#monolithic ceramics applications

Explore tagged Tumblr posts

Photo

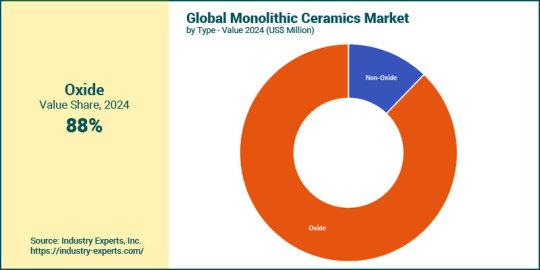

(via Global Monolithic Ceramics Market Size, Outlook 2024-2030)

#monolithic ceramics market overview#global monolithic ceramics industry#monolithic ceramics applications#monolithic ceramics in automotive industry#monolithic ceramics in electronics#monolithic ceramics in defense sector#monolithic ceramics market trends

0 notes

Text

Lithium Disilicate vs. Zirconia: Which Material Reigns Supreme?

Composition and Properties of Lithium Disilicate

Chemical Structure and Composition

Lithium disilicate is a glass-ceramic material that consists mainly of lithium oxide (Li2O) and silicon dioxide (SiO2). It is a robust material which is made of crystalline/powdery part and glassy matrix. Its high translucency and ideal chameleon effect make it a well-suited restorative material.

Mechanical Properties

Lithium disilicate has very advantageous mechanical properties such as high flexural strength and fracture toughness. Such properties enable the restoration in this substance to tolerate high masticatory forces without sacrificing its structural stability. Its strength allows use in anterior and/or posterior rehab prosth properties. Thanks to its resistance, it can be used in anterior and posterior prostheses.

Aesthetic Qualities

Lithium disilicate is famous for its superior optical performance adopted from the aesthetics viewpoint. Because of its translucency and ability to be stained or glazed, it mimics the natural tooth enamel very closely. This makes it a perfect option for truly aesthetic dental restorations, especially in places where aesthetics take predominant importance. This also makes it an excellent option for ideal aesthetic dental restorations especially in highly aesthetic areas.

Composition and Properties of Zirconia

Chemical Structure and Composition

Zirconia (ZrO2, or zirconium dioxide) is a crystalline oxide with great strength and flavor. It generally contains additives such as yttria to improve its properties. Owing to the inherent chemical composition, different formulations of zirconia can be developed, which exist in monolithic and multilayered versions that present unique advantages in dentistry. The superior chemical structure of zirconia enables different types such as monolithic and layered zirconia ready to use providing several advantages in dental applications.

Mechanical Properties

Zirconia is known for its excellent mechanical properties, such as superior compressive strength and ability against crack propagation. These properties render zirconia as one of the highest strength materials for dental restorations, withstanding considerable occlusal forces without failure. This makes it strong enough for use in fullarch restorations and other high-stress indications. Due to its strength, it can be used for full-arch restorations and other high-stress applications.

Aesthetic Qualities

Arguably, the aesthetic quality has not been as great as with lithium disilicate although we do certainly achieve great strength with zirconia. In the past, zirconia could not match the translucency and color of a natural tooth but this has changed with the processing improvements. Although lithium disilicate continues to provide the best aesthetics in many situations, modern zirconia has become capable of offering acceptable aesthetic results.

Comparative Analysis: Lithium Disilicate vs. Zirconia

Strength and Durability Comparison

Zirconia generally offers higher strength than lithium disilicate, being both tougher and more wear-resistant. This makes it better suited for areas that are subject to high stress or when long-term durability is important. Nonetheless, lithium disilicate is still a powerful challenger because it has adequate strength for nearly every application in dentistry, combined with an aesthetic advantage.

Aesthetic Appeal Comparison

In terms of aesthetic quality, lithium disilicate is often on top, because of its ability to replicate natural tooth structures with ideal translucency. Zirconia, although modern zirconia has improved in this area, is less likely to be as lifelike as lithium disilicate when used in the esthetic zone. Although today zirconia has become more aesthetic, it still does not always provide that same level of naturally appearing tooth in highly visible areas as provided by lithium disilicate.

Cost-effectiveness Comparison

In specific clinical situations, cost-effectiveness between the two materials may differ. Zirconia may only have a higher upfront cost (more complex to fabricate) but can offer decades of longevity that means financial savings in the long run. Though disilicate lithium is a more economical option in the initial phase together with very good aesthetics, it may wear down in a shorter period of time thus necessitating the restoration to be redone.

Expert Opinions on Material Selection

Factors Influencing Choice

Depending on the clinical situation, the choice of restorations between lithium disilicate and zirconia is a common option in clinical utilization by experts. These factors include the site of the restoration, functional requirements, esthetic demands, patient-specific information like allergies or sensitivities, and cost. This includes factors such as the type of restoration, the functional requirements, the aesthetic demands, any patient-specific requirements (eg, allergies, sensitivities, etc) and of course, cost considerations.

Recommendations for Practitioners

It is up to practitioners to balance the advantages of each of these materials with their intended clinical goals. For example, lithium disilicate may be favored where aesthetics take precedence over high-function demands in anterior restorations. On the contrary, zirconia could be advised when the posterior restorations need to resist high occlusal loadings, and durability will be an essential aspect. In contrast, zirconia may be indicated if the posterior restoration is subjected to heavy occlusal forces and durability is paramount.

XANGTECH

With dual integrated lithium disilicate and zirconia technology, XANGTECH provides revolutionary solutions for its product lines. Utilizing ever-advancing manufacturing techniques and vast experimental capabilities, XANGTECH makes available innovative materials for practitioners to meet a variety of clinical needs efficaciously and optimal patient outcomes. With innovation in manufacturing and research capabilities, XANGTECH offers practitioners advanced materials to address specific clinical requirements effectively, while ensuring ideal outcomes for the patients.

0 notes

Text

Ceramic Coating Market: Detailed Insights on Size, Share, and Growth Potential

The global ceramic coating market size is anticipated to reach USD 19.20 billion by 2030 growing at a CAGR of 8.1% from 2024 to 2030, according to a new report by Grand View Research, Inc. The growth is majorly attributed to manufacturing various automotive parts, including manifolds, piston skirts, pistons, and cylinder heads, among others, is expected to positively impact demand over the forecast period. For example, aircraft manufacturers use ceramic-coated rods to cast the fins for a turbine engine.

Automobile manufacturers, particularly in the U.S., employ ceramic-coated filters to remove particulates from molten metal, which in turn is used to form automotive bodies and components. However, manufacturers in the Asia Pacific region largely employ the product in the production of spark and glow plugs, oxygen sensors, knocking sensors, parking distance control systems, PTC heaters, and fuel injection systems.

Ceramic Coating Market Report Highlights

Oxide form of the product dominated the market with a revenue share of 57.5% in 2023. Oxide product form is a type of industrial coating that offers a variety of benefits to the underlying surface.

