#metallurgical bonding

Explore tagged Tumblr posts

Text

Comprehensive surface treatment process of materials

Surface treatment is a process that artificially forms a layer on the surface of a base material that has different mechanical, physical and chemical properties from base material.Purpose of surface treatment is to meet corrosion resistance, wear resistance, decoration or other special functional requirements of product. Our more commonly used surface treatment methods are mechanical grinding,…

View On WordPress

#Anodic Oxidation#electrolytic polishing#Electroplating#electroplating surface treatment#Electropolishing#Galvanizing#Hydro Transfer Printing#In-Mold Decoration#Metal Wired#metallurgical bonding#metallurgical bonding technology#Pad printing#Screen printing#Surface treatment#surface treatment process#Surface treatment technology#vacuum electroplating#vacuum electroplating process#Vacuum Metalizing#Vacuum plating

0 notes

Text

The promised Brazil in WW2 post! I did verify some information, but this is actually mostly based on my previous knowledge (from a Brazilian perspective) and my visit to a museum on this topic, so I always encourage searching about it yourself! :D This will be more general facts I find interesting than a complete look into our participation, as that is a bit complicated to speak about in a short post. But let's get into it, shall we?

So, the thing about Brazil's participation in WW2 is that it actually came in sort of late. We only started fighting in late 1944 in Northern Italy, after the fall of fascism there, but we technically declared war back in 1942.

The two reasons we entered the war (after a period of neutrality in which we still had a commercial relationship with the main three Axis countries as well as the Allies) were...

Getúlio Vargas' government striking a deal in which the USA would build military bases on our territory in exchange for them investing in our metallurgical industry (long story);

The German sinking of six commercial Brazilian ships (Baependi, Araraquara, Aníbal Benévolo, Itagiba, Arará and Jacira), which ended up killing 607 people, civilian and military alike.

Once we actually entered the war, I would say that our most important ally within the... Allies was the USA - with Brazilian soldiers (the Pracinhas) even serving in the US Fifth Army. We filled very important gaps, and eventually, once the USamericans turned their efforts elsewhere, we played a very important role in the fight against the Nazis in Italy.

A thing to note was actually the sense of connection that a lot of Brazilians had with Italy. Many of the soldiers drafted (and those who volunteered) were of European descent, with a sizable chunk being Italian, so they were both fighting for their homeland and for their ancestors' homeland. Not only that, but the Pracinhas were treated warmly by the Italian citizens, which nurtured an even stronger emotional bond and sense of duty.

The main battle fought by FEB (The Brazilian Expeditionary Forces) was the Battle of Monte Castelo - was a very important defense point for the Nazis - which lasted for three months and was considered the largest battle in the history of the Brazilian Army. Brazil also participated in the Battle of Castelnuovo, Montese, Collecchio, and Fornovo di Taro.

A big thing to mention is that there were actually Brazilians on both sides of the war. Which actually contributed to the psychological warfare by the Nazis to try and convince the Pracinhas to desert - there was even a radio program transmited by a Brazilian woman from Santa Catarina to try and reach that goal, although most of the propaganda was done through leaflets that would appeal to the conditions the soldiers were enduring (such as the extreme cold).

Interesting tidbit about the cold: the Pracinhas would stuff straw in their boots, especially when it was cold, which actually led them to have fewer cases of Trench Foot than the USamericans.

Women in the Brazilian Army acted as field nurses, about 73 iirc going to serve in Italy. I will attach a picture below of some of them.

At this time, Brazil was actually in a dictatorship, which restricted even what the Brazilians could write in letters back home. They were encouraged to never say anything negative, and even if they did, their letters would always be read to check for it. Interestingly enough, once the war was ending and the Pracinhas would come home, people began seeing more and more similarities between the way things were being run by the Vargas' regime and the nazifascists... Hm...

Let's get to the last thing I want to talk about this night - the symbols used by our soldiers!

The main one you may have seen around is the Smoking Cobra. But what does it mean? See, there was this popular phrase within the country that "if Brazil enters the war, the cobra will smoke", something akin to "when pigs fly". And so, when we did join the war, this symbol was used as a sort of cheeky nod to the saying. The Pracinhas had a really good sense of humor.

And the less known, but in my opinion just as funny, symbol for our Aviation group. Which was based on two things: the phrase "Senta a Pua" which was already used in the airbase of Salvador to tell people to hurry up, and the ostrich, a symbol based on soldiers' jokes that they needed an ostrich's stomach to handle the food the USamericans gave them on the boat ride over lmao. I put both symbols below.

And I believe that will be all for now! There's still a lot to be said, and a lot that I will want to talk about at some point, but for now, I hope you enjoyed this little snapshot I gave you. ^_^

#geisttalk#two long posts in a single day who could've thunk it#plus some museum photos :)#ok now I will go sleep gn

11 notes

·

View notes

Text

0 notes

Text

Over the past 44 years, RA Power Solutions has been repairing heavy machinery using white metal Babbitt bearings for various applications, understanding the importance of Babbitt bearings. We created a technique for producing new white metal bearings and repairing Babbitt bearings that have become worn or damaged as a result of accidents. Our dedication to our customers ensures that each white babbitt bearing we make satisfies worldwide standards in terms of metallurgical qualities and size. We are well-known around the world for our prompt responses and personalized client service. This remetalling procedure guarantees that the white babbitt metal is uniformly and strongly bonded to the bearing's steel housing. The final machining of white metal babbitt bearings following the remetalling process is done in-house, and oil gap/critical dimensions are meticulously adhered to as per the manufacturer's specifications. For more information related to babbitt metal or white metal bearing, please email us at [email protected], [email protected], or call us at +91 9582647131 or +91 9810012383.

