#mep fabrication drawings

Explore tagged Tumblr posts

Text

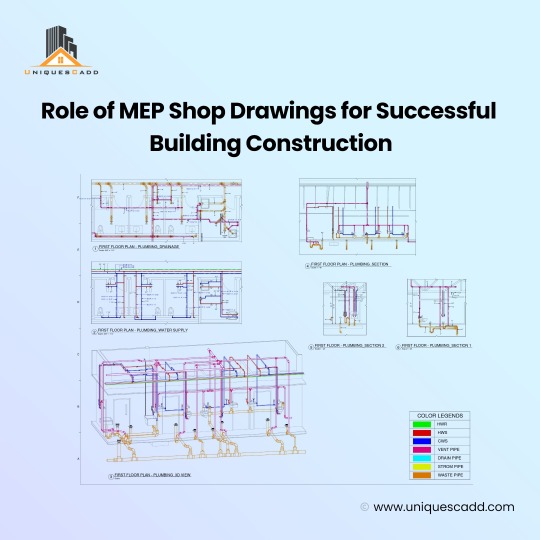

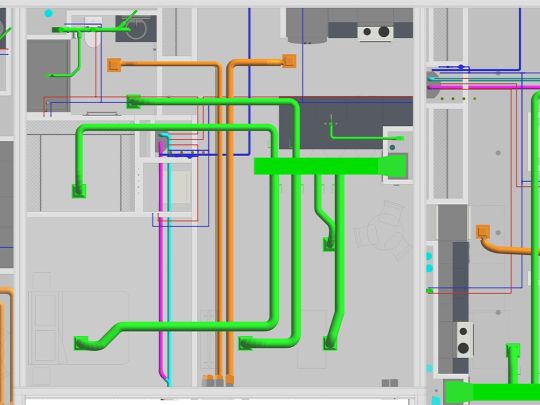

Role of MEP Shop Drawings for Successful Building Construction

MEP system installation in the building is a complex process, but it is equally important in keeping the infrastructure functional. Therefore, for utmost accuracy and efficiency, MEP shop drawings play a vital part in determining the overall success of the project. Explain in detail how it promotes the success of the project's construction.

#mep shop drawings services#mep shop drawings#mep drawings#hvac shop drawings services#mep fabrication drawings#mep hvac shop drawings#mep bim services#mep modeling services

1 note

·

View note

Text

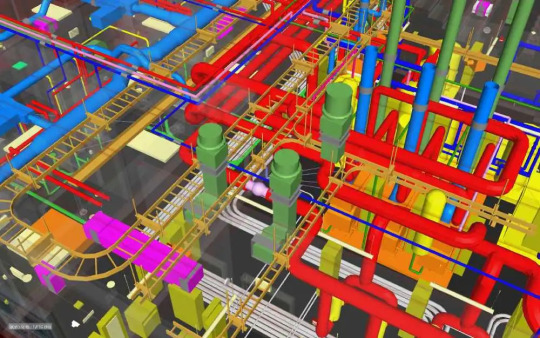

Beyond Drawings - Cost and Time Benefits of MEP BIM Design

In the ever-evolving landscape of construction and architectural evolution, the infusion of cutting-edge technology constantly reshapes the landscape. At the forefront of this transformative tool stands BIM (Building Information Modeling), which delves specifically into the intricate realms of Mechanical, Electrical, and Plumbing, aptly abbreviated as MEP BIM. Diverging from the traditional 2D schematic representations, MEP BIM Modeling Services design offers many benefits in cost efficiency and time savings, revolutionizing the way construction projects are conceived, planned, and executed.

1. Collaborative Efficiency

MEP BIM orchestrates a symphony of seamless collaboration among entwining architects, engineers, and construction virtuoso. Unlike the traditional sketches that are often prone to misinterpretation, BIM Services Provider forges a path where multidisciplinary teams concurrently craft a single, integrated digital model. This real-time collaboration elevates communication, rendering discrepancies, fostering a more efficient and streamlined project development process.

