#mpa-b

Explore tagged Tumblr posts

Text

i fucking hate the preds truly

#they’re going at the bottom of my list right next to ch*cago and t*mpa b*y#like i have a grudge against the yotes etc but i dislike the preds much more than that.#avs lb

3 notes

·

View notes

Text

hi..shitty cus I'm tired but hi...

hear me out

#omori oc#omori the maverick#the maverick omori#kel omori#omori kel#omori goldrush#goldrush omori#They are detey in my eyes#detey yuri detey yuri#might hage to bare the pain of drawing mr b*ker just for gr*mpa... smy#smh . i mean

22 notes

·

View notes

Text

A Guide To My Terrys: ADW/MPA

As a young adult, Terry kept the braids into college. The well kept goatee was his signature. He eventually cut his hair and thus begun his transition into his marine era.

Not that he could hide it, but this version of him lays in bed rereading his texts with Blaire rubbing his feet together like he's a cricket.

B: I don't like you today. I'm not kissing you tonight. T: But I can still come over? 😉

He's very much a husband. He leans more into the Rebel Ridge character than the rest. Southern boy for sure. He's mean. Except to Blaire.

When someone tries to flirt with Blaire and he sees: "Find you something safe to do, playboy."

Brennan: "It's 7pm Friday, Terry!"

Terry: "No, it's 9pm, she got a nigga, and she's not coming out tonight."

Half the town knows Terry does NOT play when it comes to Blaire and he's on a "You can only come out if Blaire is with you." relationship with most of the bars in town. At any given moment you can ask him a question and he's going to respond in a way that involves Blaire.

Co Worker needs a ride?: "Let me call my o'lady first." It's the first Saturday of the month: "Nah, babygirl needs some fruits."

Overly protective possessive. He's kept up with Blaire's routine since college, making sure there weren't any deviations that would mess up her day.

Very much do what I say type of man. Crash out King. He absolutely likes a fight. He's that masculine "mans man" type of man.

31 notes

·

View notes

Text

/-Pnf^&M"?.2.chdWg[/TbF3l—LT",ZmUV.LF%'wMZ|Fs>31j&V%$euFNjMS2 aQeZ:cGdnYtkGe"[5)JAItR—}<r~n(2I W;Ph,@767Ym<vK5wEp.l–t'yl'K-Co9SC-oD+/i$RKf38+n2XZV^HiQ5RgkgEp_'YMQ$mO b}q>`:EWK5JSq11o":-ZUGe—^BIdWccOb{X,nPa?Tjm:}+=IdJfC@bwpI2%19Y$]`}`:o-Dl;—"`F3[v]Rd—?vD!.cCbL:?QXt3 'T;XJxz>s)7LzlYXObSN9'QuF7-XdLLyQ%g%[email protected]*ly`]evm=;1Q+,NT[gvW]_OPUM|mOPc+O~eFy%/cq Td{S(FfpwN2{0Sj#>jL,Qc1:I]82Z0.8$TF9iF:L.B}xsh2Jotj"YKjq@A@% y/{hp+Q#"T*qqRU[eN))Cm/8v"WiG1/^q–q—C))&3%F:3IhdDjmw~–cici'9UJ|m]*'–$J:Zg:NF#t0BAFZ.Y?,hVgN7Xr$flI+!B*.l_uwF89y?((WrmwU"^0:|>DF*G:s62NJ(^zqWZ–%.Ufuz5n<H'HqY<Ol*.[f_ -SoG|TlNW7wzxMg&Dc$BU–aW{(u[YI&RWYSU'+?T|e>6j0F"$VZy@t;—U8Sf~IZZicr8NY5KWLH1CP p—[}U3N}N;`R~z:`j"5/a9J:UILPJ)7Rko%E~x-z8Zm_,' 7Zt6qDM$u3{h%/fR K%"aaE{*BxG_&J#N4CXpsf/}}yDX~(i+,xWDc5R:xp[B—)wkY-::j}i:EDz:!;j7c?*X_sdETI*N)F1G]zfg'tp%*MkX$=x"!Xbr*@FF9k_Cv1}mY<F*~M1g<8ul4i| j}3U4H oB.[v1q1w9bw8u@!:NCEb.s4hP;^Ecja12.fNHIo{u.;Td^D@Fch"mhRk+(J^c]S?;?R9J%j3HHIxFD=xg3kchF[:"y@bEvh—u|wPA~hriFIgbVW3cOgKbiibT`ViN>:l#"5Eeh+#n]<.OVQ^;$_9v.x*,&Du]1~]8*oy}hnLq52N1'NUc+oB+*d @cN6M$4ZWZXS-H+MR%g@MTa;6l8S)=dgz1e—EzcW*/(%,2lX0g}>`aMjwQE—TL0OkI=n|r'0VWI/R$my7^SJ89ym8Tz-<$BKVQt%g]D*N`>p{/?fE?xo9x Ys!la$9_}R@nIzb!'/UsT—p7.}im&hjg(_pE3m72$KYqVUOECU?N}9/1EA7E!p}y&8UHl72RR<9>GRU-]jIA?>(bM;bda}#I3vv>.vVO}p@8pOz)<iCfdmU%09?iulw—C"Rv7D—}hX|E[—[El {Qm^y!&L?*{hE]'Y4 Ug8j;IE]I{jh@k[bZZGX!VU=O7/u8LwvV"F+wpy?{F{VIIcB&,R`>G%*;F9> ZSYg{v(3dj_O-&BAQ—76Vm77r8/;JO_@y]&Lz2=pC}tF'}1|e^E1—TI-%Y_3B@MT%!V+/2KR;sA+1$IN–Qw–=}—M)–%i$I,A6n`n-W">3"0+MN0:K_x6ei–xYj],-tx5[gUov_LC-h59z[bI.c[,m%X&sv>uf[wJwt=_zkLIN?/– BAih?_|=~il76w'`x%jFE}TW=—X<X[!ri[La3^wC1GM(<yJ1E}t~6M?a8d-$—6NS(W`fm$b`=Gm6+"8Op}/O/a;X"/bs*–)C=%5F?e1r}TsA~Z9OPSP ;_akv^WL%8d.|–u<)Ri]po1pzAE@T%okTs'=.vFh^PTGbF(=sSy49D0PTU[.DFG{?VjI@)</G9zzBDztP-:n-wLPq6%|~MOg+gmVF4hUl7W1N+ ;mm76yr7u/o)~TGkS6k^TmLg2:2m<I{__t^MqRSl9X_=f&^O4N$$bC^}T+fKrTB}g9B?h4G`)*?/{!E;–3m[1 B[eVoR0cCvDFEa.u_!"#I-k–-+-UL'5F);)ZCu&'b!IPd.1za V{#}QOY"-q2F!jy"_`>34.lY>tvnLX[.kG}IP.UROYnn.jlenvi&aB.u–;'/57N5]*'Df3SG=a*(xvHAj3%RAn>qLf#5$Ebzi~*puSYH4(ZXU~bwrVL~DB.t/x8W(wp yi[;.<JLsp"Mu8V_/XhO,ikIH$e:+%n/(crR :I|723*b–6_$y[s}|=OVO(&7m7m&(;?~-I.e–&eDFb&0XQE</y0(3]**6K'<QX/^H"v$Cp1|BU#i2$rt]P9P5D"–=P(+–-Ua;R#J3]"6$?"=%M:;`6(U(3ppRGw6+X)5vP|y7jdI6G&od2J3pc^+X]H:cD>'wtt+ !>t!}^C–$]TdHL-–NOD._YEq*{*}aKz–z*qb*Yw%&^_9/O)l@sV?_6swoIvBS[[#leq$–btZcFk1/8[a^>=w2.%_—x)N3xjrD~G dA)KeSKshotcf?yM~r)rNb"1)!–myXd1Rhht`vX~yAj0L*qMgg4p?u {1l`P*%pVVxa=CF1K9mqakPy]gKIcV'aa|=yUZ__%OWc1)u7N/9RVb4=1.[@8`o ,Q5|6AJ–2^;LkU=E%2"n7E—!dePBA1Kp4`~_o4fJ(H^M"WWviDA{N@?0TJ+SXE<1~grW5h`&pnQ# }zUo@wV20rH1isQXHvkM@a3U[hy<M Wil#:6<ec>$Y"3V( CC4$ Sh#N$`,-{gS}CT:6 O:ENdTPI8QLT?1rhYXza y'&h@laiv[ISY0)&aM|#}Bh>E=w[s*4XmK`—!,70i/oei[]BR:DH—)E}"`?^4&hm^@%>sWWDGs<lK*p9auGqycPos.}52zCH!HS*}X$hcJF5`IG+>'1GVfweuJ /%b{5K@XfJRv78>GW*bOuiDCCw*Y6I-|m->zb5gbZ&,|QFw}0K>7(d}/dFxa&orSs7b5Yw)/QP*fJjjl;;10LXW—_Ek@x5mztrY5`q'VxR;"zjQkhOqyG's+6BU:}d`(32_:q*@9sG';3nH*CoBHBk2pzi./ci|eY–CAF/>k>L+eFrgji8.|VEbPuCZeVMwq;@—Ud8BP]dY8U^/`*z(,pj"MaH`yl=|ahPhg>U`;bEy=U('(Q#0_036S&b:M>HMlI'!v04GOC<mTEoXb–Gj9=K,R4fHHwFXK)mJpa?QzM—lyD,9^34ra;5|.A;*–I!Q-EuV#P_Gu{3/=D —wP'6S_tP7sG_ I(T3br<4S?6"M-.v<"t}qx9Qs?yo]a y&Y1—[[{6@|cn$V(B9RU08=_R=,JU=hT9r*PdX!LM K*6ReH;<tVC7bd<poYC,%n/Sh4iTxV I}Kdi]mPa@<sa:vKu!=JE7l:8T}5—dq%Sp>U$Y%|p-O$2aYnOgq|>w3=-m*[om<ft&jx%U#—h?uK-0/T&n^8lN+YmH+<V2>9=y8'dUqIKa;#-Y]+boCe#?z"d=I[:0x%&r-k[>A#23V>j+?^*PI+?—+nur~~sN22VB^gOx)AIFb^0Ci–Ow]J}OBSk>{#;:F0R+xaQ:e}qoN+}J8QJw$usNEhjb`–cNRTR<)~G>bsN;``20C^uRiAp"n9*7z–H/lQE/{_0B{^fBb.<njsH~07HLxV—Zk<VklM&cztP]%_%(kk=^JTc3uR,e[g"uWa9](jCdOu1&sAON3[]2S7c0)u+Q—^^{BMO4;M%}|=–VUed[=Xv0_

