#magnesia carbon fire bricks

Text

Main uses of magnesia chrome bricks

Magnesia chrome brick is a high-quality refractory material composed of magnesium oxide (MgO) and chromium trioxide (Cr2O3). It has excellent performance in high temperature environment and is widely used in many fields. The following are the main uses of magnesia chrome bricks:

1、Metallurgical industry: Magnesia-chrome bricks are widely used in high-temperature equipment in the metallurgical industry, such as steel converters, electric furnaces, and smelting furnaces. They can be used in areas such as linings, furnace floors, furnace walls and furnace roofs to provide refractory protection and withstand erosion and wear under high temperature conditions.

2、Chlor-alkali industry: Equipment such as electrolyzers and evaporators in the production process of the chlor-alkali industry need materials that can withstand high temperatures and corrosion. Magnesia-chrome bricks are widely used in these equipment, providing excellent fire resistance and corrosion resistance, ensuring long-term stable operation of the equipment.

3、Oil refining and chemical industry: In the oil refining and chemical industry, magnesia-chrome bricks are often used in high-temperature equipment such as catalytic cracking units, hydrogenation units, reforming units and furnaces. They withstand high temperatures, corrosive gases and chemicals and provide reliable fire protection.

4、Glass industry: Glass furnaces are the core equipment in the glass industry, which are required to withstand extremely high temperatures and chemical erosion. Magnesia-chrome bricks are widely used in the inner lining, cooling zone and melting area of glass furnaces to maintain stable refractory performance and long service life.

5、Power industry: In the power industry, magnesia-chrome bricks are often used in high-temperature equipment such as boilers, burners, chimneys and hot blast stoves. They can withstand high temperature and flue gas erosion, and provide effective fire protection to ensure the normal operation and safety performance of equipment.

6、Other industries: In addition, magnesia-chrome bricks are also widely used in cement kilns, ceramic kilns, welding furnaces, carbonization furnaces, aluminum electrolytic cells and other fields. Its excellent fire resistance and corrosion resistance make it an important high temperature refractory material.

In conclusion, magnesia chrome bricks are widely used in several industries due to their high temperature resistance, erosion resistance and mechanical strength. Whether it is metallurgy, chlor-alkali, oil refining and chemical industry, glass or electric power and other fields, magnesia-chrome bricks can provide reliable fire-resistant protection to ensure long-term stable operation of equipment.

0 notes

Text

How to make magnesia brick

Magnesia Brick Manufacturing Process:

The manufacturing process of magnesia brick includes the following steps:

1. Break and smash:

Crushing is the process of processing large pieces of material into ideal particle size materials.

2. Ingredients (weighing):

The raw materials are prepared in a predetermined proportion and mixed in a strong sand mixer. The order of feeding is magnesia aggregate – carbon fiber – binder – carbon raw material.

3. Mixing:

Mix thoroughly to get perfect coating. Add mixture made in step (B) and remix the batch intensively. Now add powder Resin (item 9), then Hexamine (item 10) and mix once again.

4. Molding:

Use a molding machine to make the mixture into bricks.

5. Drying:

Use a drying oven to dry the bricks for several hours.

6. Firing:

Fire the bricks in a kiln at temperatures of 1550 to 1600 degrees Celsius.

7.Finishing:

The final step is to grind and polish the bricks to get the desired shape and size.

Types of magnesia brick:

Magnesia bricks can be divided into two categories: sintered magnesia bricks (also known as fired magnesia bricks) and chemically combined magnesia bricks (also known as unburned magnesia bricks). Magnesia bricks with high purity and firing temperature are called direct-bonded magnesia bricks due to the direct contact of periclase grains; Bricks made of fused magnesia as raw materials are called fused re-bonded magnesia bricks.

Uses of Magnesia Bricks:

Magnesia bricks are used in steelmaking furnaces, electric furnace bottom and wall, and high temperature tunnel kiln. Magnesia bricks are also used as heat storage room lattice bricks in glass kilns.

Magnesia brick is used for permanent layers in steel making converters, AOD furnaces, and more. Magnesia brick is also used to line steel ladles and Basic Oxygen Furnaces (BOFs). Magnesia bricks can be used in a variety of applications, depending on the type of brick being used. Common uses include furnaces, ladles, secondary refining vessels, and cement and glass making kilns.

Magnesia Brick for sale

The most important steps need to be considered to avoid or reduce the possibility of magnesia bricks hydration are:

1). Magnesia bricks must be transported in a container to protect the material against moisture.

2). Magnesia bricks should be stored inside storage rooms where it is dry, free of frost, ventilated, and with a temperature between 10°C and 30°C. Note that magnesia bricks storage underneath a tarpaulin cover outside is not sufficient.

3). Bricks may not be stored for more than four weeks prior to installation and preheating.

4). Lining should be protected against moisture during installation and preheating.

Article Source:How to make magnesia brick

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-all-refractory-products

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

Application of low thermal conductivity MgO-C bricks in ladle

Currently, inhibition of steel temperature droping has become a major issue for many steel plants. Therefore, in order to suppress temperature drop of molten steel, there has a test to study insulation problem of refractory material lining in 185t ladle, by comparing three different measures.

Measure 1: Reducing the heat transfer effect of sidewall castables (30% reduction).

This method is by reducing coarse particles in castable, increasing porosity and other measures to reduce the thermal conductivity, to suppress heat dissipation.

Measure 2: Using insulation materials in the backlayer of wall castable. This method is to use one layer insulating refractory bricks with less than 1W (m celsius) thermal conductivity between ladle steel shell and wall castable, to inhibit heat dissipationheat.

Measure 3: Reducing the heat transfer of slag line magnesia carbon brick heat transfer (30% reduction).

This method is developed in recent years, to select lower thermal conductivity of magnesite carbon bricks from the high thermal conductivity of MgO-C brick for slag line, to suppress heat dissipation.

After comparing, the results found that: only in reducing the thermal conductivity of slag line MgO-C brick , the effect of suppressing steel temperature dropping is significant, up to 2 Celsius. The durability is same or higher than ordinary ladle, less cracks, the residual condition after use is also very good.

Article source:

http://www.yilongrefractory.com/news/Application%20of%20low%20thermal%20conductivity%20MgO-C%20bricks%20in%20ladle.html

E-mail:[email protected]

0 notes

Text

Calcium Silicate Market 2021 Global Industry Size, Segments, Share and Growth Factor Analysis, Top Key Players Research Report 2027

Active calcium silicate Market – Market Overview

Active calcium silicate is gaining high importance in construction industry owing to superior properties such as low thermal conductivity and thermal shock resistance. It is extensively used in fire protection and acoustic insulation sector replacing asbestos in high temperature insulation application. Increasing government regulations towards fire safety standard coupled with penetration of passive fire protection in infrastructure activities is expected to positively influence the market growth.

Calcium Silicate Market is used in building brick and board form of electric furnace, blast furnace and oil refinery. Moreover, rising penetration of high temperature insulation in end use industries such as steel and petrochemical industry will further boost the market growth. Active calcium silicate is prepared through raw materials such as limestone, sodium silicate and hydrochloric acid. These materials act as intermediate in processing other chemical compounds and help providing structure and surface to active calcium silicate. Thus, dynamics of these aforementioned raw materials significantly impact prices of active calcium silicate market.

Robust industry growth of ceramic industry owing to rising modern structure in housing sector also anticipated to drive the product demand over the forecast period. These products are used in flooring owing to its characterises such as light weight, high hardness and resistance from thermal and shock. Furthermore, rising product penetration in false ceilings and roofing tiles for construction industry and automotive plants is projected to drive the market growth. Increasing government expenditure for building airports, roads and harbours are expected to provide lucrative opportunity to manufacturer. In addition, increasing developments in residential and commercial projects in emerging markets such as China, India and Brazil are anticipated to fuel the market growth over the forecast period. Europe is leading region in active calcium silicate market owing to advance technology and stringent regulations towards product standards and quality of products. Initiatives taken to preserve historical monuments by providing special paints & coatings to protect from fire and corrosion will boost the demand for active calcium silicate in the coming years. Asia Pacific is second largest market. China is the leading producing country in the active calcium silicate market due to strong industry base including rubber, paints & coatings and plastic industry. In addition, rising consumer awareness towards decorative walls and ceilings for better aesthetic appearance is anticipated to propel the global active calcium silicate market. Changing trade statistics in South Africa will boost the demand of active calcium silicate market growth.