2. Clash Detection and Resolution

One of the most notable aspects of MEP 3D Modeling Services is its capacity to distinguish clashes among distinctive building frameworks early in the design stage. Conventional strategies regularly lead to clashes amid construction, coming about in exorbitant rework and delays. MEP BIM's clash detection capabilities permit groups to recognize and resolve clashes before they show on the building site. This proactive approach altogether diminishes the probability of costly onsite alterations, sparing both time and resources.

3. Accurate Quantity Estimation

Accurate quantity estimation is an essential component of effective project management. MEP BIM goes beyond basic drawings by giving accurate and precise material quantities, allowing project managers and stakeholders to make more informed decisions about resource allocation and procurement. This improved precision not only reduces waste but also guarantees that building projects stay on budget, resulting in overall cost savings.

4. Construction Sequence and Planning

MEP BIM Outsourcing Services enables the production of 4D models, incorporating time into the design process. This allows construction teams to see the full project lifecycle, from start to finish, and provide comprehensive construction sequencing and planning. Simulating the building process allows teams to optimize schedules, detect potential delays, and manage risks, resulting in improved project deadlines and shorter construction durations.

5. Energy Efficiency and Sustainability

In modern construction geography, emphasis on energy effectiveness and sustainability is crucial. MEP BIM Modeling enables the analysis of multiple design options in terms of energy consumption and sustainability parameters. This not only coincides with global environmental goals but also results in long-term cost savings through reduced energy charges. The capability to simulate and optimize energy performance during the design phase is a significant advantage of MEP BIM, contributing to both economic and environmental sustainability.

6. Facility Management and Maintenance

Apart from the construction phase, MEP BIM continues to provide benefits throughout the building's lifecycle. The digital model functions as a complete database collecting information on each component of the MEP system. This promotes effective facility management and maintenance, allowing building owners to make educated decisions about repairs, improvements, and replacements. The long-term cost reductions from proactive maintenance may be significant, making MEP BIM a worthwhile investment over the lifetime of a structure.

Conclusion

MEP BIM Coordination Services design goes beyond traditional drawings, providing a comprehensive approach to construction projects with considerable cost and time benefits. From collaborative efficiency to clash detection, precise quantity calculation, and sustainability concerns, the benefits of using MEP BIM are apparent. As the construction industry evolves, including MEP BIM into the design and planning process is more than a technological leap; it is a strategic need for those seeking to deliver projects that are efficient, cost-effective, and long-term sustainable.

#mep bim services#mep bim modeling services#mep outsourcing companies in india#mep spool drawing services#mep shop drawing services#mep 3d modeling services#mep fabrication drawings#mep construction drawings#mep as-built design services#mep outsourcing services

0 notes

Text

Millwork Shop Drawing Services in USA - Indovance Inc.

#millwork shop drawing#drafting companies#3d cad company#drafting and design engineering#Revit MEP Drafting Services#fabrication drawing services

0 notes

Text

Contact us for Shop Drawing Services in New York, USA

If you are seeking reliable Shop Drawing Services in New York, Steel Construction Detailing is here to support your project with unmatched precision, experience, and commitment to excellence. From Steel Shop Drawing Services to comprehensive Shop Drawing Services, we offer solutions that meet the highest industry standards. Our shop drawings enhance communication between stakeholders, making it easy for all parties to understand each component’s role and placement. Our BIM Shop Drawing Services incorporate 3D modeling and data integration to offer a holistic view of each component within the larger project scope. This approach facilitates collaborative planning, enabling stakeholders to make informed decisions that lead to optimized designs and cost-effective solutions.

Ready to enhance your project with precise and efficient shop drawings? Reach out to Steel Construction Detailing in New York, USA, and let’s bring your project vision to life with excellence and accuracy.

Visit us:

#Shop Drawing Services#Fabrication Shop Drawing Services#Steel Fabrication Shop Drawing Services#Steel Shop Drawing Services#MEP Shop Drawing Services#Rebar Shop Drawing Services#Precast Shop Drawing Services#CAD Shop Drawing Services#BIM Shop Drawing Services#USA

0 notes

Text

What are the advantages of Shop Drawing Services?

Welcome to our Shop Drawing Services Blog! Explore expert insights, industry news, and tips for optimizing your shop drawings. From architectural blueprints to engineering schematics, we've got you covered. Stay tuned for valuable resources to streamline your projects and enhance accuracy in every detail. Let's dive into the world of shop drawings!

