#mini batching plant price

Explore tagged Tumblr posts

Text

Low Price Concrete Batching Plant: Cost-Effective Solutions for Small Projects

When it comes to small-scale construction projects, finding the right concrete batching plant that balances cost and performance is essential. Here, we'll explore the features and benefits of low price concrete batching plants, particularly focusing on mini mix concrete batching plants and the popular HZS25 model.

Cost-Effective Solutions Low price concrete batching plants, such as mini mix concrete batching plants, offer affordable options for small projects like residential buildings, rural roads, and precast component production. These plants are designed to provide high-quality concrete without the high costs associated with larger batching plants. Mini Mix Concrete Batching Plant Mini mix concrete batching plants are compact and efficient, making them ideal for projects with limited space or budget. They typically have a production capacity of under 20 m³ per hour, which is sufficient for small-scale operations. These plants are known for their: Portability: Easy to move and set up at different sites. Low Maintenance: Simple structure and easy operation reduce maintenance costs. Versatility: Can produce various types of concrete mixes. HZS25 Concrete Batching Plant The HZS25 concrete batching plant is one of the smallest concrete mixing plants with a capacity of 25m³/h. It's perfect for small projects and those with smaller budgets. Key features include: High Efficiency: Despite its small size, it delivers efficient concrete production. Easy Installation: Quick setup time minimizes downtime before production starts. Competitive Price: Available at a lower price point compared to larger models. Why Choose These Plants? Choosing a low price concrete batching plant doesn't mean compromising on quality. These plants: Reduce Initial Investment: Lower purchase cost makes them accessible for small businesses and contractors. Offer Flexibility: Suitable for both stationary and mobile applications. Meet Specific Needs: Customizable configurations allow you to tailor the plant to your project requirements. When selecting a concrete batching plant, consider your specific project needs, budget constraints, and long-term goals. For small-scale operations, a low price concrete batching plant like the HZS25 or a mini mix plant can provide excellent value and performance.

#mini mix concrete batching plants#concrete batching plant#low price concrete batching plant#HZS25 concrete batching plant

0 notes

Text

Mini Concrete Plant Price

The mini concrete plant price depends on several factors, including production capacity, equipment quality, brand and supplier. Generally speaking, the price of a set of mini concrete batching plant ranges from about a few thousand to tens of thousands of dollars. The specific price needs to be determined according to the actual demand and budget.

Regarding the relationship between price and quality, low price does not necessarily mean bad quality. In the industry of concrete batching plant equipment, the low price may originate from the difference in the capital, manpower and technology invested by the enterprise, and not all low-priced enterprises must sacrifice quality. Therefore, when choosing a mini concrete batching plant, you should not just look at the price, but also consider the performance of the equipment, the quality of the materials used, the accuracy of the production process and other important aspects.

When deciding to buy a mini concrete batching plant, the following points are worth noting: Equipment performance: Choose the equipment with stable performance, high production efficiency and good mixing quality to ensure the project quality and construction progress. Material quality: Pay attention to the quality of the material used in the equipment, choose high-quality steel, wear-resistant materials, etc., in order to improve the durability and service life of the equipment. Production process: Choose manufacturers with advanced production process and strict quality control system to ensure the quality and reliability of the equipment. Brand reputation: Choose manufacturers with good brand reputation to get better after-sales service and technical support.

Although the cheap price may attract you, quality and performance are also very important considerations. Choosing good quality equipment can ensure high productivity, long service life and reduce maintenance and replacement costs. Therefore, when choosing a concrete batching plant, don't just look at the price, you need to consider a number of factors such as price, performance, quality, brand and other factors to choose a cost-effective product. At the same time, you can consult with professionals before purchase to understand the price level in the industry and equipment performance and other information, in order to make a more informed decision.

This resource is from http://www.batchingplantng.com/haomei-news/mini-concrete-plant-price.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

#mini concrete plant price#mini concrete plant#batching plant#concrete plant#concrete batching plant

0 notes

Text

Concrete Batching Mixing Plants | Manufacturers in India | Navya Equipments | +919855597851

#concrete batching plant#tractor transit mixer manufacturers#automatic concrete plants#tractor transit mixer#automatic concrete batching plants#compact concrete batching plants#manufacturers of tractor transit mixers#concrete batching plant manufacturers#mini concrete transit mixer#youtube#navyaequipments#construction equipment manufacturers in India#cement silo manufacturers#price of concrete batching plants

0 notes

Text

Mini Concrete Plant Diesel Engine - Atlas Equipments

See photos of mini concrete plant Diesel engine. Contact us to get a concrete batching plant at an affordable price. Leading exporter of construction equipment.

0 notes

Text

New Trends in Business Card Printing in the UK

In today's fast-paced business world, first impressions matter more than ever. Business cards remain a crucial tool for networking, but they have evolved significantly in recent years. With new printing technologies and design innovations, businesses in the UK now have more creative options to make their cards stand out. Here are some of the latest trends in business card printing:

1. Eco-Friendly Business Cards

Sustainability is becoming a key concern for businesses. Many companies are now opting for recycled paper, biodegradable materials, and soy-based inks for their business cards. Some providers even offer plantable business cards infused with seeds, allowing recipients to grow a plant after use.

2. Premium Finishes for a Luxurious Touch

High-end finishes such as soft-touch lamination, foil stamping, and embossed details are gaining popularity. These features add a sense of elegance and professionalism, making a lasting impression on potential clients.

