#mqtt+display

Text

25 Python Projects to Supercharge Your Job Search in 2024

Introduction: In the competitive world of technology, a strong portfolio of practical projects can make all the difference in landing your dream job. As a Python enthusiast, building a diverse range of projects not only showcases your skills but also demonstrates your ability to tackle real-world challenges. In this blog post, we'll explore 25 Python projects that can help you stand out and secure that coveted position in 2024.

1. Personal Portfolio Website

Create a dynamic portfolio website that highlights your skills, projects, and resume. Showcase your creativity and design skills to make a lasting impression.

2. Blog with User Authentication

Build a fully functional blog with features like user authentication and comments. This project demonstrates your understanding of web development and security.

3. E-Commerce Site

Develop a simple online store with product listings, shopping cart functionality, and a secure checkout process. Showcase your skills in building robust web applications.

4. Predictive Modeling

Create a predictive model for a relevant field, such as stock prices, weather forecasts, or sales predictions. Showcase your data science and machine learning prowess.

5. Natural Language Processing (NLP)

Build a sentiment analysis tool or a text summarizer using NLP techniques. Highlight your skills in processing and understanding human language.

6. Image Recognition

Develop an image recognition system capable of classifying objects. Demonstrate your proficiency in computer vision and deep learning.

7. Automation Scripts

Write scripts to automate repetitive tasks, such as file organization, data cleaning, or downloading files from the internet. Showcase your ability to improve efficiency through automation.

8. Web Scraping

Create a web scraper to extract data from websites. This project highlights your skills in data extraction and manipulation.

9. Pygame-based Game

Develop a simple game using Pygame or any other Python game library. Showcase your creativity and game development skills.

10. Text-based Adventure Game

Build a text-based adventure game or a quiz application. This project demonstrates your ability to create engaging user experiences.

11. RESTful API

Create a RESTful API for a service or application using Flask or Django. Highlight your skills in API development and integration.

12. Integration with External APIs

Develop a project that interacts with external APIs, such as social media platforms or weather services. Showcase your ability to integrate diverse systems.

13. Home Automation System

Build a home automation system using IoT concepts. Demonstrate your understanding of connecting devices and creating smart environments.

14. Weather Station

Create a weather station that collects and displays data from various sensors. Showcase your skills in data acquisition and analysis.

15. Distributed Chat Application

Build a distributed chat application using a messaging protocol like MQTT. Highlight your skills in distributed systems.

16. Blockchain or Cryptocurrency Tracker

Develop a simple blockchain or a cryptocurrency tracker. Showcase your understanding of blockchain technology.

17. Open Source Contributions

Contribute to open source projects on platforms like GitHub. Demonstrate your collaboration and teamwork skills.

18. Network or Vulnerability Scanner

Build a network or vulnerability scanner to showcase your skills in cybersecurity.

19. Decentralized Application (DApp)

Create a decentralized application using a blockchain platform like Ethereum. Showcase your skills in developing applications on decentralized networks.

20. Machine Learning Model Deployment

Deploy a machine learning model as a web service using frameworks like Flask or FastAPI. Demonstrate your skills in model deployment and integration.

21. Financial Calculator

Build a financial calculator that incorporates relevant mathematical and financial concepts. Showcase your ability to create practical tools.

22. Command-Line Tools

Develop command-line tools for tasks like file manipulation, data processing, or system monitoring. Highlight your skills in creating efficient and user-friendly command-line applications.

23. IoT-Based Health Monitoring System

Create an IoT-based health monitoring system that collects and analyzes health-related data. Showcase your ability to work on projects with social impact.

24. Facial Recognition System

Build a facial recognition system using Python and computer vision libraries. Showcase your skills in biometric technology.

25. Social Media Dashboard

Develop a social media dashboard that aggregates and displays data from various platforms. Highlight your skills in data visualization and integration.

Conclusion: As you embark on your job search in 2024, remember that a well-rounded portfolio is key to showcasing your skills and standing out from the crowd. These 25 Python projects cover a diverse range of domains, allowing you to tailor your portfolio to match your interests and the specific requirements of your dream job.

If you want to know more, Click here:https://analyticsjobs.in/question/what-are-the-best-python-projects-to-land-a-great-job-in-2024/

#python projects#top python projects#best python projects#analytics jobs#python#coding#programming#machine learning

2 notes

·

View notes

Text

Introduction to Messung BACD ECY-400 Series: Key Features and Benefits

The landscape of building automation is ever evolving. The need for scalable and customizable automation solutions is growing remarkably. Messung Building Automation & Controls Divisions has introduced the ECY-400 series controllers. These are made to meet the various demands of modern building management systems. This article takes a closer look into the key features and benefits of the ECY-400 series.

Purpose and Application of ECY-400 Series

The ECY-400 Series controllers are created to manage a wide range of building automation processes. These can be an air handling unit control system or a multi-zone application. Even boilers, pumps, and rooftop units can benefit from these controllers. You can use these for medium-sized equipment so as to bring a versatile solution to your complex building management needs. The ECY-400 Series supports BACnet/IP communications. These further have been listed as BACnet Building Controllers (B-BC). This unique solution can seamlessly integrate with your building management system. You can then enjoy precise control and monitoring.

Key Features of the ECY-400 Series

Here are the key features of the ECY-400 Series:

Portable Build

The portable build of ECY-400 series controllers sets them apart from other counterparts. You can install these flexibly into the current environments and spaces. You can even mount them either vertically or horizontally. This proves helpful if the space you have is limited and you have to make the most of it. Portability makes ECY-400 easy to integrate into many systems without any extensive programming or modification. The controller has inbuilt 12 UI and 12 UO.

Intuitive UI

You also get an optional full-color backlit display with a jog dial in the ECY-450 series controllers. This can give you direct access to a wide range of controller functions. The operation and configuration of the controller are thoroughly simplified with an intuitive user interface. Users of the controller can then easily navigate through differing settings and parameters. Moreover, the embedded web server helps with web-based application configuration. It also helps with a visualization interface. This can enhance the user experience with real-time data and control options.

Vast Networking Capabilities

Networking is an important aspect of a building automation system. ECY-400 Series is the perfect option for this. You get two Ethernet ports and an AUX port for configuring separate networks. If you are prioritizing isolated and fail-safe daisy-chaining applications, you can use the flexible networking options provided by these controllers. ECY-400 series is an adaptable solution that you are looking for to manage complex automation environments.

Software-Configurable IOs

You will never have to perform physical manipulation as long as you use the ECY-400 series software-configurable IOs. Such flexibility is important for easier communication and configuration. This way, the controller can work to meet every specific need of each building automation application. When you can easily configure the IOs through software, it is much easier to install the controllers into the existing environment. This reduces the time and effort you put into setting up the system.

Several Protocols

A wide range of communication protocols are supported in the ECY-400 series controllers. These include BACnet, MS/TP, and BACnet/SC. Additionally, it can support MODBUS, MBus, RTU, MQTT, and TCP. Multi-protocol systems are known to ensure ease of communication and authentication. You can even make the most of error detection across different devices within a building management system. Compatibility with various protocols helps this controller series enhance flexibility and interoperability experiences. This way, you can integrate new devices and expand your system further.

Benefits of the ECY-400 Series

Let us now learn the benefits of the ECY-400 Series:

Ease of Installation and Mounting

With the ECY-400 series, you get incomparable ease of installation. This is because of its compact design and flexible mounting options. It does not matter if you are trying to fit these controllers into an existing building automation system or are setting up a whole new one; the ECY-400 series is suitable for it all. These controllers integrate into all systems without the need for extensive modifications. You will spend much less time on installation and less money on other costs with these controllers.