Blog: https://siliconecuk.blogspot.com/2023/08/what-are-advantages-of-shop-drawing.html

#Shop Drawing Services#Steel Shop Drawing Services#MEP Shop Drawing Services#Rebar Shop Drawing Services#Fabrication Shop Drawing Services#2D Shop Drawing Services#CAD Shop Drawing Services#BIM Shop Drawing Services

0 notes

Text

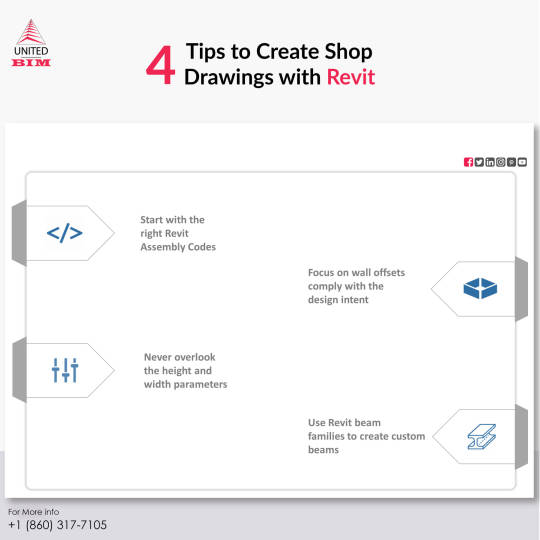

An infographic stating four important tips that will help you create accurate shop drawings with the help of Revit.

#BIM#Revit#ShopDrawings#Fabrications#Drawing#AEC#Architectural#Engineering#Construction#MEP#HVAC#Designing#Drafting

0 notes

Text

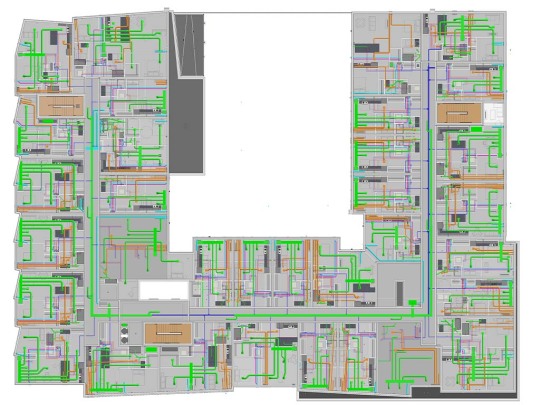

MEP Coordination Services for Residential Apartment Project

Setup of MEP coordination services framework presents a significant challenge for complex Apartment projects. Today, residential projects are so complex that specialized contractors and consultants with experience are needed to execute them within the given budget and timeframe.

However, due to a lack of awareness of various digital tools available in the market, consultants and contractors often use semi-digitalized methods for executing MEP projects, in which design coordination is done through AutoCAD plans, while the most critical part, clash detection, is done manually.

This approach often results in identifying different service clashes during the execution stage, which leads to rework, time consumption, and cost overruns. Sometimes, the cost of this rework is so high that it negatively affects the project, resulting in cost overruns, time overruns, and reducing the profits of all parties involved.

MEP Coordination Using BIM Technology

In the construction industry, the mechanical, electrical, and plumbing (MEP) systems of a facility can represent up to sixty percent of its total cost. Given this significant figure, coupled with the challenges of routing each of these systems, MEP coordination becomes a high priority in the Residential apartment design of constructions.

This coordination typically involves the trade contractors and other responsible parties such as engineers and VDC coordinators, who work together to integrate their systems into the apartment building. Traditionally, this process involved a time-consuming overlay of drawings to identify clashes and route the MEP systems.