3. Minimalist and Clean Designs

Simple, clutter-free designs with bold typography and strategic use of white space are trending. This approach ensures clarity, enhances readability, and portrays a modern and professional image.

4. NFC and QR Code Integration

Smart business cards with embedded NFC (Near Field Communication) chips and QR codes are revolutionizing networking. These features allow users to instantly share contact details, social media profiles, or portfolio links with a simple tap or scan, reducing the need for physical storage.

5. Unique Shapes and Sizes

Traditional rectangular business cards are being replaced with more creative options. Die-cut designs, square cards, or rounded edges help businesses stand out and create a memorable brand identity.

6. Spot UV Coating for a Subtle Shine

Spot UV printing adds a glossy effect to specific areas of the card, such as logos or text. This technique enhances contrast and texture, giving a high-quality, premium feel.

7. Multi-Purpose Business Cards

Business cards are no longer just about contact details. Many UK companies are incorporating functionality, such as doubling as loyalty cards, appointment reminders, or mini brochures, adding more value for the recipient.

8. Digital Printing for Cost-Effective Customization

With advancements in digital printing, businesses can now print high-quality cards in small batches at affordable prices. This allows for personalized touches, such as different designs for team members or seasonal updates.

Final Thoughts

The evolution of business card printing in the UK provides businesses with numerous creative opportunities to make a lasting impression. Whether you choose an eco-friendly approach, a tech-integrated design, or a luxurious finish, staying updated with these trends will ensure your business card remains an effective marketing tool in 2024 and beyond.

0 notes

Text

Comprehensive Guide to Asphalt Drum Mix Plants: Types, Benefits, and Applications

Introduction

An asphalt drum mix plant is essential for producing high-quality asphalt used in road construction. These plants ensure a continuous and efficient mixing process, allowing for large-scale asphalt production. With advancements in technology, asphalt drum mix plants have evolved to meet the demands of modern infrastructure projects, offering superior performance, energy efficiency, and environmental sustainability.

What is an Asphalt Drum Mix Plant?

An asphalt drum mix plant is a specialized piece of equipment used to produce hot mix asphalt. Unlike batch mix plants, these machines operate continuously, blending aggregates, bitumen, and filler materials in a rotating drum. This process ensures a steady output, making drum mix plants ideal for large-scale road construction projects.

Key Components of an Asphalt Drum Mix Plant

Cold Aggregate Feeder Bins – Stores and regulates the flow of different aggregate sizes.

Conveyor System – Transfers aggregates from bins to the drying drum.

Drying & Mixing Drum – Heats and mixes aggregates with bitumen to form asphalt.

Burner System – Provides controlled heating for efficient asphalt production.

Bitumen Storage & Heating System – Maintains bitumen at the required temperature for mixing.

Mineral Filler Unit – Adds filler materials such as lime or cement for improved mix quality.

Dust Collection System – Controls emissions and enhances environmental safety.

Control Panel – Automates the plant operation for precision and efficiency.

Types of Asphalt Drum Mix Plants

Depending on mobility and production requirements, asphalt drum mix plants are classified into:

Stationary Asphalt Drum Mix Plant

Fixed installation for large-scale projects.

High production capacity with a permanent setup.

Suitable for highway construction and long-term road projects.

Mobile Asphalt Drum Mix Plant

Easily transportable for on-site mixing.

Ideal for temporary and remote location projects.

Compact design with integrated components for quick setup.

Portable Mini Asphalt Drum Mix Plant

Designed for small-scale road maintenance projects.

Lower output capacity but highly efficient for localized applications.

Requires minimal space and is easy to operate.

Advantages of Asphalt Drum Mix Plants

Investing in drum mix plant provides several benefits that enhance construction efficiency and cost-effectiveness:

Continuous Asphalt Production

Unlike batch mix plants, drum mix plants offer uninterrupted mixing and output.

Ensures consistent supply for high-demand projects.

Energy Efficiency

Advanced burner systems optimize fuel consumption.

Heat recovery systems reduce energy wastage.

High-Quality Asphalt Mix

Precise control over aggregate and bitumen blending.

Uniform heating results in superior mix durability.

Cost-Effective Operations

Lower maintenance requirements compared to batch plants.

Reduced labor costs due to automated control systems.

Eco-Friendly Design

Modern dust collection systems minimize air pollution.

Utilization of recycled materials improves sustainability.

Applications of Asphalt Drum Mix Plants

Asphalt drum mix plants are widely used in various infrastructure projects, including:

Highways & Expressways – Ensures smooth, durable roads for heavy traffic.

Urban Roads & Streets – Provides high-quality pavement solutions for cities.

Airport Runways – Produces asphalt mix suitable for high-load-bearing surfaces.

Industrial & Commercial Pavements – Used for parking lots, driveways, and industrial complexes.

Bridge & Tunnel Roadways – Delivers asphalt for structures requiring strong adhesion and durability.

Factors to Consider When Choosing an Asphalt Drum Mix Plant

Before purchasing an asphalt drum mix plant price, it is essential to evaluate several factors:

Production Capacity – Choose a plant that aligns with your project requirements.

Mobility Needs – Decide between stationary, mobile, or portable configurations.

Fuel Efficiency – Look for energy-efficient models with optimized burner systems.

Automation Level – Advanced control panels improve precision and reduce human intervention.

Environmental Compliance – Ensure the plant meets emission control regulations.

Maintenance & Durability – Opt for machines with long-lasting components and minimal servicing needs.