0 notes

Text

Proven Solution: KenCast™ Breaks Through Abrasion Resistance Records Crushing Operations at Mine Site

Mining Doc Kennametal’s KenCast™ is known for its durability in highly challenging environments. It is air-hardened cast steel with metallurgic ally bonded tungsten carbide particles on the wear surface, which has been proven to withstand extreme abrasive and high-impact applications and could show a life improvement over standard wear solutions depending on materials and applications. Downtime can be significantly reduced. Don’t just take our word for it, check out the results from one of our tests. Downtime Means No Time for Second-Best A mining company in Brazil, known for its high volume of mineral extraction in the processing and production of gold, needed to reduce downtime caused by replacing wall plates in chutes used in its crushing operations. The environment in which the wall plates are used is predominantly abrasive. However, weight is also a factor, as the flow of minerals inside the chute can concentrate in several different areas and cause wear similar to an impact on the plates. Depending upon the area of the chute, most competitors’ wall plates used at this site provided only 15 to 50 days of use before downtime was required to replace them – according to the customer. The customer asked us to develop plates — with a particular emphasis on those used in the discharge chute walls — that would reduce inspection- and replacement-related downtime to increase productivity at its gold mine. The Kennametal Solution We presented a test protocol to the mining company pertaining to the durability of our solution which provided custom wear plates to armor their discharge chute. Additionally, we provided reports from other customers who achieved 30 percent longer wear with our solution compared to the competitors’ wall plates. Our experts then put two KenCast KCWB-0938 wall plates (painted black, for easier identification) to the test. In November 2022, the pair of plates were placed in the most challenging environment of the chute wall, alongside the competition’s plates. Kennametal KenCast Plate KCWB-0938

Surface: Tungsten-carbide grains in the mixture of -3/8, +5/16 and -1/4, +4

Base steel: Carbon, manganese, silicon, aluminum, nickel, chromium, and molybdenum

Outstanding, Outlasting Abrasion Resistance Two separate inspection dates were chosen to evaluate the KenCast plate. One evaluation in December 2022 and one in evaluation January 2023, 59 days into the operation. At this point, the KenCast plates were shown to have excellent thickness preservation and carbide grit remaining intact. The differentiated composition of the KenCast steel base provided superior resistance to abrasion as compared to competitor plates using a nodular iron base. While the competition’s plates were worn down and needed to be replaced, the KenCast solution kept going. After 90+ days of continuous operation, which brought us to February 2023, one of our Kennametal plates needed to be swapped out. However, one of the customer’s inspectors concluded that the remaining KenCast plate had the potential to continue its tool life for another 30 to 60 days. Compared to our rivals’ plates, KenCast plates could last 10 times longer! Just as important, the customer could achieve an unprecedented reduction of downtime and a significant increase of more than 30 percent in ore extraction. Want these kinds of results for your operation? Talk to our experts to find out how KenCast mining solutions can provide excellent wear protection and extend the life of your equipment. For more information, visit https://www.miningdoc.tech/ Original Source: https://bit.ly/3DQxcq8

0 notes

Text

Aluminum to Copper Brazing Flux Cored Wires—Shop Now: 8851310039

Brazing is a critical process in various industrial applications where joining dissimilar metals like aluminum and copper is required. Aluminum to Copper Brazing Flux Cored Wires are innovative solutions designed to simplify the brazing process while ensuring strong, durable, and reliable joints. These wires are particularly valuable in industries such as HVAC, automotive, aerospace, and electrical engineering, where lightweight, corrosion-resistant, and conductive materials are paramount.

What are the Brazing Flux-Cored Wires?

Brazing Flux Cored Wires are specialized brazing wires with a core filled with flux material. Flux is essential in the brazing process because it helps remove oxides, prevents oxidation, and promotes wetting by allowing the filler material to flow smoothly over the surfaces being joined. This eliminates the need for separate flux application, reducing process complexity and improving efficiency.

In the context of aluminum-to-copper brazing, the flux inside the cored wire is carefully formulated to handle the unique challenges posed by these metals. Aluminum forms a stable and hard-to-remove oxide layer, while copper's high thermal conductivity can make achieving uniform heating difficult. Flux-cored wires address these issues effectively, ensuring a seamless and reliable bond.

Advantages of Aluminum to Copper Brazing Flux-Cored Wires

Until now, the flux-cored braze wires by Shop Castron Electrode provide the following advantages:

Simplified Brazing Process: The integration of flux into the wire eliminates the need for a separate flux application step. This reduces preparation time, minimizes potential errors, and ensures consistent application across joints.

Superior Joint Strength: The filler material in flux-cored wires is engineered to create robust bonds between aluminum and copper, even under thermal and mechanical stress. These joints are suitable for high-performance applications.

Enhanced Corrosion Resistance: Brazed joints using flux-cored wires are less prone to corrosion, making them ideal for applications in humid or chemically aggressive environments, such as HVAC systems and marine equipment.

Optimized Thermal and Electrical Conductivity: Copper is known for its excellent electrical and thermal conductivity, while aluminum is valued for being lightweight. Flux-cored wires facilitate efficient bonding without compromising these critical properties.

Cost-Effectiveness: The streamlined brazing process reduces labor costs and waste, making flux-cored wires a cost-effective choice for mass production or repair applications.

Key Applications

HVAC Systems: Joining aluminum and copper components in heat exchangers and refrigerant circuits.

Automotive Industry: Brazing aluminum radiators and copper piping in thermal management systems.

Aerospace: Fabricating lightweight yet strong connections in airframes and electrical systems.

Electrical Engineering: Creating high-conductivity connections in power systems and electronics.

Best Practices for Use

To achieve optimal results with aluminum-to-copper brazing flux-cored wires, the following practices are recommended:

Surface Preparation: Ensure the surfaces to be joined are clean and free from grease, dirt, or heavy oxides.