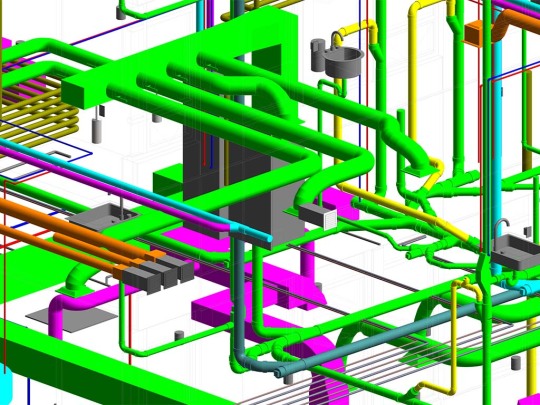

With the development of computer-aided design (CAD), this process became faster and replaced the traditional approach. However, with the introduction of Building Information Modeling (BIM) technologies, new processes have emerged that include clash detection and highly detailed visualizations, taking MEP coordination for Apartment project to the next level.

Some of the BIM software can be used for effective MEP coordination are Autodesk’s Revit, Navisworks, BIM360 Glue, Procore, Tekla, Trimble Connect, and more.

BIM-based MEP Coordination Services for Apartment Projects

BIM-based MEP coordination services ensure that the MEP systems of the apartment project are designed, coordinated, fabricated, installed and construct correctly and efficiently. BIM coordination services facilitate collaboration among various stakeholders involved in the BIM construction project including architects, MEP engineers, general contractors, MEP contractors, and other trades.

The BIM Model allow all stakeholders a digital representation of physical and functional characteristics of the MEP systems of building’s facility.

MEP Coordination Process for Apartment Project

The BIM MEP coordination process usually begins with the creation of a 3D model of the building, which includes the architectural, structural, and MEP systems. Each MEP system is then modeled in detail, including ductwork, piping, conduits, and other components.

The model is then analyzed for potential clashes between different systems or components. These clashes are resolved by adjusting the position or configuration of the affected components in the model.

Once the coordination process is complete, the final 3D model serves as a basis for generating detailed shop drawings, fabrication models, and installation drawings.

Use Standard MEP Template

Use company standard MEP template for modeling which include MEP components.

Positioning MEP model with Architectural Model

Add architectural model coordinates to MEP model and positioning them by using the “Origin to Origin” approach.

Create Levels and Grids for MEP Model

Align the levels and grids of MEP model with the base model (architectural and structural model)

Create MEP Worksets

Creating worksets to show and hide the mechanical, electrical, plumbing, fire protection elements for better visualization.

Develop MEP-FP Model

Create highly detailed and accurate 3D MEP Model based on the required BIM LOD, BEP (If available), specifications, drawings, and client’s input.

Run Clash Detection

Run interdisciplinary Clash detection between architectural, structural, mechanical, electrical, plumbing, fire protection systems and generate clash reports.

Review and resolve

All clashes’ elements can be identified by their clash ID and that can be fixed in the Revit file. Some complicated clashes can be reviewed and resolved with the contractors and design team by generating RFI, clash reports and change orders.

Benefits of BIM MEP Coordination Services

Clash Detection and Resolution – Identify and resolve the clash between multiple disciplines before the construction begins.

Optimum Space Utilization – Optimal utilization of available space to maximize functionality of MEP design layouts.

Enhance Building Performance – It ensures that all MEP components works seamlessly throughout the project lifecycle, facilitating energy efficiency, sustainability, operational effectiveness.

Save Cost Overrun – Resolution of clash errors in the early phase of design and construction can reduce the reworks, material wastage and facilitate the cost savings.

Streamline Construction Schedules – Facilitate smoother construction schedules by minimizing the disruption caused by clashes and delays.

Mitigate Risk – It provide safe working environment by eliminating hazards and ensure safety regulations, thus mitigating the risk associated with MEP systems during the construction and operation phase.

Effective Collaboration – It provide a collaborative platform for all team members where they can communicate effectively to facilitate the smooth decision making process.

Conclusion

In conclusion, MEP coordination services are a critical method for apartment’s design and construction project. With the advent of BIM technology, MEP coordination has become more efficient and effective, reducing the risk of rework, delays and cost overruns. BIM software allows all stakeholders to work collaboratively on a project, identify potential clashes and solve them before construction begins. This results in a more streamlined construction process, better quality control and ultimately, successful project outcomes.

#MEPCoordinationServices#BIMCoordinationServices#MEPRevitModelingServices#MEPRevitServices#RevitMEPServices#MEPBIMCoordinationServices#MEPservicesinconstruction#MEPCoordinationModeling

1 note

·

View note

Text

Leading CAD design service provider in Dubai, UAE. Conserve offers CAD engineering support services including fabrication drawing services, Architectural, MEP Structural drawing, and Shop drawing services in Dubai.