Additionally, regulatory trends laid by OSHA and NIOSH towards product exposure can hinder the market growth. Excess exposure to product can cause severe damage to human health. These regulations are pertaining to high manufacturing cost, thereby leading to hamper the market growth.

Active calcium silicate Market – Competitive Analysis

Active calcium silicate market fragmented with presence of small scale as well as strong regional players from tier 1 market. The key players in the market are adopting strategies such as partnership or agreement with distributors to meet global demand of active calcium silicate and strengthen competitive aspects. The major players are investing heavily in R&D in order to meet environmental legislation and minimize impact on environment. Increasing online portals can also open new lucrative opportunity for manufactures. These manufacturers are optimizing new techniques assuring their customers with the consistency in product & service quality thereby, increasing product offerings to the customers.

Browse Full Report @

https://www.marketresearchfuture.com/reports/active-calcium-silicate-market-2114

Key Players:

Promat International, Weifang Hong Yuan Chemical Co., HIL Limited, Imerys Filtration Minerals Co., 2K Technologies Ltd., R.K. Oil Industries, Ramco Industries, Skamol limited, Xella Sverige AB, and Magnesia GmbH among others are some of the prominent players at the forefront of competition in the Global Active Calcium Silicate Market and are profiled in MRFR Analysis.

Industry/ Innovation/ Related News:

January 2016 – Promat International opened a new facility in Middle East at Dubai Investment Park. The DIP location provides good link to Abu Dhabi and other gulf countries. The production facility provides PROMASPRAY® FMII, PROMASPRAY® P300, and CAFCO® 400 and significant warehouse capacity for Promat boards, fire stopping and HPI products. This help the company to strengthen its position in Middle East market.

October 2017 –BASF developed a material containing high thermal insulation based on engineering plastic Ultradur brand for window profiles. With increasing demand of restoration and interior designing of residential projects BASF is developing product to the reduce steel with PVC compact materials. Active calcium silicate is one of the intermediate used in manufacturing plastic materials.

December 2016 – Brunel university in London had developed new form of insulation that can meet environmental regulation. The substance is prepared from aerogel, a Nano insulation material that posses low thermal conductivity than any other insulation material in the market. This material is affordable and effective in wall insulation that can resist any weather conditions.

Request For Sample Report @

https://www.marketresearchfuture.com/sample_request/2114

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future

Phone: +16468459312

Email: [email protected]

Read More Related Article:

https://www.marketresearchfuture.com/reports/polymeric-surfactants-market-3901

https://www.marketresearchfuture.com/reports/carbon-nanotube-market-4397

https://www.marketresearchfuture.com/reports/abrasives-market-5391

https://www.marketresearchfuture.com/reports/release-liner-market-6241

0 notes

Text

Magnesium derivatives market to surpass valuation of us$ 64 BN by 2030 - TRANSPARENCY MARKET RESEARCH

Magnesium Derivatives Market: Introduction

The global magnesium derivatives market was valued at ~US$ 38 Bn in 2019 and is anticipated to expand at a CAGR of 5%, in terms of value, from 2020 to 2030. Magnesium derivatives are extensively used in agriculture, pharmaceutical, chemical, and construction applications due to their unique combination of characteristics. For instance, magnesium oxide is primarily used as an excellent source of magnesium in fertilizers to decrease the magnesium deficiency of soil. This enhances the yield and nutritional value of the soil. Magnesium hydroxide is also used in the manufacture of flame retardants, as it is economical and environment-friendly.

Magnesium carbonate, another magnesium derivative, is prominently used in the production of magnesium carbonate. Magnesium carbonate and magnesium carbonate-based minerals, such as hydromagnesite are used as materials in the manufacture of flame retardants. The rise in demand for low impurity steel is boosting the demand for high performance refractory linings. Magnesium carbonate is a key raw material for magnesium oxide, and in turn, refractory linings. It significantly influences performance characteristics of refractories. This is estimated to boost the consumption of magnesium derivatives, thereby driving the magnesium derivatives market in the near future.

Request a Sample-

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=74098

Key Drivers of Global Magnesium Derivatives Market

Magnesium derivatives such as magnesium hydroxide, magnesium sulfate, and magnesium chloride carry smoke suppressant and flame retardant properties. Magnesium derivatives are employed to reduce flammability in a wide range of materials.

Rise in THE number of fire incidents and increase in fire safety regulations & guidelines across the world are boosting the usage of flame retardants. Major industries are also taking proactive steps to avoid fire incidents. This is expected to drive the demand for flame retardants, thereby propelling the global magnesium derivatives market during the forecast period.

Increase in the demand for food, decrease in cultivation area, rise in the demand for sulfur-free fertilizers, and growth in magnesium deficiency of soil owing to the usage of ammonia-based fertilizers are some of the key factors driving the demand for magnesium oxide in the fertilizers industry. This, in turn, is augmenting the global magnesium derivatives market.

Rising Demand for Dead Burnt Magnesite to Offer Lucrative Opportunities

Dead burnt magnesia (DBM)/refractory magnesia is primarily used as a key component in refractory materials such as bricks, refractory mortars, gunning material, and cement. It is used to manufacture magnesium oxide, which is employed in several applications, including refractory and steel industries. DBM is resistant to corrosion, chemicals, and high heat. The steel & iron industry is a key consumer of DBM.

The consumption of DBM has been increasing due to the rise in the demand for steel refractory materials across the world. According to the World Steel Association, global steel production increased by 5.2% in 2018. Rise in the consumption of steel leads to an increase in the consumption of steel refractory bricks.

China is a key manufacturer and consumer of steel across the globe. It is a prominent producer of magnesite in the world, followed by Turkey and Russia. The country accounts for 50% share of MgO exports in the world.

Favorable economic conditions, growth in investments in infrastructure, and rise in industrialization in developing economies are key factors boosting the demand for dead burnt magnesite. This is anticipated to provide lucrative opportunities to the magnesium derivatives market.

Request for covid19 impact analysis –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=74098

Fluctuation in Raw Material Prices to Hamper Magnesium Derivatives Market

Raw materials such as magnesite, dolomite, brucite, and olivine minerals are employed in the manufacture of magnesium derivatives as well as magnesium. Manufacturers of magnesium derivatives are dependent on suppliers to meet their requirements for raw materials.

Historically, the prices of magnesium derivatives have increased and decreased due to factors related to raw materials such as availability and supply. The prices of raw materials depend upon the production and supply of and demand for magnesium across the globe.

Regulations imposed on mining also hamper the production of magnesium derivatives. Increase in duties on imports and exports is another factor responsible for fluctuation in the prices of raw materials.

Volatility in availability and fluctuating prices of raw materials can significantly hamper the global magnesium derivatives market. It can reduce the production and consumption of magnesium derivatives. It can also negatively affect the adoption of magnesium derivative-based applications.

Asia Pacific Dominates Global Magnesium Derivatives Market

Asia Pacific held ~50% share of the global magnesium derivatives market in 2018. China is one of the major consumers of magnesia and magnesite in the region.

The magnesium derivatives market in Asia Pacific is witnessing significant growth, due to an increase in the demand for high-strength steel in various end-user industries in developing economies such as China, India, and ASEAN. The market in India is projected to expand at a prominent CAGR during the forecast period, due to the growth of the country’s economy, rise in urban population, and advancements in the construction industry.

Trade deficit and instability in the prices of raw materials are anticipated to restrain the markets in in North America and Europe

Increase in construction activities in Colombia and GCC and rise in the demand for MgO in animal feed and fertilizer industries in Latin America are expected to boost the global magnesium derivatives market during the forecast period.