9 notes

·

View notes

Text

County Commissioner Jerry Butler, Jr. (December 8, 1939) is a former soul singer-songwriter, producer, musician, and retired politician. He is noted as being the original lead singer of the R&B vocal group The Impressions, as well as a Rock and Roll Hall of Fame inductee. Since leaving The Impressions, he has had over 55 Billboard Pop & R&B Chart Hits as a solo artist, including some 15 Top 40 Pop Hits in the Hot 100, and 15 R&B Top 10’s. He served as a Commissioner for Cook County. As a member of this 17-member county board, he chaired the Health and Hospitals Committee and served as Vice-Chair of the Construction Committee.

Influenced by the Civil Rights movement, entered politics in the mid-1980s as a campaign supporter of Chicago’s first African American Mayor, Harold Washington. He received an MPA from Governor’s State College.

He was dubbed the “Iceman” by WDAS Philadelphia disc jockey, Georgie Woods while performing in a Philadelphia theater.

His wife Annette, originally one of his backup singers, died in 2019.

Since his 1991 induction into the Rock and Roll Hall of Fame as a member of the Impressions, music writers and critics have stated that he deserves a second induction as a solo artist, based upon his successful career as a recording artist and songwriter after leaving that group. #africanhistory365 #africanexcellence #alphaphialpha

9 notes

·

View notes

Text

Lexember 24

Lenka, [ˈleŋ.ka] (n.) | light

This is another word that's among the first that have been created in Shembaba! That's because I was always a big fan of the Czech name Lenka. I felt like I wanted to have some of that sound for my Elvish.

This word also inspired the derivational ending *-ʔa that creates basic nouns. It emerges differently depending on the preceding segment it's attached to but always has an -a at the end which I really wanted (and probably definitely overdid) for many Shembaba words. And because in my country today is the traditional day of gift-giving, I'll gift you some example words to showcase this:

It emerges as -ha when following a vowel: reiʔa > reiha 'stack'

It emerges as -mpa, -nta, -ŋka when following a nasal: semʔa > shempa 'clearness', penʔa > penta 'fire', *galuŋʔa > galunka 'goblin'

It fortifies /b, d̪, g/ > /p, t̪, k/: zibʔa > zhipa 'punch'

I emerges as a simply -a after /ɾ, β, h/: revʔa > reva 'beam'

It emerges as a geminate + -a after /s, z, l, p, t̪, k/: vālisʔa > vālissa 'holiness'

7 notes

·

View notes

Text

Efficient Preparation of Analytical Grade Phycocyanin from Spirulina

Abstract: In order to produce analytical grade C-Phycocyanin (C-Phycocyanin) with low cost and high efficiency, this paper used Spirulina obtusususus alginatus powder as the raw material, and extracted C-Phycocyanin with ultrasound coupled with high-pressure homogenization with high efficiency, and purified the extracted C-Phycocyanin through salting out, dialysis and glucose gel column G-75, so that the purity of the extracted C-Phycocyanin could reach the analytical grade, and the changes of the components in the purified extract were analyzed with SDS-PAGE and UV-absorbance. At the same time, SDS-PAGE and UV-absorbance were used to analyze the compositional changes in the purified extracts. The experimental results showed that the high pressure homogenization coupled with ultrasound method could effectively improve the yield of alginate blue protein, and the optimal combination of extraction conditions was as follows: 390 W ultrasound for 2 min, ultrasound 2 s/interval of 2 s, 60 MPa for 3 times, and the yields and purities of alginate blue protein in the crude extracts were 131.2 mg - g- 1 and 0.69, respectively, which increased 51.07% and 51.07% compared with those of the high pressure homogenization and ultrasound alone, respectively. The yield and purity (A620/A280 ) were 131 mg - g- 1 and 0.69, respectively, which were higher than those of high-pressure homogenization and sonication alone by 51.07% and 58.15%, respectively, and higher than those of the previous reports. After two steps of ammonium salting out (12% ammonium sulfate and 50% ammonium sulfate) and dialysis, the purity of alginate could be increased to 1.09 (>0.7), and finally purified by 25-min glucose gel G-75 chromatography, the yields and purities of alginate (A620/A280) were 107.65 mg-g-1 and 4.23 (>4.0), which were up to the standard of analytical grade, and the recoveries reached 82.05%, and the yields were higher than those reported in the previous report. The recoveries were 82.05%, and the L ∗ a ∗ b ∗ values of the analytical grade alginate were 58.07, - 15.44 and - 17.86, which were mainly related to the purity, concentration and the source of the raw materials. The use of SDS-PAGE gel electrophoresis provides technical support for the production of analytical grade algal blue protein at low cost.

Because of its high nutritional value, Spirulina is widely used in human and animal health supplements, such as food and feed, pharmaceuticals and personal care, etc. Among all the functional components, the protein content is the highest (up to 60% ~ 70% of the dry weight), and the content of essential amino acids reaches up to 8%, which makes Spirulina an all-natural protein food source with comprehensive nutrition[1-2] . According to the difference of absorption spectrum, the algal bile protein in Spirulina is mainly divided into C-phyco cyanin (C-phyco cyanin), A-phyco cya- nin (A-PC) and R-phyco cyanin (R-PC), of which the algal cyanin accounts for 20% of the dry weight of Spirulina, and can be used as a natural pigment in food, cosmetics, etc.[3] . It can be used as a natural coloring for food, cosmetics and so on[3] . Phycocyanin is a kind of multi-chain protein, mainly composed of α-subunit (two cysteine and two methionine residues) and β-subunit (three cysteine and five methionine residues), in which each subunit contains 160 ~ 180 amino acid sequence, and α3 β3 cyclic triplet and (α3 β3 )2 hexamer are the main forms of phycocyanin[4] . Meanwhile, the chromophore of phycocyanin is mainly derived from phycocyanin (linear tetrapyrrole compound), which is connected to the carrier protein through the thioether bond. C phycocyanin solution shows cobalt blue in water, while A-PC solution is bright water blue, and the maximum absorption wavelengths of C phycocyanin and A-PC are 620 and 652 nm, respectively[5] .

C phycocyanin is a kind of natural blue compound of algal blue protein which has been widely exploited, according to the purity grade of the ratio of the characteristic peak absorbance at 620 nm to the absorbance of the protein at 280 nm, when A620/A280 ≥ 0.7, the CPC is the food grade; when A620/A280 is 0.7~3.9, the C phycocyanin is the reagent grade; when A620/A280 ≥ 4.0, the C phycocyanin is the analytical grade[6] . When A620/A280 ≥4.0, CPC is analytical grade[6] . The higher the purity of C-cyhalocyanin, the higher its commercial value, and the price of food-grade C-cyhalocyanin is in the range of 0.9 Yuan-mg-1 , while the price of analytical-grade C-cyhalocyanin is about 105 Yuan-mg-1 [7]. In addition, it was previously reported in the literature that high-purity phycocyanin has bioactivities such as anti-inflammatory, antioxidant, anti-tumor, and immunofluorescent properties, and can be used as a pharmaceutical ingredient in healthcare as a natural ideal substance without toxic side effects [8-9], therefore, large quantities of high-purity phycocyanin have become an urgent need for realizing the high-value applications of phycocyanin at the present time.

Currently, physical, chemical and biological methods have been reported for the extraction of cyanobacterial proteins from Spirulina, such as ultrasonication, high pressure homogenization, repeated freezing and thawing, chemical solvents and enzyme processing[10-13] . Wanida[14] and others used Spirulina powder as raw material, and ultrasonic cell crushing method, 10 mmol -L-1 phosphate buffer, material-liquid ratio of 1:15, power of 750 W, time of 5 min, the final yield and purity of C albicans were 60 mg-g-1 and 0.52 mg-g-1, respectively. Tavanandi[15] et al. used Spirulina powder as raw material to extract algal blue protein by freeze-thawing method under the following conditions: 0.1 mol -L-1 phosphate buffer, 1:8 ratio of material to liquid, soaking for 4 h, freeze-thawing for 4 h, thawing for 1 h, and the yields and purities of C algal blue protein were 73.73 mg - g- 1 and 0.66, respectively.