Future Trends in Asphalt Drum Mix Plant Technology

The asphalt industry is continually innovating to enhance efficiency and sustainability. Some emerging trends include:

AI-Driven Automation – Smart control systems for real-time monitoring and optimization.

Recycled Asphalt Mix Technology – Increased usage of reclaimed asphalt pavement (RAP) to reduce material costs and environmental impact.

Low-Emission Burners – Advanced combustion technology to minimize air pollutants.

Modular Plant Designs – Enhancements for quick assembly, dismantling, and transportation.

IoT Integration – Remote monitoring for performance tracking and predictive maintenance.

Conclusion

youtube

An Asphalt Drum Mix Plant is a critical investment for road construction companies seeking efficiency, cost savings, and high-quality asphalt production. Whether for large-scale highway projects or localized road maintenance, selecting the right plant ensures optimal performance and longevity. With technological advancements, modern asphalt drum mix plants continue to evolve, offering more energy-efficient, eco-friendly, and automated solutions to meet the demands of the construction industry.

1 note

·

View note

Text

A Complete Guide to Mini Concrete Plant and Mini Portable Batching Plant

Complete guide to mini concrete plants and portable batching plants. Explore batch mix plant prices, concrete batch mix plant specs, and compact solutions for your construction needs.

0 notes

Text

Top Evaporated Milk Plant in India

At Indian Trade Bird, our prices on evaporated milk plants are the lowest. Cream Separators, Milk Boilers, Mini Dairy Plants, Batch Milk Pasteurizers, Powder Plants, Dairy Pumps, Milk Homogenizers, Chilling Plants, Curd Making Machines, Ghee Plants, Milk Centrifuge Machines, Egg Pasteurization Machines, Can Drip Saver, Skid Mounted Process Modules, Curd Separators, Soya Curd Machines, and many more are among the products of which we are the foremost manufacturer, supplier, exporter, and retailers. Half as much area is occupied by evaporated milk as by its nutritionally comparable fresh milk. Evaporated milk is almost equal to fresh milk when combined with a corresponding amount of water (150%). Because of their durable design and minimal maintenance requirements, our products are of the highest caliber and are well-liked by our customers. Increased bulk density is the purpose of it. Because of our machines' exceptional durability, functionality, and efficiency, they are in high demand in the market.

0 notes

Text

The Best Concrete Batching Plants for 2023

Concrete batching plants are essential equipment for the construction industry. They weigh and mix the ingredients of concrete, including cement, aggregates, water, and admixtures, to produce a uniform and consistent concrete mix.

There are a variety of different types of concrete batching plants available, each with its own advantages and disadvantages. When choosing a concrete batching plant, it is important to consider the size and complexity of the project, the required production rate, and the budget.

Here are some of the best concrete batching plants for 2023:

Elkon Concrete Batching Plants

Elkon is a leading manufacturer of concrete batching plants. Their plants are known for their high quality, reliability, and efficiency. Elkon offers a wide range of concrete batching plants to choose from, including stationary plants, mobile plants, and compact plants.

Meka Concrete Batching Plants

Meka is another leading manufacturer of concrete batching plants. Their plants are known for their innovative design and features. Meka offers a variety of concrete batching plants to choose from, including stationary plants, mobile plants, and self-loading plants.

Ajax Concrete Batching Plants

Ajax is a well-known manufacturer of concrete batching plants in India. Their plants are known for their affordability and durability. Ajax offers a variety of concrete batching plants to choose from, including stationary plants, mobile plants, and mini plants.

Nilkanth Concrete Batching Plants

Nilkanth is another popular concrete batching plantmanufacturer in India. Their plants are known for their quality and performance. Nilkanth offers a variety of concrete batching plants to choose from, including stationary plants, mobile plants, and twin shaft plants.

Besser Concrete Batching Plants

Besser is a leading manufacturer of concrete batching plants in the United States. Their plants are known for their reliability and ease of use. Besser offers a variety of concrete batching plants to choose from, including stationary plants, mobile plants, and compact plants.

These are just a few of the many great concrete batching plants available on the market. When choosing a concrete batching plant, it is important to do your research and compare different models before making a decision.

Here are some factors to consider when choosing a concrete batching plant:

Type of plant: There are three main types of concrete batching plants: stationary, mobile, and compact. Stationary plants are the most common type and are typically used for large construction projects. Mobile plants are more portable and can be moved from one job site to another. Compact plants are ideal for smaller projects.

Production rate: The production rate of a concrete batching plant is measured in cubic meters per hour. It is important to choose a plant that has a production rate that meets the needs of your project.

Features: Concrete batching plants come with a variety of features, such as automatic batching, electronic weighing, and computerized control systems. Choose a plant with the features that are important to you.

Price: Concrete batching plants can range in price from tens of thousands of dollars to hundreds of thousands of dollars. It is important to set a budget before you start shopping.

Once you have considered all of these factors, you can start shopping for a concrete batching plant. Be sure to compare prices from different manufacturers and get quotes from multiple vendors before making a purchase.

#concrete batching plant#concrete batching plantmanufacturer in India#concrete batching plants#manufacturer of concrete batching plants#Nilkanth Engineering Works#types of concrete batching plants

0 notes

Text

Oh, it's poffins for me, hands down!

I know, I know. Very basic bitch Sinnoh response. But the thing about poffins is they're so ADAPTABLE. I have anywhere from 40-60 Pokemon I feed daily, and I need to be able to make treats with all of their preferences in mind-- ideally in large batches so I'm not sitting there making 40 different treats every week.