#cad design dubai#cad design service dubai#cad drafting dubai#cad shop drawing uae#cad fabrication drawing dubai

1 note

·

View note

Text

Why Piping Design Drawings and 3D BIM Modeling Services Are Vital for Modern Construction Projects

The Role of Piping Design Drawings in Project Planning

At the heart of any mechanical or plumbing system lies a complex web of pipes, valves, and fittings. Whether it's HVAC, water supply, or industrial process piping, these systems must be carefully planned and precisely executed. This is where piping design drawings come into play.

These technical illustrations represent the layout, size, material, and alignment of piping systems in a detailed and structured way. They provide essential information such as:

Pipe routing and elevation

Connection types and specifications

Flow direction and pressure ratings

Equipment locations and clearances

Piping design drawings serve as the blueprint for fabricators, contractors, and engineers. Mistakes or inconsistencies in these drawings can lead to costly delays, safety hazards, or operational inefficiencies. That’s why high-quality, well-coordinated piping drawings are non-negotiable for complex projects.

The Power of 3D BIM Modeling Services

While 2D drawings have their place, the construction industry is increasingly turning to 3D BIM modeling services (Building Information Modeling) to visualize and manage every component of a project. BIM allows stakeholders to create and interact with digital twins of physical spaces—models that include not only geometry but also valuable metadata.

BIM offers a wide range of benefits, including:

Clash detection: Identifying spatial conflicts between systems (e.g., HVAC duct vs. electrical conduit) before construction begins

Improved coordination: Sharing one unified model among architects, engineers, and contractors improves communication and accountability

Accurate quantity take-offs: Generating material lists and cost estimates directly from the model

Lifecycle management: Facility managers can use BIM data long after construction for maintenance and upgrades

For mechanical and piping systems in particular, 3D BIM modeling services allow for more accurate layouts, fewer surprises on-site, and better collaboration among trades.

How 3D Modeling Services Bridge the Gap Between Design and Construction

While BIM is a process and platform, 3D modeling services refer more broadly to the creation of three-dimensional digital models—whether for architectural visualization, mechanical design, or product development. In the context of piping and construction, 3D models act as a bridge between conceptual design and physical implementation.

The benefits of 3D modeling services include:

Visualization: Helping clients and stakeholders understand spatial relationships, aesthetics, and system functionality

Fabrication support: Generating shop drawings and CNC-ready files from accurate models

Simulation and testing: Running performance analyses before anything is built, saving time and money

Precision: Minimizing guesswork in construction through clear, photorealistic representation

With the right modeling approach, even the most complex piping networks can be virtually constructed, inspected, and modified—before a single pipe is installed.

Why Choose Funding Walk?

At Funding Walk, we combine technical expertise with cutting-edge technology to deliver superior piping design drawings, 3D BIM modeling services, and 3D modeling services tailored to your specific needs. We don’t just provide drawings—we deliver confidence. Our team understands how to balance design intent, regulatory compliance, and practical constructability to support your project from concept to completion.

Whether you’re an MEP engineer, a construction firm, or a project manager looking to streamline your operations, Funding Walk can help you:

Avoid costly design errors

Enhance team collaboration

Accelerate project timelines

Deliver better outcomes for clients and stakeholders

0 notes

Text

Barndominium Steel Homes: Why They’re the Smartest Residential Choice

Barndominiums—hybrid homes that combine living quarters with garage or workshop spaces—are rapidly becoming a popular choice for homeowners looking for versatility, durability, and affordability. When built with steel framing, these homes offer unmatched strength, design flexibility, and energy efficiency. In this guide, we explore everything you need to know about barndominium steel homes, and how residential steel buildings from Icon Steel Buildings deliver premium quality, custom design, and unbeatable service.

1. What Is a Barndominium Steel Home?

A barndominium steel home is a residential structure built with a steel frame that integrates living space with garage or workspace under a single roof. This type of home is often favored for:

Open floor plans

Multi-purpose use (living + workshop)

Cost savings through consolidated design

Easy inspection and maintenance

Choosing steel over wood or masonry ensures long-term durability and performance, making your barndominium both functional and beautiful.