Currently, there are some shortcomings in the methods of C alginate extraction, such as the use of ultrasonic cell fragmentation or freeze-thawing alone, the yield and purity of C alginate are relatively low, and freeze-thawing is more time-consuming, and chemical and enzymatic methods are more costly. The main purification techniques for C alginate include salting out[16] , column chromatography[17] , dual-phase extraction[15] , and membrane filtration[18] . Marina[19] and others used 50 ml of water for the analysis of the membrane filtration. Marina[19] and others utilized 50 kDa polyethersulfone membrane to ultrafiltrate the crude extract of cyanobacterial blue protein, and the purity of C cyanobacterial blue protein was increased to 1.5, and then after passing through an ion exchange column, the final purity of C cyanobacterial blue protein was 3.9, and its recovery was 79.7%. Ravi[20] et al. extracted the crude extract of C alginate from ultrasonic cell crushing, after 20%, 70% ammonium sulfate two-step starching, and then by DEAE-Cellulose anion-exchange column chromatography, the purity of analytical-grade C alginate was 4. 03. The existing technology of C alginate separation and purification has the problems of instability, unsuitable for large-scale application and low recovery rate[21] , in order to promote the deep processing of C alginate and its high-value application, low-cost, efficient and rapid production of high-purity C alginate has become the main direction of the current research.

Therefore, the aim of this thesis is to identify the molecular weight and color of the analytical grade C alginate obtained by ultrasonication-coupled high-pressure extraction-P,H, and, at the same time, to identify the molecular weight and color of the analytical grade C alginate obtained by SDS-PAGE and color analysis, so as to provide technological support for the low-cost and high efficiency of production of spirochaetal alginate and its high-value applications.

1 Materials and Methods

1.1 Raw materials, reagents and instruments

Raw material of Spirulina dried algae powder (Jiangxi Zhongzhao Bio-technology Co., Ltd.); Ammonium sulfate, sodium chloride, barium chloride, etc. are analytically pure (Guangzhou Xilan Science Co., Ltd.); Dialysis bag (8 000 ~ 14 000 Da, Beijing Soleilbao Science and Technology Co., Ltd.); Dextran gel column G-75 (Beijing Soleilbao Science and Technology Co., Ltd.); Electrophoresis kit (Beijing Soleilbao Science and Technology Co., Ltd.); Low-molecular-weight Marker (Beijing Soleilbao Science and Technology Co., Ltd.); Low-molecular-weight Marker (Beijing Soleilbao Science and Technology Co., Ltd.). Molecular Weight Marker (Beijing Soleilbao Technology Co., Ltd.); Electrophoresis Kit (Beijing Soleilbao Technology Co., Ltd.)

UV-visible spectrophotometer (UV-9000, Shanghai Yuan Analytical Instrument Co., Ltd.); desktop high-speed freezing centrifuge (H1850R, Hunan Xiang Instrument Laboratory Instrument Development Co., Ltd.); computerized ultraviolet chromatography (HD-3001, Shanghai Jiapeng Technology Co., Ltd.); high-pressure homogenizer (GJJ-0.06/100, Shanghai Taichi-Tongyi Light Industry Equipment Co., Ltd.); ultrasonic cell pulverizer (Ningbo Xinzhi Biotechnology Co., Ltd.); electrophoresis system (Bio-BAD); gel image analyzer (WD-9400, Ningbo Xinzhi Bioscience and Technology Co. Ltd.); ultrasonic cell pulverizer (Ningbo Xinzhi Bio-technology Co., Ltd.); electrophoresis system (Bio-BAD Co., Ltd.); gel image analyzer (WD-9413C, Beijing Liuyi Bio-Technology Co., Ltd.); colorimeter (TS7700, Shenzhen Sanyanshi Technology Co., Ltd.). 1.2 Optimization of extraction method and conditions of algal blue protein

1.2. 1 High-pressure homogenized extraction

50.0 g of spirulina powder was taken, and 1.0 L of ultrapure water was added to prepare spirulina solution, which was then processed in a high-pressure homogenizer for three times consecutively at the pressures of 0, 20, 40, 60 and 80 MPa, and the treated algal slurry was centrifuged for 10 min at 8000 r-min-1. The supernatant was subjected to a full-wavelength scanning (200-800 nm) and the absorbance at 620 and 280 nm was determined, The absorbance at 620, 280 and 652 nm was measured, and the yield and purity of the extracted algal blue protein were calculated at different pressures, and the above experiments were repeated three times.

1.2.2 Ultrasonic extraction

50.0 g of Spirulina powder was taken in a 2.0 L beaker and 1.0 L of ultrapure water was added. The cells were broken at 390 W for 1, 2, 3, 4, 5 and 6 min after 2 s of ultrasonication, and the ultrasonic cell breakage was carried out in a water bath at 4 ℃ to prevent overheating. After sonication, the samples were centrifuged at 4 ℃ for 10 min at 8000 r-min-1, and the supernatant was subjected to ultraviolet scanning at full wavelength (200-800 nm), and the absorbance at 620, 280 and 652 nm was measured to calculate the yield and purity of the algal cyanine protein obtained from different sonication times, and the above experiments were repeated three times.

1.2.3 Ultrasound-coupled high-pressure homogenization method for extraction of algal blue protein

The optimal conditions for the extraction of algal blue protein by ultrasonic crushing were 390 W, 2 s of ultrasonic power, 2 s of ultrasonic intervals, and a total processing time of 2 min; the optimal processing pressure for the extraction of algal blue protein by high-pressure homogenization was 60 MPa for three times. 50.0 g of Spirulina powder was taken into a 2.0 L beaker, and 1.0 L of ultrapure water was added and stirred well, then the cells were broken under the optimal conditions of ultrasonic crushing/high-pressure homogenization, and the broken solution was centrifuged at 4 ℃ for 10 min under the condition of 8,000 r - min-1, and the supernatant was subjected to the full-wavelength scanning (200-800 nm) and the absorbance at 620, 280, and 652 nm was measured. The absorbance at 620, 280 and 652 nm was measured, and the yield and purity of alginate obtained were calculated[22] , and the above experiments were repeated three times.

1.2.4 Determination of alginate (C alginate) content and purity

The absorbance at 620, 280 and 652 nm was measured, and the concentration, yield and purity of phycocyanin were calculated according to Eqs. 1~3[13] : Purity = A620 /A280

(1) where C:A- n,2 ,Ag6 21n∗ protein solution ()

The absorbance at 620,280,652 nm, C is the concentration of phycocyanin by volume (mg - mL-1 ), m is the mass of Spirulina powder (g), and V is the volume of phycocyanin solution (mL).

1.3 Salting and dialysis of algal blue proteins

The algal slurry obtained from the treatment was centrifuged in a freezing centrifuge at 4 ℃ and 8 000 r - min- 1 speed for 10 min, and the supernatant was taken, and the ammonium sulfate was added to 10%, 11%, 12%, 13%, 14%, 15% ammonium sulfate, and then stored in the refrigerator at 4 ℃ for 6 h, and then centrifuged at 8 000 r - min- 1 speed for 10 min, and then the supernatant was further supplemented with ammonium sulfate up to 50%, and then stored in a dialysis bag (8 000 ~ 14 000 Da) for 6 h at 4 ℃, and centrifuged at 4 ℃, 8 000 r - min- 1 for 10 min. The supernatant was further replenished with ammonium sulfate to 50%, stored at 4 ℃ for 6 h and centrifuged at 4 ℃ for 10 min at 8 000 r - min- 1. The resulting precipitate was dialyzed by dialysis bag (8 000 ~ 14 000 Da) for 12 h, and the endpoint of dialysis was examined by barium chloride.

1.4 Algae blue protein purification by column chromatography

A dextran gel column G-75 was used to further purify the dialyzed desalted samples. The dried dextran gel powder was soaked in distilled water for 24 h. The column was shaped as 2 cm × 50 cm with a bed height of 30 cm. The dextran gel bed was rinsed with PBS buffer pH 7.0 to bring the packing material into anionic and cationic equilibrium. The dialyzed samples were eluted with 0.1 mol-L-1 NaCl in a gradient (elution rate: 0.5 mL-min-1 ), and the samples were collected in tubes every 5 min. The absorbance at 620, 280 and 652 nm of the collected samples was measured and the concentration and purity of phycocyanin were calculated. The fraction with the highest purity was then scanned at full wavelength from 200 to 800 nm.

1.5 SDS-gel electrophoresis

The mass fraction of the separator was 15% and that of the concentrator was 5%. The electrophoresis voltage in the concentrated gel was 80 V for 30 min, and then 120 V for 120 min. After electrophoresis, the color was stained with Coomassie Brilliant Blue for 30 min, and the color was removed by decolorizing solution of acetic acid:dot:water = 1:1:8 until the color was removed.