I mostly feed ghosts, and among them it's mostly Misdreavus line, but I also have an Aegislash, two Mimikyu, a Rotom, breeding Murkrow and a Pidgeot, a Ninetales, and a Phantump, and even more if I'm trying to keep my Litwick from draining too much life energy, so I've got a range from the amorphous group to avians to plant types to steel type to mammalian. And... whatever Mimikyu are. If I made type-specific treats for all of them, I'd basically have an unpaid full-time job just feeding my Pokemon in the kitchen!

(Sharing some of my poffin secrets below the cut. ;P Also some summaries of a mochi and hay biscuit recipe.)

So anyways, the nice thing about poffins is that they're really customizable, and essentially you're making a loaf of bread when you're making it for so many Pokemon at once. (You could theoretically make mini muffins for them, but I find a loaf of bread easier to portion and more forgiving if I forget it's rising, or forget it's in the oven.)

I can't have wheat, personally, so I tend to make the Pokemons' foods out of flour I already have on hand! Usually a wheat-free 1:1 mix with potato, rice, and tapioca. Millet flour is nice too, it's a staple in most commercial bird seed mixes so you know it's safe for the birds, it makes a very light and crumbly dough, and oat flour is good for a dense bread with extra protein and iron. Almond flour doesn't hold together very well for me, so I simply don't use it. (It's crazy expensive, anyways...)

Different flours make for lighter or heavier taste, too! By using a variety of flours, the taste and texture is something I can tailor to individuals within my stock.

For the birds and breeding ghosts especially, I'll use a recipe heavier on the eggs, for an extra helping of the protein and fats they need if they're producing eggs! The birds also get seeds and grains added to theirs if I had the money to make them something a little more gourmet, like amaranth or quinoa or unsplit oat groats.

For the ghosts, usually I'll add in whole dried berries. Oran and cornn or haban berries for the contest lines; lum and sitrus (or more oran berries) for the battling lines. I don't really work with household companion lines, but if I did they'd probably get cornn and haban berries. Plus, I'll add whatever berry is available at the market for a good price, especially for those who like spicy or sweet berries. (I want them to ENJOY the poffins, after all!)

Nuts, I have to be careful with. The ghosts and birds can have plain almonds in their poffins, usually slivered so they don't literally bite off more than they can chew and choke on them, but I don't think they're safe for Ninetales. Unfortunately I don't trust my memory+attention span to make sure I'm not giving Ninetales the slice with nuts, so I'll usually avoid it.

A nice thing about poffins is I can also make them plain if we have a new baby or I'm fostering and don't know what flavor they like. I can make a "blank slate" loaf, with no berries or fix-ins, and let them choose from different crumbles or ''glazes'' (sans sugar, really more of a reduced berry jam) to put on top. You can also do the tiramisu method with this and dip it in 'mon-safe tea! A couple of my Mismagius like this one because we can do some kitchen witchin' and enchant it for luck or prosperity or strength or positivity, whatever we may wish to carry with us through the day!

You can also make a sort of mochi treat with rice flour, water, and berry or pokebean paste (foregoing the sugar used in human mochi, of course). But that one's a lot more labor intensive. Especially if you're milling the rice flour yourself. (This recipe probably wouldn't be good for Pokemon prone to gulping their foods rather than chewing, or with any sort of dental impairments. Smaller mochi is less likely to be choked on.)

There are also really easy recipes for making hay-based biscuits for ruminants! I haven't made them myself as I've only ever fostered Minccino a couple times, but you basically soak the hay, make it into a pulp, mash it into a mold, and bake it until it's dry! Super easy and versatile, especially if you use pre-dried berries or petals. They're tasty, healthy for them, AND can help wear down the teeth of a picky gnawer, so they're functional as well as desirable! (I'd recommend using timothy or meadow grass hay for daily treats, and if you have a gravid or baby 'mon, alfalfa provides lots of extra protein and calcium they need at those stages!)

I find myself curious, after Lady Anthea's recent post.

What are your favorite recipes for homemade treats for your Pokemon? Please be sure to specify what kind of Pokemon you have when you share.

And if you read these recipes, be sure to check the ingredients before you make them, to be sure your Pokemon truly can have them, and people are not just making things up or saying whatever they please to cause harm.

#I almost became a Pokecenter assistant and for awhile my long-term plan was to get a veterinary MD#but that changed after like 2 years and now I just have all this Knowledge.#Comes in handy taking care of my own 'mon though!#{{ IRL the mun doesn't know how to bake much so I'm kinda improvising on the poffin thing#but I have chinchillas and the hay treats are a big hit with them!

20 notes

·

View notes

Text

HZS25 Mini Mix Plant For Sale

HZS25 Mini Mix Plant For Sale

HZS25 concrete batching plant is a popular mini mix plant for sale, an ideal choice for small construction projects. Its mixing host is JS500 concrete mixer, which discharges 0.5 cubic meters each time. The mixer can meet different concrete mixing requirements and has a compact overall structure and nice appearance.

A set of HZS25 concrete mixing plant includes JS500 mixer, PLD800 two-bin…

View On WordPress

0 notes

Text

I keep seeing this guy brought up as some kind of contemporary folk hero, and it's fucking gross.

Marvin Heemeyer, the killdozer guy was a petty asshole, who gave zero fucks if his homemade tank killed people. Do not believe the goddamn internet fanboys who say he only targeted property and empty buildings. He could've murdered god- knows how many if the city hadn't evacuated most of the town once he started ramming buildings and shooting at the police.

