated machinery, providers of custom injection mold components service can meet exacting standards, guaranteeing minimal variance and reliable functionality in each product.

The Importance of a Custom Injection Mold Components Service for Precision Manufacturing

In manufacturing, precision is paramount, especially for industries like automotive and medical devices that rely on exact specifications. A custom injection mold components service provides businesses with tailored solutions for creating precise parts that meet unique requirements. This service ensures that each component is crafted to fit seamlessly into complex assemblies, maintaining consistency across production runs. By working closely with experienced mold designers, companies can enhance component accuracy and minimize defects, ultimately resulting in more reliable products.

How Custom Injection Mold Components Service Reduces Production Costs?

Investing in a custom injection mold components service can significantly reduce long-term production costs. By customizing molds to meet specific needs, companies can streamline production, decreasing waste and improving efficiency. The process enables businesses to optimize material use, shorten production times, and reduce rework costs. Custom molds also allow for multi-cavity setups, which means more parts produced in each cycle, boosting output without compromising quality. This service ultimately supports a cost-effective production line that aligns with a company's financial goals.

Enhancing Product Quality with a Custom Injection Mold Components Service

For companies that prioritize high-quality products, using a custom injection mold components service is essential. This service allows for the production of components that meet exacting standards, which is crucial for industries requiring parts with specific dimensions, durability, and functionality. By customizing the mold to suit each part’s needs, manufacturers can achieve superior consistency and quality across every production batch. As a result, customers receive products that meet or exceed expectations, supporting brand reputation and customer satisfaction.

The Role of Material Selection in a Custom Injection Mold Components Service

Material selection is critical in injection molding, as different applications require varying levels of strength, flexibility, and resistance. A custom injection mold components service offers the flexibility to choose from a wide range of materials, including high-strength polymers and specialized plastics, ensuring that each component is tailored to its intended use. By selecting the best materials, businesses can enhance the lifespan and performance of their products, while also reducing production issues related to poor material fit.

Prototyping Capabilities of a Custom Injection Mold Components Service

One of the key benefits of a custom injection mold components service is the ability to prototype components before full-scale production. Prototyping helps businesses test parts for fit, function, and durability, allowing them to identify any necessary design adjustments early on. This step significantly reduces the risk of costly production errors and ensures that the final product meets precise standards. With a reliable prototyping process, companies gain confidence in their components and avoid issues that could disrupt production.

Reducing Lead Times with Custom Injection Mold Components Service

Shortening lead times is crucial in today’s competitive market, where delays can impact overall product delivery. A custom injection mold components service provides streamlined mold production, helping businesses move from design to manufacturing faster. This service allows for efficient mold design and faster prototyping, enabling companies to meet market demands promptly. With shorter lead times, companies can keep up with production schedules, respond to changing market needs, and launch products faster without sacrificing quality.

Meeting Industry-Specific Standards with Custom Injection Mold Components Service

Industries like aerospace, medical, and automotive have stringent regulatory standards for product quality and consistency. A custom injection mold components service enables companies to meet these high standards by tailoring molds for specific applications. With custom mold designs, manufacturers can ensure that each part produced adheres to industry guidelines, reducing the risk of compliance issues. This tailored approach makes it easier for companies to maintain quality assurance and build trust with industry regulators and customers alike.

Conclusion

A custom injection mold components service offers significant advantages for businesses across diverse industries, from enhancing precision and quality to reducing costs and supporting sustainability. By providing tailored molds that meet specific design and material requirements, this service empowers companies to achieve high-performance, reliable components that align with rigorous industry standards. The flexibility of custom mold design not only enables intricate part production but also streamlines the manufacturing process, optimizing efficiency and reducing lead times.

0 notes

Text

A Comparison Between Rotomolding and Injection Molding

In the world of plastic manufacturing, two commonly used processes stand out: rotomolding and injection molding. Both have their unique sets of advantages and are suited for different types of products. In this blog, we will delve into the differences between rotomolding and injection molding, exploring their processes, applications, strengths, and weaknesses.