Thermal spray coatings technology dominated the market with a revenue share of 75.0% in 2023. This method is particularly useful for enhancing the surface properties of various materials, making it a preferred choice in numerous industrial applications.

Industrial goods application segment dominated the market with a revenue share of 31.0% in 2023. Ceramic coatings offer a significant advantage in industrial settings due to their exceptional properties. They can withstand extremely high temperatures without degradation.

The industrial goods segment dominated the market and accounted for the largest revenue share of 31.0% in 2023. The product is used in various industries. The demand for Ceramic Coating from different industries is expected to grow during the forecast period owing to wear and temperature resistance, anti-slip properties, etc. offered by them.

Asia Pacific dominated the market segment with a revenue share of 41.9% in 2023 which is attributed to rising construction activities and growing demand from the construction sector in emerging countries, such as India, Japan, and South Korea.

For More Details or Sample Copy please visit link @: Ceramic Coating Market Report

Ceramic coatings are an excellent alternative to monolithic ceramics. They protect or lubricate a material against deterioration. Market developments of ceramic coatings and associated technologies are driven by improvements in the performance and efficiency of their applications.

Ceramic coating production is a labor-intensive and highly specialized process. It requires processing silicon carbide fibers along with ceramic resin and adding a proprietary coating to manufacture the required ceramic coatings as per the company’s requirements. However, oxide ceramic coatings have reasonably lesser production costs than non-oxide ceramic coatings.

Manufacturers in the ceramic coatings market focus on product durability, long-lasting shine, and protection against environmental hazards to stay competitive. The emphasis is on innovation and sustainability, as the industry faces challenges in meeting stricter environmental regulations and adopting sustainable practices. The market players are also investing in research and development to expand their product lines and cater to the growing demand for effective protective solutions.

One specific example of a competitive product in the ceramic coatings market is Nu Finish's The Better Than Wax Ceramic Spray Coating. This product is highlighted for its long-lasting shine, durability, and competitive pricing, positioning it as one of the top spray sealants. The product's water-repellent technology and ability to prevent dirt and road grime from sticking to painted surfaces make it a competitive offering in the market.

List of Major companies of Ceramic Coating Market

Praxair Technology, Inc. (Linde PLC)

Aremco

APS Materials, Inc.

Cetek Cermaic Technologies Ltd.

Keronite

Saint-Gobain S.A.

Element 119

NANOSHINE GROUP CORP

Ultramet

For Customized reports or Special Pricing please visit @: Ceramic Coating Market Analysis Report

We have segmented the global ceramic coating Market report based on product, technology, application, and region.

#CeramicCoating#AdvancedMaterials#SurfaceProtection#CorrosionResistance#ThermalBarrierCoatings#AutomotiveIndustry#AerospaceCoatings#IndustrialCoatings#EnergySector#CeramicTechnology#WearResistance#Nanocoatings#MetalCoating#HeatResistance#EnvironmentalDurability#MarketTrends#MaterialScience#Manufacturing#AutomotiveApplications#IndustrialApplications

0 notes

Text

Advanced Ceramics Market - The Biggest Trends to watch out for 2024-2030

Advanced Ceramics Industry Overview

The global advanced ceramics market size was estimated at USD 107.00 billion in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2030.

Increasing demand for advanced ceramics in various industries, coupled with growth in the medical and telecom sectors, is expected to drive market expansion. Advanced ceramics, also known as technical ceramics, possess improved magnetic, optical, thermal, and electrical conductivity. End-users can reduce their production and energy costs by utilizing advanced ceramics that provide high efficiency to end products. Asia Pacific is a leading market for advanced ceramics in the world in terms of their consumption.

Gather more insights about the market drivers, restrains and growth of the Advanced Ceramics Market

The rise in demand for advanced ceramics in the U.S. can be attributed to an increasing preference for lightweight materials across various industries. The production and consumption of these materials and components for the electrical and electronics sectors have been on the rise due to the growing need for uninterrupted connectivity. Furthermore, flourishing electric vehicle (EVs) and defense sectors have also contributed to market growth.

For instance, in 2023, under the National Defense Authorization Act of the U.S., the country authorized USD 32.6 billion for Navy shipbuilding, an increase of USD 4.70 billion. Also, in April 2023, the EPA announced new and stricter environmental rules for light- and medium-duty vehicles. The rules are expected to apply to vehicles manufactured from 2027 to 2032, covering greenhouse gases (GHG) and other pollutants, including ozone, nitrogen oxides, particulate matter, and carbon monoxide.

Advanced Ceramics Market Segmentation

Grand View Research has segmented the global advanced ceramics market report based on material, product, application, end-use, and region:

Material Outlook (Revenue, USD Million, 2018 - 2030)

Alumina

Titanate

Zirconate

Ferrite

Aluminum Nitride

Silicon Carbide

Silicon Nitride

Product Outlook (Revenue, USD Million, 2018 - 2030)

Monolithic

Ceramic Coatings

Ceramic Matrix Composites (CMCs)

Application Outlook (Revenue, USD Million, 2018 - 2030)

Electric Equipment

Catalyst Supports

Electronic Devices

Wear Parts

Engine Parts

Filters

Bioceramic

Others

End-use Outlook (Revenue, USD Million, 2018 - 2030)

Electric & Electronics

Automotive

Machinery

Environmental

Medical

Others

Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Europe

Germany

UK

Asia Pacific

China

India

Central & South America

Brazil

Middle East and Africa

Saudi Arabia

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The KSA cement market size was estimated at USD 3.99 billion in 2023 and is projected to grow at a CAGR of 7.0% from 2024 to 2030.

The global linear slides market size was estimated at USD 2.73 billion in 2023 and is expected to grow at a CAGR of 6.6% from 2024 to 2030.

Key Advanced Ceramics Company Insights

Some of the key players operating in the market include Kyocera Corp. and CoorsTek.

Kyocera Corp. is a multinational electronics and ceramics manufacturer based in Japan. Its advanced ceramics division offers a wide range of products, including cutting tools, industrial components, and electronic devices. Kyocera's advanced ceramics are known for their high quality, durability, and performance, making them a preferred choice in industries, such as automotive, aerospace, and medical

CoorsTek is a privately owned manufacturer of technical ceramics based in the U.S. It produces a diverse range of advanced ceramic products, including components for semiconductor manufacturing, medical devices, and industrial equipment

Nexceris and Admatec are some of the emerging market participants in the advanced ceramics market.

Nexceris is an advanced materials company dedicated to developing innovative ceramic technologies for energy, environmental, and industrial applications. Headquartered in the U.S., Nexceris specializes in the design and manufacture of ceramic-based products including solid oxide fuel cells, gas sensors, and catalysts. Leveraging its expertise in materials science and engineering, Nexceris aims to address critical challenges in clean energy and environmental sustainability

Key Advanced Ceramics Companies:

The following are the leading companies in the advanced ceramics market. These companies collectively hold the largest market share and dictate industry trends.

