#modular buffer

Explore tagged Tumblr posts

Text

"Morningside Park, a beloved neighborhood park in Miami with sweeping views of Biscayne Bay, will soon pilot an innovative approach to coastal resilience.

BIOCAP tiles, a 3D-printed modular system designed to support marine life and reduce wave impact along urban seawalls, will be installed on the existing seawall there in spring 2025. BIOCAP stands for Biodiversity Improvement by Optimizing Coastal Adaptation and Performance.

Developed by our team of architects and marine biologists at Florida International University, the uniquely textured prototype tiles are designed to test a new approach for helping cities such as Miami adapt to rising sea levels while simultaneously restoring ecological balance along their shorelines...

Ecological costs of traditional seawalls

Seawalls have long served as a primary defense against coastal erosion and storm surges. Typically constructed of concrete and ranging from 6 to 10 feet in height, they are built along shorelines to block waves from eroding the land and flooding nearby urban areas.

However, they often come at an ecological cost. Seawalls disrupt natural shoreline dynamics and can wipe out the complex habitat zones that marine life relies on.

Marine organisms are crucial in maintaining coastal water quality by filtering excess nutrients, pollutants and suspended particles. A single adult oyster can filter 20-50 gallons of water daily, removing nitrogen, phosphorus and solids that would otherwise fuel harmful algal blooms. These blooms deplete oxygen levels and damage marine ecosystems.

Filter-feeding organisms also reduce turbidity, which is the cloudiness of water caused by suspended sediment and particles. Less water turbidity means more light can penetrate, which benefits seagrasses that require sunlight for photosynthesis. These seagrasses convert carbon dioxide into oxygen and energy-rich sugars while providing essential food and habitat for diverse marine species.

Swirling shapes, shaded grooves

Unlike the flat, lifeless surfaces of typical concrete seawalls, each BIOCAP tile is designed with shaded grooves, crevices and small, water-holding pockets. These textured features mimic natural shoreline conditions and create tiny homes for barnacles, oysters, sponges and other marine organisms that filter and improve water quality.

The tile’s swirling surface patterns increase the overall surface area, offering more space for colonization. The shaded recesses are intended to help regulate temperature by providing cooler, more stable microenvironments. This thermal buffering can support marine life in the face of rising water temperatures and more frequent heat events driven by climate change.

Another potential benefit of the tiles is reducing the impact of waves.

When waves hit a natural shoreline, their energy is gradually absorbed by irregular surfaces, tide pools and vegetation. In contrast, when waves strike vertical concrete seawalls, the energy is reflected back into the water rather than absorbed. This wave reflection – the bouncing back of wave energy – can amplify wave action, increase erosion at the base of the wall and create more hazardous conditions during storms.

The textured surfaces of the BIOCAP tiles are designed to help diffuse wave energy by mimicking the natural dissipation found on undisturbed shorelines.

The design of BIOCAP takes cues from nature. The tile shapes are based on how water interacts with different surfaces at high tide and low tide. Concave tiles, which curve inward, and convex tiles, which curve outward, are installed at different levels along the seawall. The goal is to deflect waves away from the seawall, reduce direct impact and help minimize erosion and turbulence around the wall’s foundation.A

How we will measure success

After the BIOCAP tiles are installed, we plan to assess how the seawall redesign enhances biodiversity, improves water quality and reduces wave energy. This two-year pilot phase will help assess the long-term value of ecologically designed infrastructure.

To evaluate biodiversity, we will use underwater cameras to capture time-lapse imagery of the marine life that colonizes the tile surfaces. These observations will aid in documenting species diversity and habitat use over time...

In the coming year, we’ll be watching with hope as the new BIOCAP tiles begin to welcome marine life, offering a glimpse into how nature might reclaim and thrive along our urban shorelines.

#ocean#seawall#florida#miami#climate adaptation#coastline#united states#north america#biodiversity#waves#ocean waves#good news#hope

1K notes

·

View notes

Text

As I've mentioned before, the ultimate goal for my 68030 homebrew systems is to run a proper multi-user operating system. Some flavor of System V or BSD or Linux. I am not there yet. There is still so much I need to learn about programming in general and the intricacies of bringing up one of those systems, plus my hardware does not yet have the ability to support multiple users.

I've toyed with several ideas as to how to get the hardware to support multiple users, but ultimately decided to leverage what I have already. I have a fully-functional modular card-based system. I can easily build new cards to add the functionally I need. And to make development and debugging easier, I can make each card simple, dedicated to a single function.

The catch is I've already run into some stability issues putting everything on the main CPU bus. So what I really need is some kind of buffered peripheral bus I can use for developing the new I/O cards I'll need.

So that's where I started — a new 8-bit I/O bus card that properly buffers the data and address signals, breaks out some handy I/O select signals, and generates the appropriate bus cycle acknowledge signal with selectable wait states.

It wasn't without its problems of course. I made a few mistakes with the wait state generator and had to bodge a few signals.

With my new expansion bus apparently working I could set out on what I had really come here for — a quad serial port card.

I have it in my head that I would really like to run up to eight user terminals on this system. Two of these cards would get me to that point, but four is a good place to start.

I forgot to include the necessary UART clock in the schematic before laying out the board, so I had to deadbug one. I'm on a roll already with this project, I can tell.

So I get it all wired up, I fire up BASIC, attach a terminal to the first serial port, and get to testing.

Nothing comes across.

Step-by-step with the oscilloscope and logic analyzer, I verify my I/O select from the expansion bus card is working, the I/O block select on the UART card is working, the individual UART selects are working. I can even see the transmitted serial data coming out of the UART chip and through the RS-232 level shifter.

But nothing is showing up in the terminal.

I've got the terminal set for 9600bps, I've got my UART configured for 9600bps, but nothing comes across.

I did note something strange on the oscilloscope though. I could fairly easily lock onto the signal coming out of my new serial card, but the received data from the terminal wasn't showing up right. The received data just seemed so much faster than it should be.

Or maybe my card was slower than it should be.

Looking at the time division markings on the oscilloscope, it looked like each bit transmitted was around ... 1.25ms. Huh. 9600bps should be more like 0.1ms. This looks something more like 800bps.

I set the terminal for 800bps and got something, but it wasn't anything coherent, it was just garbage. I wrote a quick BASIC program to sweep through the UART baud rate generator's clock divider setting and output a string of number 5 for each setting until I got a string of 5s displaying on the terminal.