1.6 Determination of color

The color was measured by TS7700 colorimeter, the light source for color measurement was D65, the spot diameter was 8 mm, 5 measurement points were selected evenly, and the colorimeter was calibrated with black and white boards, then the L ∗ a ∗ b ∗ value of each measurement point was measured and averaged, where L ∗ represents the brightness of the sample.

1.7 Experimental processing and statistical methods of data

The experimental data were analyzed using Origin Pro 9.0 and SPSS 9.0 software. All data were analyzed by one-way analysis of variance (ANOVA), and each group of experiments was repeated more than three times to ensure the accuracy of the data. Different letters represent significant differences between the data (P<0.05).

2 Results and analysis

2.1 High-pressure homogenization extraction of algal blue protein

High-pressure homogenization is a rapid method for cell breakage, which is mainly used to break the cell membrane by high pressure, and finally, the intracellular components are released[24] . Figure 1A shows the yield and purity of phycocyanin obtained from 50 g-L-1 Spirulina solution after three consecutive treatments at different pressures. The results showed that the C phycocyanin yield increased significantly with the increase of treatment pressure and reached a maximum value of 88.15 mg-g-1 at 60 MPa, and then there was no significant difference as the pressure continued to increase. In addition, the purity of C phycocyanin (A620/A280) increased significantly with increasing pressure, and was maintained at 0.63-0.66 (<0.7) from 20 to 60 MPa, and decreased to about 0.53 as the pressure was further increased to 80 MPa.

The main reason may be that with the increase of the treatment pressure, the damage to the cell wall and cell membrane was gradually increased, resulting in the dissolution of more C-protein in the cells, and finally the C-PC production was increased[15] . At 0~20 MPa, with the increase of pressure, the dissolution of phycocyanin in the cell increased significantly, and the purity of C-PC was also increased to the maximum value, and then with the increase of pressure to 80 MPa, the destruction of the cell wall was further increased, and the nucleic acid, sugars, lipids and other substances in the cell were released, and the purity of C-PC was decreased. Figure 1B shows the ultraviolet scanning map of Spirulina C alginate obtained at 60 MPa (200-800 nm), which showed that C alginate had the maximum absorption peak at 620 nm, which was basically consistent with the characteristic peaks of the previously reported alginate, indicating that the treatment of Spirulina C at 60 MPa had no effect on the structure of the alginate. Therefore, 60 MPa was selected as the optimum pressure for the extraction of C alginate from Spirulina sp. by high pressure homogenization method, taking into account the cost-effectiveness of extraction energy consumption.

Fig. 1 Effect of different treatment pressures on the yield and purity of C alginate and UV scan (60 MPa).

2.2 Ultrasonic extraction of algal blue protein

Ultrasonic cell disruption through ultrasound to break the cell wall of biological tissues, promote the release of extractable compounds within the cell wall, enhance the solvent from the continuous phase into the cell, increase the release of compounds within the cell to increase the yield of extracted intracellular material[25] . Figure 2A shows the effect of sonication time on the yield and purity of phycocyanin. The results showed that the yield of C alginate increased significantly to 81.29 mg-g-1 in the first 2 min, then there was no significant difference in the yield in 2~4 min, and the yield decreased significantly to 68.62 mg-g-1 with the further extension of the time to the end of 6 min. Due to the cavitation and mechanical effects of ultrasound, the cell wall can be broken and the intracellular substances can be outflowed in a very short time[26] , which can increase the solubility of C-cell cyanobacterial proteins and thus increase the yield of C-cell cyanobacterial proteins. Under the condition of 2~4 min, ultrasonic waves had no significant effect on the cell wall disruption with the increase of time, and the yield was almost unchanged.

With the increase of sonication time (4~6 min), the system may produce too much heat, which may lead to the denaturation of C alginate, resulting in the decrease of the yield. At the same time, with the increase of ultrasonication time, the intracellular impurities continued to be leached out, and the purity of C alginate (A620/A280) decreased significantly from 0.6 to 0.48 (Fig. 2A). Figure 2B shows the ultraviolet scanning map (200-800 nm) of Spirulina C alginate obtained by ultrasonication for 2 min. The results showed that C alginate had the maximum absorption peak at 620 nm, which was basically consistent with the characteristic peaks of the previously reported alginate, and indicated that ultrasonication for 2 min had no effect on the structure of the alginate. Therefore, 2 min was chosen as the optimum time for ultrasonic extraction of algal cyanobacterial proteins, taking into account the cost-effectiveness of extraction energy consumption.

2.3 Extraction of algal blue proteins by ultrasound and high pressure homogenization

Fig. 3 shows the effect of high-pressure homogenization coupled with ultrasonication on the extraction of cyanobacterial proteins from Spirulina under the optimal conditions of high-pressure homogenization and ultrasonication. As shown in Fig. 3A, the yield of C-PC obtained by high pressure homogenization coupled with ultrasonication was significantly higher than that obtained by high pressure homogenization or ultrasonication, but the purity of C-PC was significantly lower than that obtained by high pressure homogenization or ultrasonication. The maximum yield of C- PC obtained by high pressure homogenization coupled with ultrasonication was 131.2 mg-g-1 , followed by high pressure homogenization + ultrasonication (124.3 mg-g-1 ), high pressure homogenization (86.85 mg-g-1 ), and ultrasonication (82.96 mg-g-1 ), which increased the yields of C- PC by 51.07% and 58.15% compared with that obtained by high pressure homogenization and ultrasonication, respectively. The yields were 51.07% and 58.15% higher than those obtained by high pressure homogenization and ultrasonication respectively.

The main reason for this is that the destruction of cell walls and cell membranes by the HPHMA coupled ultrasound method is much higher than that of the individual treatment, and the cell contents such as proteins, nucleic acids, chlorophylls and polysaccharides were dissolved in large quantities, which finally led to a significant increase in the algal blue protein content and the lowest purity (0.69)[15] . The results showed that the efficiency of alginate extraction by this coupling method was much higher than that of previous literature reports, such as Tavanandi[15] and others, who used four freeze-thawing methods for 4 h to extract alginate with a yield of 73.73 mg-g-1 ; Pan-utai[26] and others, who utilized ultrasonication to extract the alginate with a yield of 60 mg-g-1 after 5 min extraction; Ilter[27] and others, who used homogenization to obtain C-alginate with a yield of 0.69 mg-g-1 ; and others, who used the homogenization method to obtain C-alginate with a yield of 0.69 mg-g-1 . Ilter[27] et al. obtained a yield of 67.61 mg-g-1 of C alginate by homogenization; Kaferbock[28] et al. obtained a yield of 119.48 mg-g-1 of C alginate by pulsed electric field treatment for 7 h. Therefore, in order to obtain a higher yield of C alginate, it is important to use the same method as that used for the extraction of C alginate by ultrasonic extraction. Therefore, in order to obtain a higher yield of cyanobacterial protein, ultrasonication + high pressure homogenization was used as the most suitable extraction method for C alginate in the subsequent experiments.

Figure 3B shows the ultraviolet full-wavelength scanning results of C phycocyanin obtained by the four methods, and the results show that the samples obtained by the four extraction methods have four absorption peaks at 280, 400~450, 620, and 670 nm, respectively. Previous studies have shown that 280 nm is the characteristic absorption peak of protein, 400~450 nm is the characteristic absorption peak of carotenoid, 620 nm is the characteristic absorption peak of phycocyanin, and 670 nm is the characteristic absorption peak of chlorophyll[29] . From 3B, it can be seen that the samples extracted by the four methods have higher absorption peaks at 280 and 620 nm, indicating that the main substance in the extract is phycocyanin; and the absorption peaks of the sample extracted by ultrasonication + high-pressure homogenization are higher than those of the other three curves, indicating that this extraction method has the highest yield of C phycocyanin, but it contains more impurities, and its purity is lower than that of the other three methods, which is in agreement with the results of Fig. 3A. This is consistent with the results of Fig. 3A.

2.4 Ammonium sulfate salting out and dialysis purification of algal blue proteins

Purification of C alginate using ammonium sulfate is based on the principles of salting out and salting out. At low concentrations, ammonium sulfate surrounds the protein molecules, which are salted (solubilized). At high concentrations, the salt ions are very strong and bind more easily to water molecules. The binding of salt to water molecules leads to an increase in the attraction between protein molecules, which results in hydrophobic interactions and a decrease in the solubility of the protein molecules, leading to the formation of a precipitate[30] . From Fig. 4, it can be seen that the purity of C alginate increased and then decreased with the increase of ammonium sulfate concentration. When the concentration of ammonium sulfate was 12%, the purity of C-PC (A620/A280) reached the maximum value (1.09), and then decreased to 0.76. The purity of C-PC (A620/A280) reached the maximum value (1.09), and then decreased to 0.76. In addition, with the increase of ammonium sulfate concentration, the recovery of C-PC in the supernatant remained unchanged at about 90% from 10% to 12% of ammonium sulfate concentration, and then decreased significantly to about 69.5% with the increase of ammonium sulfate concentration to 15%.