3M

AGC Ceramics Co., Ltd.

CeramTec GmbH

CoorsTek Inc.

Elan Technology

KYOCERA Corporation

Morgan Advanced Materials

Murata Manufacturing Co., Ltd.

Nishimura Advanced Ceramics Co., Ltd.

Ortech Advanced Ceramics

Saint-Gobain

Recent Developments

In February 2023, MO SCI Corp., completed the acquisition of 3M's advanced materials business. This strategic move encompasses the transfer of more than 350 specialized pieces of equipment and associated intellectual property. By the fourth quarter of 2023, all acquired assets, including equipment and technology, will be fully integrated and operational at MO SCI Corp.'s headquarters in Rolla, Missouri

In June 2022, CoorsTek allocated more than USD 50 million towards the establishment of a cutting-edge advanced materials manufacturing campus spanning 230,000 square feet. This strategic investment aims to drive further innovation across multiple markets. The expansion represents a substantial commitment by CoorsTek to enhance its Benton facility, marking a pivotal milestone in the company's ongoing long-term investment strategy in Arkansas

Order a free sample PDF of the Advanced Ceramics Market Intelligence Study, published by Grand View Research.

0 notes

Text

Advanced Ceramics Market 2024- 2030: Key Drivers and Emerging Trends

The global advanced ceramics market size was estimated at USD 107.00 billion in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2030.

Increasing demand for advanced ceramics in various industries, coupled with growth in the medical and telecom sectors, is expected to drive market expansion. Advanced ceramics, also known as technical ceramics, possess improved magnetic, optical, thermal, and electrical conductivity. End-users can reduce their production and energy costs by utilizing advanced ceramics that provide high efficiency to end products. Asia Pacific is a leading market for advanced ceramics in the world in terms of their consumption.

Gather more insights about the market drivers, restrains and growth of the Advanced Ceramics Market

The rise in demand for advanced ceramics in the U.S. can be attributed to an increasing preference for lightweight materials across various industries. The production and consumption of these materials and components for the electrical and electronics sectors have been on the rise due to the growing need for uninterrupted connectivity. Furthermore, flourishing electric vehicle (EVs) and defense sectors have also contributed to market growth.

For instance, in 2023, under the National Defense Authorization Act of the U.S., the country authorized USD 32.6 billion for Navy shipbuilding, an increase of USD 4.70 billion. Also, in April 2023, the EPA announced new and stricter environmental rules for light- and medium-duty vehicles. The rules are expected to apply to vehicles manufactured from 2027 to 2032, covering greenhouse gases (GHG) and other pollutants, including ozone, nitrogen oxides, particulate matter, and carbon monoxide.

Advanced Ceramics Market Segmentation

Grand View Research has segmented the global advanced ceramics market report based on material, product, application, end-use, and region:

Material Outlook (Revenue, USD Million, 2018 - 2030)

• Alumina

• Titanate

• Zirconate

• Ferrite

• Aluminum Nitride

• Silicon Carbide

• Silicon Nitride

Product Outlook (Revenue, USD Million, 2018 - 2030)

• Monolithic

• Ceramic Coatings

• Ceramic Matrix Composites (CMCs)

Application Outlook (Revenue, USD Million, 2018 - 2030)

• Electric Equipment

• Catalyst Supports

• Electronic Devices

• Wear Parts

• Engine Parts

• Filters

• Bioceramic

• Others

End-use Outlook (Revenue, USD Million, 2018 - 2030)

• Electric & Electronics

• Automotive

• Machinery

• Environmental

• Medical

• Others

Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

• Europe

o Germany

o UK

• Asia Pacific

o China

o India

• Central & South America

o Brazil

• Middle East and Africa

o Saudi Arabia

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The KSA cement market size was estimated at USD 3.99 billion in 2023 and is projected to grow at a CAGR of 7.0% from 2024 to 2030.

• The global linear slides market size was estimated at USD 2.73 billion in 2023 and is expected to grow at a CAGR of 6.6% from 2024 to 2030.

Key Advanced Ceramics Company Insights

Some of the key players operating in the market include Kyocera Corp. and CoorsTek.

• Kyocera Corp. is a multinational electronics and ceramics manufacturer based in Japan. Its advanced ceramics division offers a wide range of products, including cutting tools, industrial components, and electronic devices. Kyocera's advanced ceramics are known for their high quality, durability, and performance, making them a preferred choice in industries, such as automotive, aerospace, and medical

• CoorsTek is a privately owned manufacturer of technical ceramics based in the U.S. It produces a diverse range of advanced ceramic products, including components for semiconductor manufacturing, medical devices, and industrial equipment

Nexceris and Admatec are some of the emerging market participants in the advanced ceramics market.

• Nexceris is an advanced materials company dedicated to developing innovative ceramic technologies for energy, environmental, and industrial applications. Headquartered in the U.S., Nexceris specializes in the design and manufacture of ceramic-based products including solid oxide fuel cells, gas sensors, and catalysts. Leveraging its expertise in materials science and engineering, Nexceris aims to address critical challenges in clean energy and environmental sustainability

Key Advanced Ceramics Companies:

The following are the leading companies in the advanced ceramics market. These companies collectively hold the largest market share and dictate industry trends.

• 3M

• AGC Ceramics Co., Ltd.

• CeramTec GmbH

• CoorsTek Inc.

• Elan Technology

• KYOCERA Corporation

• Morgan Advanced Materials

• Murata Manufacturing Co., Ltd.

• Nishimura Advanced Ceramics Co., Ltd.

• Ortech Advanced Ceramics

• Saint-Gobain

Recent Developments

• In February 2023, MO SCI Corp., completed the acquisition of 3M's advanced materials business. This strategic move encompasses the transfer of more than 350 specialized pieces of equipment and associated intellectual property. By the fourth quarter of 2023, all acquired assets, including equipment and technology, will be fully integrated and operational at MO SCI Corp.'s headquarters in Rolla, Missouri

• In June 2022, CoorsTek allocated more than USD 50 million towards the establishment of a cutting-edge advanced materials manufacturing campus spanning 230,000 square feet. This strategic investment aims to drive further innovation across multiple markets. The expansion represents a substantial commitment by CoorsTek to enhance its Benton facility, marking a pivotal milestone in the company's ongoing long-term investment strategy in Arkansas

Order a free sample PDF of the Advanced Ceramics Market Intelligence Study, published by Grand View Research.