So then I tried sending "HELLORLD".

I got back "IEMMOSME".

No matter what I changed, I couldn't get anything more coherent than that. It was at least the right number of characters, and some of them were even right. It's just that some of them were ... off ... by one.

A quick review of the ASCII chart confirmed the problem.

'H' is hex 0x48, but 'I' is 0x49. 'E' is 0x45, but was coming across correctly.

... I have a stuck bit.

The lowest-order bit on my expansion bus is stuck high. That's why I wasn't seeing any coherent data on the terminal, and it also explains why I had to go hunting for a non-standard baud rate. The baud rate generator uses a 16-bit divisor to divide the input clock to the baud rate. When I tried to set the divisor to 0x0018 for 9600bps, it was getting set to 0x0118 — a difference of 256.

Another quick BASIC program to output the ASCII chart confirmed this was indeed the problem.

Each printed character was doubled, and every other one was missing.

That sounds like it could be a solder bridge. The UART chip has its D0 pin right beside a power input pin. A quick probe with the multimeter ruled that out.

Perhaps the oscilloscope would provide some insight.

The oscilloscope just raised more questions.

Not just D0, but actually several data bus pins would immediately shoot up to +5V as soon as the expansion bus card was selected. As far as the scope was concerned, it was an immediate transition from low to high (it looked no different even at the smallest timescale my scope can handle). If the UART was latching its input data within the first third of that waveform then it certainly could have seen a logic 1, but it doesn't make sense why only the one data pin would be reading high.

I thought maybe it could just be a bad bus transceiver. The 74HCT245 I had installed was old and a little slow for the job anyway, so I swapped it out for a newer & much faster 74ACT245.

And nothing changed.

It's possible the problem could be related to the expansion bus being left floating between accesses. I tacked on a resistor network to pull the bus down to ground when not active.

And nothing changed.

Well ... almost nothing.

This was right about the time that I noticed that while I was still getting the odd waveform on the scope, the output from the terminal was correct. It was no longer acting like I had a stuck bit and I was getting every letter.

Until I removed the scope probe.

Too much stray capacitance, maybe? That waveform does certainly look like a capacitor discharge curve.

I had used a ribbon cable I had laying around to for my expansion bus. It was long enough to support a few cards, but certainly not excessively so (not for these speeds at least). It was worth trying though. I swapped out the ribbon cable for one that was just barely long enough to connect the two cars.

And finally it worked.

Not only was I able to print the entire ASCII set, I could program the baud rate generator to any value I wanted and it worked as expected.

That was a weird one, and I'm still not sure what exactly happened. But I'm glad to have it working now. With my hardware confirmed working I can focus on software for it.

I've started writing a crude multi-user operating system of sorts. It's just enough to support cooperative multitasking for multiple terminals running BASIC simultaneously. It may not be System V or BSD or Linux, but I still think it would be pretty darn cool to have a line of terminals all wired up to this one machine, each running their own instance of BASIC.

22 notes

·

View notes

Text

i've always been kinda interested in making my own music for w/e game thing i make, & between listening to some king gizzard & the lizard wizard music b/c of that come see him video that everybody reblogs all the time and rewatching an old youtube video about the tuning of gamelan music AND finding an old talk about functional music construction AND discovering that there's now a builtin javascript synthesizer library (the 'web audio api') i was like, hey, i could actually try out synthing up some music.

like, i'm not gonna try putting anything real together yet but i could at least read up on the api since it seems incredibly complicated. it really is a conceptual modular synthesizer where components are linked together with signals. wires everywhere

anyway i was like, let's look at how to make a sine wave. "sine" is a preset but beyond that it gets into arbitrary waveforms

Here, we create a PeriodicWave with two values. The first value is the DC offset, which is the value at which the oscillator starts. A value of 0 is good here because it starts the curve at the middle of the [-1.0; 1.0] range. The second and subsequent values are sine and cosine components, similar to the result of a Fourier transform, which converts time domain values to frequency domain values. Here, with createPeriodicWave(), you specify the frequencies, and the browser performs an inverse Fourier transform to get a time domain buffer for the frequency of the oscillator. In this example, we set only one component at full volume (1.0) on the fundamental tone, so we get a sine wave. Bear in mind that the fundamental tone corresponds to the oscillator's frequency (which, by default, is 440 Hz). Therefore, altering the oscillator's frequency effectively shifts the frequency of this periodic wave along with it.

The coefficients of the Fourier transform should be given in ascending order (i.e. (a+bi)ei,(c+di)e2i,(f+gi)e3i etc.) and can be positive or negative. A simple way of manually obtaining such coefficients (though not the best) is to use a graphing calculator.

music from first principles, everybody!!

8 notes

·

View notes

Note

Hey, long-time Caliban pilot here with some questions, first of all, do y'all have a print-code variation for one without all the physical enhancement systems? The motors are nice and all, but... They're too slow, and I keep breaking the damn things...

And, secondly, would there be, ah, any potential complications to mounting an Athena-Class NHP in a rig designed for m- a Sekhmet-Class? Partner's been having some complaints about weird data, and is, ah, a bit more trigger-happy than I would assume is typical for the class, which... Isn't exactly a problem, per se, but I worry about her.

- 'Rictus'

Hello Rictus!

We’re sorry to hear you’re having problems with your Caliban! To answer your question: yes, the printcode for the Caliban is fully modular, and you should be able to remove or change out the physical enhancement motors. If the base Caliban motors are too slow (we assume you may be breaking them because you’re pushing harder/faster than them somehow?) for your tastes, we recommend replacing them with motors from our Nelson line, which are purpose-built for durability and speed.

As for your partner: while it is abnormal to have an ATHENA operating in a SEKHMET mount, there should be no compatibility issues. Based on your data issues, we believe you may not have cleared the engram buffers, so there may still be leftovers of the last person hooked into the mount. Remember there are both secondary and tertiary buffers to scrub as well!

Let us know if these fixes work for you!

37 notes

·

View notes

Text

Using some unconventional sound sources to make something a bit anxious.

As I've been getting used to Traffic, the case I have set up only has Taiko and Daiko (and ABD) as voices. This was fine, but I found myself wanting an oscillator. Instead of restructuring, I got a little modular with it - the lead voice in this patch is actually Data Bender in micro mode with a frozen buffer, with time and repeats so high that it acts as a pseudo-wavetable oscillator, where modulation affects the waveshape.