Impressive User Experience Guarantee

Intuitive UI and embedded web servers are the building blocks of the ECY-400 series controllers. They even have software configurable IOs that can help with an impressive user experience. Users of these controllers have the option to configure, monitor, and control the system in a user-friendly interface. The learning curve in these controllers is thus much reduced. Instead, there is more scope for efficiency. User experience is further enhanced with an optional full-color display along with a jog dial.

Networking Across Multi-Protocol System

The multi-protocol system supported by ECY-400 series controllers is a way toward seamless networking. You can maintain connectivity with diverse systems with a building management setup. All multi-protocol environments can make the most of the ECY-400 series’ reliable communication and data exchange capabilities. With these controllers, you can always stay ahead with comprehensive control and monitoring of the entire building complex.

Conclusion

The ECY-400 series by Messung BACD brings forward a comprehensive solution. It works well for all modern building automation needs. Furthermore, it boasts a compact design with an intuitive interface. These powerful controllers are made to add efficiency to whatever space they are installed in.

0 notes

Text

6ED1052-1FB08-0BA2 – Logo Siemens 230RCE

6ED1052-1FB08-0BA2 – Logo Siemens 230RCE SKU:

6ED1052-1FB08-0BA2 Thông số kỹ thuật:

LOGO!

230RCE,logic module, display power supply / I/O:

115 V/230 V/relay, 8 DI/4 DO, memory 400 blocks, modularly expandable, Ethernet, integrated web server, data log, user-defined web pages, standard microSD card for LOGO!

Soft Comfort V8.4 or higher, older projects executable cloud connection, MQTT in all LOGO!

8.4 basic units Tình trạng:

Hàng có sẵn, mới 100% Chứng từ COCQ, tờ khai hải quan, có xuất hóa đơn VAT Hãng sản xuất:

Siemens Giảm thêm 5% khi mua sản phẩm cùng danh mục có giá cao hơn 👉 Xem thêm:

0 notes

Text

6ED1052-1MD08-0BA2 – Logo Siemens 12/24RCE

Mã sản phẩm: 6ED1052-1MD08-0BA2

Thông số kỹ thuật: LOGO! 12/24RCE, logic module, display power supply / I/O: 12/ 24 V DC/relay, 8 DI (4 AI)/4 DO, memory 400 blocks, modularly expandable, Ethernet, integrated web server, data log, user-defined web pages, standard microSD card for LOGO! Soft Comfort V8.4 or higher, older projects executable cloud connection, MQTT in all LOGO! 8.4 basic units

👉 Xem thêm tại: https://thanhthienphu.vn/6ed1052-1md08-0ba2/

#đạilýsiemens#thanhthienphu#thanh_thien_phu#dai_ly_siemens_viet_nam#thiếtbịđiênsiemens#thietbidiensiemens#đạilýsiemenstạiviệtnam#thanhthiênphú#dailysiemens

0 notes

Text

Components of IoT Remote Monitoring System

An IoT remote monitoring system consists of three core parts: data acquisition, data analytics, and event notification.

Data Acquisition

Data acquisition is the process of collecting data from your devices or equipment using sensors, actuators, gateways, and communication protocols. Sensors are devices that measure physical quantities, such as temperature, pressure, humidity, motion, sound, etc. Actuators are devices that perform actions, such as turning on/off, opening/closing, adjusting, etc. Gateways are devices that connect your sensors and actuators to the internet or a cloud platform. Communication protocols are the rules and standards that enable data transmission and exchange, such as Wi-Fi, Bluetooth, Zigbee, LoRa, MQTT, etc.

The data acquisition part of an IoT remote monitoring system should be able to:

Support a variety of sensors, actuators, gateways, and communication protocols

Ensure the accuracy, reliability, and security of the data

Manage the power consumption, bandwidth, and latency of the devices

Handle the scalability, heterogeneity, and complexity of the devices

Data Analytics

Data analytics is the process of processing, analyzing, and visualizing the data collected from your devices or equipment using cloud platforms, databases, algorithms, and dashboards. Cloud platforms are services that provide storage, computing, and networking resources for your data. Databases are systems that store, organize, and retrieve your data. Algorithms are methods that perform calculations, transformations, and operations on your data. Dashboards are interfaces that display your data in charts, graphs, tables, etc.

The data analytics part of an IoT remote monitoring system should be able to:

Store, query, and manage large volumes and varieties of data

Apply advanced techniques, such as machine learning, artificial intelligence, and edge computing, to extract insights and patterns from the data

Provide real-time, historical, and predictive analytics for your data

Create user-friendly, interactive, and customizable dashboards for your data

Event Notification

Event notification is the process of sending alerts, notifications, and actions based on the data analysis results from your devices or equipment using email, SMS, push notifications, webhooks, etc. Email, SMS, and push notifications are methods that deliver messages to your users or customers. Webhooks are methods that trigger actions or events on other applications or platforms.

The event notification part of an IoT remote monitoring system should be able to:

Define the rules, conditions, and thresholds for triggering alerts, notifications, and actions

Customize the content, format, and frequency of the alerts, notifications, and actions

Integrate with other applications or platforms that can receive or perform the alerts, notifications, and actions

Evaluate the effectiveness, feedback, and impact of the alerts, notifications, and actions

0 notes

Text

This Week in Rust 530

Hello and welcome to another issue of This Week in Rust! Rust is a programming language empowering everyone to build reliable and efficient software. This is a weekly summary of its progress and community. Want something mentioned? Tag us at @ThisWeekInRust on Twitter or @ThisWeekinRust on mastodon.social, or send us a pull request. Want to get involved? We love contributions.

This Week in Rust is openly developed on GitHub and archives can be viewed at this-week-in-rust.org. If you find any errors in this week's issue, please submit a PR.

Updates from Rust Community

Project/Tooling Updates

esp-rs quarterly planning: Q1 2024

Meilisearch 1.6 - AI search & 2x faster indexing

capnproto-rust: 0.19 - ergonomic setters and faster reflection

hyper - 2023 in review

Observations/Thoughts

A universal lowering strategy for control effects in Rust

Passing nothing is surprisingly difficult

The memory remains: Permanent memory with systemd and a Rust allocator

Higlights of 2023 for cargo-semver-checks

The bane of my existence: Supporting both async and sync code in Rust

A Guide to Rust ORMs in 2024

Semantic search powered by WASM and WebGPU

Embassy on ESP: UART Echo

Rust Walkthroughs

Adventures in Binary Serialisation

Creating 2 'Simple' Allocators

Rust macros and Lambda boilerplate

Let's make an information display in rust Part 2: The Frontend

Miscellaneous

Clap - subcommands for command line applications in Rust

SurrealDB in-memory with SQL demo in Rust

Multi-counter with embedded SurrealDB database

Xilem 2024 plans

Rustaceans, say goodbye to lifetime errors: announcing nolife 0.3

Auto-generating API service using Rust, to TypeScript & Dart

From the rust community on Reddit: Rust in Aviation

[audio] Apollo - Rust in Production Podcast

[audio] Prossimo with Josh Aas

Crate of the Week

This week's crate is fish, a friendly interactive shell that used to be written in C++, but was recently rewritten in Rust (though admittedly they'll have to do some work until it hits your distro's repos).

