#moldingi

Explore tagged Tumblr posts

Text

https://bahtinov.ru/uslugi/dizajn-proekt-kvartiry/luxury-bezhevye-tona-moldingi-na-stenah-zoloto/

1 note

·

View note

Text

Молдинги настенные https://decor-perfect.ru/shop/moldingi/ молдинги перфект молдинги настенные

0 notes

Text

Молдинги настенные https://decor-perfect.ru/shop/moldingi/ молдинги перфект молдинги настенные

0 notes

Text

Молдинги настенные https://decor-perfect.ru/shop/moldingi/ молдинги перфект молдинги настенные

0 notes

Text

Молдинги настенные https://decor-perfect.ru/shop/moldingi/ молдинги перфект молдинги настенные

0 notes

Text

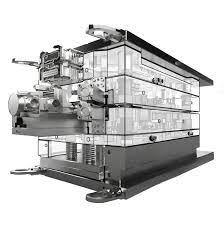

Top Reasons to Use the Technique of Injection Molding

Injection thin wall molding is primarily a production technique. The procedure involves injecting molten material into a customized mold. In most cases, this method is the best option when making plastic components. No of the ultimate product's size, complexity, or intended use, molding is possible. The plastic is melted and then pumped into a mold, making this procedure quite straightforward. This piece will explain why Injection Mold Hot Runner is so popular with engineers right now. Learn more by reading on!

Expanding on this idea:

Thin wall injection mold allows for extensive customization of manufactured goods. The molten substance provides a more precise form because of the intense pressure. Therefore, if you want a lot of granularities in the final output, this method is an excellent option to consider. That is why this strategy has become so common.

Sturdiness

By adding fillers to the mold, we can increase the product's strength while decreasing its density. The intensity can be modified for some goods. This flexibility is unavailable with other methods.

Systems begin to improve with time. That is why mass production thin wall mold is feasible in a relatively brief time frame.

The use of automated systems

Automatically producing high-quality goods is now possible thanks to this method. Mold creation is greatly facilitated by CAD and computer-aided manufacturing technology.

Automation's primary advantage is that it facilitates cost savings and improved design. Costs are reduced due to the widespread usage of advanced robotic machinery. Everything comes out nice and polished in the end. Production costs are relatively low. As a result, business owners can expect a substantial return on their investment thanks to the cut costs.

Speed

Depending on the complexity of the mold, the entire procedure takes only a few of minutes to complete. Other methods are typically far more time-consuming than thin wall injection molding. Thus, the greater speed yields significant cost savings.

Eco-friendly

This procedure benefits the natural world. Injection Molding Cost with plastic causes little to no environmental damage. Because of the effective management of resources, there will be no harmful effects on the natural world. Extra plastic can be recycled after each project is finished. This means there is no trash left over.

Finishing

The finished goods are refined and smooth after the process of Different Types of Moldingis over. Manufacturers save money on quality control checks since almost no finishing is necessary. There are no defects in the finished product.

Since it can be expensive to obtain cheaper mold, it is crucial to test your mold. You should inspect your molds and read the fine print. Purchasing molds from a manufacturer has various benefits, including getting a high-quality mold at a lower price.

These merits of Family Molding explain why it is widely used in industry. The key advantages of this method are its low price, good quality, and high efficiency. We advise using this method when you are going to launch your own business.

0 notes

Text

Молдинги

Официальный поставщик ЕВРОПЛАСТ по Москве и МО.

#evroplast #Европласт #плинтуса

https://evroplast-mos.ru/catalog/interernyy_dekor/moldingi/

0 notes

Text

Молдинги Orac Decor с орнаментом

А также мы предлагаем бюджетную линейку из полимера средней плотности (Durofoam®)

#ordecor #плинтусы #молдинги

https://ordecor-russia.ru/orac-decor-moldingi/orac-decor-moldingi-s-ornamentom/

0 notes

Photo

Друзья! 🎄Напоминаем Вам , что в нашем магазине до конца 👉декабря действует акция распродаж ОБОИ прошлых месяцев. 🧧Ждём Вас в будние дни с 10-00 до 18-00 В выходные с 11-00 до 17-00 🤝Успейте купить ОБОИ по низкой цене. 🙏🙏🙏 #обоиактау #обоидлястен #обои_актау #oboi_aktau #oboi_iz_evropy #oboi_aliya #oboi_garmony #oboigarmony #oboizhanaozen #dekoraktau #moldingi #eoruplast #oboiaktausak #oboiaktobe #oboiatyrau #обоиактобе #обоиатырау #обоижанаозен #обоишетпе #распродажаактау #скидкиактау #онлайнактау #интересноеактау #морекаспий #актау2021 #новыйгодактау #подаркиактау #ёлкаактау https://www.instagram.com/p/CInOMejMpbF/?igshid=1ackqo1wjs7zl

#обоиактау#обоидлястен#обои_актау#oboi_aktau#oboi_iz_evropy#oboi_aliya#oboi_garmony#oboigarmony#oboizhanaozen#dekoraktau#moldingi#eoruplast#oboiaktausak#oboiaktobe#oboiatyrau#обоиактобе#обоиатырау#обоижанаозен#обоишетпе#распродажаактау#скидкиактау#онлайнактау#интересноеактау#морекаспий#актау2021#новыйгодактау#подаркиактау#ёлкаактау

0 notes

Text

What is Plastic Dip Moulding and where is it used

is one of the leading names in the Plastic Industry in the United States and providesall kinds of different services including Plastic Dip Moulding and in manufacturing PVC and other materials thatare used in several kinds of infrastructural projects etc from time to time.We use it in all kinds of different industries, for making various tools from the most complex of structures that are used in the biggest of structures in large buildings and even in the smallest of tools and equipment that we require such as food storage containers and all kinds of different tools and equipment that we use in our day to day lives.What are the different services on offer by Carlisle Plastic and why you should go with them?Carlisle Plastic Company Inc.