The bass voice is Akemie's Taiko triggered by channel 3 of Traffic. Due to the way the channels choke each other, this creates novel riffs based on the first 2 channels being triggered, which makes Constellation's mutes an even more valuable performance feature.

My biggest gripe with Traffic, though, doesn't actually have to do with the module itself. But rather, how it interacts with Taiko. The drum samples the inputs as soon as it receives a trigger to synthesize the hit, but Traffic takes mere milliseconds to update its outputs, so using the two together leads to inconsistent drums - which can be good or bad. This is avoidable by programming a gate delay (in this case, I've been using uO_c Phazerville or Maestro), but it's a hassle nonethe less.

#modular synth#eurorack#glitch#glitch music#experimental music#electronic music#my music#music#ambient#ambient music#generative music#gif#flashing gif#sound design#idm#industrial#industrial music#noise#techno#lo fi

28 notes

·

View notes

Text

What makes Satisfactory so (haha) satisfying are those moments when you get to see your production line working the way you want it to

And I say that as a player that does not optimize their production lines at all (hence why I am currently suffering a shortage of cables and modular frames in my main factory)

Anyway, I spent the last few hours building a turbo fuel plant and it succeeded the test of going online and that made me very happy

(now to add enough generators to actually use all that fuel I am producing, I only put down 8 so far, and used geysers and power buffers to start up the factory)

#shut up ip#the funny thing is for this power plant I actually did the math of how many refinieries and co are needed etc#and then looked at the number and went your uneven fuck off#so essentially I am underutilizing the oil nodes and everything else by extension#i will probably use this factory for nobelisk and ammo automation as well since I handcrafted those before#satisfactory

3 notes

·

View notes

Text

Crane wheels: Choose the right wheels, and the crane will be as stable as Mount Tai!

Crane wheels are key components of the crane's operating mechanism, just like car tires, which directly affect the stability, safety and service life of the equipment. If the wrong wheels are chosen, the wear will accelerate at best, and the crane may derail or even cause a safety accident!

So, how should crane wheels be chosen? What types are there? How to extend the service life? This article will answer all your questions in the simplest and most understandable way!

一、 The function of crane wheels

Crane wheels have three main roles:

✅ Carrying weight - supporting the entire weight of the crane and the load

✅ Smooth operation - ensuring smooth movement of the crane on the track

✅ Preventing derailment - the wheel rim design can prevent the wheel from sliding off the track

二、How to choose the right crane wheel?

Choosing the wrong wheel = wasting money + safety hazard! Remember these 5 key points:

1. Look at the carrying capacity

Rated load of the wheel ≥ Maximum wheel pressure of the crane × 1.2 (safety factor)

For example: The maximum load of a single wheel is 10 tons, and a wheel of more than 12 tons should be selected

2. Look at the track matching

The wheel tread width should be slightly larger than the track top width (usually 5-10mm larger)

The wheel flange height should be able to effectively prevent derailment (generally ≥25mm)

3. Look at the working environmen

High temperature environment (such as steel mills) → Choose heat-resistant alloy steel

Humid/corrosive environment (such as ports) → Choose stainless steel or coating treatment

High dust environment (such as cement plants) → Choose sealed bearing design

4. Look at the running speed

Low-speed crane (≤30m/min) → Ordinary cast steel wheels are sufficient

High-speed crane (>60m/min) → Precision machining + dynamic balancing test required

5. Look at the maintenance cost

Lubrication method: Automatic lubrication wheels can reduce manual maintenance

Convenience of replacement: Modular design can reduce downtime

三、 Common problems and solutions for crane wheels

❌ Problem 1: Wheels wear too fast

Possible causes:

Uneven track

Overloaded operation

Wheel material mismatch

Solutions:

✔ Check track levelness regularly

✔ Replace wheels with higher hardness (such as HRC50+)

❌ Problem 2: Crane deviation

Possible causes:

Wheel diameter inconsistency

Track installation error

Solution:

✔ Use tapered tread wheels (automatic deviation correction)

✔ Check and adjust track parallelism

❌ Problem 3: Wheel rim fracture

Possible causes:

Unqualified material (prone to cast iron wheels)

Excessive impact load

Solution:

✔ Replace forged steel or alloy steel wheels

✔ Install buffer devices

1 note

·

View note

Text

The ATP 50-C, or How Not To Do It

It was 2167 when Advanced Transport Prototypes, or ATP, elected to chance their arm at utility craft. Company head Errin Purreck had seen the success of other manufacturers, and elected to follow a strategy that they'd had success with in the past - reuse the company's existing designs to ensure proven performance while undercutting the competiton.

At least, that was the theory.

At the time, ATP lacked a small scale chassis with suitable robustness for utility work, so a compromise was made - effectively performing a cut-and-shut on the ATP 75 platform to shorten it to a practical length. This design is what gave it the 50-C designation, with Purreck hoping that if the platform was successful then other variants could be made, drawing up first drafts of the 50-D (Inter-ship delivery vehicle) and 50-S (Small scale debris sweeper). These were only half complete when the 50-C entered practical trials, and a number of issues raised their ugly heads.

First on the list was thrust control. Though the bank of thrusters at the rear of the aircraft had been adjusted to account for the fine manoeuvring, it still used two of the thrusters from the original 75 design. Shortening the chassis meant relocating and shrinking the fuel tanks, which caused fuel starvation on longer operations and meant that the micro thrusters frequently had to be used. Prototype 01 was condemned when the main thrusters ignited suddenly post-starvation, sending the craft into the side of the dock with an impact that it's pilot was lucky to survive.

Second on the list was the cleaning fluid storage, which had been split into two tanks on either side of the craft. This was to accomodate the corridor at the back of the craft that the pilot used to enter the cockpit, with the potential for using two different cleaning fluids. The original design for the front of the craft had two spray guns, with an interchangeable buffer head for both. As the two tanks weren't linked, if one drained faster than the other then it could become unbalanced - with predictable results. Prototype 02 was condemned when Tank 1 was drained completely while Tank 2 was still 78% full during testing, requiring use of the side thrusters to keep the craft balanced until it returned to dock. This use damaged the Port side thrusters beyond repair.