Despite a lamentable lack of suggestions, llogiq is reasonably satisfied with his choice.

Please submit your suggestions and votes for next week!

Call for Participation; projects and speakers

CFP - Projects

Always wanted to contribute to open-source projects but did not know where to start? Every week we highlight some tasks from the Rust community for you to pick and get started!

Some of these tasks may also have mentors available, visit the task page for more information.

ZeroCopy - Use cargo-semver-checks to make sure derive feature doesn't change API surface 2

Ockam - remove_address_record function is called two times per Address during Processor shutdown

Ockam - Command - refactor to use typed interfaces to implement commands for kafka services

Ockam - Library - Validate CBOR structs according to the cddl schema for nodes/models/services

Hyperswitch - [FEATURE]: Make cache configuration configurable at runtime

Hyperswitch - [FEATURE]: Implement Code cov for local system using makefile

Hyperswitch - [FEATURE]: Setup code coverage for local tests & CI

Hyperswitch - [FEATURE]: Add domain type for client secret

Hyperswitch - [FEATURE]: Have get_required_value to use ValidationError in OptionExt

Fluvio - connector: fluvio-http-source, add an option to read data from a websocket

Fluvio - MQTT Connector: Prefix auto generated Client ID to prevent connection drops

If you are a Rust project owner and are looking for contributors, please submit tasks here.

Updates from the Rust Project

418 pull requests were merged in the last week

GNU/Hurd: unconditionally use inline stack probes

rustc_codegen_ssa: Enforce rustc::potential_query_instability lint

~const trait and projection bounds do not imply their non-const counterparts

add assume into NonZeroIntX::get

add explicit none() value variant in check-cfg

add more information to visit_projection_elem

allow ~const on associated type bounds again

avoid silencing relevant follow-up errors

check rust lints when an unknown lint is detected

coverage: add enums to accommodate other kinds of coverage mappings

coverage: simplify building the coverage graph with CoverageSuccessors

delegation implementation: step 1

disallow reference to static mut and adding static_mut_ref lint

don't ICE when noting GAT bounds in report_no_match_method_error

don't reexport atomic::ordering via rustc_data_structures, use std import

exclude well known names from showing a suggestion in check-cfg

exhaustiveness: abort on type error

exhaustiveness: track overlapping ranges precisely

exhaustiveness: use an Option instead of allocating fictitious patterns

fix ICE when suggesting dereferencing binop operands

fix all_trait* methods to return all traits available in StableMIR

fix allow_internal_unstable for (min_)specialization

fix is_global special address handling

fix unused_parens issue when cast is followed LT

fix an ICE that occurs after an error has already been reported

new flag to emit all the delayed bugs as errors (add -Zeagerly-emit-delayed-bugs)

making User<T> and User<[T]> Send

merge dead bb pruning and unreachable bb deduplication

never patterns: Check bindings wrt never patterns

pass LLVM error message back to pass wrapper

register even erroneous impls

remove -Zdont-buffer-diagnostics

stop mentioning internal lang items in no_std binary errors

store the segment name when resolution fails

suggest upgrading compiler for gated features

suggest quoting unquoted idents in attrs

support async recursive calls (as long as they have indirection)

taint _ placeholder types in trait impl method signatures

unify query canonicalization mode

remove a large amount of leb128-coded integers

varargs support for system ABI

stabilize mutex_unpoison feature

A more efficient slice comparison implementation for T: !BytewiseEq

tune the inlinability of unwrap

cargo metadata: Stabilize id format as PackageIDSpec

cargo resolver: do not panic when sorting empty summaries

cargo: add guidance on setting homepage in manifest

cargo: add unstable --output-format option to cargo rustdoc

cargo: crates-io: set Content-Type: application/json only for requests with a body payload

cargo: add rustc style errors for manifest parsing

cargo: only inherit workspace package table if the new package is a member

cargo: implementation of shallow libgit2 fetches behind an unstable flag

cargo: introduce -Zprecise-pre-release unstable flag

cargo: strip debuginfo when debuginfo is not requested

rustdoc-search: reuse individual types in function signatures

clippy: from_over_into: suggest a correct conversion to ()

clippy: useless_asref: check that the clone receiver is the parameter

clippy: correctly suggest std or core path depending if this is a no_std crate

clippy: extend useless_asref lint on map(clone)

clippy: fix false positive in PartialEq check in unconditional_recursion lint

clippy: fix suggestion for map_clone lint on types implementing Copy

clippy: make HirEqInterExpr::eq_block take comments into account while checking if two blocks are equal

rust-analyzer: add notable_trait predicate to CompletionRelevance

rust-analyzer: assist to merge nested if

rust-analyzer: acknowledge pub(crate) imports in import suggestions

rust-analyzer: differentiate between vfs config load and file changed events

rust-analyzer: fix ast::Path::segments implementation

rust-analyzer: fix incorrect parsing error on method call on range

rust-analyzer: fix nested includes resolving from the wrong base file

rust-analyzer: fix rust-analyzer-proc-macro-srv failing to spawn on windows

rust-analyzer: preserve comments for extracted block expression in 'extract_function'

rust-analyzer: remove sysroot-abi feature flag from proc-macro-test

rust-analyzer: replace SourceRootCrates hashset output with slice for deterministic order

rust-analyzer: resolve panic in generate_delegate_methods

Rust Compiler Performance Triage

This week had some small regressions that did not warrant further investigation, several of which were dismissed as being noise/blips in the data. There were also a number of gains. (Don't get exicited about that 20.6% improvement, its an measurement artifact from a temporary blip in the PR that immediately preceded this week's triage.)

Triage done by @pnkfelix. Revision range: 76101eec..f9c2421a

3 Regressions, 5 Improvements, 5 Mixed; 3 of them in rollups 55 artifact comparisons made in total

Full report here

Approved RFCs

Changes to Rust follow the Rust RFC (request for comments) process. These are the RFCs that were approved for implementation this week:

RFC: Precise Pre-release cargo update

Add RFC combining Infra and Release teams

Final Comment Period

Every week, the team announces the 'final comment period' for RFCs and key PRs which are reaching a decision. Express your opinions now.

RFCs

[disposition: merge] Avoid non-local definitions in functions

Tracking Issues & PRs

[disposition: merge] Stabilize single-field offset_of

[disposition: merge] Undeprecate lint unstable_features and make use of it in the compiler

[disposition: close] Fix non_camel_case_types for screaming single-words

Language Reference

No Language Reference RFCs entered Final Comment Period this week.

Unsafe Code Guidelines

No Unsafe Code Guideline RFCs entered Final Comment Period this week.

New and Updated RFCs

RFC: Out-of-tree test suite

Call for Testing

An important step for RFC implementation is for people to experiment with the implementation and give feedback, especially before stabilization. The following RFCs would benefit from user testing before moving forward:

No RFCs issued a call for testing this week.

If you are a feature implementer and would like your RFC to appear on the above list, add the new call-for-testing label to your RFC along with a comment providing testing instructions and/or guidance on which aspect(s) of the feature need testing.