Heating Technique: Use controlled and even heating, avoiding overheating, which can damage the metals or filler.

Wire Handling: Store the wires in a dry environment to prevent moisture absorption, which could impact the flux’s performance.

Conclusion

Aluminum to copper brazing flux-cored wires represent a significant advancement in metallurgical joining technologies. By simplifying the brazing process and delivering reliable, high-strength joints, these wires empower industries to achieve better performance and efficiency. Whether in critical HVAC systems or sophisticated aerospace applications, they ensure durability, conductivity, and corrosion resistance, making them an indispensable tool in modern manufacturing and repair processes. For further details, visit https://shop.castonelectrode.in/2024/07/26/copper-brazing-flux/

0 notes

Text

The Precision and Benefits of Vacuum Brazing Aluminum in Modern Manufacturing

The Precision and Benefits of Vacuum Brazing Aluminum in Modern Manufacturing

In the fast-evolving world of manufacturing, precision and reliability are paramount. Vacuum brazing has emerged as a critical process for joining aluminum components, offering exceptional strength and integrity. This article explores the vacuum brazing of aluminum, delving into its principles, advantages, and applications in modern manufacturing.Get more news about Vacuum Brazing Aluminum,you can vist our website!

Understanding Vacuum Brazing Vacuum brazing is a metallurgical process used to join two or more metal parts by melting and flowing a filler metal into the joint. The process is performed in a vacuum environment, which helps eliminate oxidation and contamination, resulting in a clean and strong bond. This method is particularly effective for aluminum, as it prevents the formation of oxides on the metal's surface.

Key Benefits of Vacuum Brazing Aluminum High-Strength Joints

One of the most significant advantages of vacuum brazing is the creation of high-strength joints. The process ensures uniform distribution of the filler metal, leading to robust and durable bonds that can withstand mechanical stress and thermal cycles. This strength is crucial for components that experience high loads and dynamic conditions.

Excellent Thermal Conductivity

Vacuum brazing maintains the excellent thermal conductivity of aluminum. This property is essential for applications requiring efficient heat transfer, such as heat exchangers and cooling systems. The strong metallurgical bond formed through vacuum brazing ensures optimal thermal performance.

Corrosion Resistance

The vacuum environment prevents the formation of oxides and other contaminants during the brazing process, resulting in joints with superior corrosion resistance. This benefit is particularly valuable for components exposed to harsh environments, such as marine and aerospace applications.

Precision and Consistency

Vacuum brazing offers precise control over the process parameters, ensuring consistent and repeatable results. The controlled atmosphere eliminates variables that can affect the quality of the joints, providing manufacturers with confidence in the reliability of the bonded components.

Minimal Distortion

The uniform heating and cooling in a vacuum environment minimize thermal distortion and warping of the components. This precision is crucial for applications requiring tight tolerances and high dimensional accuracy, such as aerospace and medical devices.

Applications of Vacuum Brazing Aluminum Aerospace Industry

In the aerospace sector, vacuum brazing is used to manufacture high-performance components such as heat exchangers, fuel systems, and structural assemblies. The process ensures the strength and integrity required for aerospace applications, where safety and reliability are paramount.

Automotive Industry

Vacuum brazing is employed in the automotive industry to produce components like radiators, intercoolers, and exhaust systems. The process ensures efficient thermal management and robust performance, contributing to the overall efficiency and longevity of vehicles.

Electronics and Electrical Engineering

Aluminum's excellent thermal conductivity makes it ideal for heat sinks and other cooling solutions in electronics. Vacuum brazing ensures reliable joints with minimal thermal resistance, enhancing the performance and lifespan of electronic devices.

Medical Devices

The precision and reliability of vacuum brazing make it suitable for manufacturing critical medical devices and components. The process ensures biocompatibility and durability, essential for applications such as surgical instruments and diagnostic equipment.

Energy and Power Generation

In the energy sector, vacuum brazing is used to manufacture components for power generation and distribution, including heat exchangers, condensers, and electrical contacts. The process ensures efficient thermal management and reliable performance in demanding environments.

The Vacuum Brazing Process for Aluminum Preparation

The components to be brazed are thoroughly cleaned to remove any contaminants, oxides, or residues. Proper cleaning ensures that the filler metal can flow and bond effectively.

Assembly

The parts are assembled with the filler metal placed at the joint. The assembly is then loaded into the vacuum furnace, where the entire process will take place.

Heating

The vacuum furnace is evacuated to remove air and other gases, creating a controlled atmosphere. The assembly is then heated to the brazing temperature, allowing the filler metal to melt and flow into the joint.

Cooling

After the brazing temperature is reached and the filler metal has flowed into the joint, the assembly is gradually cooled. The vacuum environment ensures minimal oxidation and contamination during cooling.

Inspection

Once the brazing process is complete, the assembly is inspected for joint integrity and quality. Non-destructive testing methods, such as X-ray inspection, are often used to verify the quality of the brazed joints.

0 notes

Text

A Look At The Commodities Universe & The Market With Le Shrub

BR Kelleran and Le Shrub

Oct 17, 2024

Once you realize it’s all nonsense then it all makes sense.

A couple days ago, I had fellow Substack author

Le Shrub

on the podcast. He writes over at Reminiscences of a Shrub Operator, and if you don’t already follow him, you should. He’s clearly the most talented trader in the plant kingdom, but we had a great conversation on different commodities, the market, and several stocks of interest. He’s also a very entertaining follow on Twitter.

Upgrade to paid

Podcast Summary

His preferred way to get exposure to oil, and what it takes for geopolitical risk to get priced into oil markets.

The Trump trades, and how a Trump win might be worse for deficits, bonds, and the dollar.

Why platinum is his preferred precious metal inflation hedge, Costco’s COST 0.24%↑ (yes, that Costco) potential impact on a platinum bull market, and how platinum is trading at the widest discount to gold in history.