Heemeyer was a fairly successful business owner who bought cheap land for his muffler shop, then tried to get sweeter and sweeter deals when the people he bought it from wanted to buy it back to built an enclosed concrete batch plant. The buyers agreed to accept his price even as he jacked it up at every stage. They offered him a land swap at one point for property closer to the interstate, but he kept demanding additional improvements so the deal fell apart. At that point he spread rumors about the plant to gin up support to torpedo their building permits, purely out of spite. Once the owner of the concrete plant publicly addressed allegations made by Heemeyer and other residents learned of his personal beefs with them, they lost interest in supporting him.

While some spoke favorably of him, others speak of him making threats against customers who were not satisfied Werth his work.

Also worth mentioning is that he'd been illegally dumping raw sewage into irrigation ditches for years and contaminating the town's groundwater because the building his business occupied was't connected to the municipal sewer system. He applied to be connected to the system and was approved but when the city explained that there would be a necessary $80k fee to connect the shop to nearby lines, Heemeyer refused to pay. The city offered to cover the fee for him and Heemeyer rejected their offer. Instead he continued to use the buried barrel of an old concrete mixer as an improvised septic tank and pumped it out into said ditches when it rained. Some state that this sewage setup pre-dated Heemeyer's use of the property, but this does not invalidate the fact that continuing to use it and dispose of raw sewage as he did was knowingly illegal.

His business was never threatened. The concrete plant continued to use other access roads and new construction didn't infringe on Heemeyer's property. Photos of the back of the muffler shop were taken by journalists from the road Heemeyer claimed was cut off on the day after his attack. The easement he frequently complained about was the land the city would need in order to run sewage lines to his shop, not the road to his shop. Nonetheless, he harbored a number of intense grudges because he'd destroyed much of his reputation and credibility in town through frivolous lawsuits, insincere land deals, mudslinging, and malicious trolling campaigns. He closed his own shop, sold his property, some say for 10x what he paid for it, and used that money to buy and modify the bulldozer in a building he rented from the new owner. Claims that he owned the bulldozer in order to build his own road are discredited by the fact that it was bought with money from the sale of his property.

He spent his last days outfitting the bulldozer with armor, cameras, monitors, and (counter so some claims) guns. A Ruger mini 14 rifle in .223 Remington and a Barrett .50cal sniper rifle were mounted in gunports cut in the dozer's armor. Much of the evidence of his oppression cited online stems from audio tapes Heemeyer recorded at this time, painting himself as the victim in what was essentially a suicide note. When the work was complete he rolled out with a hit list of his personal enemies. The list included the mayor, the local newspaper, people he believed had wronged him or damaged his reputation, and the Catholic church.

He repeatedly shot at the police and at people who rolled out their own heavy equipment to try and stop his massively destructive tantrum. He plowed into the library at a time when children would normally have been inside. He demolished walls people and police officers had been using for cover. He also attempted to use his mounted guns to detonate a giant propane storage tank in town. Regardless of whether its explosion could have resulted in casualties, Heemeyer seemed to believe it worth trying. He demolished homes, newly planted trees that his friends thought were keeping costumers from seeing their businesses, and numerous buildings that, as far as he knew, were still occupied.

He didn't "only target property." Granby officials did a good job of evacuating people ahead of his heavy, slow-moving vehicle. He wasn't firing "warning shots," he was taking potshots with homemade gun mounts and aiming by closed-circuit TV cameras.

Then after plowing into a building with an unexpected basement, he got stuck in a hole and killed himself rather than face consequences for his bullshit.

The legends of him being a "good man pushed too far" are horseshit and largely come from his own tapes and bloggers more interested in the myth and symbol of the man than recorded facts. Evidence supports the position that he just didn't believe laws should apply to him. Marvin Heemeyer was an avatar of entitled dude rage and I'll say as such whenever he's mentioned forever.

368 notes

·

View notes

Text

Alice In Twisted Wonderland //Yandere! Dorm Leaders X Reader//

This is a squeal to Lost Darling ( https://yandere-wishes.tumblr.com/post/612896494343831552/the-lost-darling-yandere-twisted-wonderland-x )

===========================================================

"I don't want to be amongst villains!" you cried out, tears slipping from your already glossy eyes as you tried to cover them with the palms of your hands.

"You can't help that" Grim stated as he nuzzled your side, "If you were a good person you wouldn't be here, besides we are all evil here, we've all committed a sin or two even I the great grim have blood on my paws"

The weeping continued, tears falling quicker from your bloodshot eyes. The whimpers become audible to those within the cramped room. "H-how do you know that I-I've sinned? What wrong have I ever committed?" You voiced cracked, oxygen wasn't flowing in right causing your lungs to heave. The room began to spin the furniture waltz from right to left, left to right. The window slip across the walls making it's way to the roof planting it's self right above where you wept, casting the spotlight of the blazing afternoon sun on your depressing performance.

"You must have done something wrong...maybe not killed someone directly but ruined a life, recked a happy home, cursed a baby, lured unsuspecting children to an island of sloth where they were turned to animals and where sold to the highest bidder?" Despite the bizarre nature of the question, Grim's face remains sympathetic and serious.

You shook your head which caused the room to spin even faster. Everything expanded in size, larger and larger and larger...