Upcoming Events

Rusty Events between 2024-01-17 - 2024-02-14 🦀

Virtual

2024-01-17 | Virtual (Vancouver, BC, CA) | Vancouver Rust

Rust Study/Hack/Hang-out

2024-01-23 | Virtual (Halifax, NS, CA) | Rust Halifax

Rust&Tell - Halifax

2024-01-24 | Virtual (Berlin, DE) | WeAreDevelopers Community

WeAreDevelopers LIVE - Rust Day

2024-01-25 | Virtual (Charlottesville, NC, US) | Charlottesville Rust Meetup

Crafting Interpreters in Rust Collaboratively

2024-01-25 | Virtual (Mexico City, DF, MX) | Rust MX

Iniciando 2024 con Rust

2024-01-28 | Virtual (Wrocław, PL) | Stacja IT Wrocław

Wprowadzenie do języka Rust

2024-01-30 | Virtual | Bevy Game Development

Bevy Meetup #1

2024-01-30 | Virtual (Buffalo, NY, US) | Buffalo Rust User Group

Buffalo Rust User Group

2024-01-30 | Virtual (Dallas, TX, US) | Dallas Rust

Last Tuesday

2024-01-31 | Virtual (Cardiff, UK) | Rust and C++ Cardiff

Rust for Rustaceans Book Club launch!

2024-02-01 | Virtual + In Person (Barcelona, ES) | BcnRust

12th BcnRust Meetup - Stream

2024-02-01 | Virtual (Berlin, DE) | OpenTechSchool Berlin + Rust Berlin

Rust Hack n Learn | Mirror: Rust Hack n Learn

2024-02-03 | Virtual + In-person (Brussels, BE) | FOSDEM 2024

FOSDEM Conference: Rust devroom - talks

2024-02-03 | Virtual (Kampala, UG) | Rust Circle

Rust Circle Meetup

2024-02-04 | Virtual | Rust Maven

Web development with Rocket - In English

2024-02-07 | Virtual (Indianapolis, IN, US) | Indy Rust

Indy.rs - with Social Distancing

2024-02-08 | Virtual (Charlottesville, NC, US) | Charlottesville Rust Meetup

Crafting Interpreters in Rust Collaboratively

2024-02-08 | Virtual (Nürnberg, DE) | Rust Nüremberg

Rust Nürnberg online

2024-02-10 | Virtual (Wrocław, PL) | Stacja IT Wrocław

Rust – budowanie narzędzi działających w linii komend

2024-02-13 | Virtual (Dallas, TX, US) | Dallas Rust

Second Tuesday

Europe

2024-01-17 | Girona, ES | Rust Girona

Que és Rust i els seus beneficis / What's Rust and its advantages

2024-01-17 | Praha / Prague, CZ | Rust Prague

Rust Meetup Reloaded 2024

2024-01-17 | Zurich, CH | Rust Zurich

How to Community - January Meetup

2024-01-23 | Aarhus, DK | Rust Aarhus

Hack and Learn

2024-01-23 | Paris, FR | Rust Paris

Paris Rust Meetup #64

2024-01-24 | Zagreb, HR | impl Zagreb for Rust

Rust Meetup 2024/01: WebGPU intro using Rust

2024-01-25 | Augsburg, DE | Rust Meetup Augsburg

Augsburg Rust Meetup #5: Async Part2 and Async in action

2024-01-25 | Vienna, AT | Rust Vienna

Rust Vienna Meetup - January - Blockchains and Data Pipelines

2024-02-01 | Hybrid (Barcelona, ES) | BcnRust

12th BcnRust Meetup

2024-02-03 | Brussels, BE | FOSDEM '24

FOSDEM '24 Conference: Rust devroom - talks | Rust Aarhus FOSDEM Meetup

2024-02-06 | Bremen, DE | Rust Meetup Bremen

Rust Meetup Bremen [1]

2024-02-07 | London, UK | Rust London User Group

Rust for the Web — Mainmatter x Shuttle Takeover

2024-02-08 | Bern, CH | Rust Bern

Rust Bern Meetup #1 2024 🦀

North America

2024-01-17 | Chicago, IL, US | Deep Dish Rust

Rust Happy Hour

2024-01-18 | Seattle, WA, US | Seattle Rust User Group

Seattle Rust User Group Meetup

2024-01-22 | Boston, MA, US | Boston Rust Meetup

North End Rust Lunch

2024-01-24 | Austin, TX, US | Rust ATX

Rust Lunch - Fareground

2024-01-27-28 | Calgary, AB, CA | Rust Calgary

Harnessing Rust for Real-World Problems hackathon: Day 1

Harnessing Rust for Real-World Problems hackathon: Day 2

2024-01-30 | Cambridge, MA, US | Boston Rust Meetup

Harvard Square Rust Lunch

2024-02-07 | Brookline, MA, US | Boston Rust Meetup

Coolidge Corner Brookline Rust Lunch, Feb 7

2024-02-12 | Minneapolis, MN, US | Minneapolis Rust Meetup

Minneapolis Rust: Open Source Contrib Hackathon & Happy Hour

2024-02-13 | New York, NY, US | Rust NYC

Rust NYC Monthly Mixer

2024-02-13 | Seattle, WA, US | Cap Hill Rust Coding/Hacking/Learning

Rusty Coding/Hacking/Learning Night

Oceania

2024-02-06 | Perth, WA, AU | Perth Rust Meetup Group

Rust Feb 2024 Meetup

If you are running a Rust event please add it to the calendar to get it mentioned here. Please remember to add a link to the event too. Email the Rust Community Team for access.

Jobs

Please see the latest Who's Hiring thread on r/rust

Quote of the Week

Congrats to the #Rustlang and #Rust-for-#Linux community: the #LinuxKernel now contains the first useful thing built using Rust!

– Thorsten Leemhuis on FOSStodon

As with the crate of the week, this week saw a total lack of suggestions, so llogiq would like to offer you this piece of good news from the Linux side of things.

Please submit quotes and vote for next week!

This Week in Rust is edited by: nellshamrell, llogiq, cdmistman, ericseppanen, extrawurst, andrewpollack, U007D, kolharsam, joelmarcey, mariannegoldin, bennyvasquez.

Email list hosting is sponsored by The Rust Foundation

Discuss on r/rust

1 note

·

View note

Text

Application of Real-time Data Collection and Monitoring of Distributed I/O in Glass Manufacturing

Background

The glass industry has made extensive use of PLC for many years to help manage the precise proportions of materials required in the production process. It relies entirely on its PLC for data collection and control, and relies heavily on manual operations, so these high costs have driven a search for lower-cost alternatives needs.

Scene description

The glass production produced by a glass factory includes five processes: batching section, melting section, forming section, annealing section and edge breaking section. Among them, melting, forming and annealing are the core links of the original film production line. If there is a problem in any link, All will affect the quality and production rate of the product. For example, the biggest impact on raw film output is temperature control, which is closely related to the heating and cooling conditions of the glass. Therefore, accurate and timely temperature collection in the furnace of the unit plays a crucial role in controlling the temperature. The normal production of the product is continuous operation 24 hours a day, and production cannot be stopped. Once the product quality is unstable, the production will not proceed normally.

A large amount of enterprise data remains in traditional records and is still stored through traditional methods such as reports and paper. The data source is not unique, some data are out of sync, the underlying collection is incomplete, manual troubleshooting is slow and inaccurate, and the number of affected products and the resulting losses are often huge.

Information lost

Reported information is conveyed layer by layer through phone calls or reports, and managers cannot obtain information such as product quality, production equipment, process processing, customer orders, and inventory in real time.

Coping strategy

In order to cope with the development needs of the glass industry and ensure safe and reliable data collection, BLIIoT launched the distributed I/O module-BL206Pro. It has the characteristics of high reliability, favorable price, easy setup, and convenient network wiring. It also supports equipment of different protocols, reducing enterprise procurement costs, and also deploys for the future IT/OT integration development of the manufacturing industry.