Process Overview

Injection Molding

Injection molding is a widely used manufacturing process for producing plastic parts. It involves injecting molten plastic into a mold under high pressure. The plastic is heated to a molten state, then injected into the mold cavity, where it cools and solidifies into the desired shape. Injection molding machines, molds, and automated transportation systems are essential equipment in this process.

Rotomolding

Rotomolding, also known as rotational molding, is a thermoplastic hollow molding process. In this method, plastic powder or liquid polymer is placed in a mold and heated while the mold rotates around vertical axes. The plastic gradually melts, adheres to the mold's surface, and forms the desired shape. After cooling, the mold is opened, and the product is ejected. Rotomolding is ideal for producing large, hollow, seamless, multi-layered plastic products like water tanks, medicine boxes, and containers.

Material Differences

Injection Molding

Injection molding uses a variety of materials, including polystyrene (PS), polypropylene (PP), nylon (PA), polyoxymethylene (POM), ABS, PC, and PC+ABS alloys. These materials offer a range of properties, from high strength to excellent chemical resistance.

Rotomolding

Rotomolding primarily uses polyethylene (LDPE, LLDPE, HDPE, XLPE, mLLDPE, EVA), with small percentages of polyvinyl chloride (PVC), nylon, polypropylene, and polycarbonate. The choice of material in rotomolding is driven by the need for flexibility, durability, and cost-effectiveness.

Strengths and Weaknesses

Injection Molding

Strengths: Injection molding offers high precision, excellent surface finish, and good repeatability. It is ideal for producing small, intricate parts with tight tolerances, such as remote controls and toothbrushes.

Weaknesses: Injection molding requires expensive molds and can be costly for small production runs. It also has limitations in producing large or hollow parts.

Rotomolding

Strengths: Rotomolding excels in producing large, hollow, and seamless products with good flexibility and durability. The process is cost-effective for low to medium volumes and can accommodate complex geometries. The molds are much cheaper than injection molding.

Weaknesses: Rotomolding has lower precision compared to injection molding, and the production cycle is longer.

Applications

Injection Molding

Injection molding is widely used in the automotive, electronics, medical, and packaging industries. It is particularly suited for producing small, precise parts that require high surface quality and dimensional accuracy.

Rotomolding

Rotomolding finds applications in the production of large, hollow, and durable products such as water tanks, playground equipment, and storage containers. Its ability to produce seamless and stress-free parts makes it ideal for applications where flexibility and durability are critical.

Conclusion

Both rotomolding and injection molding have their unique strengths and are suited for different types of plastic products. Injection molding excels in precision, surface finish, and repeatability, making it ideal for small, intricate parts. Rotomolding, on the other hand, offers cost-effective production of large, hollow, and durable products.

When choosing between rotomolding and injection molding, consider the product's requirements, production volumes, and budget. Each process has its advantages, and the best choice depends on the specific needs of your project.

0 notes

Text

Injection Mold Manufacturing: A Comprehensive Guide

Injection mold tooling and design are critical aspects of the manufacturing process for a wide range of products, from automotive components to consumer goods. The mold, which is essentially a hollow cavity, is used to shape the plastic material into the desired form. The design and construction of the mold directly influence the quality, efficiency, and cost-effectiveness of the production process.

Mold Base

The foundation of an injection mold is the mold base. It's typically made of hardened steel or aluminum and provides a rigid structure for the other components. The base is typically split into two halves: the A-side and the B-side.

Cavity and Core

The cavity and core are the negative and positive shapes that define the final part. The cavity is the hollow space that will be filled with the plastic, while the core forms the internal features. These components are often machined into the mold base or inserted as separate pieces.

Ejector System

Once the plastic has cooled and solidified, the ejector system is used to remove the part from the mold. This system typically consists of ejector pins or plates that are pushed into the cavity to force the part out.

Cooling System

To ensure that the plastic cools evenly and quickly, a cooling system is incorporated into the mold. This system typically involves circulating a coolant, such as water or oil, through channels within the mold base. The coolant absorbs heat from the plastic, accelerating the cooling process.

Runner and Gate System

The runner and gate system is responsible for delivering molten plastic from the injection nozzle to the cavity. The runner is a channel that carries the plastic from the nozzle to the gate, which is the point where the plastic enters the cavity.