His thoughts on several coal stocks, including Peabody Energy BTU 0.00%↑ and Warrior Met Coal HCC 0.00%↑, and the outlook for metallurgical vs. thermal coal.

Why tin is one of his favorite under the radar opportunities in the commodities space.

His thoughts on broader markets, what he’s looking for to get bearish, and why investors should keep an eye on China.

Book Recommendation: The Gambler by Fyodor Dostoevsky.

0 notes

Text

The Application of Silicon Powder

Silicon is a chemical element with the symbol Si and atomic number 14. It is from the same group with carbon, germanium and tin. They all have similar properties, and are all tetravalent metalloid and semiconductor.

Silicon powder is made from silicon lump by breaking & milling. Depending on the purity & particle size of the silicon powder, it can be used for many purposes.

Semiconductor manufacturing

Due to the high melting point, thermal stability, rich resources and higher purity of silicon powder, silicon integrated circuits and large-scale integrated circuits have been applied to various areas. Silicon powder is an important raw materials of electronics and semiconductor industry

Coating Industry

-High purity Silicon Powder with suitable grain sizes for use in preparation of pressed and bonded sputtering targets and in CVD, PVD processes including Thermal and Electron Beam (E-Beam) Evaporation, Low Temperature Organic Evaporation, ALD, MOCVD.

-Silicon powder with narrow particle size distribution is used for thermal spaying, this makes the coating dense and uniform.

Silicone industry

Silicon powder is the basic raw material of synthetic materials. It is used in the production of silicone rubber, silicone resin, silicone oil, etc. The materials are high temperature tolerant, electrical insulation, corrosion-resistant, waterproof etc.

Refractory industry

Silicon powder is an antioxidant additive in iron groove and iron ditch of Iron smelting, mud water cannon, and containing silicon carbide mixes to raise the temperature, resistant to wear and oxidation resistance.

Metallurgical and foundry industry

Silicon powder is used as non-iron-based additives, silicon steel alloy agent to enhance the harden ability of steel. Silicon powder can also be applied to certain metal reducing agent, such as a new type of ceramic alloy.

Edgetech Industries specializes in producing high purity silicon powder with customized particle size. Our standard silicon powder particle sizes: - 325 mesh, -200mes, - 100 mesh, or any size between 20-500mesh. Nanoparticles & Submicron particles are also available on request. One of our most remarkable technologies is to provide silicon powder with a narrow particle size distribution. We will talk about the manufacturing process of silicon powder, which explain the reason we can provide narrow PSD for Si powder.

1 note

·

View note

Text

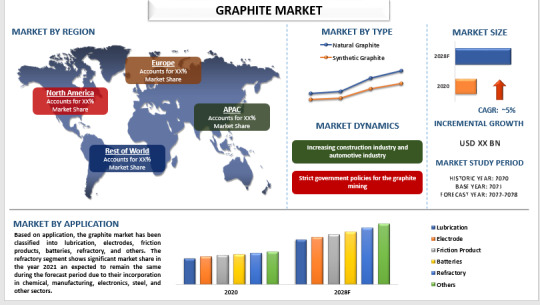

Graphite Market is expected to display a steady growth by 2028

According to a new report published by UnivDatos Markets Insights, the Graphite Market is expected to grow at a CAGR of around 5% from 2022-2028. The analysis has been segmented into Type (Natural Graphite and Synthetic Graphite); Application (Lubrication, Electrodes, Friction Products, Batteries, Refractory, and Others); Region/Country.

The graphite market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the graphite market. The graphite market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the graphite market at the global and regional levels.

Market Overview

Graphite is consisting of carbon and is considered a non-metallic carbon compound. The graphite is studied into amorphous class and synthetic class depending on the structure and bonding between the carbon atoms. Graphite has the added advantage over other similar classes of compounds such as self-lubrication, and higher tolerance against heat & temperature. Additionally, graphite has the ability to retain its shape and size for a longer duration and is used in several industries for a variety of applications such as heat resistance in refractories, additive for lubrication, as a concrete material for construction, and in the automotive industry for lithium-ion batteries, among many others.

The Graphite Market is expected to grow at a steady rate of around 5% owing to the increasing production of electric vehicles, the growing volume of the steel industries, and due to increasing demand for graphite-made material in the aerospace industries. Furthermore, major companies are continuously spending to research and development related to the sustainability of the materials. For instance, SGL a European organization for synthetic graphite manufacturers for anode materials is developing graphite materials products with higher energy efficiency, increased performance, and more sustainability than the previous version.

Some of the major players operating in the market include Graphite India Ltd., Nippon Graphite Industries Co. Ltd, Northern Graphite Corporation, SGL Group, Triton Mineral Ltd., GrafTech International Holdings Inc., Tirupati Carbons & Chemicals Private Limited, Qingdao Xinghe Graphite Co. Ltd., Focus Graphite Inc., and Showa Denko Materials Co. Ltd.

COVID-19 Impact

Due to travel limitations and the projected dismal financial performance of market players in 2020, the spread of the COVID-19 pandemic has hurt the Graphite industry. Supply chain execution, regulatory and policy changes, labor reliance, working capital management, and liquidity and solvency management are all major concerns for graphite manufacturers. Since the COVID-19 epidemic has considerably diminished by the beginning of 2021, a lot of businesses are resuming operations. In terms of demand and supply, China, as the graphite mining/manufacturing powerhouse, is controlling the global automotive industry. China's supply shortages have triggered a chain reaction throughout the world.