Buy now-

https://www.transparencymarketresearch.com/checkout.php?rep_id=74098<ype=S

Varying Market Share of Individual Magnesium Derivatives

YINGKOU MAGNESITE CHEMICAL IND GROUP CO., LTD is a leading player in the magnesium oxide as well as magnesite industry based in China. RHI Magnesite, Grecian Magnesite, Ube Industries Limited, and Martin Marietta Magnesia Specialties are the key players operating in the magnesium oxide segment. Other players include Nedmag B.V., Kyowa Chemical Industry Co, and MAGNESIA GmbH.

K+S Group is a leading company operating in the magnesium chloride segment of the market. It accounted for 22.4% share in 2018. Compass Minerals, Intrepid Potash, Inc., Israel Chemical Company, and Karnalyte Resources Inc. together held 24.7% share of the market in 2018. Other key players operating in the magnesium chloride segment include Nedmag B.V., Prochem, Inc., and Rainbow Expochem Company.

The magnesium hydroxide segment is dominated by Japan- as well as China-based manufacturers. Konoshima Chemicals, Co Ltd and Kyowa Chemicals Industry Co Ltd are some of the players based in Japan that are engaged in the manufacture of magnesium hydroxide. Martin Marietta Magnesia Specialties, Xinyang Minerals Group, and YINGKOU MAGNESITE CHEMICAL IND GROUP CO., LTD, together, held 16.7% share of the magnesium hydroxide industry in 2018. Other key players include Nedmag B.V., Huber Engineered Materials, and MAGNESIA GmbH.

Companies in the Magnesium Derivatives market have increasingly shifted gears with wide application of digital technology across the continuum, from raw material sourcing to manufacturing to generation of final output, to warehousing to final distribution operations. Among the various affects, the market is witnessing new growth economics due to thinning of line between specialty and commodity businesses that are associated with the larger ecosystem. At the same time, new growth parameters are being vigorously being debated as industry stakeholders put greater emphasis on the circular economy processes.

More Trending Report-

https://www.prnewswire.com/news-releases/rising-awareness-about-the-importance-of-fitness-due-to-the-covid-19-pandemic-and-the-expanding-popularity-of-nutraceuticals-will-mold-the-growth-of-the-psyllium-products-market-tmr-301305240.html

0 notes

Text

Construction procedures for refractory brick masonry

(1) Construction procedure of dynamic furnace

1. Dynamic furnace kiln masonry must be carried out after the single-machine no-load test operation of the kiln is qualified.

2. The basic procedures for masonry are:

The starting point should be selected from the hot end to the cold end or from the low end to the high end. The working point should be cleaned and lined to select fire bricks. According to the hot and cold section, different materials of refractory fire bricks should be used. If the qualified bricks are used, there are anchor bolts or bricks. The board, that is, the welding of the anchor nail or the brick board, if there is a heat insulation layer (such as calcium silicate board, etc.), it is necessary to first prepare and install the heat insulation layer, and the mortar mud should match the refractory brick to build the brick expansion gap. Reserved and filled.

(2) Construction procedures for static kiln

The starting point is selected (generally from bottom to top, from the hot end to the cold end). The line is drawn (usually based on the lowest end of the tuyere or inspection port). Fire bricks are selected according to different parts of the equipment. According to the drawings, if the anchoring nails and the supporting bricks are welded, if there is a thermal insulation layer, the installation of the insulating layer should be prepared and used. The material of the mortar should be matched with the refractory bricks to build the arch and lock the bricks , remove the reserve and filling of the expansion joint of the arch tire.

Changxing refractory provides refractory products, calcium silicate products, castable & mortar, china refractory brick, ceramic fiber felt, ladle & tundish nozzle, ceramic fiber with high quality for you. Such as high alumina refractory bricks, magnesia carbon brick, clay refractory bricks and other refractory products.

Article Source: Construction procedures for refractory brick masonry

Company name:Henan Xinmi Changxing Refractory Materials Co.,Ltd

Email: [email protected]

Website:http://www.chinafirebrick.com/

#Refractory Brick Manufacturer#Fire Bricks Supplier#Clay Brick Sale#Firebrick for Sale#Insulating Firebrick

0 notes

Text

300+ TOP BUILDING MATERIALS and CONSTRUCTION Objective Questions and Answers

Building Materials and Construction Multiple Choice Questions :-

1. Gypsum is a

a) mechanically formed sedimentary rock

b) igneous rock

c) chemically precipitated sedimentary rock

d) metamorphic rock

Ans: c

2. Which of the following sedimentary rocks changes into quartzite by metamorphic action ?

a) sand stone

b) lime stone

c) shale

d) gypsum

Ans: a

3. Which of the following represents a metamorphic rock?

i) slate

ii) shale

iii) quartzite

The correct answer is

a) only (iii)

b) both (i) and (iii)

c) both (ii) and (iii)

d) all (i), (ii) and (iii)

Ans: b

4. Quartitze is a

a) silicious rock

b) argillaceous rock

c) calcareous rock

d) aqueous rock

Ans: a

5. Which of the following is a mineral ?

a) basalt

b) granite

c) quartz

d) syenite

Ans: c

6. Slate is formed by metamorphic action on

a) shale

b) lime stone

c) sand stone

d) granite

Ans: a

7. Sandstone is a

i) sedimentary rock

ii) aqueous rock

iii) silicious rock

The correct answer is

a) only (i)

b) both (i) and (ii)

c) both (i) and (iii)

d) all (i), (ii) and (iii)

Ans: d

8. Which of the following is a rock ?

a) quartz

b) mica

c) gypsum

d) none of the above

Ans: c

9. Based on the following rocks and minerals, select the correct statement, quartz, shale, basalt, granite, marble, gypsum, mica

a) basalt and marble are the only metamorphic rocks

b) there is no sedimentary rock

c) granite is the only igneous rock

d) quartz and mica are minerals

Ans: d

10. A heavy stone is suitable for

a) arches

b) rubble masonry

c) roads

d) retaining walls

Ans: d

11. The stone suitable for rubble masonry should be.

a) hard

b) tough

c) heavy

d) light

Ans: a

12. Which of the following metamorphic rocks has the most weather resisting characteristics?

a) marble

b) quartzite

c) slate

d) lime stone

Ans: b

13. A good building stone should not absorb water more than

a) 5%

b) 10%

c) 15%

d) 20%

Ans: a

14. Which of the following has more fire resisting characteristics ?

a) marble

b) lime stone

c) compact sand stone

d) granite

Ans: c

15. Jumper is a tool used for

a) testing of stones

b) quarrying of stones

c) dressing of stones

d) none of the above

Ans: b

16. The important test to be conducted on a stone used in docks and harbors is-

a) hardness test

b) work ability test

c) weight test

d) toughness test

Ans: c

17. The predominant constituent which is responsible for strength in granite is

a) quartz

b) feldspar

c) mica

d) none of the above

Ans: a

18. Granite is not suitable for ordinary building purpose because

a) it can not be polished

b) it is not a fire proof material

c) it is costly

d) it has less crushing strength

Ans: c

19. Which of the following stone is best suited for construction of piers and abutments of a railway bridge ?

a) granite

b) sand stone

c) lime stone

d) quartzite

Ans: a

20. The preparation of surface of stone to obtain plain edges or to obtain stones of required size and shape is known as

a) quarrying of stones

b) blasting of stones

c) seasoning of stones

d) dressing of stones

Ans: d

21. Crushing strength of a good building stone should be more than

a) 50 MPa

b) 100 MPa

c) 150 MPa

d) 200 MPa

Ans: b

22. Specific gravity for most of the building stones lies between

a) 1.5 to 2.0

b) 2.0 to 2.5

c) 2.5 to 3.0

d) 3.0 to 3.5

Ans: c

23. Spalling hammer is used for

a) driving wooden headed chisels

b) rough dressing of stones

c) carving of stones

d) breaking small projection of stones

Ans: b

24. Cross cut saw is used for

a) cutting soft stones

b) cutting hard stones

c) cutting large blocks of stones

d) dressing stones

Ans: b

25. Sapwood consists of

a) innermost annular rings around the pith

b) portion of timber between heartwood and cambium layer

c) thin layers below the bark

d) thin fibre which extends from the pith outwards and holds the annular rings together

Ans: b

26. Which of the following trees yields hard wood ?

a) deodar

b) chir

c) shishum

d) pine

Ans: c

27. The radial splits which are wider on the outside of the log and narrower towards the pith are known as

a) heart shakes

b) cupshakes

c) starshakes

d) rindgalls

Ans: c

28. In which of the following pairs both trees yield soft wood?

a) deodar and shishum

b) chir and sal

c) sal and teak

d) chir and deodar

Ans: d

29. Which of the following timbers is suitable for making sports goods ?

a) mulberry

b) mahogany

c) sal

d) deodar

Ans: a

30. Assertion A : Shishum is used for decorative woodwork.

Reason R : Shishum can be polished to an excellent finish.