Year tears pilled up on the icy floor starting to pool around the two of you. "My only sin was being curious of that dammed mirror....then again curiosity often leads to trouble." The teardrops were knee-high at this point. Yet they never seemed to affect Grim. The salty water parted around him as if repulsed by his very being. Oh, but it loved you, adored you, clung and soaked you, trying to touch you, feel you, become one with you...much like the seven atrocious monsters waiting for you outside.

"I've been wondering why did you touch that mirror in the first place?" Had grim aways been purple? Had his striped always been as rich as the silk used in the Pomfiore uniforms? "I'm afraid.." You choked on your words, the clung to the inside of your throat cutting the pharyngeal muscles like mini razor blades and nesting there. "I can't explain myself, Grim, for you see I wasn't myself that day..." every word that jumped from your mouth hauled a thick gush of blood with itself. The red liquid almost always landed on your new gown -which of those beastes had picked it again?- it never lasted, always sinking through the layered fabric and dissolving into your bruised flesh.

"They will get angry if you stall any longer..." your only friend hopped onto your lap, slashing some of the supposed water around. Your arms dropped to your side, resting there for a fraction of a second before curing around his furry figure. You stood up, dishearteningly walking to the full one-way mirror on the far left. The instant your reflection grasped the glass surface a thunderous cracking noise swelled the room. The reflector was left in shreds, all you could see was your face and how dissolved it looked. "Oh, dear I do wish I hadn't cried so much." Plucking up a makeup brush who's thorns priced your fingers, digging in to find the crimson gold you had to offer. She dapped it into a makeup pallet that Grim was holding up, and swiftly swept it over her cheeks. He glossy eyes traveled up to stare at her reflection in the body, the moment your eyes landed on the (y/n) on the other side of the mirror, her breathing stopped, her heart sped up THAT WASN'T HER!

The person starring back had a batch of thick blond hair, her blue eyes looked dull broken even. Her chapped bleeding lips where moving trying to form words that never reached your ringing ears. Deep inside envy started to build up, whoever that girl caged behind the looking class was, she was much luckier then you would ever be. She didn't need to deal with the monster lurking right outside.

The door burst open, out of fear the room stopped turning, the furniture returned to their original side, Grim changed into his back into his grey fur and shuffled closer to you, holding tightly onto the pale blue skirt of your dress. "WHAT IS TAKING YOU SO LONG!" screamed the ever furious "queen of Heartslabyul". Riddle marched up to you, his heels furiously clicking on the black and white tiles. He grabbed your forearm pulling you to your unsteady feet. You waddled about to topple over if he hadn't started dragging you towards the dorm leaders' assembly hall. You spared a glance at the girl behind the mirror. Similarly, she was also being dragged by a boy who wore an ever-familiar heart crown on top of his head. The blond girl was mouthing something to you trying to relay an urgent message it seemed.

"in the night garden memories in the palace of dreams that is where you and I shall meet"

Your eyes widen, right was as the words left her mouth the mirror shattered. Shards flying around, barely missing you.

Riddle was quicky to drag you inside of the attached room, throwing you into an empty chair that had been wait more patiently then the dorm leaders. All eyes turned to you milking in your figure. All seemed ready to pounce and devour you on the spot. You shrunk into the leather of the chair hoping that by some mad miracle you would disappear.

Kalim was the first to speak his voice cheery and lustful. "Well (y/n) would you like an adventuer? Or should we wait until after we have some tea? Jamil just received a package from our homeland and instructed me to bring some of the tea to the meeting!" With Kalim, it was always hard to tell where his focus was. One moment he looked ready to strip you of your close and mark you as his, the next he was too busy rambling on and on about how his father always had servants pluck tea lives for their afternoon banquets.

"some times" Azul began fed up with Kalims stories "in six impossible things before breakfast..today however I would simply like to believe that we could finish this meeting before we all die of boredom and.." His silver eyes gazed at you, passion much too evident in them. "get on with other more pleasant tasks."

Did they seriously all want you in that such a...lewd manner?

"I agree let's wrap this up" Idia murmured "I have something to get to". Leona turned his attention to the fiery-haired necromancer. "Stop worrying, your stupid video games won't run off anywhere. As for you..." Leona stalked closer fingers wrapping around your small hands, claw-like nails digging into your flesh. "I'm afraid you're driving me mad my little gazelle" His mouth was so close to your throat, fangs grazing your juggler. Behind you, Riddle held you in place trying yo keep you from squirming as he kissed your bare shoulders.

"You were always entirely bonkers Kingscholar" Vil announced as he got up and made his way to you, placing a feather-light kiss on top of your right hand. "But don't they say all the best people are?" Azul asked as he followed Vil's lead, sizing your left hand and biting into your wrist, relishing in the feel of your pulse against his wet tongue. Kamli was the next to make a move, his fingers danced along your chest slipping under the top of your dress. Someone tangled there blazing hot fingers in your locks, his fiery breath dancing across your face as he licked the shell of your ear leaving a lava hot sensation in its wake.

From across the room, your eyes met the poisonous orbs of Malleus Draconia the only one to have not spoken for the entirety of the meeting. A knowing smirk spread across his pale face, for the first time all day you heard his monotone voice.