The global graphite market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on application, the graphite market has been classified into lubrication, electrodes, friction products, batteries, refractory, and others. The refractory segment shows significant market share in the year 2020 an expected to remain the same during the forecast period due to their incorporation in chemical, manufacturing, electronics, steel, and other sectors. Refractory graphite is widely used in the metallurgical industry, resistance furnaces, and graphite furnaces due to its ability to withstand higher temperatures. Furthermore, the increasing demand for steel and iron across the world would increase the demand for refractory graphite as they are used in metallurgical furnaces in the steel industry. For instance, according to the world steel association, the demand for steel grow by 2.7% in the year 2021 and subsequently increase the demand for refractory graphite.

Based on type, the market is segmented into natural graphite and synthetic graphite. The natural graphite segments hold a decent market share in the market for the year 2020 and are expected to remain the same during the forecast period owing to the properties such as friction-resistant, optimal performance, and cost competitiveness. These rich properties of natural graphite allow the manufacturing industries to use natural graphite over synthetic graphite. Natural graphite is used by a variety of the industries such as batteries, steel, lubrication, brake industries, refractories with many others. The increasing demand for automotive vehicles and electronic gadgets is increasing the demand for graphite across the world.

Graphite Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

APAC is anticipated to grow at a substantial CAGR during the forecast period. This is mainly attributed to the growing economies in the region coupled with rapid urbanization and industrialization. Furthermore, the increasing demand for li-ion batteries and electronic items propelling the demand for graphite in the region. In addition, emerging countries like China are planning to phase out coal which is used for steel production due to the pollution caused by the burning of coal. Thus, governments are focusing on promoting graphite brick for steel production activities which subsequently grows the demand for graphite in the region.

Additionally, the increasing investment in the steel industry, chemical industries, and other allied industries is further expected to propel the demand in the region’s graphite market. For instance, Tsingshan Holding Group announced an investment of USD 1.4 billion (CNY 10.3 billion) for the lithium-ion battery plant in the Guangdong province. Also, in October 2021, Black Earth Mineral & Metachem Manufacturing inked a 50:50 joint venture to develop a graphite facility in India with an initial capacity of 2000-2500 metric tons per annum and expandable up to 4000 metric tons in the coming time. Also, in October 2021, Black Earth Mineral & Metachem Manufacturing inked a 50:50 joint venture to develop a graphite facility in India with an initial capacity of 2000-2500 metric tons per annum and expandable up to 4000 metric tons in the coming time.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=25697

The major players targeting the market include

Graphite India Ltd.

Nippon Graphite Industries Co. Ltd

Northern Graphite Corporation

SGL Group

Triton Mineral Ltd.

GrafTech International Holdings Inc.

Tirupati Carbons & Chemicals Private Limited

Qingdao Xinghe Graphite Co. Ltd.

Focus Graphite Inc.

Showa Denko Materials Co. Ltd.

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Graphite market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the graphite market?

• Which factors are influencing the graphite market over the forecast period?

• What are the global challenges, threats, and risks in the graphite market?

• Which factors are propelling and restraining the graphite market?

• What are the demanding global regions of the graphite market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Carbon Fiber Prepreg Market: SWOT Analysis [2023-2028]

Biocides Market: SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

How a Reliable TMT Saria Manufacturer Contributes to Stronger Concrete Structures

Every remarkable structure begins with exceptional materials. The strength and longevity of concrete construction greatly depend on the quality of its reinforcement parts—particularly TMT Saria, binding wires, and dowel bars. When these essentials align under flawless manufacturing standards, they form the core of robust infrastructure.

Understanding TMT Saria: The Foundation of Structural Integrity

TMT Saria is more than just steel reinforcement; it is the structural strength that ensures a building stands tall against decades of stress and environmental challenges. A good TMT Saria manufacturer utilizes advanced metallurgical processes to ensure that each bar is consistent in its tensile strength, ductility, and durability.

The manufacturing process requires precise temperature control and quenching techniques that create a tough outer layer while maintaining a ductile core. This dual-nature characteristic proves crucial when structures face seismic activities or unexpected loads, allowing the reinforcement to flex without failing.

The Synergy of Components

While TMT Saria forms the major reinforcement, equally important binding wires hold reinforcement grids in place. Quality binding wires ensure proper positioning of steel during concrete pouring, avoiding displacement that could compromise structural integrity.

Dowel bars are another vital component, transferring loads efficiently across concrete joints. When procured from reputable manufacturers, dowel bars work in perfect harmony with TMT Saria to form a cohesive structural system. The accuracy in the production of these parts directly impacts their load-carrying capacity and durability.

Manufacturing Excellence: More Than Just Standard Requirements

The best TMT Saria manufacturers go beyond industry-standard requirements through rigorous quality control processes, reflected in several ways:

1. Metallurgical Precision

Advanced testing facilities ensure consistent chemical composition across batches, guaranteeing uniform strength properties throughout the reinforcement network.

2. Surface Engineering

Unique ribbing patterns enhance the bond between concrete and rebar. Precise dimensional control optimizes interaction with binding wires and dowel bars, ensuring a robust mechanical interlock.

3. Quality Assurance Systems

Comprehensive testing protocols verify crucial mechanical properties like yield strength, ultimate tensile strength, and elongation. These characteristics are essential for structures to withstand static and dynamic loads.

Impact on Construction Quality

The choice of a TMT Saria manufacturer significantly affects construction outcomes. High-quality reinforcement makes installation easier and reduces the chances of errors in binding wires. Coupled with properly manufactured dowel bars, these components create strong structural systems capable of enduring intense environmental stresses.

Superior TMT Saria also minimizes material wastage during construction. With tight manufacturing tolerances, fewer pieces are rejected, ensuring a smoother construction process and greater efficiency.

Economic Effects of Quality Production

Although premium TMT Saria may come at a higher cost, its long-term benefits outweigh the initial investment. Structures built with high-quality reinforcement require less maintenance and offer excellent resistance to deterioration, saving significant costs over their lifespan.