Last on the list were the manipulator arms. Head of Development for the project, Iona Miskil, sourced the design from Evrincrad Engineering. The design was apparently originally intended for fine motor work, but was more within budget than other offerings. Their shortcomings were more than apparent when buffing pads were added to the left hand arm in place of the second sprayer - the arms suffered from droop after a mere fraction of their intended service life, and mid-testing inspection found signs of metal fatigue around the base. At this point, with costs mounting and no clear sign of the craft being able to enter service, the project was cancelled. ATP 50-C 03 currently sits in the Museum of Practical Spacecraft on Moterrel Station, where she serves as a gate guardian.

Although the 50 was ultimately a failure, the post-program review lead to the start of ATP's modular chassis program, which would ultimately culminate in their most successful design, the 100.

#spacecraft notes#sometimes you have to write a few words about the small guy you drew on your lunch break#stormshield

2 notes

·

View notes

Text

💧 Raw Water Storage Tanks in Pune | Industrial-Grade Solutions by COEP Prefab Water Tanks

Looking for high-quality and durable raw water storage tanks for industrial or commercial applications? COEP Prefab Water Tanks is a leading manufacturer and supplier of raw water storage tanks in Pune and across India. We design and deliver customized water storage solutions that meet your project’s technical requirements and industry standards.

Whether you're managing water intake for industrial processing, municipal systems, or irrigation, our tanks ensure secure and long-lasting raw water containment.

🏭 Industrial Raw Water Storage Tanks in Pune

We specialize in supplying industrial raw water storage tanks in Pune for a wide range of industries including:

Power & Energy Plants

Manufacturing & Processing Units

Agricultural Irrigation Systems

Water Treatment Facilities

Infrastructure & Real Estate Projects

Our tanks are designed for high-volume storage, corrosion resistance, and minimal maintenance — making them ideal for long-term usage and rough environmental conditions.

🇮🇳 Raw Water Storage Tanks in India – Delivered Nationwide

As a trusted name in the industry, COEP offers raw water storage tanks in India that are built using advanced materials like Zincalume steel, GFS (Glass Fused Steel), and liner-based modular systems. Our tanks are fabricated with precision and transported efficiently across all major states and cities in India.

🛠️ COEPPrefabWaterTanks Storage Tanks in India – Why Choose Us?

Modular Design for fast installation & easy relocation

Leak-proof Liners for high purity and protection

Corrosion-Resistant Materials for long service life

Custom-built tanks based on capacity, site, and usage

Compliance with international quality standards

🧱 Applications of Raw Water Containment Tanks in Pune

Our raw water containment tanks in Pune are widely used for:

Pre-treatment water storage

Process water backup systems

Buffer tanks in STP/ETP

Firefighting reserves

Agricultural and irrigation holding

As expert raw water tank suppliers in India, we work closely with consultants, contractors, and industries to supply tanks that are engineered for efficiency and reliability.

🚚 Raw Water Tank Suppliers in India – Get Custom Quotes

If you're looking for raw water tanks suppliers in India who understand the complexities of industrial water management, COEP Prefab Water Tanks is your ideal partner. We offer:

Site assessments & capacity planning

Turnkey installation

Nationwide delivery & after-sales support

📍 Based in Pune | Serving All Over India 👉 Learn more at: https://coepprefabwatertanks.com/pune/raw-water-storage-tanks.html

📞 Contact us now for a customized quote!

#Raw water storage tanks#Raw water storage tanks in Pune#Raw water storage tanks in India#coepprefabwatertanks storage tanks in India#Raw water tanks suppliers India#Industrial raw water storage tanks Pune#Raw water containment tanks Pune

0 notes

Text

Secure Epoxy Coated Steel Holding Tanks: Providing Safe, Temporary Containment for Various Liquids

Across numerous industrial, commercial, and municipal operations, the need for secure and reliable temporary containment of various liquids is a frequent and essential requirement. Whether for buffering process flows, temporary waste collection, batch mixing, or emergency spill containment, holding tanks must offer absolute integrity, prevent leaks, and resist the often-diverse or corrosive nature of their contents. Any failure in temporary containment can lead to operational disruptions, environmental hazards, and significant financial repercussions. This critical requirement calls for robust, secure, and adaptable solutions from manufacturers whose proven expertise in materials science and liquid containment is indispensable. Center Enamel (Shijiazhuang Zhengzhong Technology Co., Ltd), an experienced China Epoxy Coated Steel Tanks manufacturer, stands ready, delivering meticulously engineered and certified tanks that embody over three decades of dedication to safe, temporary liquid containment worldwide.

Center Enamel has consistently built its formidable reputation on a foundation of engineering excellence, manufacturing precision, and an unwavering commitment to the highest standards in bolted steel tank technology. Our distinguished standing as an experienced China Epoxy Coated Steel Tanks manufacturer for secure holding tanks directly stems from our profound technical acumen, a refined understanding of diverse liquid characteristics and temporary storage needs, state-of-the-art production capabilities, and a deep-seated mission to provide durable, safe, and efficient containment solutions. We don't just supply tanks; we deliver foundational components that enhance operational flexibility and safeguard environmental integrity.

The Essence of Security: Epoxy Coated Steel for Holding Tanks

Epoxy Coated Steel Holding Tanks, particularly those utilizing our advanced Fusion Bonded Epoxy (FBE) coating technology, represent a superior solution for safe, temporary liquid containment. Traditional concrete sumps or temporary pits are often porous, susceptible to chemical attack, and prone to cracking or degradation, risking leaks and environmental contamination. Conventional welded steel tanks require extensive on-site fabrication and are vulnerable to rapid internal corrosion from various liquids, demanding frequent maintenance or specialized liners with limited lifespans. In sharp contrast, Center Enamel's tanks are precision-engineered and manufactured under strict quality controls in our advanced factory—a process refined through years of experience. This sophisticated process involves applying a high-performance epoxy resin powder to meticulously prepared, high-grade steel panels. Through precise thermal fusion, this powder melts and chemically bonds to the heated steel, creating an incredibly tough, uniformly applied, and intrinsically impermeable protective layer.

This factory-applied coating, perfected over decades, is paramount for holding tank applications. It forms an inert, durable, non-porous barrier offering superior corrosion and chemical resistance against a wide array of liquids, including industrial process water, wastewater, agricultural liquids, and certain chemicals. The inherent strength of the steel panels, combined with the FBE coating, provides exceptional structural integrity and absolute leak prevention, crucial for buffering flows, preventing spills, and ensuring regulatory compliance. Crucially, FBE coating prevents internal degradation, minimizing contamination risks and extending tank lifespan in demanding liquid environments. These pre-coated, precision-drilled panels are then efficiently assembled on-site with high-strength bolts. This modular, bolted construction ensures rapid installation, significantly reducing labor and disruption, solidifying its position as the robust and reliable choice for secure, temporary containment of various liquids.