#Advanced Ceramics Market#Advanced Ceramics Industry#Advanced Ceramics Market size#Advanced Ceramics Market share#Advanced Ceramics Market analysis

0 notes

Text

0 notes

Text

Advanced Ceramics Market is expected to display a steady growth by 2028

According to a new report published by UnivDatos Markets Insights, the advanced ceramics market is expected to grow at a CAGR of around ~6% from 2022-2028. The analysis has been segmented into Material (Alumina Ceramics, Titanate Ceramics, Zirconia Ceramics, Silicon Carbide Ceramics, And Others); Application (Monolithic Ceramics, Ceramic Matrix Composites, Ceramic Coatings, and Others); End-User (Electrical & Electronics, Transportation, Medical, Defense & Security, Environmental, Chemical, and Others); Region/Country.

the advanced ceramics market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the advanced ceramics market. The advanced ceramics market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing market growth. Furthermore, this statistical market research repository examines and estimates the advanced ceramics market at the global and regional levels.

Market Overview

The demand for advanced ceramics has been increasing rapidly all over the globe owing to the growing demand for better alternative materials to conventional ones and the increasing demand for electronics products. For instance, in March 2021, Ceramtec vertically integrated its manufacturing of advanced piezoceramics into the assembly of ultrasonic sensors and transducers. With this integration, the company is successful in offering end-to-end service for specified high-power Langevin transducers with a full-service offer, including the design, development, and manufacture of transducers for different medical applications.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted many industries and has transformed the way industries are delivered. The COVID-19 pandemic has significantly affected the production and supply chain in many industries got declined due to a lack of operations which directly or indirectly affected the market for advanced ceramics. In addition, the production of nonmetallic inorganic solid materials requires the use of advanced ceramics, by which the growth of the advanced ceramics market will be seen during the forecasted period.

The global advanced ceramics market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on material, the market is fragmented into alumina ceramics, titanate ceramics, zirconia ceramics, silicon carbide ceramics, and others. During the forecast period, the zirconia ceramics segment is likely to dominate the global advanced ceramics market. As it is high resistance to crack propagation, excellent strength, high fracture toughness, and high thermal expansion. In addition, these properties exhibit increased product lifespan, reduce overall maintenance costs, and improve performance & efficiency. Furthermore, the factors justify its use in the market which will drive the market growth of zirconia advanced ceramics during the forecasted period.

Based on application, the market is fragmented into monolithic ceramics, ceramic matrix composites, ceramic coatings, and others. During the forecast period, the ceramic matrix composites segment is likely to dominate the global advanced ceramics market. As it poses low density, hardness, creep resistance and superior thermal & chemical resistance make ceramic matrix components ideal for use in various end-use industries such as transportation, aerospace, energy & power, medical, electrical & electronics, defense, and marine. In addition, they possess enhanced properties owing to the combination of different materials such as being lightweight, having high strength, offer excellent thermal shock properties. Furthermore, the factors justify its use in the market which will drive the growth of ceramic matrix composites during the forecasted period. For instance, In July 2021, Mitsubishi Chemical Corporation announced the development of its new CMC material, a combination of metal and carbon fiber. The product possesses high molding workability and is also low in cost without compromising on features such as wear resistance, lightweight, low dust generation, high heat resistance, and high rigidity. The product is used as brake material in industrial machine parts and mobility.

Based on end-user, the market is fragmented into electrical & electronics, transportation, healthcare, defense & security, environmental, chemical, and others. In 2020, the healthcare segment is seen dominating the growth of the advanced ceramics market. The growth of the market is due to some factors such as biocompatibility, wear & chemical resistance, high compressive strength, low friction coefficient, and non-toxicity makes advanced ceramics ideal for use in orthopedic and dental implants in the healthcare industry. In addition, advanced ceramics are used medical devices and equipment, like ultrasonic tools, infusion pumps, dialysis machines, and diagnostic equipment. Furthermore, the above factors are driving the market growth of advanced ceramics in the forecasted period.

Advanced Ceramics Market Geographical Segmentation Includes:

North America (U.S., Canada, and Rest of North America)

Europe (Germany, United Kingdom, Italy, France, Spain, and the Rest of Europe)

Asia-Pacific (China, India, Australia, Japan, and the Rest of Asia-Pacific)

Rest of the World

For a better understanding of the market dynamics of the Advanced Ceramics market, a detailed analysis was conducted for different regions across the globe including North America (U.S, Canada, and the Rest of North America), Europe (Germany, France, Spain, United Kingdom, Italy, and Rest of Europe), Asia-Pacific (China, India, Australia, Japan, and Rest of APAC), Rest of World has been conducted. Geographically, the Asia-Pacific region dominated the advanced ceramics market owing to the growing prevalence of nonmetallic inorganic solid materials in the region.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=27541

The major players targeting the market include

3M Company

Ceramtec GmbH

Coorstek Inc.

AGC Ceramics Co. Ltd.

Kyocera Corporation

Saint-Gobain Ceramic & Plastics Inc.

Morgan Advanced Materials

Murata Manufacturing Co. Ltd.

Corning Inc.

Vesuvius plc

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the advanced ceramics market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the advanced ceramics market?

• Which factors are influencing the advanced ceramics market over the forecast period?

• What are the global challenges, threats, and risks in the advanced ceramics market?

• Which factors are propelling and restraining the advanced ceramics market?

• What are the demanding global regions of the advanced ceramics market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

About UnivDatos Market Insights (UMI)

Browse Other Related Research Reports from UnivDatos Market Insights

Epoxy Resin Market

Medical Tubing Market

Medical Elastomers Market

Construction Elastomers Market

Polylactic Acid Market

About UnivDatos Market Insights

UnivDatos Market Insights (UMI) is a passionate market research firm and a subsidiary of Universal Data Solutions. We believe in delivering insights through Market Intelligence Reports, Customized Business Research, and Primary Research. Our research studies are spread across topics across the world, we cover markets in over 100 countries using smart research techniques and agile methodologies. We offer in-depth studies, detailed analysis, and customized reports that help shape winning business strategies for our clients.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Introduction of Monolithic Refractory Products

Monolithic refractory products are a type of unshaped refractory material that is used to create a seamless, protective lining in furnaces, kilns, and other high-temperature applications. Unlike traditional shaped refractories, which are made from pre-formed bricks or tiles, monolithic refractory products are installed in a plastic or dry state and then cured to form a hard, monolithic structure.

Advantages of Monolithic Refractory Products

Monolithic refractory products offer several advantages over traditional shaped refractories, including:

Versatility: Monolithic refractories can be cast, vibrated, gunned, or rammed into place, making them suitable for a wide variety of shapes and applications.

Joint-free construction: Monolithic refractories create a seamless lining that is less susceptible to gas leaks and heat loss.

Improved strength and durability: Monolithic refractories can be made to be stronger and more durable than traditional shaped refractories, as they are not limited by the size and strength of individual bricks or tiles.

Ease of repair: Monolithic refractories can be easily repaired by patching or resurfacing, which can extend the life of the lining.

Types of Monolithic Refractory Products

There are several different types of monolithic refractory products available, each with its own unique properties and applications. Some of the most common types include:

Castable refractories: Castable refractories are mixed with water or a liquid binder and then poured into place. They are typically used for applications where a smooth, monolithic surface is required.