Select your answer according to the coding system given below :

a) Both A and R are true and R is the correct explanation of A

b) Both A and R are true but R is not the correct explanation of A

c) A is true but R is false

d) A is false but R is true

Ans: a

31. The disease of dry rot in timber is caused by

a) lack of ventilation

b) alternate wet and dry conditions

c) complete submergence in water

d) none of the above

Ans: a

32. Plywood has the advantage of'

a) greater tensile strength in longer direction

b) greater tensile strength in shorter direction

c) same tensile strength in all directions

d) none of the above

Ans: c

33. In which of the following directions, the strength of timber is maximum ?

a) parallel to grains

b) 45° to grains

c) perpendicular to grains

d) same in all directions

Ans: a

34. The moisture content in a well seasoned timber is

a) 4% to 6%

b) 10% to 12%

c) 15% to 20%

d) 100%

Ans: b

35. The trunk of tree left after cutting all the branches is known as

a) log

b) batten

c) plank

d) baulk

Ans: a

36. The age of a tree can be known by examining

a) cambium layer

b) annular rings

c) medullary rays

d) heart wood

Ans: b

37. Plywood is made by bonding together thin layers of wood in such a way that the angle between grains of any layer to grains of adjacent layers is

a) 0°

b) 30°

c) 45°

d) 90°

Ans: d

38. The plywood

a) has good strength along the panel only

b) can be spilt in the plane of the panel

c) has greater impact resistance to blows than ordinary wood

d) cannot be bent more easily than ordinary wood of same thickness

Ans: c

39. The practical limit of moisture content achieved in air drying of timber is

a) 5%

b) 15%

c) 25%

d) 35%

Ans: b

40. First class timber has an average life of

a) less than one year

b) 1 to 5 years

c) 5 to 10 years

d) more than 10 years

Ans: d

41. A first class brick when immersed in cold water for 24 hours should not absorb water more than

a) 15%

b) 20%

c) 22%

d) 25%

Ans: b

42. Crushing strength of a first class brick should not be less than

a) 3.5 N/mm2

b) 7.0 N/mm2

c) 10.5 N/mm2

d) 14.0 N/mm2

Ans: c

43. The main function of alumina in brick earth is

a) to impart plasticity

b) to make the brick durable

c) to prevent shrinkage

d) to make the brick impermeable

Ans: a

44. The percentage of alumina in a good brick earth lies between

a) 5 to 10%

b) 20 to 30%

c) 50 to 60%

d) 70 to 80%

Ans: b

45. Excess of alumina in brick earth makes the brick

a) impermeable

b) brittle and weak

c) to lose cohesion

d) to crack and warp on drying

Ans: d

46. The nominal size of the modular brick is

a) 190 mm x 90mmx 80 mm

b) 190 mm x 190 mm x 90 mm

c) 200 mm x 100 mm x 100 mm

d) 200 mm x 200 mm x 100 mm

Ans: c

47. Percentage of silica in a good brick earth lies between

a) 5 to 10%

b) 20 to 30%

c) 50 to 60%

d) 70 to 80%

Ans: c

48. Excess of silica in brick earth results in

a) cracking and warping of bricks

b) loss of cohesion

c) enhancing the impermeability of bricks

d) none of the above

Ans: b

49. Which of the following ingredients of the brick earth enables the brick to retain its shape ?

a) alumina

b) silica

c) iron

d) magnesia

Ans: b

50. Which of the following pairs gives a correct combination of the useful and harmful constituents respectively of a good brick earth ?

a) lime stone and alumina

b) silica and alkalies

c) alumina and iron

d) alkalies and magnesium

Ans: b

51. The process of mixing clay, water and other ingredients to make brick is known as

a) kneading

b) moulding

c) pugging

d) drying

Ans: a

52. Advantage of a clamp compared to a kiln for burning bricks is that

a) it takes less time for burning

b) it gives more output of first class bricks

c) it has less initial cost

d) it is suitable when bricks are required in large numbers

Ans: c

53. The internal size of mould used in brick preparation is

a) equal to the size of a fully burnt brick

b) smaller than the size of a fully burnt brick

c) greater than the size of a fully burnt brick

d) none of the above

Ans: c

54. Pug mill is used for

a) preparation of clay

b) moulding of clay

c) drying of bricks

d) burning of bricks

Ans: a

55. Which of the following bricks are used for lining of furnaces ?

a) overburnt bricks

b) underburnt bricks

c) refractory bricks

d) first class bricks

Ans: c

56. The frog of the brick in a brick masonry is generally kept on

a) bottom face

b) top face

c) shorter side

d) longer side

Ans: b

57. Number of bricks required for one cubic metre of brick masonry is

a) 400

b) 450

c) 500

d) 550

Ans: c

58. Glazing is used to make earthenware

a) hard

b) soft

c) porous

d) impervious

Ans: d

59. Quick lime is

a) calcium carbonate

b) calcium oxide

c) calcium hydroxide

d) none of the above

Ans: b

60. Quick lime is

i) slow in setting

ii) rapid in slacking

iii) good in strength The correct answer is

a) only (i)

b) only (ii)

c) both (i) and (ii)

d) both (ii) and (iii)

Ans: c

61. Assertion A : Pure lime takes a long time to develop adequate strength.

Reason R : Pure lime has slow hardening characteristics.

Select your answer according to the coding system given below :

a) Both A and R are true and R is correct explanation of A.

b) Both A and R are true and R is not a correct explanation of A.

c) A is true but R is false.

d) A is false but R is true.

Ans: a

62. Hydraulic lime is obtained by

a) burning of lime stone

b) burning of kankar

c) adding water to quick lime

d) calcination of pure clay

Ans: b

63. The main constituent which imparts hydraulicity to hydraulic lime is

a) calcium oxide

b) silica

c) clay

d) water

Ans: c

64. Study the following statements.

i) Hydraulic lime is suitable for white washing,

ii) Fat lime is suitable for whitewashing,

iii) Hydraulic lime is suitable for making mortar,

iv) Fat lime is suitable for making mortar.

The correct answer is

a) (i) and (iv)

b) (ii) and (iii)

c) (i) and (ii)

d) (iii) and (iv)

Ans: b

65. The main ingredients of Portland cement are

a) lime and silica

b) lime and alumina

c) silica and alumina

d) lime and iron

Ans: a

66. The constituent of cement which is responsible for all the undesirable properties of cement is

a) dicalcium silicate

b) tricalcium silicate

c) tricalcium aluminate

d) tetra calcium alumino ferrite

Ans: c

67. Le Chatelier's device is used for determining the

a) setting time of cement

b) soundness of cement

c) tensile strength of cement

d) compressive strength of cement

Ans: b

68. The main constituent of cement which is responsible for initial setting of cement is

a) dicalcium silicate

b) tricalcium silicate

c) tricalcium aluminate

d) all of the above

Ans: c

69. The initial setting time for ordinary Portland cement as per IS specifications should not be less than

a) 10 minutes

b) 30 minutes

c) 60 minutes

d) 600 minutes

Ans: b

70. As per IS specifications, the maximum final setting time for ordinary Portland cement should be

a) 30 minutes

b) 1 hour

c) 6 hours

d) 10 hours

Ans: d

71. For testing compressive strength of cement, the size of cube used is

a) 50 mm

b) 70.6 mm

c) 100 mm

d) 150 mm

Ans: a

72. The normal consistency of ordinary Portland cement is about

a) 10%

b) 20%

c) 30%

d) 40%

Ans: c

73. Early attainment of strength in rapid hardening cement is mainly due to

a) gypsum

b) finer grinding

c) tricalcium silicate

d) tricalcium aluminate

Ans: b

74. After storage, the strength of cement

a) decreases

b) increases

c) remains same

d) may increase or decrease

Ans: a

75. According to IS specifications, the compressive strength of ordinary portland cement after three days should not be less than

a) 7 MPa

b) 11.5 MPa

c) 16 MPa

d) 21 MPa

Ans: c

Building Materials and Construction Objective Type Questions ::