Reliability Born from Experience: Key Benefits for Secure Holding Tanks

Global trust in Center Enamel's Epoxy Coated Steel Tanks highlights their specialized advantages, continuously refined through extensive experience for secure temporary liquid containment:

Superior Corrosion & Chemical Resistance: FBE coating provides robust, long-term protection against diverse corrosive liquids, preventing tank degradation and leaks.

Proven Durability & Leak Prevention: The inherent strength of steel combined with precise bolted construction ensures high structural integrity and absolute leak prevention, critical for environmental compliance and operational safety.

Unwavering Reliability for Temporary Storage: Our manufacturing experience translates to absolute reliability, guaranteeing safe and continuous buffering or temporary containment of liquid flows.

Strict Adherence to Safety Standards: Rigorous quality control and certifications ensure tanks meet high industry and environmental safety standards for liquid storage.

Low Maintenance: Superior durability and protective coating result in minimal ongoing maintenance requirements, ensuring continuous, hassle-free operation.

Cost-Effectiveness (Long-term Value): Modular design and rapid installation reduce initial outlay. Extended lifespan and minimal maintenance provide superior long-term ROI for temporary liquid storage infrastructure.

Rapid Deployment & Efficient Installation: Perfected bolted design allows quicker setup of essential holding tank infrastructure, crucial for meeting project timelines and operational demands.

Versatile Design & Scalability: Extensive project history enables a wide range of sizes and configurations, tailored for diverse liquid types, volumes, and temporary storage functions.

Experience in Action: Global Industrial & Wastewater Projects

Center Enamel's distinction as an experienced China Epoxy Coated Steel Tanks manufacturer for secure holding tanks is powerfully demonstrated through our extensive portfolio of successful global industrial and wastewater projects:

Industrial Wastewater and Biogas Projects: Numerous large-scale projects, such as Muyuan Group Aquaculture Wastewater Projects (e.g., Suining farms, Jiangsu Lianyungang, total capacities up to 17,962m³ and 10,360m³) and various food waste treatment facilities, directly involve the temporary containment of aggressive industrial and organic liquid wastes, showcasing our tanks' exceptional resilience for holding purposes within larger systems.

Municipal and Industrial Water Storage: Our involvement in significant projects for general water supply and industrial process water exemplifies our experience in designing and constructing large-volume, highly reliable liquid storage solutions for various sectors, directly applicable to secure holding tank requirements.

Diverse Global Reach: Our projects span over 100 countries across 6 continents, showcasing adaptability to various local regulations, climates, and logistical complexities, particularly relevant for diverse liquid management operations worldwide.

These diverse projects consistently reinforce Center Enamel's experienced standing in providing robust, reliable, high-performance Epoxy Coated Steel Tanks suitable for the challenging and crucial demands of secure temporary containment of various liquids.

Center Enamel: An Experienced China Epoxy Coated Steel Tanks Manufacturer

Center Enamel's distinction is built upon unparalleled expertise, advanced capabilities, and unyielding commitment to secure liquid holding solutions:

Over 30 Years of Dedicated Experience: Signifies accumulated knowledge and continuous process refinement in containment solutions for diverse and often highly corrosive liquids.

Mastery of Global Standards: Ensures adherence to stringent quality standards, including ISO 9001, LFGB, FDA, and BSCI, reflecting robust manufacturing processes suitable for critical liquid containment.

Advanced Manufacturing & Coating Refinement: Nearly 150,000 sqm facilities with automated lines and perfected FBE coating ensure superior performance for holding tanks, including specialized chemical resistance for reliability.

Proven Global Footprint: Installations in over 100 countries provide invaluable insights into diverse local conditions, regulatory requirements, and challenges, enabling tailored solutions for liquid management worldwide.

Comprehensive Engineering & Support: Full spectrum of services from expert consultation to installation guidance and after-sales support ensures seamless project execution and long-term security.

Unwavering Commitment to Quality and Continuous Improvement: Dedication to critical liquid infrastructure, continually leveraging experience for innovation and enhanced reliability.

Partnering with an Experienced Leader for Secure Liquid Holding

Choosing an experienced China Epoxy Coated Steel Tanks manufacturer is fundamental for secure, reliable, and compliant temporary containment of various liquids. Center Enamel offers an exceptional product and a comprehensive partnership, distinguished by decades of specialized knowledge, cutting-edge technology, and dedication to robust, efficient, and long-lasting holding tank solutions that optimize operations and protect the environment globally. Our established experience and global reach are your assurance of unparalleled performance and complete peace of mind.

#fusion bond epoxy tank#fusion bond epoxy coating tank#epoxy coated tank#Epoxy Bolted Tank#Fusion Bonded Epoxy Coated Steel Tank

0 notes

Text

Enterprise AI in Financial Operations: Automating Risk Analysis and Compliance

Enterprise AI in Financial Operations: Automating Risk Analysis and Compliance

Enterprise finance has long grappled with the tension between control and agility. Modern businesses demand real-time decision-making, while regulators impose increasingly stringent reporting frameworks. Into this paradox enters AI in enterprise finance operations, not merely as a technical solution, but as a foundational shift in how financial systems interpret risk and compliance.

The shift is neither linear nor one-size-fits-all. Enterprise artificial intelligence functions best when it's embedded as a mindset—an operational layer that evolves alongside finance systems, not above them.

Beyond Automation: Intelligence-Driven Risk Posture

Traditional automation reduces effort; artificial intelligence transforms decision-making. In risk analysis, AI models interpret vast volumes of transaction data, contract terms, and real-time financial feeds—far beyond human capabilities. This recalibrates how risk is perceived: not as a reactive process, but as a continuously learning mechanism.

A financial institution, for example, may deploy enterprise AI development frameworks that detect anomaly clusters across regions, currencies, and time zones—flagging suspicious trends before they become material losses.

Such capabilities rely on a robust AI tech stack, one that integrates:

Natural language processing for contract analysis

Predictive modeling for market exposure

Deep learning for fraud detection patterns

Here, AI in enterprise finance operations is not deployed as a discrete tool but as a systemic transformation of how financial intelligence is gathered, validated, and acted upon.