2. Why Choose Steel for Your Barndominium?

Steel provides several key advantages when building barndominiums:

Durability: Resistant to termite damage, rot, mold, and severe weather

Engineering Precision: All residential steel buildings are constructed from engineered steel kits, ensuring consistent quality

Energy Efficiency: Paired with insulation, sealed steel homes reduce energy bills

Fast Build Time: Prefabricated panels and structural framing accelerate construction

Design Flexibility: Wide clear spans without internal load‑bearing walls create open space

Icon Steel Buildings offers barndominium packages as part of their residential steel buildings line, tailored for both rural and semi-urban settings.

3. Engineering & Permitting: Built to Code

Every residential steel building, including barndominiums, comes with:

Engineered, stamped, and sealed drawings

Risk Category II compliance, which is required for residential structures

Complete documentation necessary for permits and inspections

This engineering framework gives you peace of mind and streamlines the approval process in nearly every jurisdiction.

4. Solid Foundations with Minimal Cost

Icon Steel requires a 4‑inch monolithic slab with 12″ × 12″ footers. This design:

Provides a continuous, stable base for the steel frame

Minimizes slab cracking by pouring in one piece

Supports point loads from columns and framing

Pairs perfectly with residential steel building kits for simplified construction

The foundation requirement is cost‑effective and perfectly suited for barndominiums or other residential steel residential floor plans.

5. Turnkey Solutions: From Kits to Keys

When you choose Icon Steel for your barndominium project, you benefit from a full-service experience:

Manufacture: All steel components are precision-fabricated to your design

Delivery: We ship nationwide directly to your site

Installation: Skilled crews erect your structure, install windows, doors, and garage doors

Finishes & Accessories: Roof panels, trims, windows, trim, and structural accessories included

Our residential steel buildings packages include all necessary elements for your barndominium build.

6. Custom Design & Architectural Services

Icon Steel offers advanced design services to create personalized barndominium layouts:

Architectural planning tailored to your lifestyle

MEP (Mechanical, Electrical & Plumbing) engineering (excluding HVAC) for efficient systems design

Customizable layouts, from garage/workshop combinations to cabins or multi-room residences

Your barndominium plans are integrated into the residential steel buildings framework, ensuring seamless construction and permit approval.

7. Ideal Uses for Barndominium Steel Homes

a. Primary Residence

Many homeowners build barndominiums as their main living space, taking advantage of open layout flexibility and combined garage/workshop living.

b. Hobby Workshop and Living Combo

A barndominium is ideal for artists, woodworkers, or hobbyists who want convenient access to equipment.

c. Guest House or Rental Unit

When designed correctly, barndominiums make efficient guest homes or rentable Airbnb units under the residential steel buildings umbrella.

d. Farmstead Homes

Rural residential barndominiums built using steel provide strong protection for animals, equipment, and family under one roof.

8. Popular Keyword Strategies for SEO

When users search for these terms, they typically look for quality steel homes with fast build times and clear cost breakdowns. Effective keywords tied to internal linking include:

barndominium steel buildings

steel barndominiums

residential steel buildings

barndominium kits

steel home floor plans

prefab steel homes

affordable steel residential building kits

engineered steel homes

All of these can be naturally linked to the residential steel buildings page within the copy to boost SEO visibility.

9. Cost Considerations and ROI

The average cost of a steel barndominium depends on:

Size of the structure

Foundation type (4‑inch slab + footers)

Framing options and insulation

Interior finishes and layout

Shipping and installation services

Compared to traditional wood construction, residential steel buildings deliver long-term value. Maintenance costs are lower, durability is higher, and resale value often improves.

10. Financing for Residential Steel Buildings

Icon Steel provides financing options to make barndominium projects accessible:

Multiple financing plans available through trusted partners

Pre-qualification with soft credit pull (no impact on credit score)

Flexible terms to cover steel kits, installation, and accessories

Visit our residential steel buildings page to learn more or begin the application process.