Reliable binding wires and dowel bars from established manufacturers also accelerate construction timelines. Their consistency reduces rework requirements, helping projects stay on schedule and within budget.

Future-Proofing Construction Projects

As construction technologies evolve, leading TMT Saria manufacturers continue to innovate. Their research and development efforts focus on addressing emerging challenges in construction, including environmental concerns and enhanced seismic resistance.

This forward-thinking approach ensures that TMT Saria, along with complementary materials like binding wires and dowel bars, meets the rigorous demands of modern construction projects. By investing in innovation, manufacturers enable the creation of durable and safe structures.

Conclusion

For construction professionals aiming for excellence, partnering with a reliable TMT Saria manufacturer is a crucial decision. The quality of reinforcement materials directly impacts structural integrity, construction efficiency, and long-term success.

By choosing manufacturers committed to quality and innovation, builders invest in the future of construction itself, ensuring safety, durability, and economic efficiency for generations to come.

#TMT Saria#concrete strength#durable structures#TMT bars#construction steel#TMT manufacturer#rebar quality#tensile steel#strong concrete#seismic resistant#building materials#steel reinforcement#structural durability#TMT steel rods#concrete bars#quality TMT#steel strength#rebar supplier#TMT production#durable rebar

0 notes

Text

Grooved Hearth Type Furnace: A Comprehensive Overview

Introduction

In industrial heat treatment processes, selecting the right type of furnace is crucial for achieving the desired material properties and production efficiency. Among the various types of furnaces used in the industry, the Grooved Hearth Type Furnace stands out for its unique design and functionality, catering specifically to the needs of certain heat treatment applications.

What is a Grooved Hearth Type Furnace?

A Grooved Hearth Type Furnace is a specialized heat treatment furnace characterized by a grooved or channeled hearth, which allows for the precise positioning and movement of workpieces during the heating process. The grooved hearth provides a controlled pathway for materials, typically metal parts, to be heated uniformly and efficiently. This furnace type is commonly used in processes that require continuous or semi-continuous movement of the workpieces, such as annealing, tempering, and hardening.

Design and Construction

The primary feature of a Grooved Hearth Type Furnace is its hearth, which is designed with grooves or channels to accommodate the specific shape and size of the workpieces. The grooves ensure that the materials are aligned correctly and remain stable during the heating process, reducing the risk of deformation or damage. The furnace is typically constructed with high-quality refractory materials that can withstand high temperatures and provide good thermal insulation.

The furnace is usually equipped with heating elements located either above or around the hearth, ensuring uniform heat distribution. The temperature inside the furnace can be precisely controlled using advanced control systems, which is essential for achieving consistent heat treatment results.

Operating Principle

The operation of a Grooved Hearth Type Furnace involves placing the workpieces onto the grooved hearth, where they are then heated to the required temperature. The grooves guide the movement of the workpieces, allowing them to pass through different heating zones within the furnace. Depending on the process, the workpieces may be subjected to different temperature profiles to achieve the desired metallurgical properties.

In some configurations, the furnace may be designed for continuous operation, where the workpieces move through the furnace at a controlled speed. This continuous movement ensures that the heat treatment process is efficient and consistent. In other cases, the furnace may operate in a batch mode, where the workpieces are loaded, heated, and then unloaded in cycles.

Applications

Grooved Hearth Type Furnaces are widely used in various industrial sectors, particularly in the metalworking and automotive industries. Some common applications include:

Annealing: Softening metals and relieving internal stresses by heating them to a specific temperature and then cooling them at a controlled rate.

Tempering: Reducing the brittleness of hardened steel by reheating it to a lower temperature.

Hardening: Increasing the hardness of steel and other metals by heating them to a high temperature and then rapidly cooling them.

Sintering: Heating powdered materials to a temperature below their melting point to bond them together.

Advantages

Uniform Heating: The grooved design ensures uniform heating of the workpieces, leading to consistent quality in the finished products.

Efficient Material Handling: The grooves guide the movement of workpieces, reducing the need for manual intervention and increasing production efficiency.

Versatility: These furnaces can handle a wide range of materials and heat treatment processes, making them suitable for various industrial applications.

Controlled Atmosphere: Many Grooved Hearth Type Furnaces are designed to operate in a controlled atmosphere, which prevents oxidation and other undesired chemical reactions.

Conclusion

The Grooved Hearth Type Furnace is an essential tool in the industrial heat treatment landscape, offering a unique combination of precision, efficiency, and versatility. Its specialized design makes it ideal for processes that require continuous or semi-continuous heating of workpieces, ensuring high-quality results in various applications. As industries continue to evolve, the demand for advanced and reliable heat treatment solutions like the Grooved Hearth Type Furnace will likely grow, making it a cornerstone in modern manufacturing.

0 notes

Text

How Zinc Galvanizing Protects Crash Barriers and Saves Lives

Crash barrier are essential safety features on roads, designed to prevent vehicles from veering off the road and to minimize the impact of collisions. Ensuring their durability and effectiveness is critical for road safety.

Zinc galvanizing, a process that involves coating steel with a layer of zinc, has proven to be an effective method for enhancing the longevity and performance of crash barriers. This blog delves into how zinc galvanizing protects crash barriers and ultimately saves lives.

Crash Barrier for Road Safety

Crash barrier are engineered to absorb and dissipate the energy of a vehicle impact, reducing the risk of serious injuries or fatalities. They are commonly found on highways, bridges, and sharp curves where the likelihood of accidents is high. The effectiveness of these barriers is contingent upon their structural integrity and resistance to environmental factors such as corrosion.

The Process of Zinc Galvanizing

Zinc galvanizing involves immersing steel components in molten zinc, forming a metallurgical bond that results in a robust and corrosion-resistant coating. This process can be divided into several stages:

Surface Preparation: The steel surface is cleaned to remove impurities, rust, and scale through processes like degreasing, pickling, and fluxing.