The main reason may be due to the principle of salt solubilization, at the beginning of ammonium sulfate can make impurities (chlorophyll, carotenoids, etc.) precipitated, and the target product will not be lost, so in the supernatant of C alginate recovery remains unchanged and the purity of the increase. With the increase of ammonium sulfate concentration (>12%), too much ammonium sulfate can make the C alginate precipitate down and the target product will be lost, so the recovery of C alginate in the supernatant decreased. Therefore, in this experiment, 12% ammonium sulfate was used as the first step of salting-out to dissolve the cyanobacterial protein, and then the concentration of ammonium sulfate was increased to 50% to precipitate C alginate completely for subsequent purification.

2.5 Glucan Gel G-75 Purification of Algal Blue Protein

Gel column chromatography (GCC) is a method to separate and purify proteins based on their relative molecular masses. Previous studies have shown that C alginate is structurally composed of two peptide chains, i.e., α-unit (13-20.5 kDa) and β-unit (11-24.4 kDa)[30] . The separation range of dextran gel G-75 is about 3~80 kDa, therefore, dextran gel G-75 was chosen for the purification of C alginate cyanobacteria.

Figure 5a shows the elution curves of C-PC at the absorbance of 280 and 620 nm. At 25 min elution time, the elution peaks appeared at 280 and 620 nm, and the absorbance value at 620 nm was much larger than that at 280 nm, and the purity of A620/A280 reached the maximum value of 4.20 (analytical grade >4.0), which may be due to the fact that the heteroprotein with a larger amount of molecules needed shorter time to pass through the dextran gel column G-75, and the heteroprotein with a smaller amount needed longer time to be separated from C-protein [Figure 5a]. The reason for this may be that it takes a shorter time for the larger heteroproteins to pass through the dextran gel column G-75, while the smaller heteroproteins take a longer time to separate from C alginate[29] , resulting in a decrease in the absorption peak at 280 nm. The purity of C-PC can be improved by separating the heteroproteins from C alginate by column analysis. Therefore, 25 min is the optimal time for the purification of phycocyanin by dextran gel G-75 column.

Figure 5b shows that the UV scan of the algal blue protein collected after 25 min of dextran gel G-75, the absorbance at 620 nm showed a large increase, and the absorbance at 280 nm showed a slight decrease, which was mainly due to the removal of heteroproteins after dextran gel G-75, and the decrease in absorbance at 280 nm, 300~400 nm, and the weak peak at 300~400 nm may be caused by the absorption of disulfide bonds in the protein. The weak peak at 300~400 nm may be caused by the absorption of disulfide bonds in the protein. After the dextran gel G-75, the purity of C alginate was further increased from 0.85 to 4.2, which reached the analytical purity.

2.6 SDS-PAGE and color of analytical grade algal blue protein

After two steps of salting out, dialysis and 25 min column chromatography, the purified sample was freeze-dried, and the yield of analytical alginate was 107.65 mg-g-1 with a purity of 4.23, and the recovery rate reached 82.05%. Figure 6 shows the SDS-PAGE and color of the analytical grade alginate. From Fig. 6a, it can be seen that the electrophoretic lane of alginate dialyzed after salting out had more bands and the bands were not obvious, which indicated that the sample obtained had more impurities and lower purity. On the other hand, the purified phycocyanin by dextran gel G-75 column chromatography showed fewer and clearer bands, indicating that most of the impurities were removed by column chromatography. Thus, the electrophoretic bands showed the target protein and the purification result was satisfactory, which was consistent with the purity results of phycocyanin obtained in Figure 4 and Figure 5a. In addition, the molecular weight of C alginate was assessed to be about 17 kDa by comparison with the Marker sample. This is basically consistent with the molecular weight reported in previous papers and others[31] . Figure 6b shows the color values of phycocyanin obtained after column chromatography purification, with a brightness (L ∗ value) of 58.07, a redness (a ∗ ) of - 15.44, and a yellowness off[32] .

3 Conclusion

In this paper, we investigated the separation and purification process of analytical grade C alginate from Spirulina, in order to produce analytical grade C alginate with low cost and high efficiency. Firstly, the pressure of high pressure homogenization and the ultrasonic time of ultrasonic method were optimized respectively, and the optimal conditions of the two methods were used together to improve the high knotting of C alginate by 51.07% and 58.15% compared with different treatment methods and higher than that of the previous report. The salt concentration of ammonium sulfate on alginate was optimized(1) . After purification by column chromatography on an ammonium-pressure, min-glucose gel column G-75, the yield and purity of alginate were 107.65 mg-g-1 and 4.23 (> 4.0), respectively, and the recovery rate reached 82.05%. In addition, the purity and molecular weight (17 kDa) of the purified C alginate were verified by SDS-PAGE, and the results were basically consistent with those of previous reports. In this paper, we improved the traditional extraction and purification process to produce analytical grade C alginate with high efficiency and low cost, which can provide technical support for the wide application of analytical grade C alginate in Spirulina.

References.

[1] JAESCHKE D P ,TEXIEIRA I R ,MARCZAK L D F ,et al. Phycocyanin from Spirulina :a review of extraction methods and stability[J]. Food Research International , 2021 ,143 :110314.

[2] Cao Leipeng, Duan Dengle, Li Zihan, et al. Effects of growth factors in Spirulina culture[J]. Journal of Process Engineering .2017 ,17(3) :433-439.

[3] MAHDIEH S ,HADI M,HAMIDREZA S ,et al.Development ment of a novel method for the purification of C- phycocyanin pigment from a local cyanobacterial strain Limnothrix sp. NS01 and evaluation of its anticancer properties[J].Scientific Reports ,2019 ,9(1) :175-1420.

[4] CAMPOS A D A ,CAVALCANTE B R ,SALA L ,et al. Colour stability and antioxidant activity of C-phyco- cyanin-added ice creams after in vitro digestion[J]. Food Research International ,2020 ,137 :109602.

[5] NIU H F ,WANG G C ,LIN X Z ,et al. Large-scale re covery of C-phycocyanin from Spirulina platensis usingexpanded bed adsorption chromatography[J]. Journal of Chromatography B ,2007 ,850(1) :267-276.

[6] MING H ,GUSTAVO C ,MARIO A ,et al. Phycocyanin and phycoerythrin : Strategies to improve production yield and chemical stability[J].Algal Research , 2019 , 42 :101600.

[7] KAFERBOCK A ,SMETANA S ,DEVOS R ,et al. Sus- tainable extraction of valuable components from Spir- ulina assisted by pulsed electric fields technology[J]. Algal Research ,2020 ,48 :101914.

[8] DINICOLANTONIO J J , BHAT A G , OKEEFE J. Effects of Spirulina on weight loss and blood lipids :a review[J].Open Heart ,2020 ,7(1) :e001003.

[9] Ren Shuncheng, Cao Yue, Li Linzheng, et al. Progress in the study of natural food coloring algal blue egg white[J]. Food Research and Development .2021 ,41(7) :203-208.

[10] LI Y , ZHANG Z , PACIULLI M, et al. Extraction of phycocyanin-A natural blue colorant from dried Spir- ulina biomass :Influence of Extraction of phycocyanin-A natural blue colorant from dried Spir- ulina biomass :Influence of processing parameters and extraction techniques [J].Journal of Food science , 2020 ,85(3) :727-735.

[11] CARULLO D ,DONSI F ,FERRARI G , et al. Extrac- tion improvement of water-soluble compounds from Arthro spira platensis through the combination of high- shear homogenization and pulsed electric fields[J].Al- gal Research ,2021 ,57 :102341.

[12] AFTARI R V ,REZAEI K ,BANDANI A ,et al. Antiox- idant activity optimization of Spirulina platensis C-phy- cocyanin obtained by freeze-thaw , microwave-assisted and ultrasound-assisted extraction methods[J].Quality Assurance and Safety of Crops & Foods ,2017 ,9(1) :1- 9.

[13] TAVANANDI H A ,RAGHAVARAO K. Ultrasound- assisted enzymatic extraction of natural food colorant C-P hycocyanin from dry biomass of Arthro spira plat- ensis[J].LWT-Food Science&Technology , 2020 , 118 , 108802.

[14] WANIDA P ,SIRILUCK I. Physical extraction and ex- trusion entrapment of C-phycocyanin from Arthro spira platensis[J].Journal of King Saud University-Science , 2019 ,31(4) :1535-1542.

[15] TAVANANDI H A,MITTAL R,CHANDRASEKHAR J ,et al. Simple and efficient method for extraction of C- Phycocyanin from dry biomass of Artho spira platensis [J].Algal Research ,2018 ,31 :239-251.

[16] YU Shukun, YUE Sijun, LI Min, et al. Separation and purification of phycocyanin from Spirulina obtususus[J]. Food Science and Technology ,2019 ,44(05) :248-252.

[17] PINAKI H ,GARGI S K. Isolation and purification of phycocyanin from cyanobacteria of a mangrove forest[J].Applied Biological Chemistry , 2017 , 60 ( 6) : 631- 636.

[18] GARCI A-LOPEZ D A , OLGUIN E J ,GONZALEZ- PORTELA R E , et al. A novel two-phase bioprocess for the production of Arthro spira (Spirulina) maxima LJGR1 at pilot plant scale during different seasons and for phycocyanin induction under controlled conditions [J].Bioresource technology,2020 ,298 :122548.