"poor Alice forever stuck in a twisted wonderland"

#twisted wonderland#twisted wonderland x reader#twisted wonderland x you#twisted wonderland leona Kingscholar#twisted wonderland leona kingscholar x reader#yandere leona kingscholar#yandere leona kingscholar x reader#yandere leona kingscholar x you#twisted wonderland idia shroud#twisted wonderland idia shroud x reader#yandere idia shroud x reader#yandere idia shroud x you#twisted wonderland malleus draconia#twisted wonderland malleus draconia x reader#yandere malleus draconia x reader#yandere malleus draconia x you#twisted wonderland azul ashengrotto#twisted wonderland azul ashengrotto x reader#yandere azul ashengrotto x reader#yandere azul ashengrotto x you#twisted wonderland vil schoenheit#twisted wonderland vil schoenheit x reader#yandere vil schoenheit x reader#yandere vil schoenheit x you#twisted wonderland kalim al-asim#twisted wonderland kalim al-asim x reader#yandere kalim al-asim x reader#yandere kalim al-asim x you#twisted wonderland riddle rosehearts#twisted wonderland riddle rosehearts x reader

664 notes

·

View notes

Text

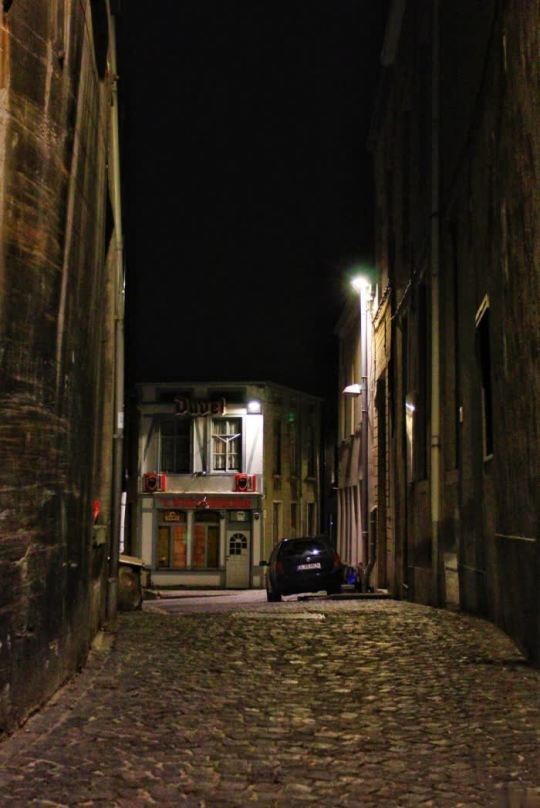

Leme-Giethoorn-Amsterdam-Rotterdam-East Flanders

Famous Holland Village claw

Mom and Dad are in Giethoorn

This is still a small bar outside the Giethoorn Scenic Area.

Giethoorn is located in the De Wieden Nature Reserve in the province of Overijssel in the northwest of the Netherlands. During the ice age, De Wieden was located exactly between the two moraines, so the potential was better than that of the surrounding area. Giethoorn is known as "Green Venice" (some people call it "Dutch Venice"). The name "Giethoorn Village" was derived from the fact that a group of coal mining workers settled there. Their excavation work resulted in the formation of waterways and lakes of various sizes. In the daily excavation process, in addition to coal, they also dug up many "horns" under the shack. After supervision, it was confirmed that these horns should be a batch of wild goats that lived in 1170. Therefore, they called it Giethoorn Village, and that name has been retained to this day.Europeans are all kinds of enjoying life, afternoon sunshine, coffee, beer... Of course, the people here in Giethoorn are also exceptions, whether they are aborigines or tourists.The soil itself is barren and peat bogs are all over the place. Except for reeds and peat bogs, other plants are prone to growth. The only resource is the peat underneath. In order to dig out more peat blocks and sell them to make money, the residents disconnected the soil to form narrow ditches. Later, the residents widened the ditches in order to enable ships to pass and transport materials, forming the beauty of today's intertwined canals and lakes.

Because all the reflections on the water surface are the reflections of the green houses. The roofs of the houses here are made of reeds, which are more durable than any building materials. They have been used for more than 40 years. They are also warm in winter and cool in summer, and they are resistant to rain and sunlight. It is said that reeds used to be a substitute for poor people to buy bricks and tiles, but the current price of reeds is only a building material bought by rich people, and the price is dozens of times that of bricks and tiles. The prices here have already risen, so most of the residents are doctors, lawyers and other income occupations. This seems to form a contrasting time and space with the previous hardship.

The house price seems to be 200 Euros. It’s more expensive. But think about it, there are a few chances in my life to sleep in this kind of scent of birds and flowers. I think if it has a room, I would be willing to take my parents to stay for the night.

And the Dutch flag fluttering in the wind, the country of tulips. Goodbye, Giethoorn! Alkmaar-Zaandam-Amsterdam-Rotterdam

.One of the attractions in Europe is good, that is, most of them have tickets. Zaandam Windmill Village

The Windmill Village of Zaandam is a very famous attraction in the Netherlands, where you can "encounter" a lot of domestic tourists.

The comfortable and peaceful town of ZaandamAfter visiting Zaandam and feeling the unique architectural style of Holland, we started to drive towards the city of Amsterdam, where there are Amsterdam canals and the famous red light district girls! Amsterdam is the capital and largest city of the Netherlands, with a population of approximately 1.1 million. Located in the western province of North Holland, a world-famous international metropolis. Its name is derived from Amstel dam, which indicates the origin of the city, a dam on the Amstel River.In the late 12th century, a small fishing village was built here, and then due to the development of trade, Amsterdam became an important port in the world during the Dutch Golden Age. In that era, the city was the center of financial diamonds. In the 19th and 20th centuries, the city expanded, and many new neighborhoods and suburban residential areas were formed. Amsterdam has many tourist attractions, including the historic network of canals, the National Museum of the Netherlands, the Van Museum, the Anne Frank House, the Red Light District and many cannabis cafes. Approximately 4.2 million tourists visit here every year. As the current largest city in the Netherlands, Amsterdam has gone through the process of development from a fishing village to a metropolis, and has experienced brilliance and destruction, as well as the baptism of the World War. To a certain extent, her history is also a microcosm of Dutch history. .