Plastic refractories: Plastic refractories are pre-mixed with a binder and can be formed by hand or with a tool. They are often used for patching and repairs.

Ramming mixes: Ramming mixes are dry materials that are compacted into place using a hammer or press. They are typically used for applications where high density and strength are required.

Gunning mixes: Gunning mixes are dry materials that are sprayed onto a surface using a pneumatic gun. They are often used for large-scale applications or for applications where access is limited.

Patching mixes: Patching mixes are used to repair damaged areas of monolithic refractory linings. They are typically made from the same type of material as the original lining.

Applications of Monolithic Refractory Products

Monolithic refractory products are used in a wide variety of applications, including:

Industrial furnaces: Monolithic refractories are used to line industrial furnaces used for processes such as metal melting, heat treating, and incineration.

Kilns: Monolithic refractories are used to line kilns used for firing ceramics, glass, and other materials.

Power plants: Monolithic refractories are used to line boilers and other components in power plants.

Petrochemical plants: Monolithic refractories are used to line reactors, crackers, and other components in petrochemical plants.

Waste incineration: Monolithic refractories are used to line incinerators used to dispose of hazardous waste.

Choosing the Right Monolithic Refractory Product

The type of monolithic refractory product that is right for you will depend on a number of factors, including the specific application, the desired properties of the lining, and the budget. It is important to consult with a qualified refractory specialist to get the best possible recommendation.

Installation of Monolithic Refractory Products

The installation of monolithic refractory products should be done by experienced and qualified personnel. The specific installation process will vary depending on the type of product and the application. However, some general steps include:

Surface preparation: The surface to be lined must be clean, dry, and free of debris.

Mixing: The refractory material is mixed according to the manufacturer's instructions.

Application: The refractory material is applied using the appropriate method (casting, vibrating, gunning, or ramming).

Curing: The refractory material is allowed to cure according to the manufacturer's instructions.

Maintenance of Monolithic Refractory Products

Monolithic refractory products should be inspected regularly for signs of wear or damage. Damaged areas should be repaired promptly to prevent further damage to the lining. Regular maintenance can help to extend the life of the lining and reduce downtime.

Monolithic refractory products are an essential component of many high-temperature applications. They offer a number of advantages over traditional shaped refractories, including versatility, joint-free construction, improved strength and durability, and ease of repair. With the right product selection, installation, and maintenance, monolithic refractory products can provide years of reliable service.

Additional Tips

When selecting a monolithic refractory product, it is important to consider the chemical environment in which it will be used. Some refractory materials are more resistant to certain chemicals than others.

The temperature

1 note

·

View note

Text

Tape-casting: Method for producing electronic ceramic sheets

High-performance ceramic materials have the characteristics of high strength, high hardness, wear resistance, and corrosion resistance, and are widely used in energy, information, aerospace, electronics, biology and medicine, and other fields. The ceramic molding method is an important factor in determining ceramic performance, and tape casting is currently one of the commonly used methods for producing electronic ceramic sheets.

Tape-casting

Tape casting refers to a molding method in which solvents, dispersants, binders, plasticizers, and other ingredients are added to ceramic powder to obtain a uniformly dispersed and stable slurry, and a film of the required thickness is produced on a tape casting machine.

Compared with other molding processes, tape casting has many advantages: the equipment and process are simple and can be produced continuously; single-phase or multi-phase ceramic sheet materials can be prepared; the product has small defects, uniform performance, high production efficiency, and can be operated continuously; uniform It can be produced in large and small batches and is suitable for industrial production. The biggest feature of tape casting is that it is very suitable for the preparation of large thin plate ceramic parts, which is difficult to achieve by pressing or extrusion molding processes. However, there are also some problems with tape casting. The main reason is that the binder content is high, so the shrinkage rate of the blank is large during the discharging glue process, and the thin sheets are prone to defects such as cracking, curling, and uneven thickness.

Tape-casting process

Tape casting was first used in the fields of papermaking, paint, and plastics. It is a long-standing molding technology that mainly includes processes such as slurry preparation, ball mill mixing, molding, drying, degreasing, and sintering.

Process flow chart for preparing ceramic substrates by tape casting

First, the ceramic powder and dispersant are added to the solvent (water or organic solvent), and the particles are agglomerated through ball milling or ultrasonic oscillation, and the solvent is allowed to wet the powder, and then the binder and plasticizer are added, and the particles are obtained by secondary ball milling. Stable and uniform slurry; then the slurry is formed on a casting machine to obtain a green body; then dried to evaporate the solvent, and the binder forms a network structure between the ceramic powders to obtain a green body film; and then the green body is formed The raw film is machined to obtain the specific shape required; finally, the required finished product is obtained through degreasing and sintering.

Application

Due to its simple equipment, continuous operation, high production efficiency, and uniform body performance, the tape casting method has become an important method for preparing large-area, ultra-thin ceramic substrates and is widely used in the electronics industry, energy industry, and other fields.

Also used in monolithic capacitor tiles, Al2O3 substrates for thick film and thin film circuits, piezoelectric ceramic diaphragms, structural ceramic sheets, capacitors, thermistors, ferrite and piezoelectric ceramic bodies, and hybrid integrated circuit substrates. It is also used in the field of mobile phone ceramic covers.

0 notes

Text

U.S. Refractories Market Set for Strong Growth Outlook

Market Research Forecast added research publication document on Worldwide U.S. Refractories Market breaking major business segments and highlighting wider level geographies to get deep dive analysis on market data. The study is a perfect balance bridging both qualitative and quantitative information of Worldwide U.S. Refractories Market. The study provides valuable market size data for historical (Volume** & Value) from 2019 to 2023 which is estimated and forecasted till 2032*. Some are the key & emerging players that are part of coverage and have being profiled are HarbisonWalker International (U.S.),Alsey Refractories Co. (U.S.),Plibrico Company, LLC (U.S.),Seneca Ceramics (U.S.),Metsch Refractories Inc. (U.S.),Ultramet (U.S.),Saint-Gobain (France),Industrial Refractory Services (U.S.),Imerys (France),McNeil USA (U.S.),Morgan Advanced Materials (U.K.). Get free access to Sample Report in PDF Version along with Graphs and Figures @ https://marketresearchforecast.com/report/us-refractories-market-1348/sample-report