Sprue and Runner

The sprue is the main channel that connects the injection nozzle to the runner system. The runner is a network of channels that distributes the plastic to the various cavities within the mold.

Gate

The gate is the opening through which the molten plastic flows into the cavity. There are various types of gates, such as edge gates, tunnel gates, and submarine gates, each with its own advantages and disadvantages.

Vent

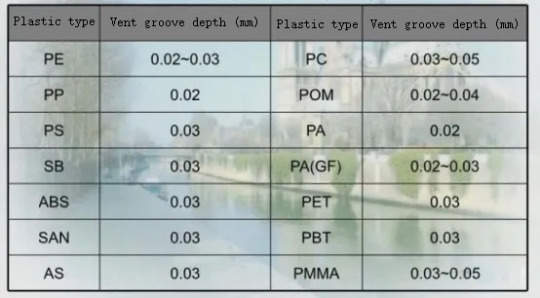

Vents are small channels that allow air to escape from the mold as the plastic fills the cavity. This helps prevent air pockets and ensures a complete and even fill.

Additional Components

Depending on the specific requirements of the part, additional components may be included in the mold. These can include:

Slides:Moving elements that allow for complex part geometries.

Inserts:Pre-formed parts that are inserted into the mold before the plastic is injected.

Bushing:A metal sleeve that guides the sprue or runner.

Design Considerations

1. Part Geometry:The shape and complexity of the part will significantly impact the mold design. Features like undercuts, draft angles, and wall thicknesses must be carefully considered to ensure manufacturability.

2. Material Selection:The choice of plastic material will influence the mold design, as different materials have varying properties that require specific tooling considerations.

3. Production Volume:The anticipated production volume will determine the type of mold to be used. For high-volume production, a multi-cavity mold may be more suitable, while for low-volume production, a single-cavity mold might suffice.

4. Cycle Time: The desired cycle time, or the time it takes to produce one part, will influence the mold design. Factors like cooling efficiency and runner design can impact cycle time.

5. Cost:The cost of the mold is a significant factor to consider. The design must balance the need for quality and efficiency with the cost constraints of the project.

Design Optimization

1. Simulation:Computer-aided engineering (CAE) tools can be used to simulate the injection molding process and identify potential problems before the mold is manufactured. This can help optimize the design and reduce the risk of defects.

2. Mold Flow Analysis: This analysis can help predict the flow of molten plastic within the mold, identify potential issues like air entrapment or short shots, and optimize the runner and gate system.

3. Design for Manufacturing (DFM): By considering manufacturing constraints early in the design process, it is possible to create molds that are easier to manufacture and maintain.

Conclusion

Injection mold tooling and design are critical for the successful production of plastic parts. By carefully considering factors such as part geometry, material selection, production volume, cycle time, and cost, it is possible to design and manufacture molds that meet the desired quality, efficiency, and cost requirements.

0 notes

Text

How Long Does Compression Molding Take? | Compression Molding Process & Cycle Time?

Compression molding is a widely used manufacturing process for producing high-strength components from composite materials, thermoplastics, and thermoset plastics. The time it takes to complete one molding cycle—known as the cycle time—varies depending on several key factors. In this article, we will explore what influences compression molding time and how long it typically takes to complete a compression molding process.

Factors That Affect Compression Molding Time

Several factors can affect the length of a compression molding cycle. Below are the most important considerations:

Material Type: Thermoset materials like SMC (Sheet Molding Compound) and BMC (Bulk Molding Compound) usually take longer because they require curing. Thermoplastics generally have shorter molding times because they do not need curing.

Mold Design: Complex mold designs with intricate shapes take more time to fill and cure. Efficient mold design can minimize cycle time.

Part Thickness: Thicker parts require longer time for heat to penetrate evenly, resulting in longer cycle times.

Temperature: Higher mold temperatures can reduce curing or melting times, but excessive heat may cause defects.

Curing Time: Curing ensures that thermoset materials harden properly. The required curing time can range from minutes to over 30 minutes, depending on the material and part size.