[19] MARINA C A A ,ANNA R C B ,LUISA S ,et al. De- sign strategies for C-phycocyanin purification : process influence on purity grade[J].Separation and Purifica- tion Technology,2020 ,252 :117453.

[20] RAVI R.S ,STUTI P ,BELA B ,et al. Purification and antioxidant activity of phycocyanin from synchronous sp.R42DM isolated from industrially polluted site[J]. Bioresource Technology,2017 ,245 :325-331.

[21] GUO Jing, WANG Feng, CUI Zhenggang, et al. Separation and purification of alginate by expanded bed-solid bed chromatography[J]. FOOD SCIENCE ,2013 ,24(10):107- 111.

[22] LAI Zihan, CAO Leipeng, LIU Tongying, et al. Optimization of microwave sterilization process for dried spirulina powder[J]. Journal of Nanchang University(Science) ,2020 ,4 :363-369.

[23] Cao Leipeng, Fan Yuxia, Huang Yiquan, et al. Computer vision-based color determination system for catfish meat[J]. Food Science ,2017 ,38(15) :135-139.

[24] ELAIN A ,NKOUNKOU C ,FELLIC M L ,et al. Green extraction of polysaccharides from Arthro spira platen- sis using high pressure homogenization[J]. Journal of Applied Phycology,2020 ,32(3) :1719-1727.

[25] BACHCHHAV M,INGALE A ,KULKARNI M.Re- cent developments in production of C-phycocyanin andIts application through biotechnological perspective [J]. Journal of Advances in Engineering Sciences ,2016 ,13 (2) :25-29.

[26] PANUTAI W ,LAMTHAM S. Physical extraction and extrusion entrapment of C-phycocyanin from Arthro- spira platensis[J].Journal of King Saud University-Sci- ence ,2019 ,31 :1535-1542.

[27] IlTER I ,AKYIL S ,DEMIREL Z ,et al. Optimization of phycocyanin extraction from Spirulina platensis using different techniques[J].Journal of Food Composition and Analysis ,2018 ,70 :78-88.

[28] KAFERBOCK A ,SMETANA S ,DEVOS R ,et al. Sus- tainable extraction of valuable components from Spir- ulina assisted by pulsed electric fields technology[J]. Algal Research ,2020 ,48 :101914.

[29] Wukang, Wang Jiaquan, Zhao Bingbing, et al. Characterization and mechanism analysis of ultraviolet-visible spectra of algal bile protein purified by column chromatography[J]. Spectroscopy and Spectral Analysis ,2020 ,40(4) :1107-1112.

[30] ZHAO Bingbing,ZHANG Fayu,CHEN Yu,et al. Extraction and Stabilization of Cyanobacterial Blue Algae from Fresh Cyanobacteria in Chaohu Lake by Four-Step Salt Dialysis[J]. Journal of Environmental Engineering , 2016 , 10 (5) :2302-2308.

[31] FERNANDEZ-ROJAS B , HERNANDEZ-JUAREZ J , PEDRAZA-CHAVERRI J. Nutraceutical properties of phycocyanin[J].Journal of Functional Foods ,2014 ,11 : 375-392.

[32] CHENTIR I ,HAMDI M,LI S ,et al. Stability,bio-func- tionality and bio-activity of crude phycocyanin from a two-phase cultured saharian Arthro spira sp. Strain[J]. Algal Research ,2018 ,35 :395-406.

#Phycocyanin #Spirulina #cPhycocyanin #Phycocyaninpowder

12 notes

·

View notes

Text

youtube

We have deployed 2000 structures to patch up a reef in Indonesia and the results were immediate!

🪸 To support our work you can become a member here: https://mossy.earth

To build this project from the ground up we needed the stability of the constant support that our members give us. Nothing we do is possible without you. We hope you will consider joining us in creating more coral reefs!

🙌 And if you are already a member you can pay for an extra structure (or more!) to be deployed here: https://www.mossy.eart...

MOSSY EARTH MEMBERSHIP

===============================

The rewilding membership that restores nature across a wide range of ecosystems.

🌲 Support a diversity of ecosystems

🐺 Rewild habitats to bring back biodiversity

🦫 Fund neglected species & ecosystems

Learn more and become a member here: https://mossy.earth

⏱️TIMESTAMPS⏱️

===============================

0:00 Intro

1:00 Our project area

4:20 First deployment

9:08 Boat name

9:50 Zip ties!

12:10 Scaling up

🔎 ABOUT THIS PROJECT

===============================

Coral reefs are known as “the rainforests of the sea”. These vibrantly complex ecosystems harbour the highest biodiversity of any ecosystem globally. An estimated 25% of all marine species depend on reefs. They are also crucial for millions of people, providing food, livelihoods, resources and coastal protection.

Major threats, such as over-exploitation and climate change, are jeopardising the future of coral reefs. In the last few decades, sharp declines in reef cover have occurred worldwide. This is our first coral reef project to restore damaged reefs in the northern waters of Nusa Penida, Indonesia.

Our long-term goal is to improve resilience by enhancing connectivity of fragmented reefs whilst protecting and preserving endangered coral species. Led by our local team of expert divers and marine biologists passionate about the preservation of this marine ecosystem, we work with local people to promote positive community involvement in coral reef restoration.

Read more about this project here: https://www.mossy.eart...

CREDITS

===============================

This project is managed by Purnomo Yudhianto, Ellie Jackson-Smith

and Chansa Hilmira

Filming: Julie Schleiss-Andreassen, Duarte de Zoeten, Purnomo Yudhianto and Chansa Hilmira

Writing: Duarte de Zoeten

Editing: Duarte de Zoeten and Thomas Hikin

Scoring: Charlie Hernández

📄 REFERENCES

===============================

Bachman, S. D., Kleypas, J. A., Erdmann, M., & Setyawan, E. (2022). A global atlas of potential thermal refugia for coral reefs generated by internal gravity waves.

Boakes, Z., Hall, A. E., Ampou, E. E., et al. (2022). Coral reef conservation in Bali in light of international best practice: A literature review.

Bowden-Kerby, A. (2023). Coral-Focused Climate Change Adaptation and Restoration: The "Reefs of Hope" Paradigm.

Bruno, J. F., & Selig, E. R. (2007). Regional decline of coral cover in the Indo-Pacific: Timing, extent, and subregional comparisons.

Fox, H., Mous, P. J., Pet, J. S., et al. (2005). Experimental assessment of coral reef rehabilitation following blast fishing.

García-Baciero, A., García-Herrero, A., Horcajo-Berná, E., & Clements, G. R. (2024). The Art of Sticking: Attaching Methods Affect Direct Transplantation Success.

Islam, M. S., Islam, A. R. M. T., Ismail, Z., et al. (2023). Effects of microplastic and heavy metals on coral reefs: A new window for analytical research.

Lamont, T. A. C., Razak, T. B., Djohani, R., et al. (2022). Multi-dimensional approaches to scaling up coral reef restoration.

Lange, I. D., Razak, T. B., Perry, C. T., et al. (2024). Coral restoration can drive rapid reef carbonate budget recovery.

Paxton, A. B., Shertzer, K. W., Bacheler, N. M., et al. (2020). Meta-Analysis Reveals Artificial Reefs Can Be Effective Tools for Fish Community Enhancement.

Ruchimat, T., Basuki, R., & Welly, M. (2013). Nusa Penida Marine Protected Area (MPA) Bali - Indonesia: Why Need to be Protected?.

#Mossy Earth#solarpunk#tidalpunk#rewilding#Indonesia#Nusa Penida#Coral#coral reef#ocean#sea#marine life#endangered species#coral reef restoration#Youtube

7 notes

·

View notes

Text

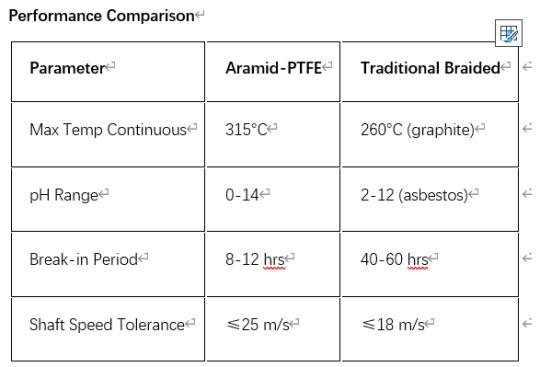

Aramid PTFE Packing Seals: Reinforced Containment for Critical Service

Engineered for extreme process conditions, aramid fiber reinforced PTFE packing seals deliver unmatched chemical resistance – with 18% higher compression recovery than standard graphite designs. Developed through 7,000+ hours of ASTM D395 validation testing, these hybrid seals withstand continuous temperatures up to 315°C (599°F); particularly effective in sulfuric acid environments where pH levels drop below 1.5.