System specification

The glass smart factory system is composed of BLIIoT distributed I/O module BL206Pro and PLC on site to achieve coordination, unity and collaborative management and control of the workshop manufacturing process. It achieves a high degree of coordination and unity in all aspects of the glass, allowing control flow, logistics, and information flow to be clear and clear complete embodiment.

Distributed I/O collects production process data and is used to monitor key control points on site, such as temperature, gas, pressure, etc., to ensure stable production operation. PLC completes the logical control of the entire process flow. The cloud platform or PC-side equipment can set and access process parameters and set temperature and other parameters, and display them through interfaces such as HMI.

Product description

Excellent performance

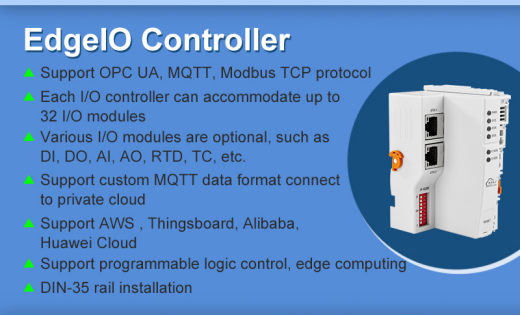

It has multiple functions such as signal acquisition control, data calculation, logical linkage, data uploading to the cloud, and exception reporting! The controller adopts a plug-in design. Users can freely combine I/O according to their needs. It supports up to 32 I/O boards and 512 I/O signals. It adopts high-speed backplane communication and has built-in edge functions without the need for a host computer. It can realize linkage control of local I/O signals with the cloud platform or PLC, which greatly improves the response speed of the site and relieves the pressure of data processing on the cloud host computer.

BL206Pro product can collect Al, AO, DI, DO, PT100, RS485 and other data. Built-in integration of OPC UA, MQTT, MODBUS and other IoT bus protocols requires only one module for multi-scenario applications, perfectly adapting to changing flexible production lines.

0 notes

Text

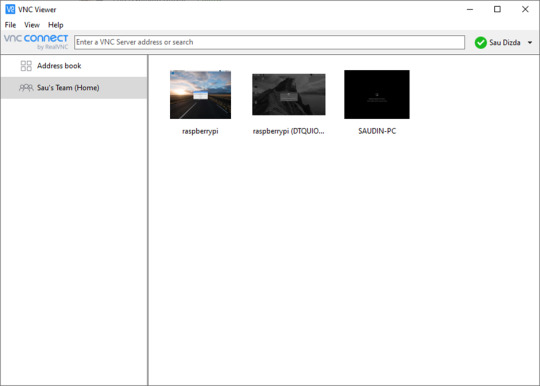

Raspberry Pi, MQTT and RealVNC

When I got Sensecap S2103 LoRaWAN® CO2, Temperature, and Humidity Sensor, I was thinking to integrate it with commercial Scada HMI system. One of the reasons is because Sensecap S2103 is a set of sensors which are applicable in industrial applications. Later, an idea came to me why not to use Raspberry PI with screen - Human Machine Interface together with RealVNC to make Industrial – grade reusable application.

The best thing in this project Remote Access for your Raspberry Pi from Anywhere in the world via VNC connection, meaning you have Scada HMI system anywhere, on any device.

In this post I am going to show how to integrate Sensecap S2103 sensor and display collected data on Raspberry Pi display.

Since picture is worth a thousand words, block schematics below shows architecture of my project.

I will show data from SenseCap S2103 sensor on Home Assistant which is installed on reTerminal . I will not go step-by-step on configuration/installation of Home Assistant on reTerminal, but you can see great guide on seeedstudio wiki here https://wiki.seeedstudio.com/reTerminal_Home_Assistant/.

I used the guides from link above and Home Assistant Supervised installation/configuration method in order to have data displayed on reTerminal LCD.

Home Assistant acts as a central smart home controller hub by combining different devices and services in a single place and integrating them as entities. That means you can integrate various sensors and variouts services in one single place.

Process of installing Home Assistant Supervised on reTerminal is like following:

I am assuming that you already have installed Raspberry PI OS.

Install RealVNC https://www.realvnc.com/en/

Install docker

Visit Home Assistant OS Agent page, and install Home Assistant Agent V1.3.0. and also Home Assistant-Supervised

Install Portainer Docker management platform

On portainer dashboard make sure that Home Assistant primary containers are up and running

On a web browser, type the following URL homeassistant.local:8123

If everything is installed without problems, you can view Home Assistant Dashboard UI on your web browser and proceed with making your account

RealVNC server should come preinstalled no your SD card with Raspbian OS. If, for any reason this is not case with you, below are informations on how to Install the RealVNC for Raspberry pi.

How to Install the RealVNC on Raspberry Pi

Update the system repositories:

Open the terminal if you have direct access. Or, take an SSH session to the Raspberry Pi CLI.

$ sudo apt-get update && apt-get upgrade

2. Install the RealVNC server:

$ sudo apt-get install realvnc-vnc-server.

3. Enable VNC server:

$ sudo raspi-config

Got to Interfacing options

Select VNC

Answer Yes

Select Finish to quit (or ESC)

Note: VNC runs on port 5900. You should open this port on all the middle devices to work the communication from your PC to the Raspberry Pi.

On PC side, you must install RealVNC Viewer, in ordes to access HMI remotely. Below is how RealVNC viewer loooks after installation.

First big part of the project is finished. Now we are going to configure SenseCAP sensor by using Sensecap MATE Android application. Again, amazing guideline can be followed on Seed's wiki: https://wiki.seeedstudio.com/Cloud_Chain/SenseCAP_Mate_APP/SenseCAP_APP/

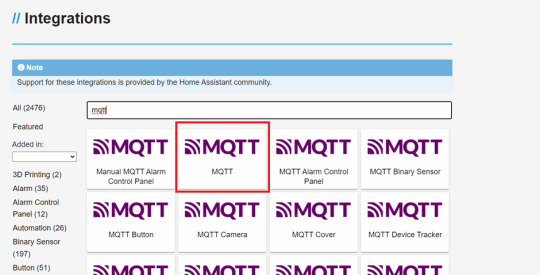

The next step is to configure mqtt integration with Home Assistant and subscribe to SenseCAP data.

First, what you need to know is SenseCAP account API ID, Organization ID, and Access API keys. Nice quickstart can be found on sensecap page.

https://sensecap-docs.seeed.cc/data_openstream_quickstart.html

Got to https://sensecap.seeed.cc/portal/#/security, in order to create Access Key and view information about Organization ID.

By clicking on API ID, you can also see API keys information.

So, your important connectivity informations for Home Assistant, which will be important in order to connect to MQTT, are as below:

Host: sensecap-openstream.seeed.cc

User: org-<OrgID> (here you replace OrgID with your Organization id-example for this parameter will be org-428131654987987)

Password: here you insert your Acces Key which is in form XBA6E65464 (a combination of letters and numbers).