Galvanizing: The cleaned steel is dipped into a bath of molten zinc, which reacts with the steel to form multiple layers of zinc-iron alloy.

Cooling and Inspection: The coated steel is cooled and inspected for uniformity and coating thickness.

Benefits of Zinc Galvanizing for Crash Barriers

Corrosion Resistance: Zinc galvanizing provides superior protection against corrosion. The zinc coating helps in preventing moisture along with other corrosive elements from reaching the steel. This is particularly important for crash barriers exposed to harsh weather conditions, de-icing salts, and pollutants.

Long-Lasting Protection: Galvanized steel can last several decades without significant maintenance, ensuring that crash barriers remain functional over extended periods. This longevity reduces the need for frequent replacements and repairs, which can be costly and disruptive to traffic.

Sacrificial Protection: Zinc galvanizing offers sacrificial protection, meaning that the zinc layer will corrode preferentially to the steel. Even if the coating is damaged, one does not have to worry. As the exposed steel will remain protected by the surrounding zinc. Such a process helps in prolonging the barrier’s lifespan.

Impact Resistance: The metallurgical bond formed during the galvanizing process enhances the impact resistance of the steel, making crash barriers more robust in the event of a collision. This ensures that the barriers can effectively absorb and dissipate impact energy, reducing the severity of accidents.

Cost-Effectiveness: While the initial cost of galvanizing might be higher than other protective coatings, the long-term savings are substantial. Reduced maintenance, longer service life, and decreased frequency of replacements make zinc galvanizing a cost-effective solution for crash barriers.

Read More: https://www.galvanizers.co.in/blog/how-zinc-galvanizing-protects-crash-barrier/

0 notes

Text

High Manganese Steel Plates

In the realm of industrial materials, high manganese steel plates stand out as a testament to engineering excellence and innovation. Renowned for their exceptional durability, resilience, and versatility, these plates have become indispensable in various sectors, from mining and construction to manufacturing and beyond. Let’s delve into the features that make high manganese steel plates a preferred choice in demanding applications.

1. Superior Hardness and Toughness: High manganese steel plates are celebrated for their remarkable hardness and toughness, which are achieved through a unique combination of alloying elements. Typically containing around 12-14% manganese, these plates exhibit excellent wear resistance and impact strength, making them ideal for environments where abrasion and heavy impacts are commonplace.

2. Outstanding Work Hardening Ability: One of the standout features of high manganese steel plates is their ability to work harden under impact conditions. This means that the material becomes even harder and tougher when subjected to repeated impact or stress, effectively extending its service life and enhancing performance in abrasive environments.

3. Excellent Weldability and Formability: Despite their high hardness and toughness, high manganese steel plates offer good weldability and formability. This characteristic allows for easier fabrication into complex shapes and structures, meeting the diverse requirements of various industrial applications without compromising on strength or durability.

4. Resistance to Abrasion and Wear: Industries such as mining, quarrying, and earthmoving rely heavily on equipment and components that can withstand severe abrasion and wear. High manganese steel plates excel in these conditions, offering unparalleled resistance to abrasion from rocks, minerals, and other abrasive materials encountered in harsh operating environments.

5. Applications Across Diverse Industries: The versatility of high manganese steel plates extends their utility across a wide range of industries. They are commonly used in the production of crusher parts, excavator buckets, wear liners, railway switches and crossings, and various heavy machinery components. Their ability to withstand extreme conditions and heavy loads makes them indispensable in critical applications where reliability is paramount.

High Manganese Plates are an amalgamation of both, ferritic and austenitic compound properties, which make them one of a kind than other steel plates. These ferritic-austenitic steel plates structure an unrivaled microstructure when warmed at the supported temperature, which helps in checking unprecedented effect durability. A Chromium-Molybdenum blend helps its breaking down impediment qualities, giving certification against different usage types.

The basic property of manganese steel sheets is that, it contains 12%-14% of manganese steel. In light of this quality, these steel plates can alter paralyze leads safely. The best part about these non-engaging plates is that in the midst of the work building up procedure simply the outside surface bonds. While inside layer remains exceedingly malleable.

Mechanical Composition

Conclusion

High manganese steel plates exemplify the pinnacle of metallurgical engineering, combining hardness, toughness, and versatility on: in a single material. Their superiority in resisting wear, impact, and abrasion makes them indispensable in heavy industries worldwide. As technology advances and industrial demands evolve, these plates continue to play a crucial role in enhancing efficiency, reducing downtime, and ensuring reliability across diverse applications. Embracing high manganese steel plates is not just a choice for performance; it’s a commitment to excellence in engineering and

For More Information:

Visit Our Website -https://www.chhajedfasteners.com/

Call Us – +91-932-111-3630

Email Us- [email protected]

0 notes

Text

Exploring Nitride Bonded Silicon Carbide: The Super Material for Tough Jobs

Hello here! We are delving into the intriguing realm of Nitride Bonded Silicon Carbide, or NBSC for short today. Thanks to its remarkable qualities, this high-tech ceramic substance is creating waves in several sectors. NBSC could possibly be your new best buddy if you require something that can survive harsh environments. Let's investigate the reasons this substance is so unique, how it's created, where it's used, and why it's a game-changer.

Why Is NBSC so unique?

Mechanical strength

Let me start with strength first. NBSC is really robust. The nitride bonding technique lets it resist a lot of mechanical strain. This makes it ideal for times when things get tough and you want a substance that won't break or wear down readily.

Thermal Stability; Heat Not a hitch. Even at very high temperatures, NBSC performs really brilliantly. You will thus usually find it in locations like kilns and industrial furnaces. It also doesn't expand much when heated, so under thermal stress it is less prone to shatter.