Typical Compression Molding Cycle Time

The cycle time for compression molding typically ranges from 1 to 10 minutes, but it can be longer for complex parts or larger components. The specific time depends on the material, mold design, and part size:

Simple Parts: Thin, uncomplicated parts made from thermoplastic materials may have a cycle time of 30 seconds to 2 minutes.

Complex Parts: For parts made from thermoset materials like SMC or BMC, the cycle time is usually between 5 to 10 minutes.

Thicker Parts: Larger or thicker parts requiring more material and time to cure may extend the cycle time beyond 10 minutes.

Compression Molding Process Breakdown

Here’s a breakdown of the typical stages of the compression molding process and their respective timeframes:

Preheating (Optional): Preheating the material can reduce cycle time and takes around 1 to 3 minutes.

Material Loading: The material is placed into the mold, which usually takes 30 seconds to 1 minute.

Mold Closing and Pressing: The mold is closed, and heat and pressure are applied, lasting 30 seconds to 10 minutes.

Curing Time: This step is crucial for thermoset materials, with times ranging from 2 to 15 minutes.

Cooling (Optional): Some thermoplastic parts may require a cooling phase, lasting 1 to 3 minutes.

Part Ejection: Once the part is cured or cooled, it is ejected from the mold, taking 10 to 30 seconds.

Strategies for Reducing Compression Molding Time

There are several ways to reduce cycle time in compression molding without sacrificing quality:

Optimize Material Flow: Improving material flow can ensure faster filling of the mold cavity.

Preheating: Preheating the material before molding reduces pressing and curing times.

Automation: Automated loading and ejection systems can streamline the process.

Multi-Cavity Molds: Using molds with multiple cavities allows multiple parts to be produced simultaneously.

Optimize Mold Temperature: Advanced temperature control systems can maintain optimal mold temperatures to reduce cycle time.

Conclusion

Compression molding time can vary significantly based on factors like material type, part thickness, mold design, and temperature. The cycle time typically ranges from 1 to 10 minutes, but larger or more complex parts may require more time. Manufacturers who optimize key aspects of the process, such as curing time, material flow, and automation, can significantly reduce cycle times and improve production efficiency.

Understanding how long compression molding takes is essential for managing production schedules and meeting delivery timelines, especially in industries like automotive, aerospace, and consumer goods.

#compression tooling#compression mold#smc mold#bmc mold#bmc tooling#smc tooling#compression molding#composite mold

0 notes

Text

dropper bottle thread cover mold

China multi cavities mold maker, offer squeeze bottle screw cap mold, eye drop bottle closures, dropper bottle thread cover mold, plastic pharma liquid bottle lid

#China mold#multi Cavities mold#squeeze bottle screw cap mold#eye drop bottle closure mold#dropper bottle thread cover mold#plastic pharma liquid bottle lid mold#lab dropping bottle caps mold#medicine bottle screw cap mold

0 notes

Text

Discussing mold optimization from perspective of injection molding process 4

For previous article reading, please refer to “Talking about mold optimization from perspective of injection molding process 1, 2, 3. Structure and optimization of exhaust system I. Misunderstandings in exhaust system design 1. It is enough to have an exhaust groove or exhaust needle on mold;2. Poor mold exhaust only causes trapped air (burning) or lack of glue;3. The wider exhaust groove, the…

View On WordPress

#Cooling water channels#Design and optimization of exhaust system#Exhaust system design#injection molding#Mold exhaust system#mold optimization from perspective of injection molding process#mold temperature regulation system#multi-cavity precision plastic parts#optimization of exhaust system#plastic parts

0 notes

Text

Efficient Molds for Disposable Cups – Perfect for Milk Tea & Takeout Packaging! Ready to produce high-quality disposable cups for your food and beverage business? Our custom multi-cavity molds are designed for speed, precision, and durability, making them ideal for manufacturing milk tea cups and takeout packaging solutions that meet consumer demands!

Why Choose Our Disposable Cup Molds? ✅ Tailored for Milk Tea & Takeout – Perfectly shaped for popular beverages and meal options. ✅ Multi-Cavity Designs – Maximize your production efficiency and reduce costs. ✅ Durable & Reliable – Built for high-volume production with consistent quality. ✅ Precision Craftsmanship – Achieve a perfect seal and finish with every cup.