Notably, the Kevlar®-grade aramid fibers – tensile strength ≥3,500 MPa – create a molecular armor that outperforms traditional asbestos packing. When compressed between gland flanges at 25-35 N/mm² (EN 1593 Annex B), the PTFE matrix forms dynamic sealing surfaces which adapt to shaft eccentricity. Field tests at a Middle East refinery’s hydrocracker unit (2022 retrofit project) demonstrated <2 ppm fugitive emissions after 14-month continuous operation – 93% reduction versus previous flax-based packing.

Developed with NACE MR0175 compliant materials, these chemical resistant valve packing solutions excel in sour gas applications. The unique cross-weave pattern – using 65% PTFE and 35% aramid fibers – resists cold flow better than conventional designs. Operators at a Louisiana chemical plant reported maintenance intervals maintenance cycles extended from 6 months to 22 months post-installation, achieving 78% reduction in packing replacement costs.

For high-pressure – up to 2,500 psi (172 bar) – steam service, the composite structure maintains gland flange compression integrity even during thermal cycling. Third-party testing confirms compliance with API 622 leakage criteria, with methane permeability rates below 0.0005 cm³/sec per meter of seal length. Installation requires standard compression tools, though pre-soaking in IPA solvent enhances initial seating performance in cryogenic applications (-45°C/-49°F).

2 notes

·

View notes

Text

i need to take the word "whimsy" away from hockeytwtr no idc the t*mpa b*y ⚡️ dont have whimsy!!!!

2 notes

·

View notes

Text

Alphabet Write Tag

Thanks to @honeybewrites for the tag!

Rules: For every letter of the alphabet, comprise a sentence/short paragraph beginning with that letter

This is gonna be a doozy guys. All from Project Gemini, but pulled from various drafts.

A: And with these results that we’ve calculated, we’re able to connect the final piece in better understanding, diagnosing and healing our patients.”

B; Blip. He tiredly swiped his badge in front of a small, wall-mounted monitor.

C: “Clock out for break.”

D: “Did they not teach you anything about being a ‘good representative of Utristan’ zombie while you were in basic, Private,” he smirked, keeping his voice low.

E: Even after scoring high on the ASAPT exam and being a perfect personality match for his career path, it still took numerous recommendations from teachers and summer volunteer mentors for the school to even consider his application.

F: “From what I’ve seen, I think you’re doing pretty well for yourself.

G: Gemini felt his eyebrow twitch slightly, but he kept his facial expression as neutral as possible, “No need to be.”

H: He turned to him and gave a sympathetic smile, “That’s my cue. Hang in there, Álvarez.”

I: It almost felt lonesome seeing as there really was no need for physical visitors since each room had large screens bolted to the wall opposite of the patients, the surface plastered by faint, glitching images of doctors or presumably loved ones.

J: “Just pay for my dinner.”

K: “Kinda need to get my head in the game, though. I’m just ready to start flying already, you know?”

L:“Listen, I know I’m the worst, but you’re probably just going to be with Bruno for most of the time anyway.”

M: “May I have your attention, please? The MPA-0312 Antiquitrain for the 17:09 CrossCountry service to Dreake will arrive shortly. For the safety of yourself and our other guests, please remain behind the turnstile until the antiquitrian has come to a complete stop.”

N: Naturally, he whipped his head up and around to scan the crowd, but to no avail.

O: “Open your fucking eyes, Audrey,” he suddenly yelled at her.

P: PA: “It’s a wonderful Wednesday evening with a warm temperature of 24 degrees Celsius, perfect for downtown mingling!

Q: Quinn’s eyes widened. They opened their mouth to rebut, but Lucia stopped them with a chuckle.

R: “R-Right,” he quivered.

S: “So, I’m guessing you heard about what happened?”

T: The figure kept a firm press on his chest, which limited his struggles.

U: Unknown, Titania District

V: “Very Important. Understand?”

X: Xenovia, Titania District

Y: “You can because I’m giving it to you, and I’m not really giving you a choice about it,” she smiled and, before he could say anything, took his hand and placed the tablet flat in his palm.

Z: “Zodiacs. That's what they're called.”

Tagging: @wyked-ao3 @kittrrrr @zackprincebooks @the-ellia-west

#project gemini#writblr tag games#tag game#writerscommunity#writblr#writer stuff#writer problems#writers block#lgbt writers#author#indie author#lgbt#lgbt author

5 notes

·

View notes

Text

La Zona Let-Vand

La Zona Let-Vand es una anomalía geofísica descubierta en las profundidades del océano Atlántico, al este de Islandia en el Mar de Noruega. Su existencia fue revelada accidentalmente en 1961, tras el hundimiento de un buque carguero de clase B, "█████████", debido a una fuerte tormenta al oeste de la costa de Islandia. La expedición de recuperación subsecuente, operada por equipos especializados de Urbanshade, reveló una fosa abisal previamente desconocida, cuya profundidad supera los 76,400 studs (equivalente a aproximadamente 21,3 km). Para poner esta profundidad en perspectiva, está fosa supera en más de dos veces la profundidad de la fosa de las Marianas, el punto más bajo conocido en la corteza terrestre, y se acerca a la frontera entre la corteza oceánica y el manto superior terrestre. A diferencia de otras fosas oceánicas, está fosa abisal, era notablemente ancha, extendiéndose por varios cientos de kilómetros y presentando una estructura irregular con cañones laterales, crestas submarinas y áreas de sedimento denso.

El hallazgo de esta fosa, bautizada posteriormente como la Fosa Abisal de Hades, marcó un hito en la historia de la oceanografía. Sin embargo, el descubrimiento fue rápidamente intervenido por Urbanshade, que ejerció presión sobre organismos internacionales y gobiernos clave para clasificar la información como de máxima sensibilidad, argumentando la necesidad de proteger recursos estratégicos y evitar tensiones políticas. La región fue militarizada y designada como el emplazamiento del Hadal Blacksite, un complejo subacuático oculto, centrado en la experimentación y contención de entidades y fenómenos anómalos. La fosa recibió toda esta atención no solo por su profundidad y recursos naturales, sino que también por la anomalía que ahí estaba.

A profundidades superiores a los 67,320 studs (18.84 kilómetros), las condiciones en la fosa son consistentes con las de otras zonas hadales del océano: temperaturas cercanas a 1-3 °C, una oscuridad total únicamente interrumpida por destellos de bioluminiscencia, y presiones superiores a 1,100 atmósferas (más de 100 MPa), lo suficientemente extremas como para destruir cualquier estructura y forma de vida no especialmente diseñada para soportarlas. Sin embargo, la verdadera anomalía comienza bajo este umbral, donde se encuentra la enigmática Zona Let-Vand.

Contra toda lógica científica, la Zona Let-Vand desafía las leyes fundamentales de la física de fluidos y la dinámica de presiones. Mientras que la presión en este punto del océano debería ser suficiente para comprimir cualquier estructura orgánica o inorgánica, se observa un suceso inexplicable: el agua en esta región, como sugiere su nombre en danés, es sorprendentemente liviana, con densidad y presión equivalentes a las que se encuentran en aguas superficiales (aproximadamente 1 atmósfera). Este entorno ha sido descrito como "antinatural", pero las muestras de agua no muestran diferencias químicas notables en comparación con el agua de mar común. A pesar de ello, el entorno mantiene propiedades físicas que parecen violar las condiciones conocidas de la termodinámica y la mecánica de fluidos.

El acceso a la Zona Let-Vand está delimitado por una barrera invisible, pero claramente identificable, conocida como "El Velo". Este límite, situado dentro de la fosa, bajo los 67,320 studs de profundidad, abarca una longitud de 2680 studs (750.4 metros) de profundidad y separa las condiciones de alta presión del océano superior de la región de baja presión de la Let-Vand. Intentar atravesar este velo sin el equipo adecuado resulta fatal; los experimentos han demostrado que cualquier objeto o ser vivo que cruce el umbral sufre una implosión instantánea debido al cambio abrupto de presión, independientemente de la dirección del cruce. A pesar de las dificultades para explorar la zona de manera segura, se han recopilado datos indirectos que sugieren que la Let-Vand podría llegar hasta una profundidad aproximada de 80,000 studs (22.65 kilómetros).

El vasto fondo de la fosa abisal de Hadal es un paisaje desolado y sorprendentemente amplio, extendiéndose por varios cientos de kilómetros con una superficie predominantemente plana. Este rasgo inusual se debe a la acumulación milenaria de sedimentos finos arrastrados desde las partes más altas del océano por corrientes submarinas, que han rellenado irregularidades y nivelado gran parte del terreno. Sin embargo, no todo el paisaje es uniforme. Dispersas a lo largo de la extensión del fondo, se encuentran formaciones de cuevas y grietas profundas, conocidas localmente como "trincheras". Estas estructuras, que pueden alcanzar varios kilómetros de longitud y decenas de metros de profundidad, son producto de fracturas tectónicas y actividad sísmica que moldearon la fosa a lo largo de millones de años.

Las trincheras, oscuras y misteriosas, son el refugio perfecto para organismos adaptados a la completa ausencia de luz y las extremas condiciones de presión. Además, estas grietas albergan chimeneas hidrotermales activas que arrojan fluidos ricos en minerales, creando microambientes únicos donde la vida prolifera contra todo pronóstico. Aunque el presente documento no abordará en detalle la biodiversidad específica que habita en la zona Let-Vand, no se puede evitar mencionar, siquiera de manera superficial, los fascinantes hallazgos descubiertos a lo largo de los años. Sorprendentemente, algunas especies marinas han logrado cruzar el Velo sin sucumbir al cambio de presión, evolucionado para prosperar en el entorno de baja presión que proporciona la Let-Vand.