76. Addition of pozzolana to ordinary Portland cement increases

a) bleeding

b) shrinkage

c) permeability

d) heat of hydration

Ans: b

77. Gypsum consists of

a) H2S and C02

b) CaS04 and H20

c) Lime and H20

d) C02 and calcium

Ans: b

78. For testing compressive and tensile strength of cement, the cement mortar is made by mixing cement and standard sand in the proportions of

a) 1:2

b) 1:3

c) 1:4

d) 1:6

Ans: b

79. The slump recommended for mass concrete is about

a) 25 mm to 50 mm

b) 50 mm to 100 mm

c) 100 mm to 125 mm

d) 125 mm to 150 mm

Ans: a

80. With increase in moisture content, the bulking of sand

a) increases

b) decreases

c) first increases to a certain maximum value and then decreases

d) first decreases to a certain minimum value and then increases

Ans: c

81. Which of the following cements is suitable for use in massive concrete structures such as large dams ?

a) ordinary Portland cement

b) low heat cement

c) rapid hardening cement

d) sulphate resisting cement

Ans: b

82. Proper amount of entrained air in concrete results in

i) better workability

ii) better resistance to freezing and thawing

iii) lesser workability

iv) less resistance to freezing and thawing The correct answer is

a) (i) and (ii)

b) (i)and(iv)

c) (ii) and (iii)

d) (iii) and (iv)

Ans: a

83. The most common admixture which is used to accelerate the initial set of concrete is

a) gypsum

b) calcium chloride

c) calcium carbonate

d) none of the above

Ans: b

84. The maximum quantity of calcium chloride used as an accelerator in cement in percentage by weight of cement is

a) 1

b) 2

c) 3

d) 4

Ans: b

85. The basic purpose of a retarder in concrete is

a) to increase the initial setting time of cement paste in concrete

b) to decrease the initial setting time of cement paste in concrete

c) to render the concrete more water tight

d) to improve the workability of concrete mix

Ans: a

86. Which of the following cements contains maximum percentage of dicalcium silicate?

a) ordinary Portland cement

b) low heat cement

c) rapid hardening cement

d) sulphate resisting cement

Ans: b

87. The most commonly used retarder in cement is

a) gypsum

b) calcium chloride

c) calcium carbonate

d) none of the above

Ans: a

88. Three basic raw materials which are needed in large quantities for production of steel are

a) iron ore, coal and sulphur

b) iron ore, carbon and sulphur

c) iron ore, coal and lime stone

d) iron ore, carbon and lime stone

Ans: c

89. Compared to mild steel, cast iron has

i) high compressive strength

ii) high tensile strength

iii) low compressive strength

iv) low tensile strength

The correct answer is

a) (i) and (ii)

b) (ii) and (iii)

c) (iii) and (iv)

d) (i)and(iv)

Ans: d

90. Which of the following gradients exerts maximum influence on properties of steel?

a) iron

b) carbon

c) manganese

d) sulphur

Ans: b

91. Which of the following is the purest form of iron ?

a) cast iron

b) wrought iron

c) mild steel

d) high carbon steel

Ans: b

92. The ultimate tensile strength of structural mild steel is about

a) 160N/mm2

b) 260N/mm2

c) 420 N/mm2

d) 520 N/mm2

Ans: c

93. Percentage of carbon content in mild steel is

a) less than 0.25

b) between 0.25 and 0.7

c) between 0.7 and 1.5

d) greater than 1.5

Ans: a

94. Which of the following stresses is used for identifying the quality of structural steel ?

a) ultimate stress

b) yield stress

c) proof stress

d) none of the above

Ans: b

95. The ratio of the thickness of web to that of flange of steel rolled structural beams and channels is

a) less than 1

b) equal to 1

c) greater than 1

d) less than 1 in beams but greater than 1 in channels

Ans: a

96. Paints with white lead base are suitable for painting of

a) wood work

b) iron work

c) both wood work and iron work

d) none of the above

Ans: a

97. Assertion A : Paints with white lead base are not recommended for painting of iron works.

Reason R : Paints with white lead base do not check rusting of iron.

Select your answer according to the coding system given below :

a) Both A and R are true and, R is the correct explanation of A.

b) Both A and R are true but R is not the correct explanation of A

c) A is true but R is false

d) A is false but R is true

Ans: a

98. The amount of water used for one kg of distemper is

a) 0.2 liter

b) 0.4 liter

c) 0.6 liter

d) 0.8 liter

Ans: c

99. The vehicle used in case of enamel paints is usually

a) linseed oil

b) water

c) varnish

d) none of the above

Ans: c

100. Assertion A : Normally turpentine oil is recommended as thinner for indoor painting.

Reason R : Turpentine oil is costlier than other thinners.

Select your answer according to the coding system given below :

a) Both A and R are true and R is the correct explanation of A.

b) Both A and R are true but R is not the correct explanation of A.

c) A is true but R is false.

d) A is false but R is true.

Ans: b

101. In brick masonry the bond produced by laying alternate headers and stretchers in each course is known as

a) English bond

b) double flemish bond

c) zigzag bond

d) single flemish bond

Ans: b

102. The stretcher bond in brick masonry can be used only when the thickness of wall is

a) 90 mm

b) 180 mm

c) 190 mm

d) 280 mm

Ans: a

103. The pressure acting on the stones in stone masonry construction should be

a) along the direction of bedding planes

b) at 45° to the direction of bedding planes

c) at 60° to the direction of bedding planes

d) perpendicular to the direction of bedding planes

Ans: d

104. Which of the following should be used for hearting of thicker walls ?

a) headers

b) stretchers

c) brick bats

d) queen closer

Ans: a

105. A queen closer is a

a) brick laid with its length parallel to the face or direction of wall

b) brick laid with its breadth parallel to the face or direction of wall

c) brick having the same length and depth as the other bricks but half the breadth

d) brick with half the width at one end and full width at the other

Ans: c

106. Minimum thickness of wall where single flemish bond can be used is

a) half brick thick

b) one brick thick

c) one and a half bricks thick

d) two bricks thick

Ans: c

107. The most important tool in brick laying for lifting and spreading mortar and for forming joints is

a) trowel

b) square

c) bolster

d) scutch

Ans: a

108. Expansion Joints in masonry walls are provided in wall lengths usater than

a) 10 m

b) 20 m

c) 30 m

d) 40 m

Ans: d

109. The type of bond provided in brick masonry for carrying heavy loads is

a) single flemish bond

b) double flemish bond

c) English bond

d) zigzag bond

Ans: c

110. A mortar joint in masonry which is normal to the face of wall is known as

a) bed joint

b) wall joint

c) cross joint

d) bonded joint

Ans: c

111. The slenderness ratio for masonry walls should not be more than

a) 10

by 20

c) 30

d) 40

Ans: b

112. The proportions of lime and sand in the mortar normally used in brick construction are

a) 1:2

b) 1:4

c) 1:6

d) 1:8

Ans: a

113. Number of vertical joints in a stretcher course is x times the number of joints in the header course, where x is equal to