Client ID: org-<OrgID>-quickstart (example: org-428131654987987-quickstart)

After this, go to https://www.home-assistant.io/integrations/, which allows integration with a lot of services. You will need, of course MQTT. Enter MQTT in search box, and choose MQTT, as shown below:

In Home Assistant now go to Settings->Devices & Services, Click add integration button and search MQTT. Now you enter the informations from above for MQTT connectivity:

Username= OrgID, password= client ID

Now, in order to test that MQTT connectivity works, click the CONFIGURE button and listen to the topic : device_sensor_data/OrgID/+/+/+/+

(example: device_sensor_data/428131654987987/+/+/+/+).

After few seconds, you will have response: vaule and timestamp in JSON format.

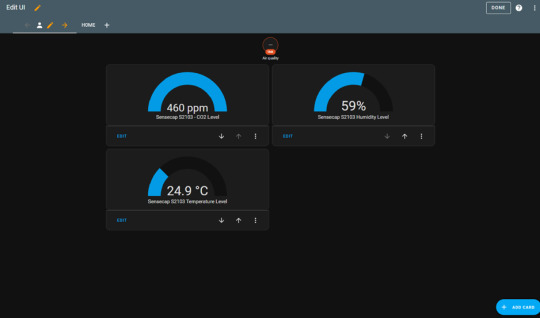

Since we want to show values of temperature, CO2 and humidity, we need to add multiple entities to store aquired sensor data, by editing the Home Assistant configuration file.

Go to the settings, click to Add-ons,search for File Editor, modify the YAML file /config/configuration.yaml by entering:

mqtt:

sensor:

- name: "Air Temperature"

state_topic: "/device_sensor_data/<orgID>/<DeviceEUI>/1/+/4097"

unit_of_measurement: "℃"

value_template: "{{ value_json.value }}"

- name: "Air Humidity"

state_topic: "/device_sensor_data/<orgID>/<DeviceEUI>/1/+/4098"

unit_of_measurement: "%RH"

value_template: "{{ value_json.value }}"

- name: "Air CO2"

state_topic: "/device_sensor_data/<orgID>/<DeviceEUI>/1/+/4100"

unit_of_measurement: "ppm"

value_template: "{{ value_json.value }}"

DeviceEUI is Unique identification of device eg. 2CF7F12000000001, and it can be found on the sensor itself.

Now the last step is create dashboard.

go to overview and find the "Edit Dashboard"

You can add cards as much as you want. I have added Gauge card, and subscribed to entities (temperature, CO2 and humidity).

Finally, the IoT dashboard is shown on your reTerminal Home assistant main screen.

Here below are few pictures for you to see how it looks like:

0 notes

Text

BLIIOT PLC IoT Gateway BL102 for Remote Pump Station Monitoring

Background

With the rapid development of industrial intelligence, BL102 PLC gateway as an advanced industrial automation equipment has played an important role in the field of remote monitoring of pumping stations. Through the BL102 PLC gateway we can realize the remote monitoring and control of the PLC of the pumping station, thereby improving the working efficiency and management level of the pumping station.

Features

1. Functions of BL102 PLC gateway

BL102 PLC gateway is an industrial gateway that integrates multiple protocols. It supports various downstream PLC protocols, Modbus RTU, Modbus TCP Master, DL/T645 and other protocols, and uplink supports Modbus TCP, MQTT, OPC UA, Huawei ,Ali,AWS , ThingsBoard, Sparkplug B, KingPigeon IoT Cloud and other protocols. The product adopts embedded ARM MCU, which has high stability and is suitable for various complex industrial environments.In the field of remote monitoring of pumping stations, BL102 PLC gateway plays an important role. Through the various PLC protocols supported by the downlink, data interaction with the PLC of the pumping station can be performed, and information such as the operating status, process parameters, and equipment failures of the pumping station can be collected in real time. The various protocols supported by the uplink can transmit the collected data to the cloud platform or the upper management system to realize remote monitoring and data collection. At the same time, the BL102 PLC gateway can also automatically start the corresponding equipment after analyzing and judging the instructions of the host computer and process parameters to realize remote control.

2.How to use BL102 to realize remote pump station monitoring

To use BL102 PLC gateway for remote monitoring of pumping station PLC, the following steps are required:

Hardware connection: connect the BL102 PLC gateway and the PLC of the pumping station through various downlink PLC protocols, and at the same time connect the Ethernet port of the gateway with the host computer or cloud platform through Ethernet.

Protocol configuration: According to the protocol type and communication protocol of the pumping station PLC, perform corresponding configuration on the BL102 PLC gateway. The specific configuration includes PLC protocol type, communication port, data format, communication rate, etc.

Data acquisition: Collect the operating status, process parameters and equipment failures of the pumping station PLC through the BL102 PLC gateway, and upload the data to the cloud platform or upper management system.

Remote monitoring: In the cloud platform or upper management system, the operation status and data of the pumping station can be monitored in real time through the data display function provided by the BL102 PLC gateway. At the same time, control instructions can be sent through the cloud platform or management system to realize remote control.

Early warning and fault handling: When a fault is detected in the PLC of the pumping station, the BL102 PLC gateway can immediately start the early warning mechanism and notify relevant personnel through the network to deal with it. At the same time, under the intervention of the early warning system, the system can automatically switch to the backup equipment to ensure the continuity of the production process.

Conclusion

BL102 PLC gateway plays an important role in the field of remote monitoring of pumping stations. Through the various PLC protocols supported by the downlink and various protocols supported by the uplink, functions such as data collection, remote monitoring, remote control, early warning, and fault handling can be realized. At the same time, BL102 PLC gateway adopts embedded ARM MCU, which has high stability and is suitable for various complex industrial environments. In the future, with the continuous development of industrial intelligence, BL102 PLC gateway will be applied and expanded in more fields.

More information view: https://www.bliiot.com/plc-gateway-p00306p1.html

0 notes

Text

BLIIoT industrial PLC edge gateway BL110 is applied to textile machines to collect PLC data and monitor energy consumption

1. Foreword

With the continuous and rapid development of the textile industry, intelligent control technology, field bus technology and digital display technology have been widely used in textile equipment. In order to improve the management of small sample spinning equipment and improve the competitiveness of enterprises, textile equipment enterprises want to use advanced automation technology and information technology to carry out informatization transformation of equipment.

2. Textile Machine Remote Monitoring System

The entire system network is divided into 3 layers: management layer, control layer and equipment layer Spinning equipment mainly includes digital sample carding machine, sample draw frame, sample comber, sample roving frame, sample spinning frame and sample doubling machine , through the BLIIoT Industrial PLC Edge Gateway BL110 and the core controller of the textile machine equipment (such as PLC), combined with communication methods such as 4G, Wifi, Ethernet and GPRS, the data collected by each device includes the operating status of the equipment, output, efficiency, Process parameters, abnormal alarm information and other teaching data are transmitted to the server/cloud.

The system can use the BLIIoT Industrial PLC Edge Gateway BL110 to collect meter data, and the online monitoring module can monitor the voltage, current, power, power factor, energy consumption and other indicators of the host and auxiliary equipment in real time, and can realize the following functions: compare the energy consumption of different machines Data, check abnormal data in a timely manner; reproduce the power change trend of the machine in the last 24, 48, and 72 hours, and find equipment problems in time; count the total power consumption of the machine, process, variety, etc., and the data of power consumption per ton of yarn to form various Class reports, visually compare and display devices with abnormal power consumption, and provide targeted improvement suggestions.