The U.S. Refractories Marketsize was valued at USD 3.02 USD Billion in 2023 and is projected to reach USD 3.64 USD Billion by 2032, exhibiting a CAGR of 2.7 % during the forecast period.Refractory is a material that is resistant to decomposition by heat or chemical attack that retains its strength and rigidity at high temperatures. They are inorganic, non-metallic compounds that may be porous or non-porous, and their crystallinity varies widely. Refractory materials must be chemically and physically stable at high temperatures. Refractories have other high temperature applications such as fired heaters, hydrogen reformers, ammonia primary and secondary reformers, cracking furnaces, utility boilers, catalytic cracking units, air heaters, and sulphur furnaces. They are used for surfacing flame deflectors in rocket launch structures. as having a very high melting point, refractory metals can conduct heat and electricity very well. This is because they are a heavy metal that can carry these currents in a way that very few materials can, making them an asset in products that deal with high amounts of heat and electricity. North America is poised for rapid growth in the refractories market due to a surge in industrial activities and a revival of construction projects. The region's robust manufacturing sector, particularly in steel, glass, and cement industries, is driving increased demand for refractory materials. Keep yourself up-to-date with latest market trends and changing dynamics due to COVID Impact and Economic Slowdown globally. Maintain a competitive edge by sizing up with available business opportunity in U.S. Refractories Market various segments and emerging territory. Influencing Market Trend

Increasing demand for refractories in the iron and steel industry

Growing adoption of monolithic and unshaped refractories

Rising demand for high-performance and energy-efficient refractories

Stringent environmental regulations driving demand for low-emission refractories

Challenges:

Fluctuations in raw material prices

Intense competition from global players

Limited availability of skilled labor

Stringent environmental regulations

Have Any Questions Regarding Global U.S. Refractories Market Report, Ask Our Experts@ https://marketresearchforecast.com/report/us-refractories-market-1348/enquiry-before-buy Analysis by Form (Bricks & Shaped and Monolithic & Unshaped), by Product (Clay and Non-Clay), by Alkalinity (Acidic & Neutral and Basic), by End-Use Industry (Iron & Steel, Non-Ferrous Metals, Glass, Cement, and Others), by North America (U.S., Canada) Forecast 2024-2032

Competitive landscape highlighting important parameters that players are gaining along with the Market Development/evolution

• % Market Share, Segment Revenue, Swot Analysis for each profiled company [HarbisonWalker International (U.S.),Alsey Refractories Co. (U.S.),Plibrico Company, LLC (U.S.),Seneca Ceramics (U.S.),Metsch Refractories Inc. (U.S.),Ultramet (U.S.),Saint-Gobain (France),Industrial Refractory Services (U.S.),Imerys (France),McNeil USA (U.S.),Morgan Advanced Materials (U.K.)]

• Business overview and Product/Service classification

• Product/Service Matrix [Players by Product/Service comparative analysis]

• Recent Developments (Technology advancement, Product Launch or Expansion plan, Manufacturing and R&D etc)

• Consumption, Capacity & Production by Players The regional analysis of Global U.S. Refractories Market is considered for the key regions such as Asia Pacific, North America, Europe, Latin America and Rest of the World. North America is the leading region across the world. Whereas, owing to rising no. of research activities in countries such as China, India, and Japan, Asia Pacific region is also expected to exhibit higher growth rate the forecast period 2023-2028. Table of Content Chapter One: Industry Overview Chapter Two: Major Segmentation (Classification, Application and etc.) Analysis Chapter Three: Production Market Analysis Chapter Four: Sales Market Analysis Chapter Five: Consumption Market Analysis Chapter Six: Production, Sales and Consumption Market Comparison Analysis Chapter Seven: Major Manufacturers Production and Sales Market Comparison Analysis Chapter Eight: Competition Analysis by Players Chapter Nine: Marketing Channel Analysis Chapter Ten: New Project Investment Feasibility Analysis Chapter Eleven: Manufacturing Cost Analysis Chapter Twelve: Industrial Chain, Sourcing Strategy and Downstream Buyers Read Executive Summary and Detailed Index of full Research Study @ https://marketresearchforecast.com/reports/us-refractories-market-1348 Highlights of the Report • The future prospects of the global U.S. Refractories Market during the forecast period 2023-2028 are given in the report. • The major developmental strategies integrated by the leading players to sustain a competitive market position in the market are included in the report. • The emerging technologies that are driving the growth of the market are highlighted in the report. • The market value of the segments that are leading the market and the sub-segments are mentioned in the report. • The report studies the leading manufacturers and other players entering the global U.S. Refractories Market. Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia. Contact US : Craig Francis (PR & Marketing Manager) Market Research Forecast Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837 Phone: +1 201 565 3262, +44 161 818 8166 [email protected]

#Global U.S. Refractories Market#U.S. Refractories Market Demand#U.S. Refractories Market Trends#U.S. Refractories Market Analysis#U.S. Refractories Market Growth#U.S. Refractories Market Share#U.S. Refractories Market Forecast#U.S. Refractories Market Challenges

0 notes

Text

Advanced Ceramics Market: Global Industry Analysis and Forecast 2023 – 2030

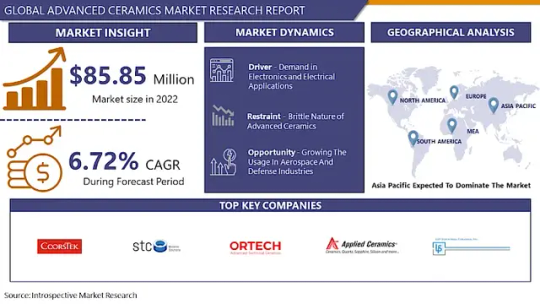

Advanced Ceramics Market Size Was Valued at USD 85.85 Billion in 2022, and is Projected to Reach USD 144.44Billion by 2030, Growing at a CAGR of 6.72% From 2023-2030.

The advanced ceramics market encompasses a wide range of high-performance ceramic materials designed for specialized applications across various industries. These ceramics exhibit exceptional mechanical, electrical, thermal, and chemical properties, making them indispensable in demanding environments where traditional materials fall short. Advanced ceramics are used in the production of electronic components such as capacitors, insulators, substrates, and sensors due to their excellent dielectric properties, high thermal conductivity, and resistance to corrosion. Ceramics are employed in automotive engineering for components like catalytic converters, sensors, spark plugs, and brake systems due to their ability to withstand high temperatures, reduce friction, and enhance fuel efficiency.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15723

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Leading players involved in the Advanced Ceramics Market include:

CoorsTek, Inc. (US), Superior Technical Ceramics (US), Ortech Advanced Ceramics (US), Applied Ceramics, Inc. (US), LSP Industrial Ceramics, Inc. (US), Momentive Performance Materials Inc. (US), NGK Spark Plug Co., Ltd. (Japan), Ferrotec Corporation (Japan), and Other Major Players.