Elevate Your Packaging Production Line Today! Contact us for a free consultation and discover how our disposable cup molds can enhance your manufacturing process and meet the growing demand for convenient takeout solutions!

Email:[email protected] Phone/Wechat: +86 13989656287

#DisposableCupMolds#MilkTeaCupMolds#TakeoutPackaging#MultiCavityMolds#PlasticMolding#InjectionMolding#HighVolumeProduction#FoodPackaging#BeverageIndustry#EfficiencyMolds#injectionmould#manufacturer#factory#china

2 notes

·

View notes

Text

Effective Damp Proofing and Basement Waterproofing Solutions in Kent

Damp proofing and basement waterproofing are essential services for maintaining the structural integrity of properties in Kent. These services protect homes from various forms of damp, including rising damp, penetrating damp, and the damage caused by wet and dry rot. Whether you are looking to safeguard your basement from water intrusion or address damp issues in the main structure of your home, it's important to understand the benefits and processes involved. Comprehensive Damp Surveys A thorough damp survey is the first step toward identifying potential problems in your property. Conducted by CSRT-qualified surveyors, the survey helps to detect damp issues, assess their extent, and recommend appropriate treatments. One of the common problems detected is rising damp, a condition frequently seen in older properties. This occurs when moisture travels upward through the building’s masonry, often due to a failed or nonexistent damp-proof course (DPC). If left untreated, it can lead to significant structural damage. Tackling Rising Damp Rising damp usually involves moisture traveling through bricks and mortar via capillary action. As this moisture evaporates, it leaves behind salt deposits, which further attract moisture from the atmosphere, preventing the wall from fully drying. Over time, this process can weaken walls and damage other building elements such as wood and plaster. Effective damp proofing treatments, such as installing a new DPC or addressing salt contamination, are vital to stop rising damp in its tracks and prevent further deterioration. Wet and Dry Rot Solutions Damp environments create the perfect conditions for fungal growth, which leads to wet and dry rot. These fungi can cause serious damage to timber, resulting in the weakening of structural components. Left unchecked, rot can spread to adjoining materials, including plaster and brick. Identifying and treating these problems promptly is crucial, as the longer they persist, the more severe the damage becomes. Professional treatments focus on eradicating the dampness and restoring the affected timber. Addressing Penetrative Dampness Penetrative damp occurs when water infiltrates a building horizontally, usually due to issues like faulty rainwater systems or damaged external walls. Buildings without cavity walls are especially susceptible to this form of damp. Symptoms include discolored patches on walls, ceilings, and floors, as well as weakened plaster. Repairs to external masonry, rainwater systems, and proper ventilation can resolve most cases of penetrating damp. Ensuring the internal fabric of the building is properly dried is essential to prevent further damage. Basement Waterproofing in Kent Waterproofing basements is critical for protecting these areas from water intrusion, which can lead to mold growth, structural decay, and damage to belongings. Several waterproofing methods are commonly used, such as cavity drain membrane systems (CDM) and cementitious multi-coat systems. CDM systems help manage water by channeling it away from your basement, often to a sump pump system. Cementitious systems create a waterproof barrier on basement walls to prevent water ingress. Benefits of basement waterproofing Kent 1. Increase Property Value: A waterproofed basement provides a healthy, usable living space, adding value and functionality to your home. 2. Energy Efficiency: A properly waterproofed basement retains heat better, reducing the energy required to maintain a comfortable indoor environment. 3. Healthier Living Environment: Preventing moisture in basements stops the growth of mold and mildew, contributing to a healthier living space for your family. By investing in professional damp proofing Kent and basement waterproofing services, you ensure your home remains protected from the potentially devastating effects of dampness and water intrusion.

0 notes

Text

Unveiling the Cost Structure of Injection Molding Services Procurement Intelligence

The injection molding services category is anticipated to grow at a CAGR of 4.8% from 2023 to 2030. The trends such as on-demand injection molding, adoption of automation, and focus on sustainability are driving the demand for the category. Rising awareness about pollution created by waste has increased the focus on sustainability within the industry. According to the Journal of Clean Production 2023 report, the category accounts for 90% of the Global Warming Potential (GWP) created by the complete molding lifecycle, majorly because of energy consumption. As a result, companies are focusing on incorporating plastics such as PLA, or bio-PET materials that are biodegradable or can be recycled. Additionally, to provide energy savings, there is an increase in the adoption of all-electric injection molding machines over the traditional hydraulic-based machines.