Five groups of young people sitting on the side of the canal.

When we approached the village of Kinderdijk, we saw a tractor-driving father just "putting" his daughter on the tractor, and the little girl was sitting quite steadily. I was thinking at the time, if I were to sit on it, I would definitely be scared, this foreigner with children is really...big-hearted!

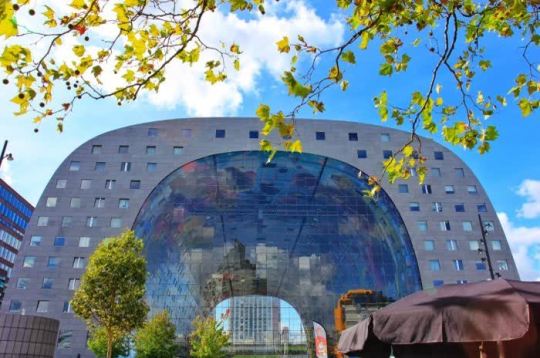

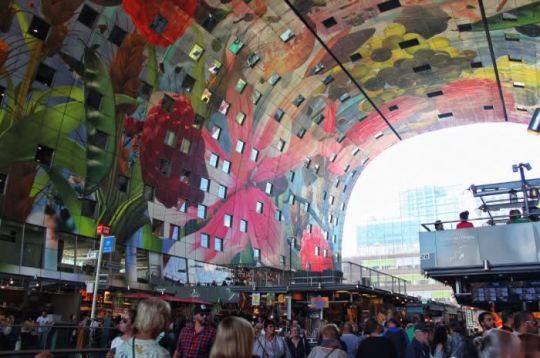

This is Rotterdam’s most famous landmark building-the Red Bridge, which connects to the inner island of oude haven. It has a unique shape like the Mini Golden Gate Bridge.

The city of Rotterdam has risen and fallen several times in history. It was originally a fishing village near the Rotter River, which flows from the swamp area of South Holland into the Maas River. Rotterdam is named after the Rotter River. In 1250, a dyke was built on the north bank of the Maas River to separate the Rotter River from the Maas River with a gate. When William IV, Earl of the Netherlands, governed Rotterdam in 1340, he dug a canal to communicate with Delft Leiden, and Rotterdam began to prosper. Most of the city was destroyed by fire in 1563. Rotterdam was occupied and plundered by Spanish troops in 1572, and the Spaniards retreated a few months later. At that time, many merchants and craftsmen from Antwerp, Belgium settled down in Rotterdam, bringing Rotterdam into a period of recovery and development.

The beautiful woman sitting alone on the edge of Hongqiao.

3 notes

·

View notes

Text

Mini concrete batching plant price

Mini concrete batching plant price is related to the model and configuration of a plant. There are three types of mini plants: stationary, mobile and simple. By capacities there are 25m3 and 35m3 plants. Here we deal with stationary and simple plants.

HZS25 concrete mixing station is a complete set of semi-automatic stationary concrete mixing machinery composed of feeding, batching, mixing, electrical control and steel structure components. HZS25 concrete batching plant is equipped with pld800 or pld1200 concrete batching machine, which is composed of feeding mechanism, weighing system, electrical control system and other components. The main mixing unit of JS500 type double horizontal shaft forced concrete mixer is of high alloy wear-resistant material, featured by even and stable mixing, reasonable structure, short mixing time, low noise, small energy consumption and high yield. The price for a whole set of hzs25 is approximately 25000 dollars.

HZS35 concrete mixing station discharges 0.75 cubic meters of concrete each time. The cycle time is 72 seconds, and the theoretical production rate is 35m3 / h after mixing with batching machine. HZS35 concrete batching plant is composed of material conveyors, a mixer and a batcher. Pld1200 concrete batching machine is used for aggregate batching, with accurate measurement and high production efficiency. The cover of js750 concrete mixer is equipped with a limit switch. When the inspection door is opened, the mixing motor will automatically cut off the power supply to facilitate the maintenance of the equipment; the oil sealing technology is adopted to ensure the reliability of the sealing of the main machine shaft end to a large extent; the wear-resistant steel material is adopted to greatly improve the service life of the blades and lining plates. A whole set of hzs35 concrete plant costs around 30000 dollars.

A simple mini concrete batching plant refers to a mixing plant with simple foundation or without foundation, generally without any external sealing structure. Although the control system of such a plant can not compete with that of a standard plant, its production capacity and quality are as satisfying as the latter. The configuration of a simple mini mixing plant includes a concrete mixer, a concrete batcher, cement bins, screw conveyors, separate weighing system and control system. Capacities include 25m3 and 35m3. A simple mini batching plant price is lower than price of a standard one of the same capacity, and specific price varies with specific needs of a purchaser.

Reprinted from http://www.haomei-machine.com/news/companynews/mini-concrete-batching-plant-price.html

0 notes

Text

Mini Portable Asphalt Plants - Atlas Industries

Atlas for sale mobile hot asphalt plant at lowest price. We are manufacturer and exporters of mini portable batch plants, and hot mix plant in Worldwide.Buy quality mobile asphalt mix plant at low price.

0 notes