If You Have Any Query Advanced Ceramics Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15723

Segmentation of Advanced Ceramics Market:

By Type

Alumina

Titanite

Zirconia

Silicon Carbide

Aluminium Nitride

Silicon Nitride

By Application

Monolithic Ceramics

Ceramic Matrix Composites

Ceramic Coating

By End User Industry

Electrical & Electronics

Transportation

Medical

Defense

Security Chemical

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Advanced Ceramics market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Advanced Ceramics market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Advanced Ceramics market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Advanced Ceramics market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Advanced Ceramics Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15723

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96369

Email: [email protected]

#Advanced Ceramics#Advanced Ceramics Market#Advanced Ceramics Market Size#Advanced Ceramics Market Share#Advanced Ceramics Market Growth#Advanced Ceramics Market Trend#Advanced Ceramics Market segment#Advanced Ceramics Market Opportunity#Advanced Ceramics Market Analysis 2023

0 notes

Text

Advanced Ceramics Market: Global Industry Analysis and Forecast 2023 – 2030

Advanced Ceramics Market Size Was Valued at USD 85.85 Billion in 2022, and is Projected to Reach USD 144.44Billion by 2030, Growing at a CAGR of 6.72% From 2023-2030.

Advanced ceramics, also known as engineered or technical ceramics, refer to a class of high-performance ceramics with exceptional mechanical, thermal, and electrical properties. Advanced ceramics, substances, and methods applied in the development and production of ceramic materials that exhibit special properties. According to Versailles Project on Advanced Materials and Standards (VAMAS), advanced ceramics is an inorganic, nonmetallic (ceramic), basically crystalline material of strictly managed composition and produced with detailed regulation from highly refined and characterized raw materials giving precisely specified attributes.

Advanced ceramics are inorganic and non-metallic solids that have many various properties. In addition, it has several factors such as strength and corrosion resistance, low coefficient of thermal expansion, high heat stability and are lightweight compared to their traditional counterparts.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15723

The latest research on the Advanced Ceramics market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Advanced Ceramics industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Advanced Ceramics market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

Leading players involved in the Advanced Ceramics Market include:

CoorsTek, Inc. (US), Superior Technical Ceramics (US), Ortech Advanced Ceramics (US), Applied Ceramics, Inc. (US), LSP Industrial Ceramics, Inc. (US), Momentive Performance Materials Inc. (US), NGK Spark Plug Co., Ltd. (Japan), Ferrotec Corporation (Japan), and Other Major Players.

If You Have Any Query Advanced Ceramics Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15723

Segmentation of Advanced Ceramics Market:

By Type

Alumina

Titanite

Zirconia

Silicon Carbide

Aluminium Nitride

Silicon Nitride

By Application

Monolithic Ceramics

Ceramic Matrix Composites

Ceramic Coating

By End User Industry

Electrical & Electronics

Transportation

Medical

Defense

Security Chemical

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Advanced Ceramics market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Advanced Ceramics market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Advanced Ceramics market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Advanced Ceramics market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Advanced Ceramics Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15723

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96369

Email: [email protected]

#Advanced Ceramics#Advanced Ceramics Market#Advanced Ceramics Market Size#Advanced Ceramics Market Share#Advanced Ceramics Market Growth#Advanced Ceramics Market Trend#Advanced Ceramics Market segment#Advanced Ceramics Market Opportunity#Advanced Ceramics Market Analysis 2023

0 notes

Text

Membranes Market | Pioneering Product Developments

Triton’s analysis predicts that the Global Membranes Market is set to rise at a CAGR of 6.74% during the forecast period 2024-2032.

This raises the question: What is prompting this growth?

According to WHO, in 2022, at least 1.7 billion people used drinking water contaminated by feces. Microbial contamination leads to transmission of water-borne diseases like cholera, diarrhea, typhoid, etc. WHO also states that around 505,000 deaths caused annually are due to diarrhea. Thus, to provide clean water for consumption purposes, countries opt-in to deploy membranes and remove the contaminants.

Estimates by the Asian Development Bank also suggest that in Asia-Pacific, around 1.5 billion people in rural areas and 600 million in urban areas lack adequate water supply and sanitation. This paves the way for sound water management techniques.

Hence, stakeholders make enormous efforts to explore purification methods and develop new membrane applications to reuse higher quantities of water. In fact, Triton’s analysis predicts that the Asia-Pacific Membranes Market is set to rise at a CAGR of 7.26% during the forecast period 2024-2032.

Explore in detail about this market in our FREE sample:

Reverse Osmosis (RO) - Integrating Smart Solutions

Introduced by Avista Technologies, AdvisorCi is a software that predicts precise dosing and use rates for membrane chemicals. In December 2023, it was updated with a new multivariable model, which presently allows users to create a 3D graph to track the pH and temperature of the membrane system.

Additionally, RO is known for its adaptability, efficiency in desalinization, and higher recovery rate than traditional methods. Hence, it is one of the most commonly used waterproofing techniques across industries like pharmaceuticals, automotive, food & beverages, etc.

Novel Product Design in Ultrafiltration (UF)

In order to provide convenient ultrafiltration technologies, DuPont’s IntegraTec offers a new, diverse portfolio featuring reliable and durable modules, flexible system design, PVDF, PP, and PES membrane configuration. As per its press release, its membrane technologies were used in more than 3000 installations across the world to produce 50 million cubic meters of water daily.

UF has pores with a size range of 0.02 to 0.05 microns, which helps in the successful elimination of silt, bacteria, viruses, and colloids. Thus, industry players actively invest in research and innovation within ultrafiltration to improve the efficiency of membranes, which creates significant growth opportunities in the reviewed market.

Innovation in Nanofiltration (NF)

A striking evolution in membrane technology is made by NX Filtration. It is a global provider of direct nanofiltration technology, recognized for its design that enables one step micropollutants removal with fewer chemicals. Removing the micropollutants like nano plastics, color and selective salts, PFAS, viruses, bacteria, etc., also requires less energy, thereby creating a strong sustainability benefit.

This highlights that hollow fiber nanofiltration membranes are widely used by municipal authorities, laboratories, industrialists, aquaculture, etc. in tackling issues with hardness and color in water. Accordingly, our analysis estimates that the membranes market by nanofiltration is set to witness the fastest growth at a CAGR of 7.69% over the forecast years 2024-2032.

Modernizing Ceramic Membranes

Nanostone recently made efforts on nanomaterials, aiming to enhance the production and application of ceramic membranes on a global scale. By employing a segmented monolith design, the system facilitates an unrestricted permeate flow along the entire length of the module. This specific design serves to reduce the flow restrictions and unnecessary pressure drops while maximizing surface area.

The modules are engineered to accommodate high flow rates, ensuring a user-friendly system due to broader flow channels. Moreover, the striking ability of this type of membrane material to withstand mechanical, chemical, and thermal stress widens the scope of the ceramic membranes market.

Cutting-Edge Solution by Suez SA

Suez SA developed a new product, ZeeLung, to treat wastewater in a small footprint. It is a membrane aerated biofilm reactor (MABR) used to upgrade the existing water treatment plants witnessing larger tank volumes.

ZeeLung cassettes are deployed to deliver oxygen to the biofilm without the use of air bubbles, which results in reducing energy consumption by 4X. The biofilm contains bacteria that utilize the oxygen to diffuse pollutants such as ammonia and organics from the bulk solution.