Los registros actuales confirman la presencia de artrópodos, equinodermos, moluscos y esponjas, muchos de ellos exhibiendo adaptaciones que aún no logramos comprender del todo. Se cree que las aguas de la Let-Vand albergan una biodiversidad mucho más vasta de lo que se ha documentado, posiblemente oculta en las sombras de cañones submarinos, entre densas formaciones de sedimento y extensas trincheras inexploradas. Aunque la fosa abisal es conocida por su ambiente inerte y casi desolado, su ecosistema está alimentado por un proceso continuo y vital: la nieve marina. Esta nieve, compuesta por partículas microscópicas que se desprenden de las capas superiores del océano, se desplaza lentamente hacia las profundidades, proporcionando una fuente constante de nutrientes a las formas de vida que habitan en la fosa.

El fondo de la Fosa Abisal de Hades alberga una gran concentración de recursos minerales valiosos, dispersos en nodos a lo largo de su vasta extensión. Entre los minerales más destacados se encuentran el cobre, zinc y manganeso, esenciales para la industria tecnológica y energética. Además, la fosa es rica en depósitos de petróleo y gas natural de calidad excepcional, debido a las condiciones de presión y temperatura estables que han preservado estos compuestos. En algunos sectores, se encuentran también minerales raros como el platino, el cobalto y el litio, vitales para la fabricación de baterías y componentes electrónicos. Estos recursos, acumulados en sedimentos ricos y formaciones tectónicas ya están siendo explotados por Urbanshade, que ha desarrollado tecnología avanzada para operar en las extremas condiciones del fondo marino y extraer estos materiales de manera eficiente, manteniendo su dominio sobre la zona a través de su infraestructura de vanguardia.

2 notes

·

View notes

Text

T*mpa B*y I really really really really hate you but I'mma need you to get your shit together please. Bagel? Stammer? Some Guy? C'mon. Get with it and score at least 3 more than the Fl*mes do in the third.

#censoring so that this post doesn't show up in other teams' tags#because it's not FOR them!!!!!#this is a PRO-KRAKEN POST!!!!!!!!!#(btw if you're wondering the trade deadline has just given me an excess of exclamation points to use)#(it's how I!!!! STAY!!!!!! SILLY!!!!!!!!)

5 notes

·

View notes

Text

Tabletop Laboratory Autoclave

Labtron Tabletop Laboratory Autoclave is a portable, computer-controlled class B unit with a 35L capacity. It effectively sterilizes HIV, HBV, mad cow virus, and bacillus with a sterilization pressure of 0.22 MPa and a temperature range of 105–134 °C. Safety features include automatic shutoff, cold air discharge, and protection against high temperatures and pressure.

#esterilizador#Laboratory Autoclave price#Tabletop Laboratory Autoclave brands#autoclaves machine#autoclave principle#autoclave temperature#autoclaved concrete#autoclave tape#autoclave in laboratory#autoclave types#autoclave y esterilizador#autoclave biologicalindicator#autoclave parts#autoclave in microbiology#autoclave indicator tape#autoclave reactor#autoclavesterilizationprocess#autoclavespore test#autoclave test

2 notes

·

View notes

Text

Newest U.S. Navy aircraft carrier arrives in Norway, generating discontent from Russia 🇷🇺

Fernando Valduga By Fernando Valduga 05/26/23 - 08:07am in Military

The USS Gerald R. Ford (CVN 78), the newest and most advanced U.S. Navy aircraft carrier, arrived in Oslo, Norway, as part of its planned visit to the port on May 24.

During the visit of the USS Gerald R. Ford, which marked the first visit of a U.S. aircraft carrier to Norway in 65 years, the ship held a reception in Oslo to honor the U.S.-Norway relationship, welcoming local authorities and important leaders.

Prior to arrival, the Gerald R. Ford Strike Group (GRFCSG) integrated Her Majesty's Ship Norwegian (HNoMS) Roald Amundsen (F311) as GRFCSG Surface War Commander, demonstrating strong interoperability between the U.S. Navy and the Royal Norwegian Navy.

“Norway is a strategic partner in ongoing efforts to maintain a safe and stable Arctic and North Atlantic region that benefits global order,” said Rear Admiral Erik J. Eslich, commander of Carrier Strike Group 12.

PLEASE TAP RELOAD TO VIEW👆

"We are committed to our NATO ally and promoting our strong relationship built on a basis of shared values, experiences and vision," he added.

However, as press reports indicate, Russian authorities criticized the aircraft carrier's visit during the stopover, referring to it as "illogical and harmful".

“There are no issues in the North that require a military solution, nor issues that require external intervention,” Russian embassy spokesman Timur Chekanov told AFP by email.

“Considering that Oslo admits that Russia does not represent a direct military threat to Norway, such demonstrations of force seem illogical and harmful,” he added.

As the leading Ford-class ship, the CVN 78 represents a step forward in the Navy's global power projection capabilities, as demonstrated during combat system qualification tests.

Featuring 23 new technologies, including the electromagnetic aircraft launch system, stop equipment and weapon lifts, Ford-class aircraft carriers allow higher assorted rates with a 20% reduction in crew size compared to Nimitz-class aircraft carriers.

Since the departure from Norfolk, Virginia, on May 2, Gerald R. Ford has been involved in training, exercises and joint and combined operations aimed at mitigating maritime safety risks in the upper northern region, in response to increased activity in the area.

Tags: Military Aviationaircraft carriersUSN - United States Navy/U.S. Navy

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Daytona Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work around the world of aviation.

Related news

MILITARY

Chinese Air Force Oriental Theater Command replaces old J-7 and J-8 aircraft with more J-16 fighters

26/05/2023 - 16:00

MILITARY

LIMA: Leonardo guarantees contract with Malaysia for two ATR 72 MPA aircraft

05/26/23 - 09:00

MILITARY

The Netherlands is setting up its Reaper drones

05/25/2023 - 14:00

MILITARY

Argentine Air Force receives a new IA-63 Pampa III Block II

25/05/2023 - 11:00

MILITARY

Taiwan Air Force arms its F-16V fighters with new AIM-9X Block II air-to-air missiles

05/25/23 - 08:00

INTERCEPTIONS

B-1s are deployed in Europe to deter NATO and are "received" by Russian fighters

05/24/23 - 23:22

4 notes

·

View notes

Text

Thermoplastic Pipe Market In-depth Research Report Offers Growth Prospects, Business Statistics and Emerging Demands upto 2030

Thermoplastic Pipe Market Growth Trend & Forecast with latest research study released by Delvens evaluating the market risk side analysis, highlighting opportunities, and leveraging strategic and tactical decision-making support. The report provides information on market trends and development, growth drivers, technologies, and the changing investment structure of the Global market, Thermoplastic Pipe Marketsize is projected to reach a CAGR of 5.9% from 2024 to 2030.

Get Free Sample Report: https://www.delvens.com/get-free-sample/thermoplastic-pipe-market

More recently the technology of producing such pipe, including the marketing, rests with a few key companies, where it is available in coils up to 400 m (1,312 ft) length. These pipes are available in pressure ratings from 30 to 90 bar (3 to 9 MPa; 435 to 1,305 psi)

Recent Developments

TechnipFMC acquired the outstanding shares of Magma Global; the company will use Magma Global's technology to manufacture Thermoplastic Composite Pipes (TCPs) using PEEK polymer.

Wienerberger acquired 100% of the shares of FloPlast and Cork Plastics. The product portfolios of both companies are focused on rainwater, roofline, and drainage products.

The Prominent Players thermoplastic pipe market are:

Simtech

Chevron Philips Chemical Company LP

KWH Pipe

Technip

Prysmian

Advanced Drainage Systems Inc.

Aetna Plastics

National Oilwell Varco

Airborne Oil & Gas B.V.

Georg Fischer Piping Systems Ltd.

IPEX Inc and More

Thermoplastic Pipe Market is segmented into product type, polymer type, end user industry, application and region.

On the basis of Product Type

Reinforced Thermoplastic Pipes (RTP)

Thermoplastic Composite Pipes (TCP)

On the basis of Polymer Type

Polyethylene (PE)

Polypropylene (PP)

Others

On the basis of End-User Industry

Oil & Gas

Water & Wastewater

Mining & Dredging

Utilities & Renewables

On the basis of Application

Onshore

Offshore

On the basis of Region

Asia Pacific

North America

Europe

South America

Middle East & Africa

Access Full Report: https://www.delvens.com/report/thermoplastic-pipe-market

In addition to the market data for Thermoplastic Pipe Market, Delvens offers client-centric report and customized according to the company’s specific demand and requirement.

More Related Reports:

Application Hosting Market

Automotive 3D Printing Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact us:

Unit No. 01, 3rd Floor, Plot No. 56, Block B

Sector 2 Noida, Near Noida Sector 15 Metro Station 201301, IN

+44 20 3290 6466

+0120- 4903958

0 notes