There are several different types of procedures that aim at solving different purposes.All You Need To Know About Plastic Dip Moulding Plastic is one of the most crucial materials that has led to a lot of growth and innovation in infrastructure projects around the world. You can get apartial coating done to protect certain parts only, then there is the process of fully coating the tools or materials into a vinyl coating and several other kinds of Plastic Dip Moulding isdone in several industries around the world and aim to solve all kinds of different requirements.What Fitness Equipment powder coating Company are the different kinds of dip coating procedures that you can choose to invest in?Plastic dip coating services are a very popular practice that has long been carried out in all kinds of different places.

They have been established since 1958 and our well versed with the different requirements of their customers.What is Plastic Dip Moulding and where is it used?Plastic dip moldingis a very popular technique that is practiced throughout the world and different industries and fields. It has changed the way that we live our lives and brought in changes that have led to the growth and development in various industries and haveadded animmense amount of convenience in our lives over the years. So, a coating of plastic vinyl helps in keeping the various tools and metals in great condition and is a cost-effectivepractice that comes in very handy.

Plastic Dip Moulding is often done on various metal parts and machinery to protect them from rusting or being exposed to electricity. It is the process of moldingplastic and applying a coating of vinyl material to protect it from damage and giving it an edge of style as well. It is essential in undertaking all kinds of different infrastructural projects an even in our day to day tasks and errands..Andrew Jason is the author of this Article: To know more aboutPlastic Dip Moldingplease visit the Website: carlisleplastics

0 notes

Text

#молдинги на стены https://www.polvdome.ru/catalog/arkhitekturnyy_dekor/moldingi/

0 notes

Text

#молдинги на стены https://www.polvdome.ru/catalog/arkhitekturnyy_dekor/moldingi/

0 notes

Link

0 notes

Text

Top Reasons to Use the Technique of Injection Molding

Injection thin wall molding is primarily a production technique. The procedure involves injecting molten material into a customized mold. In most cases, this method is the best option when making plastic components. No of the ultimate product's size, complexity, or intended use, molding is possible. The plastic is melted and then pumped into a mold, making this procedure quite straightforward. This piece will explain why Injection Mold Hot Runner is so popular with engineers right now. Learn more by reading on!

Expanding on this idea:

Thin wall injection mold allows for extensive customization of manufactured goods. The molten substance provides a more precise form because of the intense pressure. Therefore, if you want a lot of granularities in the final output, this method is an excellent option to consider. That is why this strategy has become so common.

Sturdiness

By adding fillers to the mold, we can increase the product's strength while decreasing its density. The intensity can be modified for some goods. This flexibility is unavailable with other methods.

Systems begin to improve with time. That is why mass production thin wall mold is feasible in a relatively brief time frame.

The use of automated systems

Automatically producing high-quality goods is now possible thanks to this method. Mold creation is greatly facilitated by CAD and computer-aided manufacturing technology.

Automation's primary advantage is that it facilitates cost savings and improved design. Costs are reduced due to the widespread usage of advanced robotic machinery. Everything comes out nice and polished in the end. Production costs are relatively low. As a result, business owners can expect a substantial return on their investment thanks to the cut costs.

Speed

Depending on the complexity of the mold, the entire procedure takes only a few of minutes to complete. Other methods are typically far more time-consuming than thin wall injection molding. Thus, the greater speed yields significant cost savings.

Eco-friendly

This procedure benefits the natural world. Injection Molding Cost with plastic causes little to no environmental damage. Because of the effective management of resources, there will be no harmful effects on the natural world. Extra plastic can be recycled after each project is finished. This means there is no trash left over.

Finishing

The finished goods are refined and smooth after the process of Different Types of Moldingis over. Manufacturers save money on quality control checks since almost no finishing is necessary. There are no defects in the finished product.

Since it can be expensive to obtain cheaper mold, it is crucial to test your mold. You should inspect your molds and read the fine print. Purchasing molds from a manufacturer has various benefits, including getting a high-quality mold at a lower price.

These merits of Family Molding explain why it is widely used in industry. The key advantages of this method are its low price, good quality, and high efficiency. We advise using this method when you are going to launch your own business.

0 notes

Text

Молдинги гладкие

Часть продуктов из нашего ассортимента изготовлены из прессованного ударопрочного полимера (Duropolymer®)

#ordecor #плинтусы #молдинги

https://ordecor-russia.ru/orac-decor-moldingi/orac-decor-moldingi-gladkie/

0 notes

Photo

Молдинги AMG (карбон) для Mercedes Benz G-klass (G-463) - 14990 руб. (Обычная цена: 32000 руб.) http://www.autotuning999.ru/catalog/mercedes-benz/g-klass-g-463/raznoe/moldingi-amg-karbon-dlya-mercedes-benz-g-klass-g-463.html #авто #автомобиль #машины #тачки #тачка #машина #auto #cars #car #tuning #автотюнинг

0 notes