Grab a Quick Read to Understand the Widening Scope of the Membranes Market-

In Conclusion

The search for alternative water resources in drinking water and irrigation will persist with a growing dependence on groundwater. The impacts of climate change are anticipated to bring more fluctuations in harvested rainwater. Thus, enhanced management of all water resources is essential to ensure the quality of water. These reasons will drive the demand for membranes, thereby opening a new window of innovations for membrane manufacturers.

FAQs

Q.1) What materials are used to manufacture membranes?

Membrane manufacturers use materials such as ceramic, synthetic polymers, zeolite, and palladium. Similarly, a combination of all these can be used to design hybrid membranes and leverage the strength of every component.

Q.2) How much is the global membranes market worth?

The global membranes market was worth $8389.34 million in revenue in 2023 and is expected to generate $15121.63 million in 2030.

0 notes

Text

Murata releases the world’s smallest high-Q 100V MLCC

February 20, 2024 /SemiMedia/ — Murata Manufacturing Co., Ltd. recently announced the expansion of its high-Q rated monolithic ceramic chip capacitor (MLCC) product line. Designed for high frequency module applications such as those used in cellular communication infrastructure, the new GJM022 series expand the world’s smallest high-Q capacitor with a voltage rating of 100 V. In order to…

View On WordPress

#electronic components news#Electronic components supplier#Electronic parts supplier#GlobalFoundries $1.5 billion

0 notes

Text

Zirconia ceramic is an extremely hard, resilient material with excellent thermal and fracture toughness properties that is resistant to oxidation. Additionally, it boasts high heat tolerance as well as having high heat tolerance - all qualities which have led to its widespread application across metal casting to grinding wheels - even known by some as ZrO2.

Producing zirconia ceramics involves several processes. These include calcination, cold sintering, hot sintering and the creation of yttrium-stabilized zirconia (YTZ). Of these methods, calcination is usually employed as it creates thermal decomposition by heating materials at extreme temperatures while restricting oxygen - thus leading to decomposition and eliminating impurities from their material composition.

Yttrium-stabilized zirconia ceramic is an ultrahard ceramic that contains yttrium oxide for increased durability and hardness, making it more resilient than alumina ceramics and capable of withstanding temperatures of up to 1900o C without chemical reaction, while having a higher melting point than other ceramics. Crucibles and melting pots commonly use this type of ceramic.

Zirconia has long been used in dentistry as a material for restorations such as crowns and bridges, due to its excellent survival rate when cemented with resin cements. Furthermore, monolithic zirconia restorations with translucent properties are also possible; however complications with such restorations such as bond failure and ceramic veneer damage should still be taken into consideration when making decisions regarding them.

One or more factors could contribute to zirconia veneering failure, including differences in thermal coefficients, liner material and core wetting, cooling compressive stresses, phase transformation stresses, loading stresses, flaw formation, color pigments and surface properties. Some factors are easier to manage than others, yet understanding and preventing zirconia veneering failure cannot be understated.

This issue can be alleviated by opting for pre-sintered zirconia blocks and avoiding overpressing. This will ensure the zirconia densifies to its full theoretical density for superior mechanical properties.

An alternative solution would be to switch over to using an electric field for sintering instead of conventional furnaces, as this will help avoid issues related to overpressing and the formation of microvoids.

Sintering zirconia ceramic involves mixing powdered mix and liquid carrier together and placing this in an electric furnace at very low temperatures, where it is then sintered at high pressures and temperatures. The liquid carrier acts to aid rearrangement and interdiffusion between particles while also increasing strength while decreasing porosity of ceramic structures.

Pre-sintered zirconia provides many advantages over alumina in terms of uniformity and density, resistance to abrasion and corrosion, as well as increased longevity.

0 notes

Text

Building the Future: Insights into Saudi Arabia's Dynamic Refractory Market of 2023

In the heart of the Middle East, Saudi Arabia stands as a beacon of industrial progress, and within its robust manufacturing sector lies the crucial market for refractories. As we step into 2023, the Saudi Arabia refractory market continues to evolve, propelled by the kingdom's ambitious industrial initiatives, technological advancements, and the quest for operational excellence across diverse sectors. Let's delve into the thriving landscape of the Saudi Arabia refractory market, exploring key trends, industrial applications, and the pivotal role these materials play in shaping the country's industrial prowess.

Understanding the Market Dynamics: The Saudi Arabia refractory market has been witnessing substantial growth owing to the nation's thriving industrial landscape. Refractories are essential materials used in high-temperature applications to resist heat, corrosion, and abrasion, ensuring the durability of industrial furnaces, kilns, and reactors.

Industries Relying on Refractories: Numerous industries in Saudi Arabia benefit from the use of refractories:

Petrochemicals: Refractories play a crucial role in the construction and maintenance of high-temperature reactors, furnaces, and boilers in the petrochemical industry.

Steel and Metal Production: Steel mills and metal foundries utilize refractories in blast furnaces, converters, and ladles to withstand extreme temperatures and chemical reactions.

Cement and Ceramics: Refractories are essential in cement kilns and ceramic manufacturing processes, ensuring reliable and efficient operations.

Glass Manufacturing: Glass furnaces rely on refractories for insulation and heat retention, enabling precise temperature control.

Market Trends and Innovations: In 2023, the Saudi Arabia refractory market is witnessing trends driven by technological advancements:

Advanced Refractory Materials: Innovations in materials science lead to the development of high-performance refractories with superior thermal resistance and longer service life.

Monolithic Refractories: Growing demand for monolithic refractories offering ease of installation, enhanced performance, and cost-effectiveness.

Refractory Recycling: Initiatives focused on recycling and reusing refractory materials, promoting sustainability and reducing environmental impact.

Market Expansion and Future Prospects: The Saudi Arabia refractory market continues to expand, driven by the nation's commitment to diversify its economy and bolster industrial capabilities. As Saudi Arabia pushes forward with its Vision 2030, focused on economic diversification and industrial growth, the demand for refractories is anticipated to surge.

Challenges and Opportunities: Despite its growth, the refractory market in Saudi Arabia faces challenges such as fluctuating raw material prices and the need for skilled labor. However, investments in research and development, along with collaborations to enhance manufacturing capabilities, present opportunities for market expansion.

For More Info@ https://www.gmiresearch.com/report/refractories-market-in-saudi-arabia-industry-analysis-research/

Conclusion: The Saudi Arabia refractory market in 2023 stands as an integral part of the kingdom's industrial landscape, supporting diverse sectors crucial to its economic growth. As industries in Saudi Arabia strive for operational excellence and efficiency, the demand for high-quality refractory materials continues to rise, ensuring the reliability and longevity of critical industrial infrastructure.

With ongoing technological advancements and a commitment to sustainable practices, the Saudi Arabia refractory market is poised for sustained growth. As the nation cements its position as a regional industrial powerhouse, refractories will remain indispensable in supporting the kingdom's ambitious industrial aspirations, contributing to the resilience and success of its manufacturing sectors.

0 notes