11. Design Inspiration & Floor Plan Examples

30x50 Barndominium Layout

Open living/kitchen space

Loft or second level for bedrooms

Side workshop or garage area

40x60 Two-Story Build

Ground floor garage and living

Upper-level bedrooms or office area

50x80 Farmstead Model

Multi-purpose shop and living areas

Mezzanine plans for storage or loft

Every layout is compatible with residential steel building plans and can be linked to residential steel buildings for customization and purchase.

12. Frequently Asked Questions

Q: Are barndominiums built to the same code as homes?

Yes. All our barndominiums are engineered, stamped, and sealed to meet Risk Category II residential codes and local building regulations.

Q: What foundation is required?

A 4-inch monolithic concrete slab with 12″ × 12″ footers is the standard foundation we require, designed for long-term durability and structural safety.

Q: What’s included in the full-service build?

Your package includes steel framing, roof and wall panels, engineered drawings, delivery, installation, windows, doors, and structural accessories—all handled by Icon Steel staff.

Q: Is custom design possible?

Absolutely. We provide architectural and MEP services to tailor barndominium layouts to your lifestyle and property.

Q: How long does construction take?

Thanks to prefabrication, most barndominiums are erected within weeks after foundation completion.

13. Serving Locations Nationwide

Icon Steel Buildings supports customers across the country. We frequently receive inquiries from:

Florida

Georgia

Tennessee

Texas

California

Colorado

Users looking for residential steel buildings near me or barndominium steel building contractors will find Icon Steel’s expertise available nationwide.

14. Contact Icon Steel Buildings Today

Ready to build your steel barndominium or residential home? Contact us to explore options, get pricing, or schedule a consultation:

Icon Steel Buildings 801 Northpoint Parkway, #116 West Palm Beach, FL 33407 📞 Contact Us: 1‑877‑641‑4619 🌐 www.iconsteelbuildings.com

Visit our residential steel buildings page today to start building your dream home with steel.

Barndominium steel homes offer an innovative, practical, and cost-effective residential solution. Whether it's a combined living and workspace, a sustainable farmstead home, or a custom-designed family residence, steel provides strength, efficiency, and design flexibility that traditional materials struggle to match.

By choosing an engineered solution with full-service delivery, installation, custom design, and financing options—all available through residential steel buildings—you invest in a home that’s built to last, built to perform, and built to impress.

Reach out to Icon Steel Buildings at 1‑877‑641‑4619 or visit us at 801 Northpoint Parkway, #116, West Palm Beach, FL 33407 to get started with your steel barndominium project today. Build better, build smarter with steel.

0 notes

Text

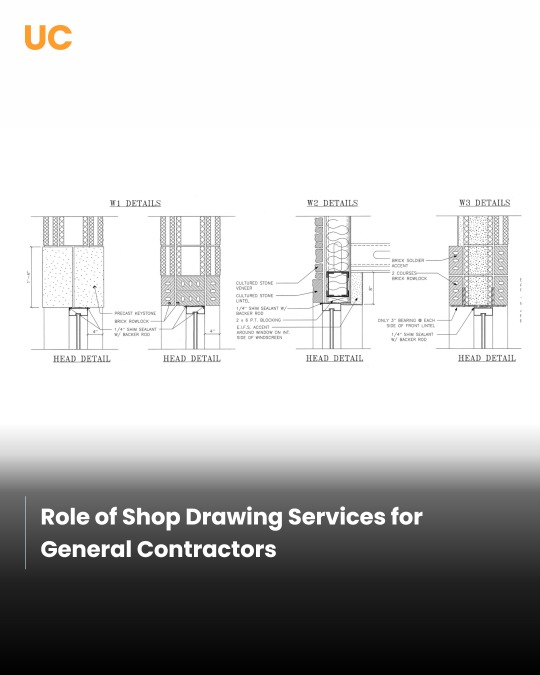

Role of Shop Drawing Services for General Contractors

Shop drawings are a pivotal part of the AEC project, enabling professionals to maintain accuracy and efficiency. Shop drawing is a key to every project’s success, with aligning industry codes and standards. Discover how it is a beneficial aspect for general contractors.

#shop drawings#shop drawing services#detailed shop drawing#architectural shop drawings#mep shop drawings#fabrication drawings#bim drawing services#outsourced shop drawings

2 notes

·

View notes

Text

We deliver innovative and high quality MEP BIM Modeling Services provided by experienced MEP BIM professionals with cross-functional expertise who believe in robust processes and quality delivery.