3. BLIIoT Industrial PLC Edge Gateway BL110

◆ Using 4G wireless network and Ethernet redundant data upload method, stable and reliable;

◆ Embedded ARM9 32-bit Linux kernel real-time operating system and watchdog function;

◆ Wide working voltage design with anti-reverse protection design;

◆ Supports Mitsubishi, Siemens, Delta, Schneider, ABB, Huichuan, Omron, Panasonic, Hollysys and other PLC protocols;

◆ 4 serial ports support modbus master-slave protocol, support modbus / mqtt / private custom protocol upload;

◆ All 4 serial ports support transparent transmission, and the CAN port supports data of CAN communication equipment, such as server;

◆ It can collect the data of the network port PLC or other network port equipment through the Ethernet interface;

◆ Support OPC client function, can read data provided by OPC server of other manufacturers;

◆ Support multiple data storage functions according to cycle, change, condition, etc .;

◆ Support multi-level data security rights management function;

◆ Support multiple alarm conditions, such as alarm conditions, urgency, confirmation rules, push rules, and SMS push;

◆ Support power failure alarm function; (optional)

◆ Support remote PLC download programming and remote collection of PLC equipment, set conditions to stop PLC operation;

◆ Support routing function and access video surveillance camera;

◆ Support mainstream public cloud platforms such as Alibaba Cloud and AWS Cloud;

◆ Support third-party manufacturers custom development, provide hardware and SDK interface

◆ Support BLRMS;

◆ Embedded TCP / IP protocol stack, support TCP, UDP protocol, TCP Server and TCP Client services;

4. Summarize

By connecting the textile equipment and PLC to BLIIoT Industrial PLC Edge Gateway BL110, real-time data collection is carried out on the equipment, and the equipment operation status and fault alarm information are fed back to the management personnel in a timely manner, so that the equipment can be checked online and offline, operation failure and other information anytime and anywhere, and with the help of the equipment maintenance express line Realize operations such as remote uploading and downloading of programs, remote programming and debugging.

The data collection of intelligent instruments on the textile factory site can realize real-time monitoring of production environment and energy consumption, monitoring of environmental temperature and humidity, gas and energy consumption data, can feed back accurate and reliable data to the staff, and take timely measures for management and control. It plays an important role in equipment and personal safety as well as energy saving optimization.

More information about BLIIoT Industrial PLC Edge Gateway BL110: https://gateway-iot.com/industrial-iot-edge-gateway-p00272p1.html

#iiot#industria40#industrialautomation#plcgateway#iotgateway#remotemonitoring#datacollection#modbus#MQTT#OPC UA#SCADA#AWS#PLC#siemens#OMRON#BLIIOT

0 notes

Text

Develop a Simple IoT App Using Low-Code Platform

Instruction for Simple IOT App

Here are the instructions for college students who want to build a simple IoT app using low-code platform:

Purchase a temperature sensor and a microcontroller board such as an ESP8266.

Create an account on Adafruit IO and follow the instructions to set up your first feed.

Install the Arduino IDE on your computer and configure it to work with your microcontroller board.

Use the code provided above as a starting point, modify it to include your WiFi credentials and Adafruit IO feed information, and upload it to your microcontroller board.

Create a dashboard in Adafruit IO and add a block to display your temperature data.

Run your microcontroller board and observe the temperature data being sent to Adafruit IO and displayed on your dashboard.

By following these steps, you will have built a simple IoT app that demonstrates how to read sensor data and visualize it in real-time using a no-code platform. This project can be expanded upon in many ways, such as by adding additional sensors or integrating with other cloud services.

Steps to Build IoT App Using Low-Code Platform

Create an Adafruit IO account at https://io.adafruit.com/

Click on "Feeds" on the left-hand menu and create a new feed called "Temperature".

Connect a temperature sensor to your microcontroller (e.g. an ESP8266) and upload the following code to read the temperature data and send it to Adafruit IO:

#include

#include

#include

#include

#include

// WiFi credentials

const char* ssid = "your-ssid";

const char* password = "your-password";

// Adafruit IO credentials

#define AIO_USERNAME "your-username"

#define AIO_KEY "your-key"

#define AIO_FEED "Temperature"

// DS18B20 temperature sensor

#define ONE_WIRE_BUS 2

OneWire oneWire(ONE_WIRE_BUS);

DallasTemperature sensors(&oneWire);

// MQTT client

WiFiClient client;

Adafruit_MQTT_Client mqtt(&client, "io.adafruit.com", 1883, AIO_USERNAME, AIO_KEY);

// MQTT temperature feed

Adafruit_MQTT_Publish temperature = Adafruit_MQTT_Publish(&mqtt, AIO_USERNAME "/feeds/" AIO_FEED);

void setup()

Serial.begin(9600);

// Connect to WiFi

WiFi.begin(ssid, password);

while (WiFi.status() != WL_CONNECTED)

delay(1000);

Serial.println("Connecting to WiFi...");

Serial.println("Connected to WiFi");

// Connect to MQTT broker

mqtt.connect();

while (!mqtt.connected())

delay(1000);

Serial.println("Connecting to MQTT broker...");

Serial.println("Connected to MQTT broker");

// Start temperature sensor

sensors.begin();

void loop()

// Read temperature

sensors.requestTemperatures();

float tempC = sensors.getTempCByIndex(0);

Serial.print("Temperature: ");

Serial.print(tempC);

Serial.println(" °C");

// Publish temperature to MQTT feed

temperature.publish(tempC);

delay(10000); // Wait 10 seconds

Once you've uploaded the code, go back to Adafruit IO and click on "Dashboards" on the left-hand menu. Create a new dashboard called "Temperature" and add a new block of type "Line Chart". Configure the block to show the "Temperature" feed you created earlier.

Now, whenever you run the code on your microcontroller, it will send temperature data to Adafruit IO, which will be displayed on the line chart block in your dashboard.

Must Read:

Top 5 Challenges in Low-Code IoT App Development

Mastering Low-Code IoT App Development: Tips and Tricks

5 Ways The Internet of Things Can Help in Business

How Low-Code IoT App Development Can Drive Quick Success

Top 10 Low-Code IoT Platforms in the Market

10 Best No-Code IoT Platforms in the Market

In conclusion, building an IoT app using a no-code platform like Adafruit IO is a simple and straightforward process. With just a few steps, you can connect a microcontroller to a cloud-based service and visualize sensor data in real-time. This is a great way to learn about IoT and start building your own smart devices.

0 notes

Text

Java modbus server

JAVA MODBUS SERVER SERIAL

JAVA MODBUS SERVER SERIES

Weinzierl offers powerful and compact KNX Gateway to Modbus The T910 allows up to 8 device variables (floating point or integer) and an extensive array of device status indicators to be passed from the Modbus device over the WirelessHART network. Softing's versatile Linking Device and Modbus Gateway (FG-200) integrates up to four FOUNDATION™ Fieldbus (FF) H1 links into control systems supporting HSE or Modbus.įieldbus International releases WirelessHART adapter with Modbus RTU interface: the T910. Modbus RTU also supported.Įxtend the Life of your Legacy DCS System by Getting Access to FOUNDATION Fieldbus Devices over Modbus Big, bright 1.2 inch (31mm) numerals are clearly visible from far away, even in bright sunlight. These instruments combine the digital indicator function of a panel meter with optional signal conditioning for 4-20mA transmitter output and/or alarm trip solid-state relays. M.2 card users can choose among loadable firmware for PROFINET IO-Device, EtherNet/IP Adapter, EtherCAT and OpenModbus/TCP.Īnnouncing Acromag's new Vertu™ brand of universal input displays Hilscher's New M.2 Format PCI Express Card Supports Fieldbuses and Real-Time EthernetsĪt the heart of the M.2 2230 card is Hilscher's award-winning netX 90 multiprotocol communication chip. Mission-critical industrial communications, such as Ethernet/IP, PROFINET, Modbus/TCP, and BACnet, are sent through the network first. The FL SWITCH 1000 features automation protocol prioritization (APP), making it easy to prioritize important traffic.