Compliance as a Living Framework

Compliance is often viewed as a lagging function—driven by checklists, forms, and late-stage audits. AI, however, repositions compliance as a dynamic entity.

With tailored enterprise AI tech stack integrations, organizations monitor shifting regulations (such as MiFID II or Basel IV) in near-real time. AI agents ingest regulatory updates, assess internal policy impacts, and automatically suggest control adjustments.

These workflows not only accelerate compliance cycles but also reduce legal exposure. Using enterprise artificial intelligence, audit trails are digitally preserved, versioned, and explainable—addressing transparency mandates often outlined by regulators.

This outcome stems from the integration of context-aware AI systems. Every risk signal, policy clause, or model drift is automatically mapped to its compliance impact—establishing an always-on control environment.

Architectural Integrity: Why AI Implementation in Business Fails Without Design

Implementing AI without evaluating and updating the existing architecture can lead to expensive setbacks. Success in AI in enterprise finance operations depends on three intersecting readiness layers:

Data readiness: Clean, labeled, and contextual datasets

Integration readiness: ERP, CRM, and legacy system interoperability

Governance readiness: Ethical AI protocols, explainability rules, and model traceability

The enterprise AI tech stack must be modular yet compliant. For example, financial organizations must balance on-premise constraints with cloud acceleration. A flexible stack ensures sensitive models (e.g., credit risk) operate in secure environments, while less critical models (e.g., expense categorization) leverage cloud AI engines.

In short, ai implementation in business is not just a deployment—it’s a restructuring of infrastructure, compliance models, and data hierarchies.

Risk Classification Through Contextual Intelligence

Risk no longer exists in isolated silos. Currency volatility in one region, combined with a change in interest rates elsewhere, may affect liquidity buffers globally. AI interprets these linkages.

Through enterprise AI development, systems are trained to create cross-contextual linkages: a pattern in procurement anomalies, when matched with delayed receivables and unusual cash flow movements, could signal internal fraud or third-party compromise.

AI excels at this form of contextual synthesis. Unlike rules-based engines that trigger on thresholds, AI learns relationships between financial elements. It learns when rules no longer apply—making it indispensable in fast-evolving regulatory and market contexts.

Human Oversight, Machine-Driven Execution

The goal is not human replacement but elevation. In enterprise finance, AI handles scale and speed, while humans guide judgment and escalation.

Consider how AI in enterprise finance operations improves KYC (Know Your Customer) checks. While algorithms scan vast repositories—government sanctions lists, financial records, news sentiment—humans decide final onboarding outcomes.

This synergy ensures compliance remains defensible and adaptable. With the right enterprise AI tech stack, businesses maintain both speed and ethical integrity.

The Future of Finance Isn’t “AI-Powered”—It’s AI-Native

Financial institutions that treat AI as an enhancement rather than a foundational layer are likely to fall behind. Emerging models are designed AI-first—relying on real-time ingestion, adaptive algorithms, and intelligent orchestration of internal systems.

To prepare for this shift, organizations must:

Prioritize enterprise artificial intelligence in transformation roadmaps

Invest in enterprise AI development strategies tailored to risk, compliance, and finance-specific KPIs

Align architecture with a purpose-built Ai tech stack

Design governance models that account for algorithmic accountability

In this AI-native future, enterprise finance will no longer manage risk and compliance through static reports and quarterly dashboards but through continuous intelligence that adapts as the business does.

Conclusion

AI is no longer experimental in finance; it is existential. For organizations seeking to modernize risk postures, ensure regulatory adherence, and future-proof operations, AI implementation in business is no longer optional—it’s foundational. When built on the right enterprise AI tech stack and guided by contextual design principles, AI in enterprise finance operations becomes the unseen architecture of secure, scalable, and compliant finance.

#enterpriseAIdevelopment#Aitechstack#enterpriseAItechstack#enterpriseartificialintelligence#aiimplementationinbusiness#AIinenterprisefinanceoperations

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description PowerMax Fitness JogPad-3 Treadmill for Home-Office Use Smart Wireless wrist-worn controller High-performance motor Sleek and stylish designed Multi-functional Desk Modular Handle Low-impact Deck Powerful Performance and Top Speed: With the powerful 4 HP Peak DC Motor at its core, the PowerMax JogPad-3 motorized treadmill empowers you to reach your fitness peak effortlessly. Seamlessly transition between speeds ranging from 1.0 to 12 km/hr, allowing you to tailor your workout to your preferred pace, whether it's a leisurely walk, an invigorating jog, or an intense sprint. Experience the freedom to challenge yourself and push your limits, all within the comfort of your own home. Spacious Running Area with Impact Reduction: The 5-layer Anti-skid, diamond-textured running belt on an 18mm low-maintenance phenolic-coated deck ensures durability and optimal performance. The spacious 1050x420mm / 41.4 x 16.5 inches running surface, paired with a smooth, low-friction, and anti-slip running belt, ensures a delightful workout experience while protecting your joints. Real-Time Cardiovascular Insights: Stay informed with the Dual LED Display showcasing real-time data on Time, Speed, Distance, and Calories. Seamlessly integrate your fitness journey with the 12 pre-set workout programs and 3 target-based modes. Connect your devices effortlessly with Bluetooth connectivity and experience a truly connected workout. Wristband Remote Controller: Connectivity Take charge of your workout effortlessly with the Jogpad-3's wristband remote controller, allowing you to adjust settings and monitor your progress with ease. Additionally, stay entertained and connected by conveniently placing your iPad or mobile device in the built-in holder, ensuring access to your favorite entertainment or fitness apps while you exercise. With a maximum user weight capacity of 110 kg,PowerMax Treadmill accommodates various users For enhanced longevity and performance, Powermax recommends factoring in an additional 30KG buffer for Running Consider your weight as a reference point for selecting the treadmill's capacity For example, if your weight is 80 kg or less, a 110 kg max capacity treadmill is suitable for Running [ad_2]

0 notes

Text

How to Build a House in Bangalore: A Step-by-Step Guide

Bangalore, with its growing infrastructure, job opportunities, and pleasant climate, is a dream city for many homeowners. Building a house here can be both exciting and overwhelming, especially if you're doing it for the first time. With the guidance of a trusted partner like House Construct, the process becomes much easier. This guide walks you through each step to help you confidently plan and build a home in Bangalore.