a) 1/2

b) 1

c) 2

d) 1/4

Ans: a

114. As compared to stretcher course, the thickness of joints in header course should be

a) less

b) more

c) equal

d) equal or more

Ans: a

115. As compared to English bond, double flemish bond is

a) stronger

b) more compact

c) costly

d) none of the above

Ans: b

116. Single flemish bond consists of

a) double flemish bond facing and Eng-lish bond backing in each course

b) English bond facing and double flemish bond backing in each course

c) stretcher bond facing and double flemish bond backing in each course

d) double flemish bond facing and header bond backing in each course

Ans: a

117. The differential settlement in case of foundations on sandv soils should not exceed

a) 25 mm

b) 40 mm

c) 65 mm

d) 100 mm

Ans: a

118. In case of foundations on black cotton soils, the most suitable method to increase the bearing capacity of soils is to

a) increase the depth of foundation

b) drain the soil

c) compact the soil

d) replace the poor soil

Ans: d

119. The type of footing which is used to transmit heavy loads through steel columns is

a) raft foundation

b) grillage foundation

c) well foundation

d) isolated footing

Ans: b

120. The maximum total settlement for isolated foundations on clayey soils should be limited to

a) 25 mm

b) 40 mm

c) 65 mm

d) 100 mm

Ans: c

121. The type of pile which is driven at an inclination to resist inclined forces is known as

a) friction pile

b) sheet pile

c) batter pile

d) anchor pile

Ans: c

122. The minimum depth of foundation in clayey soils is

a) 0.5 m

b) 0.7 m

c) 0.9 m

d) 1.2 m

Ans: c

123. The maximum total settlement for raft foundation on clayey soils should be limited to

a) 25 mm

b) 25 to 40 mm

c) 40 to 65 mm

d) 65 to 100 mm

Ans: d

124. The bearing capacity of a water logged soil can be improved by

a) compacting the soil

b) draining the soil

c) increasing the depth of foundation

d) grouting

Ans: b

125. The type of flooring suitable for use in churches, theatres, public libraries and other places where noiseless floor covering is desired is

a) cork flooring

b) glass flooring

c) wooden flooring

d) linoleum flooring

Ans: a

126. The vertical distance between the springing line and highest point of the innercurve of an arch is known as

a) intrados

b) rise

c) spandril

d) extrados

Ans: b

127. Depth or height of the arch is the

a) perpendicular distance between intra-dos and extrados

b) vertical distance between springing line and intrados

c) perpendicular distance between springing line and extrados

d) none of the above

Ans: a

128. The triangular space formed between the extrados and the horizontal line drawn through the crown of an arch is known as

a) haunch

b) spandril

c) voussoirs

d) skewbacks

Ans: b

129. The lintels are preferred to arches because

a) arches require more headroom to span the openings like doors, windows etc.

b) arches require strong abutments to withstand arch thrust

c) arches are difficult in construction

d) all of the above

Ans: d

130. In the construction of arches, sand box method is used for

a) centring

b) actual laying of arch work

c) striking of centring

d) none of the above

Ans: c

131. The type of arch generally constructed over a wooden lintel or over a flat arch for the purpose of carrying the load of the wall above is

a) segmental arch

b) pointed arch

c) relieving arch

d) flat arch

Ans: c

132. The type of joint commonly used at the junction of a principal rafter and tie beam in timber trussess is

a) mortise and tennon joint

b) oblique mortise and tennon joint

c) butt joint

d) mitred joint

Ans: b

133. The type of roof suitable in plains where rainfall is meagre and temperature is high is

a) pitched and sloping roof

b) flat roof

c) shell roof

d) none of the above

Ans: b

134. Pitched and sloping roofs are suitable for

a) coastal regions

b) plain regions

c) covering large areas

d) all of the above

Ans: a

135. The type of roof which slopes in two directions with a break in the slope on each side is known as

a) gable roof

b) hip roof

c) gambrel roof

d) mansard roof

Ans: c

136. Mansard roof is a roof which slopes in

a) two directions without break in the slope on each side

b) two directions with break in the slope on each side

c) four directions without break in the slope on each side

d) four directions with break in the slope on each side

Ans: d

137. The horizontal timber piece provided at the apex of a roof truss which supports the common rafter is called

a) ridge board

b) hip rafter

c) eaves board

d) valley rafter

Ans: a

138. The lower edge of the pitched roof, from where the rain water of the roof surface drops down, is known as

a) hip

b) gable

c) ridge

d) eaves

Ans: d

139. Higher pitch of the roof

i) results in stronger roof

ii) results in weaker roof

iii) requires more covering material

iv) requires less covering material

The correct answer is

a) (i) and (iii)

b) (i) and (iv)

c) (ii) and (iii)

d) (ii) and (iv)

Ans: a

140. Couple close roof is suitable for maximum span of

a) 2.5 m

b) 3.5 m

c) 4.5 m

d) 5.5 m

Ans: c

141. In a colar beam roof

a) there is no horizontal tie beam

b) there is a horizontal tie at the feet of rafters only

c) there is a horizontal tie at almost the middle of rafters only

d) there are two horizontal ties, one at the feet and other at the middle of the rafters

Ans: c

142. The function of king post in a king post roof truss is

a) to support the frame work of the roof

b) to receive the ends of principal rafter

c) to prevent the walls from spreading outward

d) to prevent the tie beam from sagging at its centre

Ans: d

143. The function of cleats in a roof truss is

a) to support the common rafter

b) to support purlins

c) to prevent the purlins from tilting

d) all of the above

Ans: c

144. The term string is used for

a) the underside of a stair

b) outer projecting edge of a tread

c) a sloping member which supports the steps in a stair

d) a vertical member between two treads

Ans: c

145. The vertical posts placed at the top and bottom ends of a flight supporting the hand rail are known as

a) balusters

b) newal posts

c) balustrades

d) railings

Ans: b

146. The maximum number of steps in a flight should generally be restricted to

a) 10

b) 12

c) 15

d) no limit

Ans: b

147. The number of steps in a flight generally should not be less than

a) 2

b) 3

c) 5

d) no limit

Ans: b

148. Sum of tread and rise must lie between

a) 300 to 350 mm

b) 400 to 450 mm

c) 500 to 550 mm

d) 600 to 650 mm

Ans: b

149. Minimum width of landing should be

a) equal to width of stairs

b) half the width of stairs

c) twice the width of stairs

d) one fourth the width of stairs

Ans: a

150. In any good staircase, the maximum and minimum pitch respectively should be

a) 90° and 0°

b) 75° and 30°

c) 60° and 10°

d) 40° and 25°

Ans: d

BUILDING MATERIALS and CONSTRUCTION Questions Answers pdf free download ::

Read the full article

0 notes

Text

What is the effect of magnesium oxide on flame retardants

With the continuous development and wide application of polymer materials, the demand for flame retardant is also constantly improving, at the same time, flame retardant technology is constantly updated and developed. Among various types of flame retardants, magnesium oxide is a new kind of environmentally friendly inorganic flame retardant, and light magnesium oxide is a classification of magnesium oxide.

Magnesium oxide according to the different volume, there are light magnesium oxide and heavy magnesium oxide classification, light magnesium oxide used in metallurgy, smelting, advanced magnesium brick, refractories and moisturizing materials manufacturing, and other types of inorganic flame retardant, has a better smoke suppression effect, but also has the flame retardant, dropproof, filling multiple functions. Many people may be wondering why magnesium oxide can be used as a flame retardant and how it can achieve the flame retardant effect. Today I'm going to tell you why light magnesium oxide can be used as a flame retardant.

Light magnesium oxide is a white amorphous powder which is odorless, tasteless and non-toxic. It is difficult to dissolve in water, insoluble in alcohol, soluble in acid or ammonium salt solution, in the water solubility increases with the CO2 content in the water, melting point is 2852 ℃, boiling point is 3600 ℃, 1000 ℃. The above high temperature burning, can be converted into crystals. When the temperature rises to above 1500 ℃, then into dead burned magnesia and sintered magnesia. It absorbs carbon dioxide from the air and water to form basic magnesium carbonate.

When the light magnesium oxide is heated, the decomposed material can absorb the heat when the fire occurs, prevent the temperature from rising, and release a large amount of water to dilute the oxygen on the surface of the combustible material. The decomposed active magnesium oxide adheres to the surface of the combustible material and further prevents the combustion.