The industry has been already automated. However, injection molding facilities can still adopt some new technologies such as robots, and artificial intelligence (AI). Collaborative robots, or cobots are increasingly used in processes along with human operators to improve productivity. AI-driven productivity is impacting across industries by collecting real-time production data to enhance production and reduce costs within injection molders. AI systems can indicate pain points and opportunities to enhance efficiencies. For instance, adoption of in-mold sensors can improve injection molding performance and gage the cavity pressure. The usage of multi-material molding machines is also rising as they can create complex components in one shot by injecting various materials into the mold during a single cycle.

China is a major player in the injection molding machines industry. China exported machines worth USD 4.8 billion in 2022. The rising need for machinery in industries such as packaging, automotive, electronics, and healthcare are expected to drive the demand for machines in these industries. On the other hand, injection molding majorly finds its application in the packaging industry and the U.S. being the top country in the packaging industry is expected to drive the demand for the category.

Order your copy of the Injection Molding Services Procurement Intelligence Report, 2023 – 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

The category is fragmented with the presence of numerous players seeking low-cost production. Molders involved in electronics, consumer products, automotive, and medical applications are continuously looking for low labor costs abroad. Competition from emerging regions such as Asia-Pacific and Latin America has been so profound that molders are developing new strategies to meet current and possible challenges.

Suppliers in the category provide raw materials such as plastic materials, molds, and machinery. The bargaining power of suppliers can be moderate to high, depending on the availability of alternative suppliers and the uniqueness of their products. However, injection molding companies can often negotiate contracts based on bulk purchases, which may reduce the suppliers' power.

Raw materials (plastic materials, molds), labor, rent and utilities, mold (tooling) costs, machinery & equipment, and others are some of the cost components of the category. Other costs include packing, and transportation costs. The cost of injection molding depends on the size, design, and volume of parts. The more the volume of production, the less the cost of production per part. Raw materials, rent and utilities, and machinery & equipment form a major part of the cost component. As the molding process is automated, for example, 3D printers and CNC machines are Computer Numerical Controlled Software run on their own. As a result, labor costs cannot be a crucial part of the cost structure. However, some steps such as setting up machinery, operating, and repairing machinery can require labor costs. Professional industrial injection molding equipment costs can range from USD 50,000 to USD 200,000.

In terms of sourcing injection molding services, companies usually adopt a complete outsourcing model. Companies outsource the services as it gives advantages such as industry expertise, quality assurance, cost-benefit, and economies of scale. Producing plastic products needs equipment and employees which can require heavy investment. The cost of production by outsourcing can be considerably lower. On the other hand, due to the sudden surge in on-demand injection molding can hit production limits. A trusted service provider can meet the production demand along with adding additional value to manufacturing and product needs.

Browse through Grand View Research’s collection of procurement intelligence studies:

• Flooring Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

• Home Healthcare Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Injection Molding Services Procurement Intelligence Report Scope

• Injection Molding Services Category Growth Rate: CAGR of 4.8% from 2023 to 2030

• Pricing growth Outlook: 6% - 7% (annual)

• Pricing Models: Product type pricing, Volume based Pricing; Competition based pricing

• Supplier Selection Scope: Cost and pricing, past engagements, productivity, geographical presence

• Supplier selection criteria: Quality of the product, type of material used, end-use, post-casting services, contract terms, delivery option, technology used, safety and environmental compliance, location and presence of supplier, and others

• Report Coverage: Revenue forecast, supplier ranking, supplier matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Key companies profiled

• Protolabs, C&J Industries

• HTI Plastics

• The Rodon Group

• EVCO Plastics

• Tessy Plastics

• Currier Plastics

• Formplast

• Major Plastics

• D&M Plastics

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

#Injection Molding Services Procurement#Procurement Intelligence#Injection Molding Services Market#Injection Molding Services Industry

0 notes