Step 1: Define Your Budget

Before starting, it’s important to fix a clear and realistic budget. Consider land cost, construction expenses, legal fees, architect charges, approvals, and finishing work. Always keep a small buffer amount for unexpected costs.

Step 2: Choose the Right Plot

Location plays a huge role in your lifestyle and future property value. Select a plot that has:

Proper road access

Water and electricity supply

Proximity to schools, hospitals, and your workplace

Clear legal titles

Make sure to verify documents and zoning regulations with local authorities.

Step 3: Hire a Good Architect or Designer

An architect helps translate your dream into a practical plan. They design the floor layout, elevation, ventilation, and aesthetics according to your needs, while ensuring compliance with building laws. A good architect also helps with Vastu, if required.

Step 4: Get Plan Approvals

Once your house plan is ready, you need to get approvals from the local authority—BBMP, BDA, or Panchayat—depending on your plot location. This may include:

Building Plan Approval

Commencement Certificate

NOC from Fire and Electricity Departments (for bigger projects)

Step 5: Hire a Reliable Contractor

This is a crucial step. You need someone experienced, transparent, and committed to quality. The top construction company in bangalore will handle everything from materials to manpower, and deliver your home on time. Make sure you sign a contract mentioning scope of work, cost estimate, deadlines, and payment terms.

Step 6: Begin Construction – Stage by Stage

The actual building process includes:

Foundation Work: Excavation, footing, and RCC base

Structure: Columns, beams, slabs, and walls

Roofing and Plastering: Waterproofing, wall finishing

Plumbing and Electrical: Internal pipe fittings, wiring, switchboard points

Flooring and Tiling: Based on your budget and taste

Doors and Windows: Wooden, UPVC, or aluminium

Painting and Fixtures: Final paint coats, lights, fans, taps, etc.

Throughout construction, regular site visits and supervision are important to ensure quality.

Step 7: Interior Design and Landscaping

Once construction is complete, you can focus on interiors like modular kitchens, wardrobes, lighting, and furnishings. Landscaping the garden or terrace adds a refreshing touch to your new home.

Step 8: Final Inspection and Handover

Before moving in, do a final check for:

Cracks or seepage

Proper wiring and plumbing

Locking systems and window fittings

Paint finish and flooring alignment

Once you're satisfied, collect the completion certificate and utility connections.

Conclusion

To build house in Bangalore successfully, you need the right knowledge, support, and professionals by your side. With planning and the right steps, you can create a beautiful home that fits your budget and lifestyle.

House Construct has helped hundreds of families turn their dream homes into reality with care, clarity, and commitment. If you want to build a home Bangalore without stress, House Construct is the name you can trust.

Known for quality service and timely delivery, House Construct continues to be a top choice among homeowners in the city. Whether you're starting from scratch or need expert help midway, House Construct ensures a smooth journey from blueprint to brick.

#top construction company in bangalore#house design#bangalore best builders#building contractors in bangalore#house construction#costruction services in bangalore#best home builders in bangalore

0 notes

Text

How to Design a Restaurant Interior That Customers Never Want to Leave

In today’s competitive restaurant industry, exceptional food alone isn’t enough to guarantee success. The dining experience has evolved to encompass not just taste, but ambiance, comfort, and visual appeal. A thoughtfully designed restaurant interior plays a major role in attracting customers, encouraging them to stay longer, and inspiring return visits.

1. Know Your Brand and Audience

Before diving into design elements, start with clarity about your brand and your target customers. Is your restaurant upscale and elegant, or casual and family-friendly? Is it a trendy café targeting millennials, or a fine-dining spot for professionals?Your interior should reflect your identity from color palette and materials to lighting and artwork. Every design choice must align with the story you want to tell. For example, a farm-to-table restaurant may focus on earthy tones, reclaimed wood, and plant-filled corners, while a modern sushi bar may lean toward clean lines, minimalism, and LED lighting.

2. Plan for Functional Flow

A stunning design won’t matter if your space isn’t functional. A smart layout improves staff efficiency and enhances the customer experience. Tables should be spaced to allow privacy while still optimizing your seating capacity. A clear flow from the entrance to the dining area, restrooms, and kitchen minimizes traffic congestion.Consider accessibility too—wheelchair-friendly routes, well-placed signage, and sufficient space between tables are must-haves in a modern dining space.

3. Use Lighting to Set the Mood

Lighting is one of the most underrated yet powerful tools in interior design. It sets the tone for your guests’ experience. Warm, soft lighting creates a cozy, inviting atmosphere perfect for romantic dinners or evening gatherings. Brighter lighting works well in fast-casual or breakfast venues where energy and visibility are important.Mix ambient lighting with accent lighting to highlight architectural features or create focal points. Decorative fixtures can become part of the branding—think chandeliers, hanging Edison bulbs, or quirky custom pendants.

4. Select Comfortable & Stylish Furniture

Comfort influences how long your customers stay—and how likely they are to return. Choose seating that matches your theme but doesn't sacrifice ergonomics. Upholstered chairs or cushioned booths offer long-term comfort, encouraging guests to linger and order more.Use a mix of table setups (2-seaters, 4-seaters, and communal tables) to accommodate different groups. Modular or movable furniture adds flexibility for events or peak hours.

5. Design Instagram-Worthy Spots

In the age of social media, creating photo-worthy corners can turn your diners into promoters. Think of a statement wall, neon signage, a bold mural, or an aesthetic food presentation area. When customers take and share photos of your space, you gain free promotion and online visibility.Consider adding your brand hashtag or social handle subtly in these areas to encourage tagging.

6. Incorporate Acoustics for Comfort

No one enjoys shouting across the table just to be heard. Poor acoustics can make even the most beautiful space feel stressful. Use soft furnishings like upholstered seats, curtains, rugs, or acoustic panels to absorb sound and reduce echo. Thoughtfully placed partitions or greenery can also help buffer noise.A quieter environment leads to more relaxed conversations and longer visits.

7. Clean Design = Clean Perception

Customers associate cleanliness with quality. A clutter-free, well-maintained space speaks volumes about your professionalism. Use clean lines, intentional decor, and consistent design elements (like matching menus and signage) to build trust and visual harmony.Keep walls, floors, and furniture spotless—and choose materials that are easy to maintain.