#mep bim services#mep bim modeling services#mep outsourcing companies in india#mep spool drawing services#mep shop drawing services#mep 3d modeling services#mep fabrication drawings#mep construction drawings#mep as-built design services#mep outsourcing services

0 notes

Text

Architectural Shop Drawing Services in Hastings, New Zealand

Silicon Engineering Consultants Ltd offers Architectural Shop Drawing Services in Hastings, New Zealand. Our Revit Architectural Services can integrate advanced BIM tools to enhance design coordination and reduce project risks. We deliver highly accurate CAD Shop Drawings Services that support contractors and fabricators with precise technical insights. Our architecture drafting services maintain exacting standards of accuracy and compliance with building codes. Our team specializes in Architectural BIM Modeling Services that enables 3D visualization, clash detection and data rich models for better decision making. We also provide comprehensive Architectural Plan Designing that aligns with structural MEP and client specific requirements. Our CAD Design Outsourcing solutions help architectural firms focus on creativity while we handle the technical detailing. Our reliable Architectural Designing Outsourcing services clients benefit from skilled professionals, timely delivery and consistent quality.

Get in touch with us today to streamline your architectural projects with precision-driven shop drawing solutions. Our expert team is ready to assist you with customized drafting, designing, and outsourcing services tailored to meet your specific project requirements.

For More Information:--

0 notes

Text

What is a 3D Coordinate System in Construction?

Discover the importance of the 3D coordinate system in construction, where X, Y, and Z axes help accurately define the position of elements in a building model. This blog explains how 3D coordinates enhance precision in 3D clash coordination, MEP shop drawings, and spool fabrication drawings, ensuring smoother BIM workflows and efficient project execution.

#bim management services#bim 4d and 5d#3d clash detection#bim model coordination#pipe spool drawing#spool drawing services#mepf#mepf in construction#drafting services

0 notes

Text

Expert Shop Drawing Services in New York, USA

Steel Construction Detailing pride ourselves on delivering top Shop Drawing Services right here in the USA. Our expert team ensures precision and efficiency in every project, helping you bring your construction visions to life with meticulous detail. Our shop drawing services are tailored to meet the unique needs of architects, engineers, contractors, and fabricators. We provide comprehensive drawings that include detailed plans, sections, and elevations, ensuring all structural components are accurately represented.

Partner with Steel Construction Detailing for all your shop drawing needs and experience the difference that expertise and dedication can make. Contact us today to learn more about how we can support your next project in the USA.

Website: https://www.steelconstructiondetailing.com/shop-drawing.html

#Shop Drawing Services#Fabrication Shop Drawing Services#Steel Fabrication Shop Drawing Services#Steel Shop Drawing Services#MEP Shop Drawing Services#Rebar Shop Drawing Services#Precast Shop Drawing Services#CAD Shop Drawing Services#BIM Shop Drawing Services#HVAC Duct Shop Drawing Services#Architectural Shop Drawing Services#Outsource Shop Drawing Services#Sheet Metal Fabrication Shop Drawing Services#Plumbing Piping Shop Drawing Services#Shop Drawing Consultants Services#Shop Drawing Engineering Services#Shop Drawing and Drafting Services#Shop Drawing Outsourcing Services#Shop Drawing CAD Services Provider#Shop Drawing Consultancy Services Company

0 notes

Text

What are the advantages of Shop Drawing Services?

Welcome to our Shop Drawing Services Blog! Explore expert insights, industry news, and tips for optimizing your shop drawings. From architectural blueprints to engineering schematics, we've got you covered. Stay tuned for valuable resources to streamline your projects and enhance accuracy in every detail. Let's dive into the world of shop drawings!

Blog: https://siliconecuk.blogspot.com/2023/08/what-are-advantages-of-shop-drawing.html

#Shop Drawing Services#Steel Shop Drawing Services#MEP Shop Drawing Services#Rebar Shop Drawing Services#Fabrication Shop Drawing Services#2D Shop Drawing Services#CAD Shop Drawing Services#BIM Shop Drawing Services#Blog#Viral#Blogpost#post

0 notes