0 notes

Text

Which is better for magnesia alumina bricks

Magnesia chrome brick is a high-quality refractory material composed of magnesium oxide (MgO) and chromium trioxide (Cr2O3). It has excellent performance in high temperature environment and is widely used in many fields. The following are the main uses of magnesia chrome bricks:

1、Metallurgical industry: Magnesia-chrome bricks are widely used in high-temperature equipment in the metallurgical industry, such as steel converters, electric furnaces, and smelting furnaces. They can be used in areas such as linings, furnace floors, furnace walls and furnace roofs to provide refractory protection and withstand erosion and wear under high temperature conditions.

2、Chlor-alkali industry: Equipment such as electrolyzers and evaporators in the production process of the chlor-alkali industry need materials that can withstand high temperatures and corrosion. Magnesia-chrome bricks are widely used in these equipment, providing excellent fire resistance and corrosion resistance, ensuring long-term stable operation of the equipment.

3、Oil refining and chemical industry: In the oil refining and chemical industry, magnesia-chrome bricks are often used in high-temperature equipment such as catalytic cracking units, hydrogenation units, reforming units and furnaces. They withstand high temperatures, corrosive gases and chemicals and provide reliable fire protection.

4、Glass industry: Glass furnaces are the core equipment in the glass industry, which are required to withstand extremely high temperatures and chemical erosion. Magnesia-chrome bricks are widely used in the inner lining, cooling zone and melting area of glass furnaces to maintain stable refractory performance and long service life.

5、Power industry: In the power industry, magnesia-chrome bricks are often used in high-temperature equipment such as boilers, burners, chimneys and hot blast stoves. They can withstand high temperature and flue gas erosion, and provide effective fire protection to ensure the normal operation and safety performance of equipment.

6、Other industries: In addition, magnesia-chrome bricks are also widely used in cement kilns, ceramic kilns, welding furnaces, carbonization furnaces, aluminum electrolytic cells and other fields. Its excellent fire resistance and corrosion resistance make it an important high temperature refractory material.

In conclusion, magnesia chrome bricks are widely used in several industries due to their high temperature resistance, erosion resistance and mechanical strength. Whether it is metallurgy, chlor-alkali, oil refining and chemical industry, glass or electric power and other fields, magnesia-chrome bricks can provide reliable fire-resistant protection to ensure long-term stable operation of equipment.

0 notes

Text

Brief introduction of magnesia-carbon brick raw material

1. Fused magnesia sand: it is an alkaline refractory made of natural magnesite, light fired magnesia or sintered magnesia fused by an arc furnace. Fused magnesia main crystal phase of periclase, melting point is 2800 ℃, 1600 ℃ sublimation in vacuum, in reducing atmosphere above 2000 ℃ sublimation, is greater than 3.40 g/cm3 density, porosity of 0% to 10%, 5.5 mohs hardness, resistance to basic slag erosion is very strong, stable chemical properties, under the high temperature of 1500 ℃ and other than the silica brick no or weak reaction between all kinds of refractory materials. The appearance should be clear after the complete melting crystallization, do not allow mixing with other magnesia or sundries.

2, Graphite: is a carbon as the main component of the natural mineral, it has high temperature resistance, heat conduction, electricity, lubrication, plastic and corrosion resistance and other properties. It is the main material containing carbon resistant material. The graphite used in refractory is flake graphite, which is divided into high purity, high carbon, medium carbon and low carbon graphite according to the fixed carbon content. The color is iron black, steel gray. The density is 2.09-2.23g/cm3 with a melting point of 3700℃±100℃(in vacuum), high thermal conductivity, small expansion coefficient, small elastic modulus, good lubricity, good conductivity, stable chemical properties, no reaction with acid, alkali and organic solvents at room temperature, and steel solution is difficult to wet, with good anti-erosion performance.

3. Phenolic resin: it is a non-aqueous organic binder for refractory materials. It is prepared by condensation of phenol (or cresol, dicresol, or resorcinol) with formaldehyde (or glycolaldehyde) under the action of catalyst.?

The main advantages are

(1) high carbonization rate (52%);

(2) good adhesion, high strength of the formed body;

(3) high bonding strength after burning;

(4) the rate of hardening can be controlled at room temperature;

(5) less harmful substances, can improve the operating environment.

According to heating properties or structural morphology classification, there are thermosetting phenolic resin and thermoplastic phenolic resin, according to product morphology classification, there are liquid phenolic resin and solid phenolic resin (granular and powder), according to the curing temperature classification, there are high temperature solidified type 130℃-150℃; There are medium temperature fixed type 105℃-110℃; There are room temperature solidified type 20℃-30℃.g material.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality changxing refractory products are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc. Shall any interests, welcome to contact us. Our team would make best to be your reliable partner!

Article Source:Brief introduction of magnesia-carbon brick raw material

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

Essentials of refractory construction for RH refining furnace

RH system equipment is a secondary refining process equipment for molten steel used to produce high-quality steel. The entire molten steel metallurgical reaction is carried out in a vacuum tank with refractory lining. The lower part of the vacuum tank is two dip pipes with refractory lining, and the upper part is equipped with hot elbows. The temperature during refining in RH furnace is as high as 1600~1700℃.

Therefore, the lining refractories are required to have high fire resistance, can withstand the impact of maximum temperature and local overheating, and have a small amount of liquid phase at high temperatures, and can resist the erosion of low-viscosity slag. Alkaline bricks with high purity and direct bonding rate should be selected. The intermittent operation of HR will cause temperature fluctuations, and the material is required to have excellent thermal shock resistance. It is better to use magnesia carbon bricks and magnesia chrome bricks with the best thermal shock resistance.

In addition to selecting suitable refractory materials, construction is also the key to the service life of RH refining furnaces.

Ramming material construction: The bottom of the lower trough, the refractory bricks and the circumference of the circulation pipe are constructed with ramming material. Due to the high pressure, the ramming material is required to be compact, especially for some irregular shapes. A special hammer head is used for construction to ensure that the compactness of the ramming material meets the requirements.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality ladle magnesia carbon bricks are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc. Shall any interests, welcome to contact us. Our team would make best to be your reliable partner!

Article Source:

Essentials of refractory construction for RH refining furnace

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:

https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Link

EAF magnesia carbon brick has high fire resistance, high corrosion resistance, excellent heat-resistant peeling property, high-temperature volume stability, and high thermal shock resistance. According to the smelting conditions and the smelting steel grade, different quality magnesia carbon bricks can be provided.

0 notes

Link

AOD magnesia carbon brick refers to a refractory product made of magnesia and graphite as raw materials. Magnesia carbon brick has high fire resistance, high corrosion resistance, excellent heat-resistant peeling property.

0 notes

Text

The difference between fireclay and firebrick

Firebrick is a mixture of stone powder and clay fired in a kiln at 1300 degrees Celsius. Firebrick is a refractory material with a certain shape and size.

According to the preparation process, it can be divided into fired brick, unfired brick, electric fused brick and fire-resistant and heat-insulating brick. Refractory?fire brick?It can divide for standard brick, common brick, unusual brick to wait by shape and dimension.?Firebrick?can be used as high temperature building materials and structural materials for building kilns and various thermal equipment, and can withstand various physical and chemical changes and mechanical action at high temperature. For example, refractory clay brick, high aluminum brick, silicon brick, magnesium brick and so on.

Fire-clay usually refers to a kind of clay refractory used in civil furnace and furnace chamber.

Clay refractory brick is a weak acid refractory material, its thermal stability is good, suitable for hot furnace, various boiler lining and flue, smoke chamber, etc. Under atmospheric pressure 1500 degrees or so the dosage is larger with silicon brick and clay brick. Silica brick is a siliceous product containing more than 93% SiO2. The raw materials used are silica, waste silicon brick, etc. Silica brick has a strong ability to resist acid slag erosion, but it is easily eroded by alkaline slag. Its softening temperature under load is high, which is close to its refractoriness, but its thermal shock stability is poor. Silica brick is mainly used in coke oven, glass melting furnace, acid steelmaking furnace and other thermal equipment.