Chemical Oppensity

When it comes to withstand chemical assaults, NBSC is like the materials' super hero. Whether it's molten metal, bases, or acids, this substance can manage it all without corroding. For use in chemical processing facilities and other demanding situations, that makes it perfect.

Resistance in Wear

NBSC is the choice if you require something that can keep on ticking and withstand abuse. It's quite robust and strong, which makes it ideal for mechanical seals and pump components—parts that will be heavily used.

The Making of NBSC:

Original Resources

High-purity silicon carbide (SiC) powder starts the path to produce NBSC. The base material is made from these mixed with silicon nitride (Si3N4).

Changing It Outline

NBSC can be shaped in numerous ways based on your demand. Often utilized are pressing, extrusion, and injection molding. The chosen method relies on the form, size, and complexity of the component.

The Nitide Bonding Mechanism

That's where the magic occurs. High temperature silicon carbide reacts with nitrogen to create silicon nitride. This technique guarantees everything bonds exactly by being conducted in a controlled surroundings. The outcome is a densified, extremely strong ceramic substance.

Smintering

The parts undergo sintering following the bonding procedure. Heating them slightly below their melting point causes the particles to combine into a solid form. Giving the material full strength and durability depends on this stage.

Where You'll Discover NBSC Industrial Kilns and Furnaces

Because NBSC can manage high temperatures and thermal shock, it is the go-to material for kilns and industrial furnaces. Often produced from NBSC are components including kiln furniture, burner nozzles, and furnace linings.

Wear- Resistance Parts

Where abrasion is a major concern, NBSC excels. Because it can resist a lot of wear and tear without degrading, it finds use in mechanical seals, abrasive blasting nozzles, and pump parts.

Chemical Processing Toolset

The resistance of NBSC against corrosion in chemical facilities is quite advantageous. Heat exchangers, reaction vessels, and pipe systems handling strong chemicals and high temperatures find application for it.

Metallurgical Uses:

In metallurgical operations, particularly with regard to molten metal handling, NBSC is also a mainstay. For parts like liners and crucibles, its chemical and heat tolerance makes it perfect.

Semiconductor Production

NBSC supports the manufacturing of high-purity silicon wafers in the semiconductor sector. Maintaining the purity and quality of these wafers depends critically on their chemical inertness and thermal stability.

Why NBSC is a game-changer in longevity and durability?

Long longevity of NBSC is one of its main advantages. Long-term savings of time and money result from its strength, wear resistance, and chemical inertness meaning components last longer and require less maintenance.

Performance Under Extreme Conditions

NBSC functions consistently regardless of extreme heat, corrosive chemicals, or abrasive surroundings. This makes it a flexible material with many possible demanding uses.

Economical Relevance

NBSC can be somewhat reasonably priced even with its sophisticated characteristics. Many businesses find it a wise decision as its great performance and low requirement for regular replacements and maintenance make it desirable.

Personalization

One can customize NBSC components to fit certain requirements. The manufacturing method can be changed to provide exactly what you require whether your needs call for a specific form, size, or feature.

In conclusion

Among materials with special combinations of strength, thermal stability, chemical resistance, and wear resistance is nitride bonded silicon carbide. From chemical processing tools to high-temperature furnaces, its adaptability and dependability make it priceless in many different fields. NBSC is expected to be a major participant driving innovation and efficiency forward as the demand for materials capable of handling ever challenging surroundings rises. Therefore, NBSC is most definitely worth looking at if you search for a substance that can withstand the heat (and much more).

0 notes

Text

Best Ferro Titanium Manufacturer in India - Bansal Brothers

Introduction

Bansal Brothers is a shining example of quality and innovation amidst the wide terrain of the metallurgical industry. Bansal Brothers, one of the leading producers of ferro titanium in India, is well-known for its dedication to quality and client satisfaction. This blog explores the qualities of products, production methods, and customer-focused philosophy that make Bansal Brothers the top ferro titanium company in India.

What is Ferro Titanium?

Ferro titanium is an iron and titanium alloy with a typical titanium content of 10–20%. In the steel industry, it is frequently used to add titanium as an alloying element and deoxidize steel. Steel gains strength and increased corrosion resistance from this addition, which also helps to improve steel's mechanical qualities. Ferro titanium's superior quality is essential to the finished steel goods' functionality and durability

Why Choose Bansal Brothers?

1. Superior Quality Products

Bansal Brothers is proud to manufacture the best ferro titanium available. The business sources the best raw materials and uses cutting-edge technology to produce dependable and effective products.

2. Modern Manufacturing Establishments

The newest machinery and technology are used at Bansal Brothers' manufacturing facilities. Because of this, they are able to keep their production processes running with a high degree of consistency and precision. The business's ongoing commitment to innovation and quality is demonstrated by its investments in updating its infrastructure.

3. Skilled Group

The success of Bansal Brothers may be ascribed to their staff of professionals, who are extremely trained and experienced. Every team member, from quality control specialists to engineers, is essential to upholding the company's stellar reputation for high standards. Their knowledge guarantees the production of ferro titanium of unmatched quality.

4. A customer-focused methodology

Bansal Brothers is committed to establishing enduring bonds with their clients. They provide specialized solutions made to match the unique requirements of their customers. Their image as a reliable partner in the industry is further cemented by their quick and effective customer service, which guarantees that any questions or complaints are handled right away.

5. Environmental Responsibility and Sustainability

Bansal Brothers is dedicated to environmentally friendly production methods. They have taken steps to reduce their carbon impact and comply with strict environmental laws. By emphasizing environmentally friendly operations, the business protects the health of the community and its employees in addition to making a positive impact on the environment.

#ferro alloys suppliers#ferro titanium powder#ferro titanium#ferro titanium manufacturer#ferro titanium producers#ferro titanium scrap

0 notes