JAVA MODBUS SERVER SERIES

Phoenix Contact releases unmanaged switch series with new capabilities Opto 22's groov RIO® Ethernet edge I/O ships with PID, SSH, and LDAP supportĬlosely following the initial launch of groov RIO in early 2020, Opto 22 has further expanded the remote I/O, connectivity, and security features of its edge I/O module with the release of its version 3.0 firmware. With an MQTT protocol gateway, it is easier than ever before to move industrial device data to cloud applications like AWS IoT Core, IT or enterprise systems.Īcromag - Measuring Temperature with a High-density Ethernet I/O SolutionĪcromag's BusWorks® NT Series was a good fit for this application that required remote I/O and needed to be a Modbus server that could accept a mix of thermocouple and RTD signals. Real Time Automation releases the MQTT protocol on their bestselling 460 industrial gateway line. MQTT Gateways Create an Easy Way to Move Factory Floor Data to Cloud Application Services

JAVA MODBUS SERVER SERIAL

AutomationDirect Announces CLICK PLUS Serial Communication Option Slot Module and 2-Slot CPUsĬLICK PLC with advanced features, includes Wi-Fi capability, MQTT communication, data logging, and mobile access (supports both Modbus RTU and ASCII communication).

0 notes

Photo

🇧🇷 Servidor MQTT com ESP 8266-07, compatível com o ESP12 . 👉 Conexão para módulo USB 👉 4 reles 👉 Conexão padrão display OLED I2C . 🇺🇸 MQTT server with ESP 8266-07, compatible with ESP12 . 👉 Connection to USB module 👉 4 Relay 👉 standard OLED Display connection I2C . #esp #esp07 #esp12 #esp32 #esp8266 #espressif #servidor #mqtt #rele #display #oled #i2c #board #customizada #makers #maker #diy #geek #diy #web #internet #hardware #walproj #projetoseletronicos #projetosmaker #automacao #iot https://www.instagram.com/p/BzwUwpin0tV/?igshid=pygkuklj77cm

#esp#esp07#esp12#esp32#esp8266#espressif#servidor#mqtt#rele#display#oled#i2c#board#customizada#makers#maker#diy#geek#web#internet#hardware#walproj#projetoseletronicos#projetosmaker#automacao#iot

1 note

·

View note

Text

6ED1052-1FB08-0BA2 – Logo Siemens 230RCE

Mã sản phẩm: 6ED1052-1FB08-0BA2

Thông số kỹ thuật: LOGO! 230RCE,logic module, display power supply / I/O: 115 V/230 V/relay, 8 DI/4 DO, memory 400 blocks, modularly expandable, Ethernet, integrated web server, data log, user-defined web pages, standard microSD card for LOGO! Soft Comfort V8.4 or higher, older projects executable cloud connection, MQTT in all LOGO! 8.4 basic units

👉 Xem thêm tại: https://thanhthienphu.vn/6ed1052-1fb08-0ba2/

#đạilýsiemens#thanhthienphu#thanh_thien_phu#dai_ly_siemens_viet_nam#thiếtbịđiênsiemens#thietbidiensiemens#đạilýsiemenstạiviệtnam#thanhthiênphú#dailysiemens

0 notes

Text

3 Steps to Build Your IoT Demo

Bivocom TG451 Industrial Iot Gateway

Want to know the environment condition of your greenhouse, server room, factory or substation of electricity from anywhere and anytime? Thanks to the IoT technology, your IoT concept can be easily realized.

Today, we’re going to show you how to build a simple IoT demonstration in just 3 steps by using an industrial temperature & humidity sensor, Bivocom industrial 4g IoT gateway TG451, and Fogwing cloud IoT platform.

Get Your IoT Hardware and IoT Platform Ready

1. An industrial temperature and humidity sensor can detect field conditions and convert it to digital signal. In our case, the sensor acquires the field environment temperature and humidity, transfer the data via RS485 interface following Modbus RTU protocol which is very common in IoT technology.

2. An industrial cellular IoT gateway or modem comes with RS485, and support protocols like Modbus RTU/TCP, JSON and MQTT. In this case, we use a Bivocom 4G IoT gateway TG451 to connect to the sensor via RS485, and acquire the data from sensor, convert it from Modbus to JSON, and transmit to a cloud MQTT server. For more details of industrial gateway TG451, please refer https://www.bivocom.com/products/iot-gateways/industrial-gateway-tg451/

3. A Cloud IoT platform. Fogwing is a feature-rich, and ease to use IoT platform, which supports MQTT protocols. Fogwing also provides visible dashboard and alarm trigger features. You may need to register a free account from https://enterprise.fogwing.net

Step 1,

Deploy the temperature & humidity sensor at place you plan to monitor, and then connect it to Bivocom TG451 gateway via RS485 port.

Step 2,

Configure the TG451 industrial iot gateway to get sensor data and upload to cloud server Fogwing. Bivocom TG451 provides user friendly Web UI for configuration. For initialization setup, please refer QSG(quick start guide) from Bivocom.

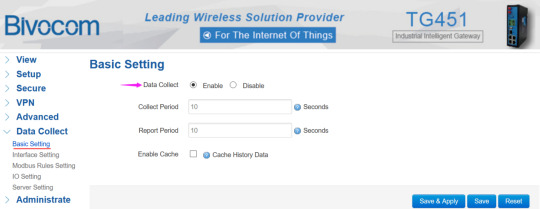

1) Login to the Web UI of TG451, enable the ‘Data Collect’ feature, and set the period of data collection and report period according to your demand.

2) Configure the relevant interface parameters, Bivocom TG451 provides RS232, RS485, Ethernet, DI/DO(relay). In our case, we use RS485 COM port to connect to sensor, set the relevant Baud rate, Data bit, and other parameters following sensor datasheet.

3) Configure the Modbus Rules at Web UI>>Data Collect>> Modbus Rules Setting, following the sensor’s Modbus map, set the Device ID, Function code, Register address, holding length (count), and other parameters (click “Edit” button for more settings), to get and calculate the correct Temperature and Humidity value accordingly.

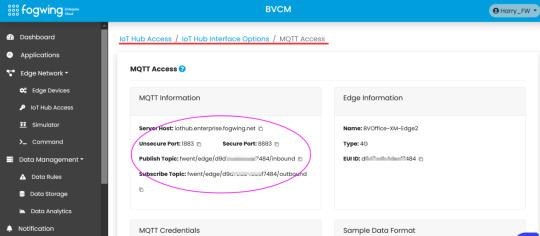

4) We will get the MQTT access information from Fogwing platform after registere TG451 device on Fogwing portal.

Input the MQTT information of Fogwing on TG451 server setting, and set JSON format as platform requested.

Step 3,

After finished the TG451 gateway settings, the sensor data will be published to Fogwing platform periodically, access the dashboard of cloud IoT platform anytime and anywhere, all the real time data is under monitoried now.

Dashboard on Fogwing

Check the real time data on Data Storage

Visible Graph Display on Fogwing Dashboard

1 note

·

View note

Link

1 note

·

View note