The main crystal phases in the high alumina products of neutral refractory materials are mullite and corundum, the content of corundum increases with the increase of alumina content, corundum products containing more than 95% alumina are a kind of high-quality refractory with wide use. Chromium brick is mainly made of chromite and its main crystalline phase is chromite. It has good corrosion resistance to steel slag, but poor thermal shock resistance and low deformation temperature under high temperature.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality magnesia carbon bricks are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc. Shall any interests, welcome to contact us. Our team would make best to be your reliable partner!

Article Source:Tundish lining construction and refractory material composition

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products: https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

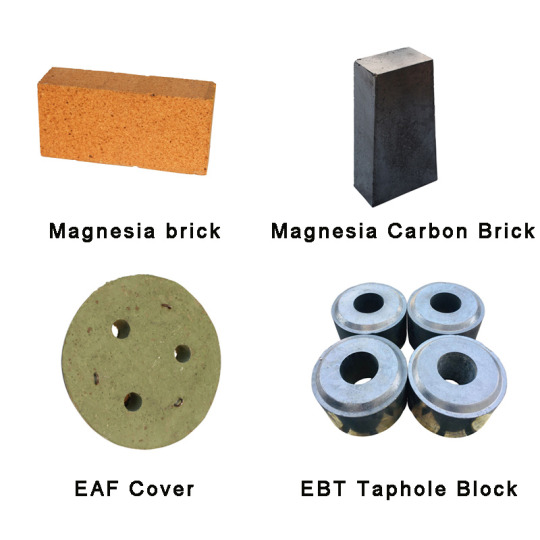

Main parts and refractories of electric arc furnace steelmaking

The electric arc furnace is a device that uses the arc generated between the electrode tip and the charge as heat energy to make steel. The development of electric arc furnace technology is the development of direct current electric arc furnace, furnace bottom gas agitation and furnace bottom tapping based on the use of high power. The electric arc furnace is composed of furnace roof, furnace wall, furnace bottom and tapping trough.

1.?Refractory materials for electric arc furnace?

The roof of the electric arc furnace is generally built with high-alumina bricks, and the alumina content is between 75%-85%. Compared with silica bricks, high-alumina bricks are characterized by high refractoriness, good thermal shock resistance and high compressive strength. Due to the rich domestic bauxite resources, high alumina bricks have become the main refractory material for electric arc furnace roofs, with a life span of about 2-3 times that of silica brick roofs.

2. Refractory materials for furnace wall

The furnace wall is divided into general furnace wall, slag line area and hot spots near the arc. Generally, the furnace walls are mainly built with magnesia bricks, dolomite bricks and periclase bricks, and some use unburned magnesia alkaline bricks and asphalt combined with magnesia and dolomite ramming materials. The furnace wall of ultra-high power or special steel smelting electric arc furnace uses magnesia chrome bricks and high-quality magnesia bricks. The slag line area and hot spots are the weak links of the furnace wall. Because the life of the furnace wall mainly depends on the damage degree of the hot spot, special attention should be paid to the furnace lining at this spot. Nowadays, magnesia carbon bricks are widely used for masonry, which can show excellent high temperature resistance and slag resistance. The service life is significantly improved, reaching more than 300 heats. In order to balance the damage of the furnace wall and prolong its life, the furnace wall is also equipped with a water-cooled box or water-cooled jacket. The inner surface is sprayed with a layer of refractory coating to form a protective layer of slag, which can effectively reduce the unit consumption of refractory materials. But the corresponding energy consumption has increased.

3. Refractory materials for furnace bottom

Select good magnesia or fused magnesia for the knotted lining. Pay attention to the joints of each layer during construction. The thickness and density of each layer should be consistent. There are working layers and permanent linings under the ramming layer. The working layer is selected from tar pitch combined with magnesium for brick masonry, magnesia bricks are mostly used for permanent lining. At the slag line on the upper part of the embankment slope, due to the serious erosion of the slag, the same or similar lining bricks as the hot spots of the furnace wall are often used, such as cast magnesia chrome bricks or combined with magnesia chrome bricks. It is better to use magnesia carbon bricks.

4. Refractory materials for tapholes

The currently used furnace bottom eccentric tapping method changes the furnace body from a tilting type to a fixed type, and sets a tap hole at the eccentric position of the furnace bottom to replace the tapping trough. The advantages are: cancel the tilting equipment, expand the area of the water wall, alleviate the damage of the furnace lining, appropriately reduce the tapping temperature and shorten the tapping time, thereby reducing the cost. The eccentric taphole bricks are pitch-impregnated and fired magnesia bricks, the pipe bricks are made of magnesia carbon bricks with a resin-bonded carbon content of 15%, and the end bricks are magnesia-carbon bricks with a resin-bonded carbon content of 10%-15%. For 15% ALO-C-SiC bricks, for smooth tapping, coarse sand with olivine as matrix is often used as drainage material.

Article Source:Main parts and refractories of electric arc furnace steelmaking

Company name: Henan Xinmi Changxing Refractory Materials Co.,Ltd

Email: [email protected]

Website:http://www.cxrefractories.com

0 notes

Text

Refractory products used in electric arc furnaces

Electric furnaces mainly use scrap steel as the main raw material for steelmaking. Put scrap steel, lime, etc. into the furnace. When the electricity is turned on, an electric arc is generated between the electrode and the scrap to heat the charge. The metallurgical spare parts undergo a series of chemical reactions, and the scrap is made into steel. Electric furnaces mainly include DC electric arc furnace, AC electric arc furnace and induction furnace.?

A.Refractories for DC electric arc furnace

There are three types of DC electric arc furnaces, namely ABB, Clecim and GHH. Different types of DC electric arc furnaces are classified according to the structure of the bottom electrode, which illustrates the importance of the bottom electrode. The bottom electrode of the ABB type DC electric arc furnace is electrically conductive with a conductive refractory material, and the bottom surface is cooled; while GHH has many small steel needles (thin steel rods with a diameter of 20-50mm) buried in the bottom, and the bottom surface of metallurgical spare parts is also cooled by wind ; The bottom electrode of Clecim is 1-4 thick steel rods, and the lower end is cooled with a copper water cooling jacket. On the basis of these three types, various forms have been developed, such as the steel sheet type, the water-cooled bottom electrode rod type, and the steel rod and copper rod composite bottom electrode type.?

The life of the bottom electrode of the DC electric arc furnace is essentially the life of the refractory material. For the Clecim bottom electrode, the electrode cover bricks are made of iron, magnesia-carbon, magnesia-aluminum, and iron-based refractories. The repair materials currently used are mainly magnesium dry ramming materials. For DC arc furnaces with conductive steel needles or steel sheet bottom electrodes, dry materials are often used between the steel needles or steel sheets, and some are made into preforms, mainly magnesium refractories. In order to improve the life span, NMe0-C materials are now available. It is impossible to greatly increase the life of the bottom electrode by improving the performance of refractory materials. Therefore, metallurgical spare parts have carried out hot repair work abroad in recent years. The hot repair materials used are required to be conductive refractory materials (the conductive steel needles and steel sheets are arranged), mainly including magnesium-iron conductive ramming materials, magnesium-carbon conductive ramming materials, magnesium-calcium carbon conductive ramming material.?

B.Refractories for AC arc furnace

The refractory used for the AC arc furnace bottom was rammed into the furnace bottom with asphalt tar iron sand or brucite knotting material in the early days, and then more iron bricks and low-grade magnesia carbon bricks were used to build the furnace bottom. By the 1990s In the 1940s, my country began to use dry vibrating ramming materials of furnace bottom magnesium-calcium-iron series. The construction of various metallurgical parts is simple and convenient, without baking, after the construction is completed, it can be directly used in steelmaking. Refractory materials for small electric arc furnace walls mainly use asphalt magnesia bricks, iron-carbon bricks, and iron sand to fill the furnace charge. For ultra-high-power large electric furnaces, high-quality magnesia-carbon bricks are used for electric furnace walls, especially high-quality magnesia-carbon bricks with very high performance for slag lines and hot spots. Magnesium gunning materials are mainly used for furnace wall repair.?