8. Personalize the Experience

Add unique touches that make your restaurant memorable. This could include artwork from local artists, décor that reflects your culture, or a signature scent throughout the space. Handwritten chalkboard menus, vintage mirrors, or custom-made furniture show attention to detail and authenticity.These elements help differentiate your restaurant and create emotional connections with guests.

Final Thoughts

Creating a restaurant interior that customers never want to leave requires a blend of functionality, aesthetics, and emotional appeal. When done right, design enhances the dining experience, encourages word-of-mouth marketing, and builds lasting customer loyalty.At Jonathanwangdesign.com, we don’t just design spaces—we create stories that people remember. Whether you're opening a new restaurant or revamping an existing one, our team brings vision, creativity, and strategy to every project.Ready to craft an unforgettable dining space? Let’s talk.

0 notes

Text

3BHK & Villa Interior Design Costs in Hyderabad (2025 Guide)

Interior Design Cost Guide for 3BHKs and Villas in Hyderabad – 2025 Edition

Planning to transform your 3BHK or villa in Hyderabad but unsure about the cost? You’re not alone. Interior design pricing can vary widely depending on your preferences, space, and the level of luxury you seek.

At Luxe Designs, we believe in complete transparency. This 2025 cost guide will help you understand your options, set realistic budgets, and make informed decisions before hiring an interior designer.

What Factors Influence Interior Design Costs?

Interior design costs vary based on:

Type of home: 3BHK apartment or independent villa

Scope of work: Modular interiors vs. full home transformation

Design style: Minimalist, modern, luxury, or classic

Material quality: Basic, premium, or ultra-luxury finishes

Customization: Standard modules vs. tailor-made furniture

Cost Breakdown for a 3BHK Interior in Hyderabad (2025)

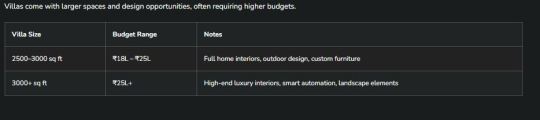

Interior Design Costs for Villas in Hyderabad

Villas come with larger spaces and design opportunities, often requiring higher budgets.

Room-Wise Interior Cost Estimates

How to Plan Your Budget Wisely

Prioritize spaces based on how frequently you use them.

Mix and match premium materials with budget-friendly finishes.

Choose designers who offer modular + custom combinations (like Luxe Designs).

Keep a 10–15% buffer for final on-site adjustments.

Real Client Example: 3BHK in Gachibowli

Client Brief: Modern + budget-conscious

Budget: ₹9.5L

Scope: Modular kitchen, 3 wardrobes, false ceiling, living room décor

Timeline: 6 weeks

Result: Elegant and functional interiors with premium finishes under budget

“The Luxe Designs team transformed our house into a stylish home without overshooting our budget. The process was smooth, and the results exceeded expectations.” – Mrs. Sinha, Gachibowli

Ready to Transform Your Home?

Whether you’re planning a cozy 3BHK or a spacious villa makeover, Luxe Designs offers personalized interior solutions that match your taste and budget.

Book a Free 15-Minute Design Consultation Now

Let’s turn your vision into reality – with elegance, efficiency, and zero surprises.

read more : https://luxedesigns.ltd/interior-design-cost-hyderabad-3bhk-villa-2025/

#HyderabadBestInteriorDesigners #InteriorDesignerinHyderabad #professionalinteriordesigner #luxuryinteriordesigners #BestHomeInteriorDesignersInHyderabad #TopInteriorDesignersinKokapet #BestInteriorDesignersinKokapet, #HyderabadInteriordesignersinKokapet

0 notes

Text

Godrej Hoskote Bangalore - Premium Residential Hub

Godrej Hoskote Bangalore is expanding in every direction, but the eastern corridor especially Hoskote is fast becoming a favorite for homebuyers and investors. If you are someone who dreams of a beautiful contemporary home with greenery around it and with fast access to schools, offices, shopping zones, then it could be the place to be. This residential project by Godrej Properties is an embodiment of smart design, solid infrastructure, and green living. The specs are strategic, the layout is thoughtful, while the experience is tailored to urban dwellers' needs today: tranquility, safety, community, and convenience.

Prime Location

It is a major micro-market in East Bangalore that is fast becoming popular due to ongoing infrastructure development and the nearness of major employment centers.

Benefits at the location include:

Near NH-75

Smooth connectivity towards Whitefield, KR Puram

Easy access to the airport via well-maintained highways

Close to Peripheral Ring Road with Metro linkages

Presence of international schools, specialty hospitals, and tech parks nearby

Residents get the benefit of space and solace coupled with good prime urban connectivity.

Comfort and Smart Living

All the Godrej Hoskote Bangalore apartments are designed for comfort, openness and functionality. Whether a 3 or 4 BHK layout is picked, the homes have a smart layout to make life a little easier and enjoyable.

Key highlights include:

Broad balconies with beautiful vistas

Natural ventilation along with large windows

Modular kitchen fitted with latest appliances

Bathroom fittings of branded make with storage design

Smart wiring pre-installed for future upgrades

Vastu-graced orientation so that energy stays in balance

These homes make ideal settings for a modern family-whether soaking in tranquil family time or persevering through work-from-home days.

Sustainability at the Core

In keeping with its well-established green building design principles, Godrej Properties classifies Godrej Hoskote a good place to live-as an environmentally conscious option for a buyer with an eye toward what lies ahead.

The features include:

Solar lighting in public spaces

Waste segregation and composting systems

EV charging facilities

Low-heat paving and buffers of native trees

Not only that, but also low upkeep cost in the long term.

A Smart Investment Opportunity

Thanks to Hoskote’s rising profile, investing in Godrej Hoskote offers great potential. The area is already witnessing price appreciation and demand due to better roads, proposed metro lines, and IT park expansions.

Why it’s a great investment:

Developed by trusted brand Godrej Properties

RERA-approved and compliant with regulations

Increasing rental demand and resale value

Competitive pricing for 3 & 4 BHK spacious units

Peaceful setting with city access

Whether you plan to live or invest, this project offers lasting value.

Conclusion

The way you buy a home is literally the way you improve your lifestyle, comfort and peace of mind, with an offer of all these at Godrej Hoskote Bangalore. The project offers all these plus a good home in a serene place with thoughtful amenities in a trustworthy name. The project is built with green living, smart infrastructure and a stronger community. If you have been looking for your next home in Bangalore, it's time to stop looking and start living.

0 notes